Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81results about How to "Sufficient mechanical property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

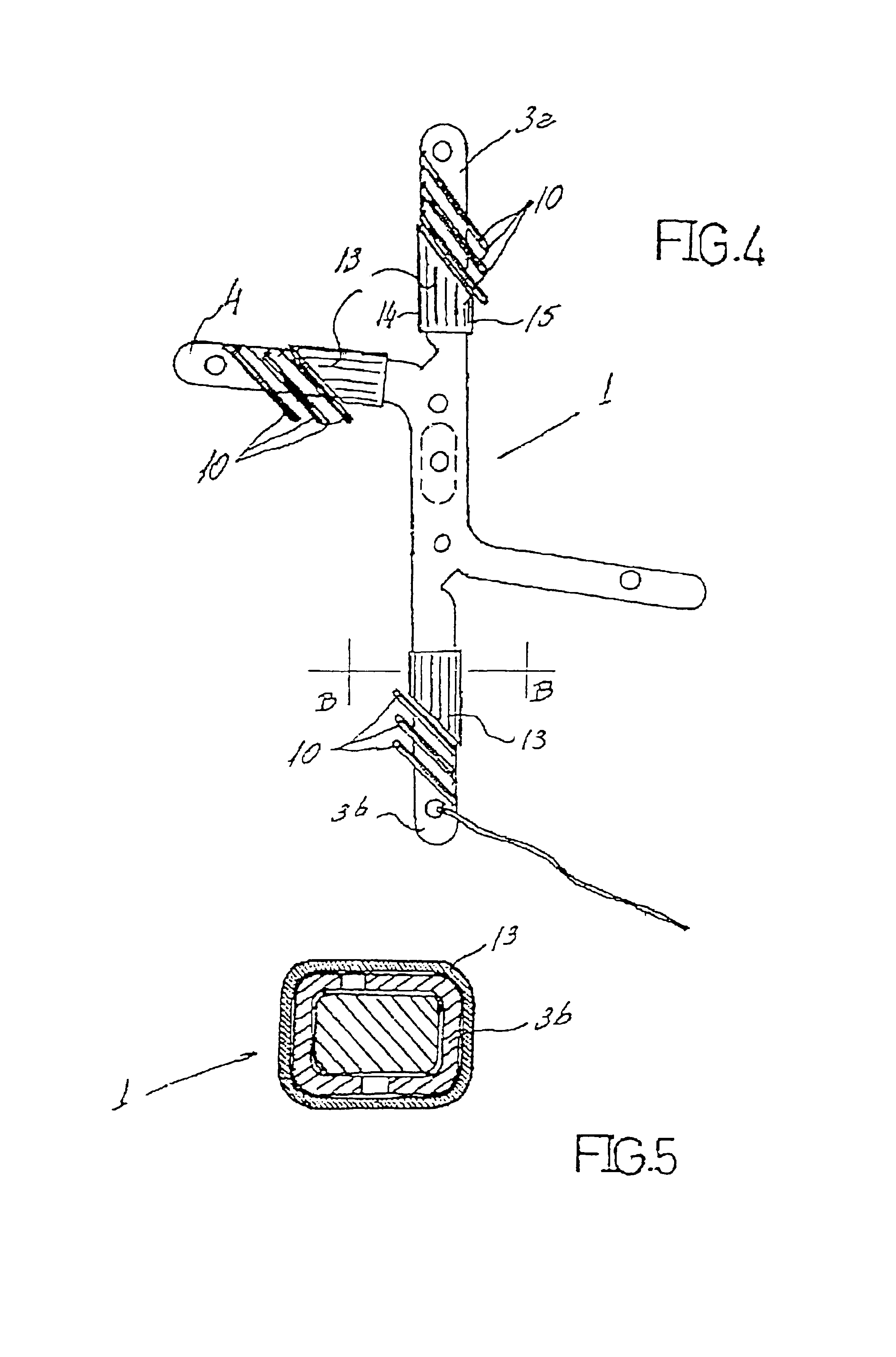

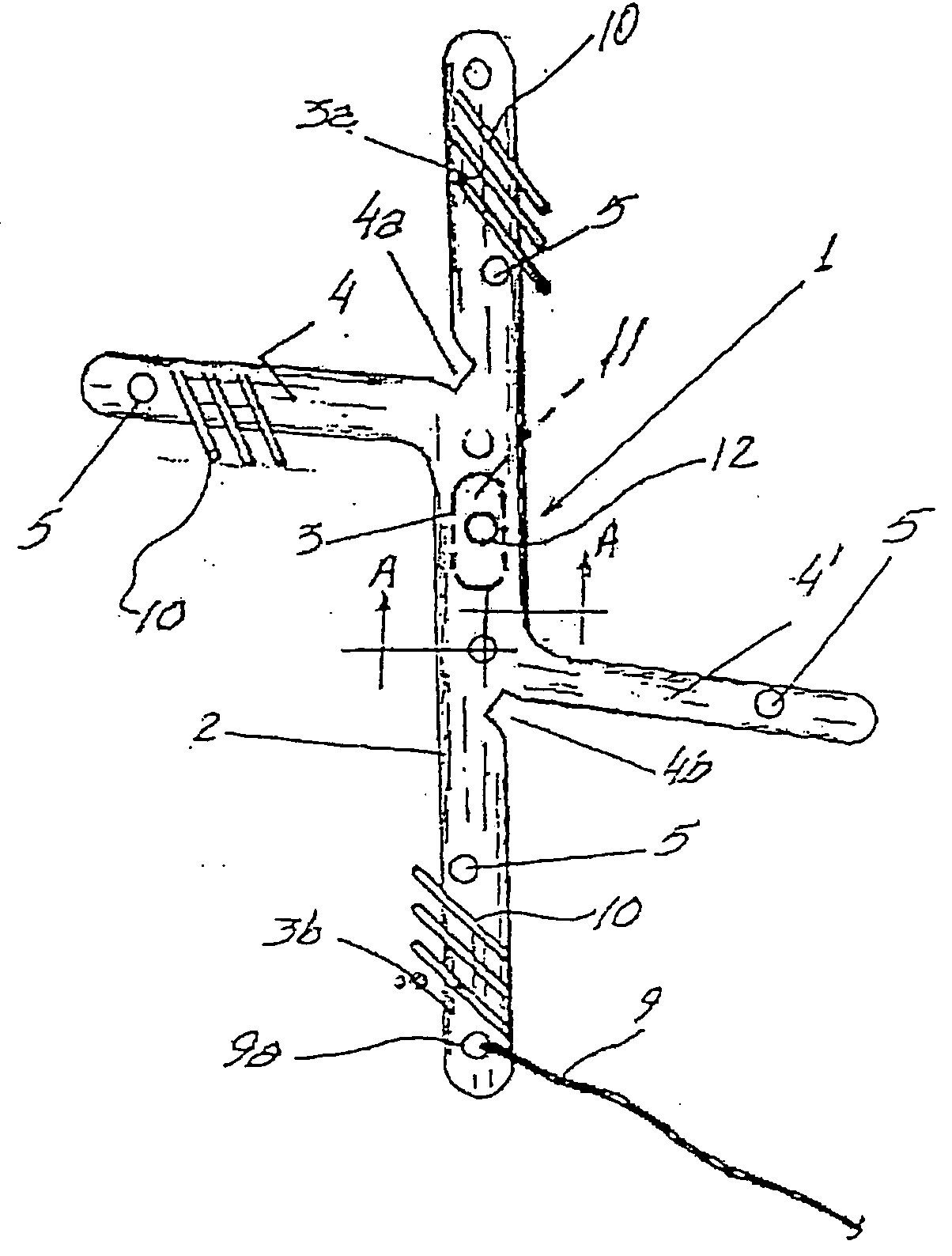

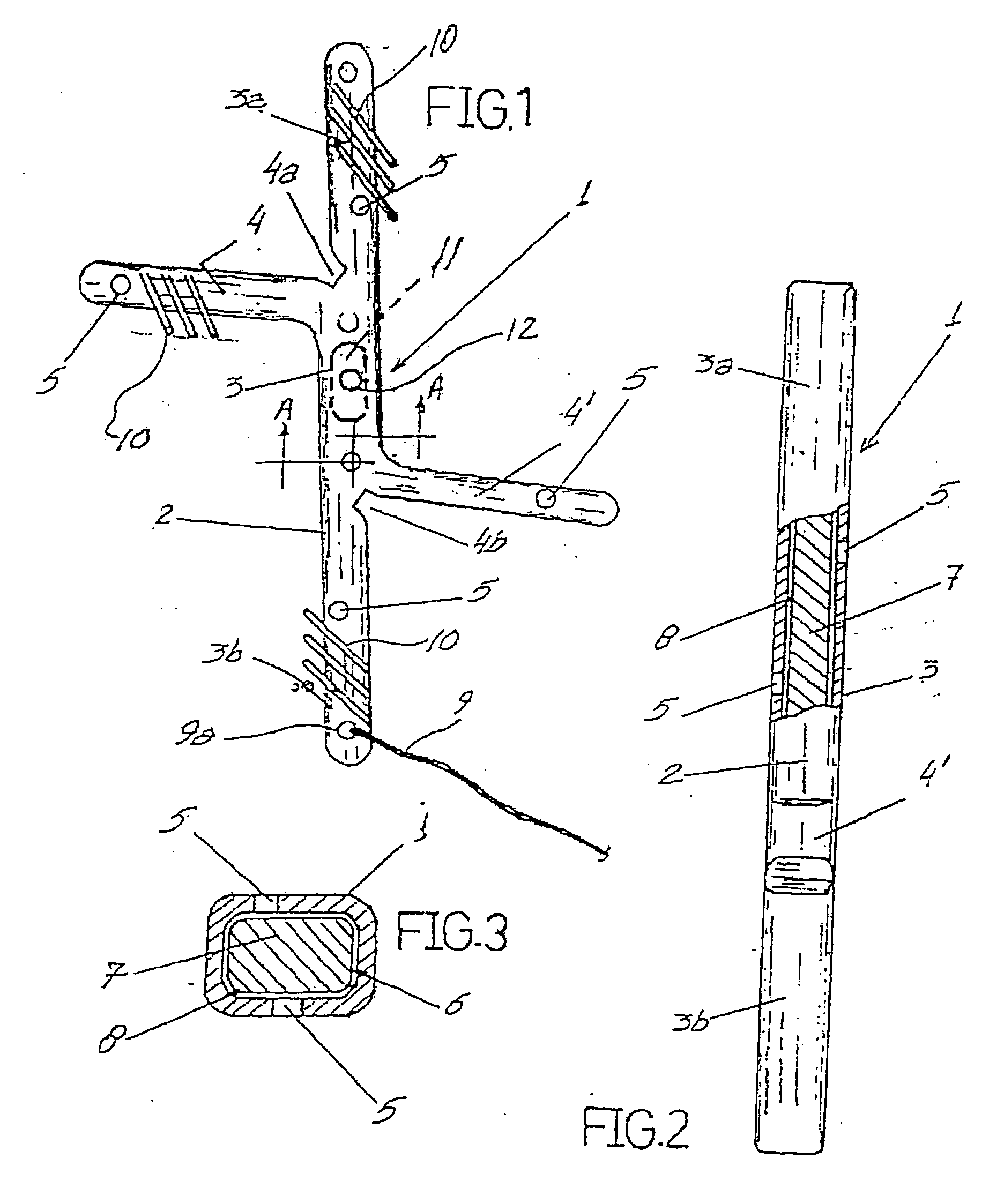

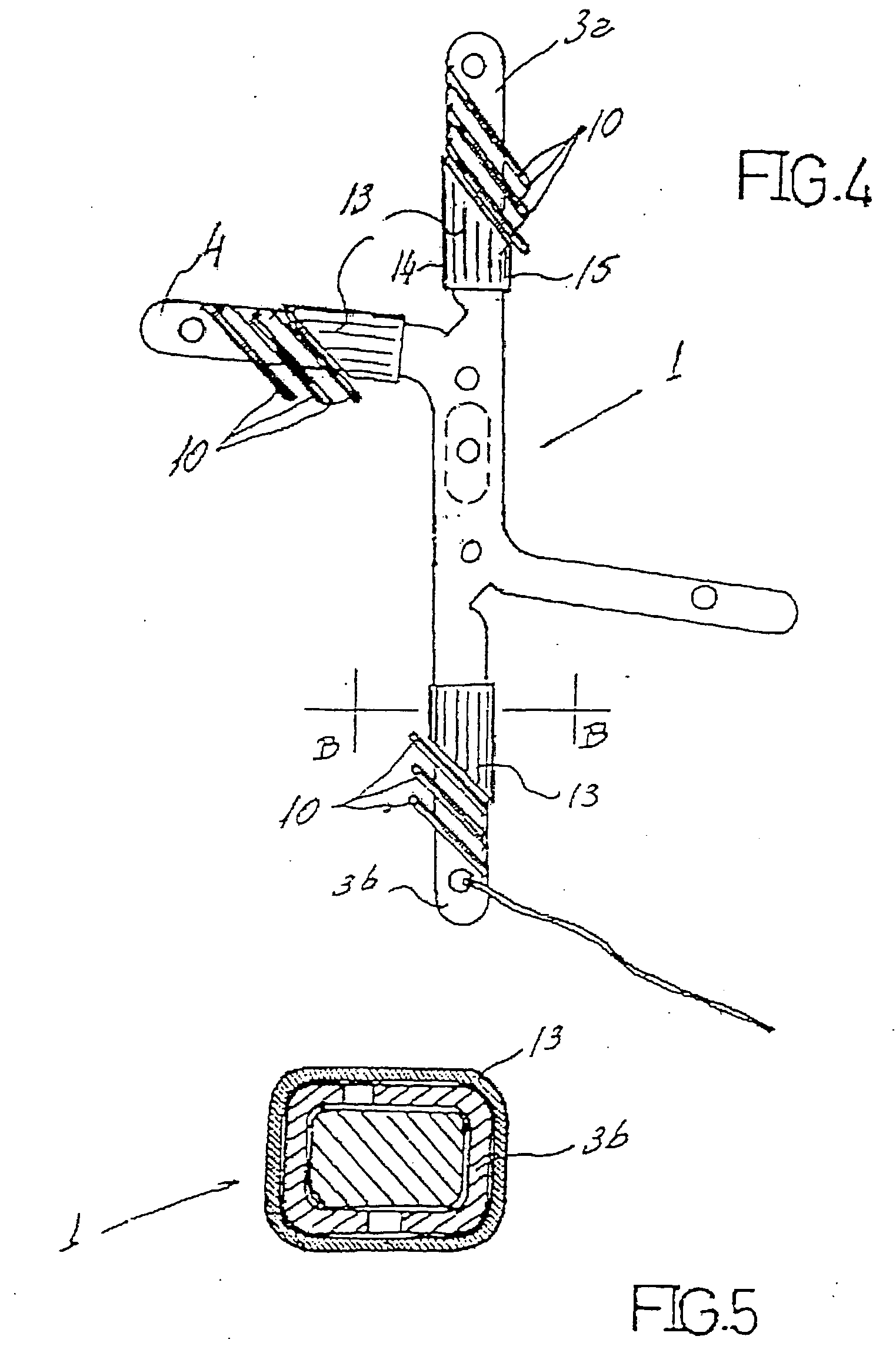

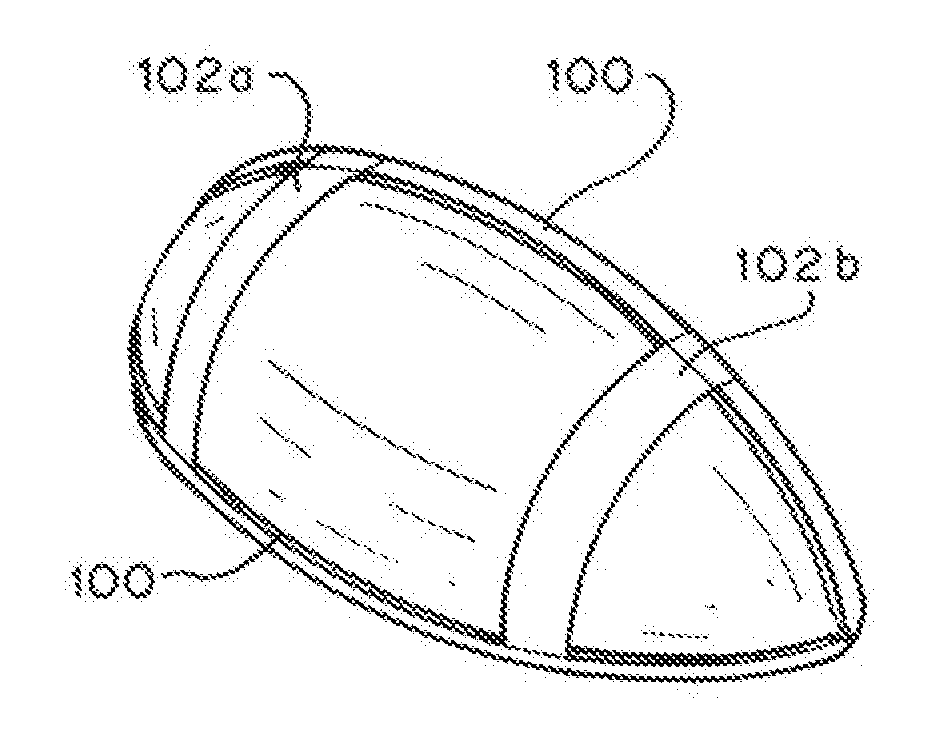

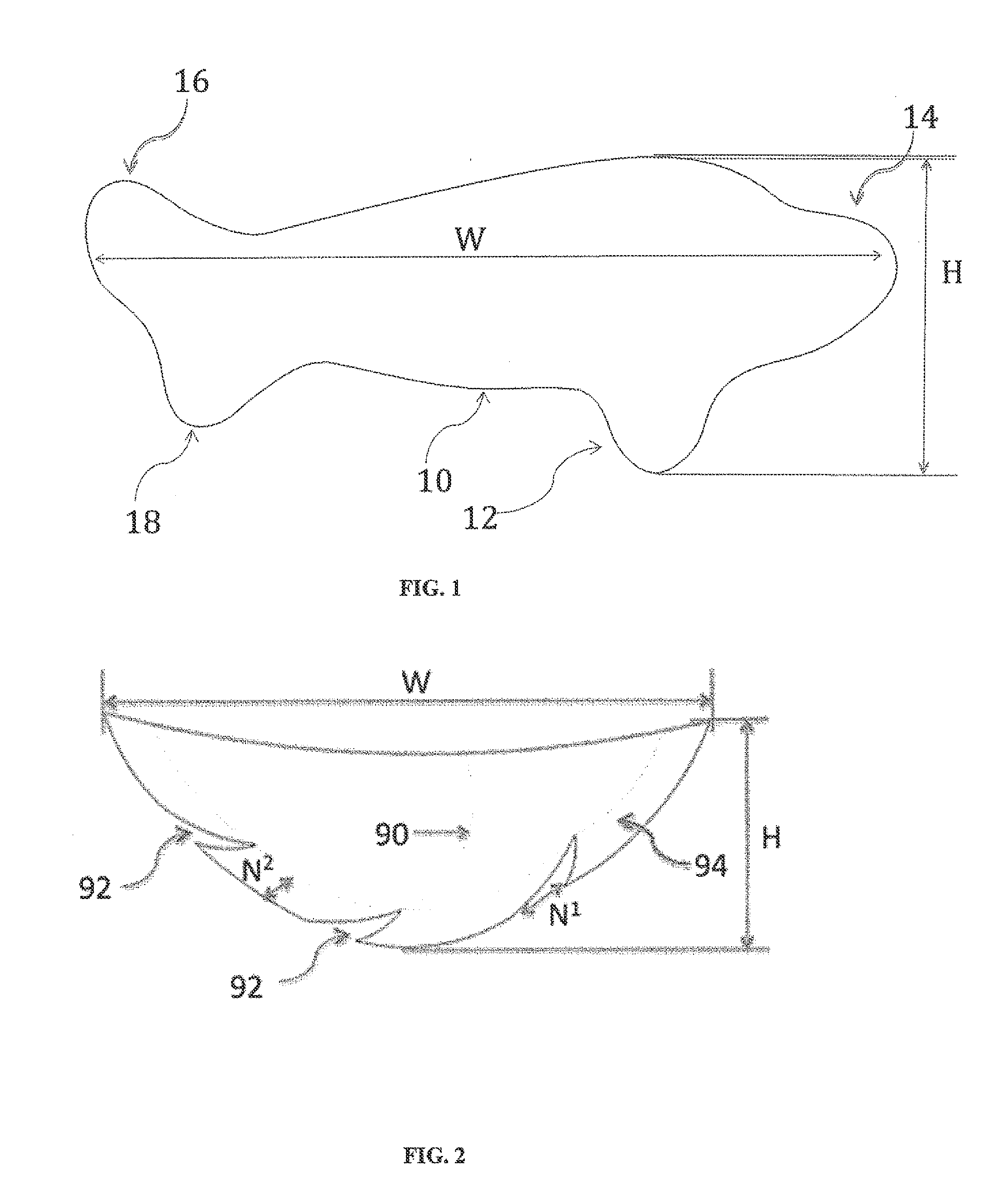

Absorbable implants for plastic surgery

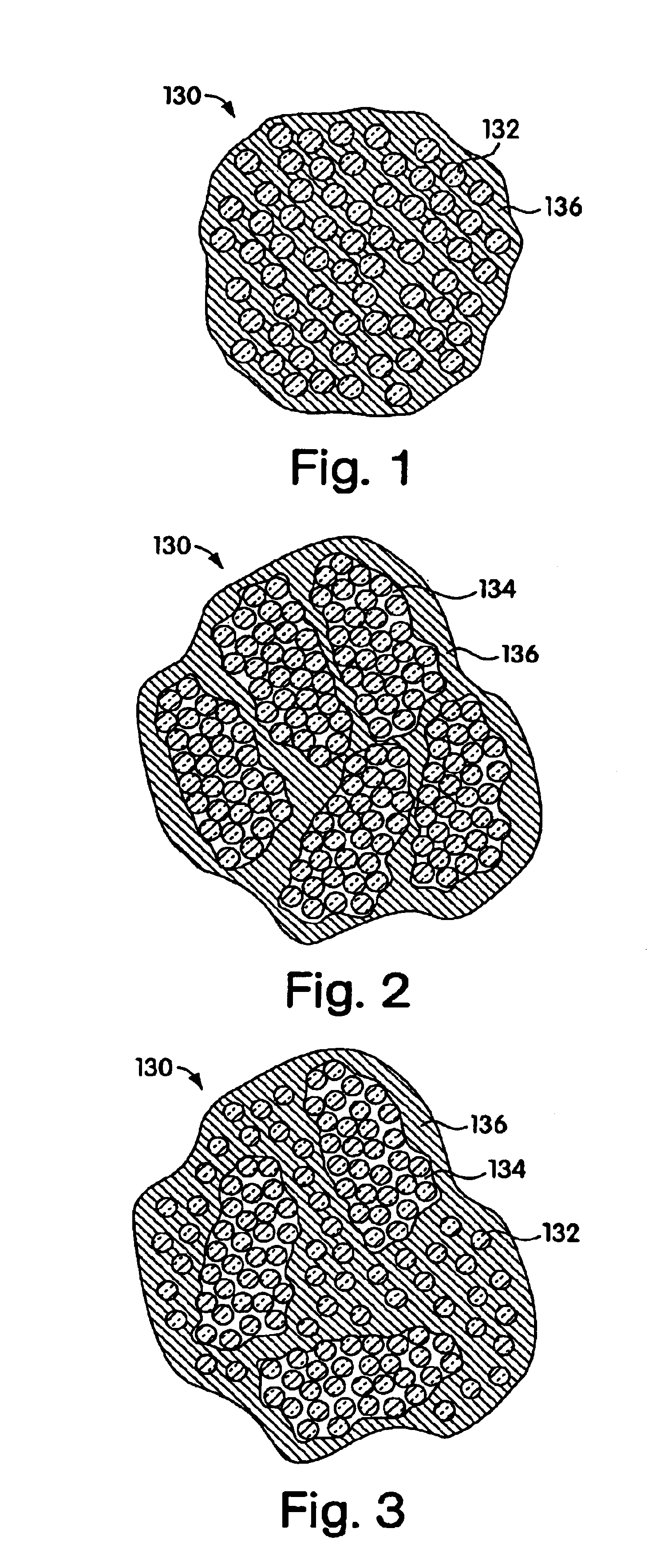

ActiveUS20150223928A1Solve the lack of mechanical propertiesMinimization requirementsMammary implantsDiagnosticsPullout strengthThree dimensional shape

