Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Sufficient processability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Perforated film

InactiveUS20120244412A1Improve stabilitySufficient processabilityMembranesSemi-permeable membranesPolymer chemistry

Owner:EVONIK DEGUSSA GMBH

Natural rubber and method for producing the same, rubber composition and pneumatic tire using the same, modified natural rubber and method for producing the same, and rubber composition for tread or for covering carcass cord and pneumatic tire using the same

InactiveUS20110253285A1Easy to processImprove fuel economySpecial tyresPneumatic tyre reinforcementsEngineeringTread

Owner:SUMITOMO RUBBER IND LTD

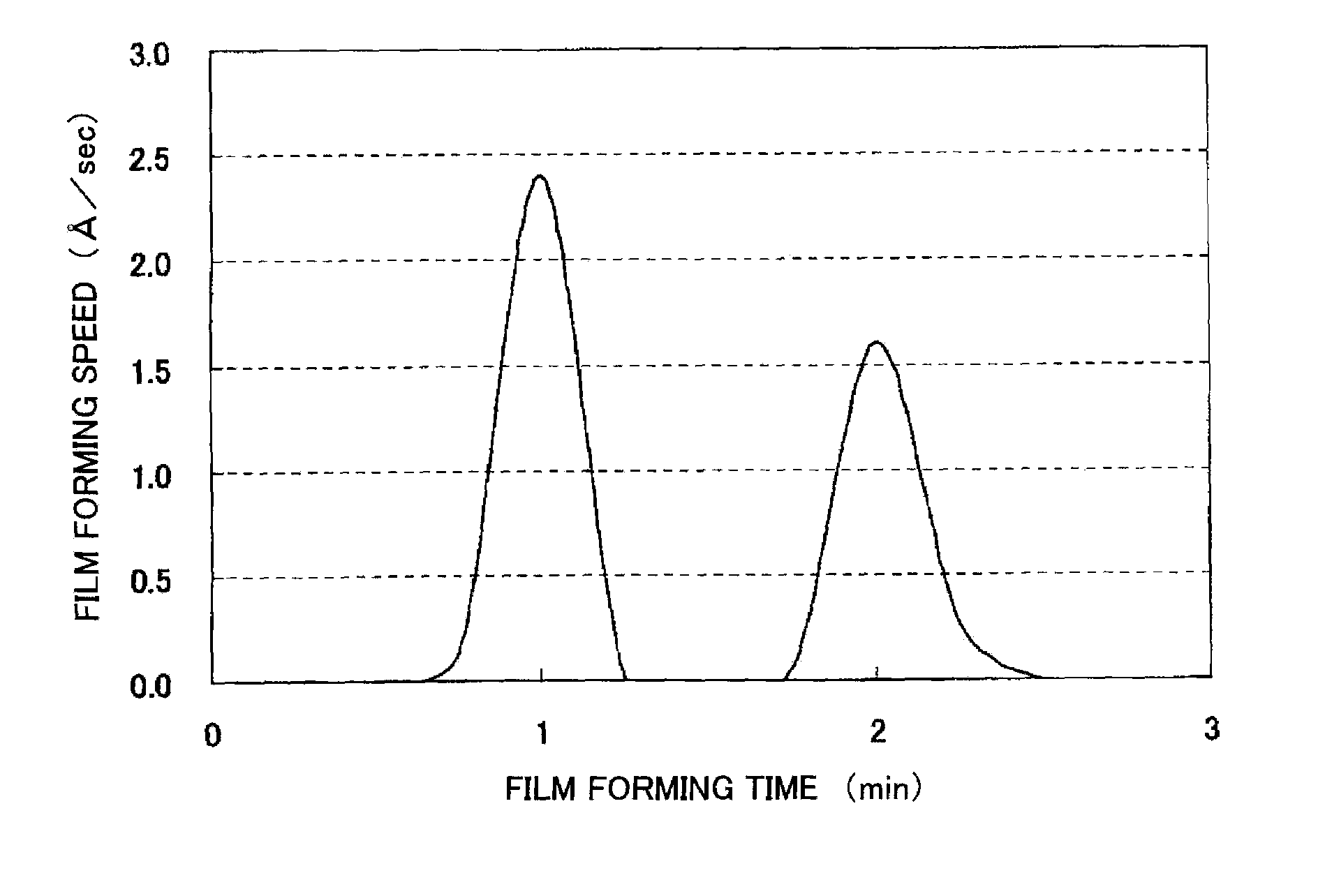

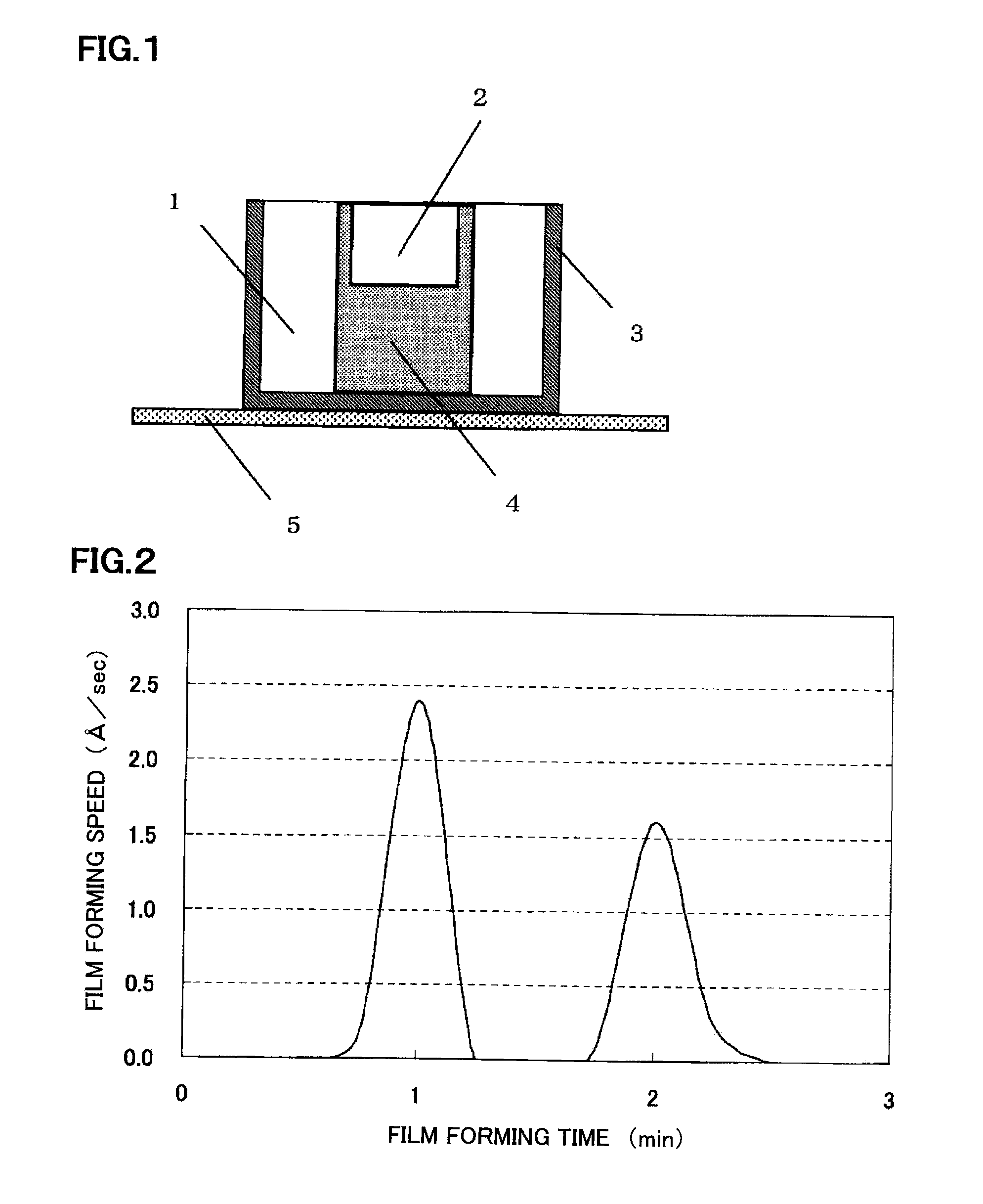

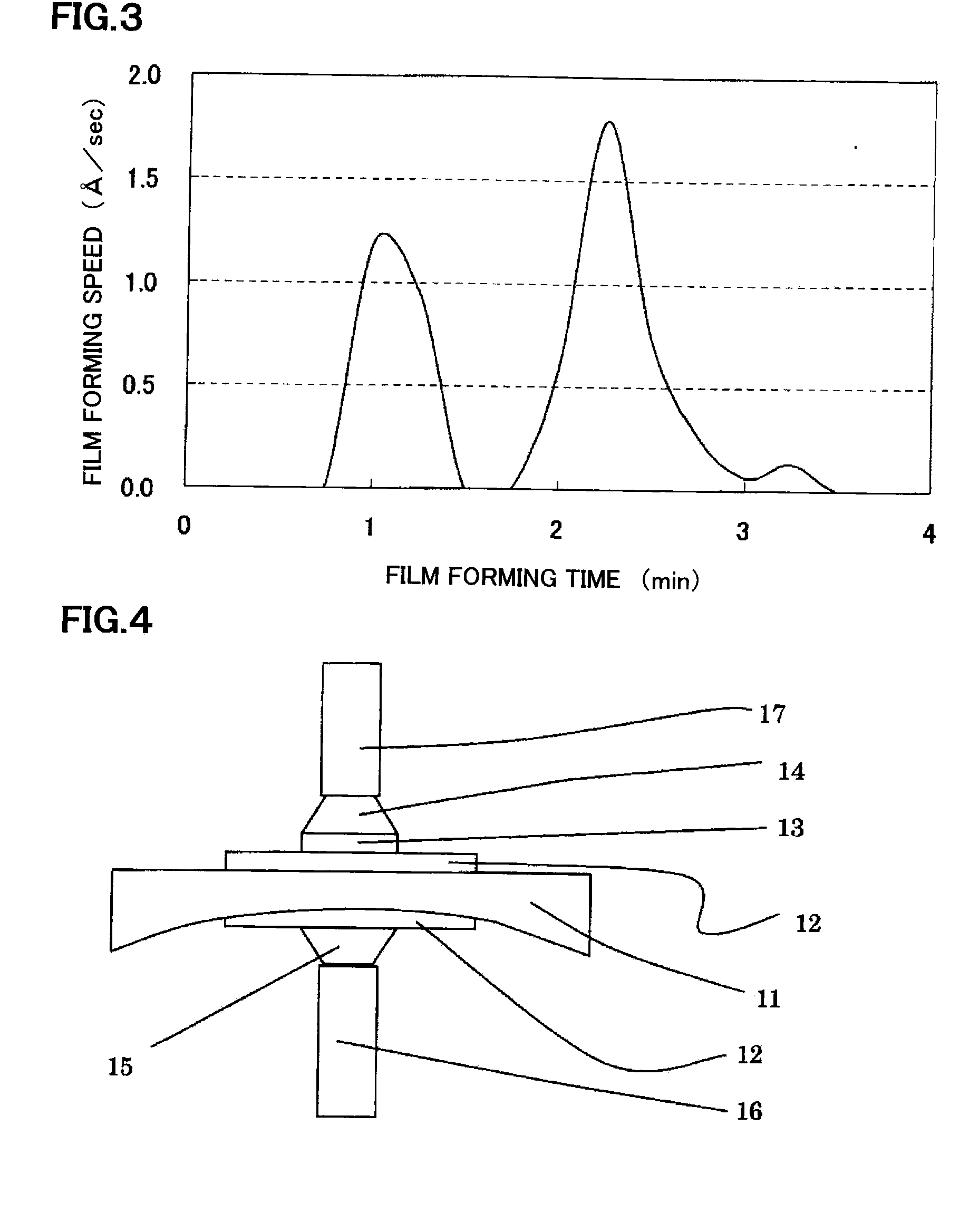

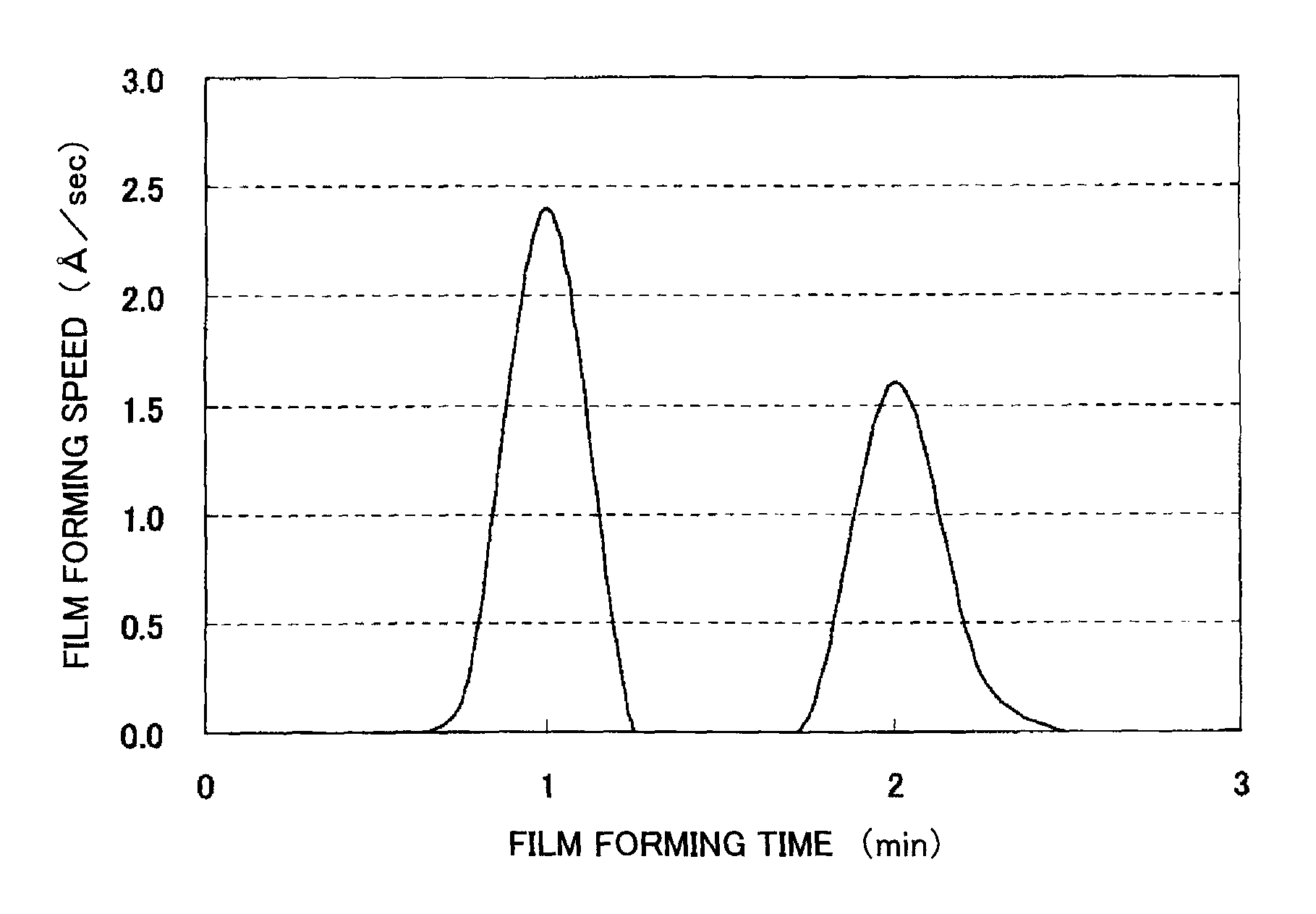

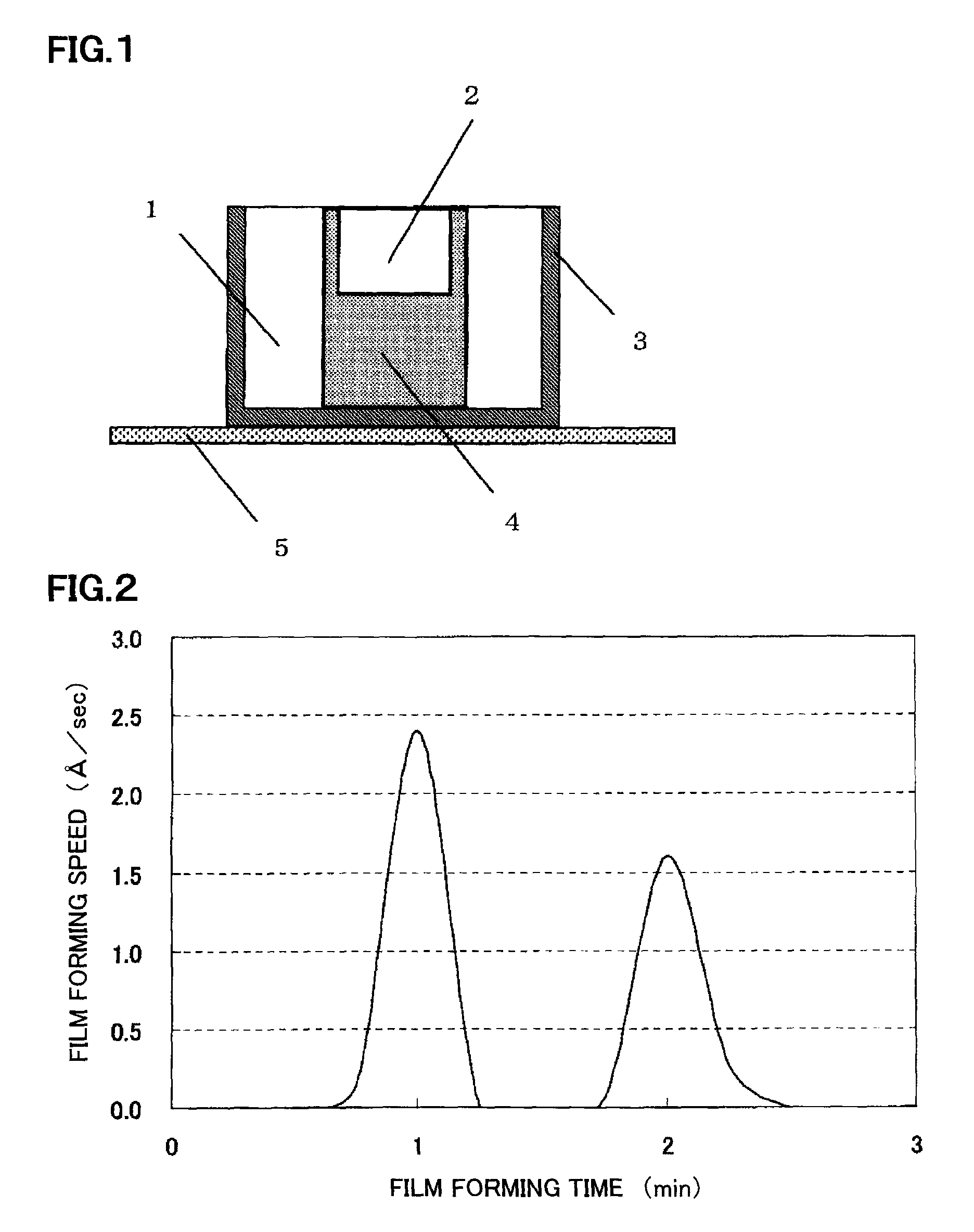

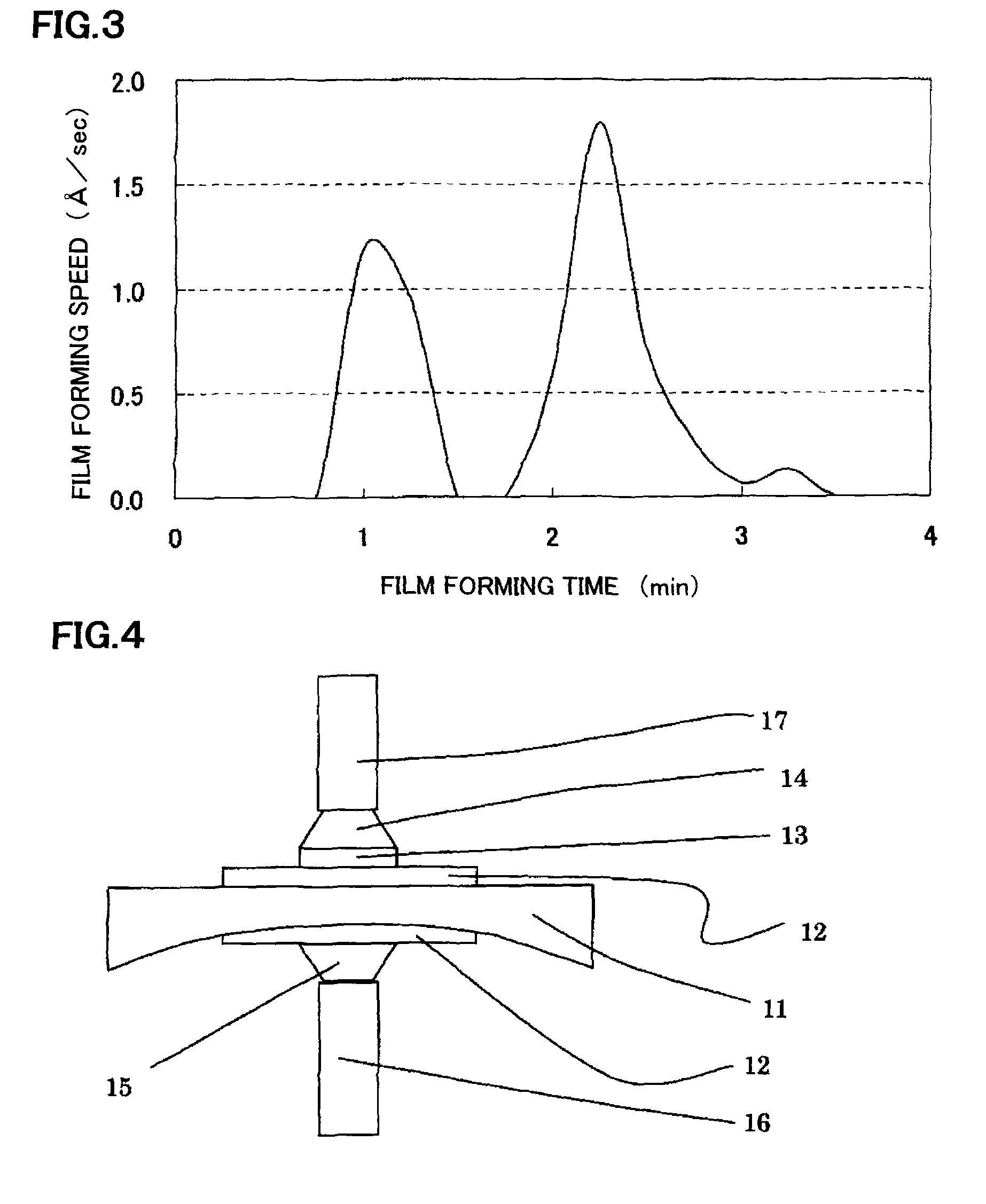

Spectacle lens and method for producing the same

ActiveUS20090257022A1Sufficient processabilityLower coefficient of dynamic frictionSpectales/gogglesSynthetic resin layered productsEyewearLens plate

