Coating device and coating method

A technology of coating device and coating method, which can be applied to devices, coatings, electrical components and other directions for coating liquid on the surface, which can solve the problems of deterioration of electrode characteristics and poor sealing, and achieve the effect of good efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

[0125]

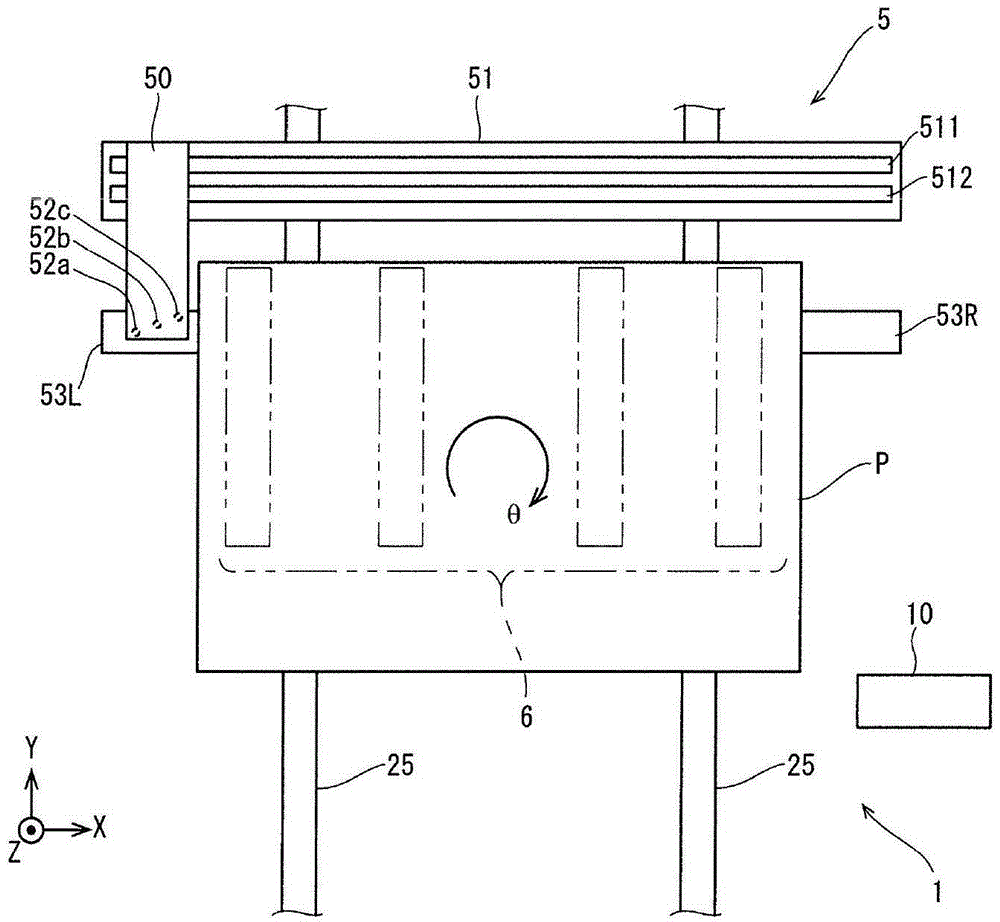

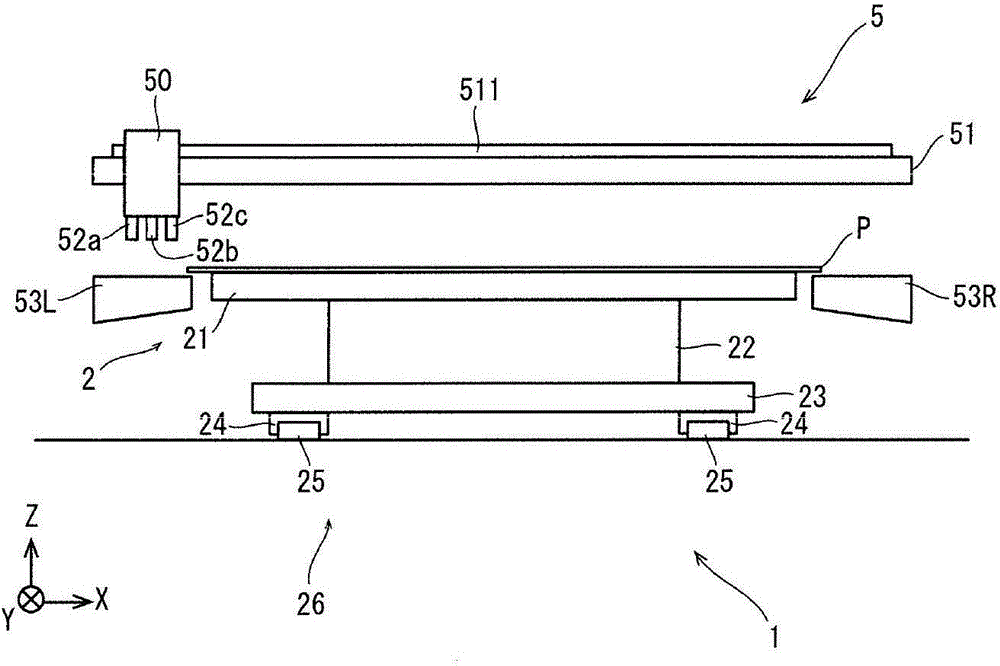

[0126] figure 1 It is a schematic plan view of the coating apparatus 1 of 1st Embodiment. and, figure 2 yes figure 1 A schematic front view of the coating device 1 is shown.

[0127] The coating device 1 is configured as a device for manufacturing an organic EL display device using a fluid material such as an organic EL liquid, a hole transport material, or a hole injection material as a coating liquid. In addition, in the coating device 1, various coating liquids such as an organic EL liquid, a hole transport material, and a hole injection material can be used, but in the following description, the organic EL liquid which is a representative of these coating liquid 3 will be described as a coating solution.

