Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "Molar mass distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

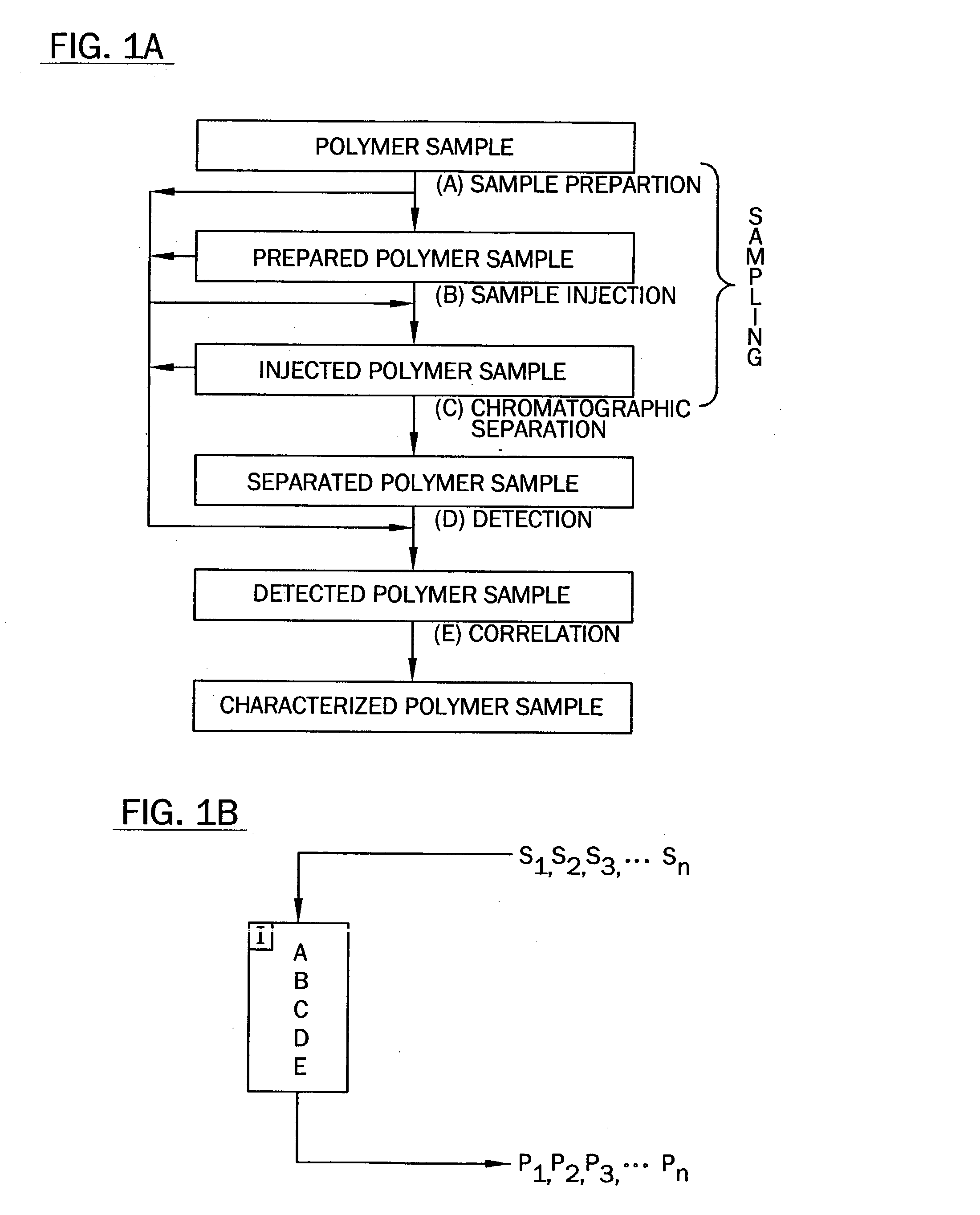

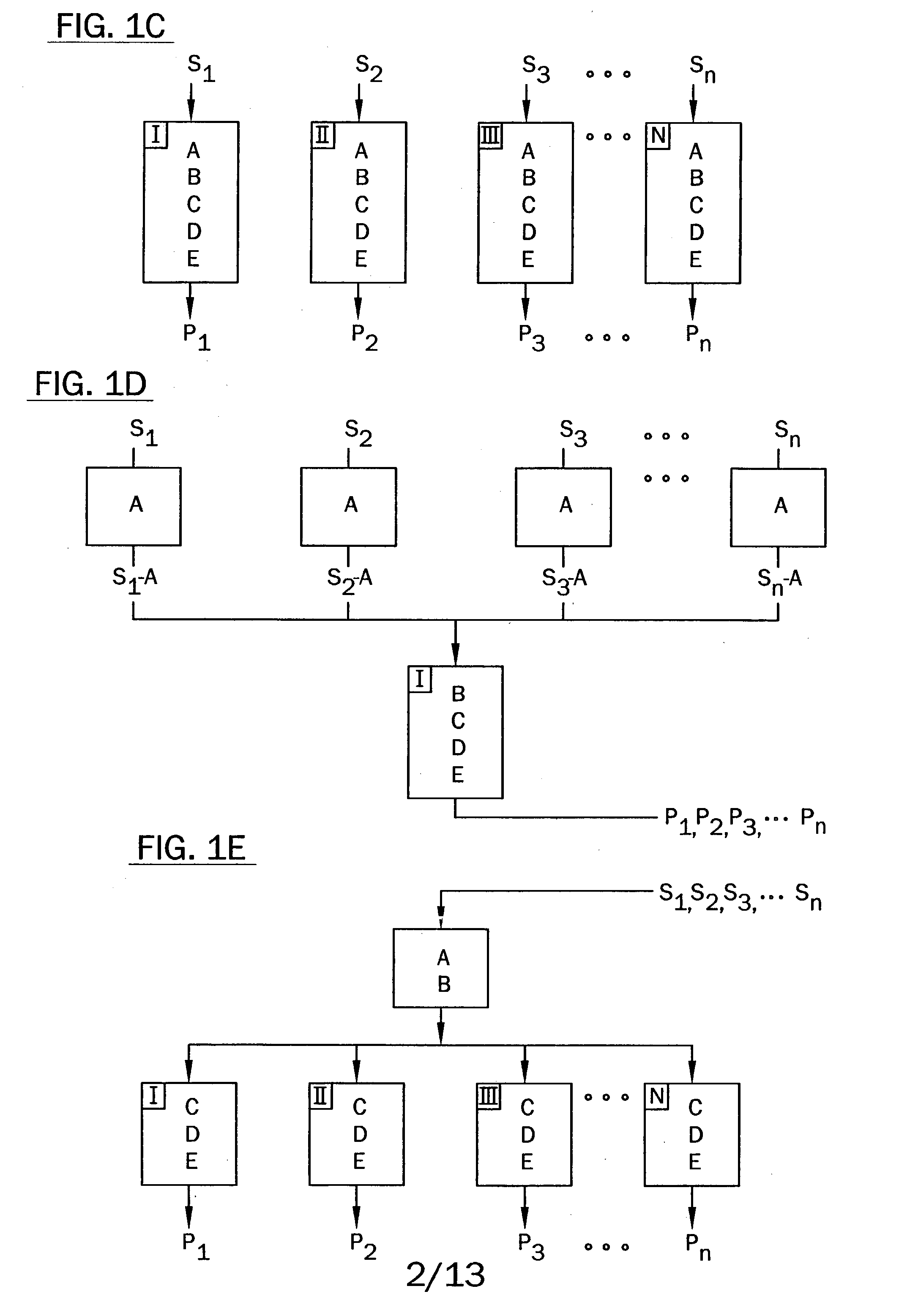

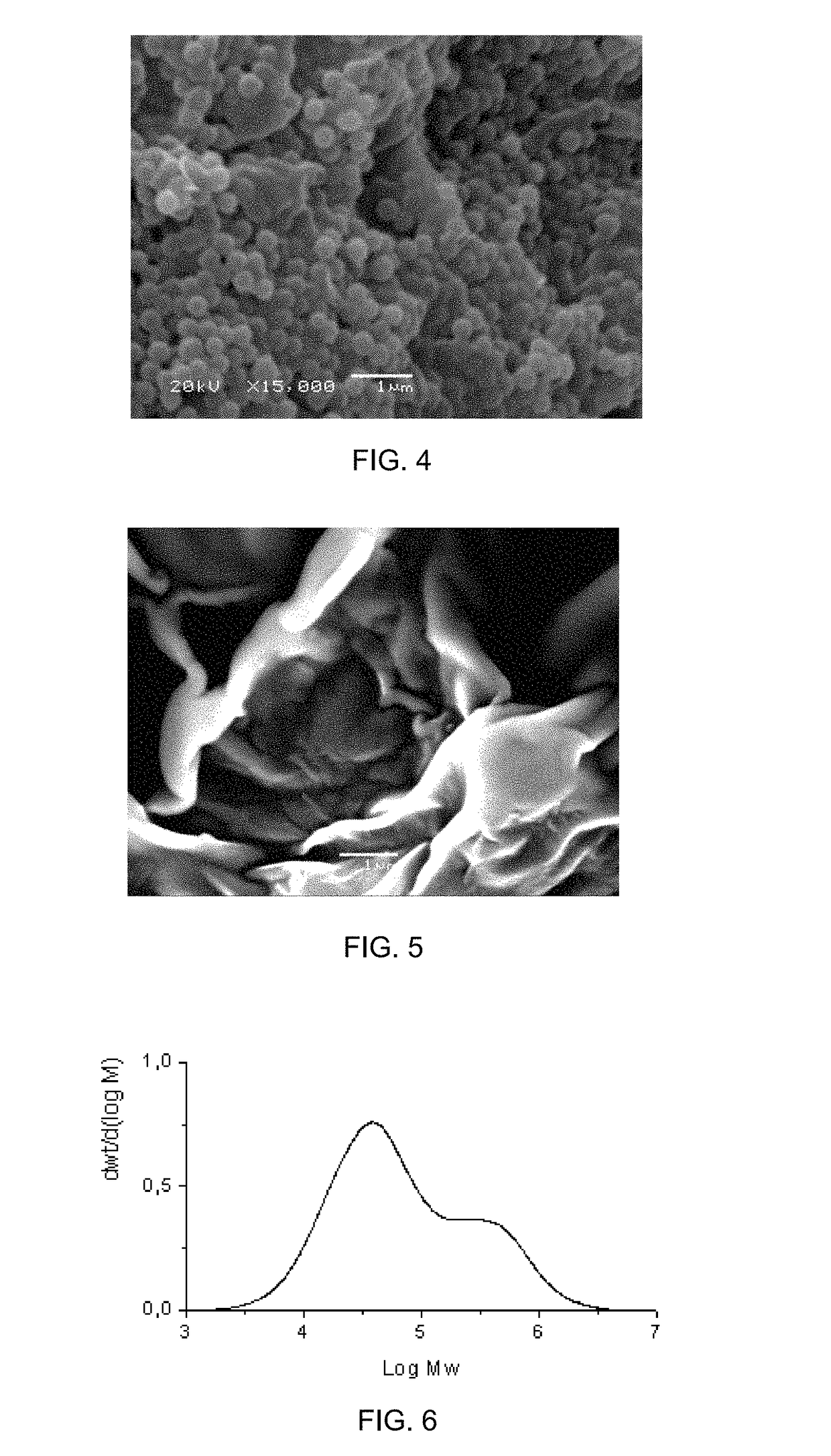

In linear polymers the individual polymer chains rarely have exactly the same degree of polymerization and molar mass, and there is always a distribution around an average value. The molar mass distribution (or molecular weight distribution) describes the relationship between the number of moles of each polymer species (Nᵢ) and the molar mass (Mᵢ) of that species. The molar mass distribution of a polymer may be modified by polymer fractionation.