The disclosure relates to a spectacle lens comprising: a lens base member; a multi-layered anti-reflection film placed on the lens base member, and including a layer mainly made of silicon dioxide as an outermost layer; and a water-and-oil repellent layer provided in contact with the outermost layer of the multi-layered anti-reflection film, and made by using, as raw materials: at least one kind of a first fluorine-substituted alkyl group-containing organosilicon compound and a second fluorine-substituted alkyl group-containing organosilicon compound. The disclosure also relates to methods of producing a spectacle lens that is capable of retaining a sufficient water-and-oil repellency over an extended period, and having sufficient edge processability.

Owner:NIKON ESSILOR

Rubber composition for sidewall, insulation or breaker cushion, production method thereof, and pneumatic tire

InactiveUS8623956B2Eliminate needImprove economySpecial tyresRolling resistance optimizationEngineeringChewing food

The present invention provides a rubber composition for a sidewall, an insulation, or a breaker cushion, which can achieve both excellent fuel economy (low heat build-up) and high flex crack growth resistance while having processability excellent enough to eliminate the need for mastication, and also provides a pneumatic tire produced using the rubber composition. The present invention relates to a rubber composition for a sidewall, an insulation, or a breaker cushion, including: a rubber component that contains a modified natural rubber with a phosphorus content of 200 ppm or less; and carbon black and / or a white filler.

Owner:SUMITOMO RUBBER IND LTD

Hard coating film

ActiveUS20150252210A1Maintain good propertiesHigh hardnessSynthetic resin layered productsCasings/cabinets/drawers detailsTransmittanceHardness

Disclosed is a hard coating film with high physical properties including hardness, scratch resistance, impact resistance, transparency, durability, light resistance, and light transmittance. The hard coating film can find useful applications in various fields thanks to its excellent physical properties.