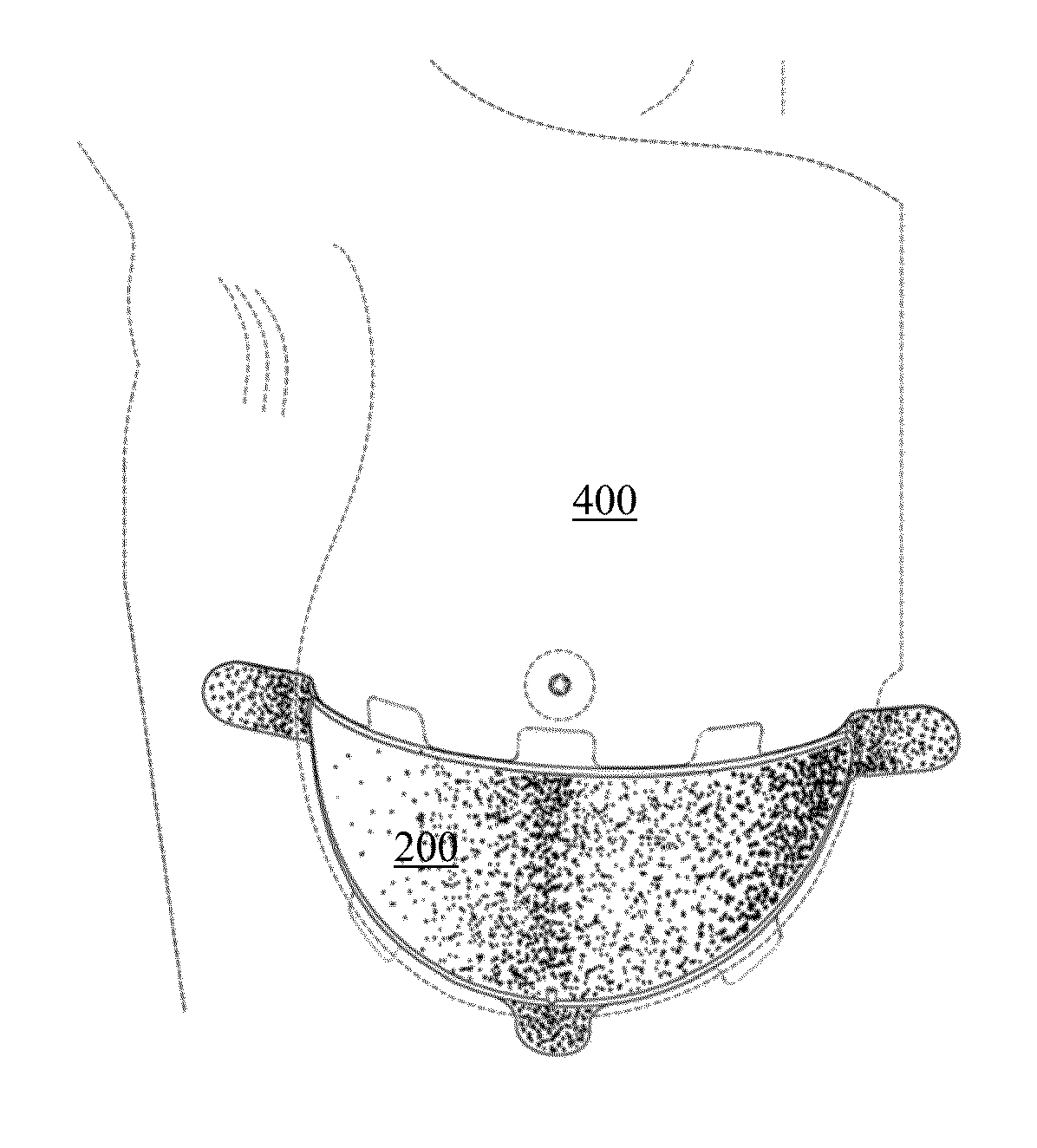

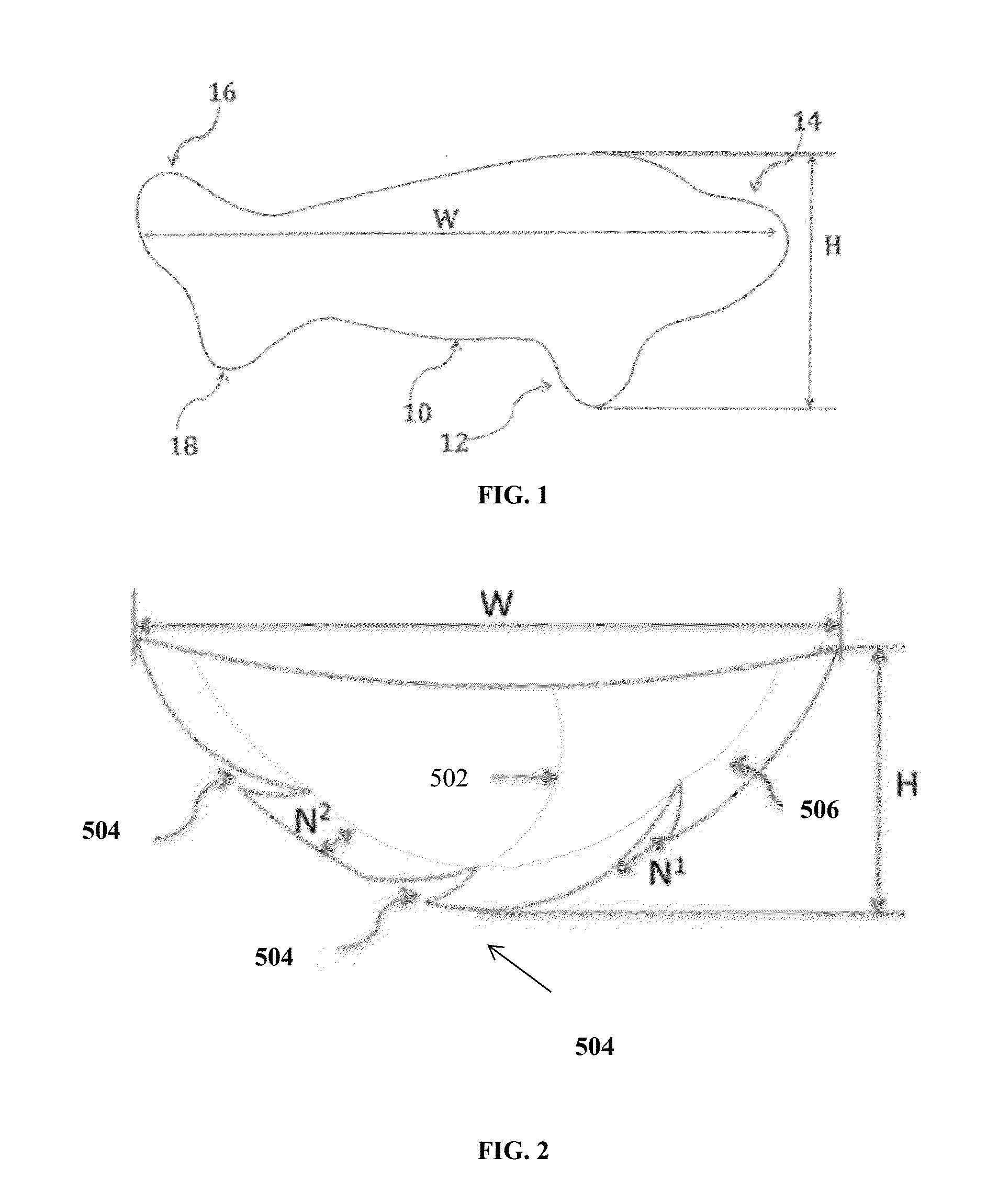

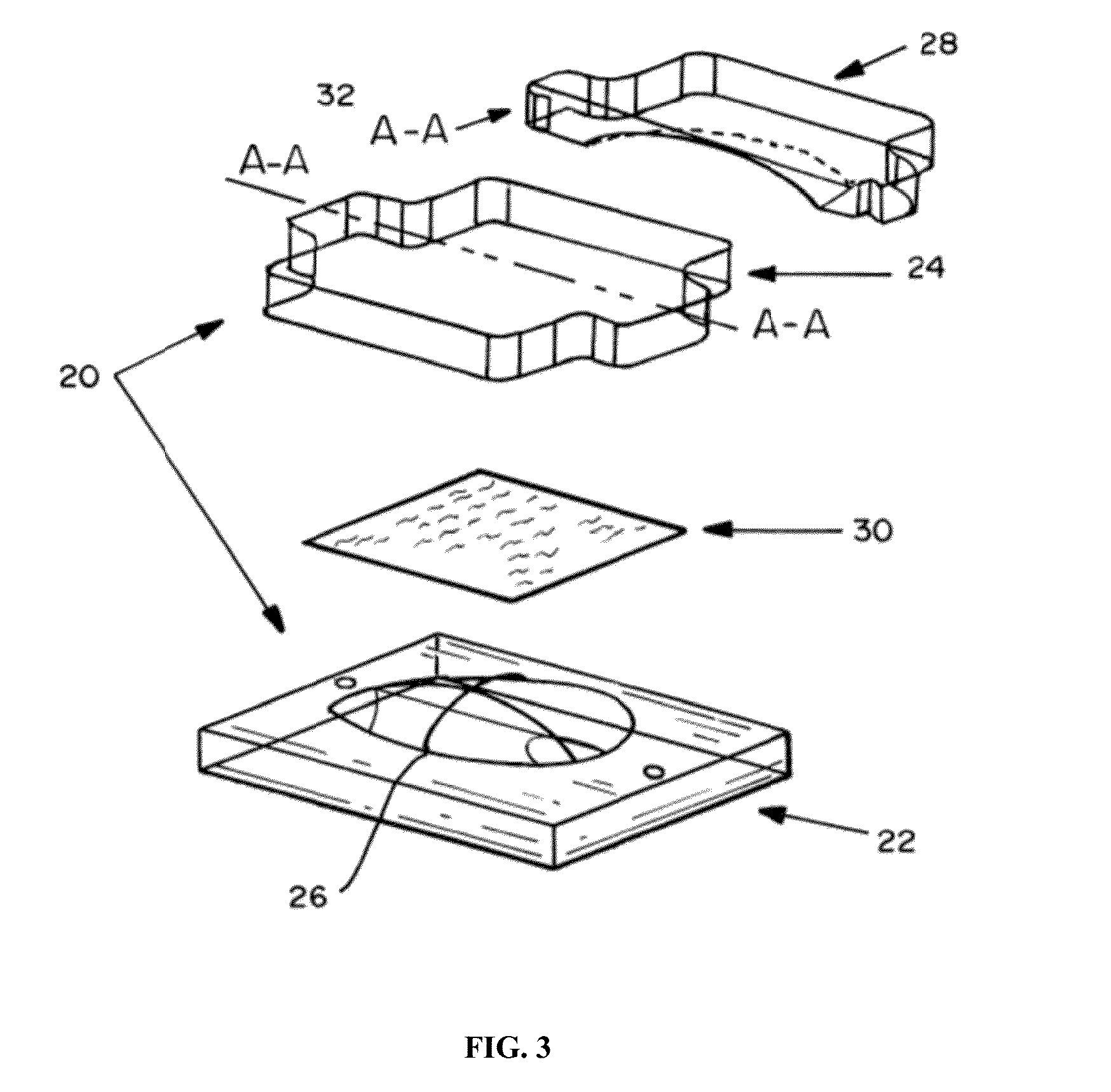

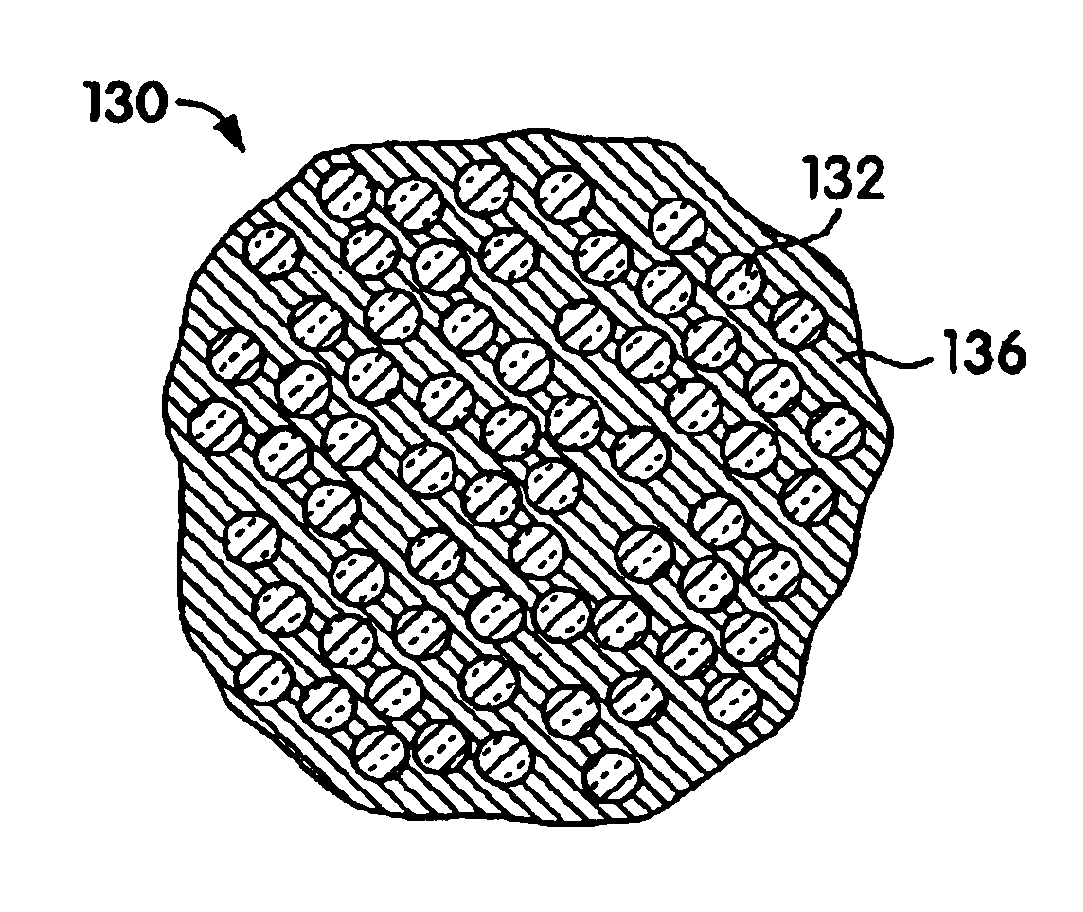

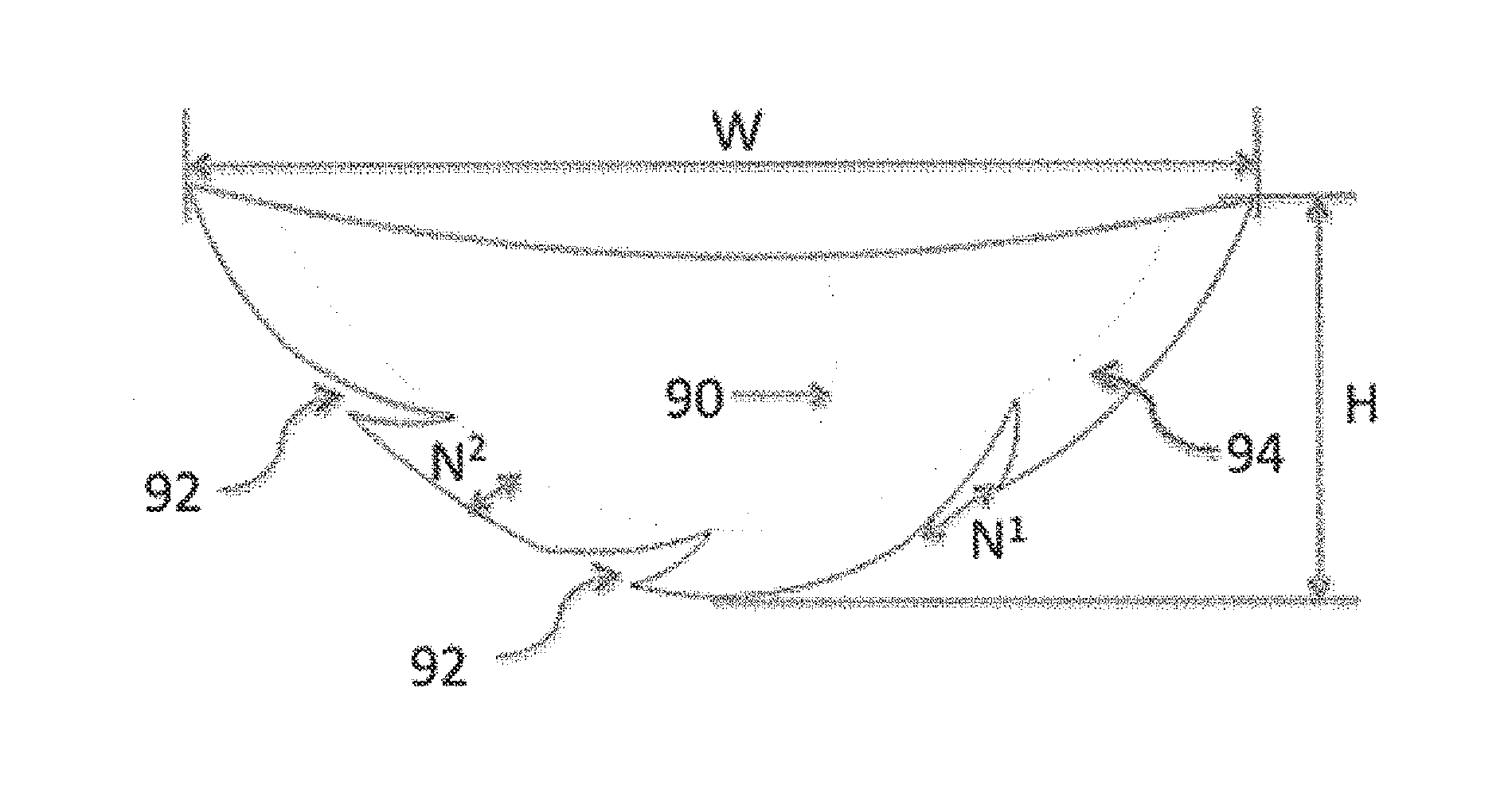

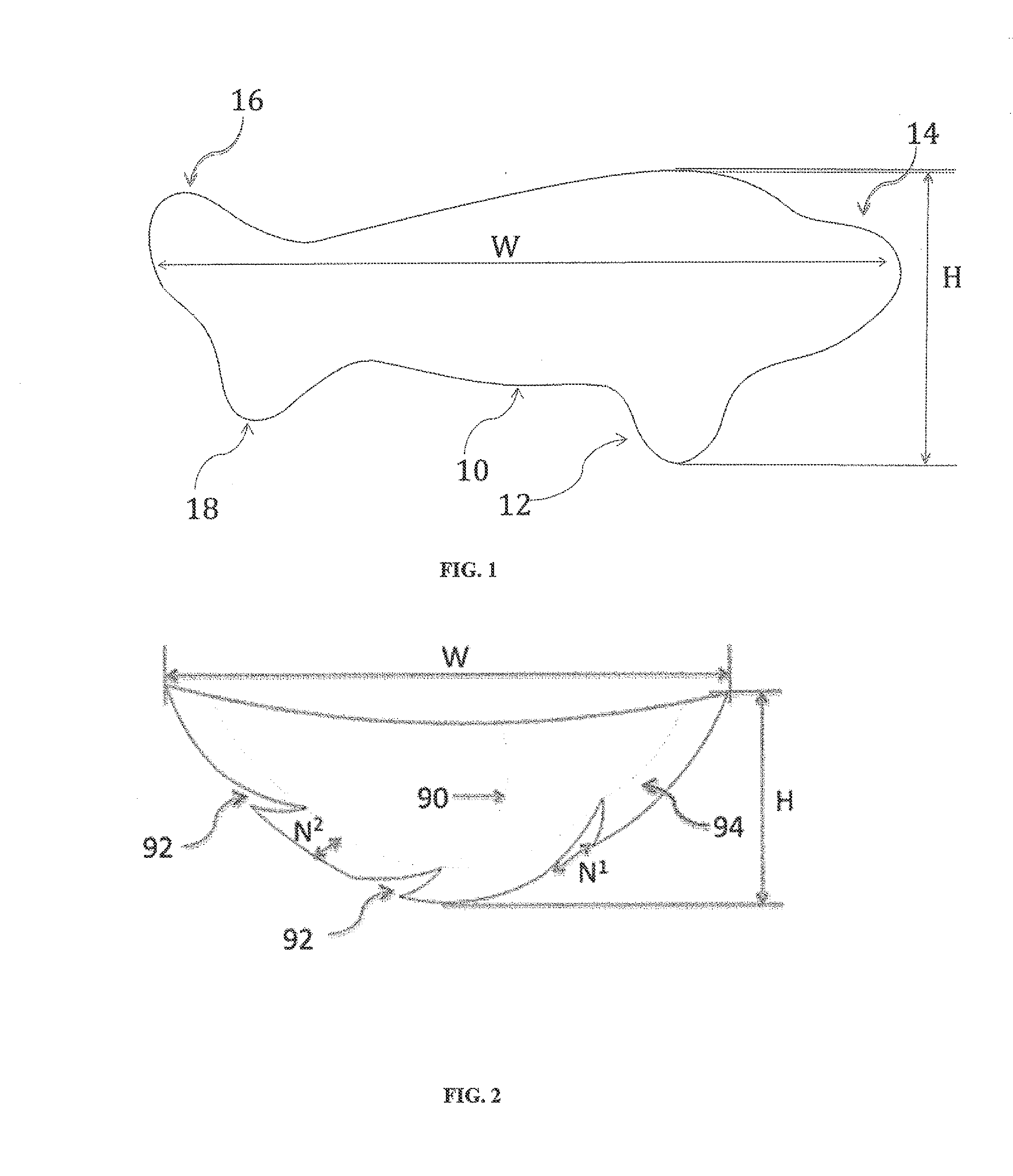

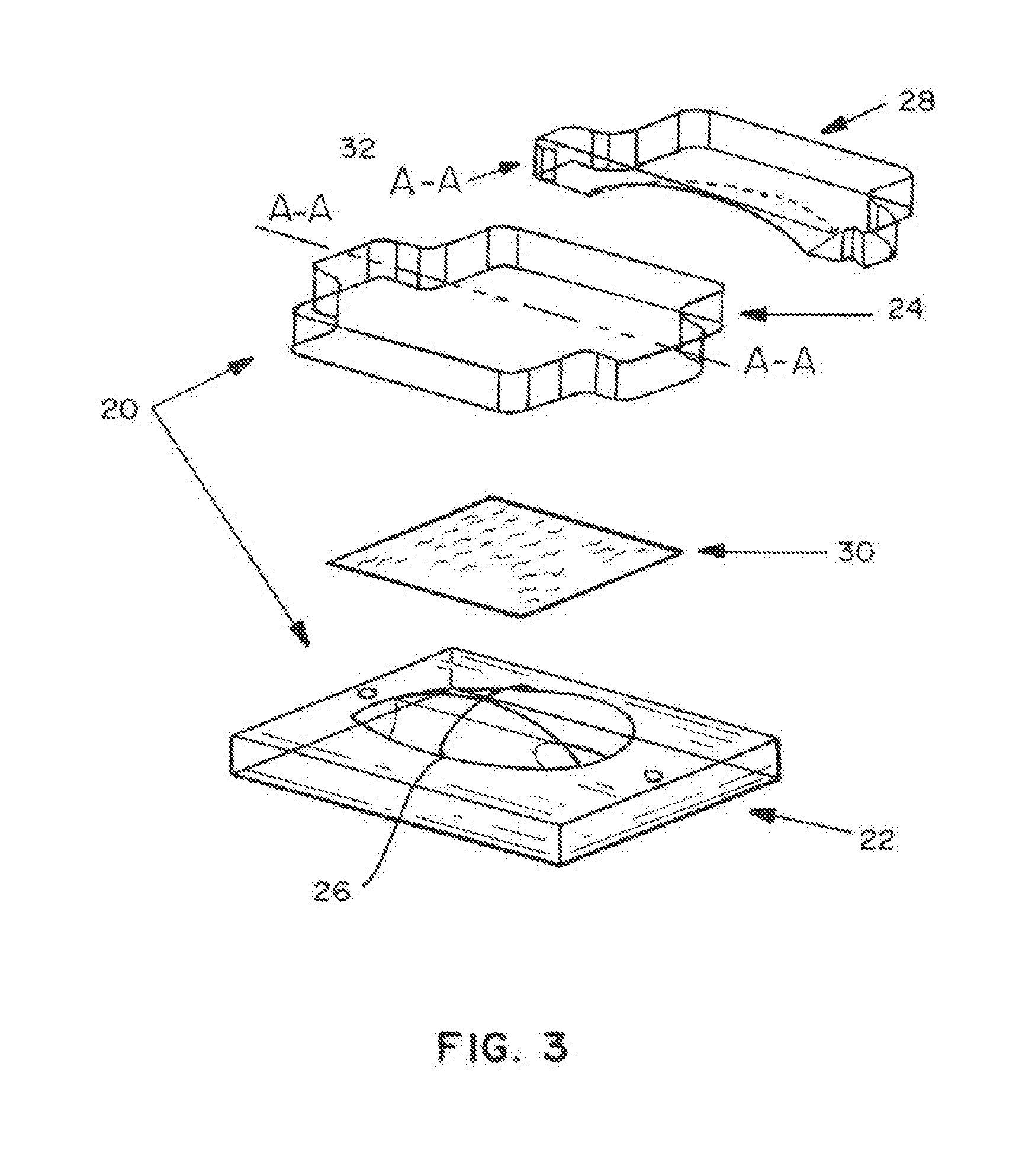

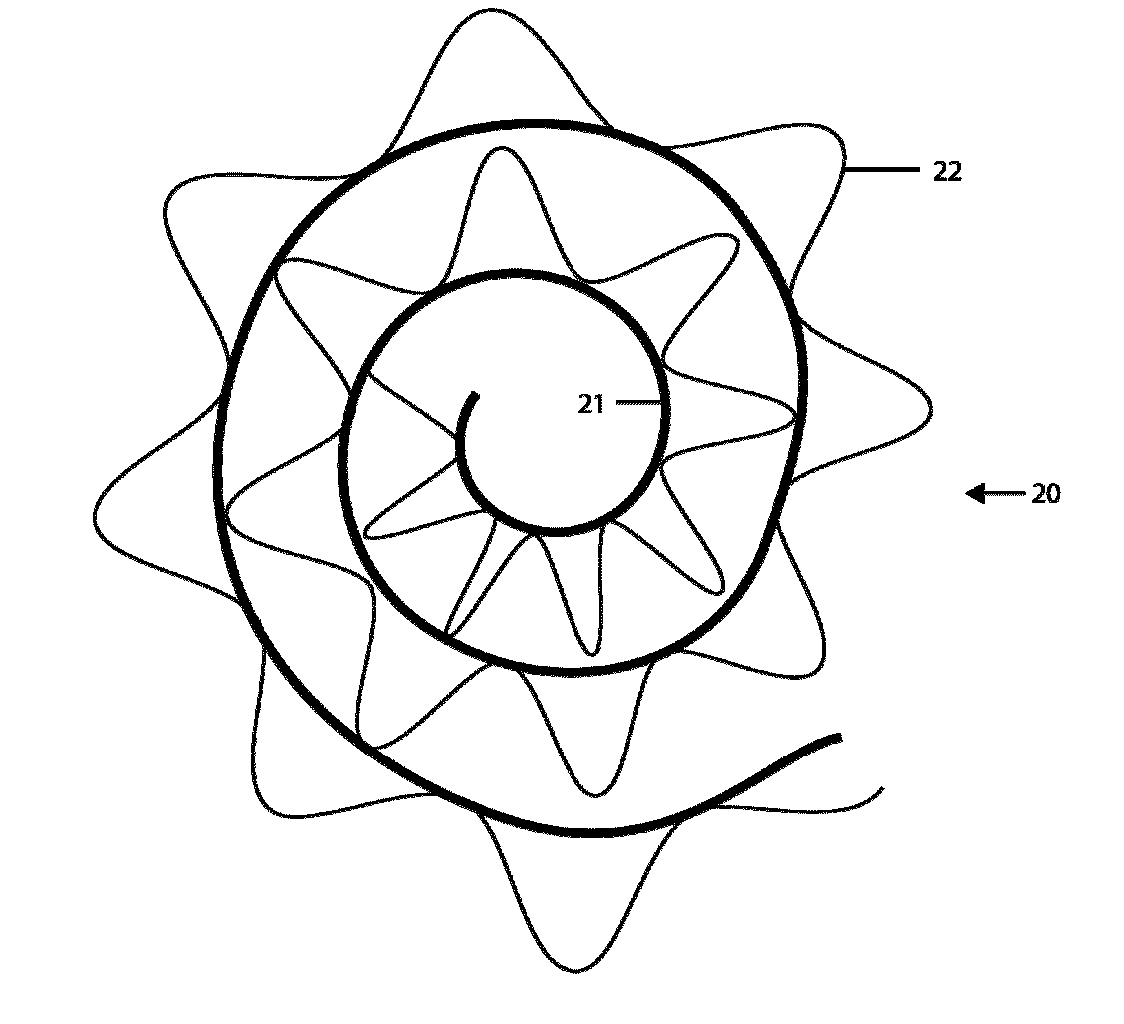

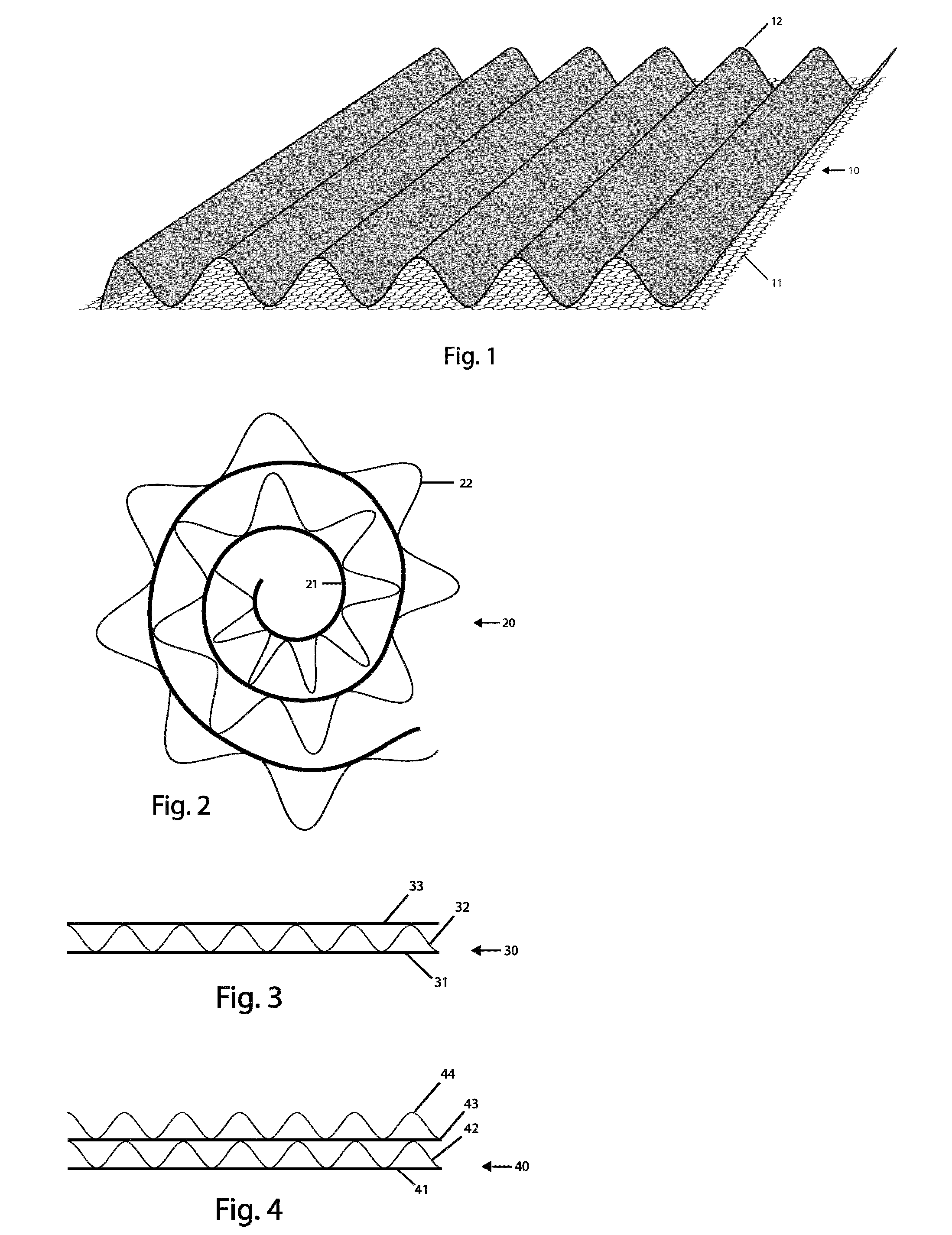

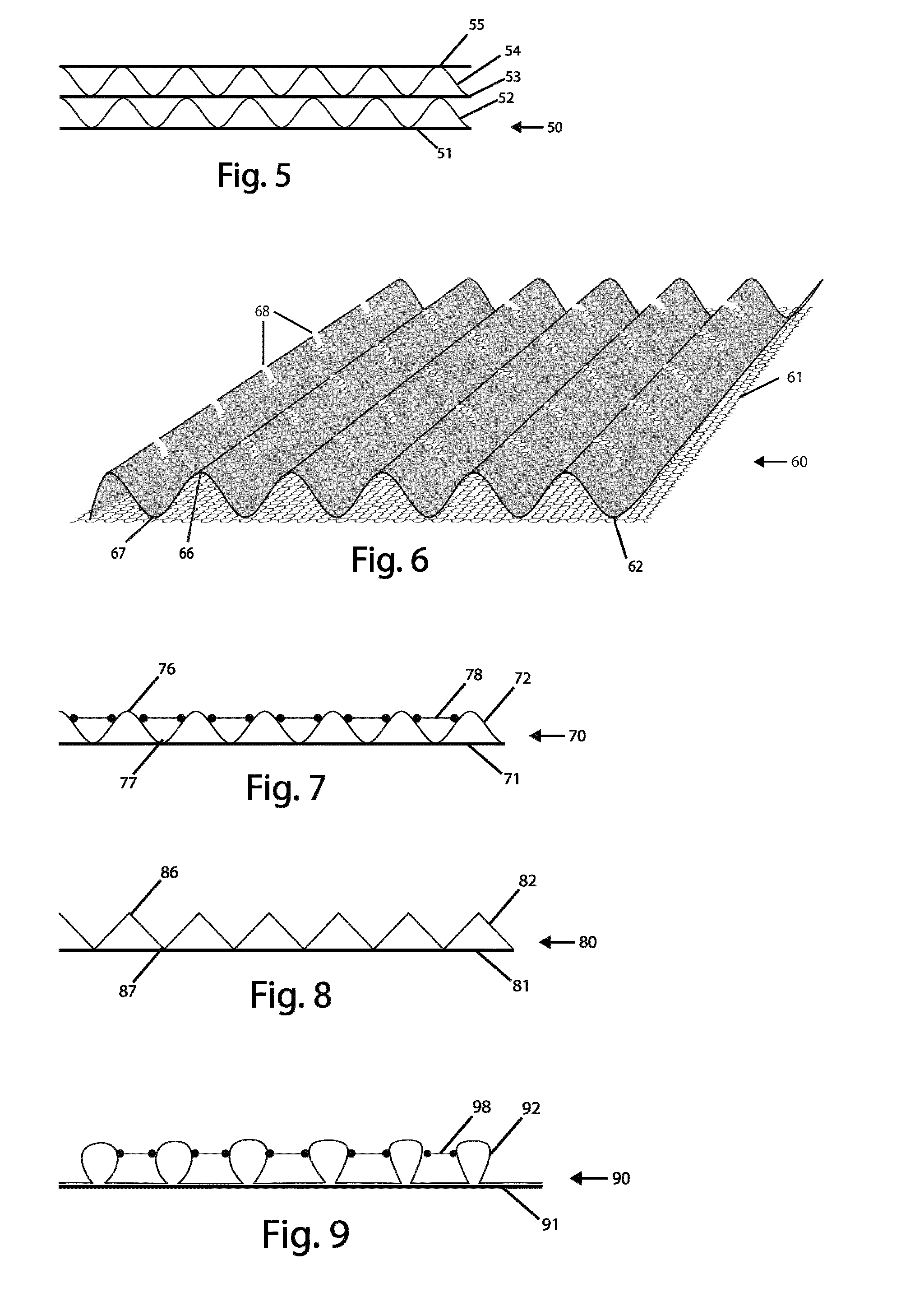

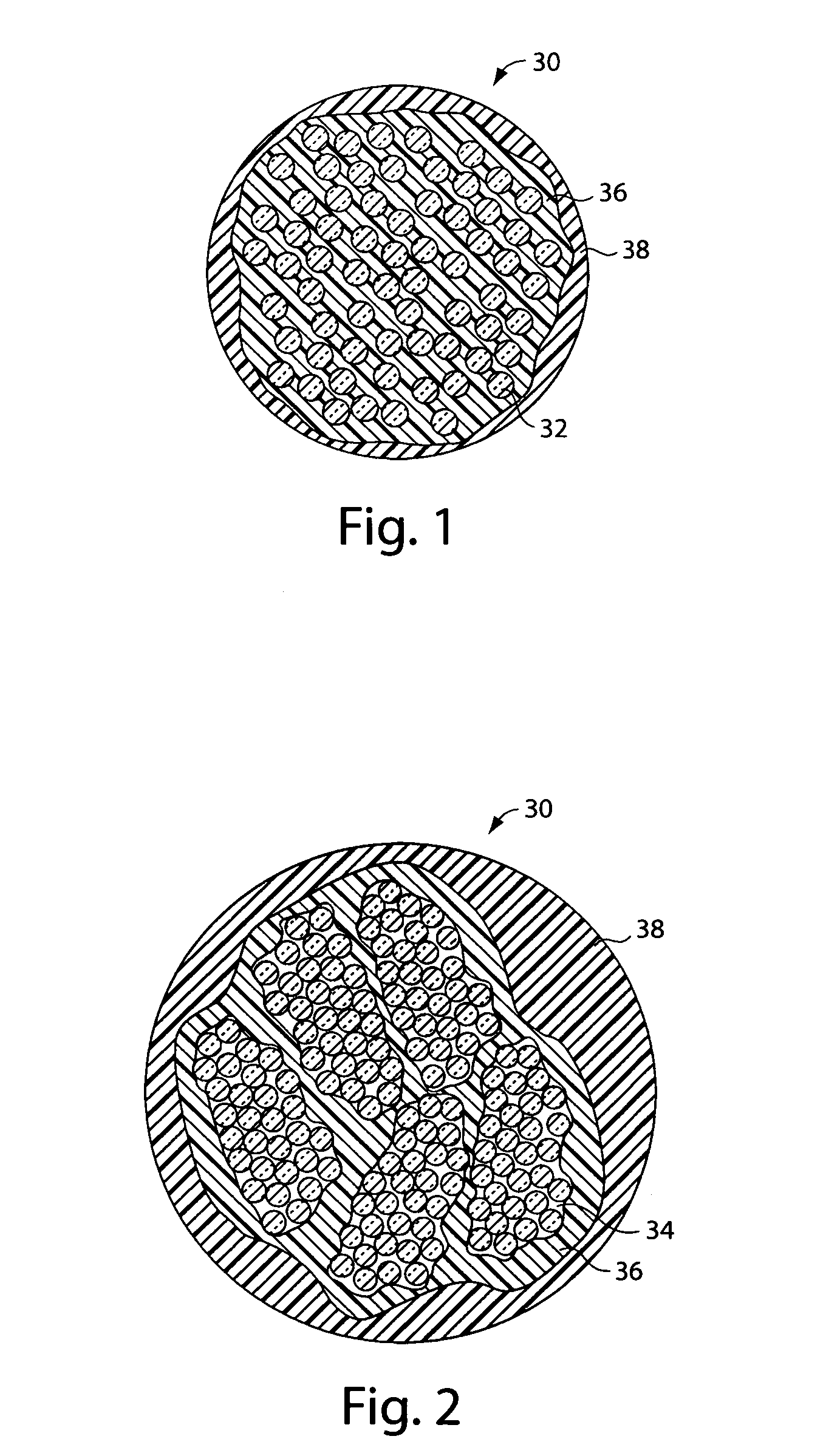

Absorbable implants for breast surgery that conform to the breast parenchyma and surrounding chest wall have been developed. These implants support newly lifted breast parenchyma, and / or a breast implant. The implants have mechanical properties sufficient to support a reconstructed breast, and allow the in-growth of tissue into the implant as it degrades. The implants have a strength retention profile allowing the support of the breast to be transitioned from the implant to regenerated host tissue, without significant loss of support. Three-dimensional implants for use in minimally invasive mastopexy / breast reconstruction procedures are also described, that confer shape to a patient's breast. These implants are self-reinforced, can be temporarily deformed, implanted in a suitably dissected tissue plane, and resume their preformed three-dimensional shape. The implants are preferably made from poly-4-hydroxybutyrate (P4HB) and copolymers thereof. The implants have suture pullout strengths that can resist the mechanical loads exerted on the reconstructed breast.