Fiber optic apparatus and use thereof in combinatorial material science

InactiveUS6519032B1Facilitate the discovery of commercially important polymericEffectively and efficiently characterizingSequential/parallel process reactionsComponent separationFiberHigh-Throughput Screening Methods

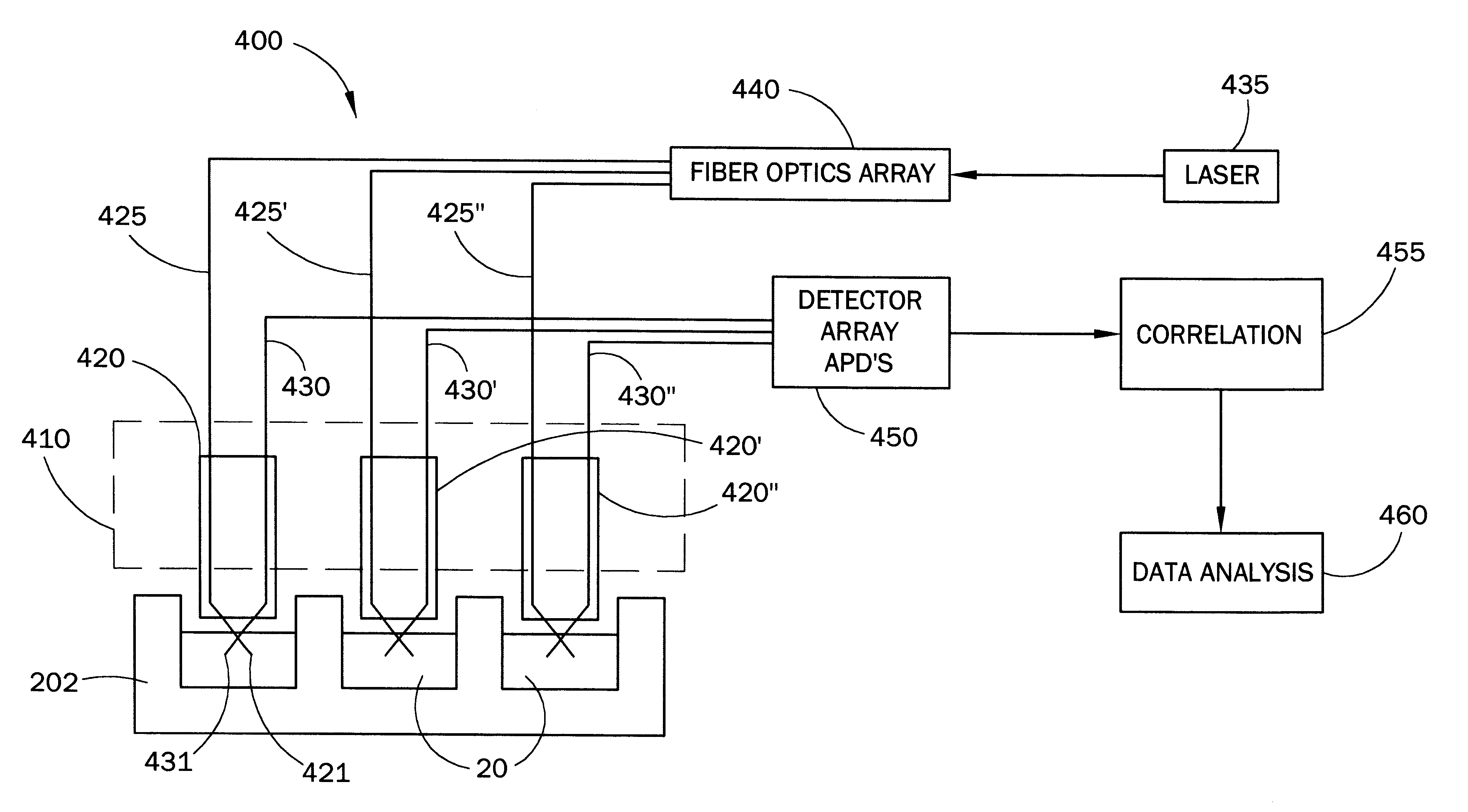

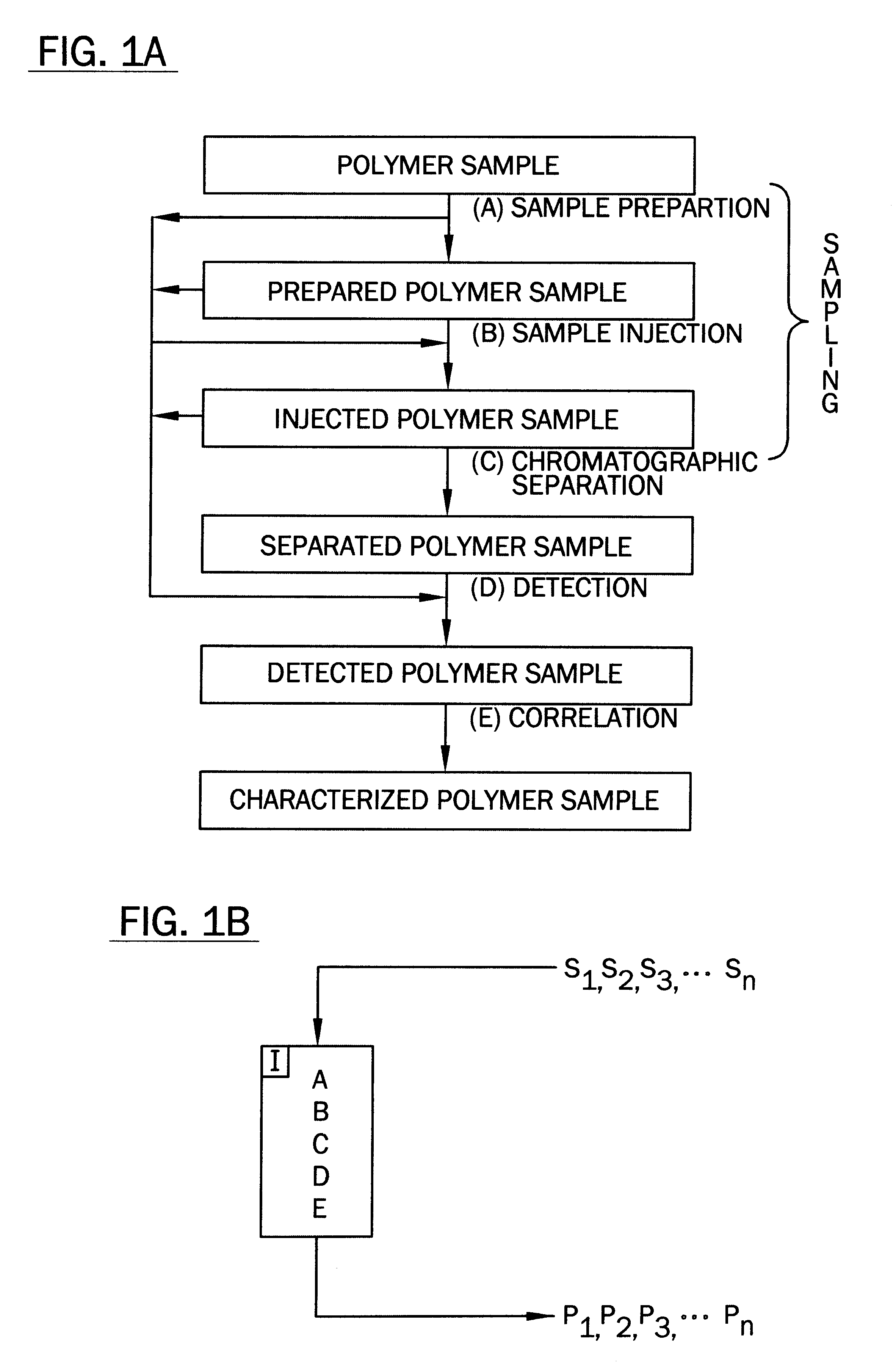

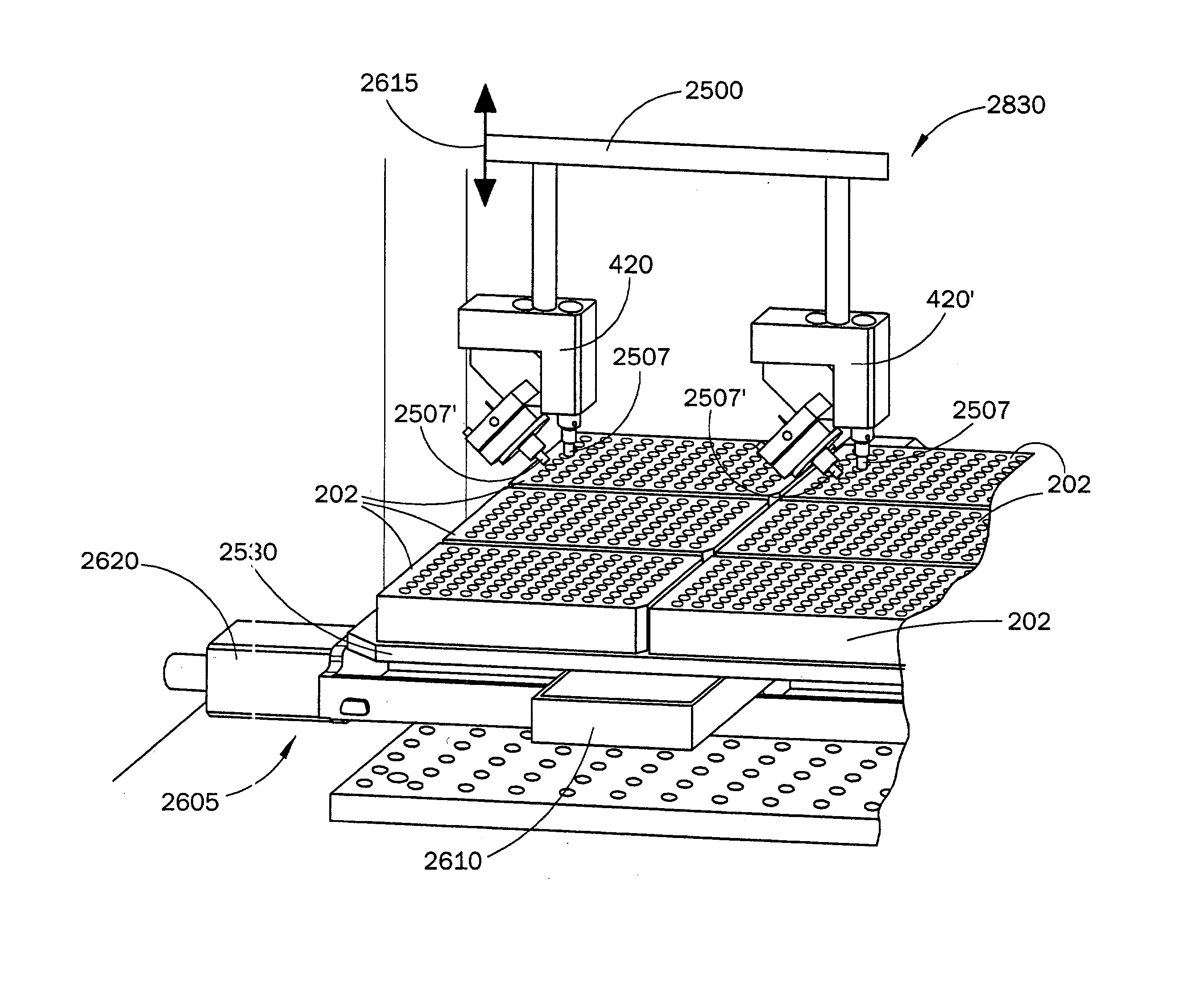

Methods, systems and devices are described for rapid characterization and screening of liquid samples to determine properties (e.g., particle size, particle size distribution, molar mass and / or molar mass distribution) thereof with static light scattering and / or dynamic light scattering. The liquid samples can be solutions, emulsions, suspensions or dispersions. One method, includes providing a vessel containing a liquid sample having an exposed surface that defines