Owner:LG CHEM LTD

Coating composition and coated metal plate, metal container and metal closure coated with the coating composition

ActiveUS20150125643A1Increase crosslink densityReduce molecular movementLiquid surface applicatorsAnti-corrosive paintsPolymer sciencePtru catalyst

The present invention relates to a polyester coating composition used for forming a coating film of a coated metal plate, a metal container, a metal closure, etc. The coating composition has a crosslinking agent and a curing catalyst incorporated into a mixed polyester resin comprising a mixture of a polyester resin (A) having an acid value of 2 to 50 mg KOH / g and a glass transition temperature (Tg) of 35 to 100° C. and a polyester resin (B) having an acid value of 0 to 50 mg KOH / g and a glass transition temperature (Tg) of −20 to 25° C. Thus, a coating composition excellent in resistance to embrittlement over time, corrosion resistance, scrape resistance, retort resistance, and blocking resistance can be provided.

Owner:TOYO SEIKAN GRP HLDG LTD +2

Hard coating film

ActiveUS9783698B2Maintain good propertiesHigh hardnessSynthetic resin layered productsCasings/cabinets/drawers detailsTransmittanceHardness

Disclosed is a hard coating film with high physical properties including hardness, scratch resistance, impact resistance, transparency, durability, light resistance, and light transmittance. The hard coating film can find useful applications in various fields thanks to its excellent physical properties.

Owner:LG CHEM LTD

Process for Increasing the Adhesion of a Reinforcing Inorganic Material in a Polymeric Matrix, a Reinforcing Inorganic Material, a Process for Obtaining a Thermoplastic Composite Material, a Thermoplastic Composite Material, and a Thermoplastic Composite Article

InactiveUS20160251499A1High mechanical strengthSufficient processabilityPigment treatment with organosilicon compoundsParticulatesOrganic solvent

Process for increasing the adhesion of a reinforcing inorganic material in an organic matrix: includes subjecting a dry load of particulate or fibrous reinforcing inorganic material presenting hydroxyls in its surface, to a first surface treatment with a coupling agent of the siloxane type containing amine groups, dissolved in an organic solvent free of water and with an acid pH and, after a curing step, to a new surface treatment with a coupling agent of the siloxane type dissolved in a solution containing an organic solvent and water, to be subjected to a new curing step. The reinforcement material may be mixed to a load of organic material defined by a polymer or by a monomer, to obtain a composite mixture to form a composite polymeric material which may present the desired final form or a raw form, to be ground or pelletized into a particulate form for posterior processing.

Owner:UNIVERSIDADE FEDERAL DE SANTA CATARINA

Rubber composition and tire

InactiveUS20170218170A1Good rubber performanceMaintaining energy efficiencySpecial tyresWithout separate inflatable insertsPolymer scienceSilicon dioxide

A rubber composition comprising silica that has a BET specific surface area of not more than 130 m2 / g and hardness of granulated particles as measured based on JIS K6221-1982 6.3.3 of not less than 23.5 cN can provide a rubber composition which is excellent in rubber physical properties while maintaining energy efficiency. A tire comprising a component consisted of the rubber composition can be also provided.

Owner:SUMITOMO RUBBER IND LTD

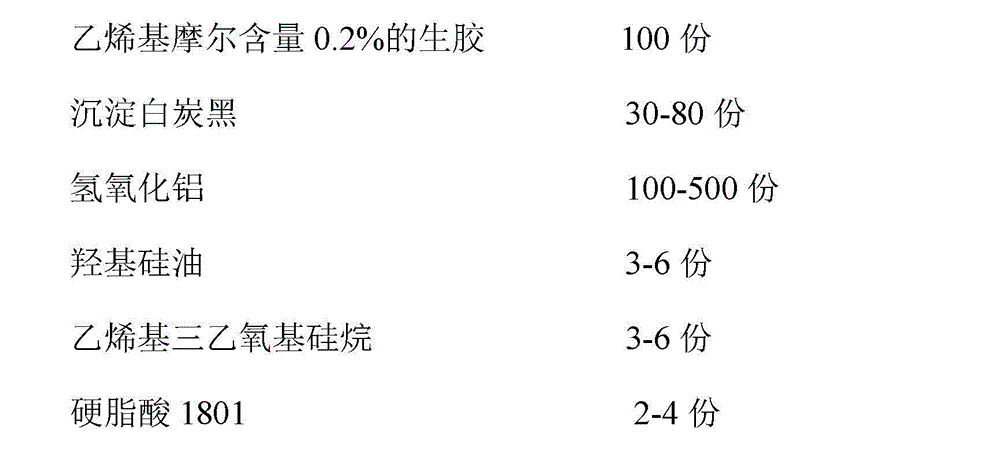

High-strength insulator silica gel and preparation method thereof

InactiveCN103333505AFulfil requirementsHigh strength propertiesComposite insulatorsVinyltriethoxysilane

The invention discloses a high-strength insulator silica gel and a preparation method thereof. The high-strength insulator silica gel comprises crude rubber, precipitated silica, aluminium hydroxide, hydroxyl silicone oil, vinyltriethoxysilane, stearic acid and the like. The ingredients above are mixed by a kneader. The high-strength insulator silica gel possesses high strength and hardness, and excellent processability; is difficult to distort; is capable of meeting the requirements of an composite insulator; and has a wider application range.

Owner:JIANGSU TIANCHEN NEW MATERIALS

Spectacle lens and method for producing the same

ActiveUS7954944B2Lower coefficient of dynamic frictionHigh coefficient of kinetic frictionSpectales/gogglesSynthetic resin layered productsSilicon dioxideOrganosilicon

The disclosure relates to a spectacle lens comprising: a lens base member; a multi-layered anti-reflection film placed on the lens base member, and including a layer mainly made of silicon dioxide as an outermost layer; and a water-and-oil repellent layer provided in contact with the outermost layer of the multi-layered anti-reflection film, and made by using, as raw materials: at least one kind of a first fluorine-substituted alkyl group-containing organosilicon compound and a second fluorine-substituted alkyl group-containing organosilicon compound. The disclosure also relates to methods of producing a spectacle lens that is capable of retaining a sufficient water-and-oil repellency over an extended period, and having sufficient edge processability.

Owner:NIKON ESSILOR

Oil-extended natural rubber and method for producing the same rubber composition and tire using the same

ActiveUS20100222488A1Sufficient processabilityExcellent tensile strength and wear resistanceSpecial tyresNatural rubber latexPolystyrene

This invention relates to an oil-extended natural rubber capable of improving a tensile strength and a wear resistance of a rubber composition, and more particularly to an oil-extended natural rubber formed by adding an emulsified extension oil to a natural rubber latex and further coagulating and drying them. An amount of the extension oil added is preferable to be within a range of 5-80% by mass based on a rubber component in the natural rubber latex and the oil-extended natural rubber is preferable to have a weight average molecular weight as converted to polystyrene of a rubber component of not less than 1,500,000.

Owner:BRIDGESTONE CORP

Copolymer polyester resin and molded product using same

Owner:SK CHEM CO LTD

Coating composition and coated metal plate, metal container and metal closure coated with the coating composition

ActiveUS10508214B2Increase crosslink densityDeterioration of processabilityLiquid surface applicatorsAnti-corrosive paintsAcid valuePolyester resin

The present invention relates to a polyester coating composition used for forming a coating film of a coated metal plate, a metal container, a metal closure, etc. The coating composition has a crosslinking agent and a curing catalyst incorporated into a mixed polyester resin comprising a mixture of a polyester resin (A) having an acid value of 2 to 50 mg KOH / g and a glass transition temperature (Tg) of 35 to 100° C. and a polyester resin (B) having an acid value of 0 to 50 mg KOH / g and a glass transition temperature (Tg) of −20 to 25° C. Thus, a coating composition excellent in resistance to embrittlement over time, corrosion resistance, scrape resistance, retort resistance, and blocking resistance can be provided.

Owner:TOYO SEIKAN GRP HLDG LTD +2

Fluorinated surfactant-free aqueous dispersion of a vinylidene fluoride copolymer comprising hydroxyl groups

ActiveUS20190284428A1Sufficient stability against coagulationAdequate shelf-lifeCell component detailsElectrically-conductive paintsPolymer scienceEnd-group

The present invention pertains to a fluorosurfactant free aqueous dispersion of an acrylic-modified vinylidene fluoride polymer, possessing a melt viscosity of at least 30 kPoise, and possessing an amount of end groups of formula —CH2—OH of at least 5 mmol / kg, to a method for its preparation and to its use for the manufacture of electrochemical cell components, such as electrodes and / or composite separators.

