Method for cutting laminated film, cutting device, and method for manufacturing optical display device

A cutting method and laminated film technology, applied in metal processing, adhesives, etc., can solve the problems of cutting surface burrs, surface protective film floating, defects, etc., and achieve the effect of suppressing cracks, suppressing burrs or floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0089] Next, although an Example is given and this invention is demonstrated in detail, this invention is not limited to this.

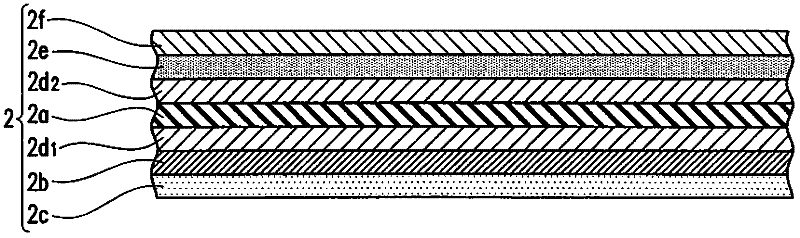

[0090] laminated film

[0091] In Examples and Comparative Examples, the following samples A (product name, NPF-VEG1724DU, manufactured by Nitto Denko Co., Ltd.), B (product name, NTB-EFCVEQ-K1, manufactured by Nitto Denko Co., Ltd.) and C ( Product name, NZB-CVEQ-ST19, manufactured by Nitto Denko Co., Ltd.) these three kinds of polarizing films.

[0092] These polarizing films were prepared as rolls with a width of 400 mm and a length of 50 m.

