Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Good rubber performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

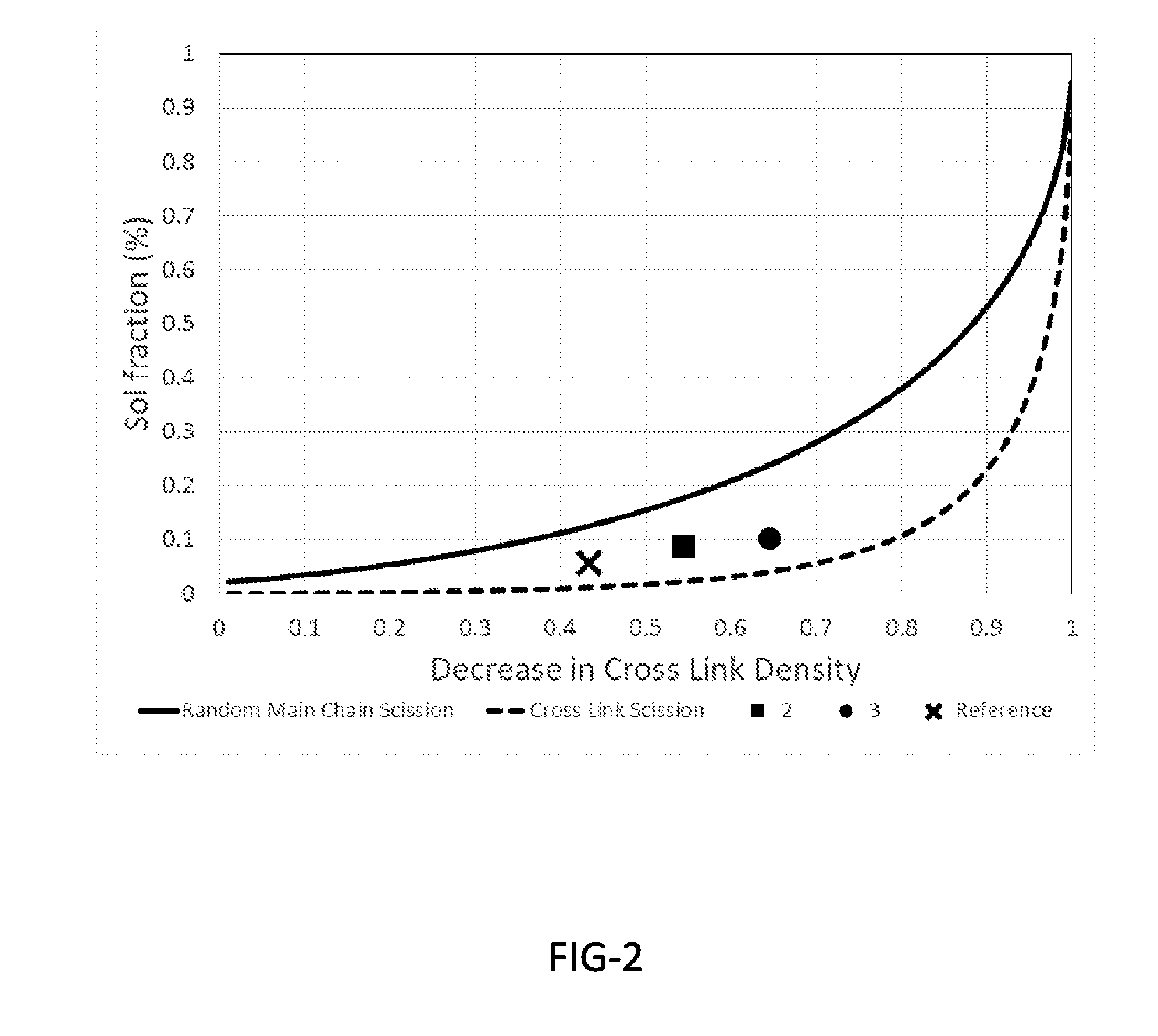

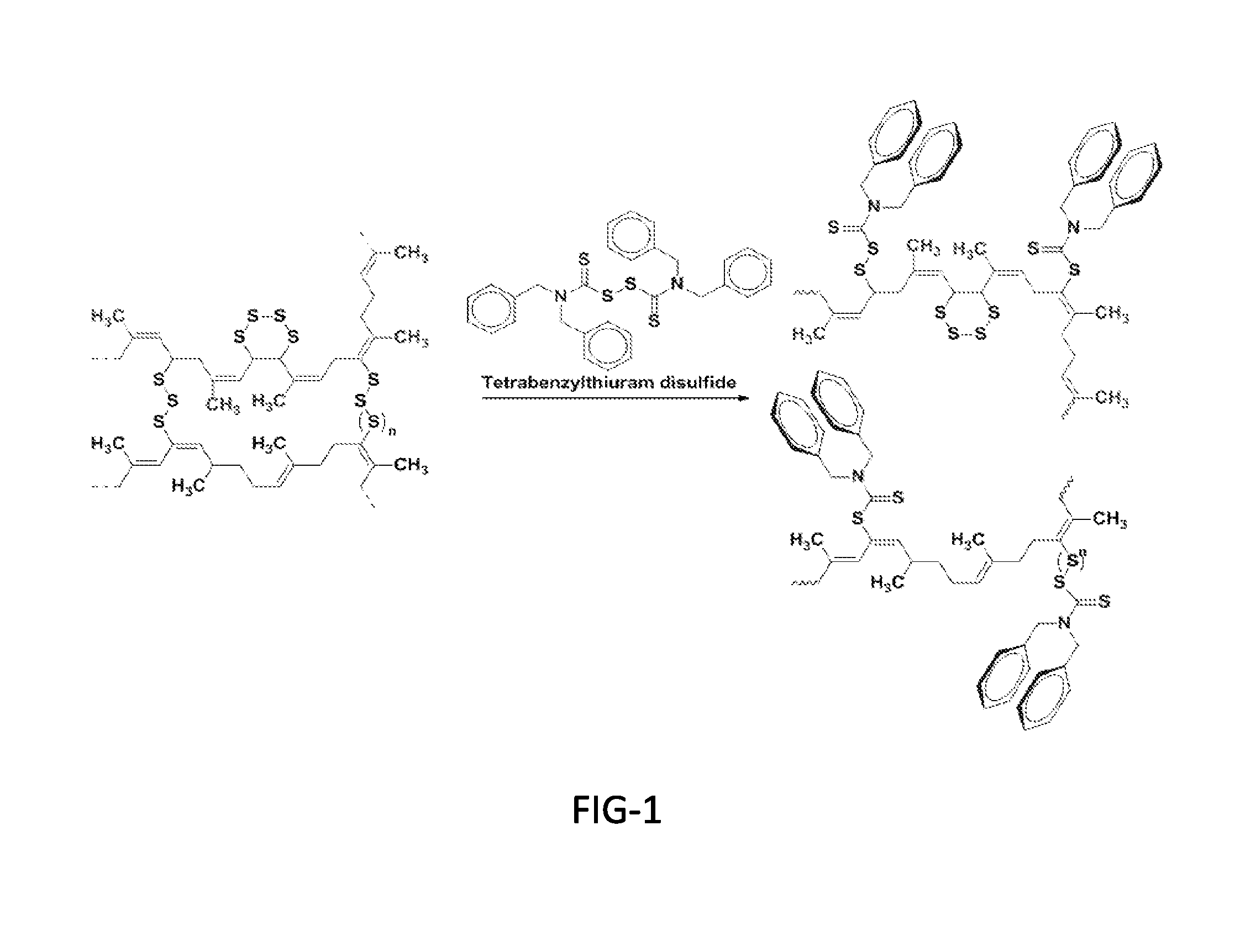

Chemically functionalized renewed rubber composition

ActiveUS20160152805A1Low hysteretic propertyImprove energy consumption efficiencySpecial tyresPneumatic tyre reinforcementsSolubilityElastomer

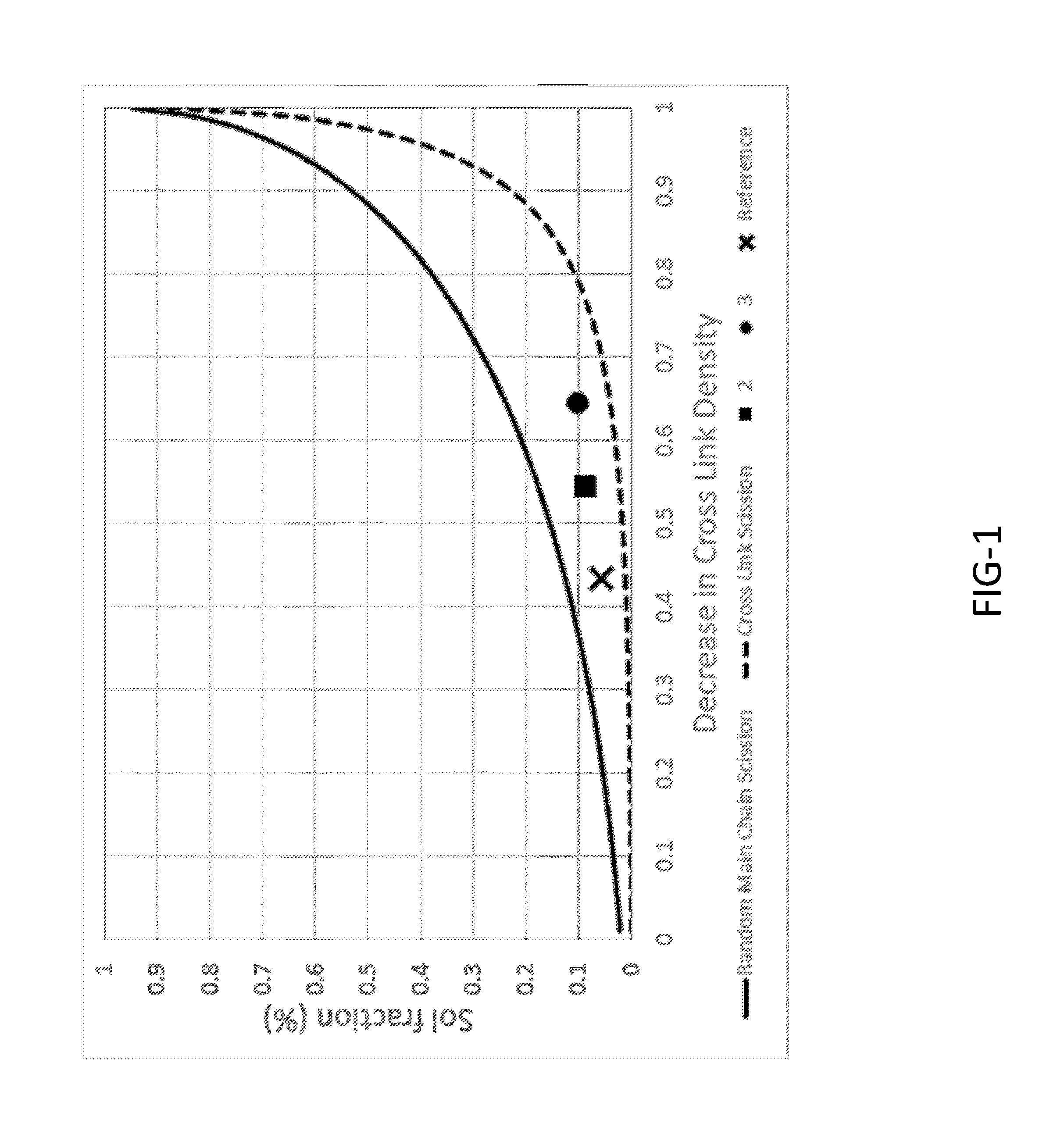

This invention relates to certain rubber formulations which exhibit a low level of hysteresis which are comprised of a chemically functionalized renewed rubber and virgin solution styrene-butadiene rubber. These rubber formulations are loaded with a reinforcing silica. The rubber formulations of this invention can be utilized in making rubber products such as, tires, tracks, and conveyor belts which will promote energy savings by virtue of their low hysteretic properties. The present invention more specifically discloses a rubber composition which is comprised of (1) a solution styrene-butadiene rubber; (2) a functionalized renewed rubber composition which is comprised of an elastomeric polymer and a stabilizer; wherein the rubber composition has a crosslink density which is within the range of 0.05 to 2.0×10−5 mole / g, and wherein the rubber composition has a solubility fraction of less than 90 percent; and (3) a reinforcing filler including reinforcing silica.