Owner:TEPHA INC

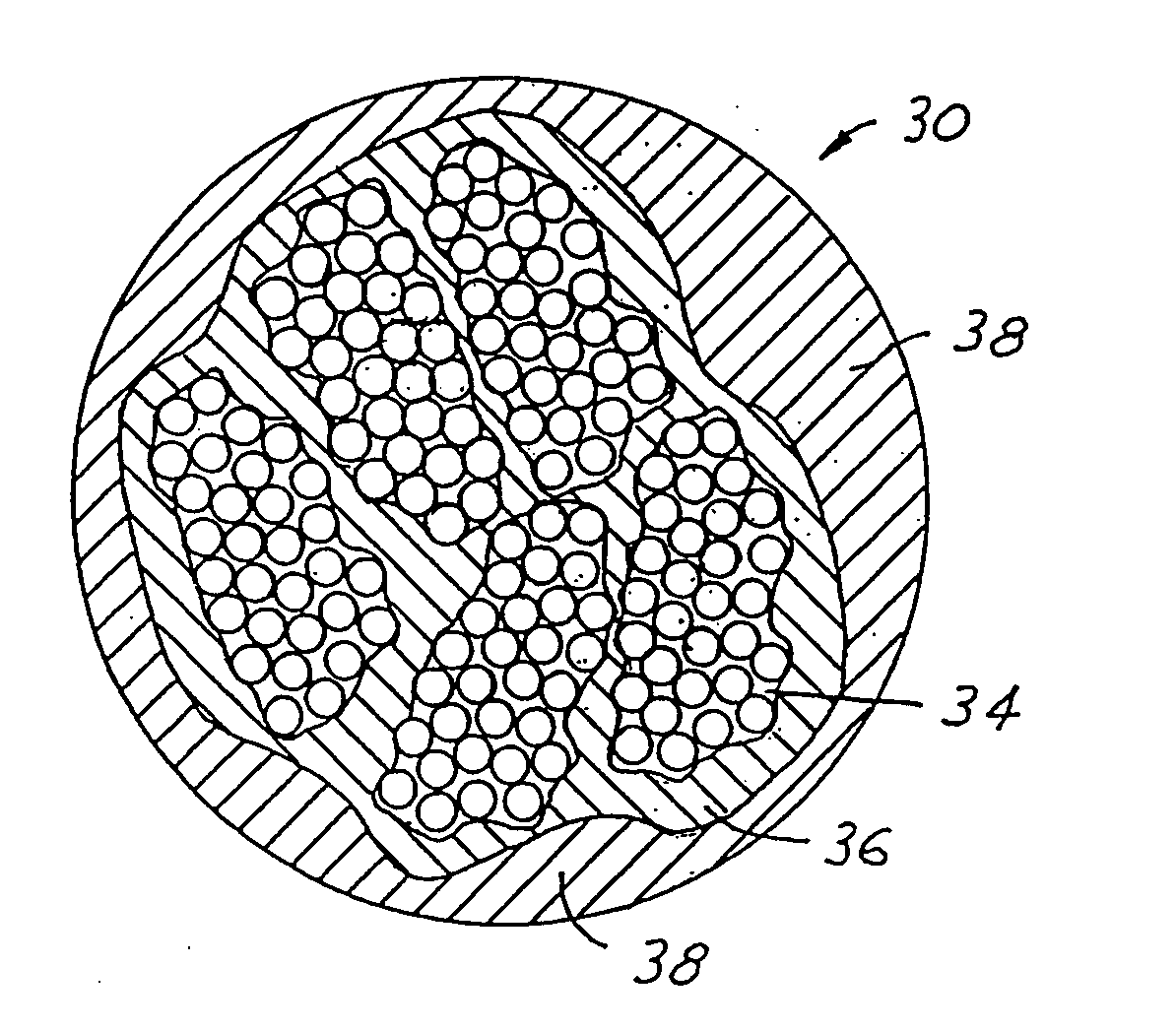

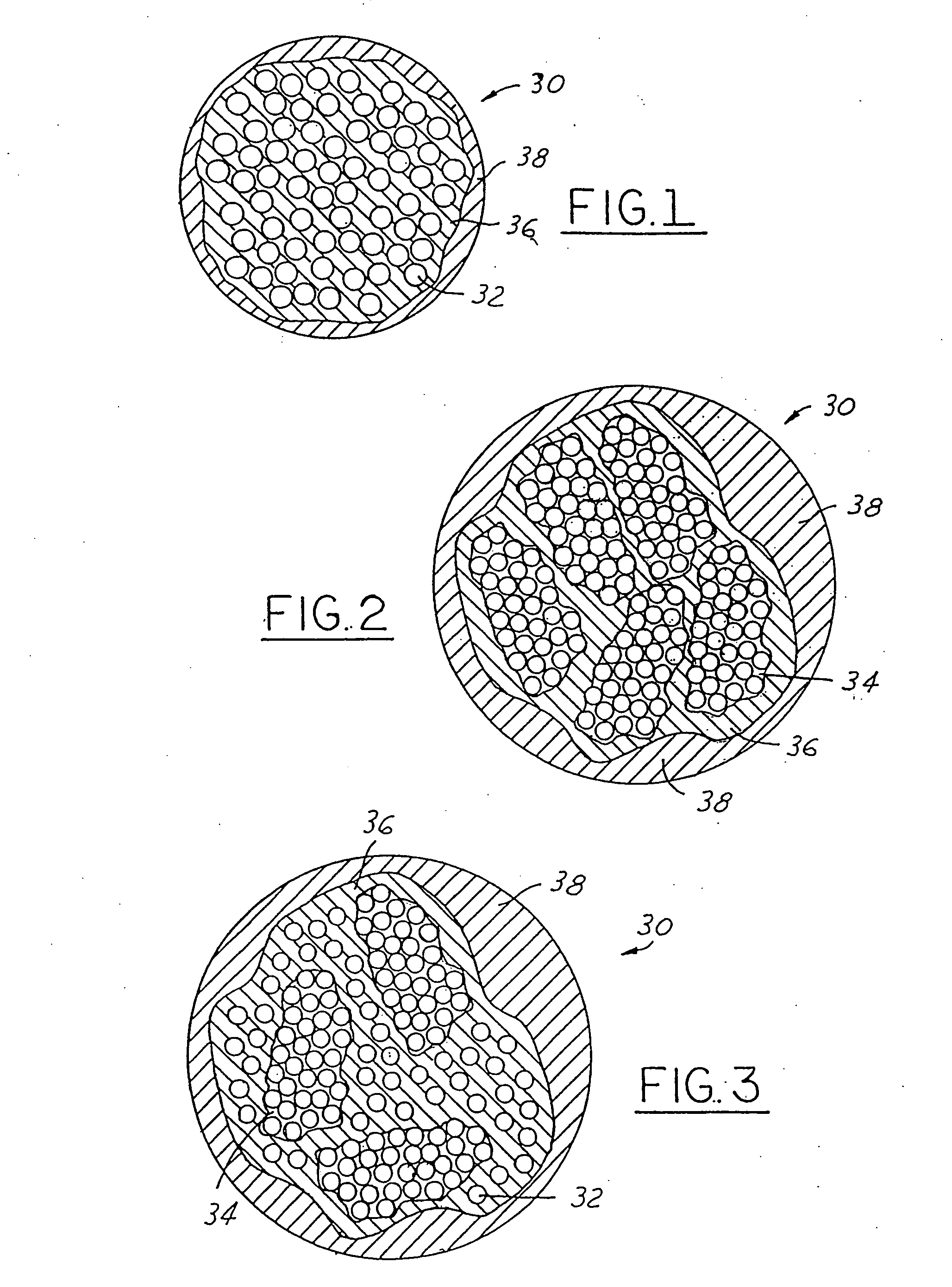

Low cost, high performance, rodent resistant, flexible reinforcement for communications cable

InactiveUS6897382B2Low costImprove performancePlastic/resin/waxes insulatorsPower cables with screens/conductive layersTelecommunicationsCopper

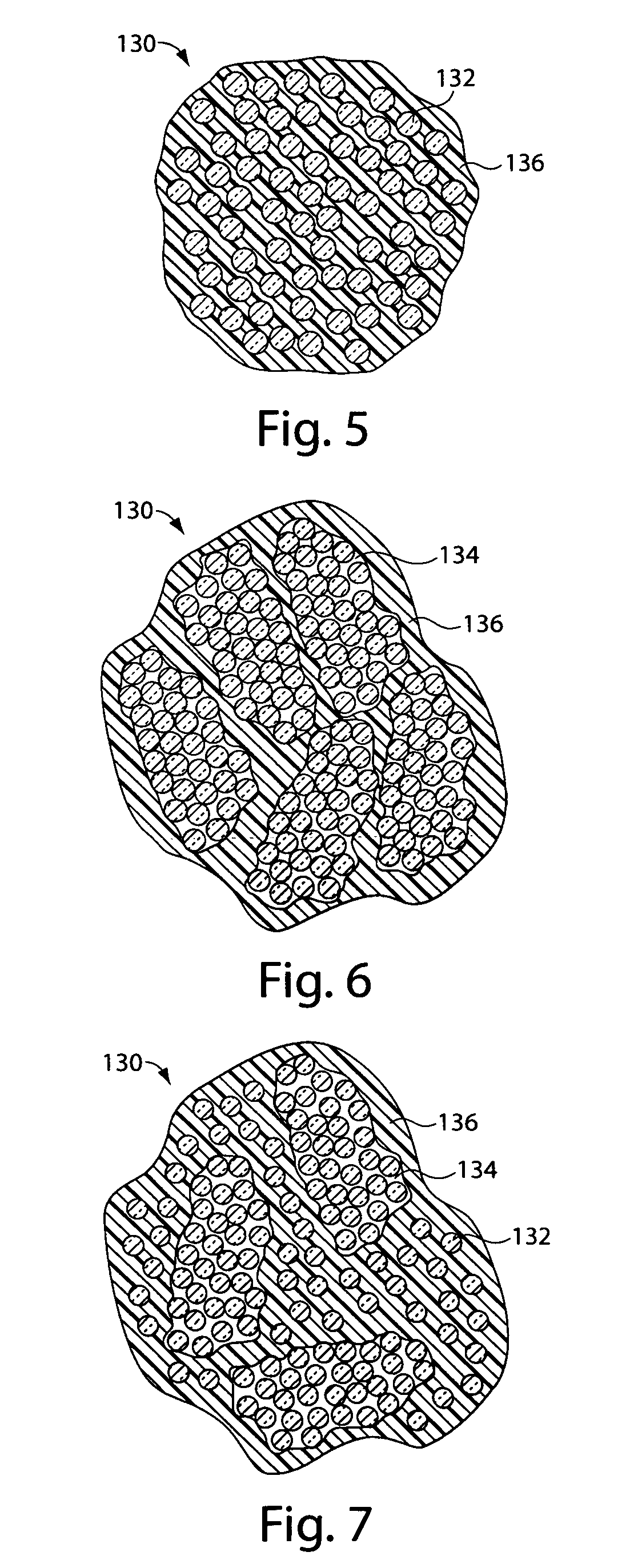

A low cost, high performance flexible, rodent resistant reinforcement member that can be used for both optical and copper communications cable. The reinforcement members made according to the preferred process are more rigid than known reinforcement members, but are less rigid than glass pultruded rods. Communications cables utilizing these members are lightweight and exhibit an improved combination of strength and flexibility compared to traditional communications cables. Further, these communication cables may then be installed into underground ducts using more economical and faster installation techniques.

Owner:NEPTCO JV LLC

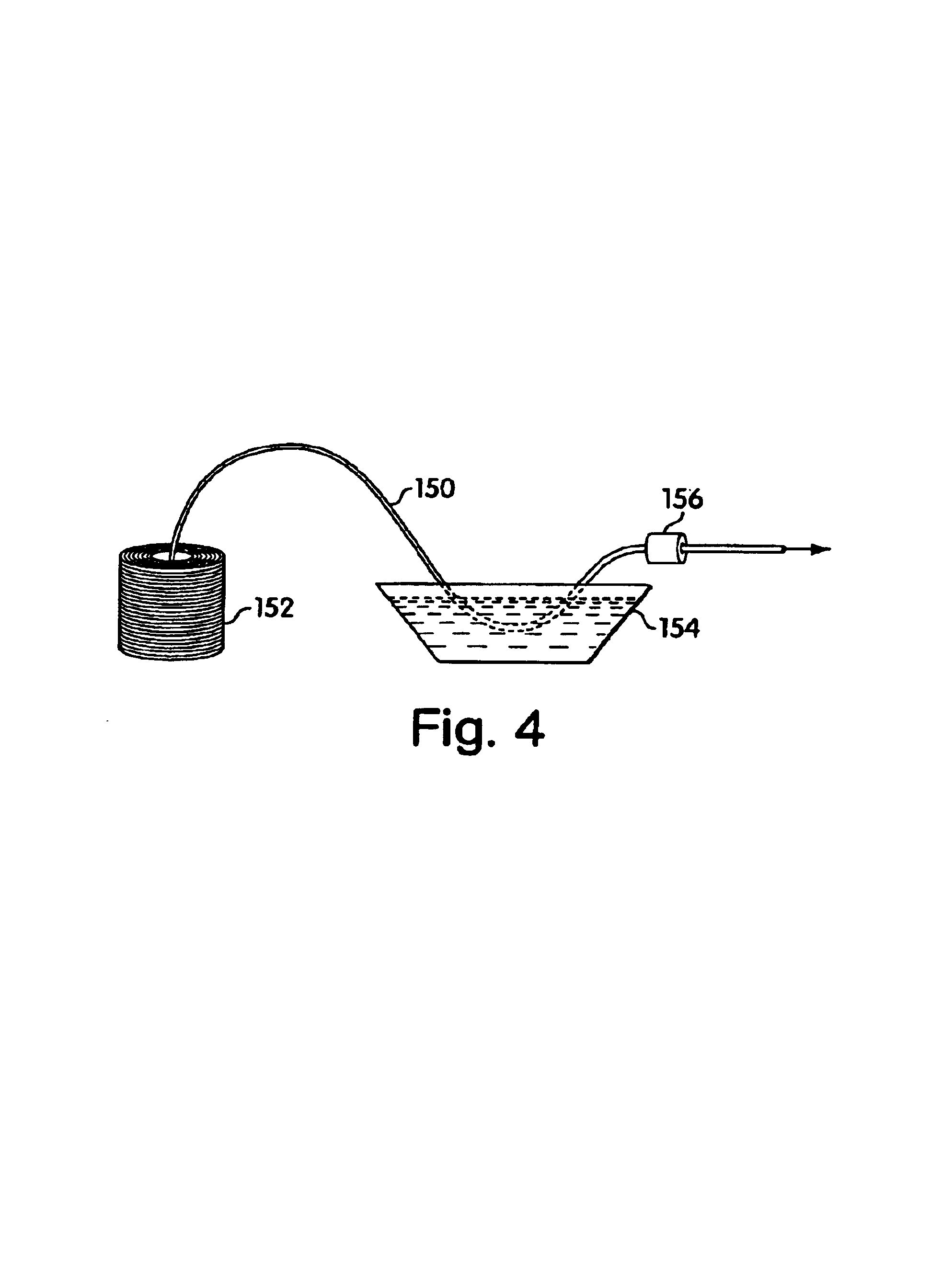

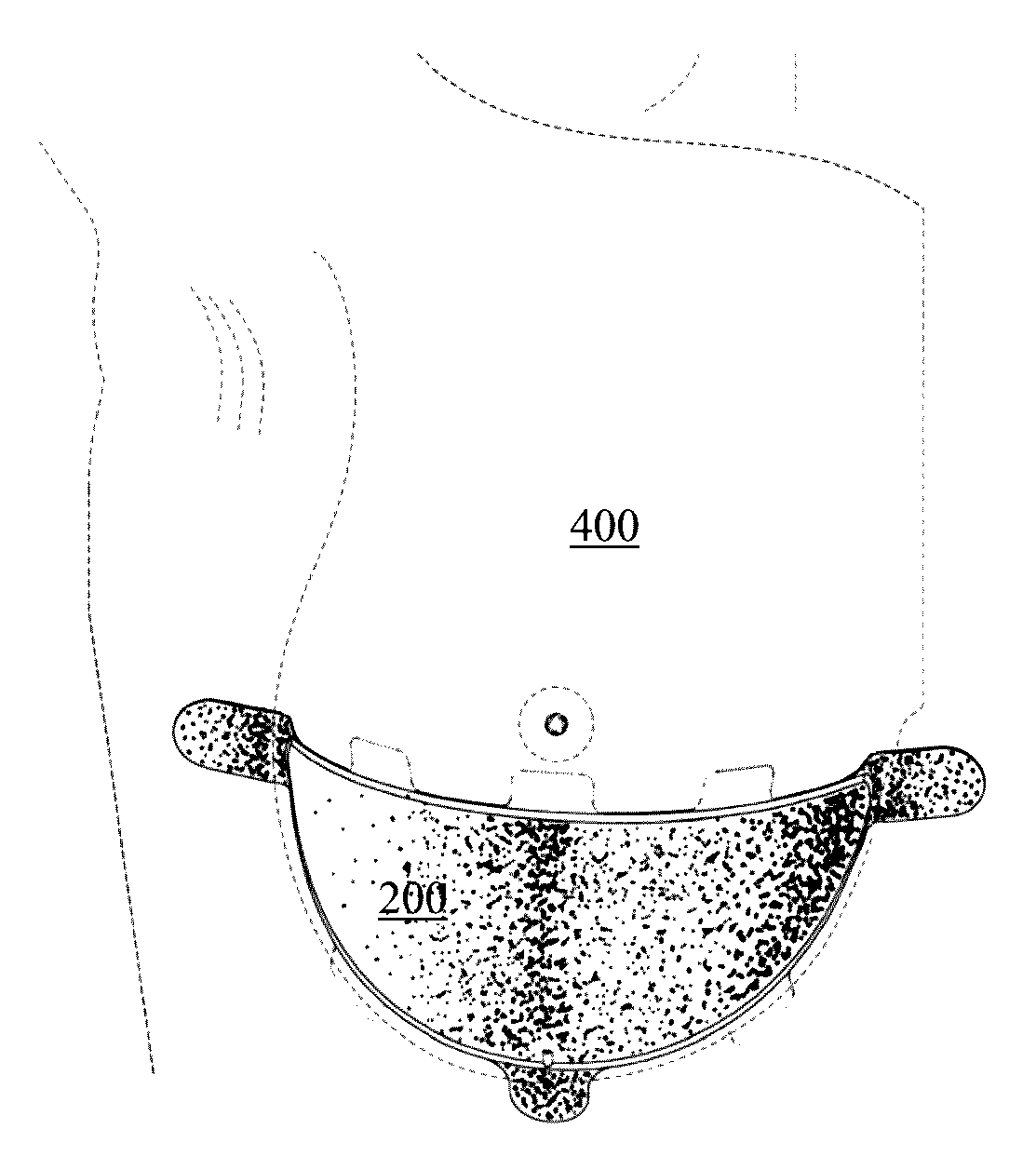

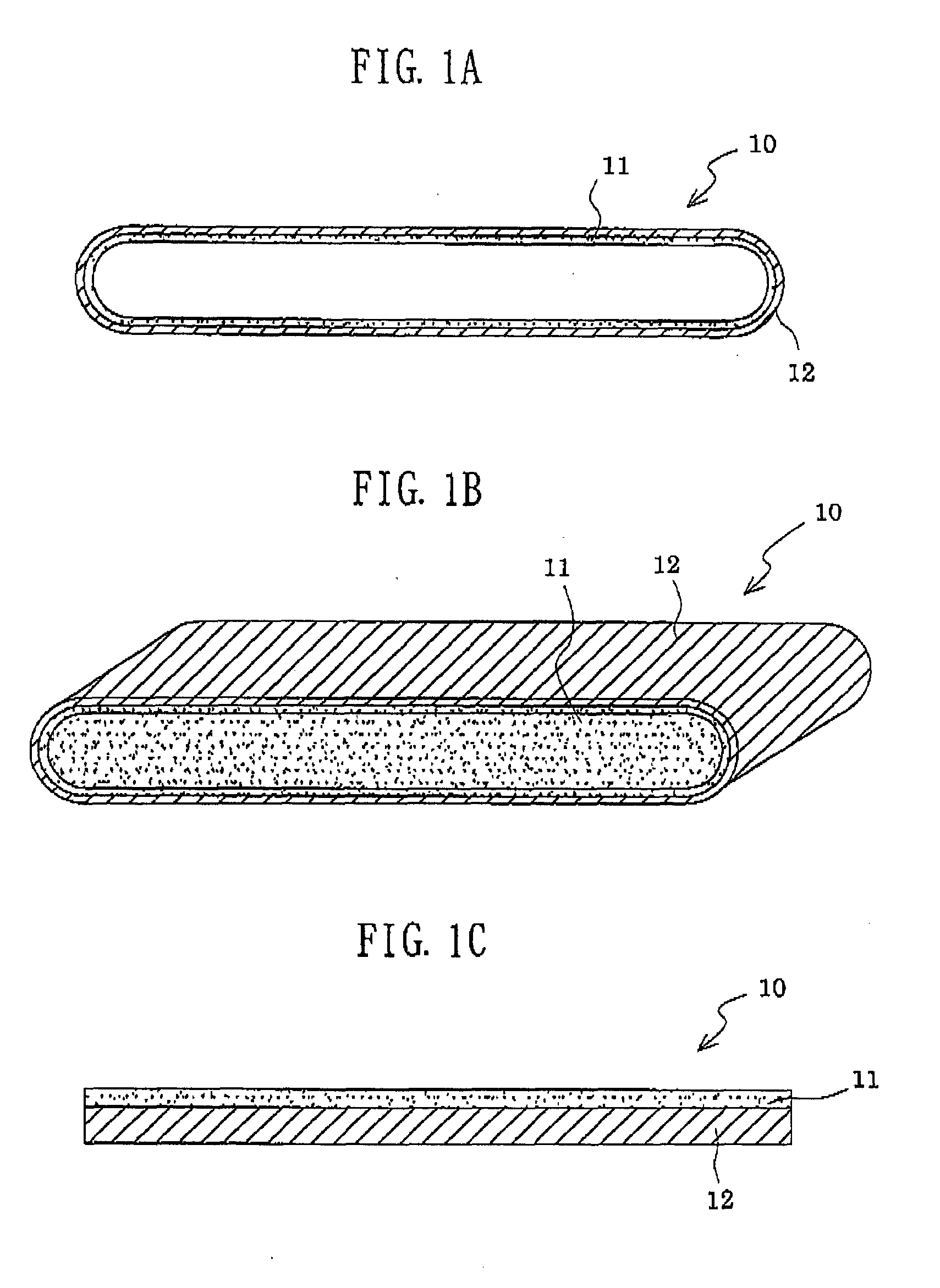

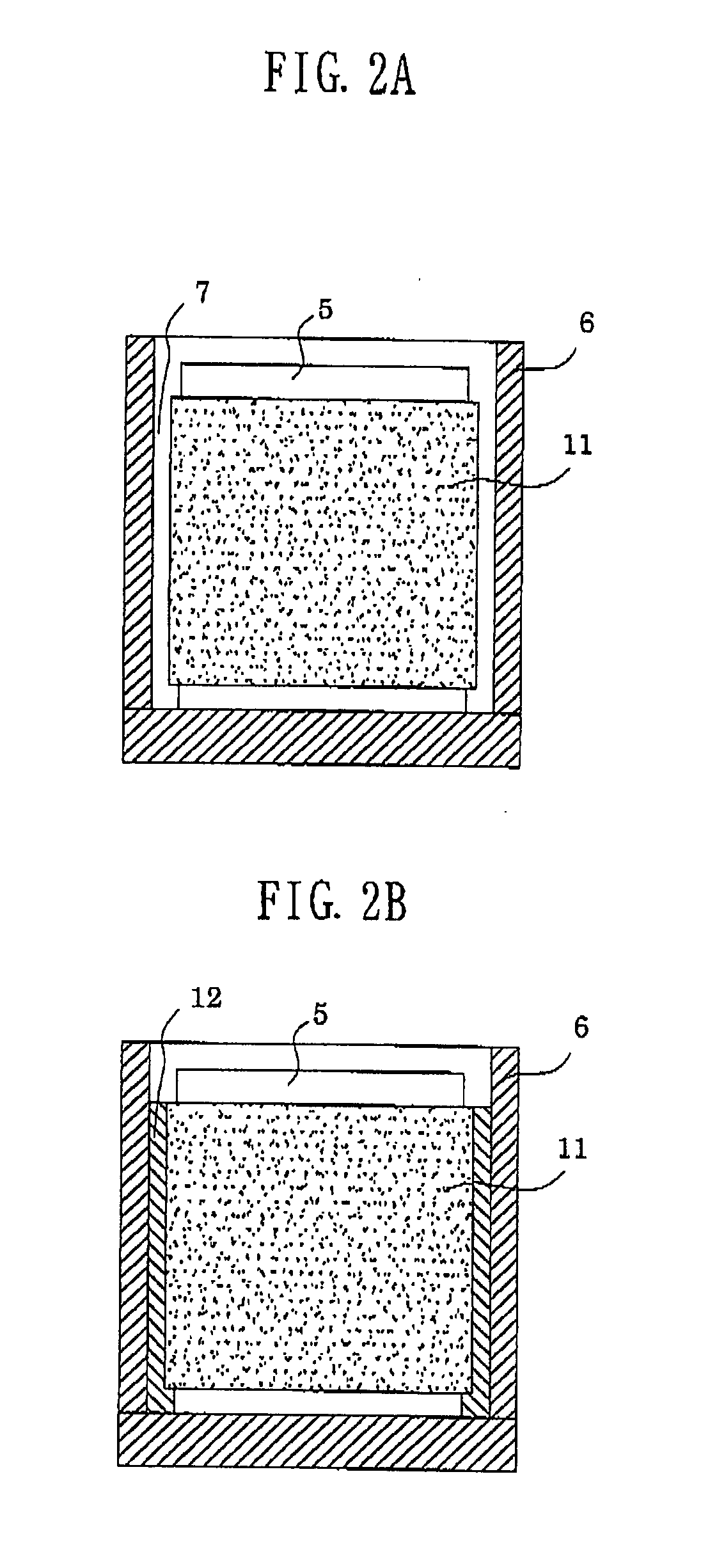

Intravaginal devices containing progesterone for estrus synchronization and related proceses

InactiveUS6939558B2Solve the lack of flexibilitySolving the Insufficiency of ElasticityAnimal reproductionPharmaceutical delivery mechanismMedicineEstrus synchronization

Embodiments of the present invention generally relate to devices and processes related to estrus synchronization. Particular embodiments of devices and processes of the present invention slowly release progesterone over a period of time for estrus synchronization.

Owner:AKZO NOBEL NV

Intravaginal devices containing progesterone for estrus synchronization and related proceses

InactiveUS20050021009A1Solve the lack of flexibilitySolving the Insufficiency of ElasticityAnimal reproductionFemale contraceptivesMedicineEstrus synchronization

Embodiments of the present invention generally relate to devices and processes related to estrus synchronization. Particular embodiments of devices and processes of the present invention slowly release progesterone over a period of time for estrus synchronization.

