Acrylate compound, photocurable composition containing same, photocurable cured film, and image display device

A photocurable, acrylate technology, applied in the field of invention, can solve the problems of increased viscosity, low double bond concentration, difficult to cure structures, etc., and achieve the effects of inhibiting oxygen polymerization, promoting chain transfer, and fully processability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

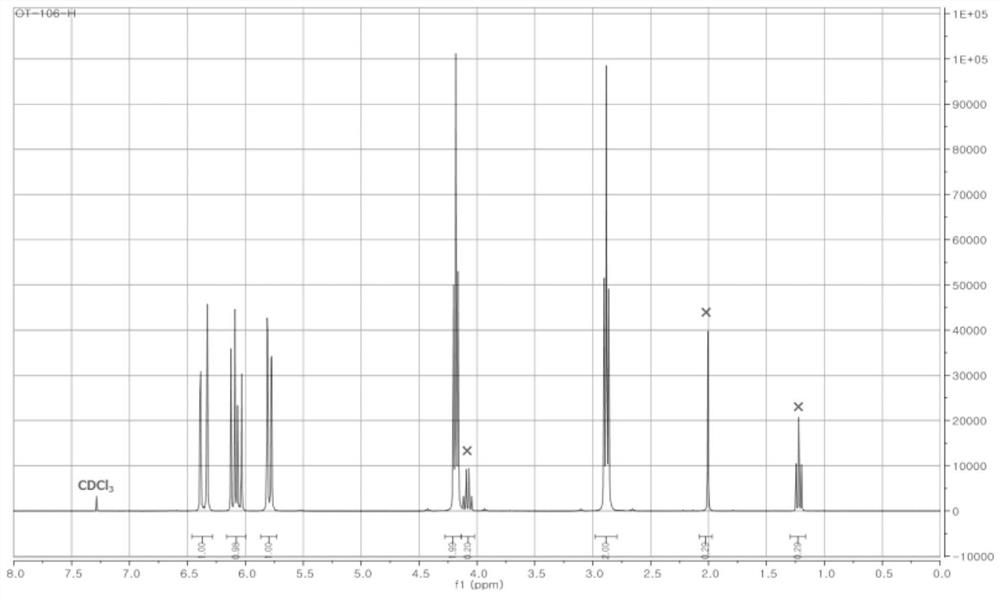

Synthetic example 1

[0104]Synthesis Example 1: Made of three (acryloyloxyethyl) amine (acrylate a)

[0105]After connecting the drip funnel and the condenser with 1L round bottom flask, it is replaced with a nitrogen atmosphere, and the tetrahydrofuran is injected with 200 ml, so that three (hydroxy ethanol) amine (TCI) 25.0 g (0.17 mol) and 2,6-dimethyl Cool to -5 ° C after dissolving 71.8 g (0.67 mol) 71.8 g (0.67 mol). Acryloyl chloride (TCI) 50.0 g (0.55 mol) was dissolved in tetrahydrofuran 150ml, and the drip funnel was placed while preventing temperature from being slowly added after 2 hours. After the drop is completed, the temperature rises to Almost temperature and stirred for 1 hour. Then, the reactants were heated at 65 ° C, and the mixture was further stirred at a reflux condition of tetrahydrofuran for 6 hours. After completion of the reaction, the reactants were again cooled to -5 ° C, and after the aqueous solution of sodium bicarbonate was added, the organic layer was extracted with ethyl...

manufacture example 1

[0110]Production Example 1: Made of photocurable composition

[0111]The photocurable resin compositions of Examples 1 to 4 and Comparative Examples 1 to 5 were separately produced using the composition of the following Table 1. The unit of the following table 1 is by weight.

[0112][Table 1]

[0113]

[0114]A: Three-functional acrylate compound represented by chemical formula 2

[0115]A-1: 异 冰 片 酯 (Ib: (strain) Xinzhong Village Chemical Industry Manufacturing) [Chemical Style 3]

[0116]A-2: 1,6-hethylene glycol diacrylate (A-HD-N: (strain) New Time Mini Chemical Industry Manufacturing [Chemical Formula 4]

[0117]A-3: Ethoxylated trimethylpropane trisyl acrylate (A-TMPT-3EO: (strain) Xinzhong Village Chemical Industry Manufacturing) [Chemical Formula 5]

[0118]A-4: Ethoxylated triglyceride (A-GLY-3EO: (strain) Xinzhong Village Chemical Industry Manufacturing [Chemicals 6]

[0119]A-5: Trihydroxypropino trisol (A-TMPT: (strain) Chemical Industry Made in Xinzhong Village [Chemicals 7]

[0120]B: The oxime es...

manufacture example 2

[0134]Production Example 2: Manufacture of Curing Film

[0135]InThe thickness of the glass substrate (EAGLE 2000; Corning Co., Ltd. manufactured), a Silicon Nitride, is applied to the film, using a spin coater to solidify the film. Coating is carried out in a manner having a thickness of 3.0 μm. After spin coating, it was placed on the platform for 5 minutes, and it was placed in an acrylic box. After replacing a nitrogen atmosphere, the UV curing device (model: LZ-UVC-F402-CMD) was used to illuminate 150MW / cm2(UV-A region measurement) irradiated 20 seconds to obtain a cured coating film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com