Owner:LEHIGH TECH INC

Rubber composition containing cross linkable polyethylene

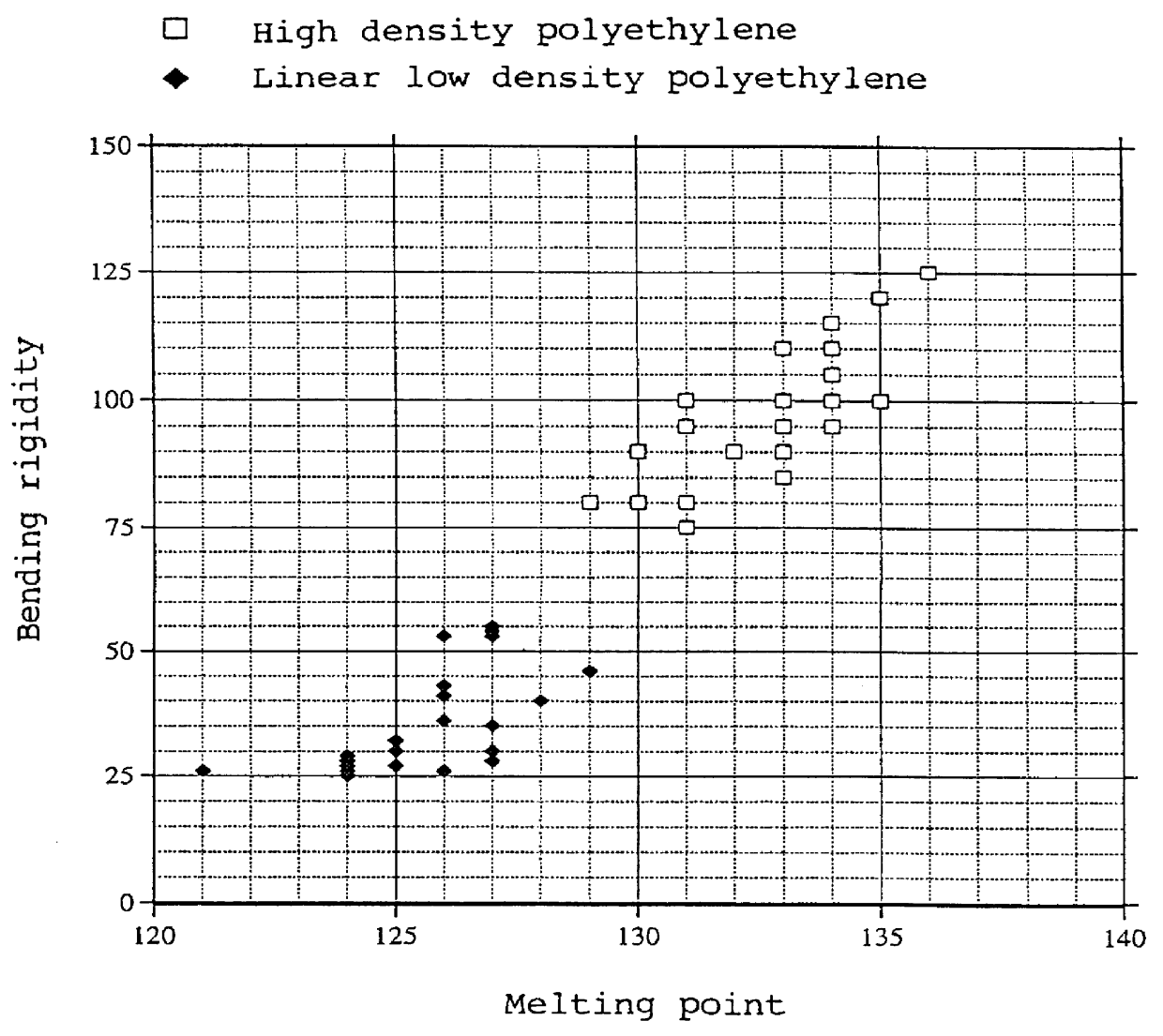

The present invention provides a rubber composition in which the coexistence of low heat build-up, heat resistance and high hardness can be achieved without damaging failure characteristics. According to the present invention, a rubber composition comprising a 100 parts by weight of matrix rubber and a 2-75 parts by weight of a polyethylene composition which contains 0-80% by weight of polyethylene and 20% by weight or more of a composite comprising a polyethylene component and a rubber component previously bonded via a coupling agent to the polyethylene component, said rubber component is crosslinked with the matrix rubber. At least at one of the kneading stages before the final stage, the compound is kneaded so that the maximum temperature of the compound of the kneading of that stage is higher than the melting point of the polyethylene component mixed, preferably, by 10 DEG C. or more.

Owner:BRIDGESTONE CORP

Ethylene/alpha-olefin/non-conjugated polyene copolymer, and production process and use thereof

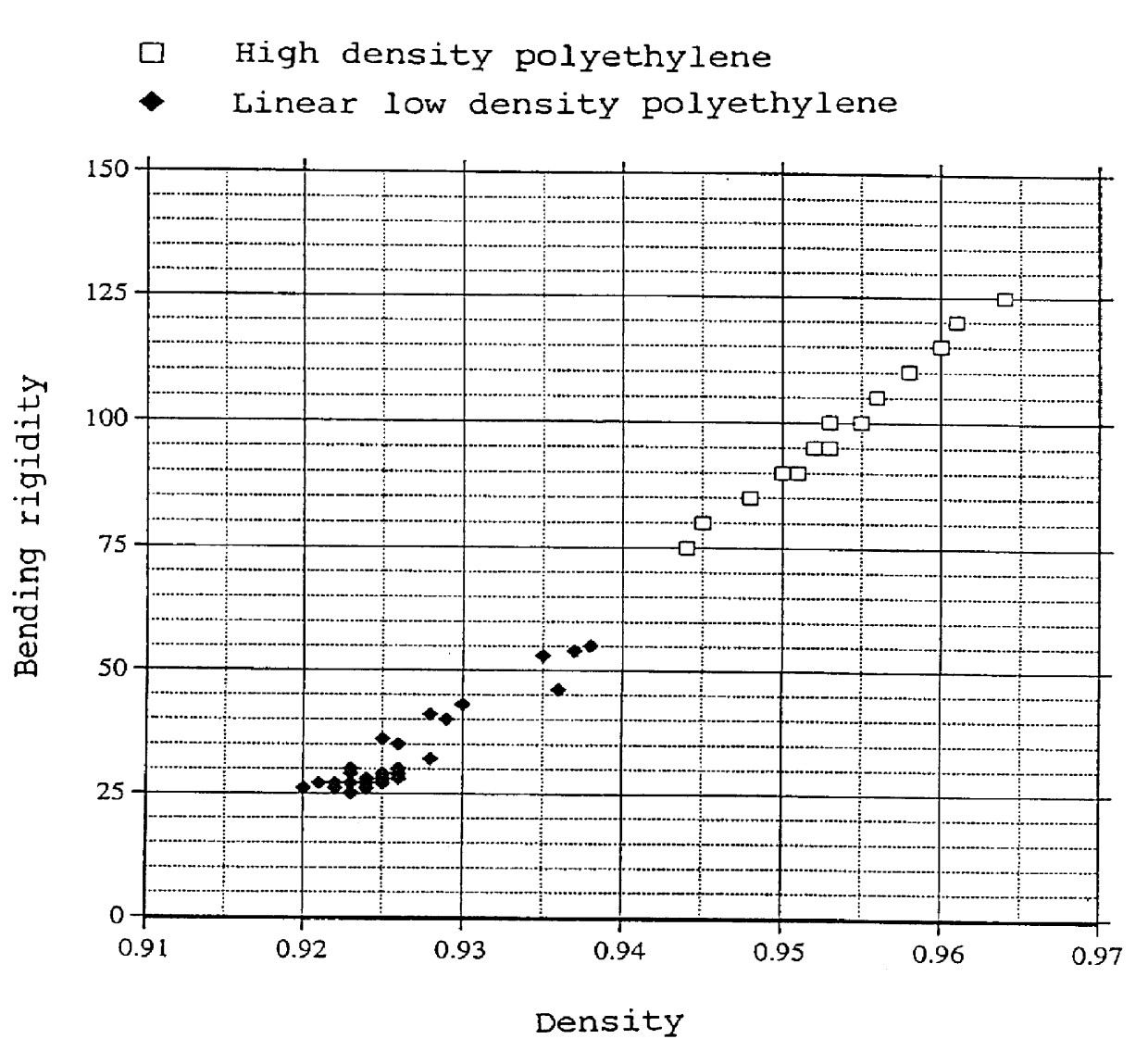

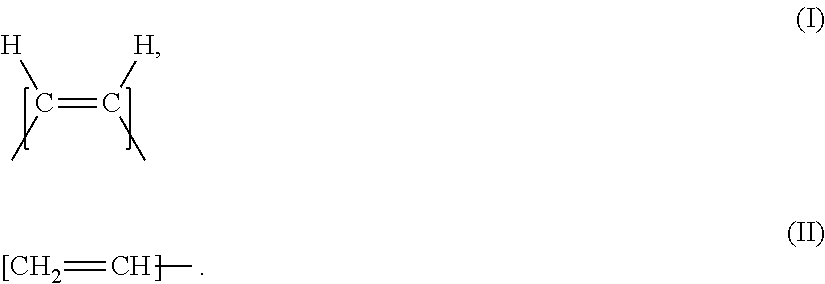

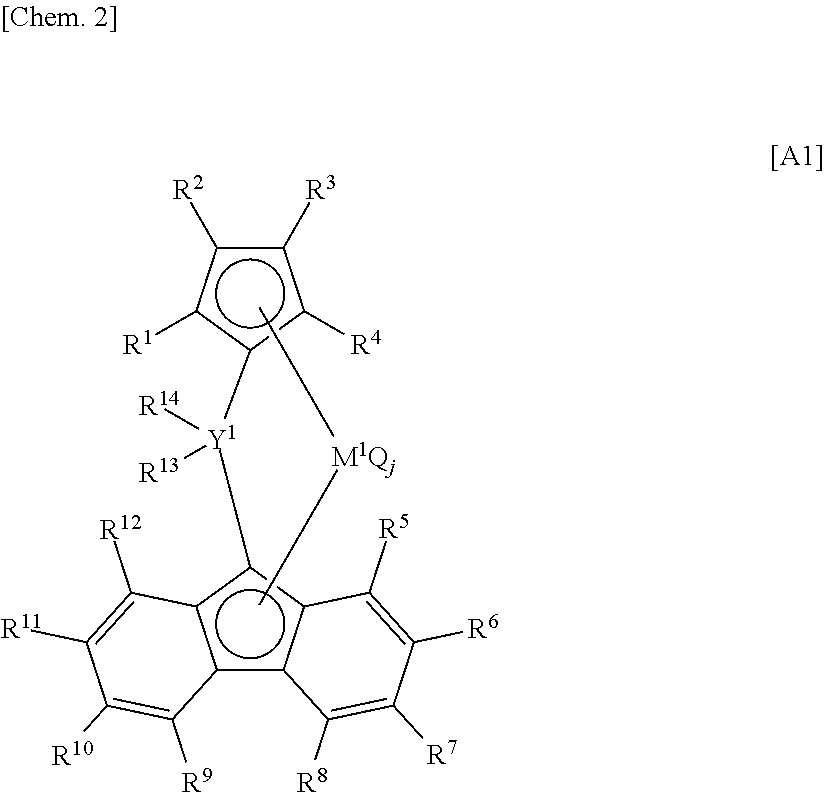

ActiveUS20160355622A1Small long-chain branch contentExcellent curing propertyPlastic/resin/waxes insulatorsSpecial tyresChemistryStructural unit

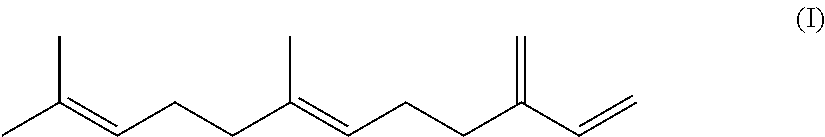

A novel ethylene / α-olefin / non-conjugated polyene copolymer comprising structural units derived from ethylene (A), an α-olefin (B) of 3 to 20 carbon atoms, and a non-conjugated polyene (C) containing intramolecularly two or more partial structures in total selected from the group consisting of structures of Formulae (I) and (II), and having a small number of long-chain branches,The novel ethylene / α-olefin / non-conjugated polyene copolymer contains a non-conjugated polyene such as VNB as a copolymerization component and a small long-chain branch content and is excellent in curing properties in the case of crosslinking using peroxide; and a process for producing the ethylene / α-olefin / non-conjugated polyene copolymer, and a use thereof are provided.

Owner:MITSUI CHEM INC

Silica-reinforced rubber compounded with blocked mercaptosilanes and alkyl alkoxysilanes

The invention provides a sulfur vulcanizable silica-reinforced elastomeric compound having improved tensile mechanical and dynamic viscoelastic properties. The compounds are formed by mixing an elastomer optionally having an alkoxysilane terminal group, with silica in the presence of an alkyl alkoxysilane and a blocked mercaptosilane. In particular, the mercaptosilane moiety of the blocked mercaptosilane and the alkyl alkoxysilane are present in a weight ratio of about 0.001:1 to about 0.20:1. Preferably, the blocked mercaptosilane and the alkyl alkoxysilane are compounded with the elastomer and the silica at high temperature to facilitate the silica-silane reaction. A deblocking agent is added at any desired mixing stage, optionally with the cure package, to allow binding of the mercaptosilane to the polymer.

Owner:BRIDGESTONE CORP

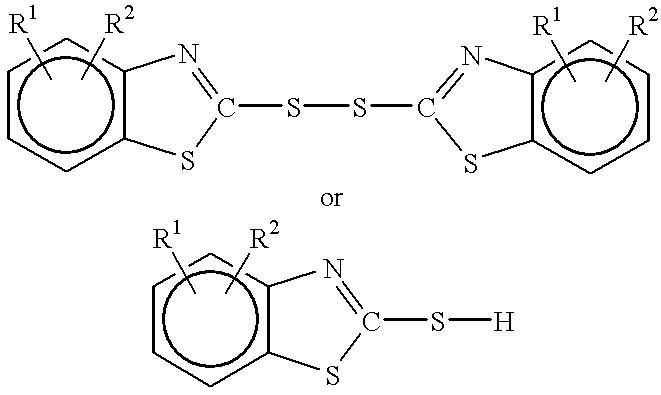

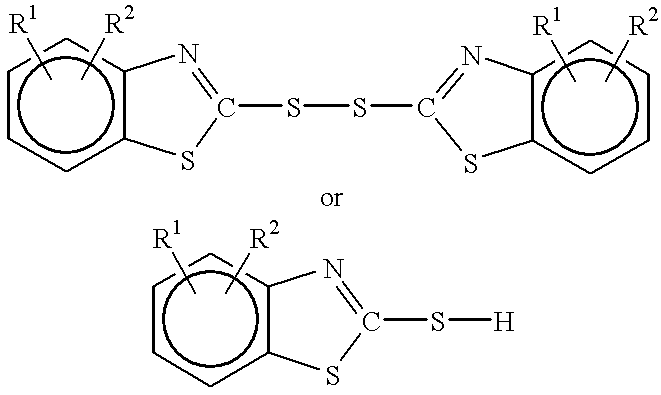

Pneumatic tire containing a vulcanization accelerator

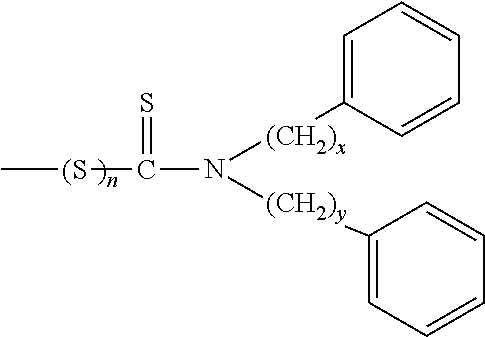

InactiveUS6330897B1Reduce rolling resistanceEasy to separateSpecial tyresPneumatic tyre reinforcementsArylVulcanization

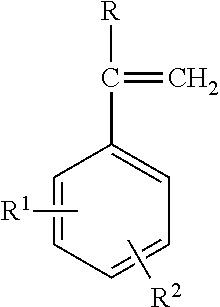

A pneumatic tire formed by using a rubber composition comprising a vulcanization accelerator represented by the following general formula: ##STR1## wherein R.sup.1 represents a hydrogen atom, an alkyl group, or an aryl group, and R.sup.2 represents an alkyl group or an aryl group when R.sup.1 represents a hydrogen atom, and represents a hydrogen atom, an alkyl group, or an aryl group when R.sup.1 represents an alkyl group or an aryl group, in an amount of 0.2 to 8.0 parts by weight per 100 parts by weight of a rubber component. A pneumatic tire which maintains low rolling resistance and is improved to prevent resistance to ply-end separation throughout the entire term of tire use, a pneumatic tire which shows excellent controllability and durability in the last stage of tire use, and a pneumatic tire which prevents heat aging of belt layers and a decrease in the adhesion of steel cord with a rubber composition and shows excellent durability are provided.

