Acrylate Compound, Photocurable Composition Comprising the Same, photocurable film and image display device

An acrylate and light-curable technology, which is applied in the field of invention, can solve problems such as increased viscosity, difficult-to-cure structures, and low double bond concentration, and achieve the effects of inhibiting oxygen inhibition, sufficient processability, and promoting chain transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

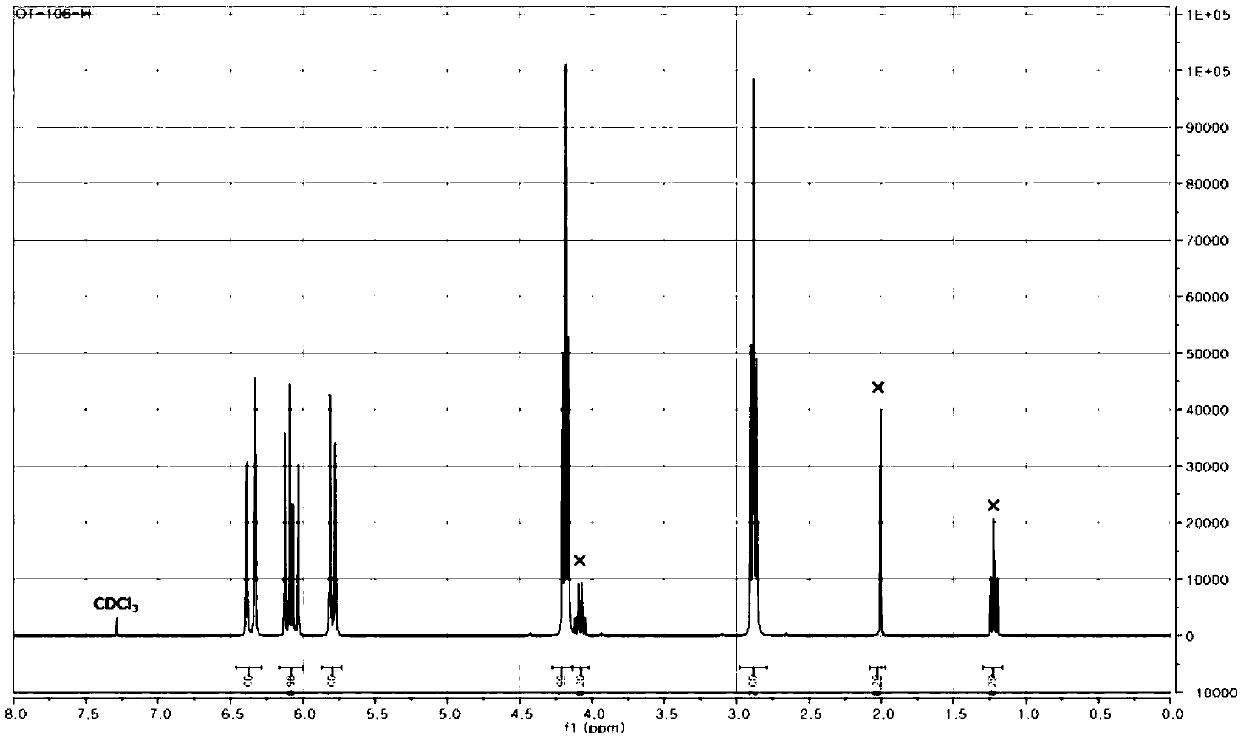

[0104] Synthesis Example 1: Production of Tris(acryloyloxyethyl)amine (Acrylate A)

[0105] After connecting the dropping funnel and the condenser tube to a 1L round bottom flask, the atmosphere was replaced with nitrogen, and 200 mL of tetrahydrofuran was injected, and 25.0 g (0.17 mol) of tris(hydroxyethanol)amine (manufactured by TCI) and 2,6-dimethyl After dissolving 71.8 g (0.67 mol) of pyridine (manufactured by Sigma-Aldrich), it was cooled to -5°C. A solution obtained by dissolving 50.0 g (0.55 mol) of acryloyl chloride (manufactured by TCI) in 150 mL of tetrahydrofuran was put into a dropping funnel, and slowly added dropwise over 2 hours while preventing a sharp rise in temperature. After the dropwise addition, the temperature was raised to At room temperature and stirred for 1 hour. Then, the reactant was heated at 65° C. and further stirred for 6 hours under the reflux condition of tetrahydrofuran. After the reaction was completed, the reactant was cooled to -5°C ...

manufacture example 1

[0110] Production Example 1: Production of Photocurable Composition

[0111] Using the composition of the following Table 1, the photocurable resin compositions of Examples 1-4 and Comparative Examples 1-5 were manufactured, respectively. The unit in Table 1 below is % by weight.

[0112] [Table 1]

[0113]

[0114] a: trifunctional acrylate compound represented by chemical formula 2

[0115] a-1: Isobornyl acrylate (IB: manufactured by Shin-Nakamura Chemical Industry Co., Ltd.) [chemical formula 3]

[0116] a-2: 1,6-hexanediol diacrylate (A-HD-N: manufactured by Shin-Nakamura Chemical Industry Co., Ltd.) [chemical formula 4]

[0117] a-3: Ethoxylated trimethylolpropane triacrylate (A-TMPT-3EO: manufactured by Shin-Nakamura Chemical Industry Co., Ltd.) [chemical formula 5]

[0118] a-4: Ethoxylated glycerin triacrylate (A-GLY-3EO: manufactured by Shin-Nakamura Chemical Industry Co., Ltd.) [chemical formula 6]

[0119] a-5: Trimethylolpropane triacrylate (A-TMPT: manufa...

manufacture example 2

[0134] Production example 2: Production of cured film

[0135] in the Silicon Nitride (Silicon Nitride) was deposited on a glass substrate (Eagle 2000; manufactured by Corning Incorporated) with a size of 50 mm × 50 mm to a thickness of 100 Å. Coating was performed so as to have a thickness of 3.0 μm. After spin coating (Spin Coating), place it on the platform for 5 minutes, put it in an acrylic box, and replace it with a nitrogen atmosphere. cm 2 (UV-A area measurement) It irradiated for 20 seconds, and obtained the cured coating film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com