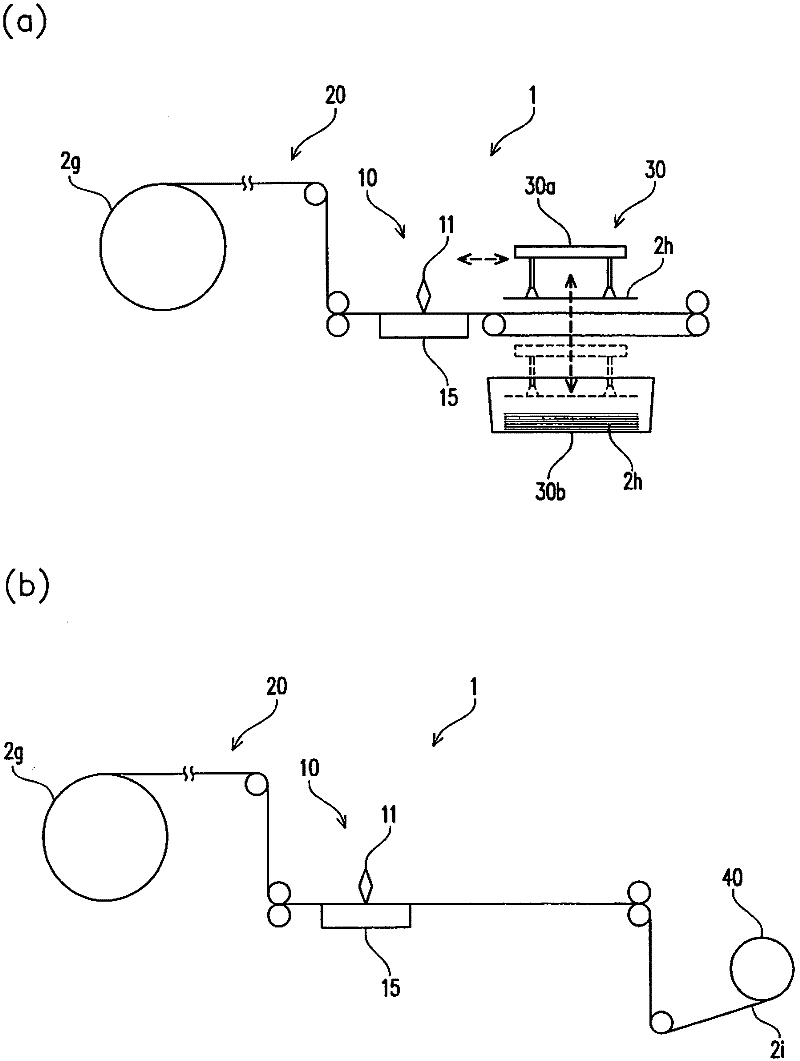

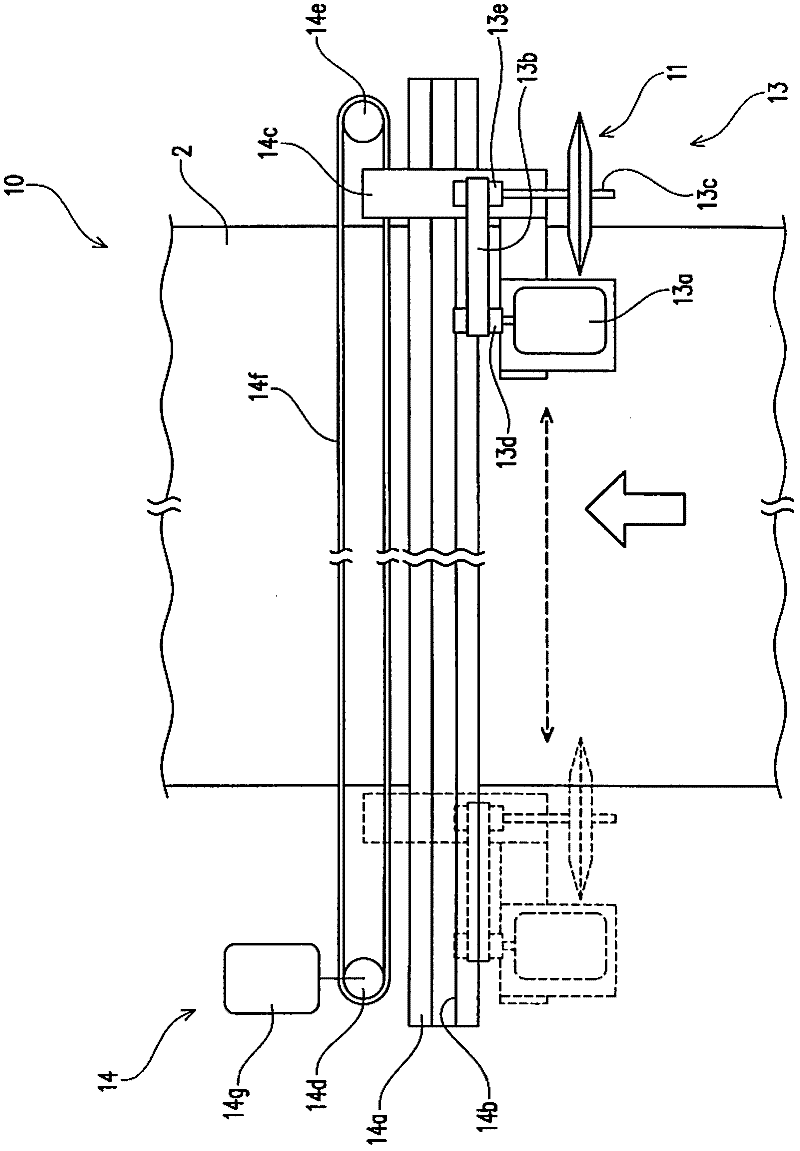

[0093] device

[0094] As the cutting device, a roller-feeding type self-rotating circular knife cutting test machine having the above-mentioned structure was used.

[0095]As the round cutter, Kyocera Corporation's ultra-hard round cutter FW05 was used, and the following five sizes were prepared.

[0096] Blade diameter = 60mm, blade thickness = 0.5mm, tip angle = 20°

[0097] Blade diameter = 80mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com