Owner:SOLVAY SOLEXIS

Silicone rubber for insulators and method for preparing silicone rubber

The invention discloses a technology for manufacturing silicone rubber materials, and particularly relates to silicone rubber for insulators and a method for manufacturing the silicone rubber. The silicone rubber comprises, by weight, 100 parts of raw rubber with the vinyl molar content of 0.2%, 30-80 parts of gas-phase white carbon black, 100-500 parts of aluminum hydroxide, 3-6 parts of hydroxyl silicone oil, 3-6 parts of vinyl hydroxyl silicone oil and 2-4 parts of stearic acid. The silicone rubber in a formula and the method have the advantages that various raw materials are reasonably selected and are reasonably matched with one another, the specific method is implemented, various parameters are strictly controlled in preparation procedures, accordingly, the silicone rubber is high in strength, sufficient in hardness and processability and difficult to deform, and requirements of the composite insulators can be completely met.

Owner:JIANGSU TIANCHEN NEW MATERIALS

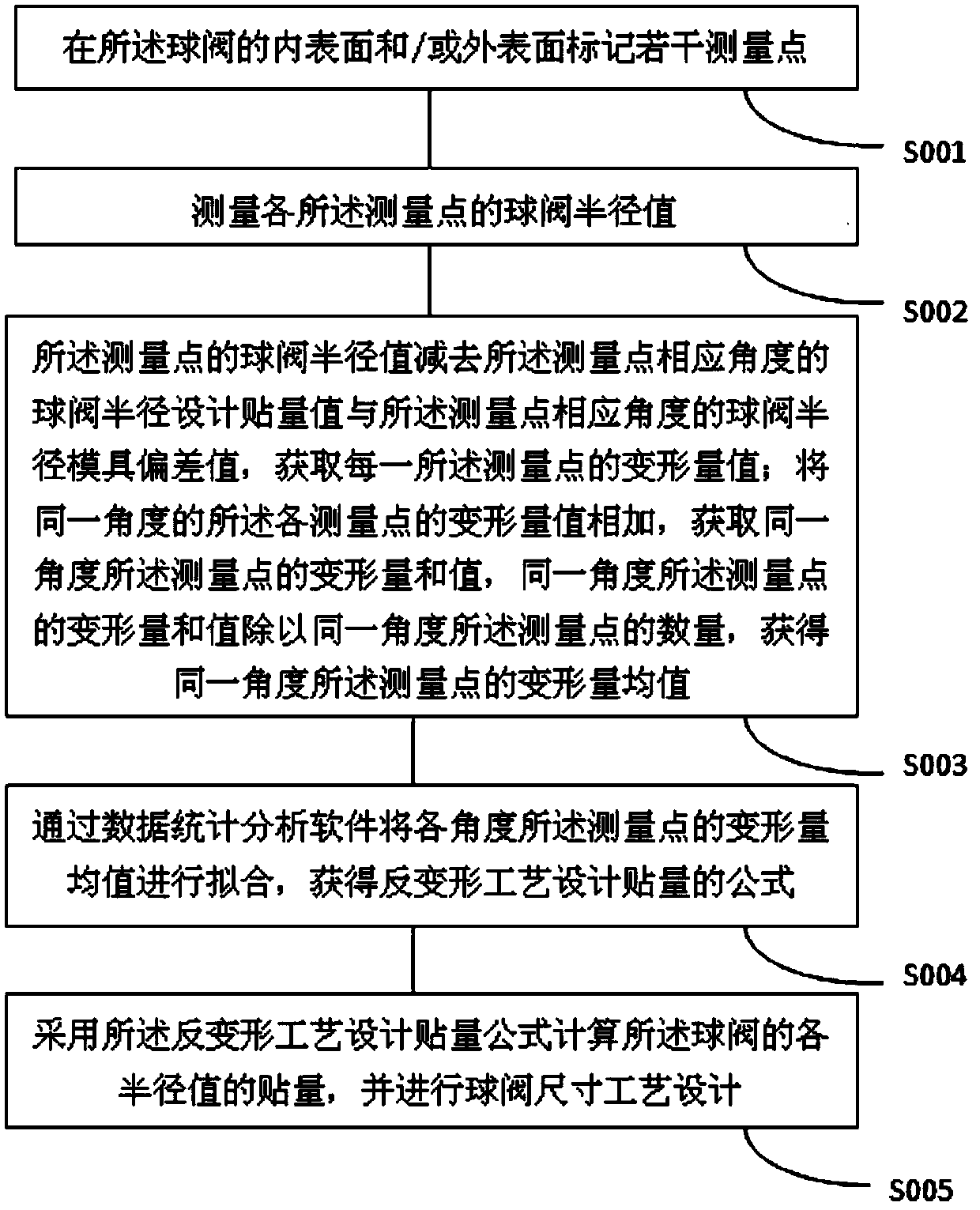

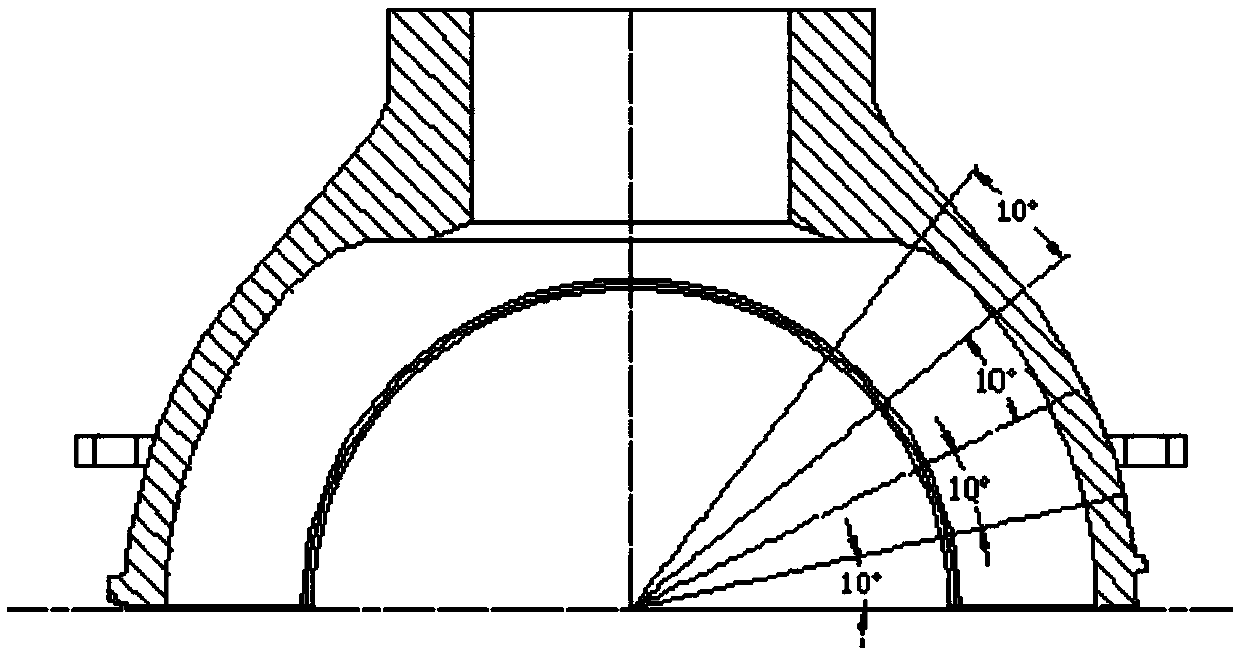

Size design method of a large thin-wall ball valve

ActiveCN109657280AMeet standard tolerance requirementsReduce processing timeGeometric CADDesign optimisation/simulationStatistical analysisEngineering

The invention belongs to the technical field of casting, and relates to a size design method of a large thin-wall ball valve, which comprises the following steps of: marking a plurality of measuring points on the inner surface and / or the outer surface of the ball valve; Measuring the ball valve radius value of each measuring point; Subtracting the ball valve radius design sticking value of the corresponding angle measuring point from the ball valve radius value of the measuring point and the ball valve radius mold deviation value of the measuring point to obtain a deformation value; Adding thedeformation values to obtain the deformation sum value of the same angle measurement point, and dividing the deformation sum value of the same angle measurement point by the number of the same anglemeasurement points to obtain a deformation mean value of the same angle measurement point; Fitting the mean value of the deformation amounts of the angle measurement points through data statistical analysis software to obtain a formula of the anti-deformation process design sticking amount; According to the method, the sticking amount of each radius value of the ball valve is calculated by adopting a sticking amount formula designed by adopting a reverse deformation process, and the size process design of the ball valve is performed, so that the production period is remarkably prolonged and the cost is saved through the reverse deformation size process design of the method.

