Adhesive composition, adhesive sheet, and surface protective film

A surface protective film and composition technology, applied in the direction of adhesive types, ester copolymer adhesives, film/sheet adhesives, etc. The effect of reducing pollution and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

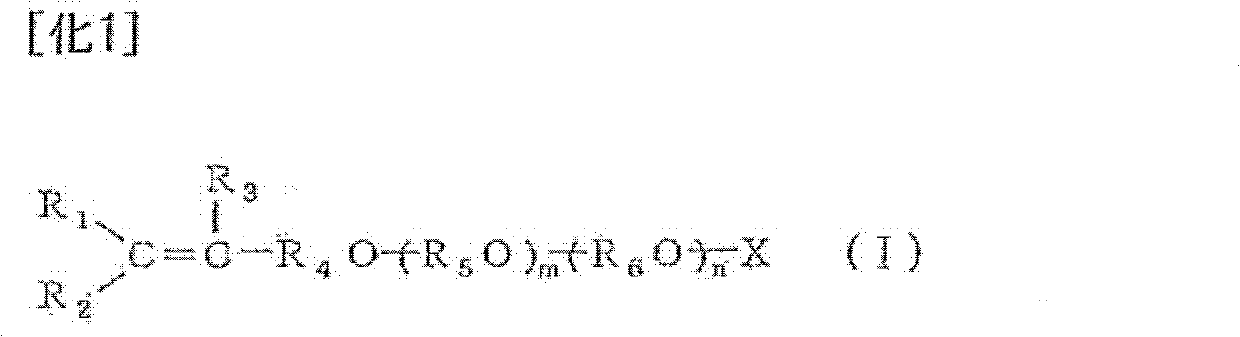

Method used

Image

Examples

preparation example Construction

[0249]

[0250](acrylic polymer (a))

[0251] 199 parts by weight of 2-ethylhexyl acrylate and a reactive surfactant (manufactured by Kao Corporation, LATEMUL PD-420) were added to a 4-necked flask equipped with a stirring paddle, a thermometer, a nitrogen introduction tube, a condenser, and a dropping funnel. 1 part by weight, 8 parts by weight of 2-hydroxyethyl acrylate, 0.4 parts by weight of 2,2'-azobisisobutyronitrile as a polymerization initiator, and 386 parts by weight of ethyl acetate, nitrogen gas was introduced while slowly stirring, and the flask The liquid temperature inside was kept at around 65° C., and a polymerization reaction was performed for 6 hours to prepare an acrylic polymer (a) solution (35% by weight). The acrylic polymer (a) had Tg=-10°C or lower, a weight average molecular weight of 410,000, and an acid value of 0.0.

[0252] (acrylic polymer (b))

[0253] In a 4-necked flask equipped with a stirring paddle, a thermometer, a nitrogen inlet tube,...

Embodiment 1

[0275] (Preparation of Adhesive Composition)

[0276] Dilute the above-mentioned acrylic polymer (a) solution (35% by weight) with ethyl acetate to 60 parts by weight of the solution obtained by 20% by weight, and dilute the above-mentioned acrylic polymer (b) solution (35% by weight) with ethyl acetate %) to 40 parts by weight of the solution obtained by diluting to 20% by weight, 1-butyl-3-methylpyridinium bis(trifluoromethanesulfonyl)imide (manufactured by Nippon CARLIT Co., Ltd., CIL-312, 25° C. liquid state) 0.07 parts by weight, 0.3 parts by weight of isocyanurate body of hexamethylene diisocyanate (manufactured by Nippon Polyurethane Industry Co., Ltd., Coronate HX), dibutyltin dilaurate (1% by weight acetic acid ethyl ester solution) 0.4 parts by weight, and mixed and stirred at 25° C. for about 1 minute to prepare an acrylic adhesive solution (1).