Owner:BRIDGESTONE CORP

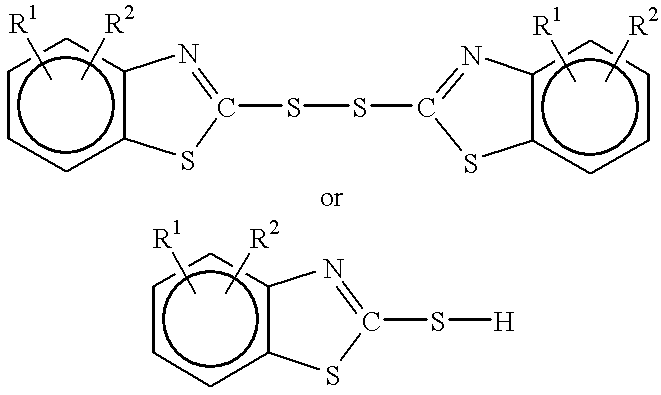

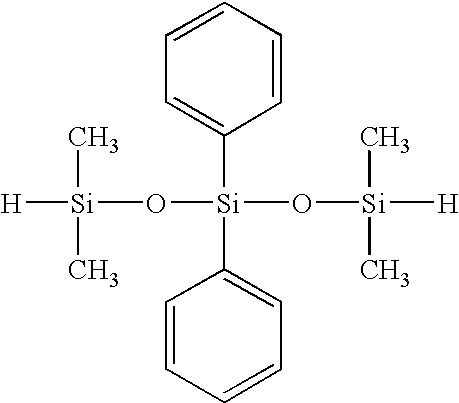

Rubber compound

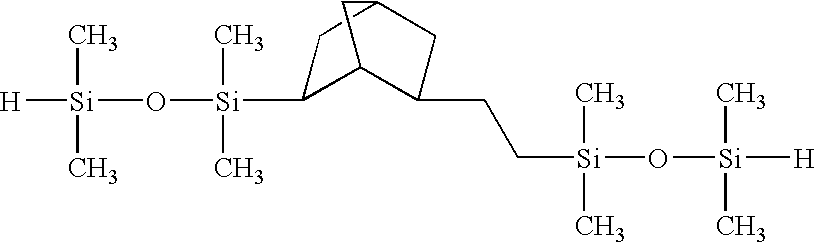

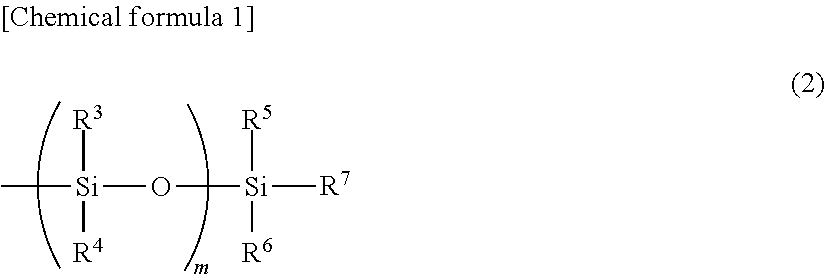

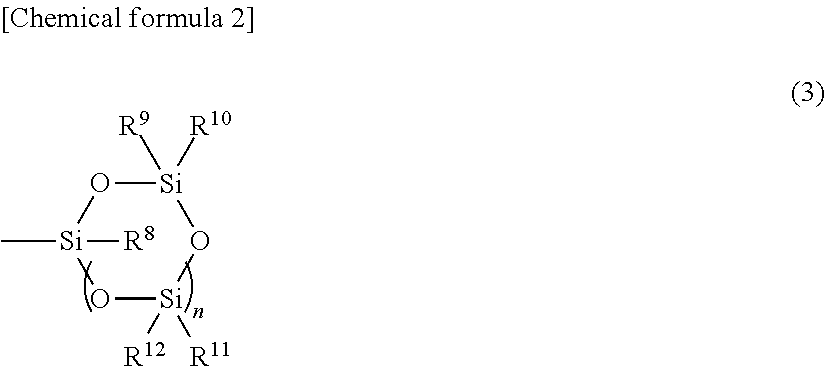

ActiveUS7714053B2Good rubber performanceHigh elongationOther chemical processesUnspecified rubber coatingsCompound aCross-link

A method for producing a rubber compound wherein the mechanical properties thereof are improved. In particular, the rubber compound has an increased elongation at rupture and / or increased tensile strength and / or increased tear strength and also a reduced compression set (DVR). The rubber compound includes a rubber which has at least two functional groups which can be cross-linked by hydrosilylation, a cross-linking agent consisting of hydrosiloxane or a hydrosiloxane derivative or a mixture of several hydrosiloxanes or derivatives, which include at least two SiH-groups per molecule in the center, a hydrosilylation catalyst system, at least one filling material and a coagent which can be cross-linked by hydrosilylation.

Owner:CARL FREUDENBERG KG

Flame retardant rubber composition and obtained therefrom, rubber product and electric wire coating material

InactiveUS20090099293A1Good flame retardancySatisfactory mechanical strengthRubber insulatorsMonomerElectrical wiring

The present invention lies in a flame-retardant rubber composition comprising, as essential components, a synthetic rubber (a component A), a flame-retardant (a component B), sulfur (a component C) and a polyfunctional monomer la component D), wherein an amount of the component B is 10 to 200 parts by masse an amount of the component C is 0.1 to 15 parts by mass and an amount of the component D is 3 to 30 parts by mass, all relative to 100 parts by mass of the component A. It is a technical task of the present invention to provide a flame-retardant rubber composition which has excellent flame retardancy and can give a fully satisfactory mechanical strength (particularly, tensile strength at break) even when subjected to steam cure generally regarded to be difficult to impart a strength.

