Anti-dumping hand-push electrical mower

An anti-dumping, hand-push technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of unfavorable implementation of machine transportation, increased weight of lawn mowers, and increased costs, and achieves reduction of materials and volume. Reduce and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

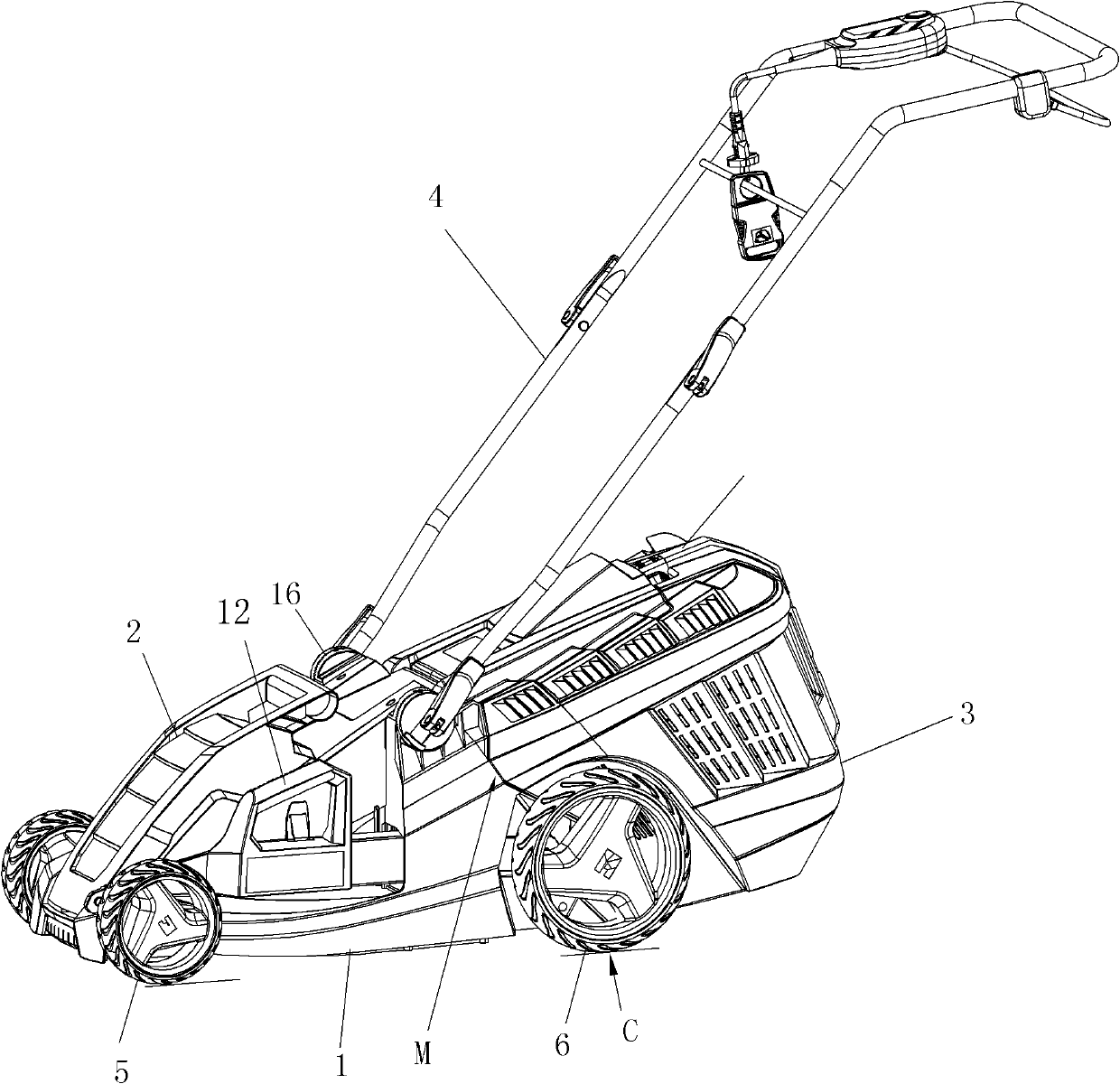

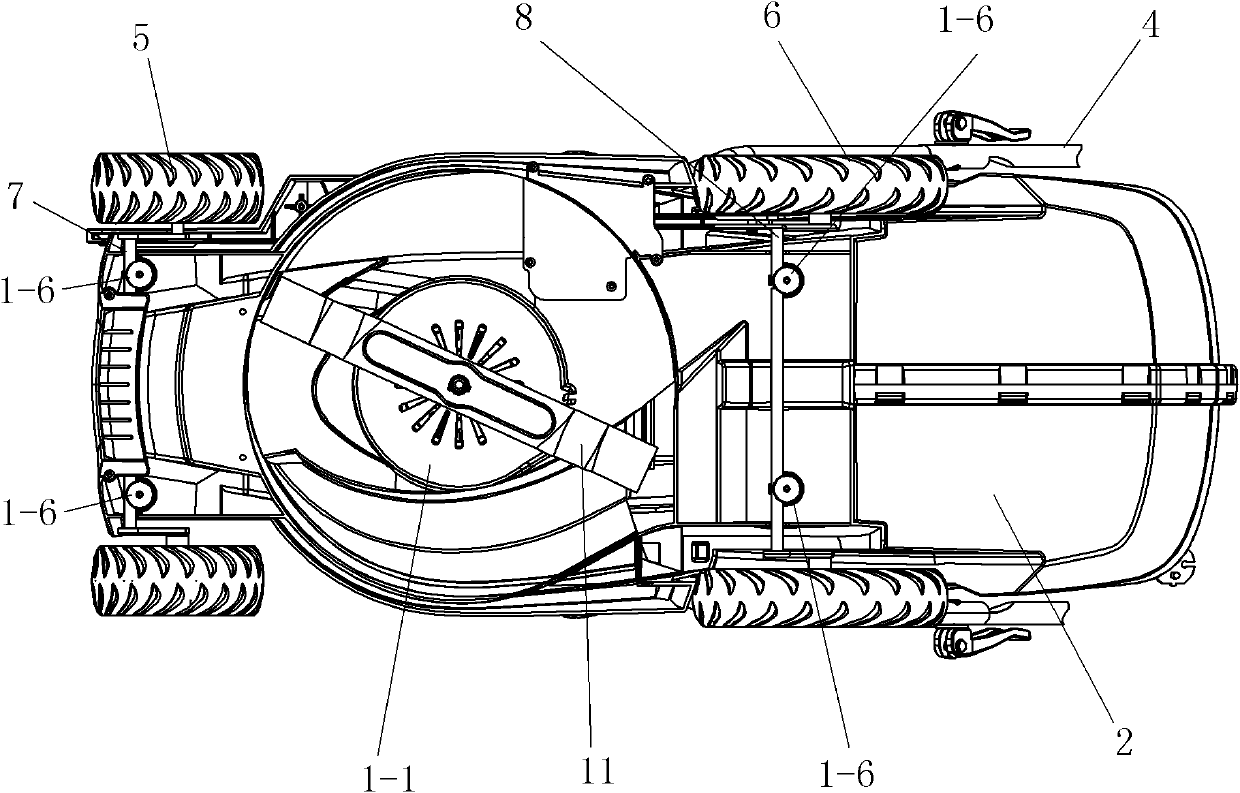

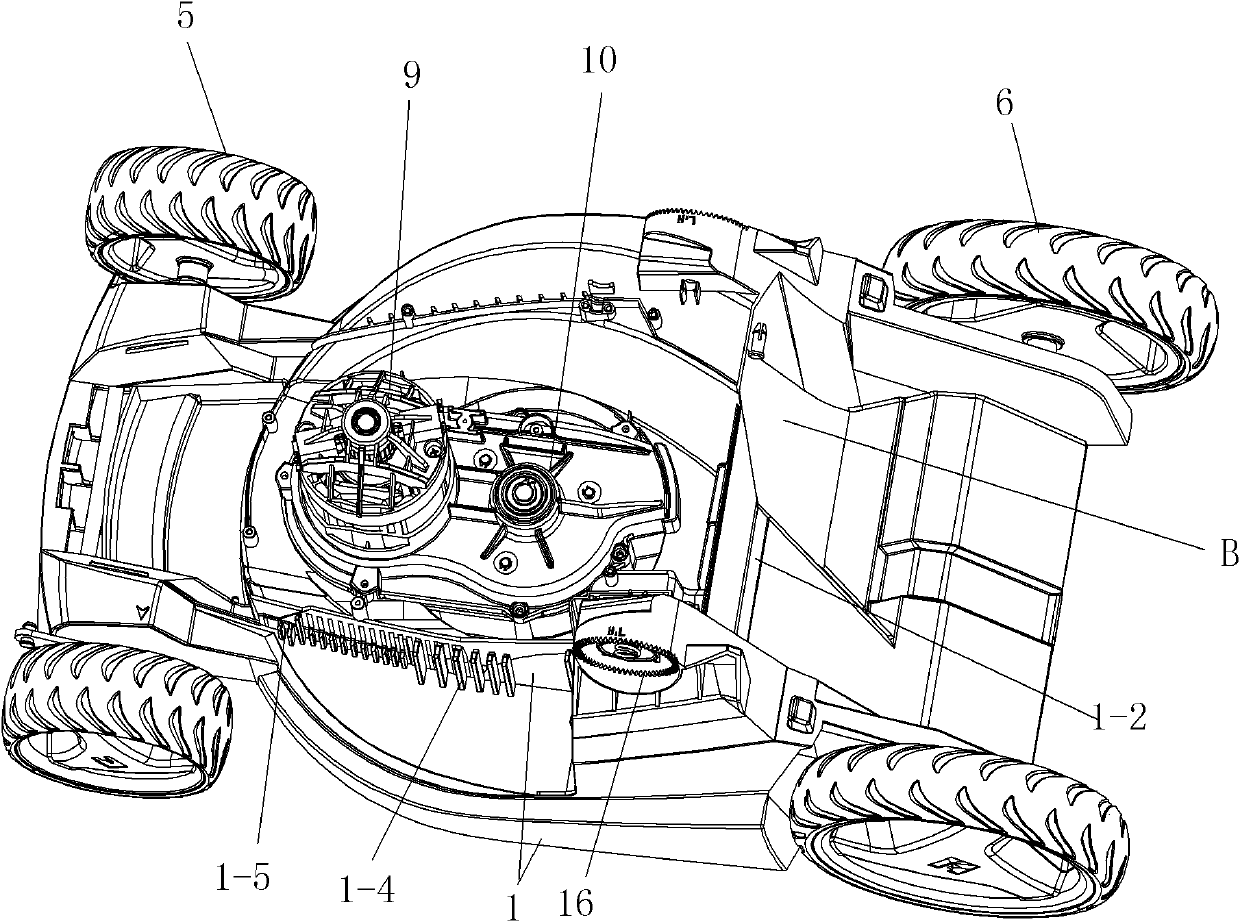

[0013] See attached Figures 1 to 8 , the present embodiment has a casing 1, a power mechanism, a loam cake 2, a grass bucket 3 and an armrest 4, a front wheel set and a rear wheel set, the loam cake 2 is connected to the top of the casing 1, and the grass bucket 3 is in the The rear of shell 1. The armrest 4 is connected with the casing 1 through a toothed disc 16 . Said casing 1 is provided with a side-by-side main machine room and grass air duct B, and the power mechanism is arranged in the main machine room. The power mechanism includes a series motor 9 and a main shaft. The main shaft is supported by the bearing in the bearing housing 10, and the series motor Belt transmission between the main shaft and the bottom plate 1-1 of the main shaft is provided with a cutter assembly 11. The power mechanism is a front type, that is, the series excitation motor 9 is in front of the bearing seat 10. The cut grass is thrown into the grass bucket 3 through the grass air channel B. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com