Owner:AKZO NOBEL NV

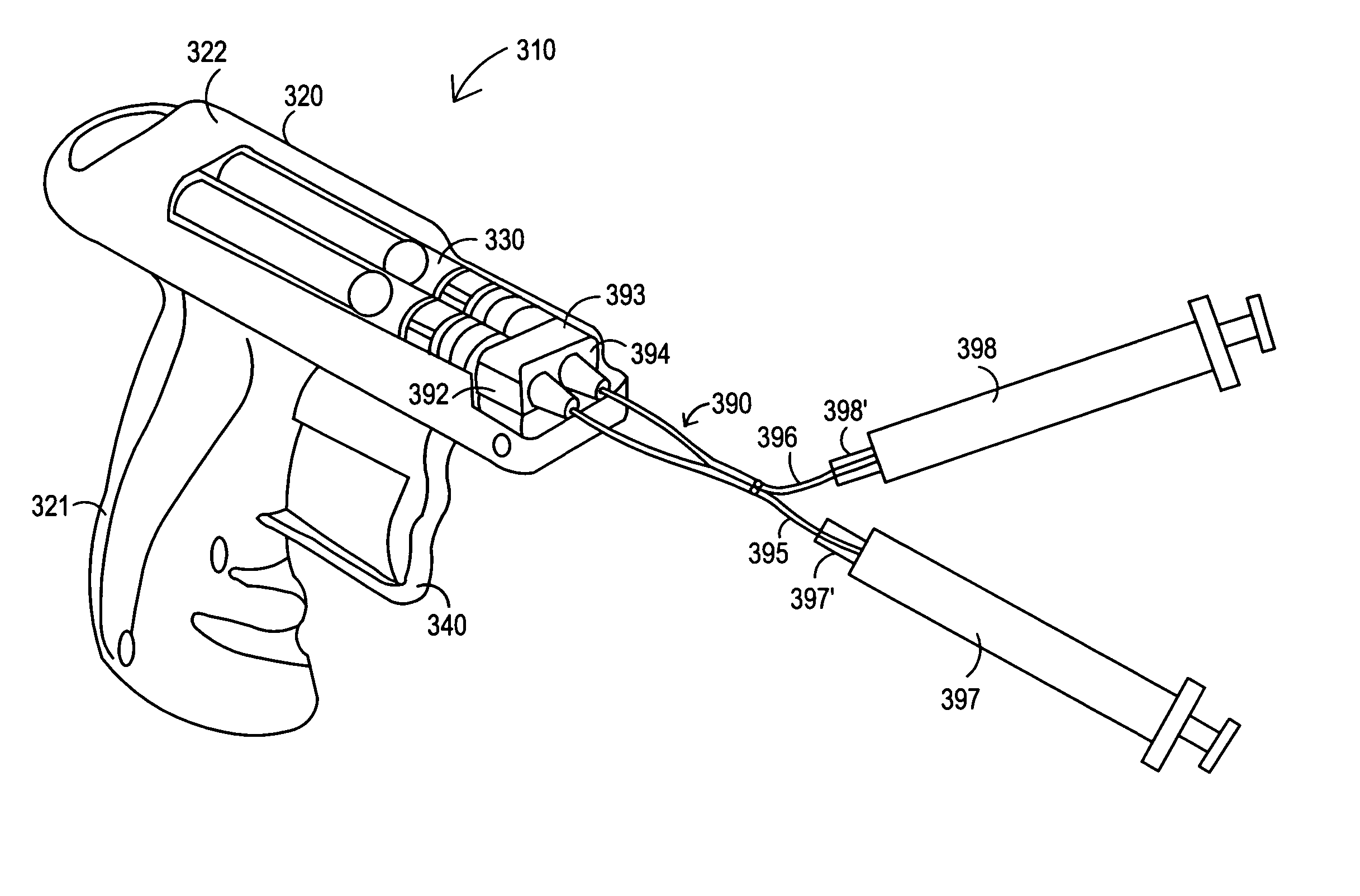

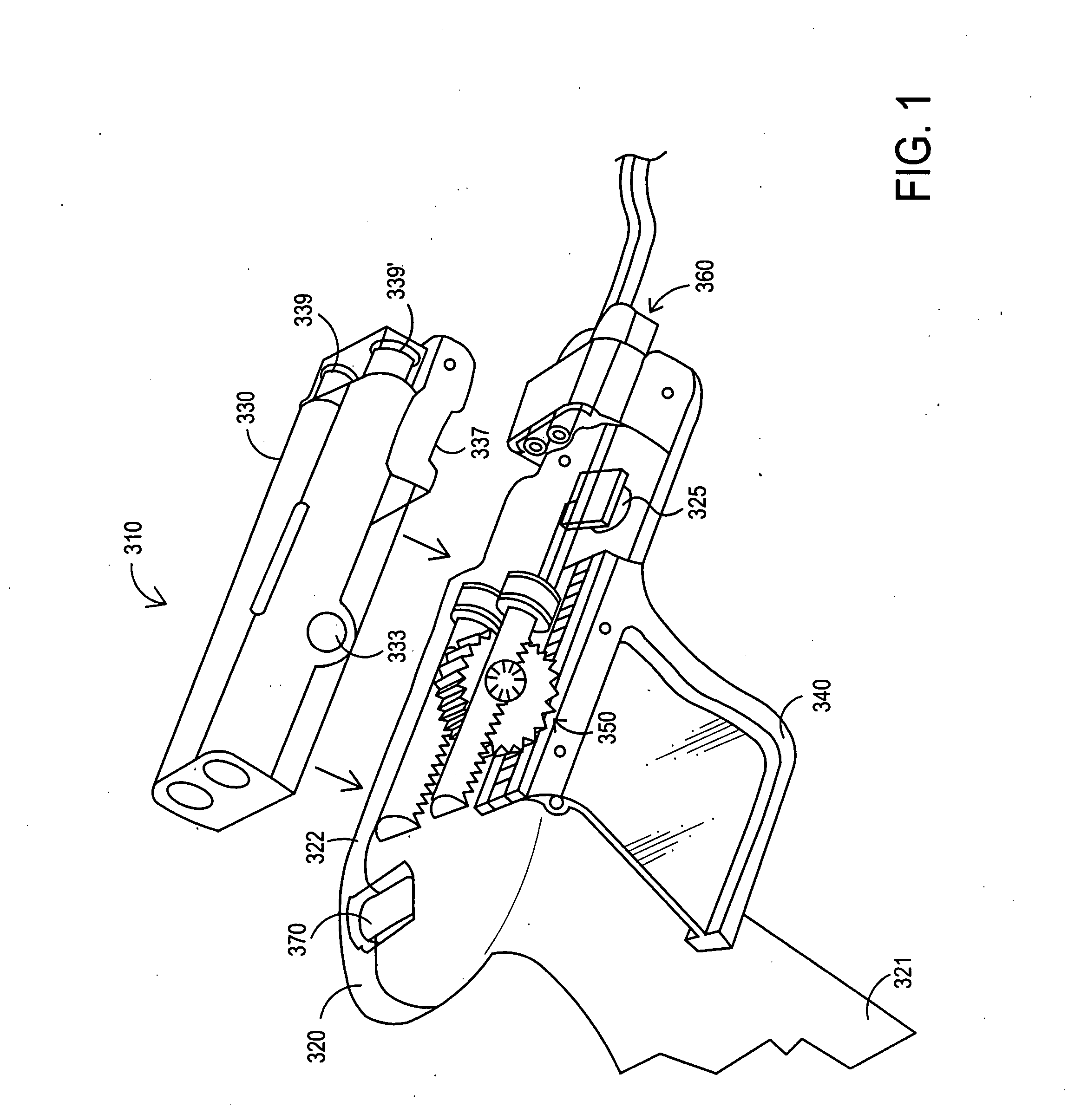

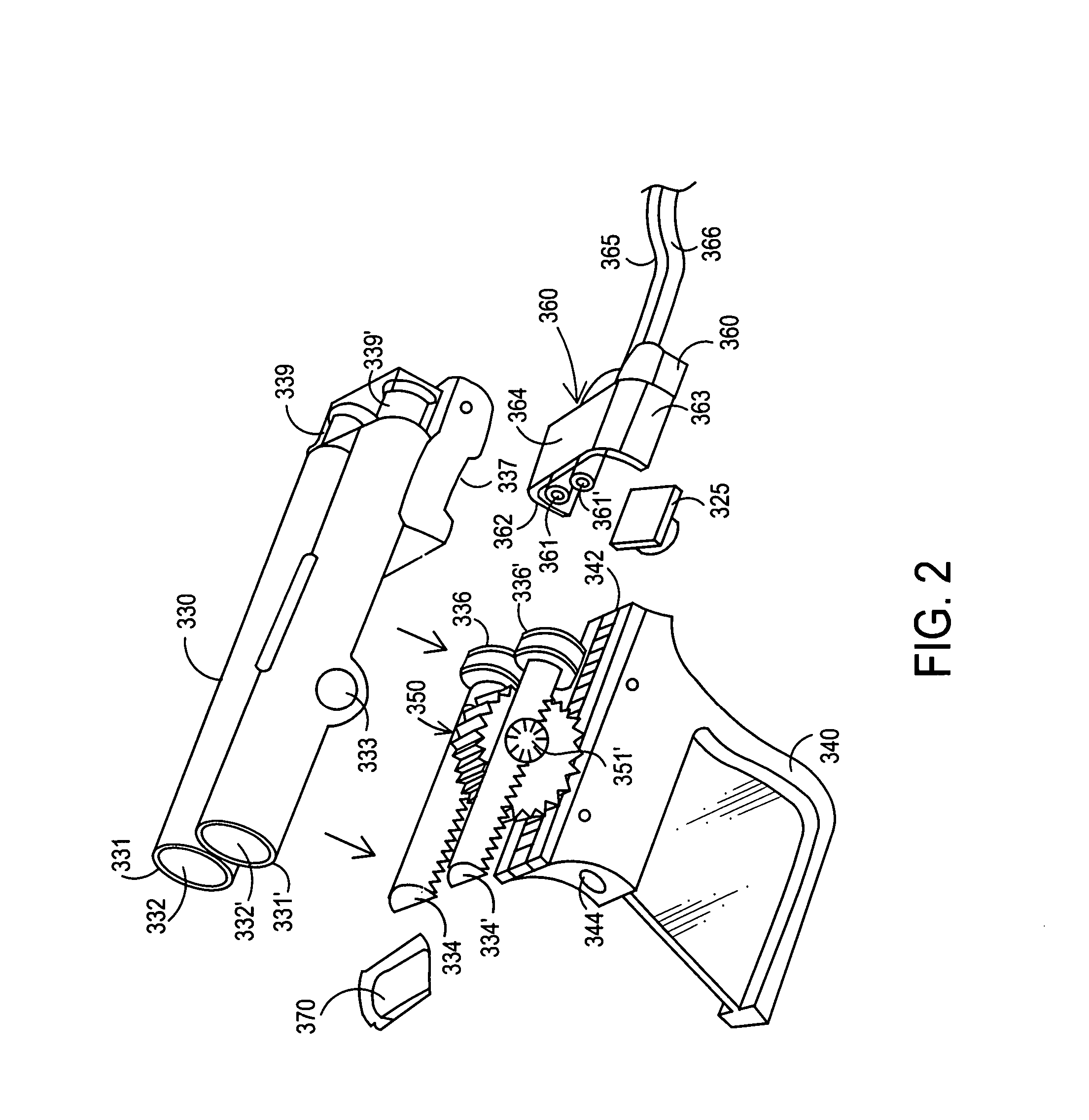

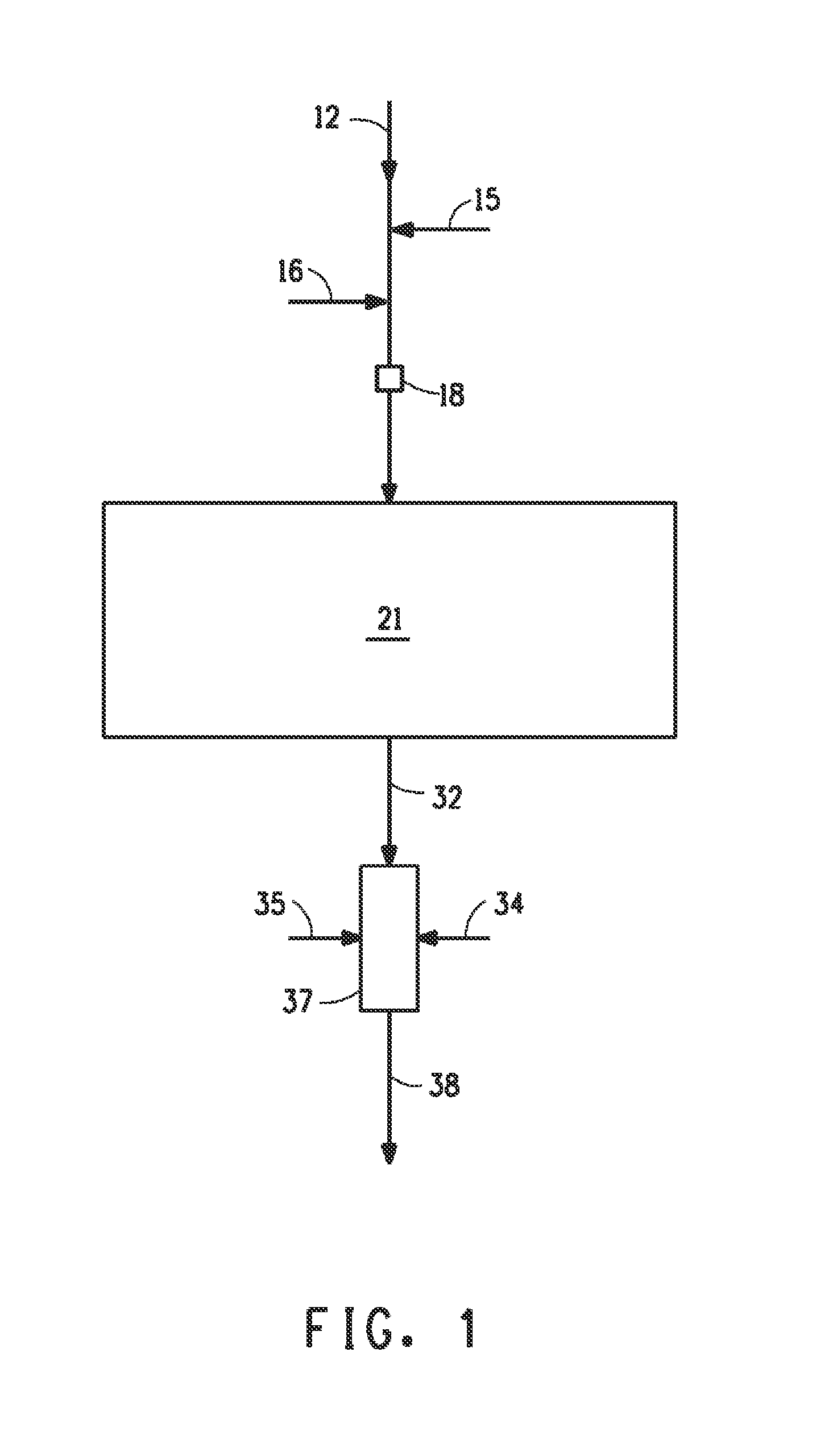

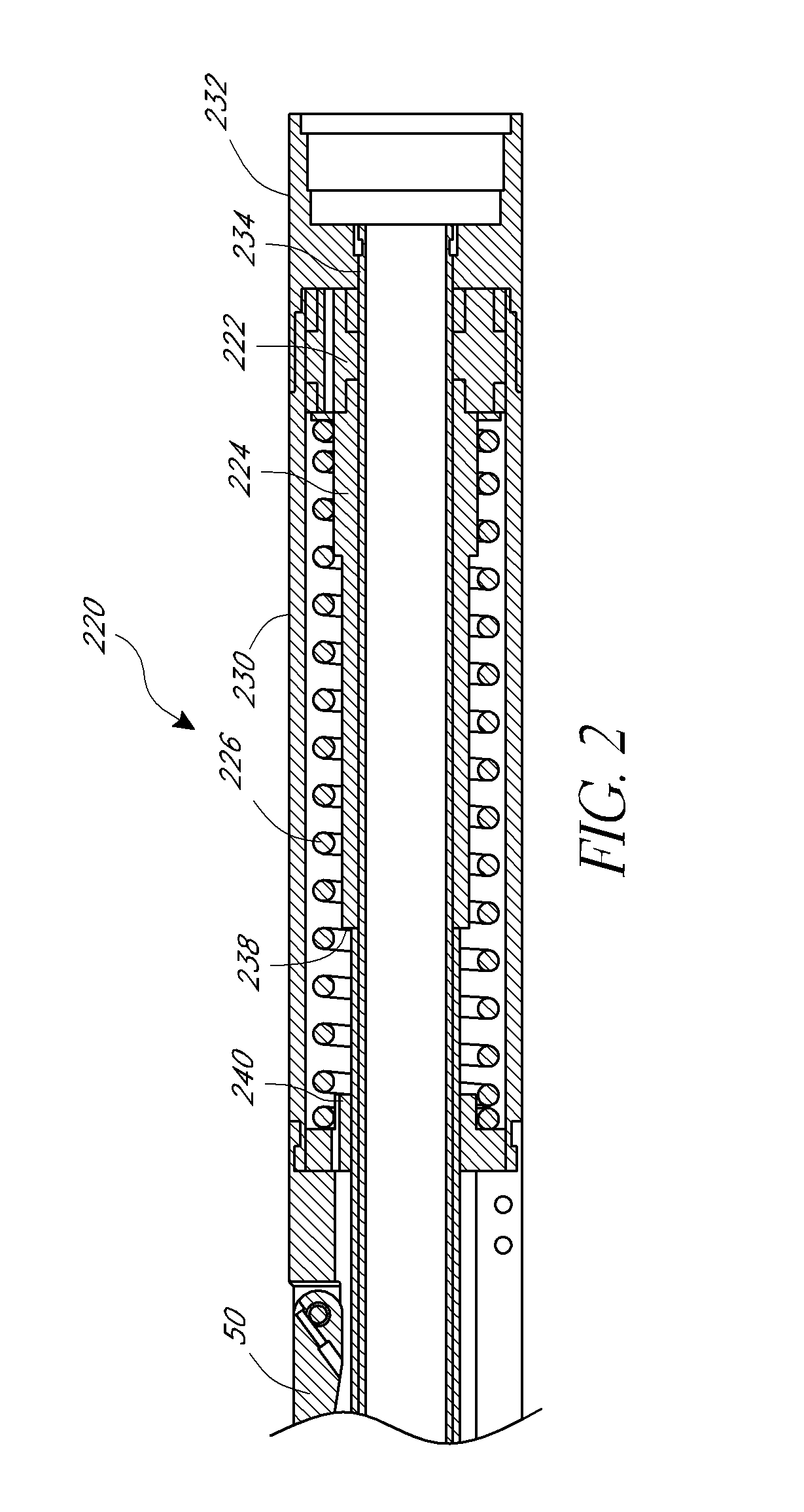

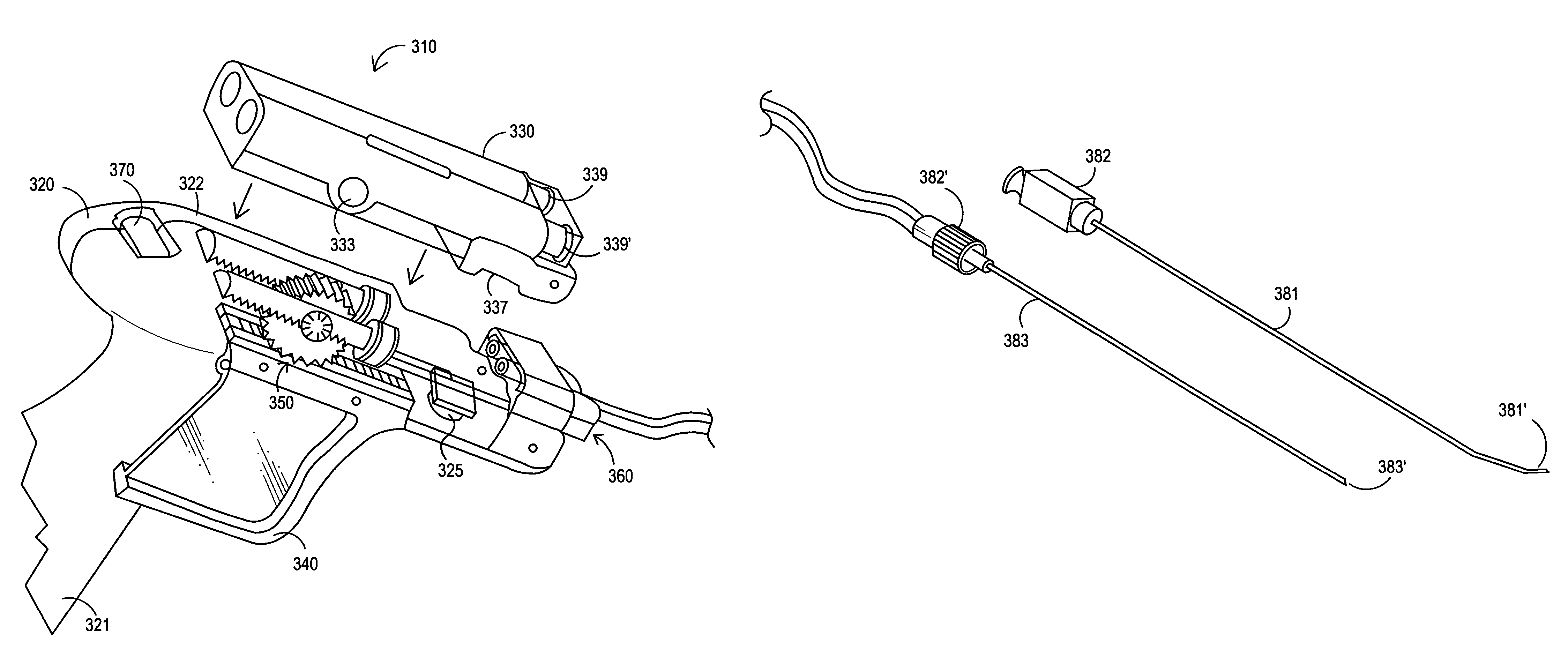

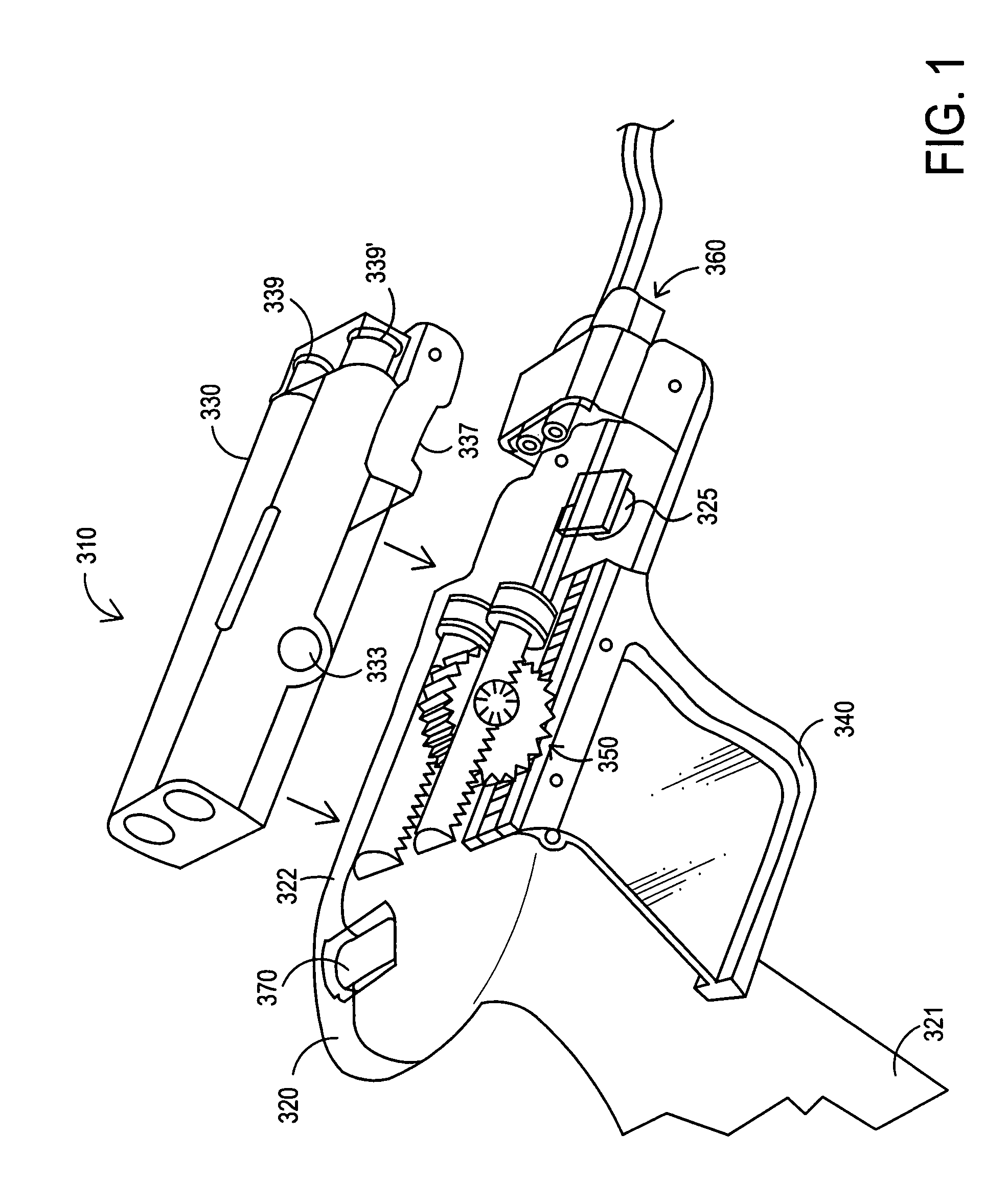

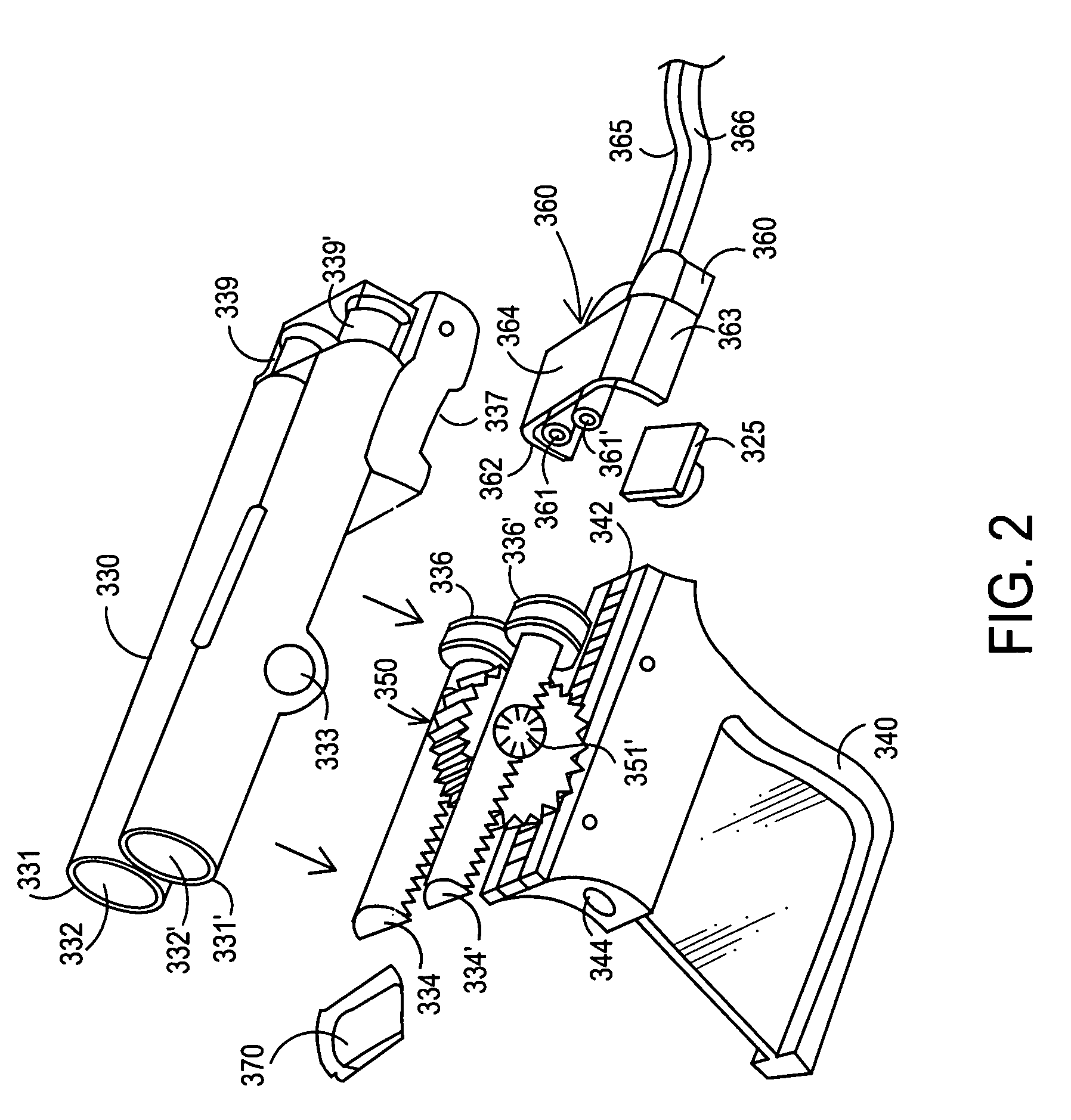

Apparatus and method for delivery of biologic sealant

ActiveUS20080060970A1Good pain reliefReduce setup timeLiquid surface applicatorsSurgical adhesivesBiological materialsSealant

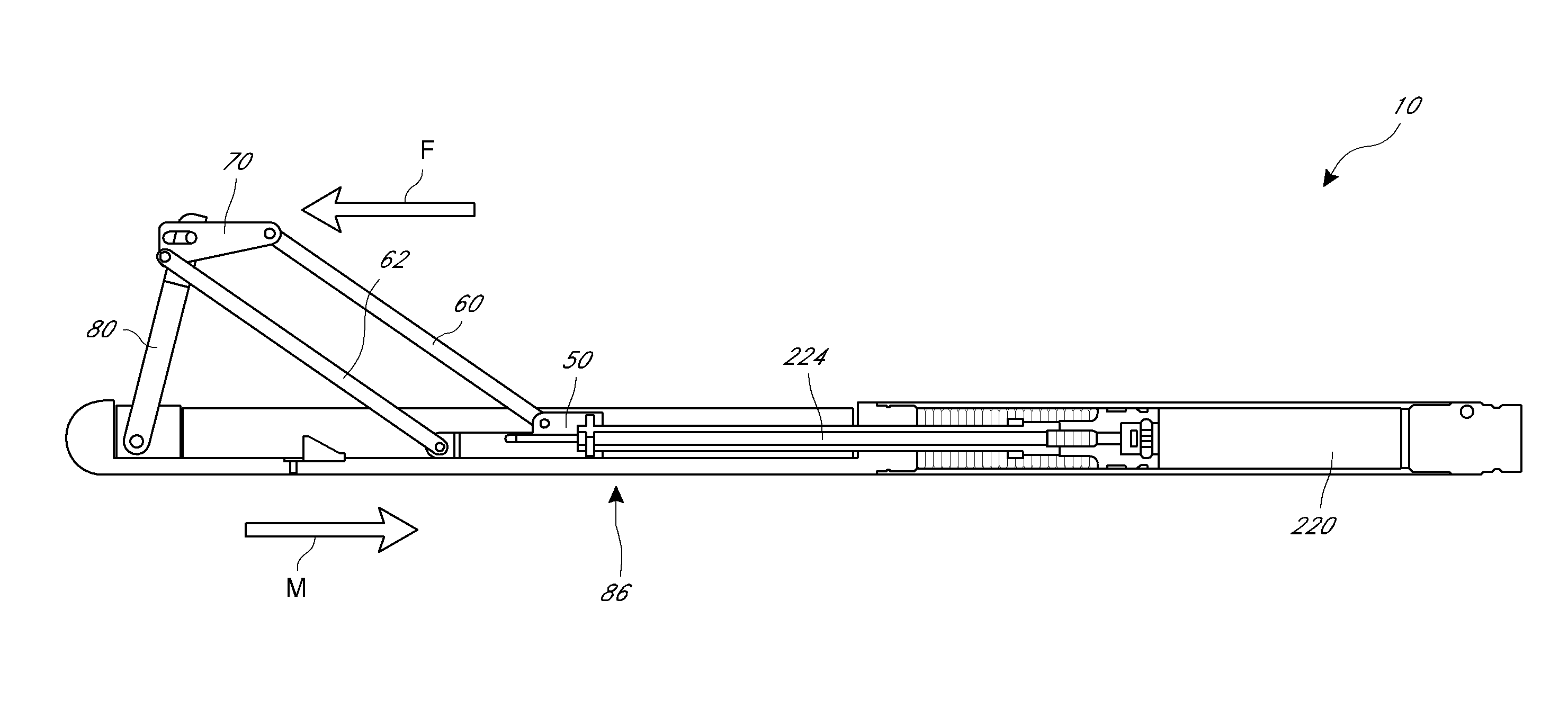

A device for delivery of biologic materials, comprising: a cartridge having at least two cylinder bores for fluids to be delivered, wherein each cylinder includes an exit port for a fluid, a plunger within each cylinder for pushing the fluids out of the cylinder, a housing adapted to receive the cartridge, wherein the housing or cartridge includes an adaptor to receive and lock a manifold that operably connects to the exit ports of the cartridge, at least two toothed rams, wherein each toothed ram is at least partially within a cylinder bore, a trigger connected to the housing, wherein the trigger includes a toothed drive rack, a toothed wheel assembly that cooperates with the toothed drive rack and with the toothed rams, as well as methods of making the device, methods of using the device to treat discs, kits including the device.