Owner:JSR CORPORATIOON

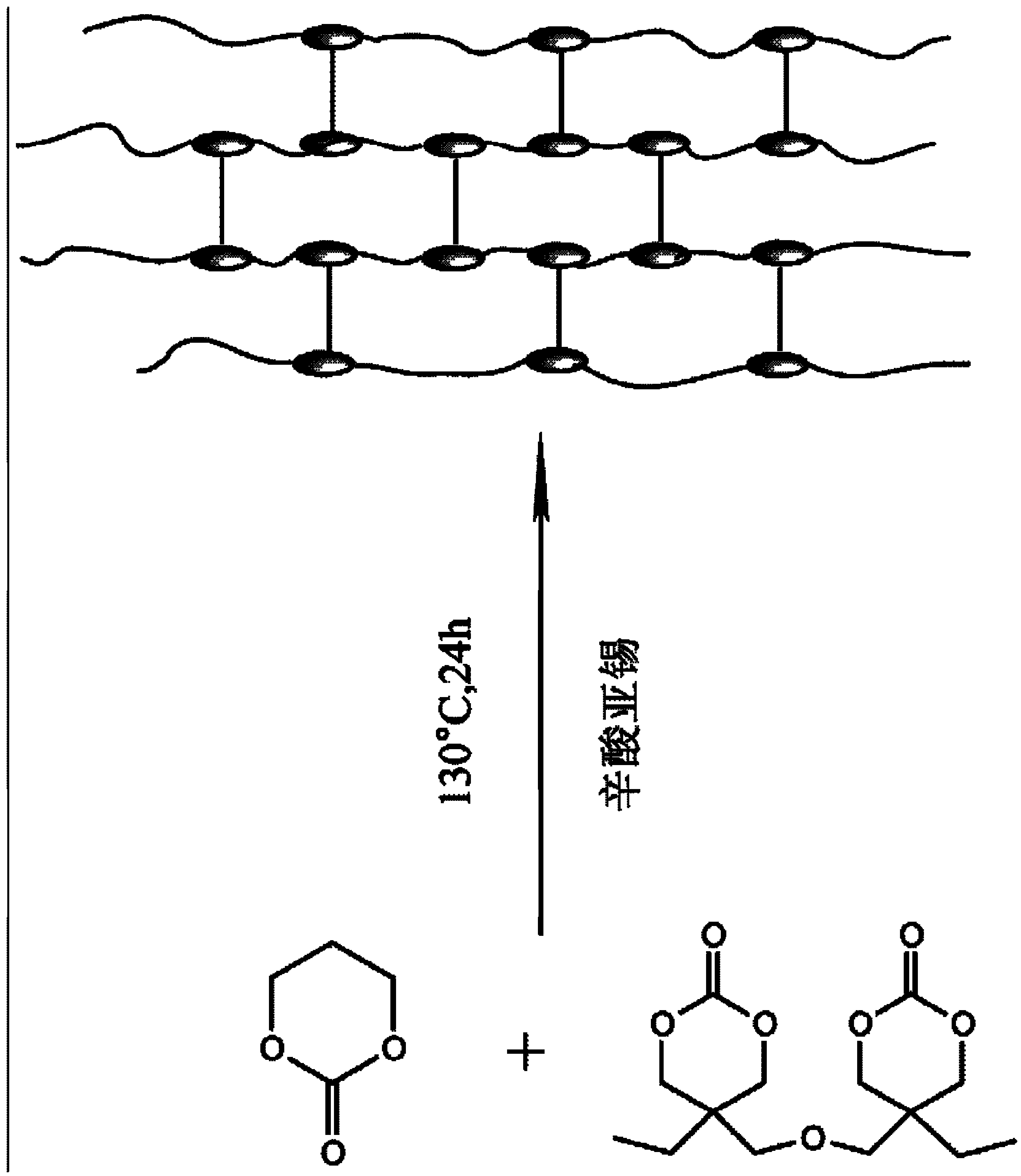

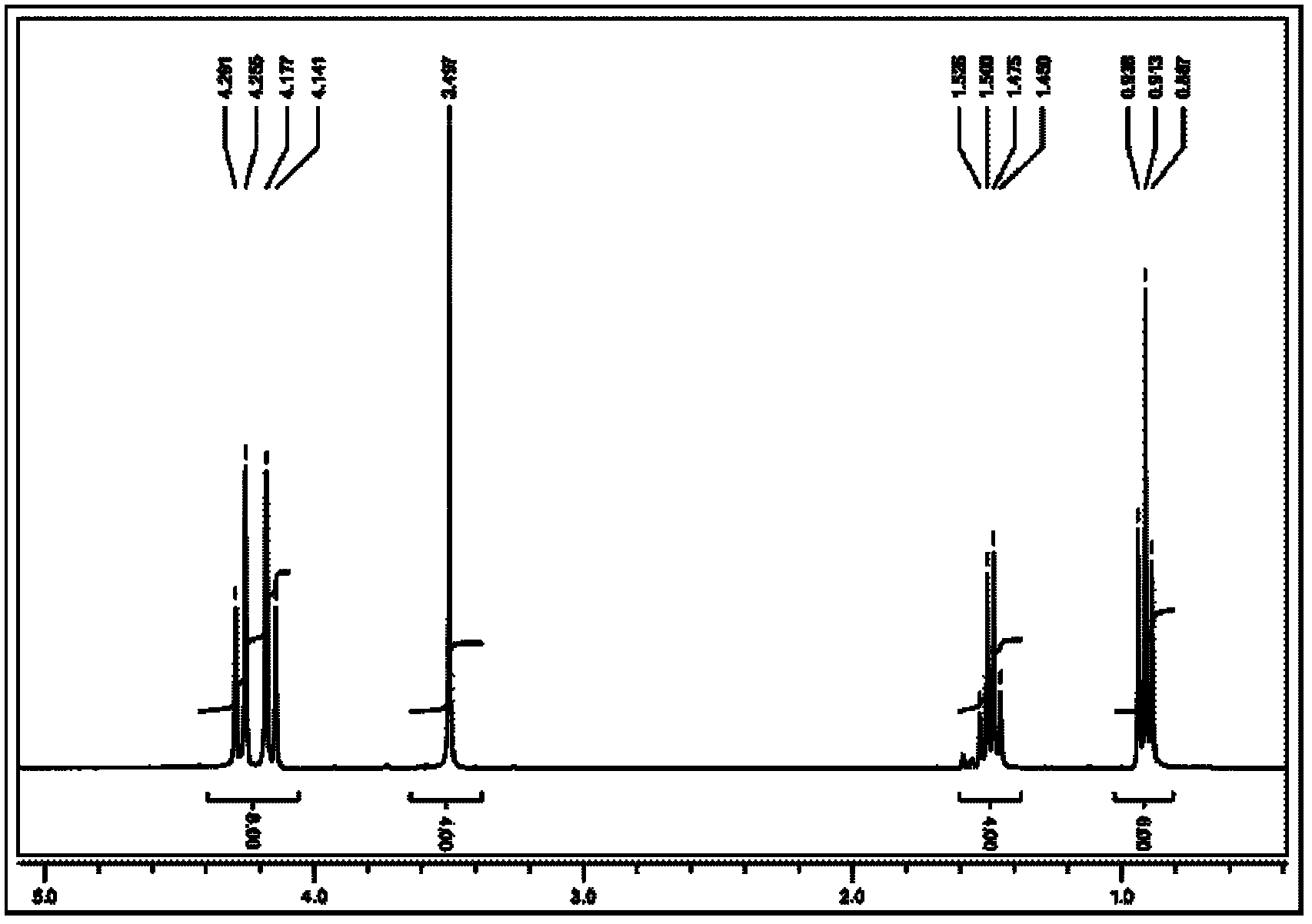

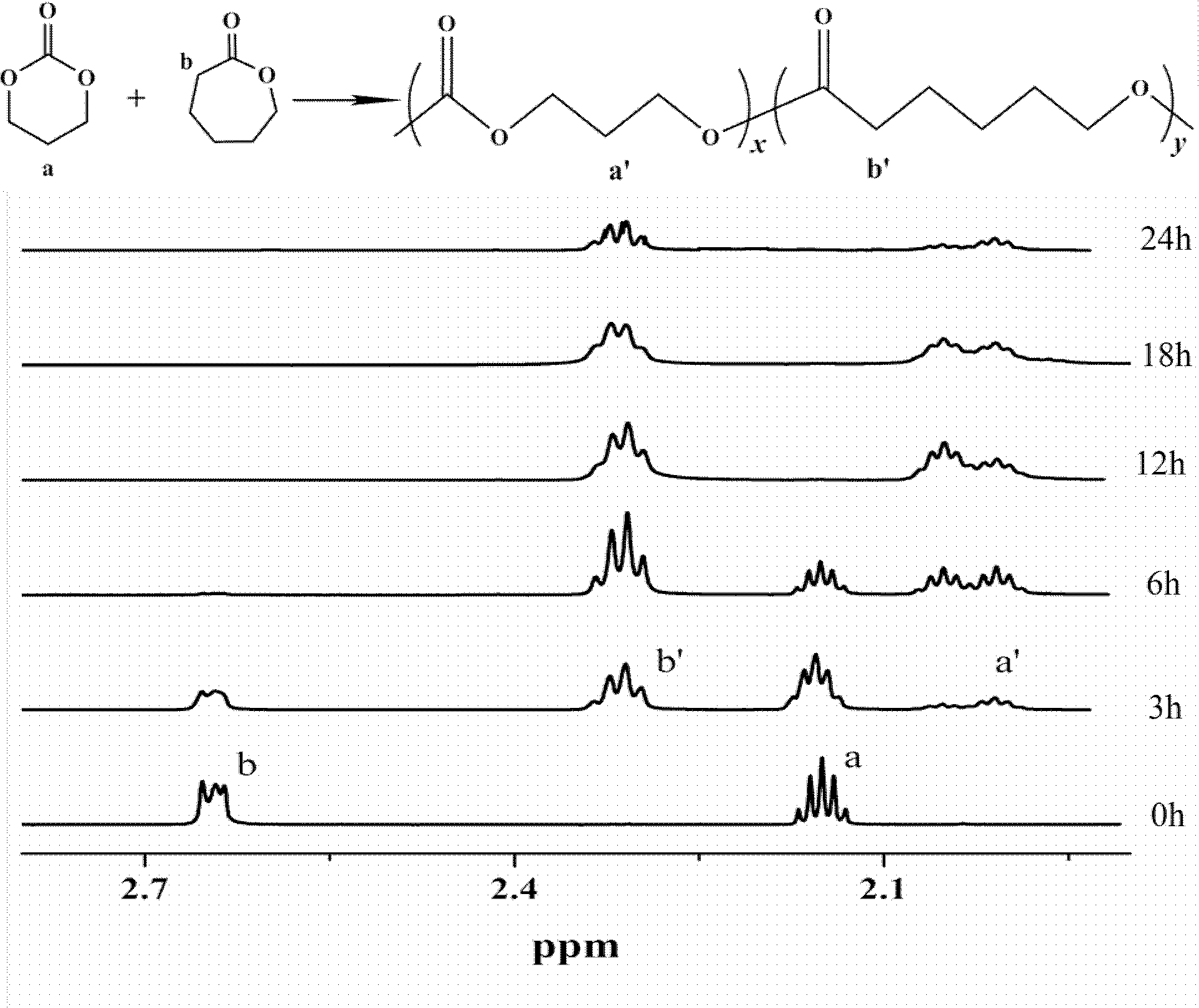

Application of hexahydric cyclic carbonate in biodegradable materials

The invention relates to application of a hexahydric cyclic carbonate in biodegradable materials, belonging to the field of medical high polymer materials. The invention provides application of a hexahydric cyclic carbonate in biodegradable materials. The hexahydric cyclic carbonate is 5,5'-oxybis(methylene)bis(5-ethyl-1,3-dio-xan-2-one). The 5,5'-oxybis(methylene)bis(5-ethyl-1,3-dio-xan-2-one) can be self-crosslinked or crosslinked with any other aliphatic cyclic ester monomer to obtain a crosslinked polymer; and the obtained crosslinked polymer can be used as a biodegradable material.

Owner:杨立群

Ring-opening polymer of cyclopentene and method of production of same

There is provided a ring-opening polymer of cyclopentene wherein a cis ratio of cyclopentene-derived structural units is 30% or more, the weight average molecular weight (Mw) is 100,000 to 1,000,000, and an oxysilyl group is included at an end of the polymer chain. For example, the ring-opening polymer of cyclopentene can be obtained by ring opening polymerization of cyclopentene in the presence of a compound of a transition metal belonging to Group 6 in the Periodic Table, an organoaluminum compound represented by the following general formula (1), and an olefinically unsaturated hydrocarbon containing an oxysilyl group.(R1)3-xAl(OR2)x (1)(in the general formula (1), R1 and R2 represent a hydrocarbon group having 1 to 20 carbon atoms and x satisfies the requirement 0<x<3.)

Owner:ZEON CORP

Thermoplastic elastomer composition and method for producing the same

ActiveUS20110003928A1Good rubber performanceExcellent formabilityOrganic dyesConjugated dieneCarbon atom

The present invention provides a thermoplastic elastomer composition obtained by dynamically crosslinking, under a melting condition, 100 parts by mass of a block copolymer (I), 1 to 1,000 parts by mass of a polar resin (II), 1 to 500 parts by mass of a modified polymer (III), and 0.01 to 50 parts by mass of a crosslinking agent (IV), wherein the block copolymer (I) comprises at least one polymer block (A) comprising as a main component an alkylene unit, and / or at least one copolymer block (B) comprising as main components an alkylene unit (b-1) and a vinyl aromatic monomer unit (b-2), and comprises at least one unsaturated block (C) comprising as a main component a conjugated diene monomer unit having 5 or more carbon atoms at an end.

Owner:ASAHI KASEI CHEM CORP

Elastomer blend and use in tires

InactiveUS6166140AImprove propertiesAdvantageously producedConfectioneryPress rollersElastomerPolymer science

High viscosity elastomers are often difficult to utilize in rubber compositions without first creating a pre-blend of the high viscosity elastomer and a rubber processing oil to reduce their overall viscosity. This invention relates to utilization of a specialized pre-blend of high viscosity and low viscosity elastomers for use in rubber compositions and to the resulting rubber composition. The use of such resulting rubber composition may be for component(s) of tires, particularly including tire treads. The specialized pre-blend of high and low viscosity elastomers is required to be created by blending individual latices or, alternatively, by blending individual polymerizates of elastomers with diverse viscosities.

Owner:THE GOODYEAR TIRE & RUBBER CO

Elastomer blend and use in tires

High viscosity elastomers are often difficult to utilize in rubber compositions without first creating a pre-blend of the high viscosity elastomer and a rubber processing oil to reduce their overall viscosity. This invention relates to utilization of a specialized pre-blend of high viscosity and low viscosity elastomers for use in rubber compositions and to the resulting rubber composition. The use of such resulting rubber composition may be for component(s) of tires, particularly including tire treads. The specialized pre-blend of high and low viscosity elastomers is required to be created by blending individual latices or, alternatively, by blending individual polymerizates of elastomers with diverse viscosities.

Owner:THE GOODYEAR TIRE & RUBBER CO

Sealing material for cap and process for producing cap using the same

The invention provides a sealing material for caps, e.g., metal caps for food containers, which is reduced in swelling with substances dissolved out or alcoholic beverages and in adsorption of the odor thereof and which comprises a tough and nonyellowing polyurethane elastomer and has satisfactory sealing performance. and to provide a manufacturing method for the lid using the sealing material. The sealing material is made of the polyurethane elastomer that is given by reacting the following elements (A), (B), (C), where (A) is a polyisocyanate element which is given by modifying an aliphatic isocyanate and / or an alicyclic isocyanate, contains isocyanate groups of 5 to 38 mass%, and shows an average functional group number of 2 to 3, (B) is a polyol element which has a hydroxyl group value of 20 to 350 (mgKOH / g) and shows an average functional group number of 2 to 3, and (C) is a fatty acid glycerol ester having hydroxyl groups.

Owner:TOYO SEIKAN KAISHA LTD +2

Directional metal wire-filled anti-EMI silica gel liner and preparation method thereof

ActiveCN103980711ANot easy to fall outGood rubber performanceCoatingsColloidal silicaMetallic materials

The invention provides a directional metal wire-filled anti-EMI silica gel liner and a preparation method thereof. The directional metal wire-filled anti-EMI silica gel liner comprises colloidal silica, and the metal wire is directly and uniformly distributed in the colloidal silica. The provided anti-EMI silica gel liner has high elasticity as common rubber, and has conductive reliability of metal material.

