Directional metal wire-filled anti-EMI silica gel liner and preparation method thereof

A technology of metal wire and silica gel, applied in the direction of coating, etc., can solve the problem of high cost, and achieve the effects of excellent resilience, good moisture resistance, and good moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A kind of preparation method of the anti-EMI silica gel liner that directional wire fills, it may further comprise the steps:

[0037] 1) Metal wire pre-treatment: degrease the metal wire and treat the surface with silane coupling agent or titanate coupling agent;

[0038] 2) Uniform wire distribution: the metal wire is evenly wound on the rectangular metal frame, the wire-wrapped metal frame and the non-wire-wrapped metal frame are pressed together at intervals, and the mold cavity is sealed with a sealant;

[0039] 3) Glue injection: defoam the liquid glue in a mixer, then fill the membrane cavity, and place the cavity in a vacuum defoaming machine for defoaming;

[0040] 4) Vulcanization molding;

[0041] 5) Cutting: Cut rubber sheets of various thicknesses according to customer needs, and the cutting direction is perpendicular to the direction of wire arrangement.

[0042] Wherein, in step 1, the surface of the wire is cleaned with a silane coupling agent or a tit...

Embodiment 1

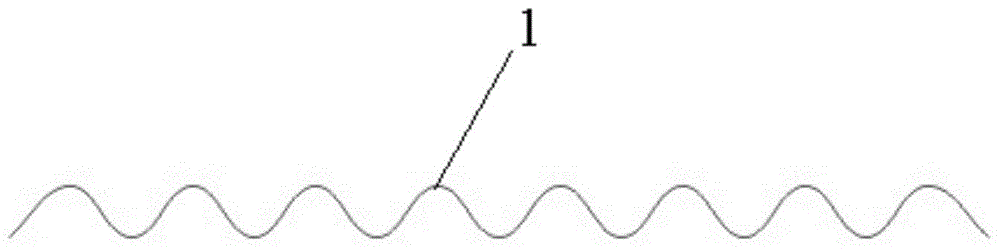

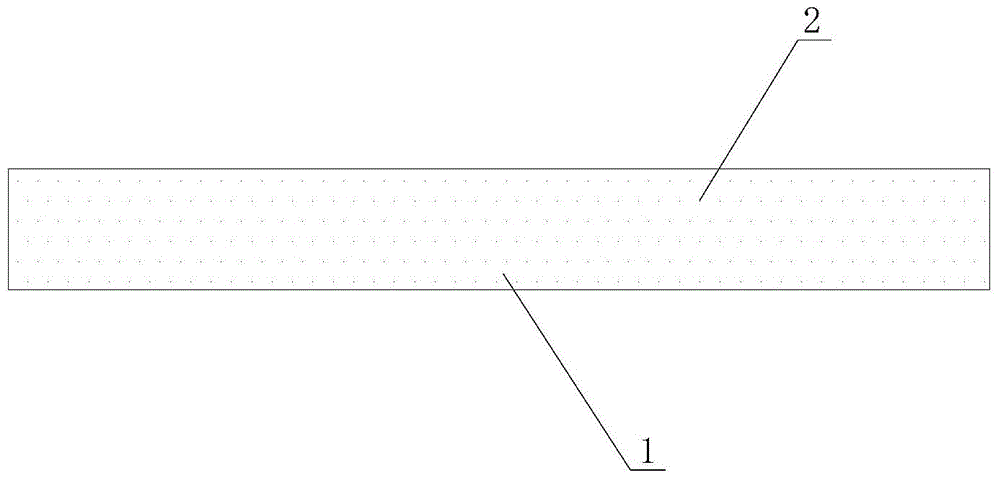

[0046] Such as figure 1 and figure 2 As shown, this embodiment is an anti-EMI silicone gasket filled with directional wires, which includes a silicone body 1 , and metal wires 2 are oriented and evenly distributed in the silicone body. The metal wire 2 is a Monel wire with a wire diameter of 0.15 mm and pressed into a sinusoidal shape.

[0047] Among them, the peak height of the sinusoidal Monel wire is 0.2 mm.

[0048] The preparation method of the anti-EMI silica gel liner that above-mentioned directional wire fills may further comprise the steps:

[0049] 1) Monel wire pre-treatment: Press the Monel wire into a sinusoidal shape, and treat the surface with a silane coupling agent after degreasing to ensure sufficient adhesion between the metal wire and the rubber;

[0050] 2) Uniform wire distribution: Wind the Monel wire evenly on the rectangular metal frame, press the wrapped metal frame and the non-wired metal frame at intervals, and seal the outside of the mold cavit...

Embodiment 2

[0056] Such as figure 1 and figure 2 As shown, this embodiment is an anti-EMI silicone gasket filled with directional wires, which includes a silicone body 1 , and metal wires 2 are oriented and evenly distributed in the silicone body. The metal wire 2 is a Monel wire with a wire diameter of 0.1 mm and pressed into a sinusoidal shape.

[0057] Among them, the peak height of the sinusoidal Monel wire is 0.05mm

[0058] The preparation method of the anti-EMI silica gel liner that above-mentioned directional wire fills may further comprise the steps:

[0059] 1) Monel wire pre-treatment: Press the Monel wire into a sinusoidal shape, and treat the surface with a silane coupling agent after degreasing to ensure sufficient adhesion between the metal wire and the rubber;

[0060] 2) Uniform wire distribution: Wind the Monel wire evenly on the rectangular metal frame, press the wrapped metal frame and the non-wired metal frame at intervals, and seal the outside of the mold cavity wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com