[0128] The coating device 1 includes a substrate holding device 2, an organic EL coating mechanism 5, a mask mechanism 6, and a cleaning mechanism 7 (refer to Figure 7 ) and the control unit 10.

[0129] Such as figure 2 As shown, the substrate holdi...

no. 2 approach >

[0188]

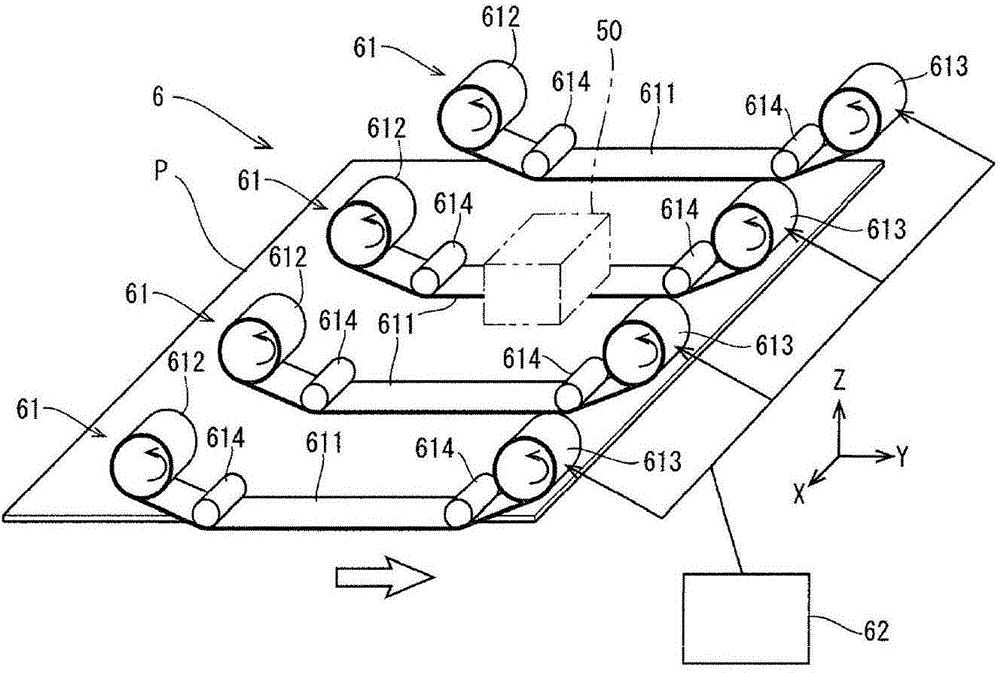

[0189] Figure 13 It is a schematic plan view of 1 A of coating apparatuses of 2nd Embodiment. and, Figure 14 yes Figure 13 A schematic front view of the coating apparatus 1A is shown.

[0190] Also, although not shown, a heating mechanism for preheating the substrate P coated with the organic EL liquid 3 on the surface of the stage 21 is provided inside the stage 21, and the substrate P is adsorbed from below and A suction mechanism for holding, a delivery pin mechanism used for delivering the substrate P between the transfer mechanism, and the like. The stage 21 is a holding portion that holds the substrate P with a flat upper surface. In addition, although the details will be described later, a plurality of magnets 91 are buried inside the platform 21 . The plurality of magnets 91 is an example of a magnetic body that attracts the mask tape 611C to the stage 21 via the substrate P by generating a magnetic field.

[0191] Figure 15 It is a schematic pers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com