Owner:北京泰派斯特科技发展有限公司

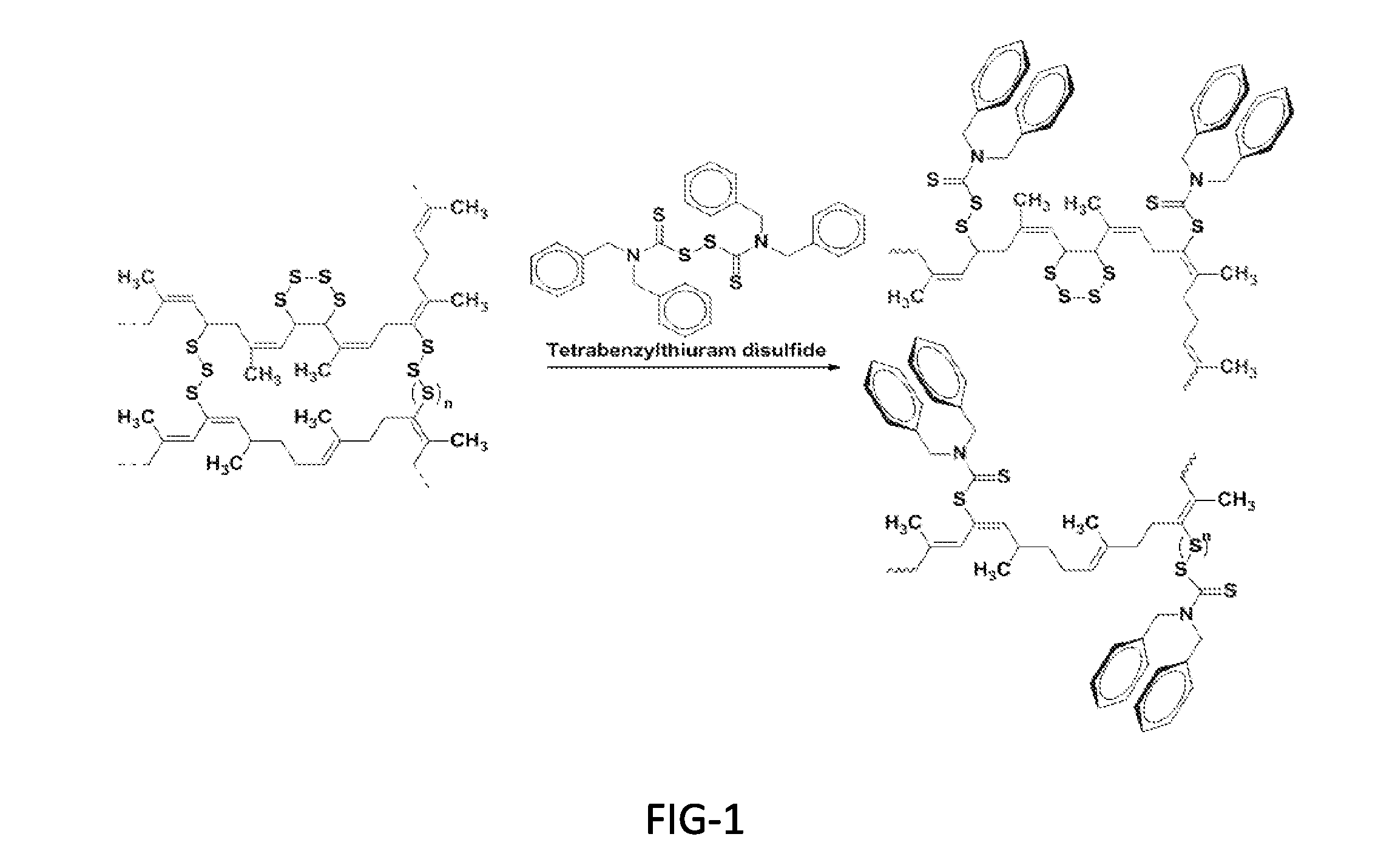

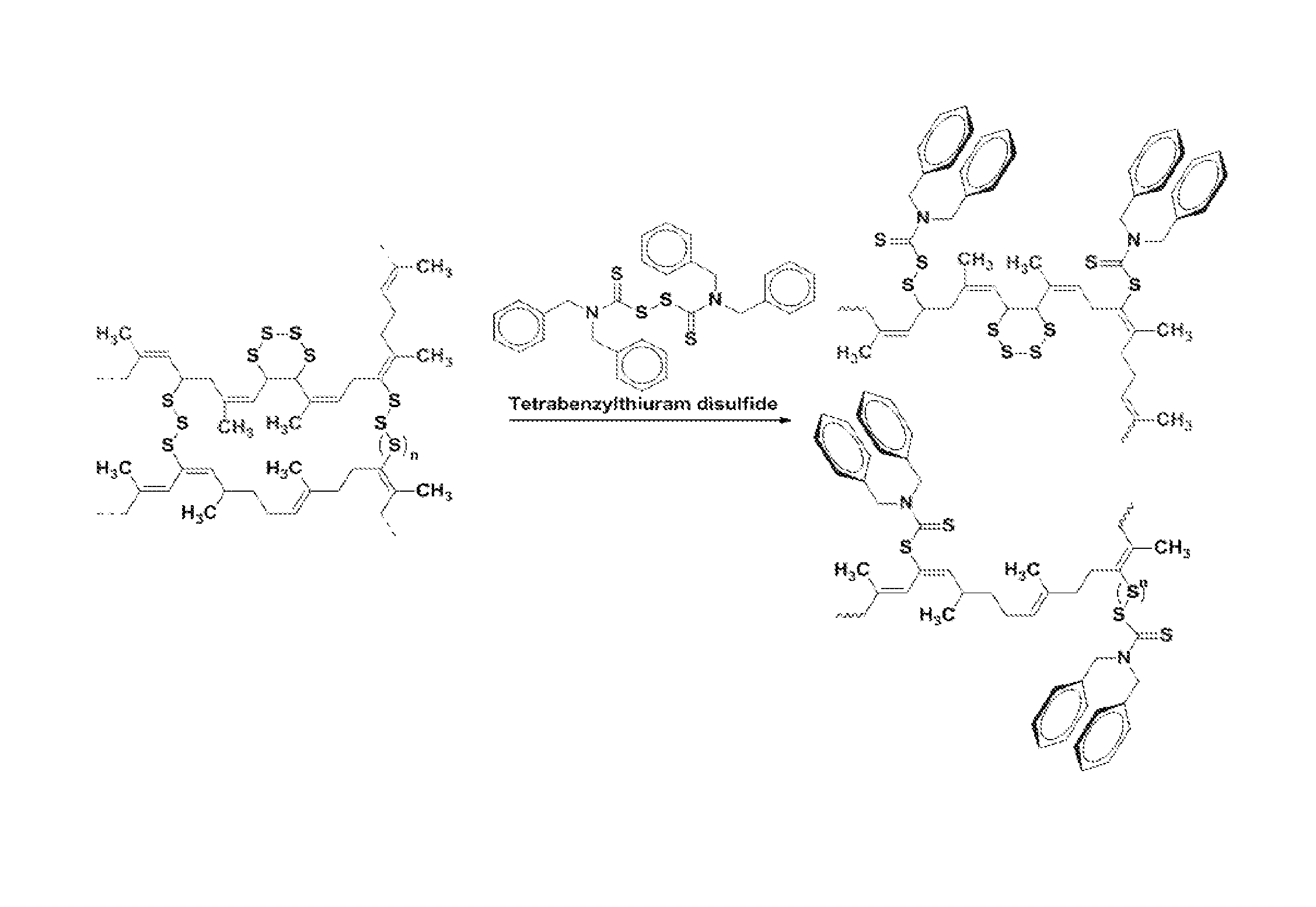

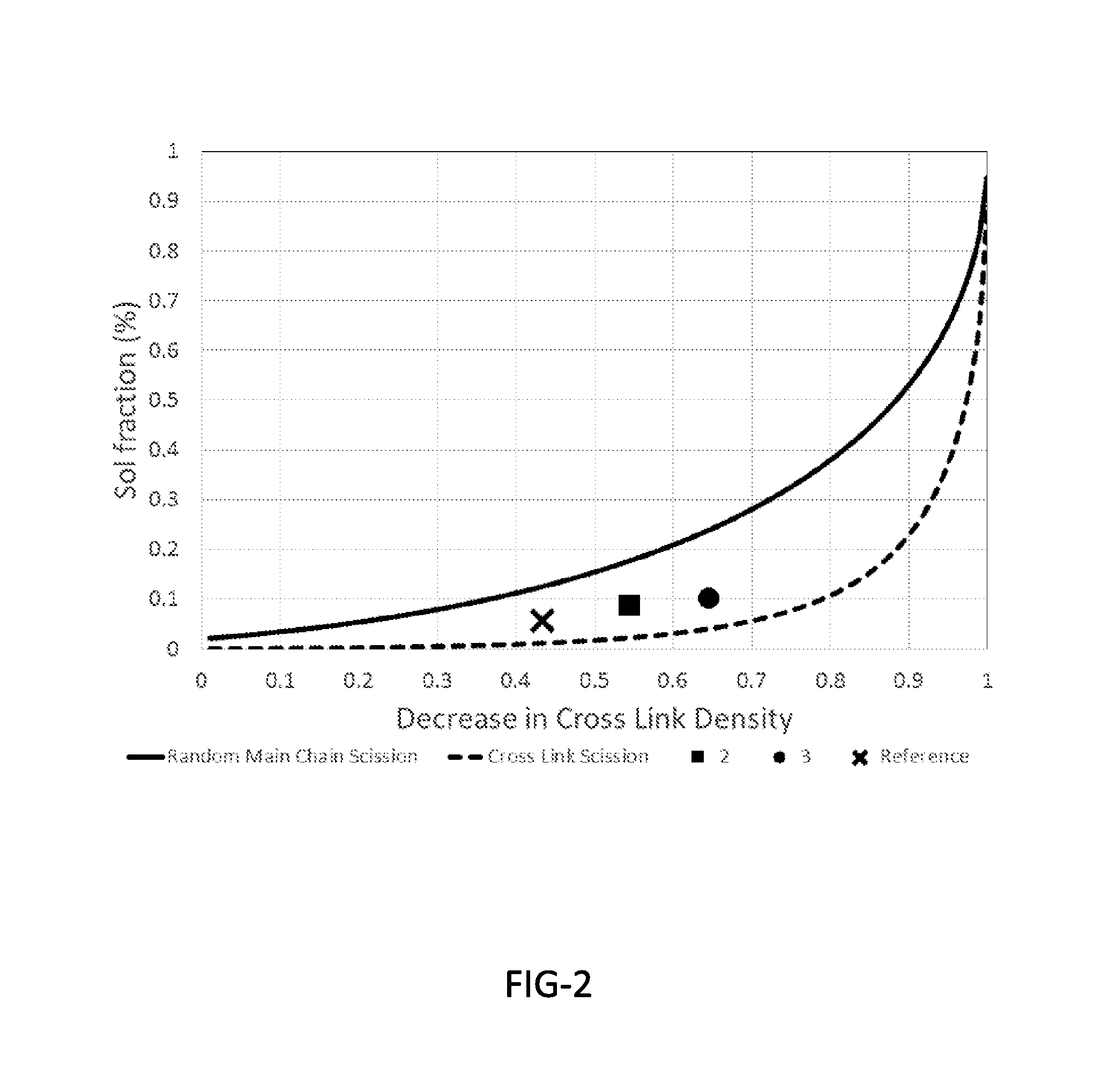

Chemically functionalized renewed rubber composition

ActiveUS20150315363A1Cured rubber propertyMinimal variationPlastic recyclingSpecial tyresPolymer scienceChemical functionalization

The renewed rubber of this invention can be used in rubber formulations that are used in manufacturing a wide array of rubber products, including tires, power transmission belts, conveyor belts, hoses, and a wide array of other products. The present invention more specifically discloses a method for manufacturing an environmentally friendly, chemically functionalized, renewed rubber composition having a highly desirable combination of physical properties and which exhibits excellent processability comprising the steps of (1) blending a micronized rubber powder with a processing aid and a chemical functionalizing agent to produce a blended mixture; (2) processing the blended mixture under conditions of high shear and low temperature to produce a reacted mixture; (3) adding a stabilizer to the reacted mixture to produce the chemically functionalized renewed rubber composition.

Owner:LEHIGH TECH INC

Rubber Composition and Pneumatic Tire Using Same

ActiveUS20170158842A1Good dispersibilityImprove rolling resistanceSpecial tyresRolling resistance optimizationPolymer scienceSilicon dioxide

The present technology provides a rubber composition containing: (A) a diene rubber, (B) from 5 to 200 parts by mass of silica per 100 parts by mass of the diene rubber, (C) from 1 to 20 mass % of a sulfur-containing silane coupling agent relative to the amount of the silica, (D) for example, from 1 to 20 mass % of n-octyltriethoxysilane relative to the amount of the silica; and (E) from 1 to 20 mass % of a glycerol monofatty acid ester derived from a fatty acid having from 8 to 24 carbons relative to the mass of the silica (B).

Owner:THE YOKOHAMA RUBBER CO LTD

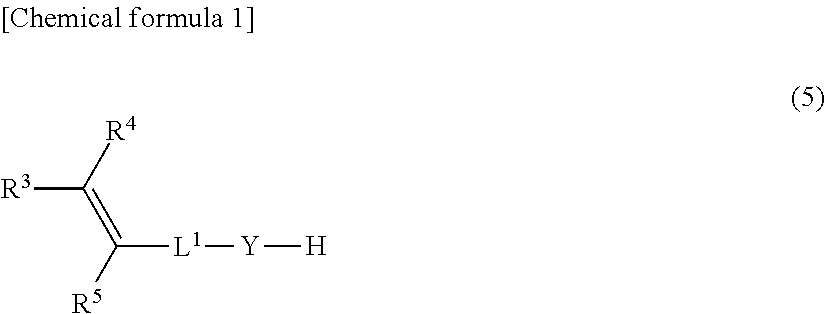

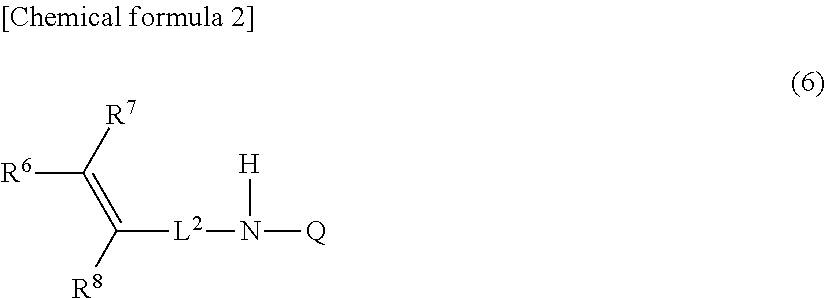

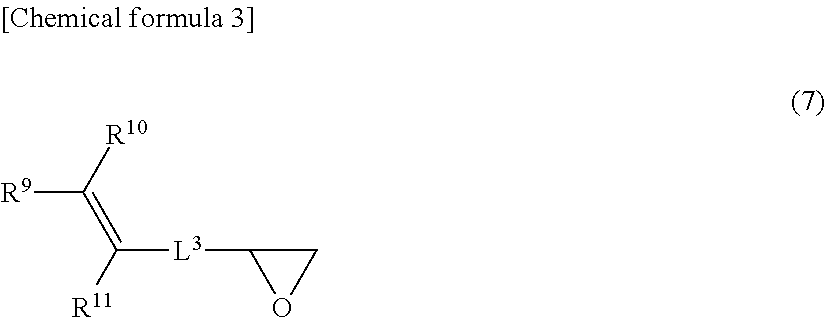

Ring-opening polymer of cyclopentene and method of production of same

There is provided a ring-opening polymer of cyclopentene wherein a cis ratio of the cyclopentene-derived structural units is 30% or more, a weight average molecular weight (Mw) is 100,000 to 1,000,000, and a functional group containing a structure represented by the general formula (1) or (2) is included at an end of the polymer chain.—Y—H (1)(in the above general formula (1), Y represents an oxygen atom or a sulfur atom.)—NH-Q (2)(in the above general formula (2), Q represents a hydrogen atom or a hydrocarbon group or a silyl group which may have a substituent group.)