Owner:PAUZA KEVIN

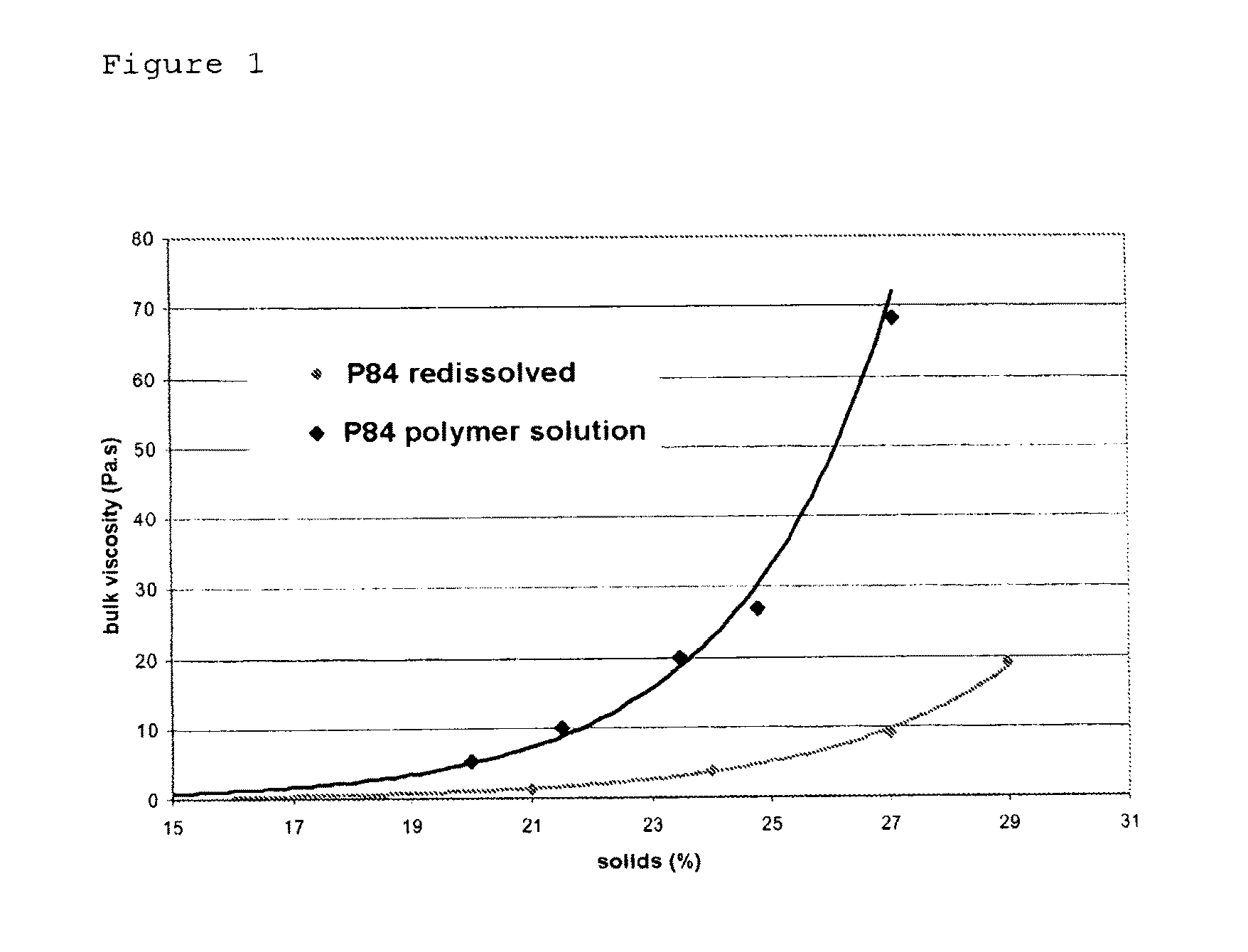

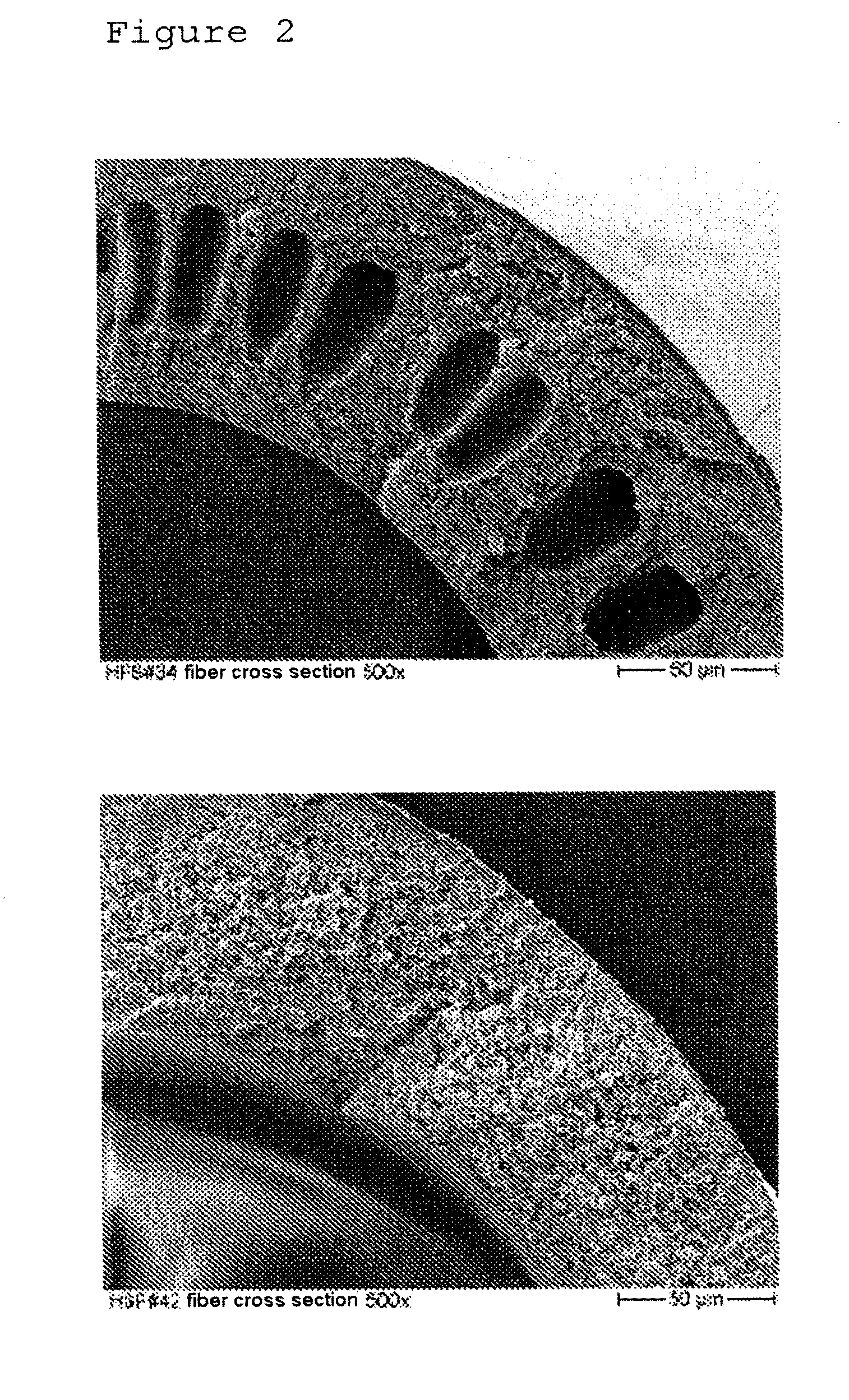

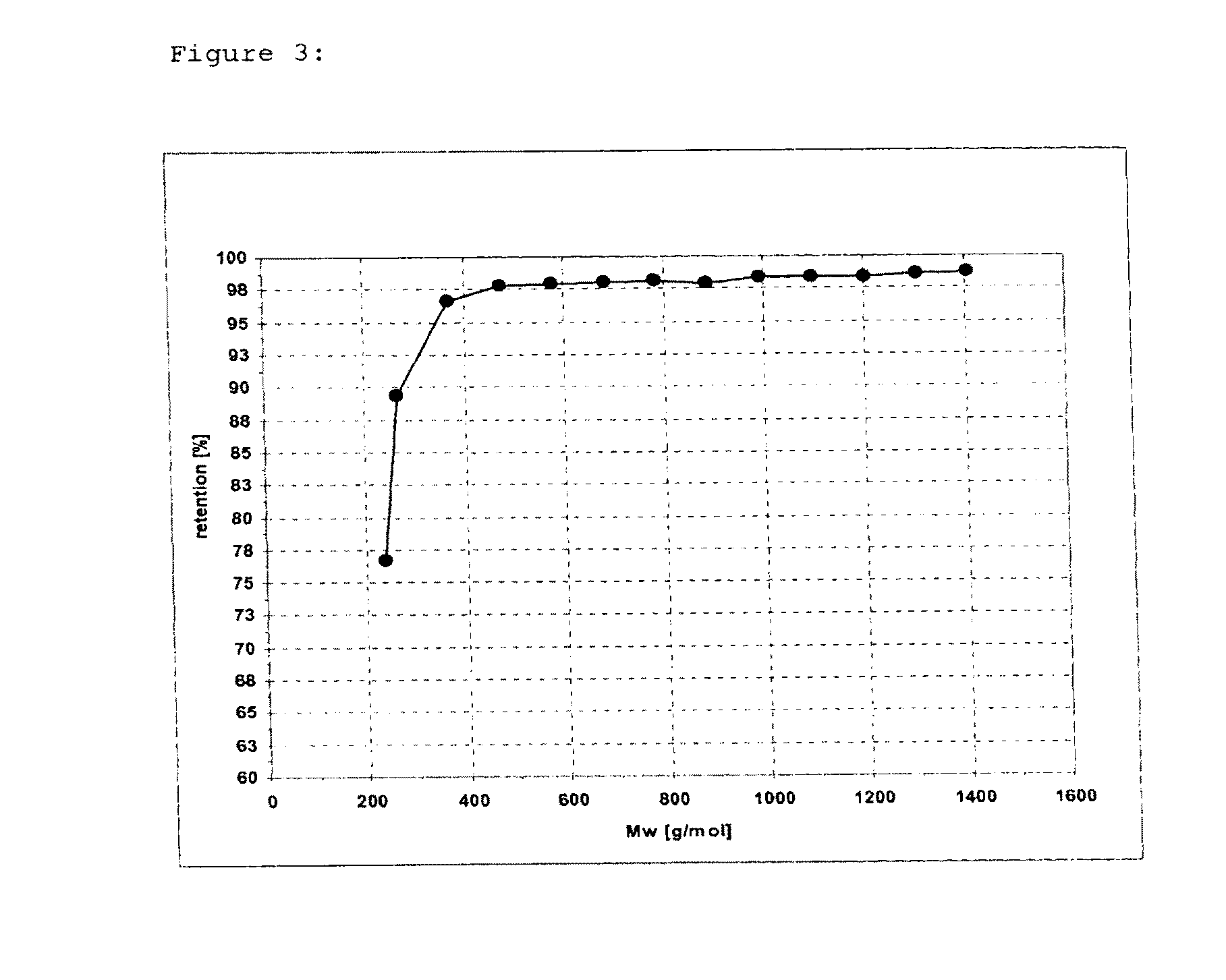

Polyimide membranes made of polymerization solutions

InactiveUS20120123079A1Sufficient mechanical propertySemi-permeable membranesMembranesPolyimide membranePhotochemistry

The invention relates to polyimide membranes and to a phase inversion method for the production thereof. The polyimide membranes can be used to separate different gas mixtures.

Owner:EVONIK FIBERS

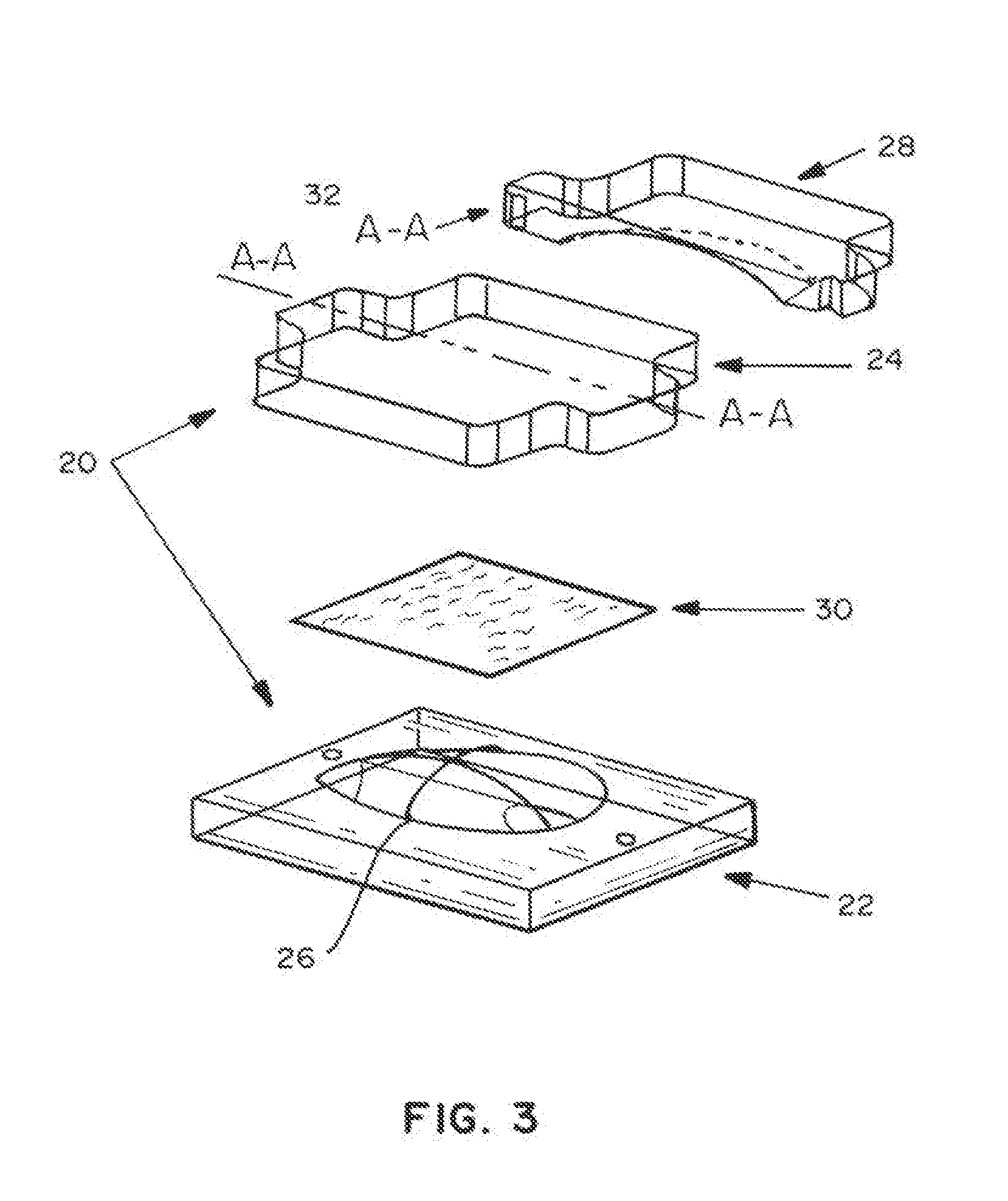

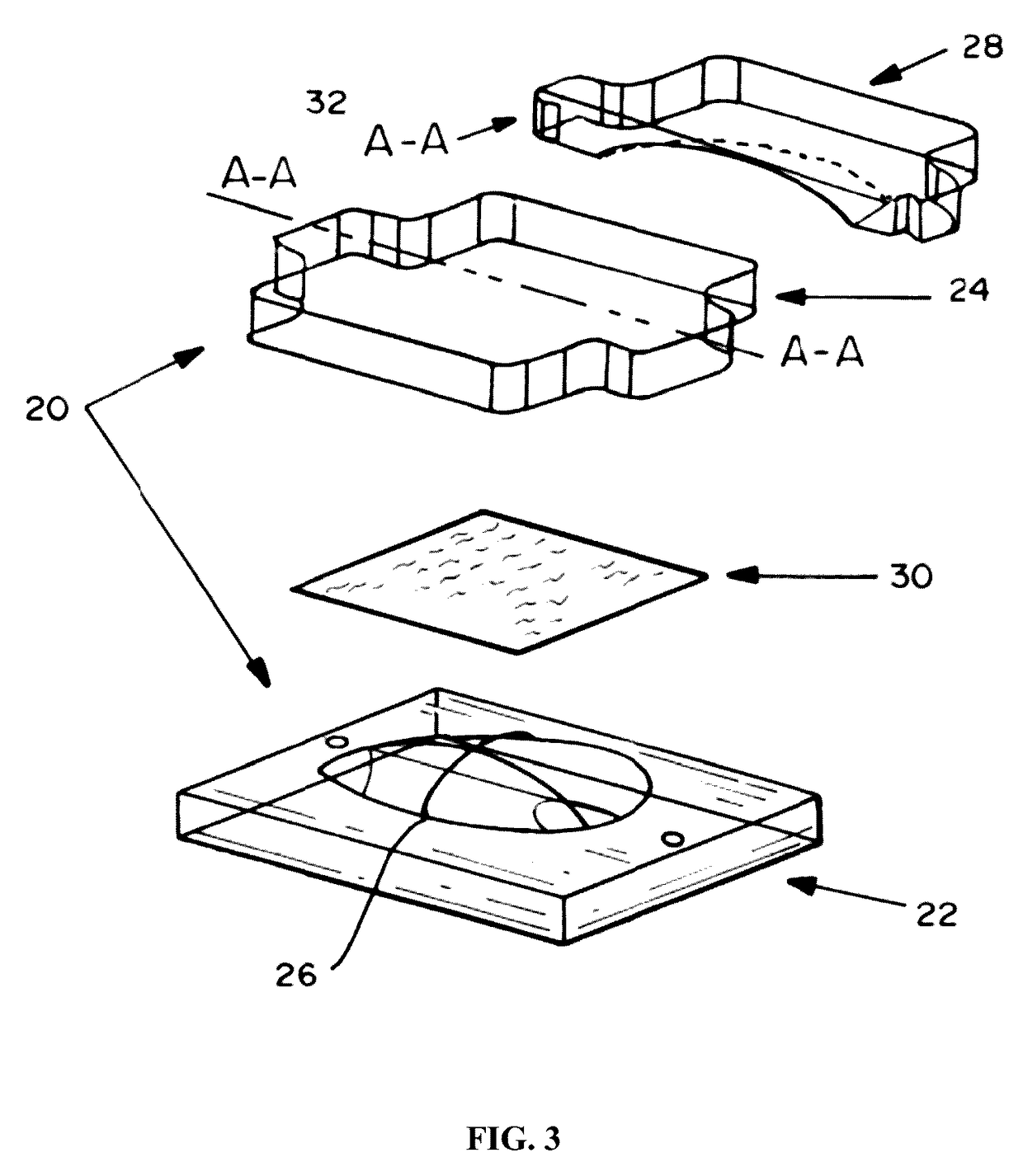

Absorbable implants for plastic surgery

ActiveUS20150112434A1Solve the lack of mechanical propertiesMinimization requirementsMammary implantsArtificial flowers and garlandsMastopexyEngineering

Absorbable implants for breast surgery that conform to the breast parenchyma and surrounding chest wall have been developed. These implants support newly lifted breast parenchyma, and / or a breast implant. The implants have mechanical properties sufficient to support a reconstructed breast, and allow the in-growth of tissue into the implant as it degrades. The implants have a strength retention profile allowing the support of the breast to be transitioned from the implant to regenerated host tissue, without significant loss of support. Three-dimensional implants for use in minimally invasive mastopexy / breast reconstruction procedures are also described, that confer shape to a patient's breast. These implants are self-reinforced, can be temporarily deformed, implanted in a suitably dissected tissue plane, and resume their preformed three-dimensional shape. The implants are preferably made from poly-4-hydroxybutyrate (P4HB) and copolymers thereof. The implants have suture pullout strengths that can resist the mechanical loads exerted on the reconstructed breast.

Owner:TEPHA INC

Absorbable implants for plastic surgery

ActiveUS9655715B2Sufficient mechanical propertyMinimization requirementsMammary implantsSurgeryMastopexyBreast reconstruction

Absorbable implants for breast surgery that conform to the breast parenchyma and surrounding chest wall have been developed. These implants support newly lifted breast parenchyma, and / or a breast implant. The implants have mechanical properties sufficient to support a reconstructed breast, and allow the in-growth of tissue into the implant as it degrades. The implants have a strength retention profile allowing the support of the breast to be transitioned from the implant to regenerated host tissue, without significant loss of support. Three-dimensional implants for use in minimally invasive mastopexy / breast reconstruction procedures are also described, that confer shape to a patient's breast. These implants are self-reinforced, can be temporarily deformed, implanted in a suitably dissected tissue plane, and resume their preformed three-dimensional shape. The implants are preferably made from poly-4-hydroxybutyrate (P4HB) and copolymers thereof. The implants have suture pullout strengths that can resist the mechanical loads exerted on the reconstructed breast.

Owner:TEPHA INC

Absorbable Implants for Plastic Surgery

ActiveUS20160022416A1Sufficient mechanical propertyMinimization requirementsMammary implantsSurgeryPullout strengthThree dimensional shape

Absorbable implants for breast surgery that conform to the breast parenchyma and surrounding chest wall have been developed. These implants support newly lifted breast parenchyma, and / or a breast implant. The implants have mechanical properties sufficient to support a reconstructed breast, and allow the ingrowth of tissue into the implant as it degrades. The implants have a strength retention profile allowing the support of the breast to be transitioned from the implant to regenerated host tissue, without significant loss of support. Three-dimensional implants for use in minimally invasive mastopexy / breast reconstruction procedures are also described, that confer shape to a patient's breast. These implants are self-reinforced, can be temporarily deformed, implanted in a suitably dissected tissue plane, and resume their preformed three-dimensional shape. The implants are preferably made from poly-4-hydroxybutyrate (P4HB) and copolymers thereof. The implants have suture pullout strengths that can resist the mechanical loads exerted on the reconstructed breast

Owner:TEPHA INC

Three-dimensional polymeric medical implants

ActiveUS20140222161A1Rapid tissue in-growthSufficient mechanical propertyMammary implantsBiomedical engineeringMedical treatment

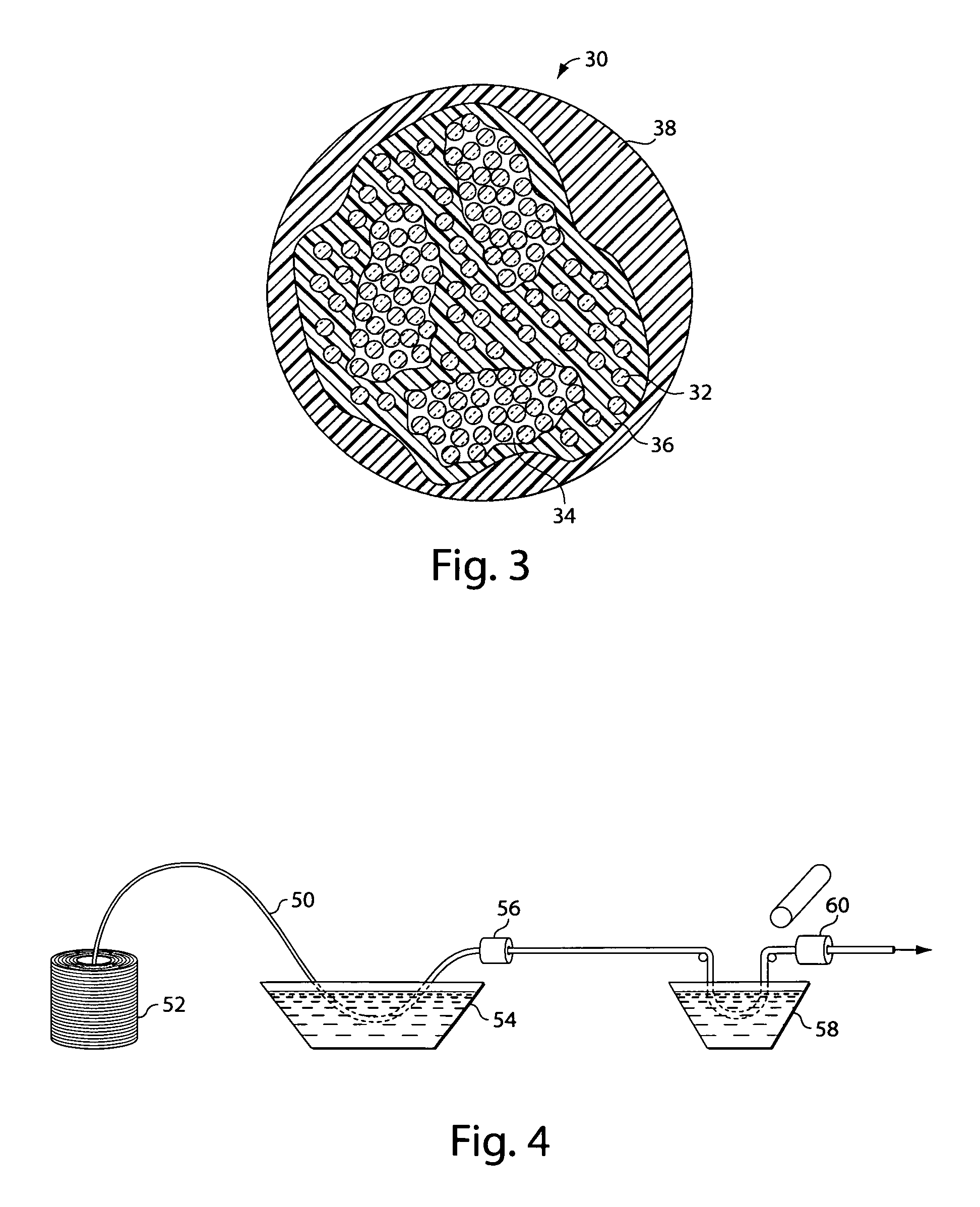

The invention relates to a three-dimensional medical implant, comprising a first thin porous component, and a first load-bearing and volume-creating component, which is connected to the first thin porous component; wherein the load-bearing and volume-creating component comprises an organized structure.

Owner:NOVUS SCI

PROCESS FOR HYDRAULIC FRACTURING WITH pH CONTROL

InactiveUS20130206398A1High in ironSufficient mechanical propertySurveyFluid removalPh controlFracturing fluid

A process for hydraulic fracturing including the steps of (a) providing a fracturing fluid by combining water, proppant, an oxidizing biocide, and a friction reducer; (b) introducing the fracturing fluid into a well; and (c) controlling the pH of the fracturing fluid to a pH of at least about 4.5.

Owner:THE CHEMOURS CO FC LLC

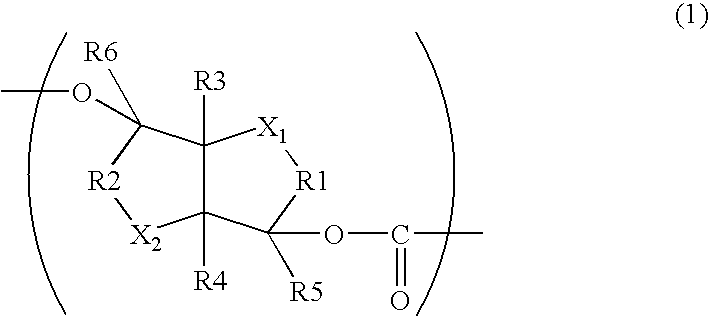

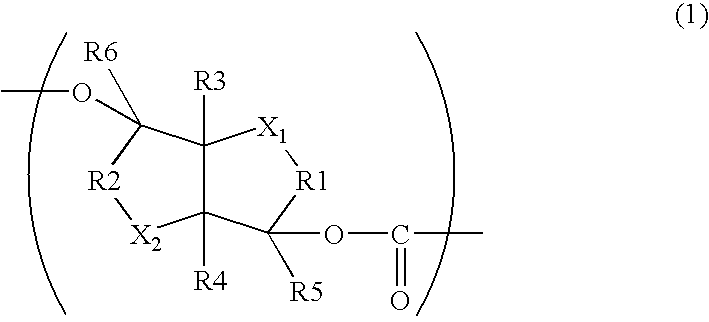

Aliphatic Polyester Copolymer

InactiveUS20080015331A1Improve heat resistanceSolve the lack of mechanical propertiesBiocideLactams stabilisationPolyesterMolten state

An aliphatic polyester copolymer comprising an aliphatic carbonate unit (a) and an aliphatic polyester unit (b), and a molded body composed of said aliphatic polyester copolymer. The aliphatic polyester copolymer is excellent in heat resistance while having adequate mechanical properties and properties in the molten state.

Owner:MITSUI CHEM INC

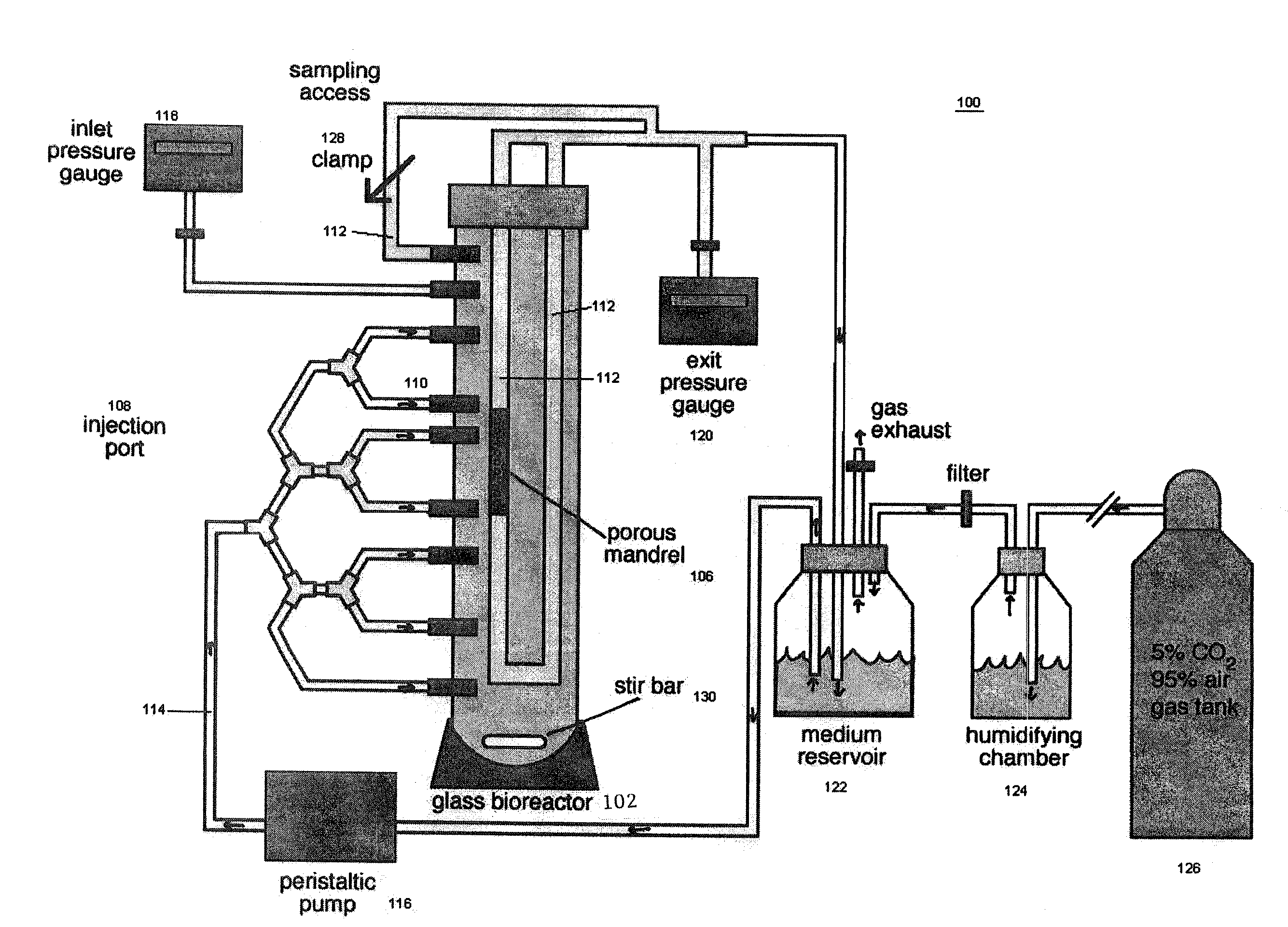

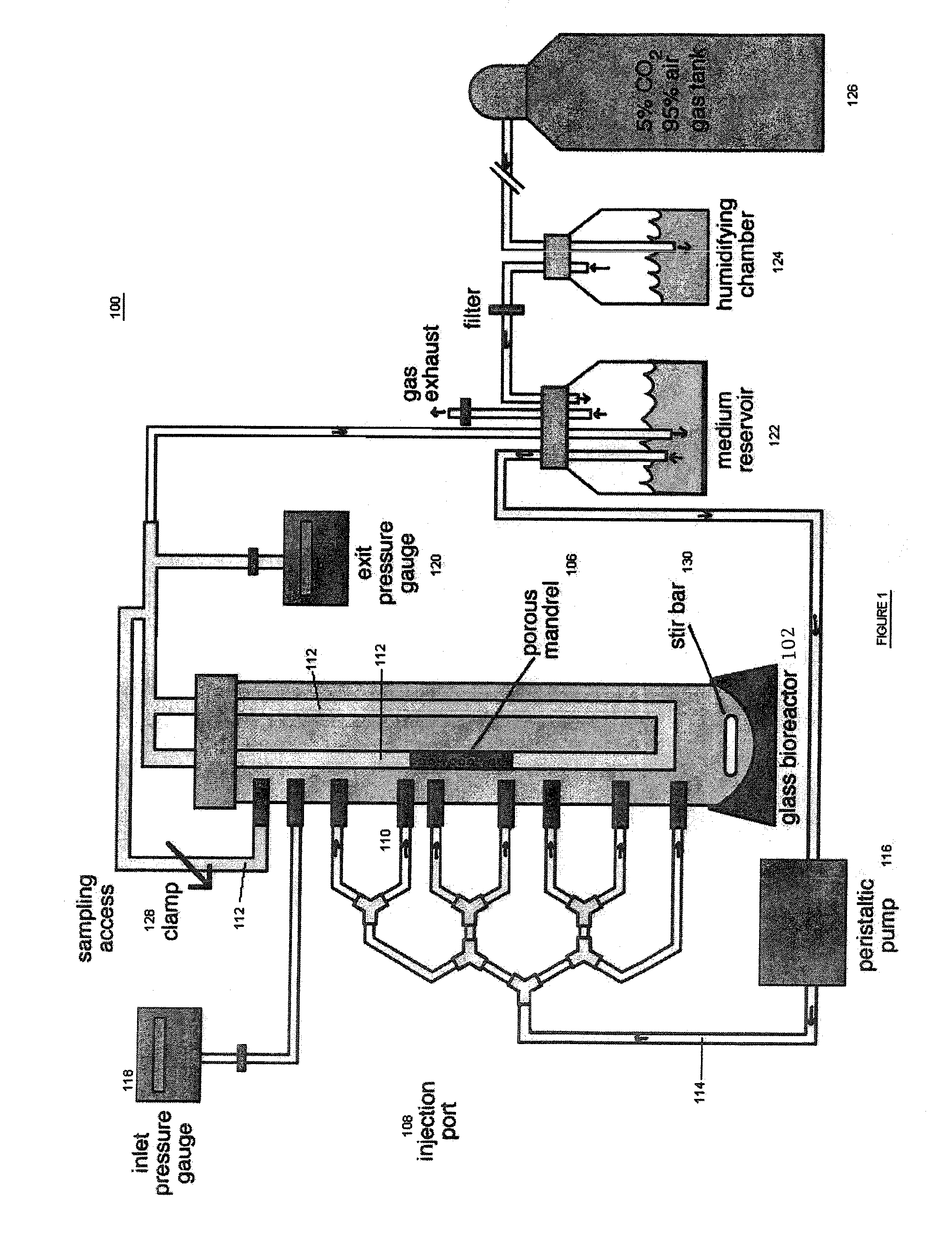

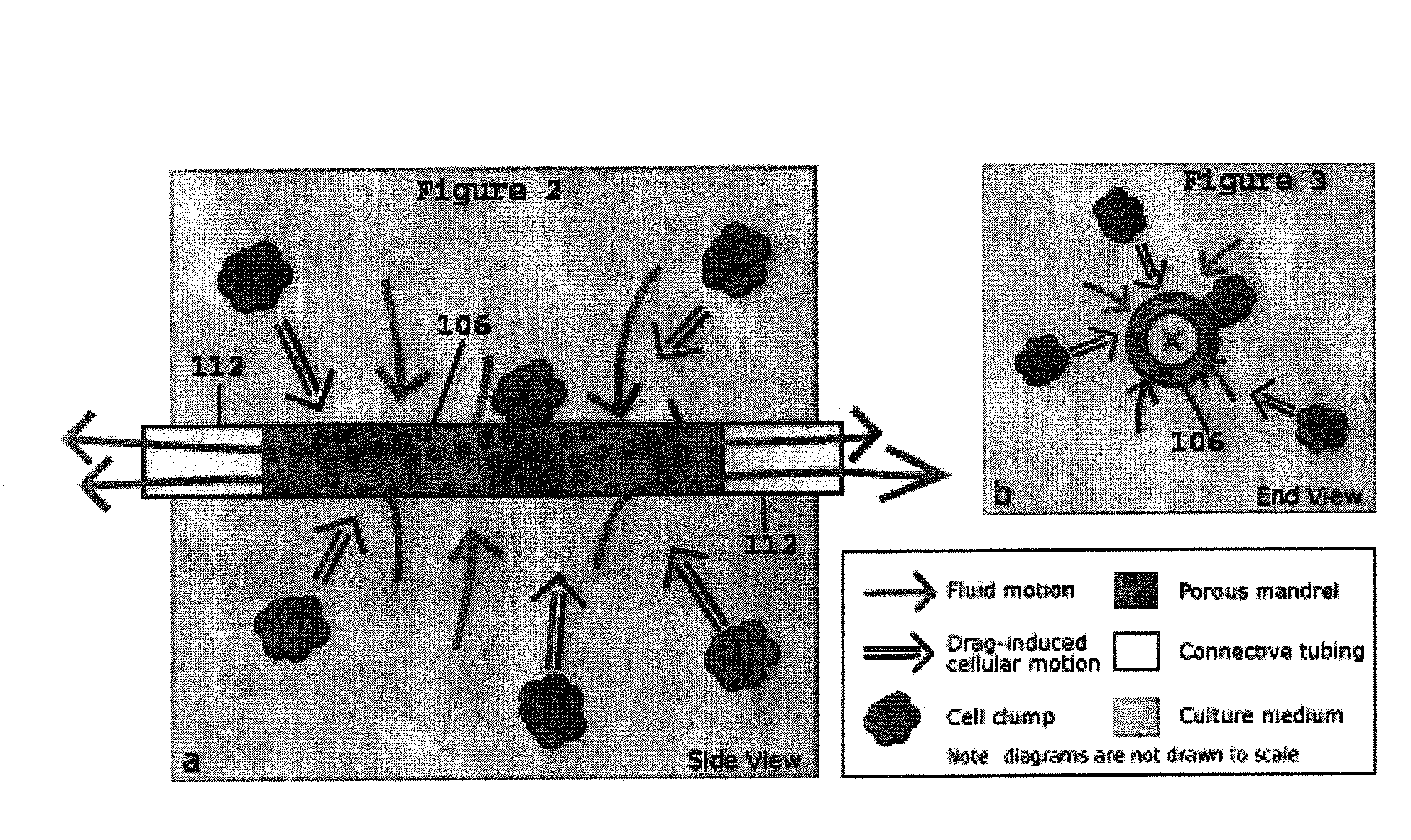

Convective flow tissue assembly

InactiveUS7439057B2Accurate tissue morphologyAvoid delaminationBioreactor/fermenter combinationsBiological substance pretreatmentsIn vivoBiology

The present invention provides for an improved in vitro tissue assembly system and related methods that includes and uses a bioreactor, a porous mandrel disposed in the bioreactor, and components that provide for the circulation of culture media and cell suspensions within the bioreactor and through the porous mandrel. The circulation of the culture media and cell suspensions within the bioreactor produces a radial, convective flow and drag forces that result in the deposition of cells on the mandrel to form a tissue construct. Upon completion of the culture and tissue formation process, the tissue construct may be removed from the mandrel for subsequent in vivo use.