a gas-liquid sample interface, and analyzing the sample by light scattering methods that include transmitting light through the gas-liquid sample interface into the sample, and detecting light scattered from the sample or from a component thereof. Additional methods are directed to characterizing a plurality of liquid samples or components thereof. The methods, systems, and devices have applications in high-throughput screening, and particularly, in combinatorial materials research and in industrial process control.

Owner:WYATT TECH

Fiber optic apparatus and use thereof in combinatorial material science

InactiveUS20030142309A1Facilitate the discovery of commercially important polymericSequential/parallel process reactionsSamplingFiberHigh-Throughput Screening Methods

Methods, systems and devices are described for rapid characterization and screening of liquid samples to determine properties (e.g., particle size, particle size distribution, molar mass and / or molar mass distribution) thereof with static light scattering and / or dynamic light scattering. The liquid samples can be solutions, emulsions, suspensions or dispersions. One method, includes providing a vessel containing a liquid sample having an exposed surface that defines a gas-liquid sample interface, and analyzing the sample by light scattering methods that include transmitting light through the gas-liquid sample interface into the sample, and detecting light scattered from the sample or from a component thereof. Additional methods are directed to characterizing a plurality of liquid samples or components thereof. The methods, systems, and devices have applications in high-throughput screening, and particularly, in combinatorial materials research and in industrial process control.