Owner:KOCEL STEEL

Copolymer polyester resin and molded product using same

ActiveUS8580898B2Easy to controlReduce shrinkage stressWood working apparatusFlat articlesCyclohexanedimethanolShrinkage rate

The present invention relates to a copolymer polyester resin and a molded product using the same, and more specifically to a copolymer polyester resin that contains 10˜80 mol % of 1,4-cyclohexane dimethanol, 0.1˜50 mol % of a diol compound expressed as HO—(CH2)a—CO—(CH2)b—OH (where a and b are integers in the range 1˜5), and ethylene glycol or other diols so that the sum of its entire diol composition is 100 mol % based on dicarboxylic acid. The copolymer polyester resin of the present invention enables reduction of cycle time, improvement of product processability and prevention of PET bottle deformation during mold processing with a heat-shrinking label by complementing low temperature shrinkage, maintaining a high shrinkage rate, and reducing shrinkage stress.

Owner:SK CHEM CO LTD

Fluorinated surfactant-free aqueous dispersion of a vinylidene fluoride copolymer comprising hydroxyl groups

ActiveUS10968362B2Sufficient stability against coagulationHigh molecular weightCell component detailsElectrically-conductive paintsEnd-groupActive agent

Owner:SOLVAY SOLEXIS

Method for stabilizing aqueous dispersions of fluorinated polymers

ActiveUS20200362118A1Sufficient stability against coagulationSufficient processabilityHybrid capacitor separatorsHybrid capacitor electrodesPolymer scienceFluoride

The present invention relates to a method for stabilizing aqueous dispersions, notably of polymers based on vinylidene fluoride (VDF), and to the use of the stabilized aqueous dispersion thus obtained in electrochemical applications.

Owner:SOLVAY SOLEXIS

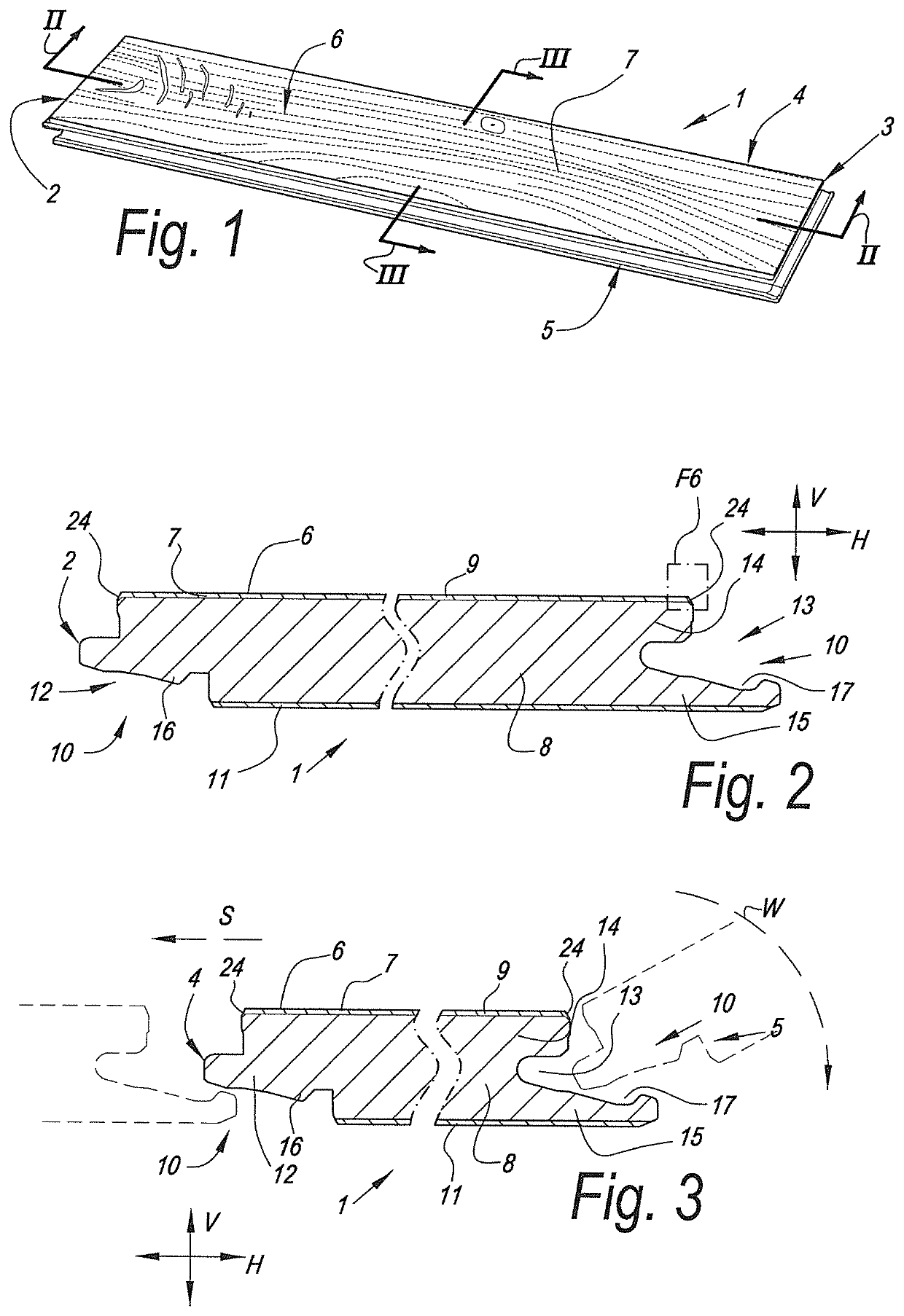

Method for manufacturing floor panels

ActiveUS11174647B2Good color consistencyLess irritatingSynthetic resin layered productsSpecial ornamental structuresEngineeringLow density

A method for manufacturing a floor panel with a substrate and a top layer of laminate, which floor panel, at one or more edges, is provided with a lower edge region, where the laminate extends in one piece from the actual upper surface of the substrate over the lower edge region at least up to a point. The laminate surface is situated at a level in a horizontal plane which intersects the substrate and that the substrate material, at the location of the lower edge region, has the same or a lower density than at the actual upper surface of the substrate material.

Owner:FLOORING IND LTD

Light-fixable and heat-curing compounds based on epoxy resins and thiols

ActiveUS11485887B2Reliably curedSufficient processing timeNon-macromolecular adhesive additivesOther chemical processesEpoxyPolymer science