Owner:LA JOLLA BIOENG INST

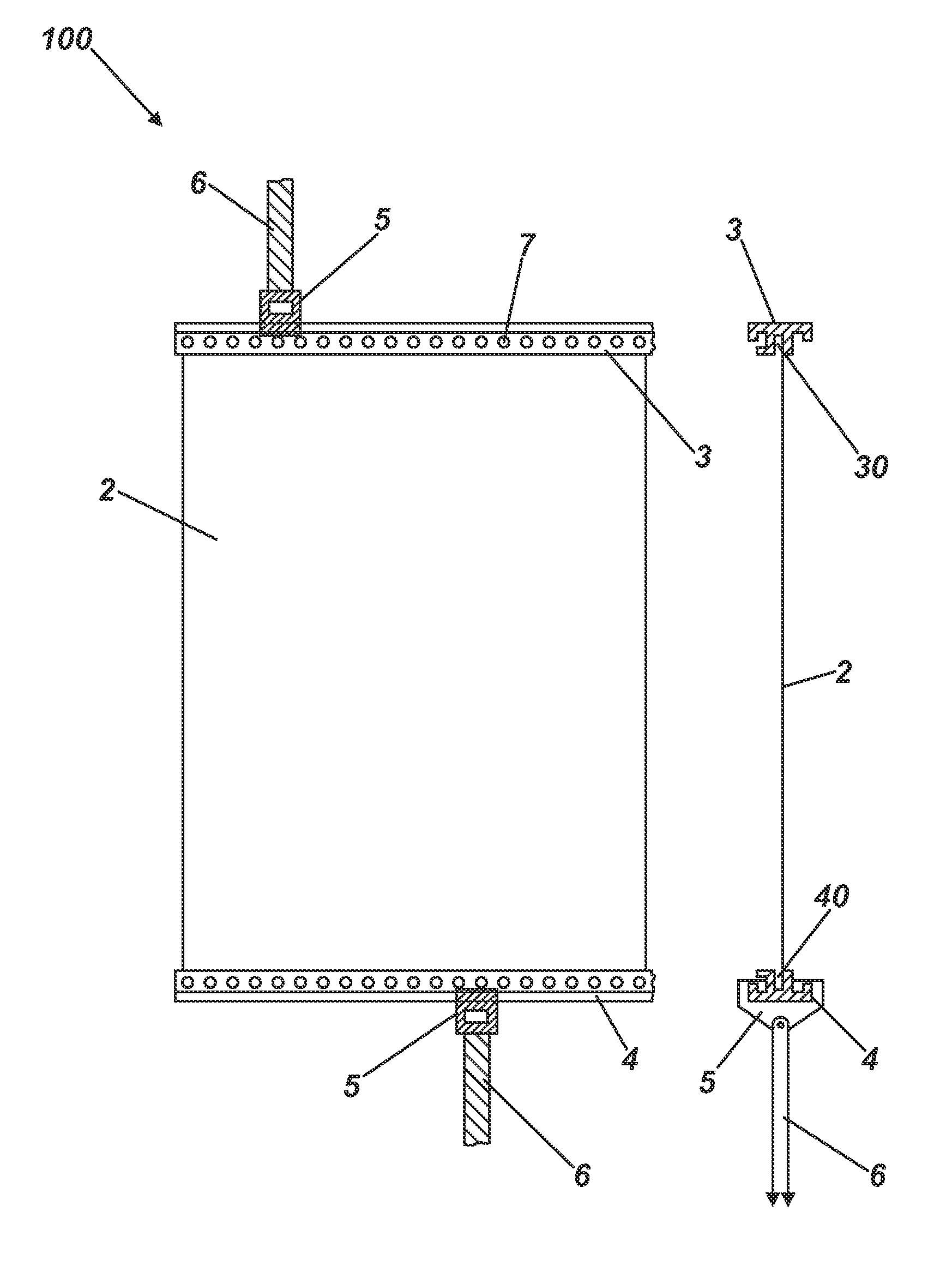

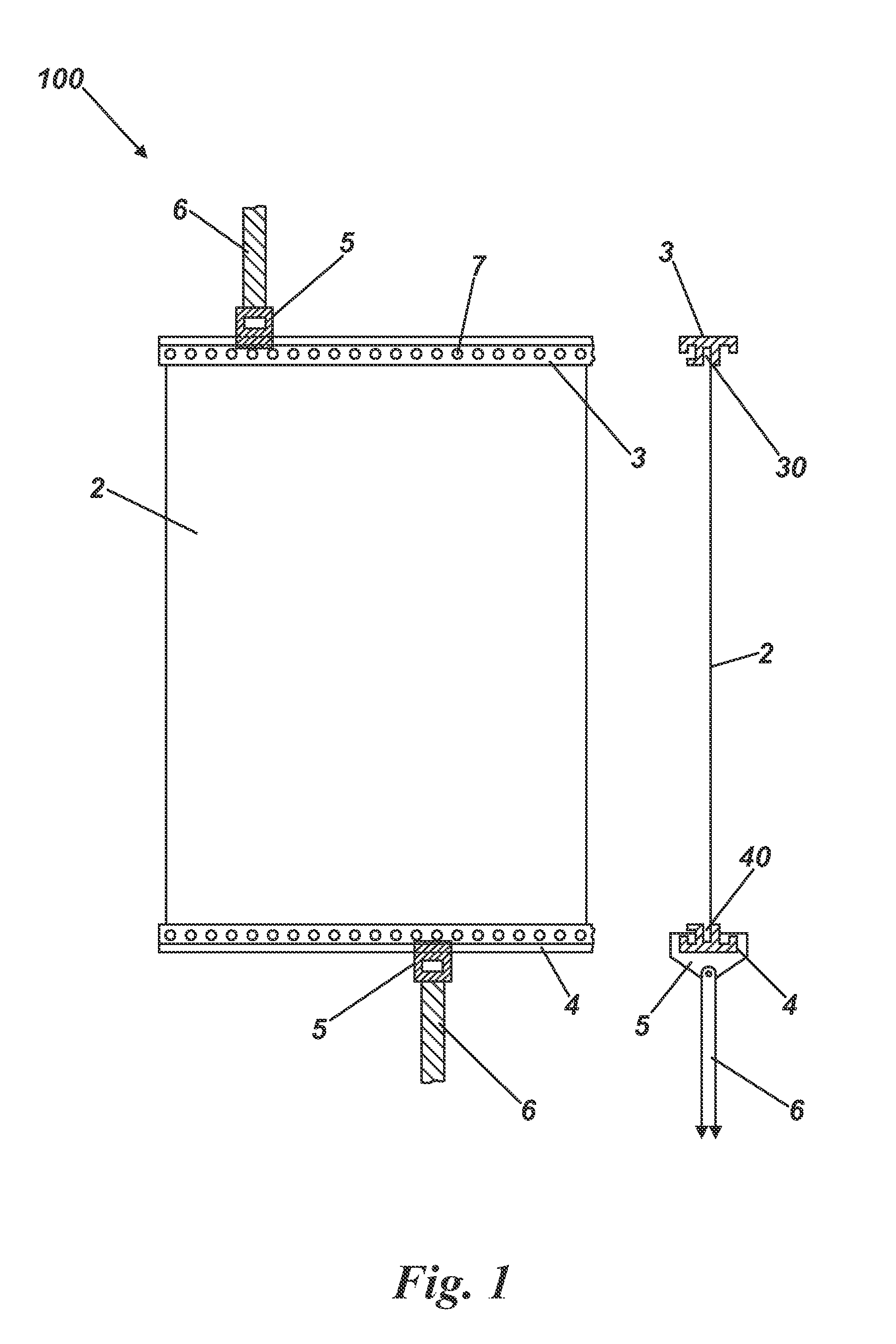

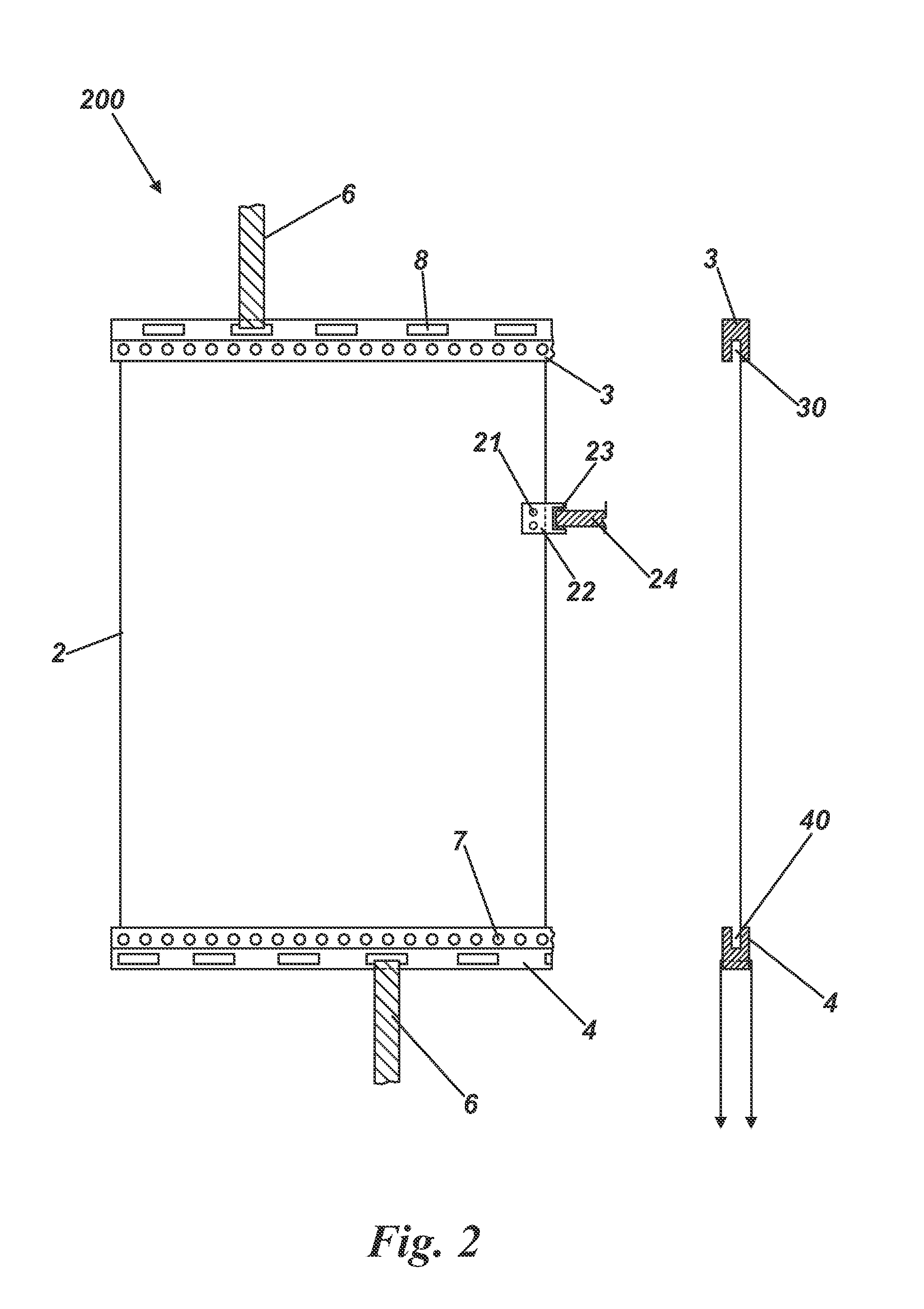

Projection apparatuses and associated methods

ActiveUS20110261450A1Improve mechanical propertiesEasy to disassembleProjectorsDomestic articlesBiomedical engineeringPolymer

Projection apparatuses and associated methods are provided. A representative apparatus includes: a support frame defining a projection area; a polymeric screen of sheet material sized and shaped to span at least a portion of the projection area; a retention member operative to contact the polymeric screen along an edge thereof; and a tensioning assembly operative to apply tension to the screen via the retention member, the tensioning assembly being operative to selectively reposition the retention member relative to the support frame.

Owner:MUSION IP LTD

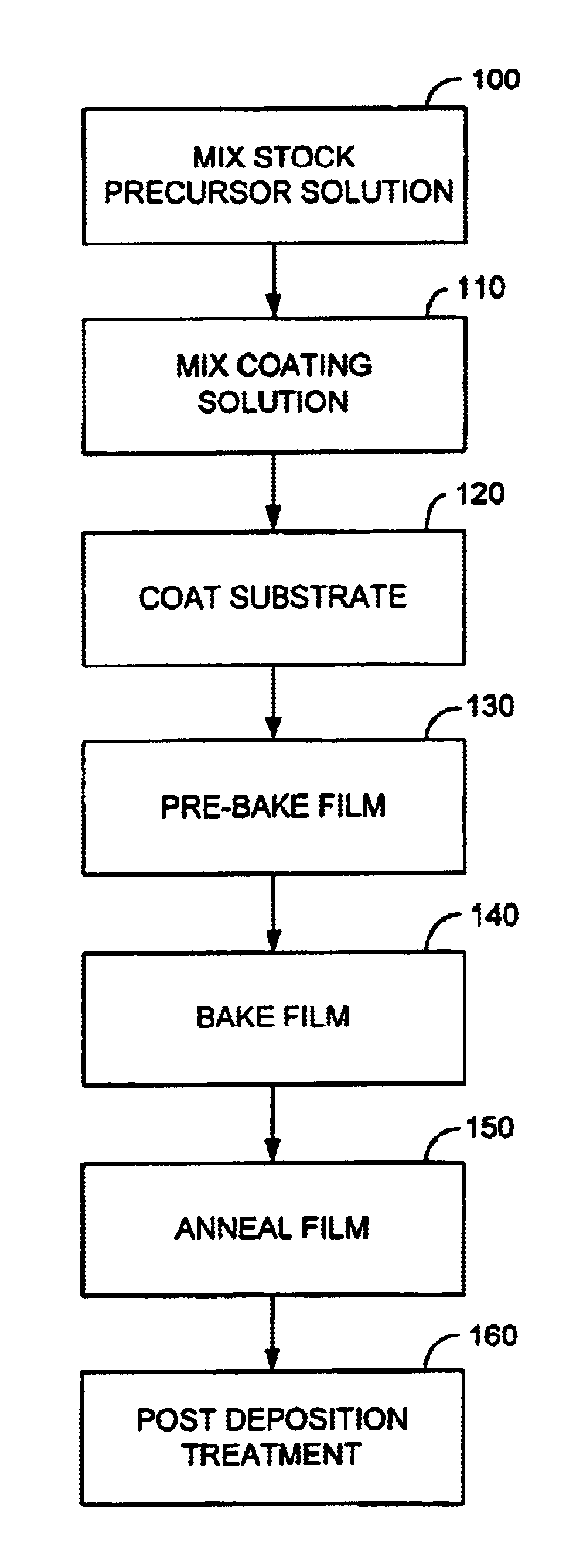

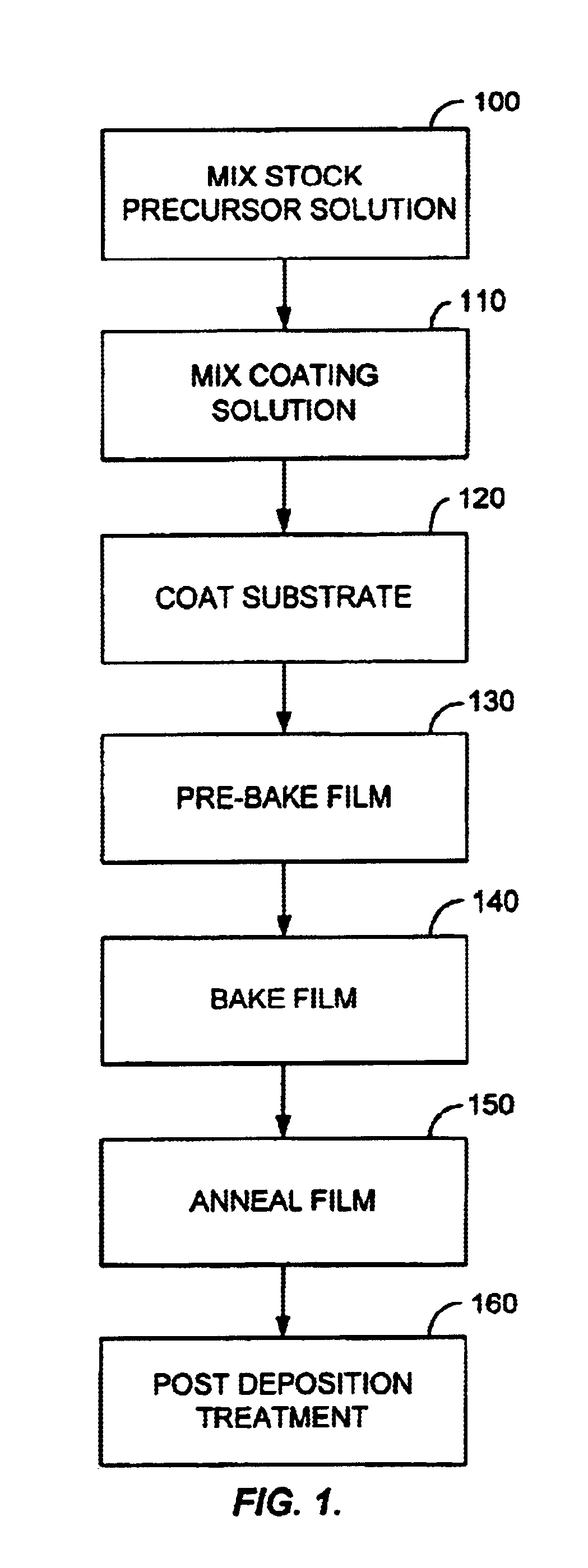

Ionic additives for extreme low dielectric constant chemical formulations

InactiveUS6896955B2Minimal levelSufficient mechanical propertySilicaLayered productsAlkali ionsPhosphate

A process for depositing porous silicon oxide-based films using a sol-gel approach utilizing a precursor solution formulation which includes a purified nonionic surfactant and an additive among other components, where the additive is either an ionic additive or an amine additive which forms an ionic ammonium type salt in the acidic precursor solution. Using this precursor solution formulation enables formation of a film having a dielectric constant less than 2.5, appropriate mechanical properties, and minimal levels of alkali metal impurities. In one embodiment, this is achieved by purifying the surfactant and adding ionic or amine additives such as tetraalkylammonium salts and amines to the stock precursor solution. In some embodiments, the ionic additive is a compound chosen from a group of cationic additives of the general composition [NR(CH3)3]+A−, where R is a hydrophobic ligand of chain length 1 to 24, including tetramethylammonium and cetyltrimethylammonium, and A− is an anion, which may be chosen from the group consisting essentially of formate, nitrate, oxalate, acetate, phosphate, carbonate, and hydroxide and combinations thereof. Tetramethylammonium salts, or more generally tetraalkylammonium salts, or tetraorganoammonium salts or organoamines in acidic media are added to surfactant templated porous oxide precursor formulations to increase the ionic content, replacing alkali ion impurities (sodium and potassium) removed during surfactant purification, but which are found to exhibit beneficial effects in promoting the formation of the resulting dielectric.