Owner:ZEON CORP

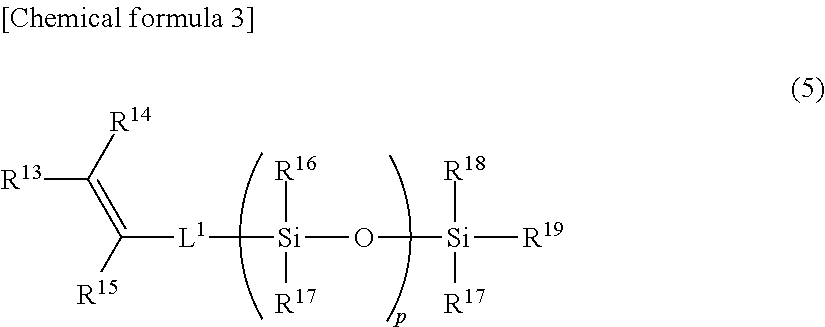

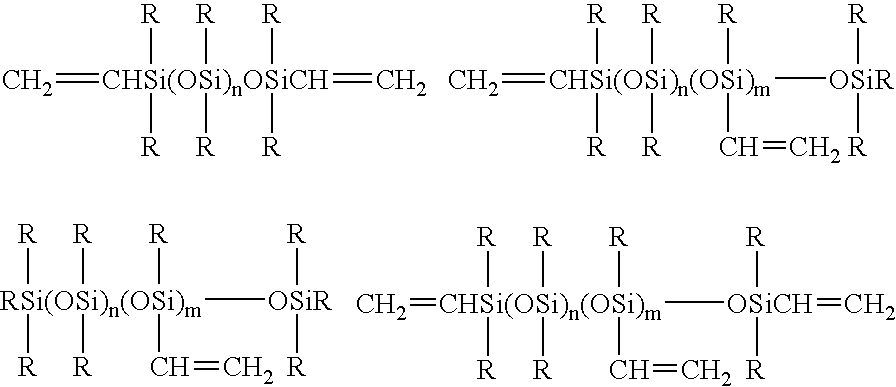

Ultraviolet curable silicone composition and cured product of same

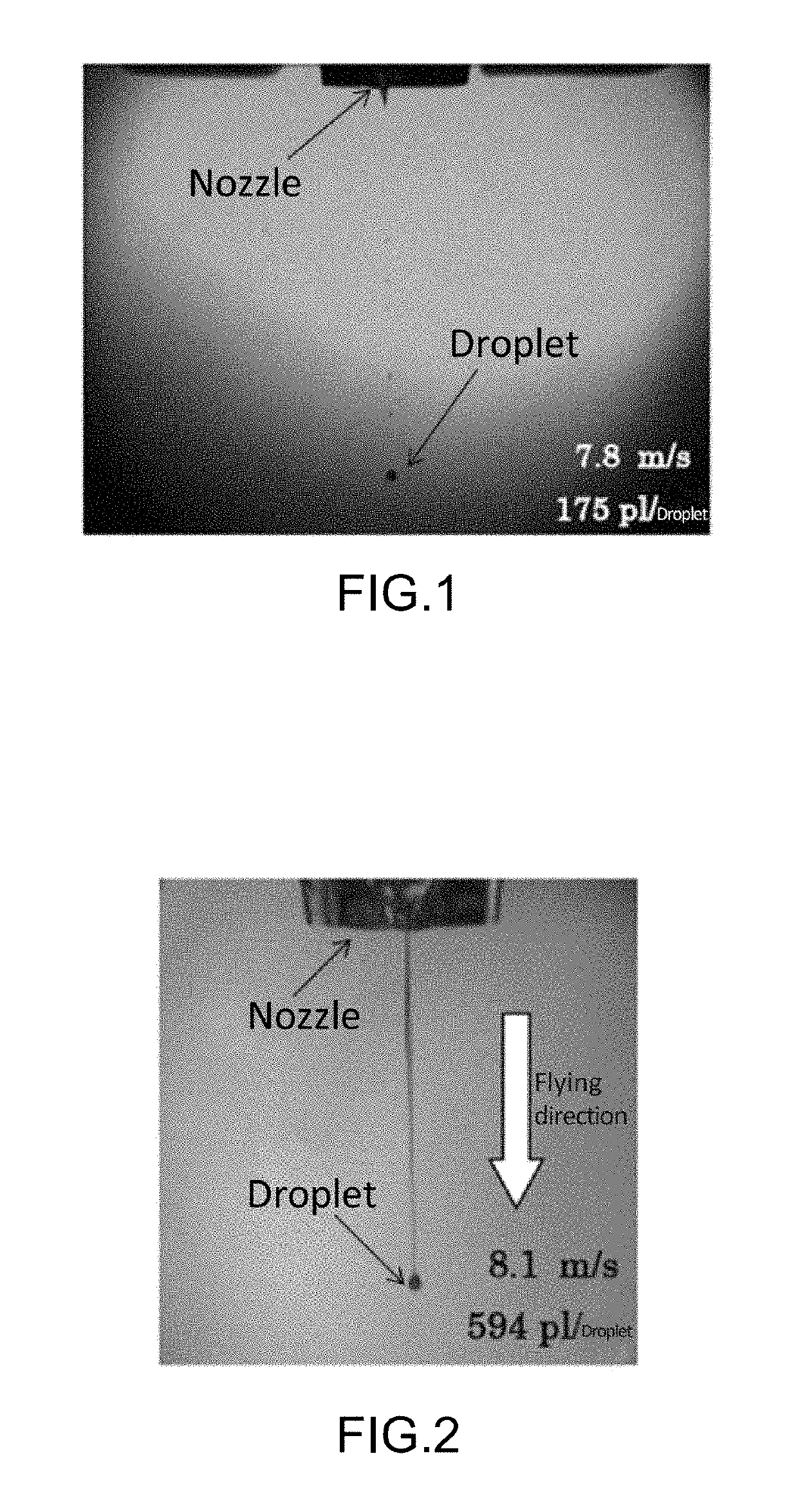

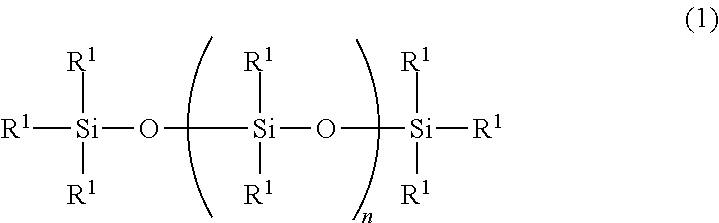

InactiveUS20190233670A1Excellent curabilityIncrease surface tensionAdditive manufacturing apparatusDuplicating/marking methodsUV curingMeth-

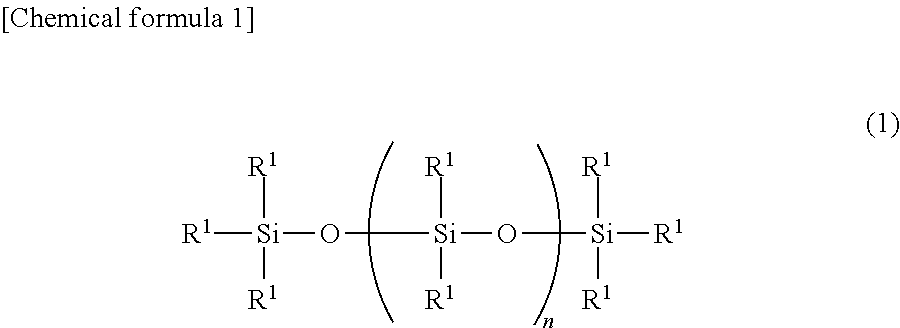

Provided is an ultraviolet curable silicone composition capable of being ejected via inkjet ejection. The composition of the invention is an ultraviolet curable silicone composition comprising:(A) an organopolysiloxane represented by the following general formula (1)wherein each R1 independently represents a group selected from a monovalent aliphatic hydrocarbon group having 1 to 10 carbon atoms, an acryloyl group, a methacryloyl group, an alkyl acrylate group and an alkyl methacrylate group, while the component (A) has per molecule at least two groups selected from an acryloyl group, a methacryloyl group, an alkyl acrylate group and an alkyl methacrylate group; n represents a number satisfying 10≤n≤1,000;(B) a monofunctional (meth)acrylate compound having no siloxane structure; and / or(C) a multifunctional (meth)acrylate compound having no siloxane structure; and(D) a photopolymerization initiator.

Owner:SHIN ETSU CHEM IND CO LTD

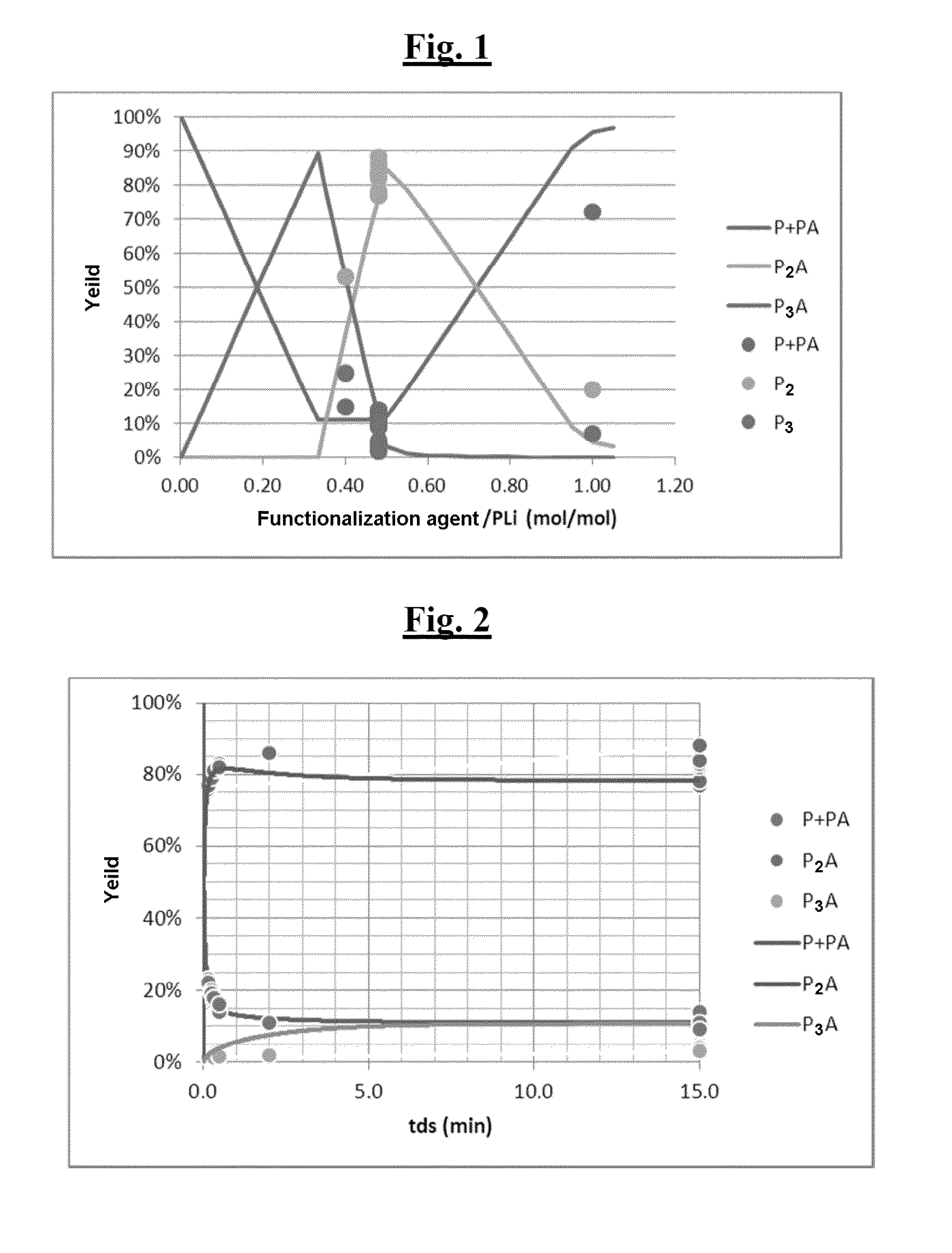

Modified diene elastomer, synthesis method for same, and rubber composition comprising modified diene elastomer

ActiveUS20160160015A1Improving compromise in hysteresisImproving in processing propertyElastomerHydrogen atom

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

Natural rubber, rubber composition containing natural rubber, and the production process of the same, and tire

InactiveUS20130303681A1Increase resistanceImprove wear resistanceSpecial tyresPolymer scienceLight scatter measurement

The natural rubber of the present invention is obtained by gelatinizing or multi-coupling a natural rubber latex or a natural rubber and comprises 15% by mass or more of a high molecular weight component, P1, having a molecular weight of 5,000,000 to 50,000,000 and 40% by mass or less of an ultrahigh molecular weight component, P2, having a molecular weight of exceeding 50,000,000, and the relation between mass % of P1 and mass % of P2 is 1.5×mass % of P1≧mass % of P2, each measured by the following measuring method, wherein a measuring method for a rubber molecular weight is measured by means of a field flow fractionation equipment with a multi-angle light scattering detector for a soluble part of a centrifuged rubber solution at a centrifugal acceleration of 10,000 to 1,000,000 G.

Owner:BRIDGESTONE CORP

Azodicarbonamide treatment for carbon black and rubber compounds

InactiveUS7053137B2Enhanced interactionGood rubber performanceSpecial tyresOrganic dyesCompound aHysteresis

Owner:LION COPOLYMER GEISMAR +1

Silicone rubber composition for the tire production and a method of producing the same

InactiveUS20060293441A1Good in wettability to plasterExcellent curing propertySpecial tyresChemistryInorganic filler

A silicone rubber composition for the tire production comprises (A) 100 parts by weight of a specified alkenyl group-containing straight-chain diorganopolysiloxane, (B) 1-20 parts by weight of a specified hydrogen atom-containing organohydrogenpolysiloxane, (C) 30-60 parts by weight of an inorganic filler, (D) 0.5-20 parts by weight of a specified alkenyl group-containing straight-chain diorganopolysiloxane having a weight average molecular weight smaller than that of the component (A), and (E) 5-300 ppm of a platinum group metal catalyst as a conversion by weight of platinum group metal to the total amount of the components (A), (B) and (D), provided that the component (D) is previously uniformly mixed with the component (E) and then mixed with the remaining components.