Owner:DELO INDKLEBSTOFFE

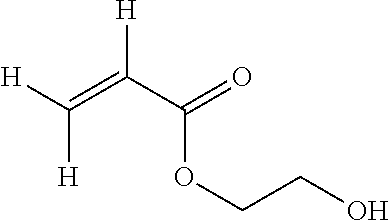

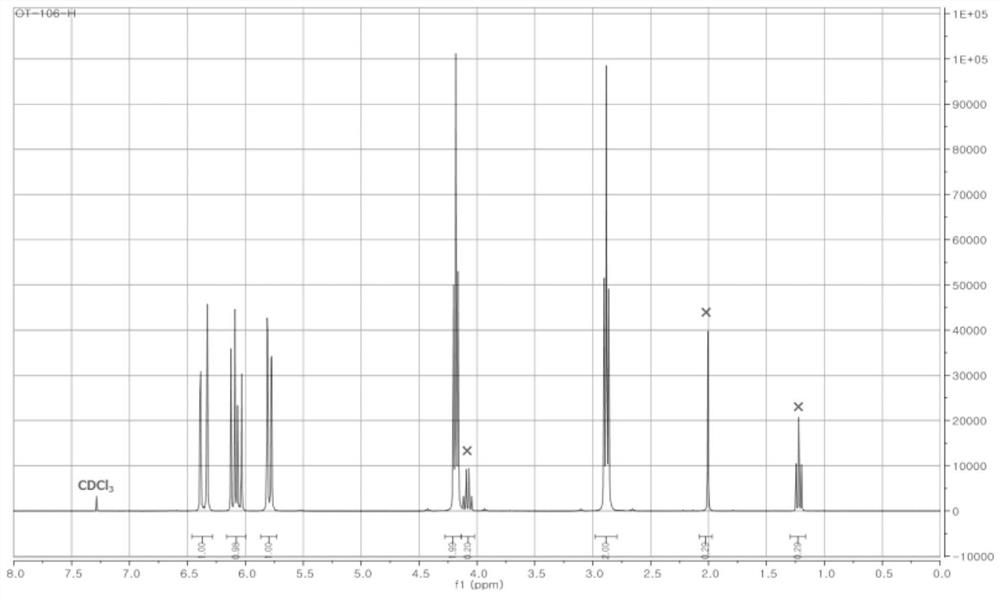

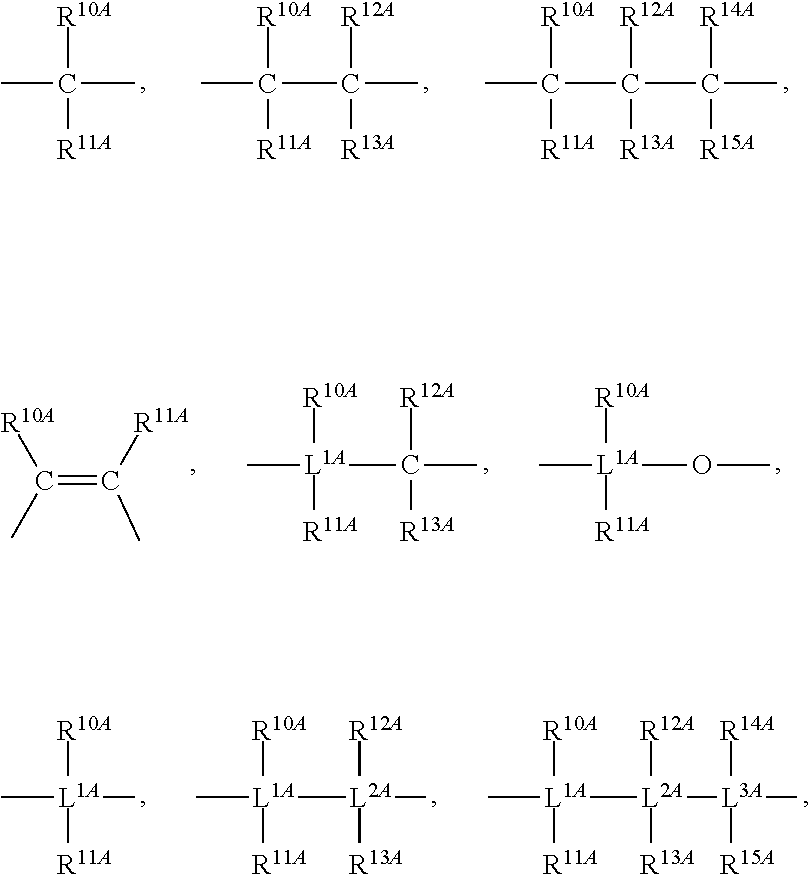

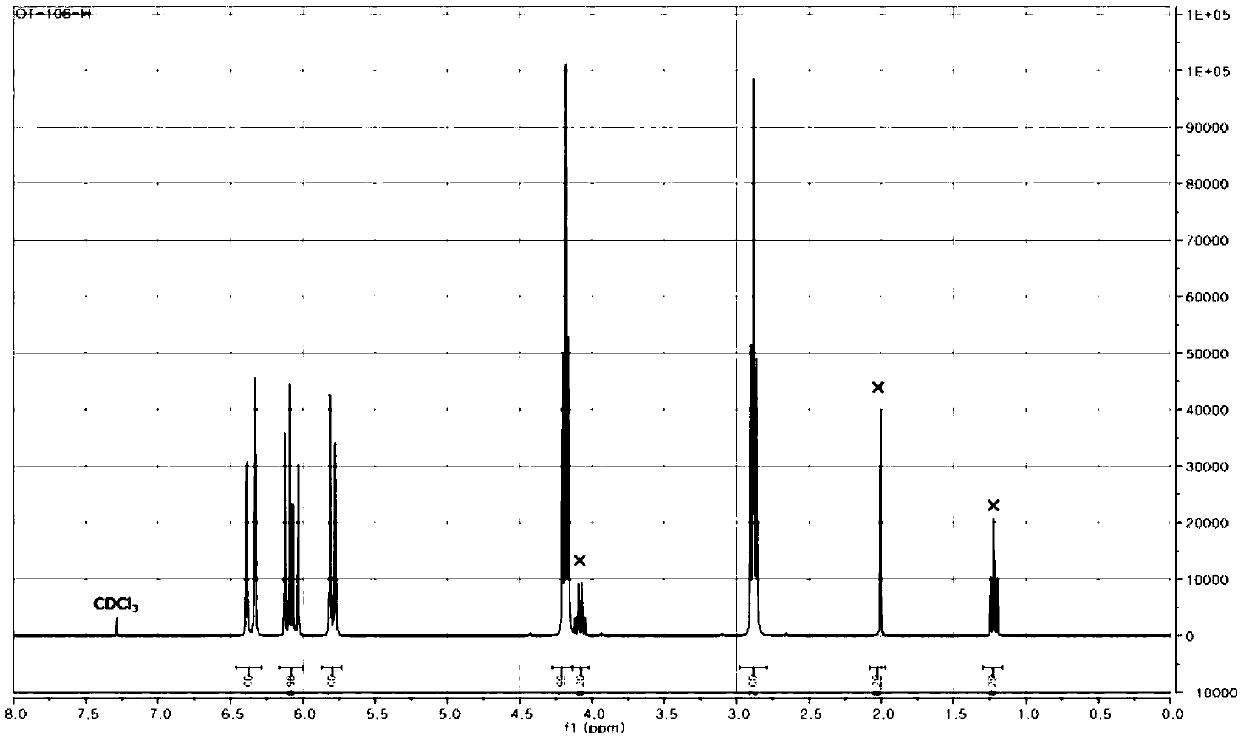

Acrylate compound, photocurable composition containing same, photocurable cured film, and image display device

ActiveCN109517101BEasy transferSufficient processabilityOrganic chemistryPhotomechanical apparatusPolymer scienceMeth-

The present invention provides an acrylate compound represented by Chemical Formula 1, a photocurable composition including the acrylate compound, a photocurable cured film, and an image display device. By using the acrylate compound of the present invention, it is possible to form a solid cured structure equal to or higher than conventional high-viscosity polyfunctional acrylates, and to manufacture solvent-free low Viscosity photocurable composition. In the chemical formula 1, R is hydrogen or methyl, and n is an integer of 2-6. chemical formula 1