Owner:VERSUM MATERIALS US LLC

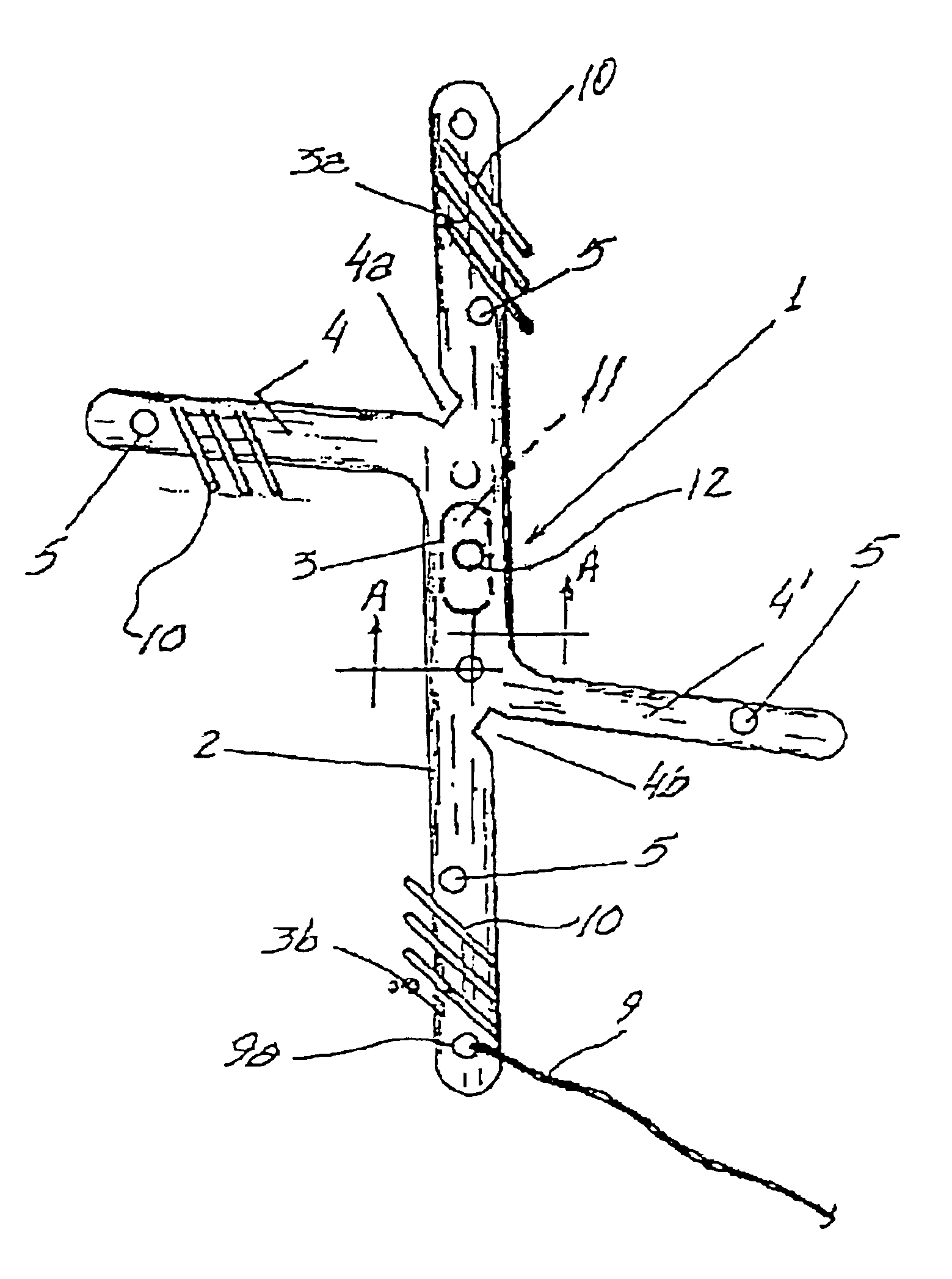

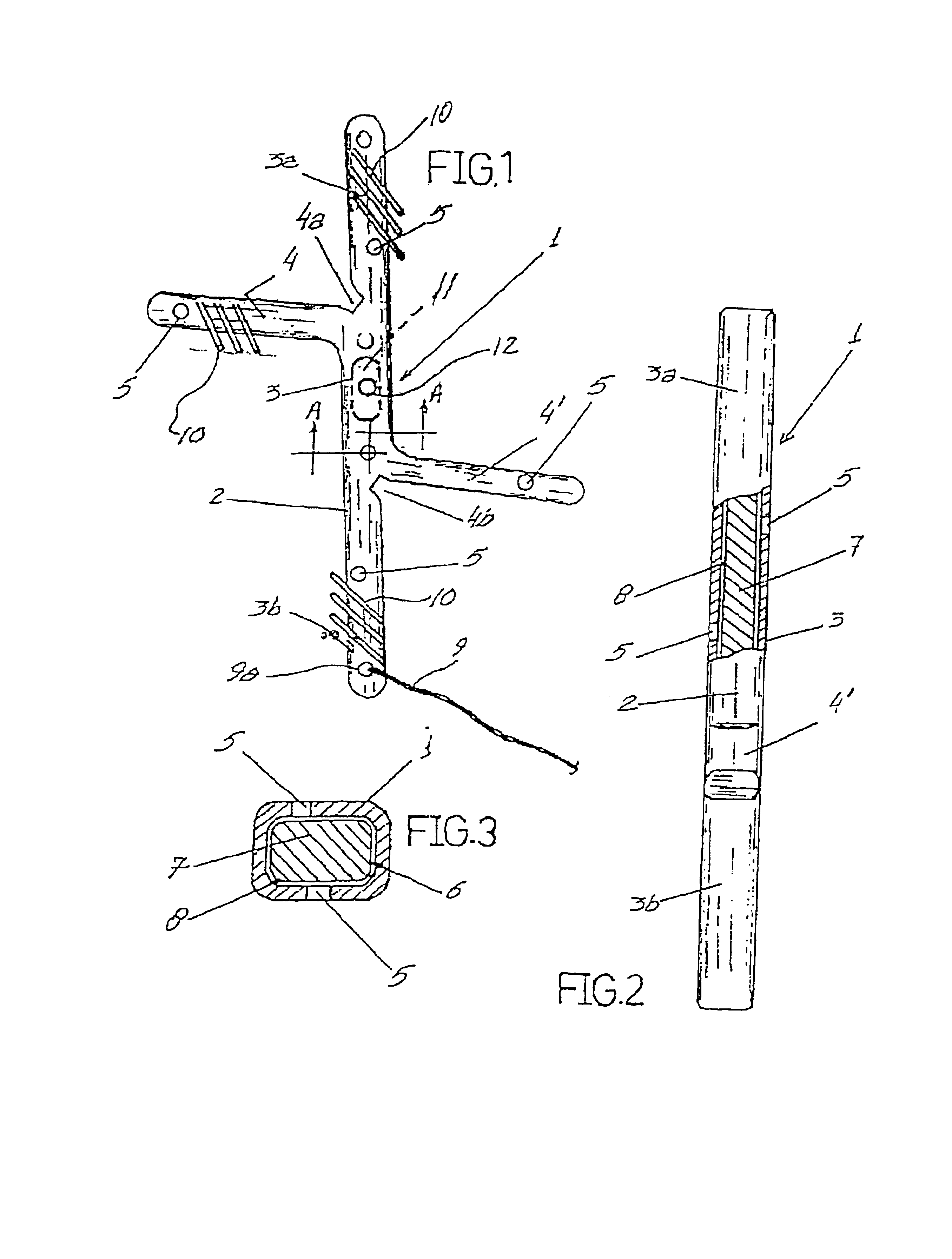

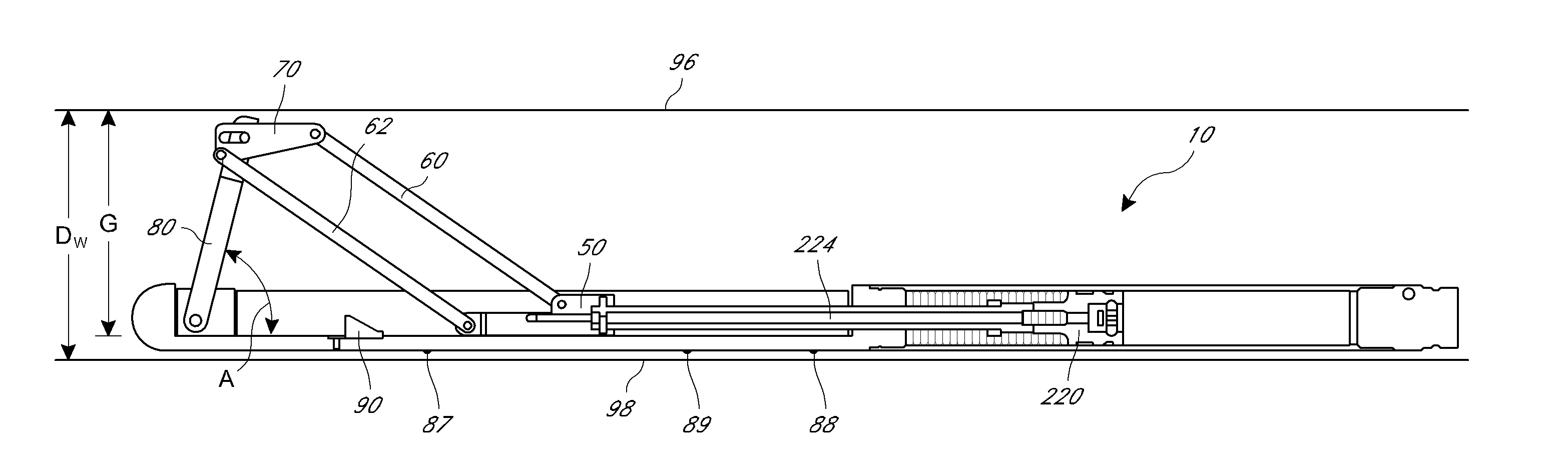

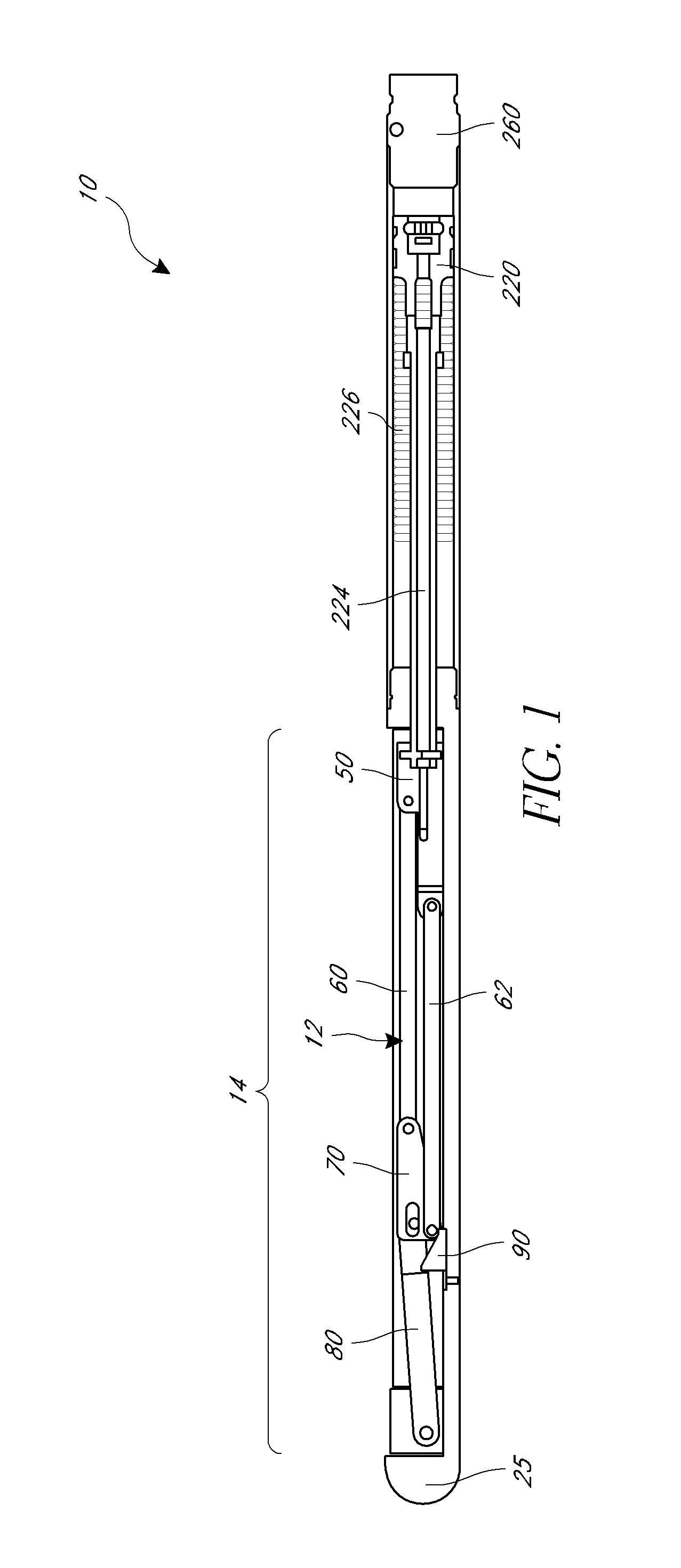

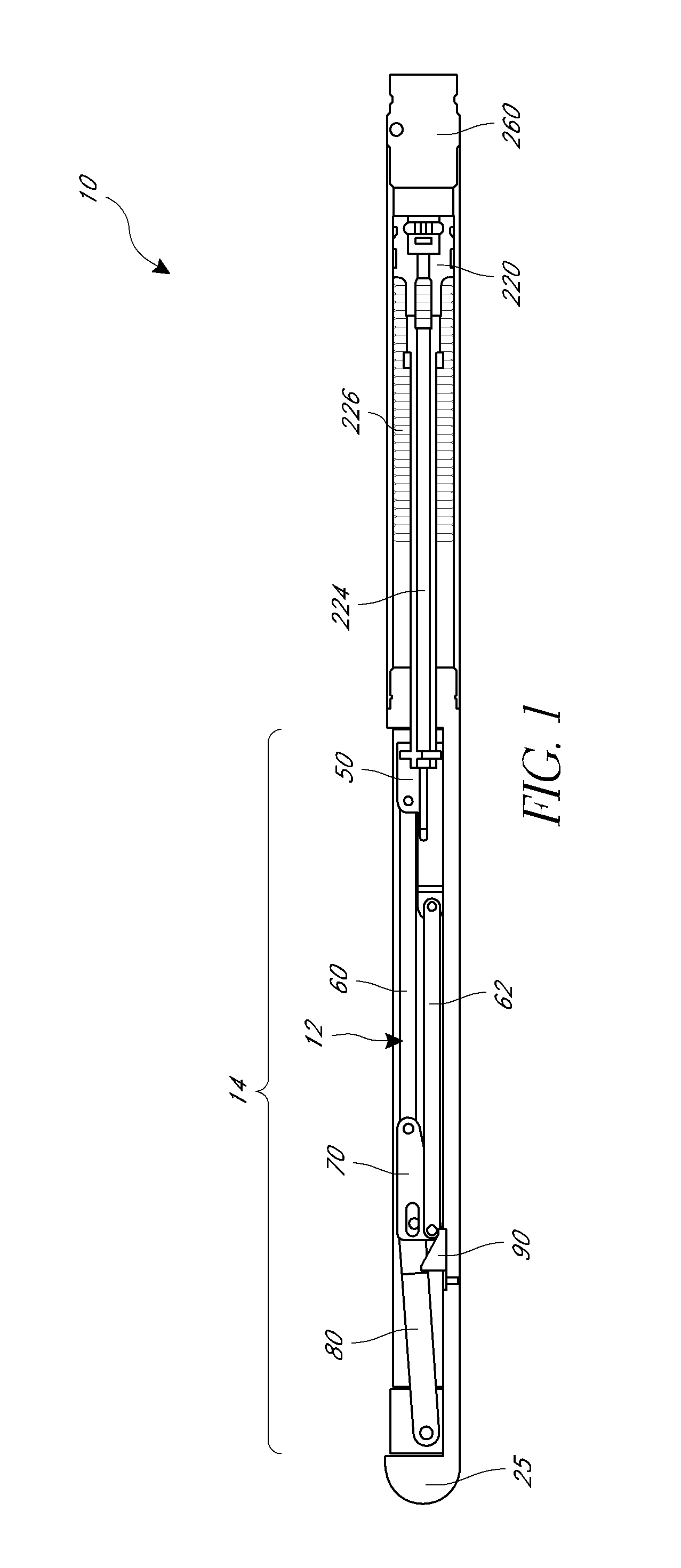

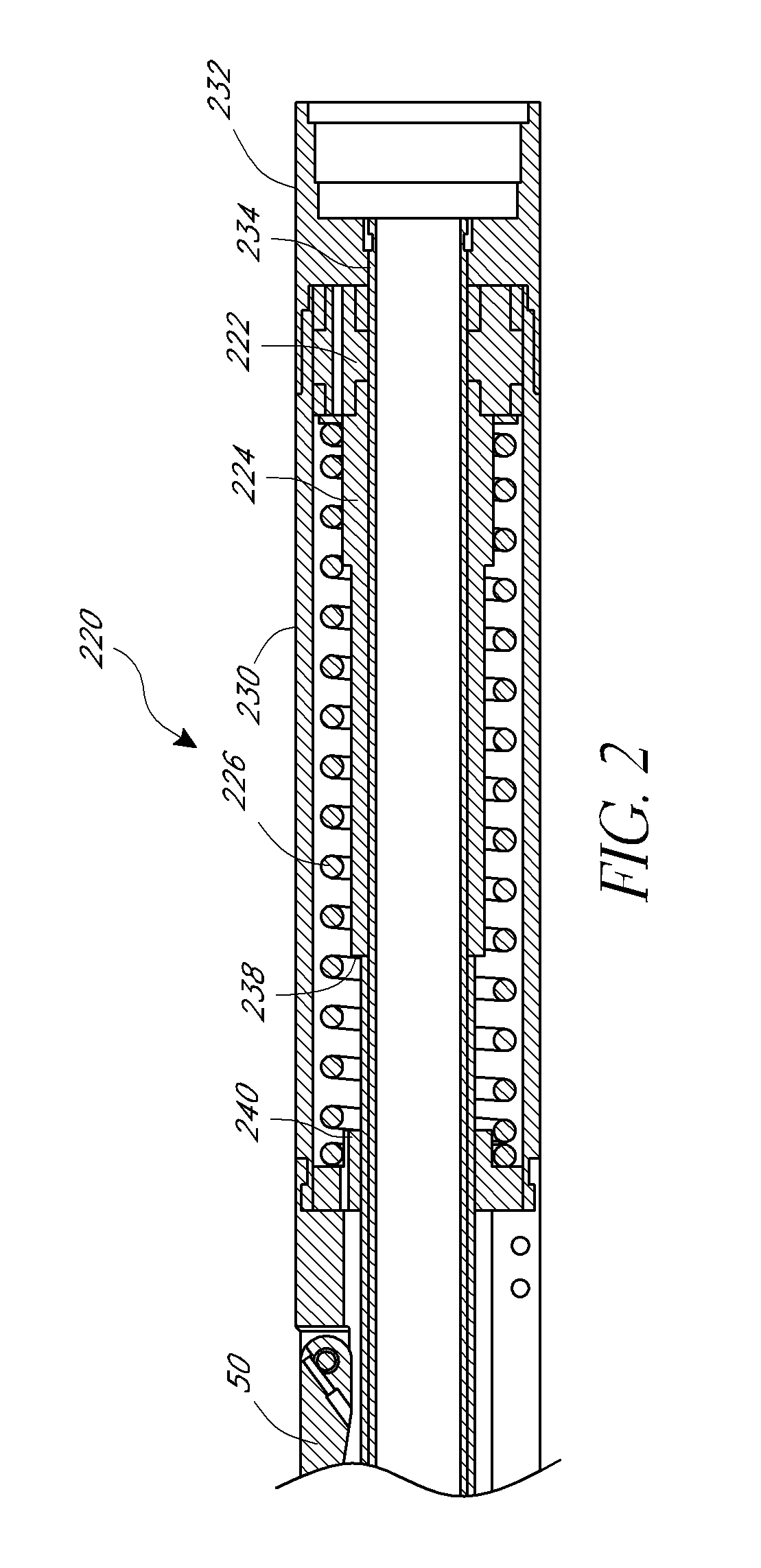

Eccentric linkage gripper

ActiveUS20150211312A1Solve the lack of mechanical propertiesGuaranteed uptimeFluid removalBorehole drivesAxial forceEngineering

A gripper mechanism for a downhole tool is disclosed that includes an eccentric linkage mechanism. In operation, an axial force generated by a power section of the gripper expands the linkage mechanism, which applies a radial force to the interior surface of a wellbore or passage. A sliding portion allows the gripper to slide along a surface of the formation in response to the radial force applied to the interior surface of the wellbore or passage.

Owner:WWT NORTH AMERICA HLDG +1

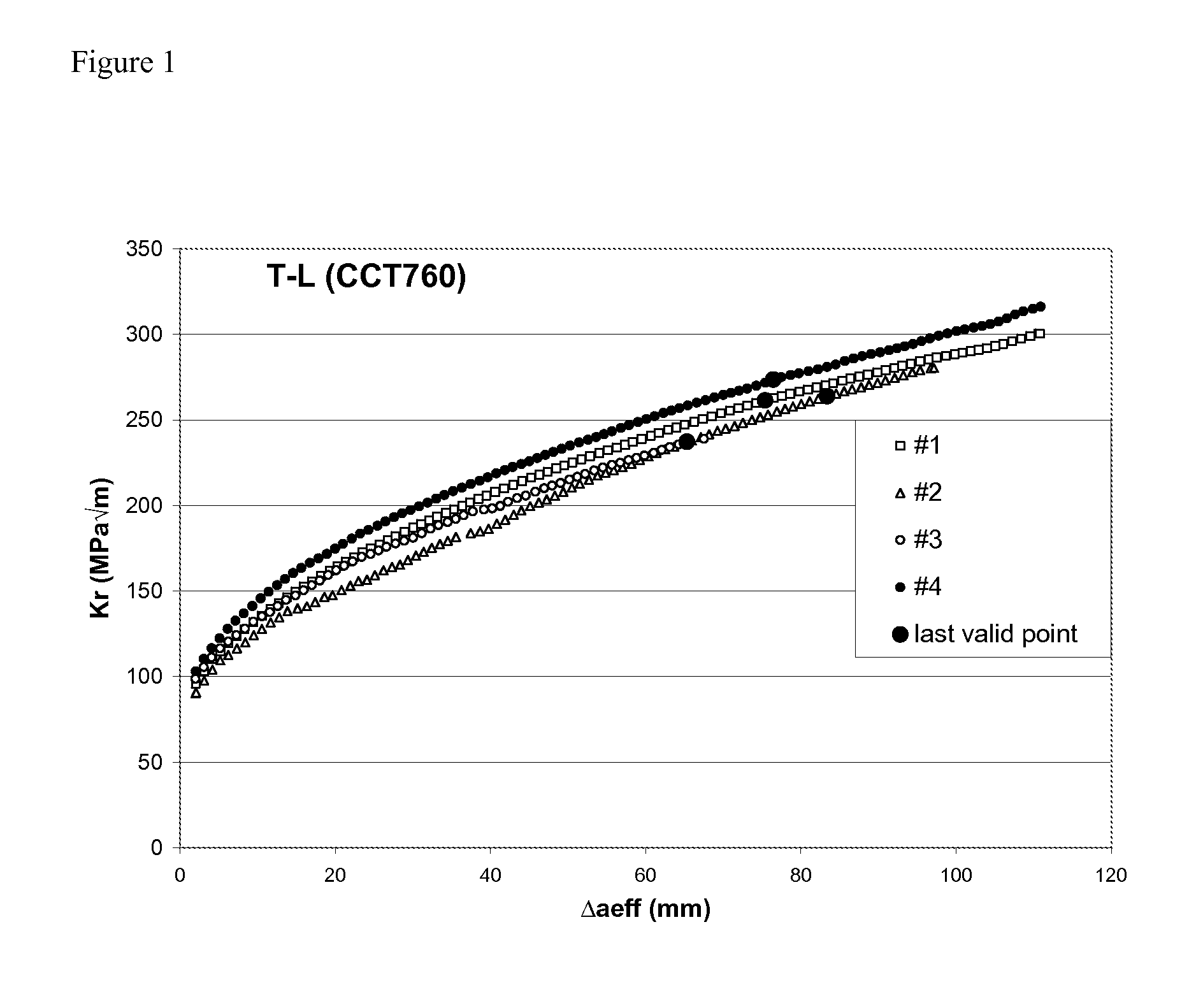

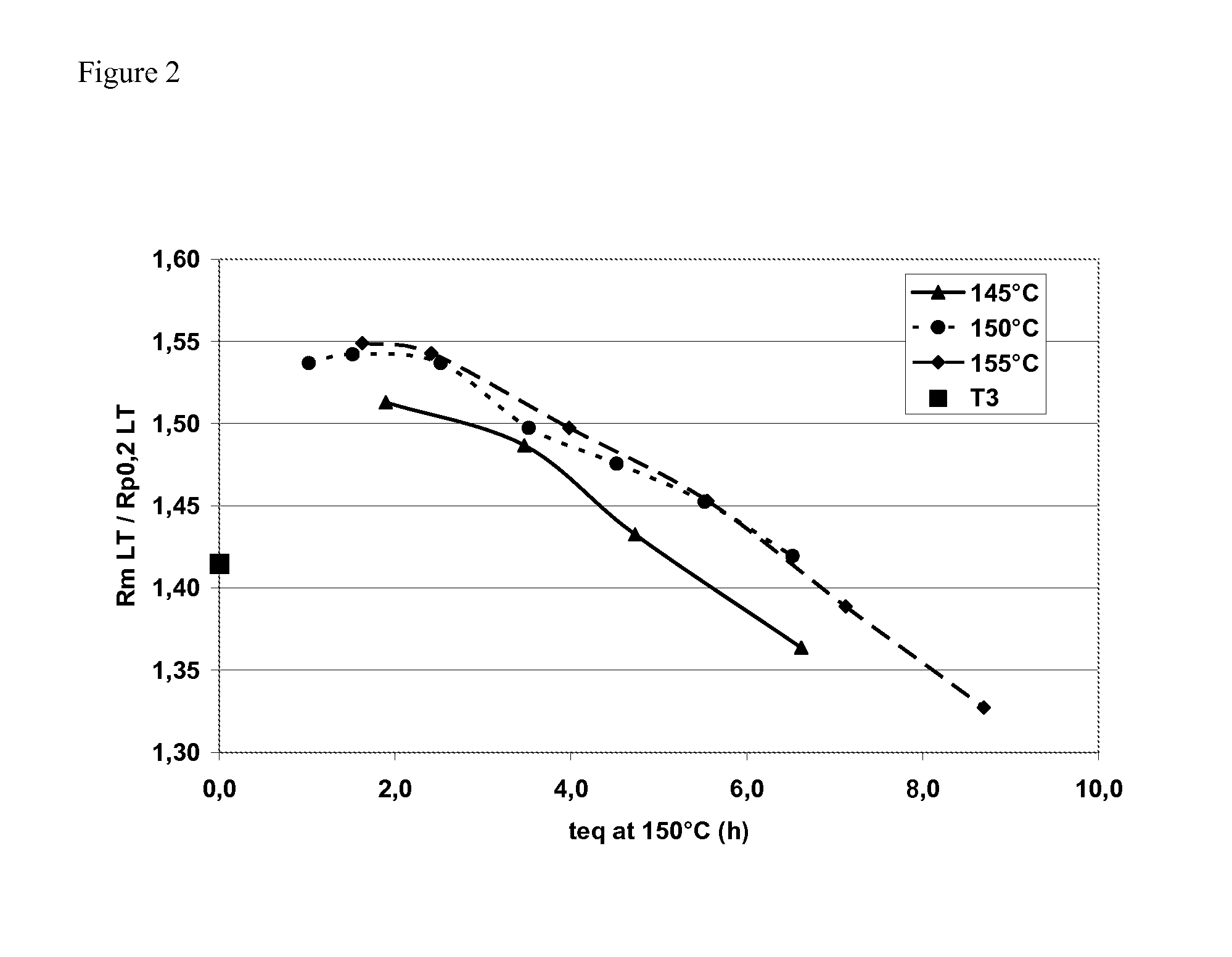

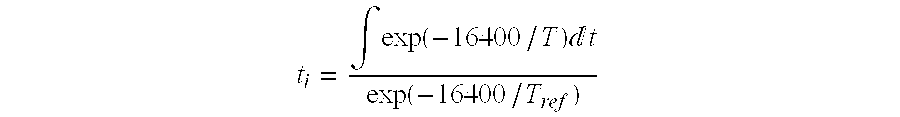

Transformation process of Al-Cu-Li alloy sheets

The invention concerns a process to manufacture a flat-rolled product, notably for the aeronautic industry containing aluminum alloy comprising 2.1% to 3.9% Cu by weight, 0.7% to 2.0% Li by weight, 0.1% to 1,0% Mg by weight, 0% to 0.6% Ag by weight, 0% to 1% Zn by weight, at least 0.20% Fe+Si by weight, at least one element chosen from Zr, Mn, Cr, Sc, Hf and Ti, the quantity of said element, if chosen, being 0.05% to 0.18% by weight for Zn, 0.1% to 0.6% by weight for Mn, 0.05% to 0.3% by weight for Cr, 0.02% to 0.2% by weight for Sc, 0.05% to 0.5% by weight for Hf and 0.01% to 0.15% by weight for Ti, the other elements at most 0.05% by weight each and 0.15% by weight in total, the rest being aluminum, in which, notably a flattening and / or stretching is performed with a cumulated deformation of at least 0.5% and less than 3%, and a short heat-treatment is performed in which the sheet reaches a temperature between 130° C. and 170° C. for a period of 0.1 to 13 hours. The invention notably makes it possible to simplify the forming process of fuselage skins and to improve the balance between static mechanical strength properties and damage tolerance properties.

Owner:CONSTELLIUM ISSOIRE

Composition Coextrudable with PVDF and having no stress-whitening effect

InactiveUS20050187354A1Good mechanical integritySolve the lack of mechanical propertiesSynthetic resin layered productsThin material handlingMeth-Ultraviolet

The present invention relates to a composition coextrudable with PVDF and comprising: 30 to 50 parts of PVDF; 70 to 50 parts of a copolymer comprising, by weight, 90 to 50% of methyl methacrylate (MMA) per 10 to 50% of an alkyl (meth)acrylate respectively, the alkyl having from 2 to 24 carbon atoms; 1 to 4 parts of a UV absorber; the total making 100 parts. The invention also relates to coextruded films consisting of this composition as the adhesive layer and a PVDF-based layer of 50 to 100 parts of PVDF per 50 to 0 parts of PMMA respectively. These films possess mechanical properties sufficient to allow them to be used as a coating transparent to visible light but opaque to UV radiation.

Owner:ARKEMA FRANCE SA

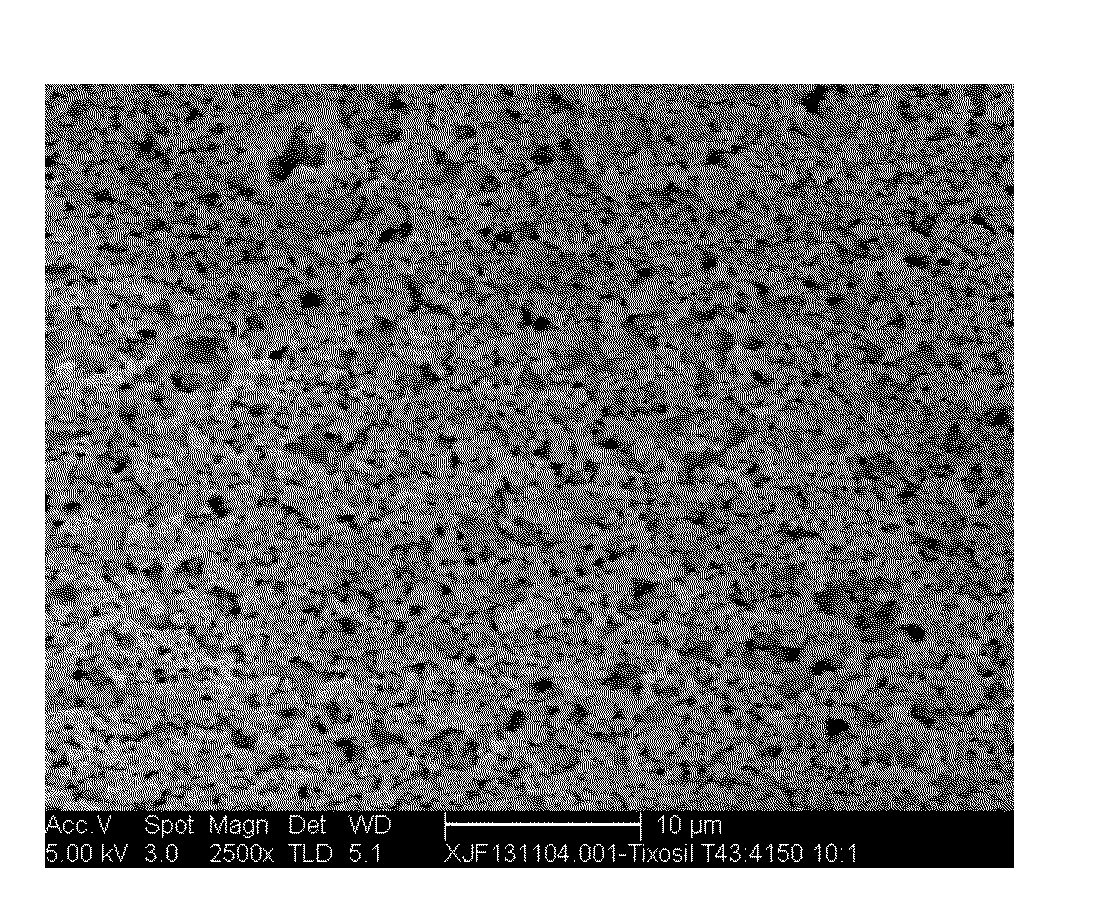

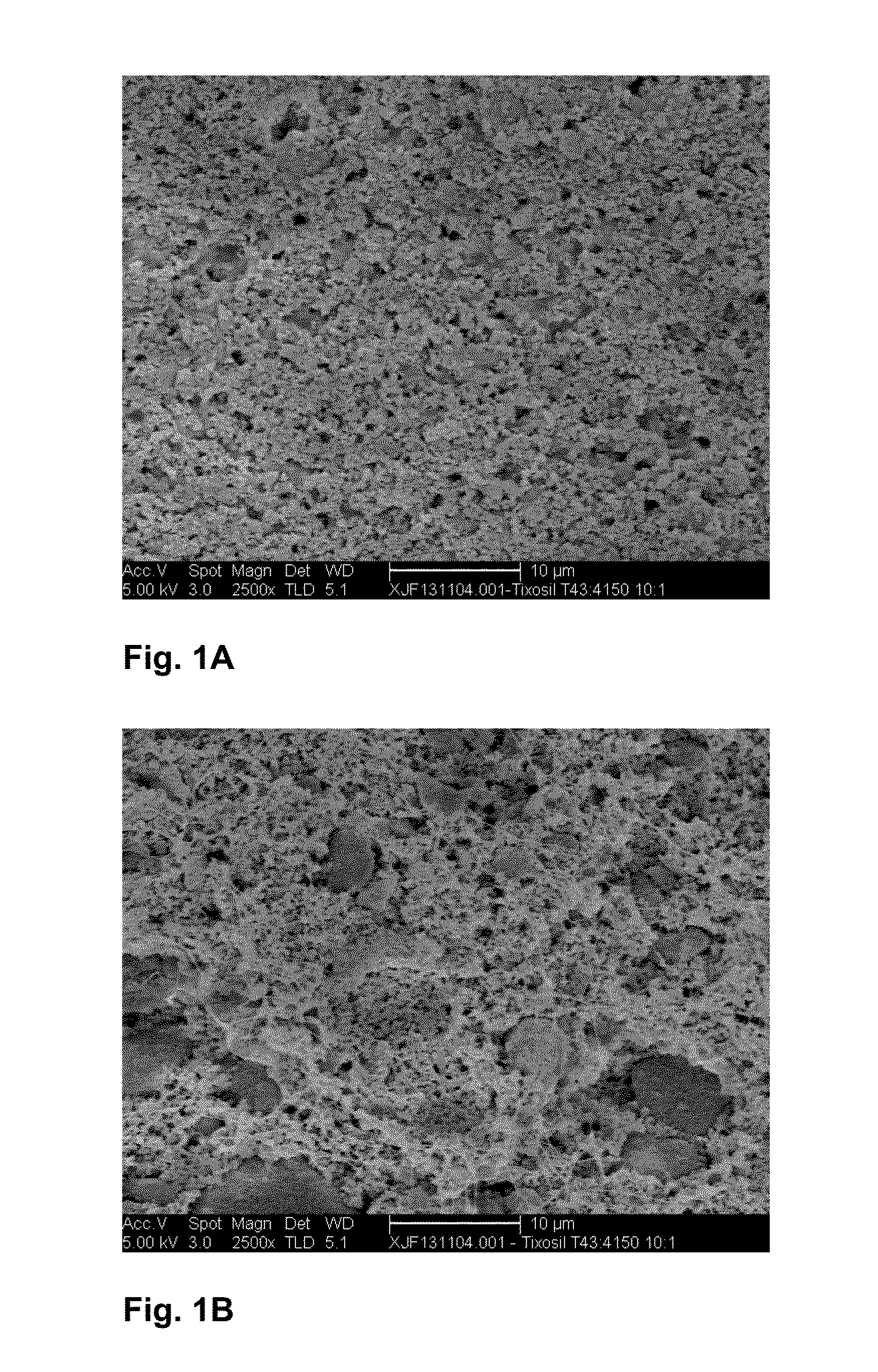

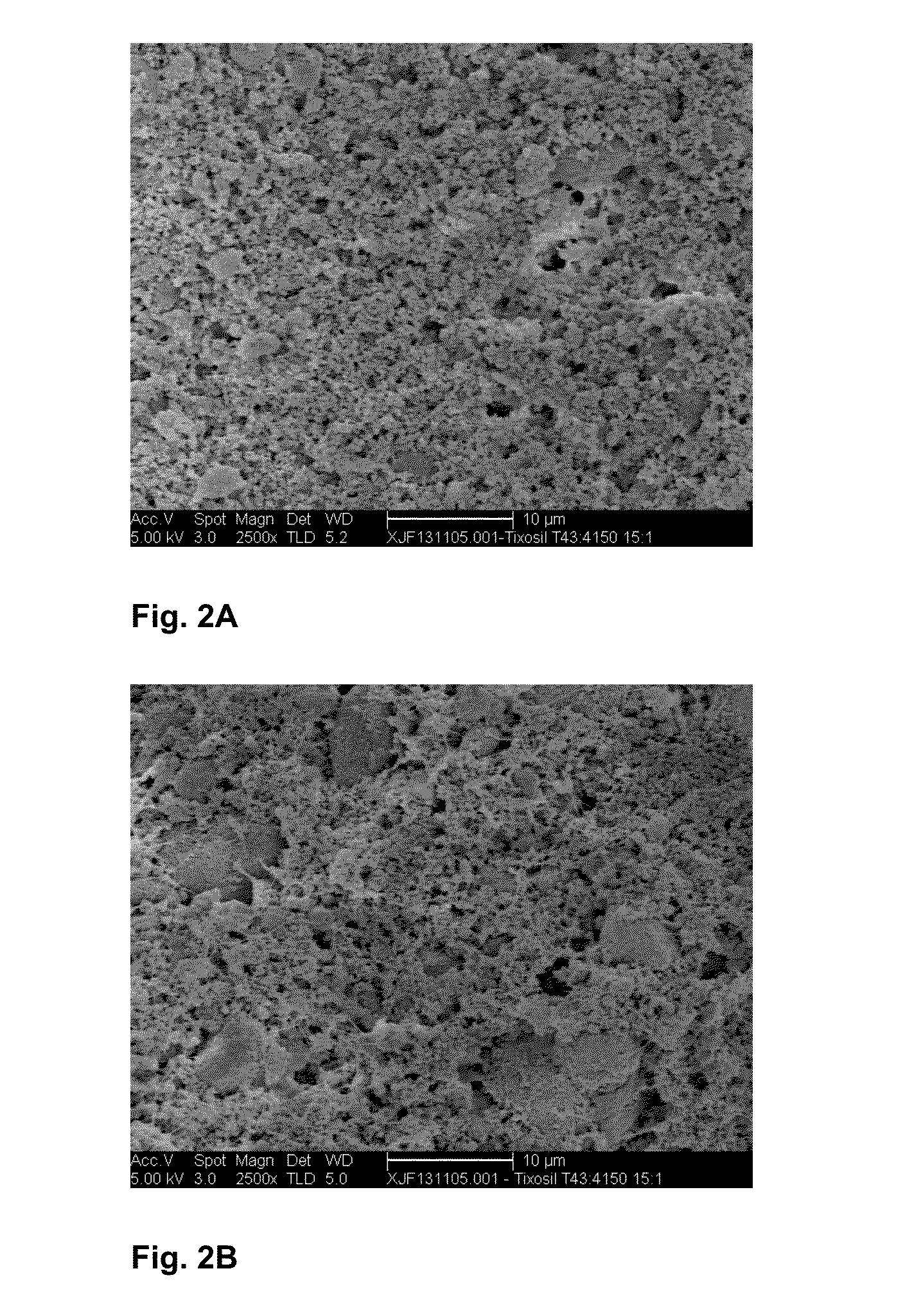

High porosity silica-containing microporous sheets

ActiveUS20150207121A1High porosityImprove mechanical propertiesLead-acid accumulatorsCell component detailsPorosityPolymer science

A flexible microporous polymer sheet having first and second opposite major surfaces comprises a polymer matrix binding a filler component that exhibits high oil absorption capacity in its initial state before the start of material processing. The polymer matrix includes a polyolefin component and has three-dimensional interconnecting and interpenetrating pore and polymer networks through which the bound filler component is distributed from the first major surface to the second major surface. The polyolefin and filler components are included in amounts that result in a microporous polymer sheet having between about 75% and about 90% porosity and containing less than about 10 wt. % polyolefin component. Preferred polyolefin and filler components include ultrahigh molecular weight polyethylene and high oil absorption precipitated silica, respectively.

Owner:AMTEK RES INT

Polyethylene Molding Composition for Producing Blown Films Having Improved Processability

InactiveUS20080139750A1Improve drawing capabilityConstant thicknessMolar mass distributionMachinability

The invention relates to a polyethylene molding composition having a multimodal molar mass distribution particularly suitable for blow molding films having a thickness in the range from 8 to 200 μm. The molding composition has a density at a temperature of 23° C. in the range from 0.953 to 0.960 g / cm3 and an MFR190 / 5 of the final product after extrusion in the range from 0.10 to 0.50 dg / min. The composition comprises from 30 to 60% by weight of a first ethylene polymer fraction made of a homopolymer A having a first molecular weight, from 22 to 40% by weight of a second ethylene polymer fraction made of a further homopolymer or first copolymer B of ethylene and at least one first comonomer from the group of olefins having from 4 to 8 carbon atoms, the first copolymer B having a second molecular weight higher than the first molecular weight, and from 10 to 30% by weight of a third ethylene polymer fraction made of a second copolymer C having a third molecular weight higher than the second molecular weight. The molding composition of the invention allows to produce thin films having improved processability without impairing the mechanical properties.