Owner:BRIDGESTONE CORP +1

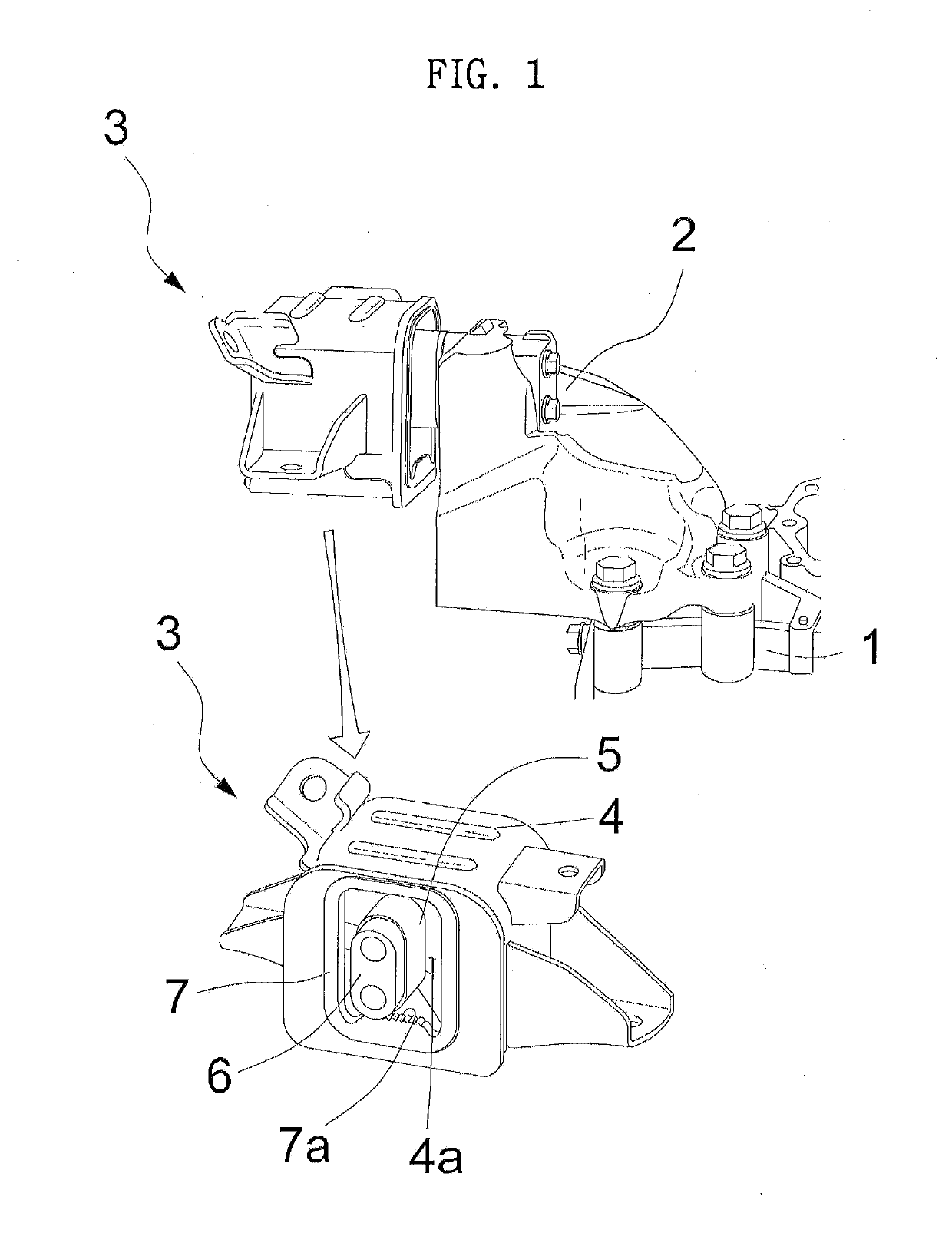

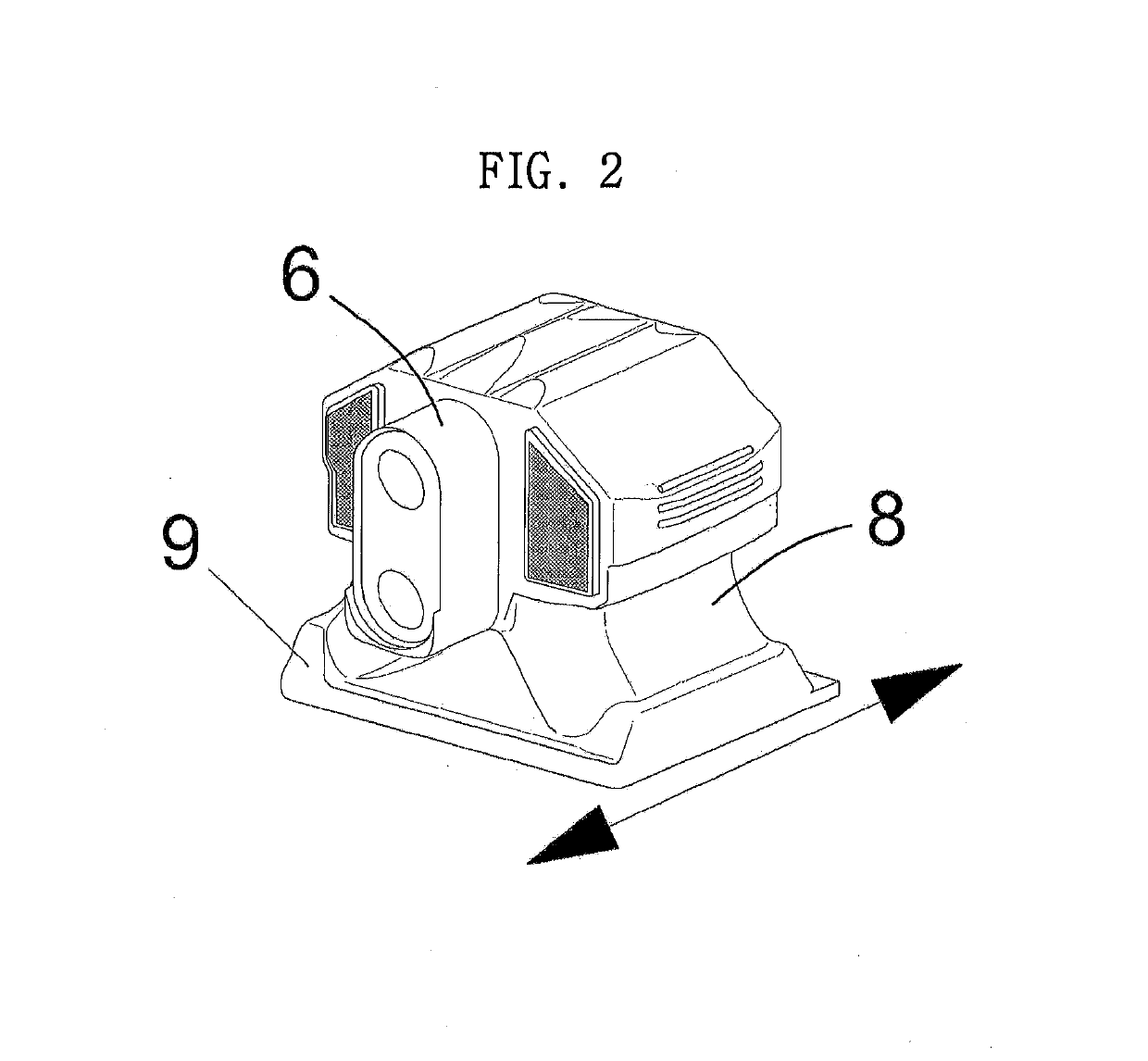

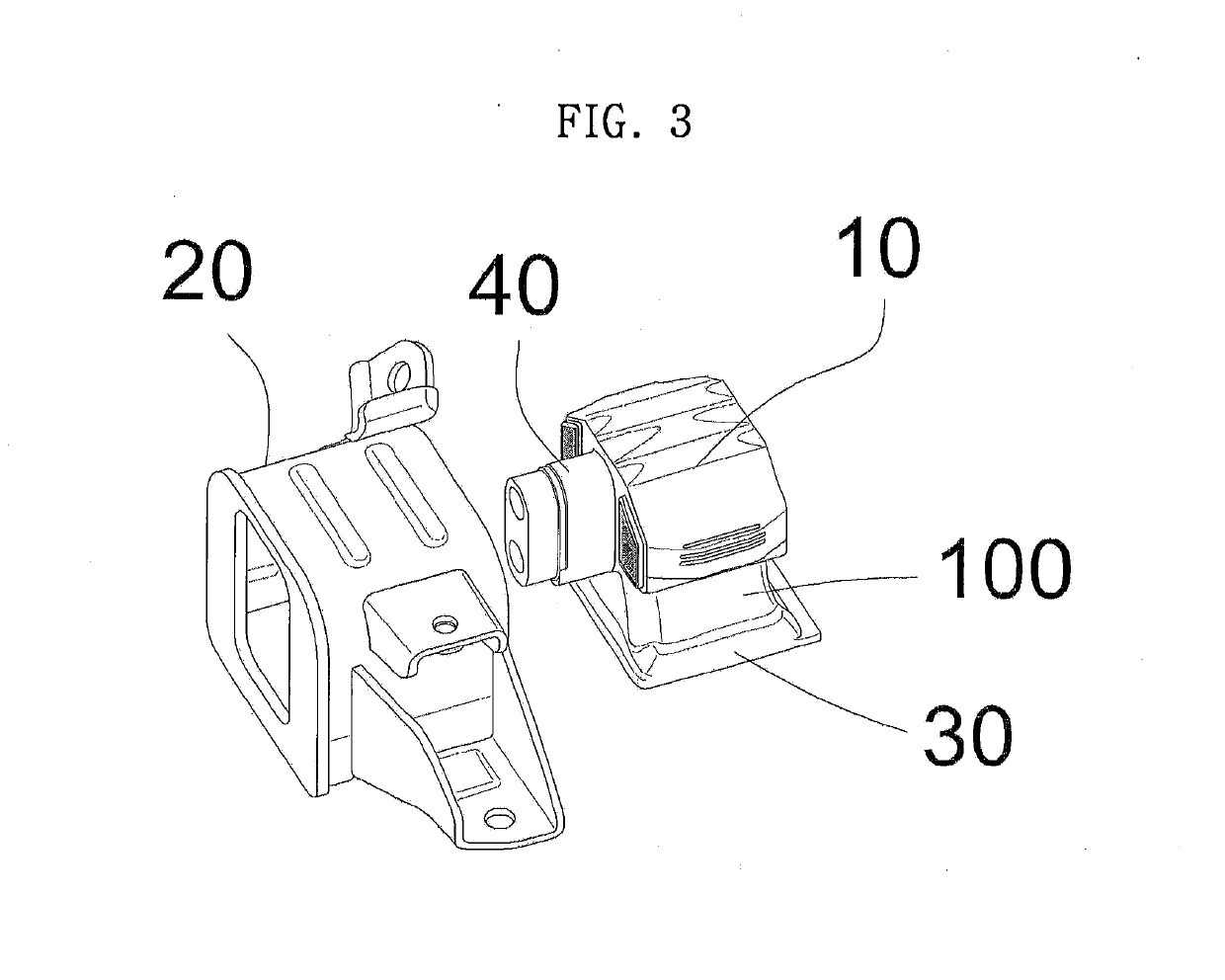

Stopper for transmission mount

ActiveUS20190154097A1Low costReduce weightSpringsVehicle sub-unit featuresEngineeringLateral displacement

The present disclosure relates to a transmission (TM) mount that is capable of reducing costs and a weight by removing a separate stopper (component). The transmission (TM) mount improves handling performance taking advantage of elastic properties of a rubber component in a left / right direction (lateral direction). The stopper for a transmission (TM) mount includes a housing bracket into which an insulator is press-fitted, a lower plate which is positioned at a lower end of the insulator and connected, together with the housing bracket, to a vehicle body through a curling structure, an inner core which is disposed at a central portion of the insulator, and a bridge which is installed at a lower side of the inner core so as to control a lateral displacement. The bridge is tightly fixed to a fixing piece formed in the lower plate.

Owner:HYUNDAI MOTOR CO LTD +2

Rubber composition and tire

ActiveUS20160200902A1Improve performanceImprove stabilitySpecial tyresRolling resistance optimizationFarnesenePolymer

The present invention provides a rubber composition capable of producing a rubber molded article that is excellent in rolling resistance performance, steering stability, mechanical strength and abrasion resistance, and a tire obtained by using the rubber composition in at least a part thereof. The present invention relates to a rubber composition including (A) a rubber component including at least one rubber selected from the group consisting of a synthetic rubber and a natural rubber, (B) silica and (C) a modified polymer of farnesene obtained by introducing a functional group into a polymer of farnesene, in which a content of the silica (B) in the rubber composition is from 20 to 150 parts by mass on the basis of 100 parts by mass of the rubber component (A), and a content of the modified farnesene polymer (C) in the rubber composition is from 2 to 10 parts by mass on the basis of 100 parts by mass of the silica (B).

Owner:KURARAY CO LTD +1

Rubber composition and tire

InactiveUS20170218170A1Good rubber performanceMaintaining energy efficiencySpecial tyresWithout separate inflatable insertsPolymer scienceSilicon dioxide

A rubber composition comprising silica that has a BET specific surface area of not more than 130 m2 / g and hardness of granulated particles as measured based on JIS K6221-1982 6.3.3 of not less than 23.5 cN can provide a rubber composition which is excellent in rubber physical properties while maintaining energy efficiency. A tire comprising a component consisted of the rubber composition can be also provided.

Owner:SUMITOMO RUBBER IND LTD

Sealing gasket for closure and process for production of closure using the same

A sealing gasket for closure, made of a polyurethane elastomer obtained by reacting the following (A), (B) and (C):(A) a polyisocyanate component having an isocyanate group content of 5 to 38% by weight and average 2 to 3 functional groups, obtained by modifying an aliphatic isocyanate and / or an alicyclic isocyanate,(B) a polyol component having a hydroxyl value of 20 to 350 mgKOH / g and average 2 to 3 functional groups, and(C) a glycerin fatty acid ester having hydroxyl group(s);and a process for producing a closure using such a sealing gasket.The closure sealing gasket made of a polyurethane elastomer, obtained by the present invention, when used for a closure (e.g. a metal closure of a food container having good sealing properties), is little eluted, is less in swelling with an alcoholic beverage and less in the absorption of the odor of the alcoholic beverage into the closure sealing gasket, and is tough, and causes no yellowing.

Owner:TOYO SEIKAN KAISHA LTD +2

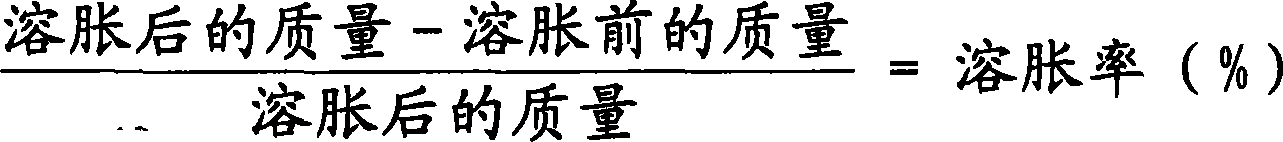

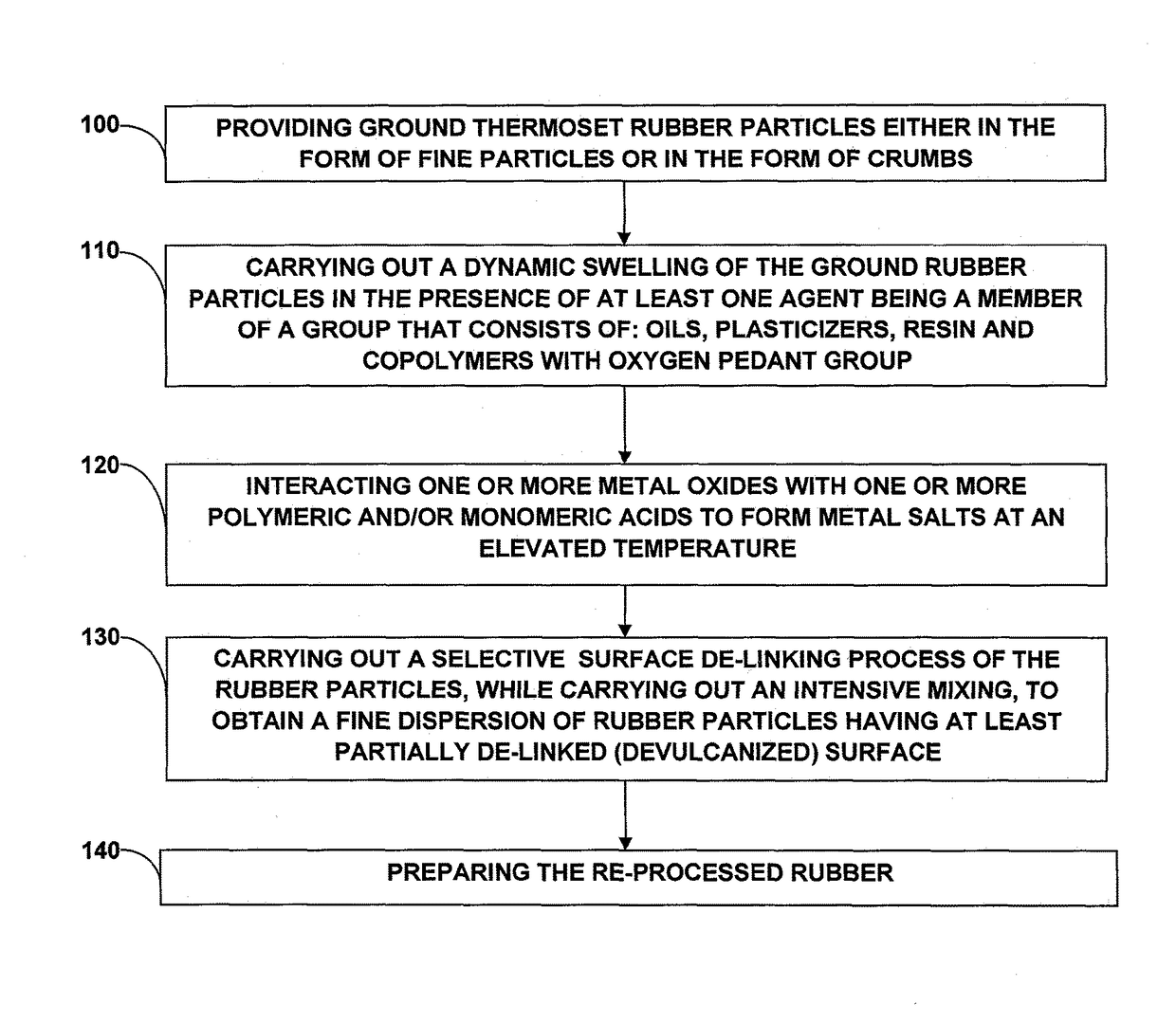

Re-processed rubber and a method for producing same

InactiveUS9902831B2Good rubber performanceGood dispersionPlastic recyclingPolymer scienceDynamic swelling

A method is provided for preparing a reprocessed rubber from thermoset rubber particles. The method includes providing a plurality of thermoset rubber particles, inducing dynamic swelling and dynamic compatibilization of the plurality of rubber particles, admixing at least one de-linking agent with the swelled and wetted rubber particles, and wherein the step of admixing the at least one de-linking agent is carried out under thermo-mechanical mixing.