Owner:DONGWOO FINE CHEM CO LTD

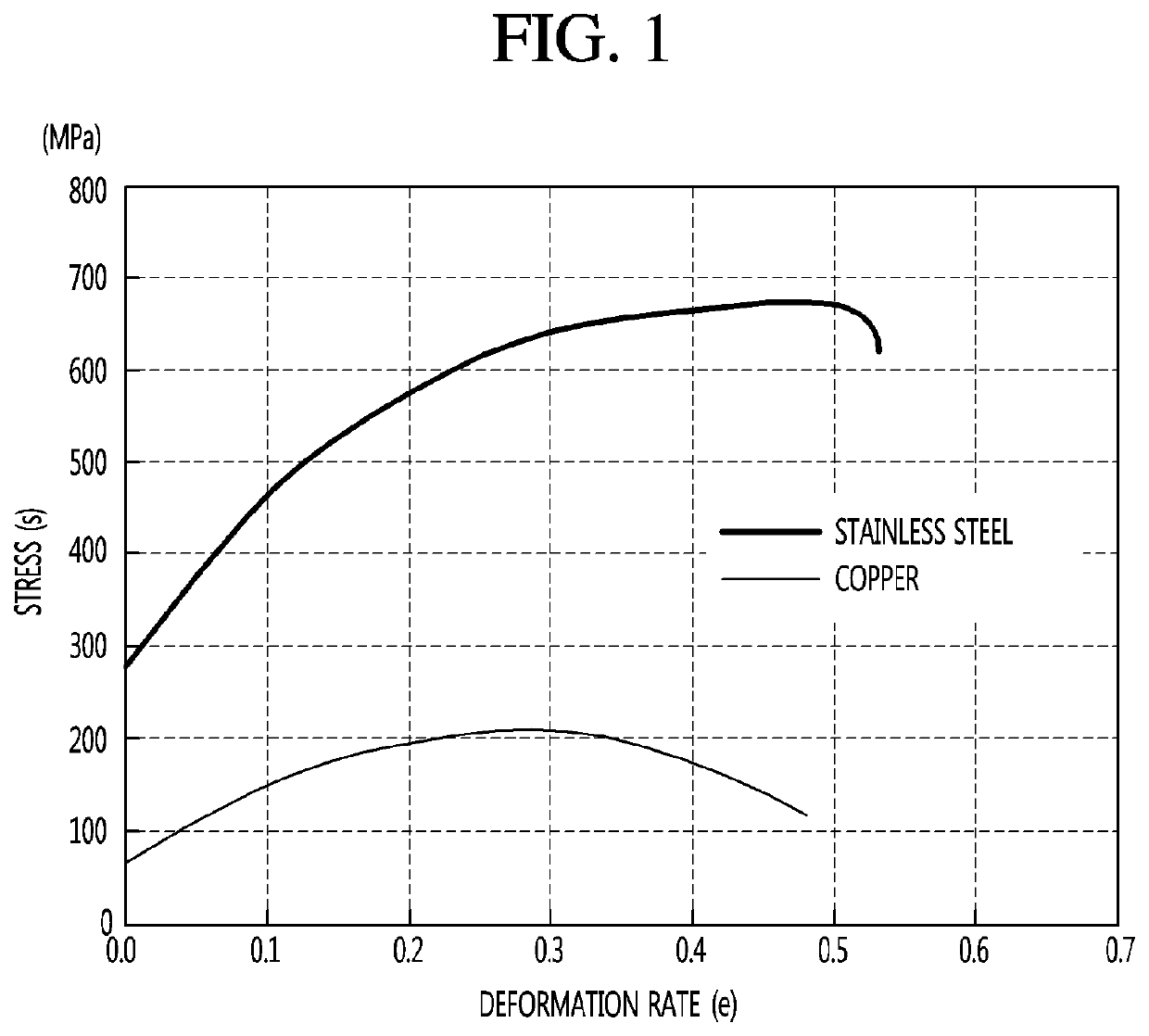

Stainless steel and pipe made thereof

ActiveUS10627168B2Reduce intensityReduce hardnessHeat exhanger conduitsFurnace typesSS - Stainless steelUltimate tensile strength

Disclosed are a stainless steel having a new composition, which has properties of low strength as compared with a conventional stainless steel, that includes, percent by weight, C: 0.03% or less, Si: exceeding 0 to 1.7% or less, Mn: 1.5 to 3.5%, Cr: 15.0 to 18.0%, Ni: 7.0 to 9.0%, Cu: 1.0 to 4.0%, Mo: 0.03% or less, P: 0.04% or less, S: 0.04% or less, N: 0.03% or less, residue: Fe, and incidental impurities, and has an austenite matrix structure and an average diameter of 30 to 60 μm, and a system such as an air conditioner including the stainless steel thereof.

Owner:LG ELECTRONICS INC

Rubber composition for inner liner and pneumatic tire

The present invention provides a rubber composition for an inner liner, which can achieve both excellent low heat build-up and high flex crack growth resistance while having processability excellent enough to eliminate the need for mastication, and further has good air impermeability, and also provides a pneumatic tire produced using the rubber composition. The present invention relates to a rubber composition for an inner liner, including: a rubber component that contains a modified natural rubber with a phosphorus content of 200 ppm or less, and carbon black and / or a white filler.

Owner:SUMITOMO RUBBER IND LTD

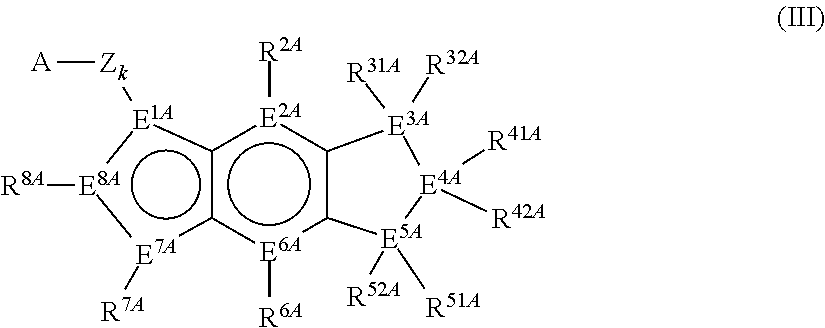

Mono-hydroindacenyl complexes

ActiveUS8247587B2Improve performanceNarrow distributionGroup 8/9/10/18 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsElastomerPolymer science

The present invention relates to monohydroindacenyl complexes as active catalytic components in the copolymerization of ethylene. The complexes are suitable for direct preparation of ethylene copolymers having a narrow molecular distribution as well as the desired levels of low density and preferably a predetermined value of glass transition temperature Tg. The produced copolymers showing improved elastomeric performance can be prepared in a single step during polymerization reaction, thus avoiding a blending step following the polymerization step.

Owner:BASELL POLYOLEFINE GMBH

Acrylate Compound, Photocurable Composition Comprising the Same, photocurable film and image display device

ActiveCN109517101AEasy transferSufficient processabilityOrganic chemistryPhotomechanical apparatusHydrogenSolvent

The present invention relates to an acrylate compound represented by chemical formula 1, and a photocurable composition including the same, a photocurable film and an image display device. Through using the acrylate compound of the invention, a cured object with firmity which is equal with or higher than previous high-viscosity multifunctional acrylate can be formed, and furthermore a no-solvent low-viscosity photocurable composition which has flatness and sufficient process in inkjet equipment can be manufactured. In chemical formula 1, R is hydrogen or a methyl group and n is an integer of 2to 6.

Owner:DONGWOO FINE CHEM CO LTD

Manufacturing process of high-pressure boiler tube

PendingCN114645221AHigh temperature creep rupture strengthHigh resistance to high temperature steam corrosionSteam pressurePipe

The invention relates to a manufacturing process of a high-pressure boiler pipe. The manufacturing process comprises two aspects of smelting a stainless steel blank and manufacturing a steel pipe. When a stainless steel blank is smelted, the carbon content in the corresponding steel grade is increased, and the contents of Ti and Nb in the steel grade containing Ti and Nb are strictly controlled. In the steel pipe manufacturing process, the respective hot tapping temperature of different steel types is controlled; the cold deformation is controlled to be 55% or below; and carrying out heat treatment at a proper softening temperature of the product and a proper solid solution temperature of the finished product. The high-pressure boiler steel pipe manufactured according to the manufacturing process provided by the invention has the advantages of high creep rupture strength, high high-temperature steam corrosion resistance, sufficient toughness, machinability and weldability. And the requirements of higher and higher boiler steam pressure and temperature parameters on the steel pipe can be met. The problem that an existing high-pressure boiler pipe is tedious and inconvenient to manufacture is solved, the manufacturing quality of the steel pipe is improved, and the high-pressure boiler pipe has the advantages of being simple in manufacturing process, few in used equipment and low in cost and is quite convenient to popularize and use on a large scale.

Owner:CHINA NAT CHEM ENG NO 16 CONSTR

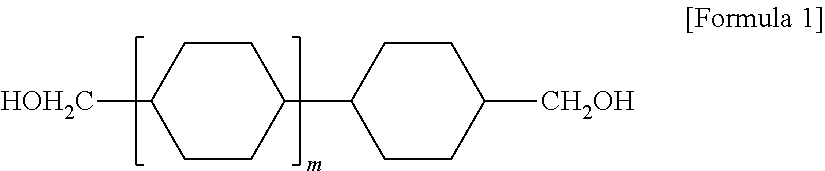

Copolymer polyester resin and molded product using same

ActiveUS20110230634A1Avoid deformationAvoid turbidityCeramic shaping apparatusCyclohexanedimethanolDiol

The present invention relates to a copolymer polyester resin and a molded product using the same and more specifically to a copolymer polyester resin that contains 10˜80 mol % of 1,4-cyclohexane dimethanol, 0.1˜30 mol % of a cyclohexane dimethanol compound expressed as HOH2C—[C6H12]m—[C6H12]—CH2OH (where m is an integer from 1˜10), and ethylene glycol as the remainder so that the sum of the entire diol composition may be 100 mol % based on an aromatic dicarboxylic acid. The copolymer polyester of the present invention enables superior products to be provided that reduce cycle time and enhance product processability during mold processing using a heat-shrinking label by complementing low temperature shrinkage properties that may be exhibited by the polyester resin of the prior art copolymerized with 1,4-cyclohexane dimethanol.

Owner:SK CHEM CO LTD

Mono-hydroindacenyl complexes

ActiveUS20120022226A1Improve mechanical propertiesImprove performanceOrganic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compoundsElastomerLow density

The present invention relates to monohydroindacenyl complexes as active catalytic components in the copolymerization of ethylene. The complexes are suitable for direct preparation of ethylene copolymers having a narrow molecular distribution as well as the desired levels of low density and preferably a predetermined value of glass transition temperature Tg. The produced copolymers showing improved elastomeric performance can be prepared in a single step during polymerization reaction, thus avoiding a blending step following the polymerization step.

Owner:BASELL POLYOLEFINE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com