Owner:BASELL POLYOLEFINE GMBH

Polyethylene Molding Composition for Producing Blown Films Having Improved Mechanical Properties and Processability

InactiveUS20080199674A1Good drawing effectAdequate film bubble stabilitySynthetic resin layered productsCeramic shaping apparatusBlow moldingMolar mass distribution

The invention relates to a polyethylene molding composition having a multimodal molar mass distribution particularly suitable for blow molding films having a thickness in the range from 8 to 200 μm. The molding composition has a density at a temperature of 23° C. in the range from 0.948 to 0.953 g / cm3 and an MFR190 / 5 of the final product after extrusion in the range from 0.10 to 0.50 dg / min. The composition comprises from 30 to 60% by weight of a first ethylene polymer fraction made of a homopolymer A having a first molecular weight, from 22 to 40% by weight of a second ethylene polymer fraction made of a further homopolymer or first copolymer B of ethylene and at least one first comonomer from the group of olefins having from 4 to 8 carbon atoms, the first copolymer B having a second molecular weight higher than the first molecular weight, and from 10 to 30% by weight of a third ethylene polymer fraction made of a second copolymer C having a third molecular weight higher than the second molecular weight. The molding composition of the invention allows to produce films having a good balance between processability and mechanical properties.

Owner:BASELL POLYOLEFINE GMBH

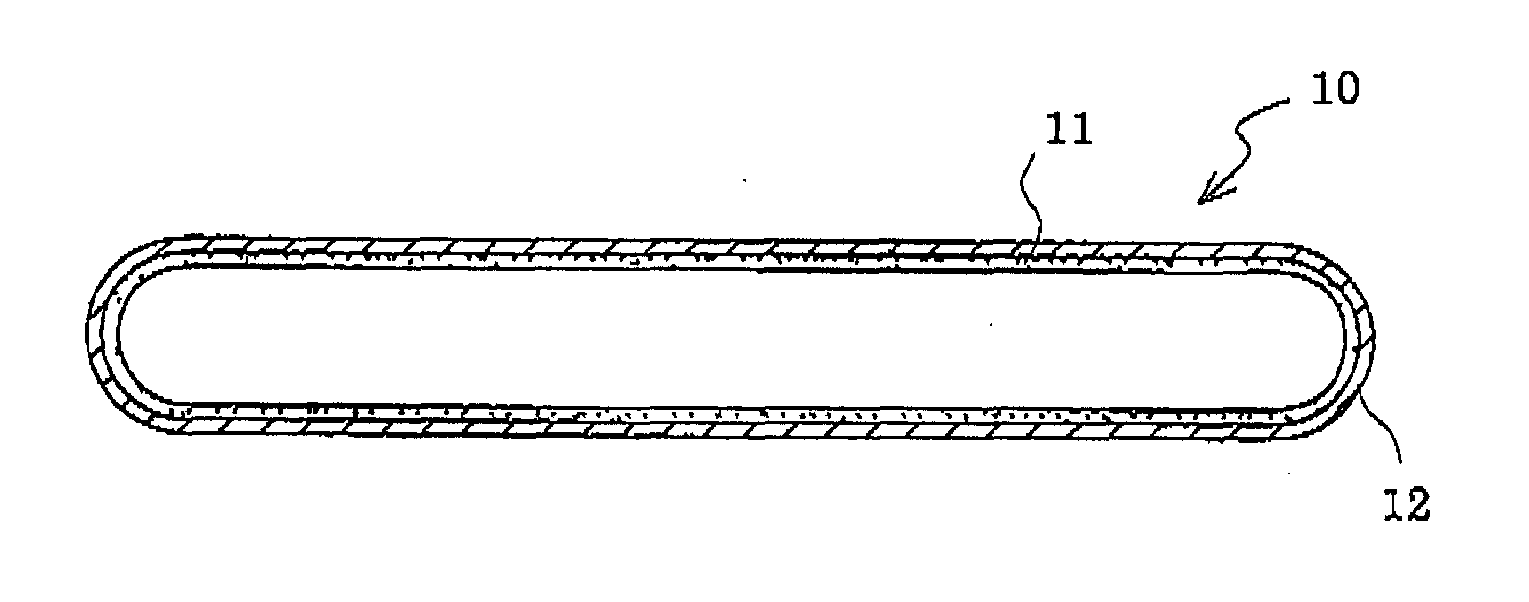

Endless belt for conveying paper sheet and method for producing the endless belt

InactiveUS20070213157A1Increased durabilitySufficient mechanical propertyV-beltsRopes and cables for vehicles/pulleyPaper sheet

Owner:SYNZTEC

Apparatus and method for delivery of biologic sealant

ActiveUS8047407B2Restore hydrostatic pressureFacilitate extended pain reliefLiquid surface applicatorsSurgical adhesivesEngineeringSealant

A device for delivery of biologic materials, comprising: a cartridge having at least two cylinder bores for fluids to be delivered, wherein each cylinder includes an exit port for a fluid, a plunger within each cylinder for pushing the fluids out of the cylinder, a housing adapted to receive the cartridge, wherein the housing or cartridge includes an adaptor to receive and lock a manifold that operably connects to the exit ports of the cartridge, at least two toothed rams, wherein each toothed ram is at least partially within a cylinder bore, a trigger connected to the housing, wherein the trigger includes a toothed drive rack, a toothed wheel assembly that cooperates with the toothed drive rack and with the toothed rams, as well as methods of making the device, methods of using the device to treat discs, kits including the device.

Owner:PAUZA KEVIN

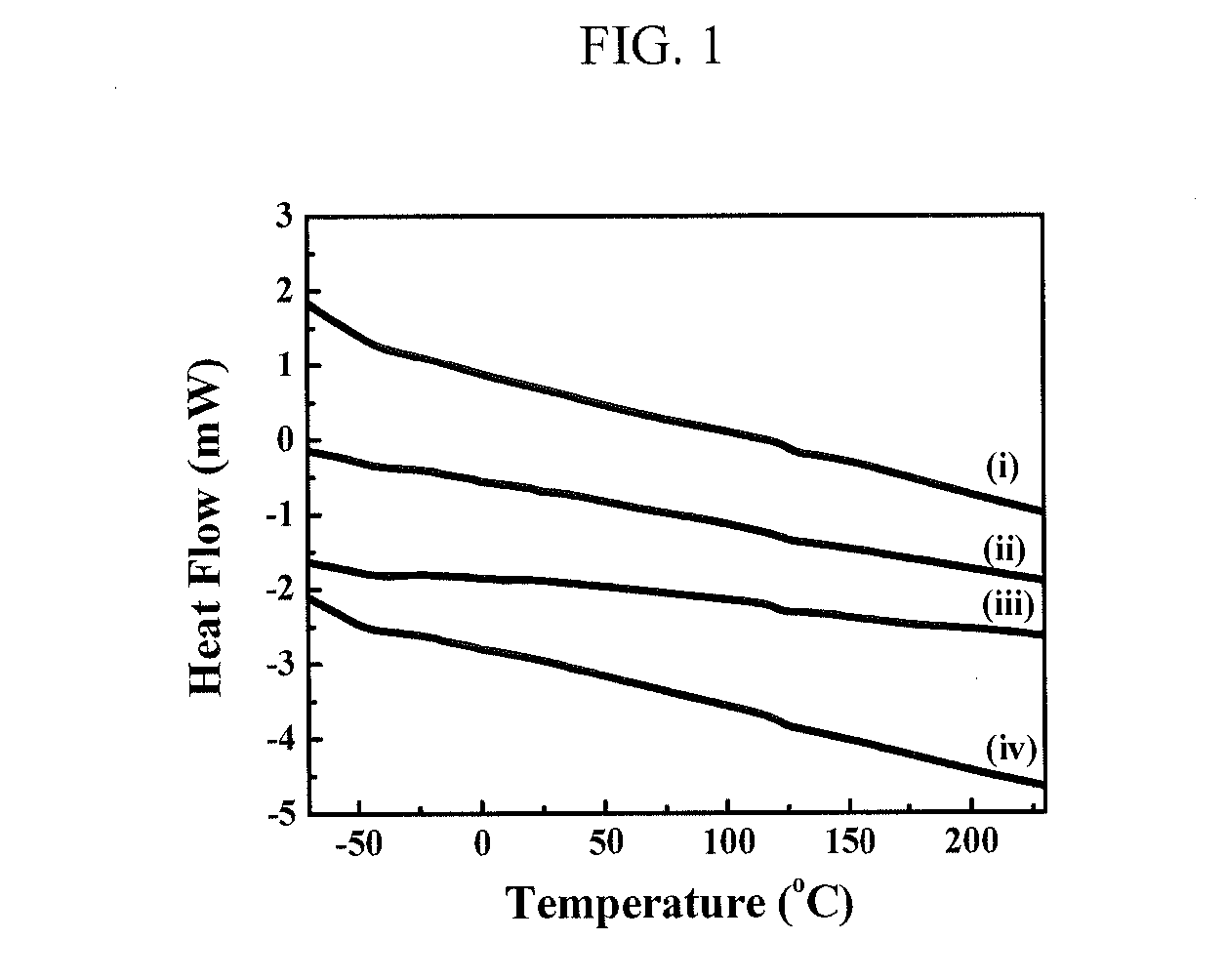

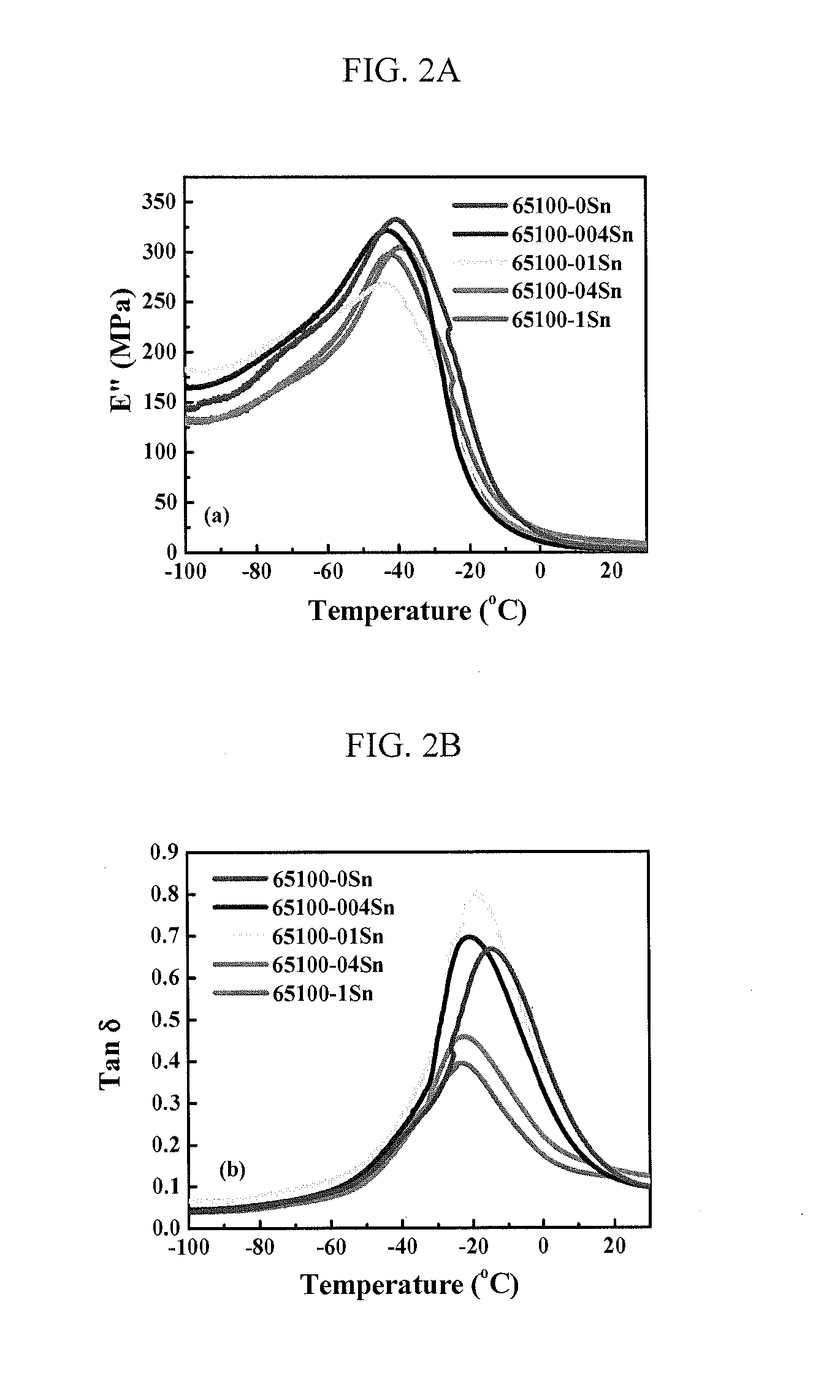

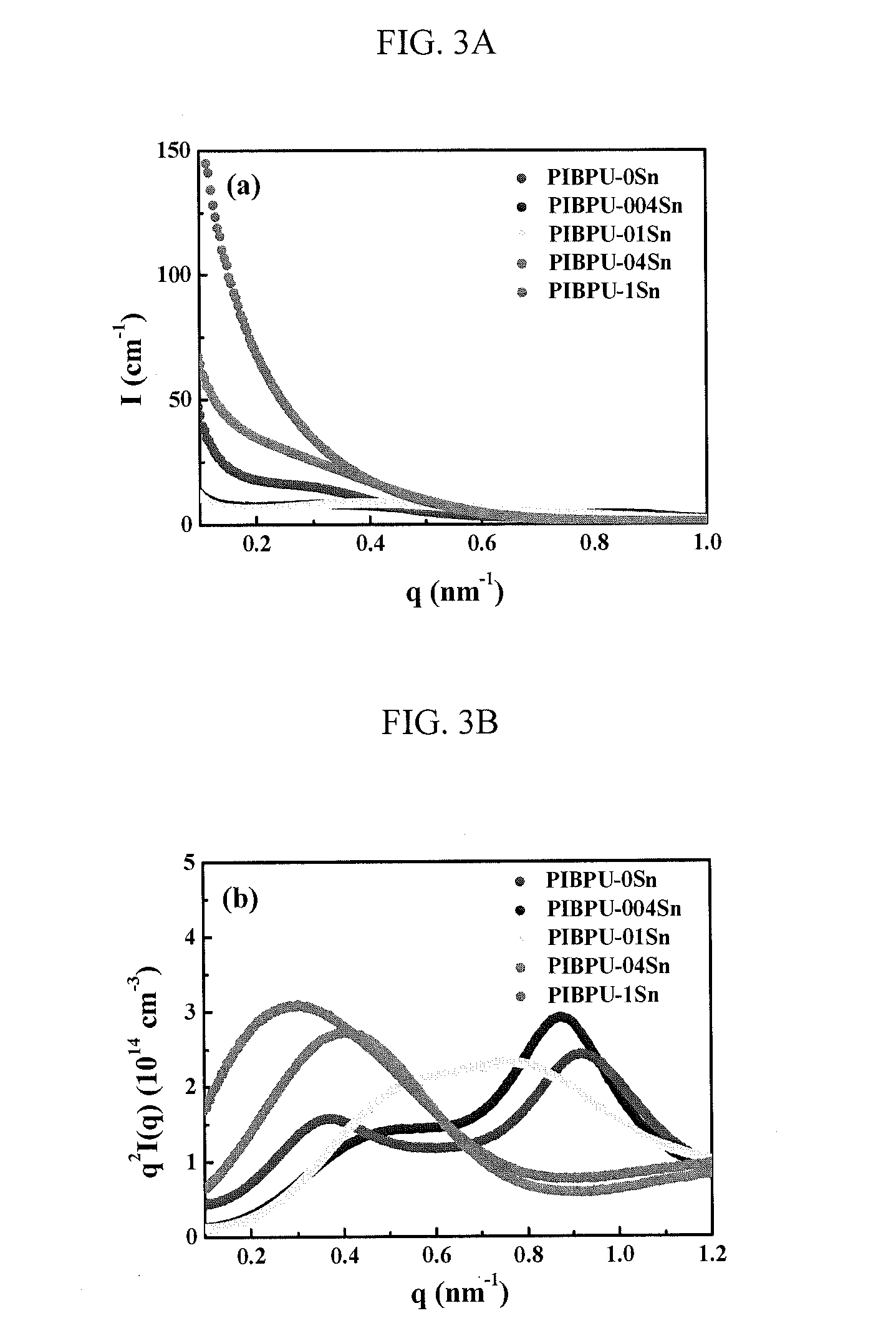

High strength polyisobutylene polyurethanes

An elastomeric polymer, comprising (1) a hard segment in the amount of 10% to 60% by weight of the elastomeric polymer, wherein the hard segment includes a urethane, urea, or urethaneurea; and (2) a soft segment in the amount of 40% to 90% by weight of the elastomeric polymer, wherein the soft segment includes a polyisobutylene macrodiol and / or diamine. Additionally disclosed is a method of forming a polyisobutylene-based thermoplastic urethane, comprising the steps of (a) reacting a polyisobutylene macrodiol and / or diamine with a diisocyanate to form a first reaction mixture; (b) combining a metal catalyst and a chain extender with the first reaction mixture to create a second reaction mixture, a molar ratio of the metal catalyst to the diisocyanate being greater than 0.0:1 and less than or equal to 0.4:1; and (c) reacting the second reaction mixture for a period of time sufficient to form the polyisobutylene-based thermoplastic urethane.

Owner:UNIV OF MASSACHUSETTS

Process for preparing a blown film from a polyethylene molding composition

InactiveUS20110171450A1Improve stabilityReduce pressureSynthetic resin layered productsBlow moldingMolar mass distribution

The invention relates to a polyethylene molding composition having a multimodal molar mass distribution particularly suitable for blow molding films having a thickness in the range from 8 to 200 μm. The molding composition has a density at a temperature of 23° C. in the range from 0.948 to 0.953 g / cm3 and an MFR190 / 5 of the final product after extrusion in the range from 0.10 to 0.50 dg / min. The composition comprises from 30 to 60% by weight of a first ethylene polymer fraction made of a homopolymer A having a first molecular weight, from 22 to 40% by weight of a second ethylene polymer fraction made of a further homopolymer or first copolymer B of ethylene and at least one first comonomer from the group of olefins having from 4 to 8 carbon atoms, the first copolymer B having a second molecular weight higher than the first molecular weight, and from 10 to 30% by weight of a third ethylene polymer fraction made of a second copolymer C having a third molecular weight higher than the second molecular weight. The molding composition of the invention allows to produce films having a good balance between processability and mechanical properties.

Owner:BASELL POLYOLEFINE GMBH

Low Cost, High Performance Flexible Reinforcement for Communications Cable

InactiveUS20080310802A1Low costImprove performanceInsulated cablesFibre mechanical structuresEngineeringCopper

A low cost, high performance flexible reinforcement member that can be used for both optical and copper communications cable. The reinforcement members made according to the preferred process are more rigid than known reinforcement members, but are less rigid than glass pultruded rods. Communications cables utilizing these members are lightweight and exhibit an improved combination of strength and flexibility compared to traditional communications cables. Further, these communication cables may then be installed into underground ducts using more economical and faster installation techniques.

Owner:ROBLON US INC

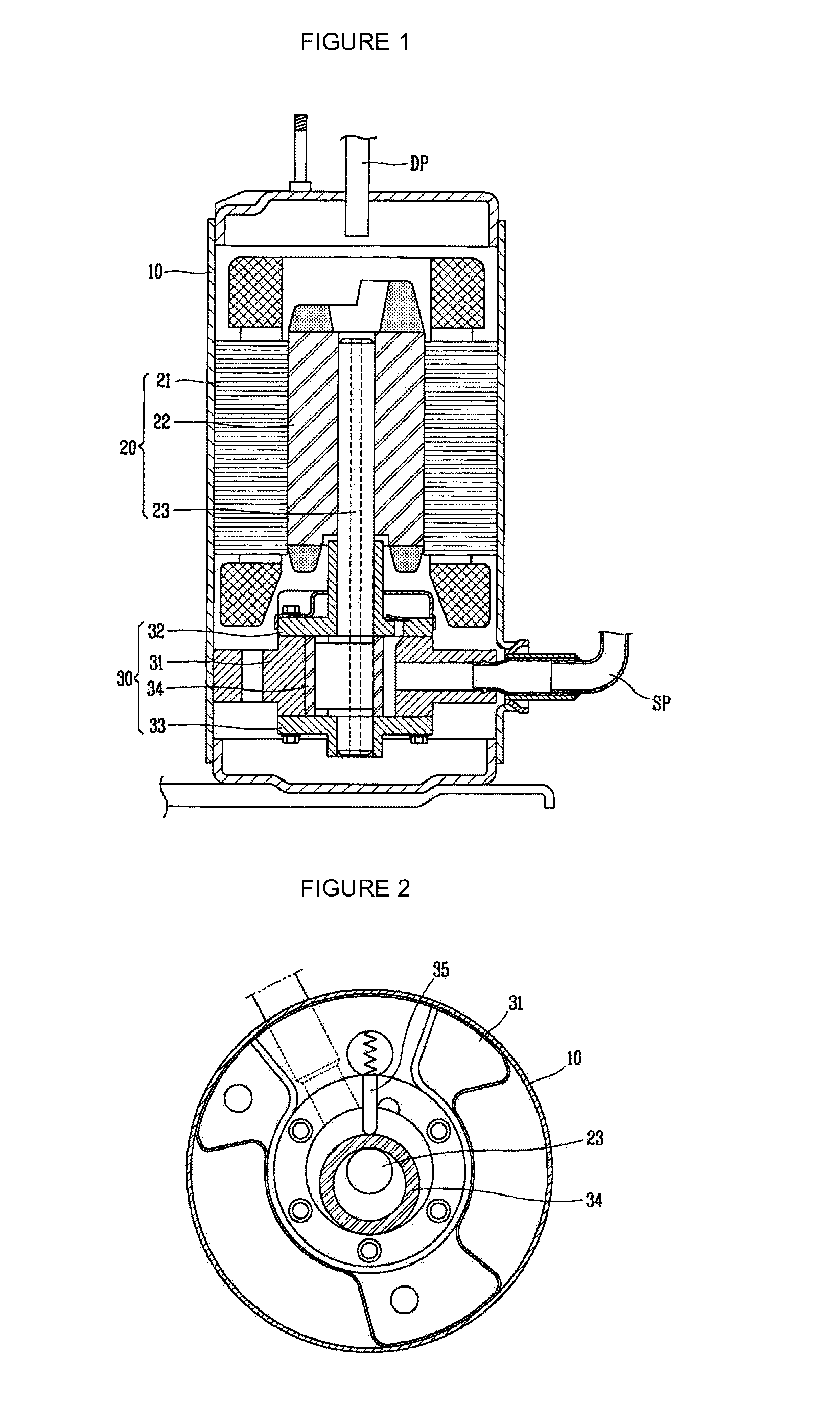

Alloy cast iron and manufacturing method of rolling piston using the same

InactiveUS20130118652A1Reduce manufacturing costSolve the lack of mechanical propertiesRotary piston pumpsFurnace typesSulfurManganese

An alloy cast iron, and a method of manufacturing a rolling piston for a rotary compressor includes, by weight, 3.0˜3.5% carbon (C), 2.2˜2.4% silicon (Si), 0.5˜1.0% manganese (Mn), 0.1˜0.3% phosphorus (P), 0.06˜0.08% sulfur (S), 0.7˜1.0% chrome (Cr), 0.6˜1.0% copper (Cu), and a residue formed of Fe and inevitable impurities, wherein 3˜8 vol % steadite structure is formed.

Owner:LG ELECTRONICS INC

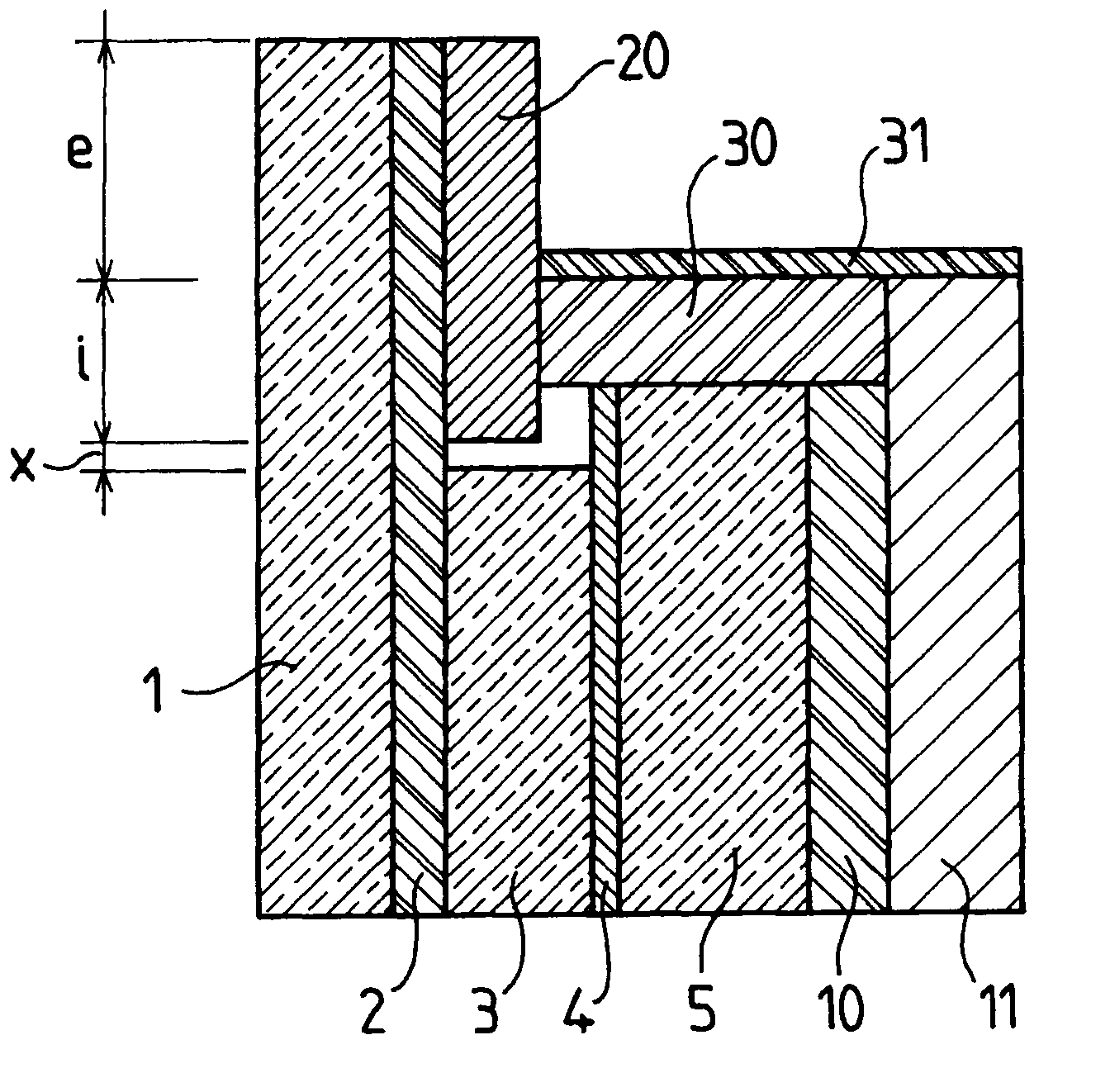

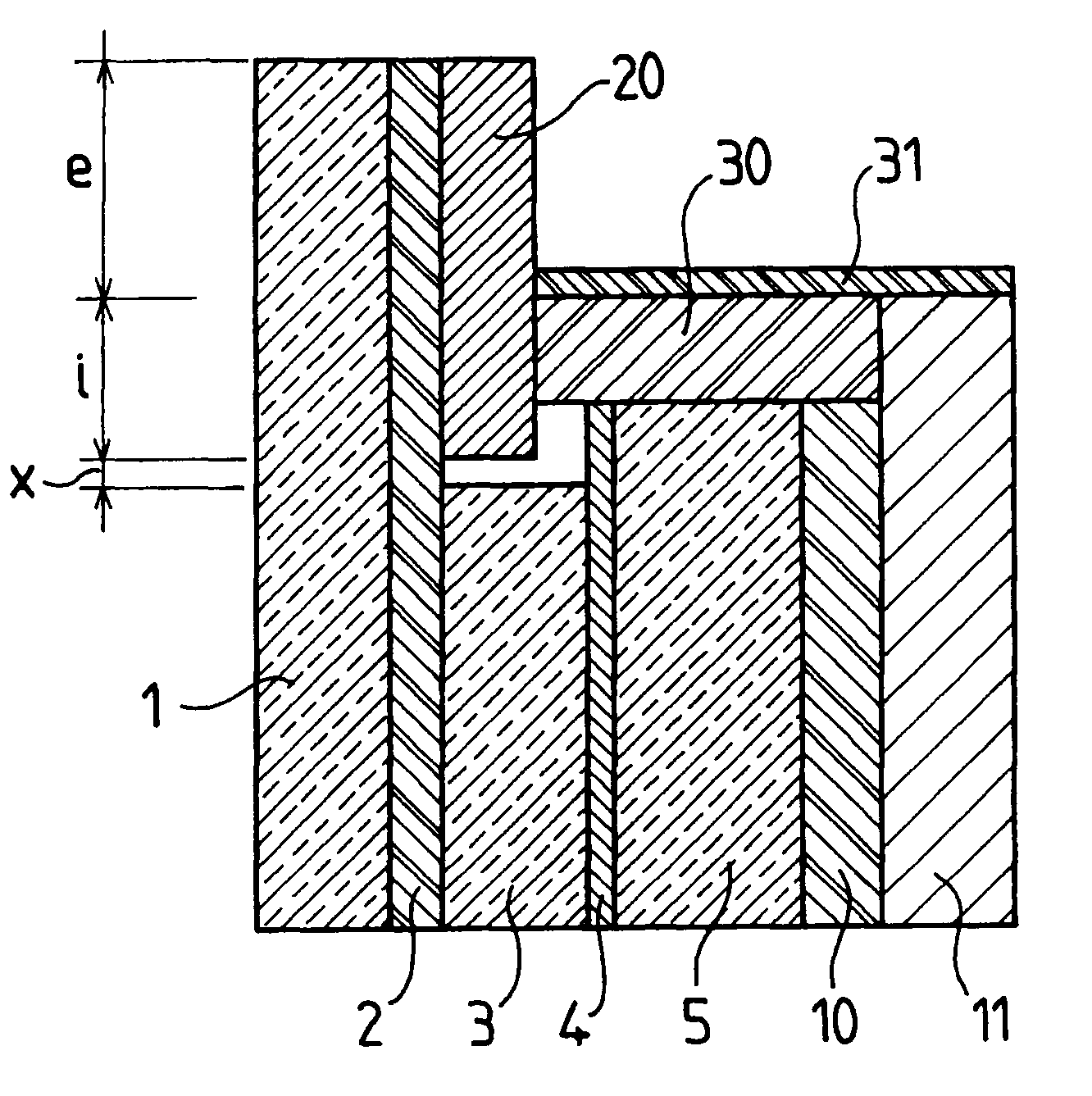

Ballistic resistant laminated structure

ActiveUS7908958B2Prevent penetrationInhibition effectDefensive equipmentArmoured vehiclesEngineeringGlass sheet

The invention relates to a ballistic resistant laminated structure comprising at least three glass sheets (1, 3, 5) a polycarbonate sheet (11) which are bound by adhesive layers (2, 4, 10) and a shielding insert (20), wherein a space delimited by said insert (20), the end face of the sheet (5) and the edge of the sheet (11) are provided with a material (30, 31) for absorbing the energy of a projectile. Said materials (30, 31) are embodied in the form of an yielding material (30) for degassing during assembling said stricture and an encapsulating material (31). A highly ballistic resistant glazing for a building or a transport vehicle comprising the inventive structure is also disclosed.

Owner:ISOCLIMA

Low cost, high performance flexible reinforcement for communications cable

InactiveUS7435909B2Low costImprove performanceFlat/ribbon cablesFibre mechanical structuresEngineeringCopper

A low cost, high performance flexible reinforcement member that can be used for both optical and copper communications cable. The reinforcement members made according to the preferred process are more rigid than known reinforcement members, but are less rigid than glass pultruded rods. Communications cables utilizing these members are lightweight and exhibit an improved combination of strength and flexibility compared to traditional communications cables. Further, these communication cables may then be installed into underground ducts using more economical and faster installation techniques.

Owner:NEPTCO JV LLC

Eccentric linkage gripper

ActiveUS9488020B2Sufficient mechanical propertyMinimize their detrimental effectBorehole drivesBorehole/well accessoriesAxial forceWellbore

A gripper mechanism for a downhole tool is disclosed that includes an eccentric linkage mechanism. In operation, an axial force generated by a power section of the gripper expands the linkage mechanism, which applies a radial force to the interior surface of a wellbore or passage. A sliding portion allows the gripper to slide along a surface of the formation in response to the radial force applied to the interior surface of the wellbore or passage.

Owner:WWT NORTH AMERICA HLDG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com