Owner:ECOTECH RECYCLING

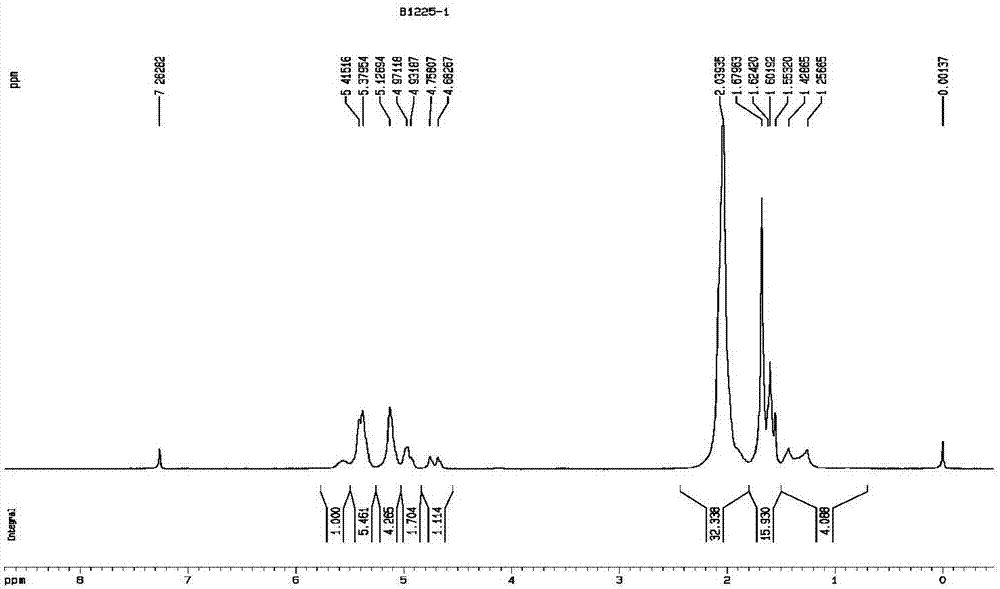

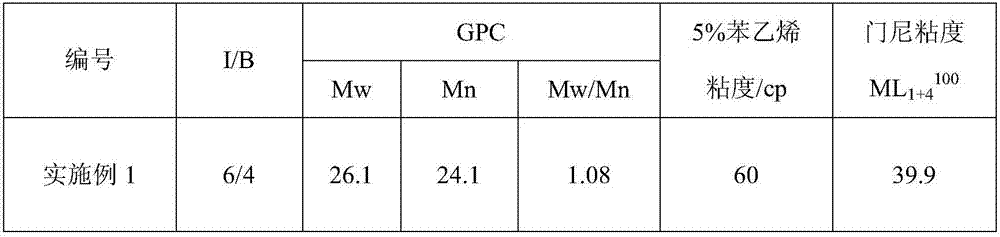

Application of butadiene-b-isoprene polymer

The invention discloses application of a butadiene-b-isoprene polymer. The application is to copolymerize the linear or star-shaped butadiene-b-isoprene polymer with styrene in a grafted manner to prepare high impact polystyrene. The prepared high impact polystyrene is high in impact strength and high in bending performance; furthermore, the heat resistance and the elongation are obviously improved when compared with the heat resistance and the elongation of HIPS (high impact polystyrene) resin prepared from polybutadiene rubber.

Owner:CHINA PETROLEUM & CHEM CORP +1

Chemically functionalized renewed rubber composition

ActiveUS9574069B2Easy to processGood rubber performancePlastic recyclingSpecial tyresWide areaProcedure Agents

The renewed rubber of this invention can be used in rubber formulations that are used in manufacturing a wide array of rubber products, including tires, power transmission belts, conveyor belts, hoses, and a wide array of other products. The present invention more specifically discloses a method for manufacturing an environmentally friendly, chemically functionalized, renewed rubber composition having a highly desirable combination of physical properties and which exhibits excellent processability comprising the steps of (1) blending a micronized rubber powder with a processing aid and a chemical functionalizing agent to produce a blended mixture; (2) processing the blended mixture under conditions of high shear and low temperature to produce a reacted mixture; (3) adding a stabilizer to the reacted mixture to produce the chemically functionalized renewed rubber composition.

Owner:LEHIGH TECH INC

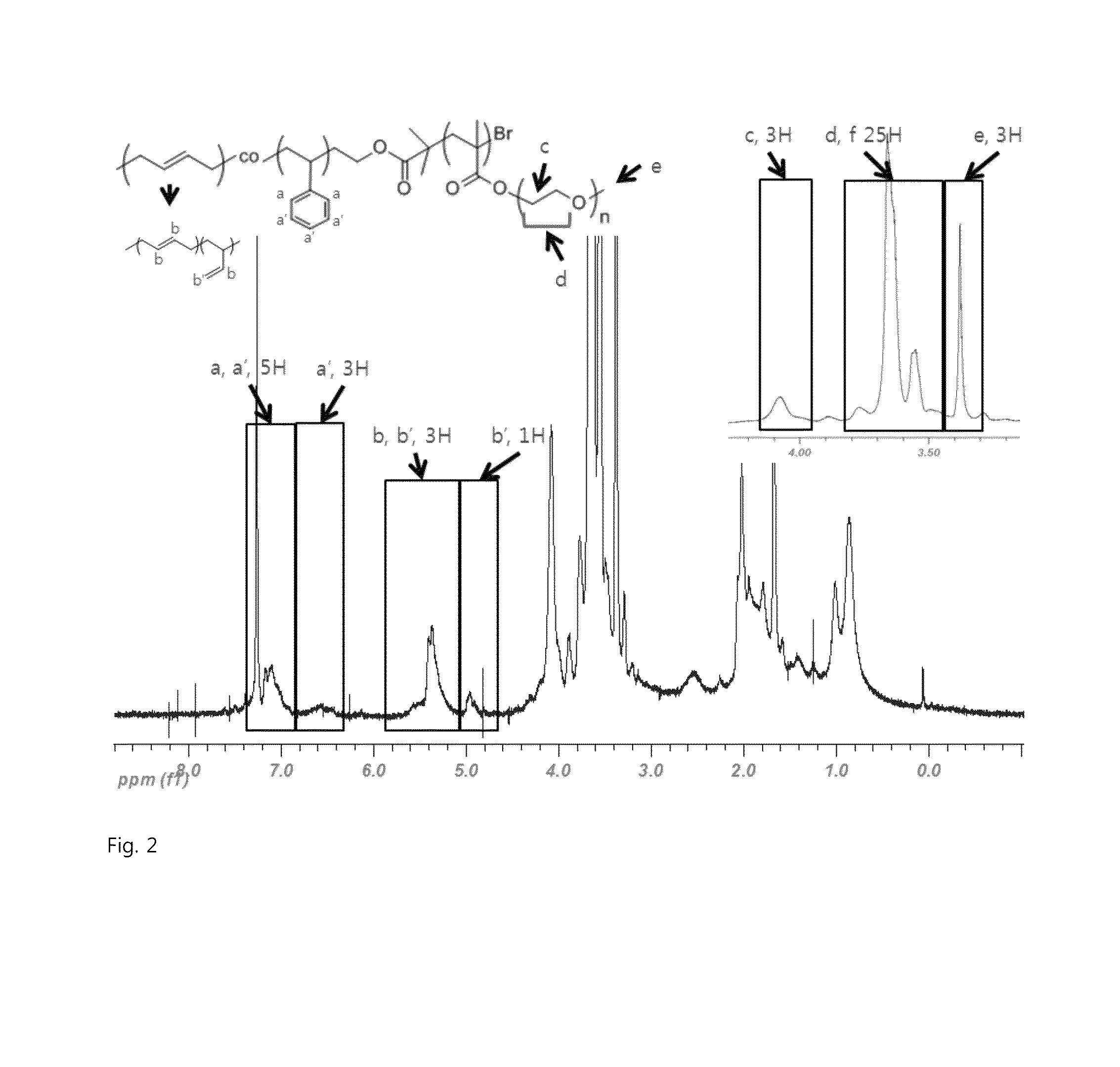

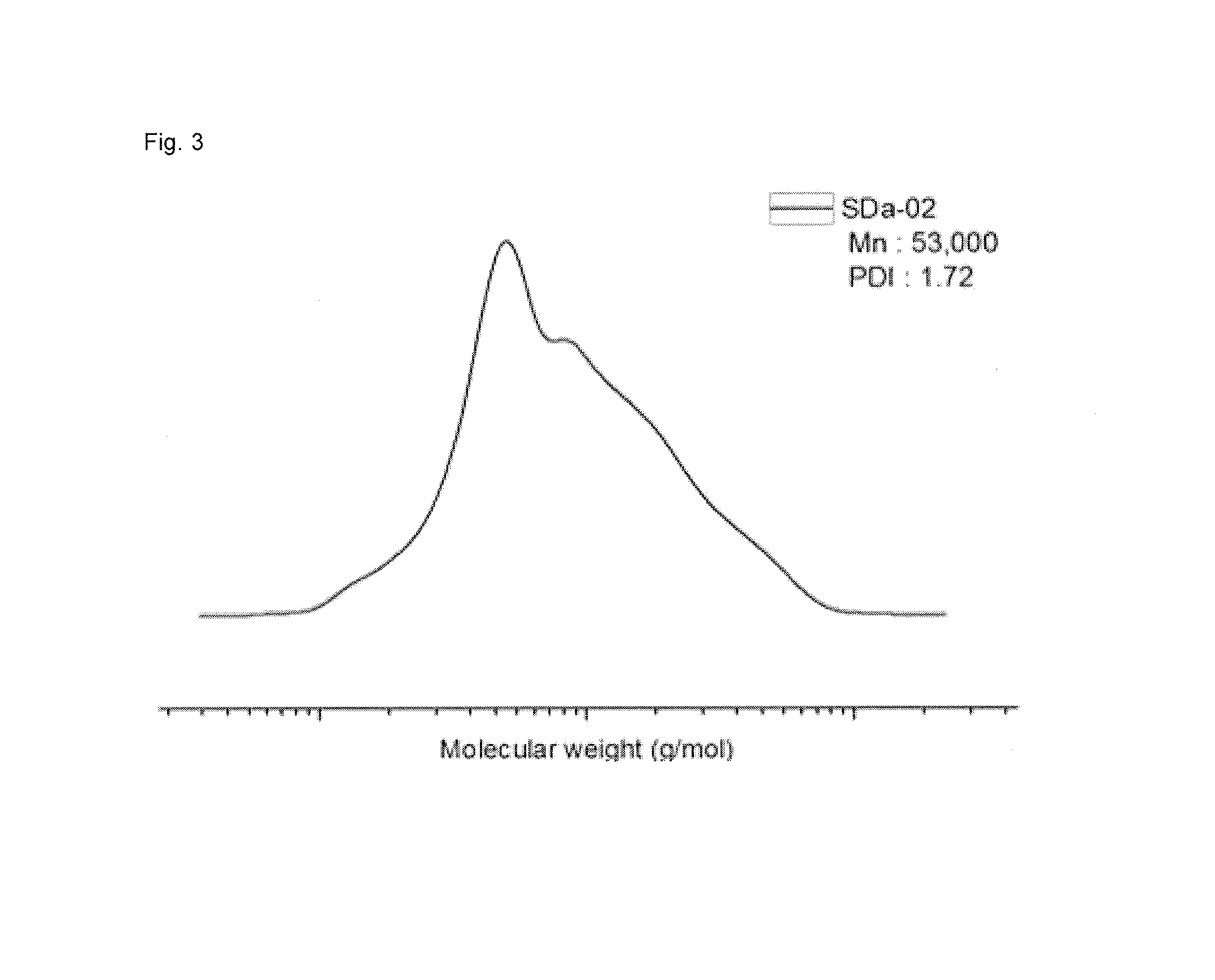

Interfacial polymer for rubber-silica network

InactiveUS8987387B2Improve compatibilityImprove propertiesRolling resistance optimizationPolymer scienceRolling resistance

Disclosed is an interfacial polymer for a network used as a coupling agent in mixing of rubber-silica. More particularly, the interfacial polymer for a rubber-silica network is a block copolymer containing a copolymer of conjugated diene and vinyl aromatic monomers, in which when used as a coupling agent in the mixing of synthetic rubber and silica (an inorganic material), the polymer enhances silica dispersibility within the rubber, and improves compatibility and processability, resulting in considerable improvement in the dynamic property as well as the mechanical property of the rubber, and when used in a tire, etc., it enhances automobile braking performance and reduces rolling resistance.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com