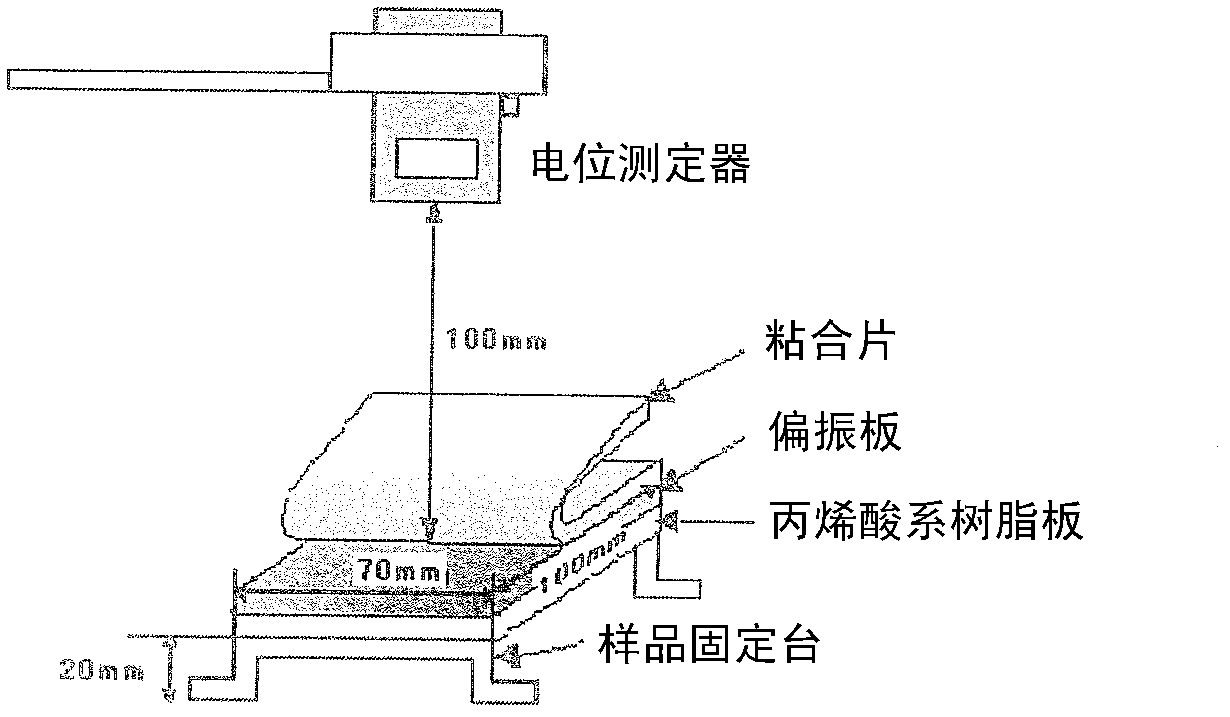

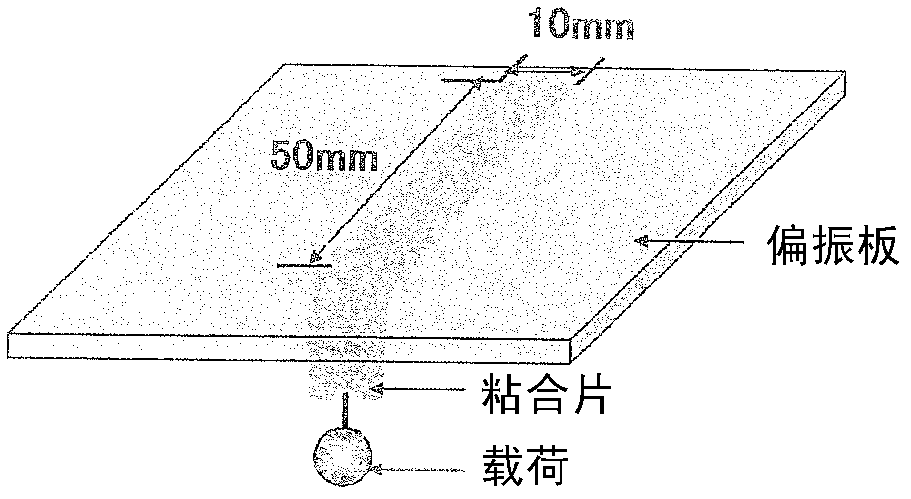

[0277] (production of adhesive sheet)

[0278] The above-mentioned acrylic adhesive solution (1) was applied to the su...

Embodiment 2

[0280] (Preparation of Adhesive Composition)

[0281] Using 50 parts by weight of a solution obtained by diluting the above-mentioned acrylic polymer (a) solution (35% by weight) to 20% by weight with ethyl acetate, and diluting the above-mentioned acrylic polymer (b) solution (35% by weight) with ethyl acetate %) was diluted to 20% by weight to obtain 50 parts by weight of the solution, and an acrylic adhesive solution (2) was prepared in the same manner as in Example 1.

[0282] (production of adhesive sheet)

[0283] A pressure-sensitive adhesive sheet was produced in the same manner as in Example 1 except that the above-mentioned acrylic pressure-sensitive adhesive solution (2) was used instead of the above-mentioned acrylic pressure-sensitive adhesive solution (1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com