Owner:WYATT TECH

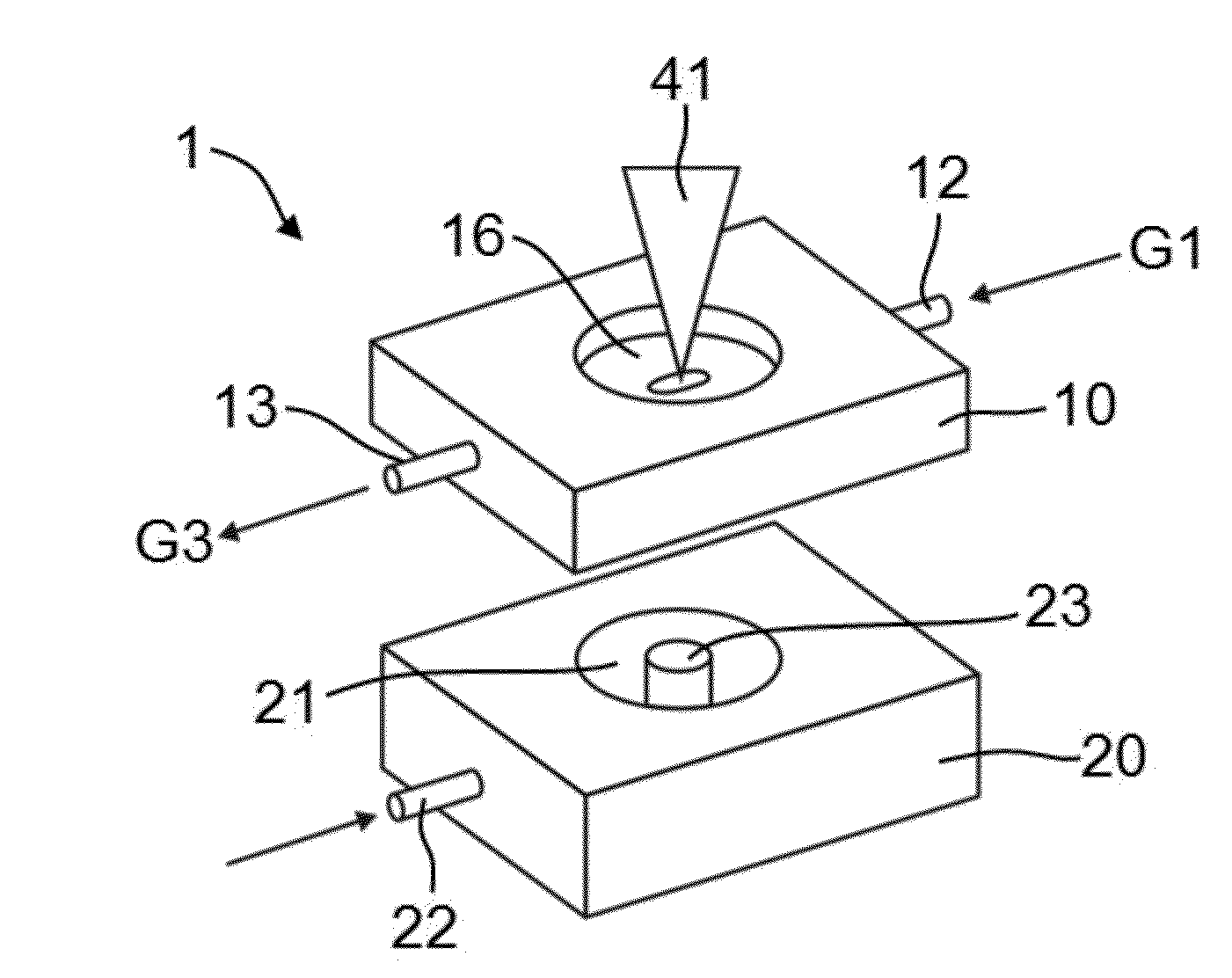

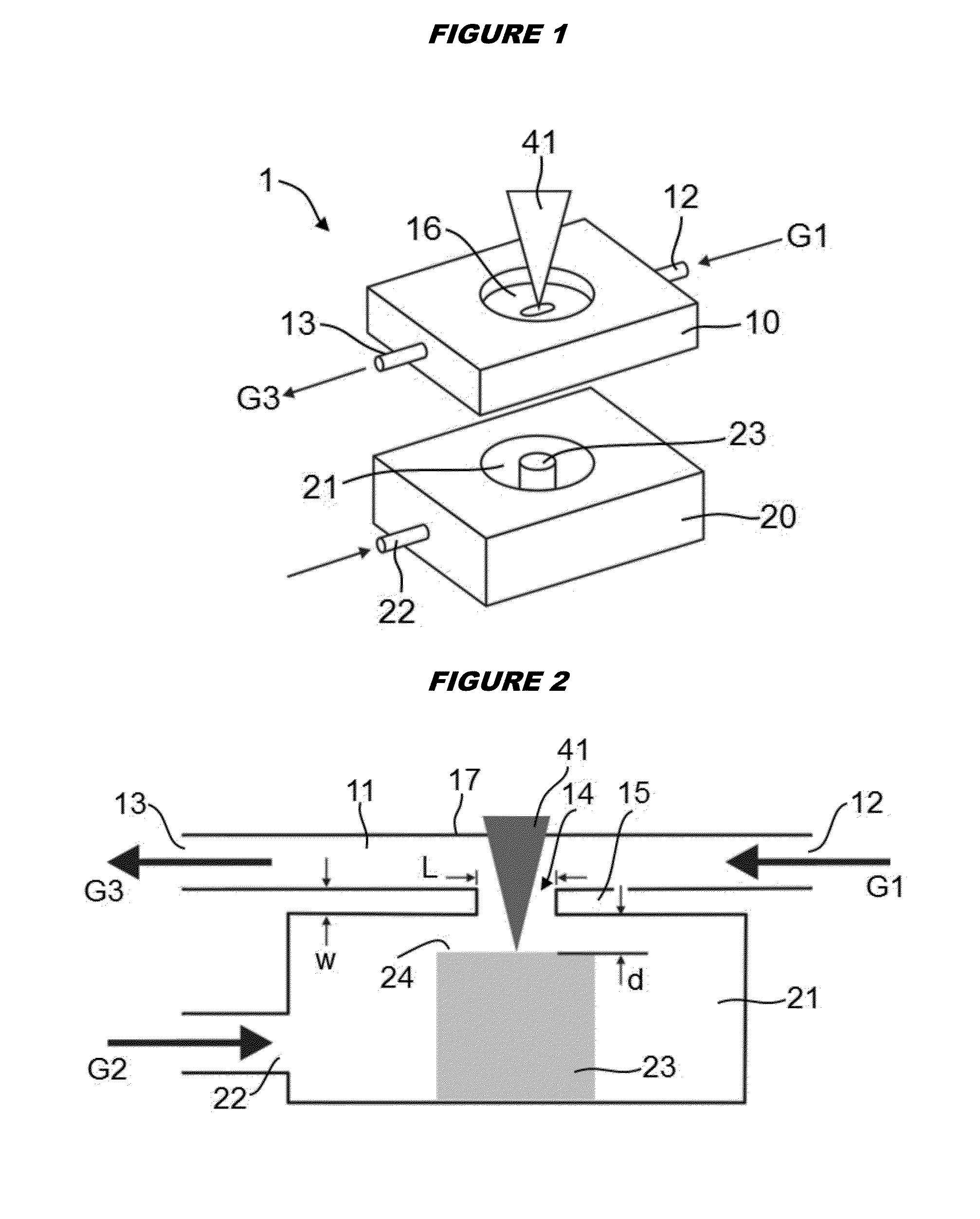

Laser ablation cell

ActiveUS20140287953A1Short aerosol washout timeShort timeTime-of-flight spectrometersSamples introduction/extractionMolar mass distributionInductively coupled plasma

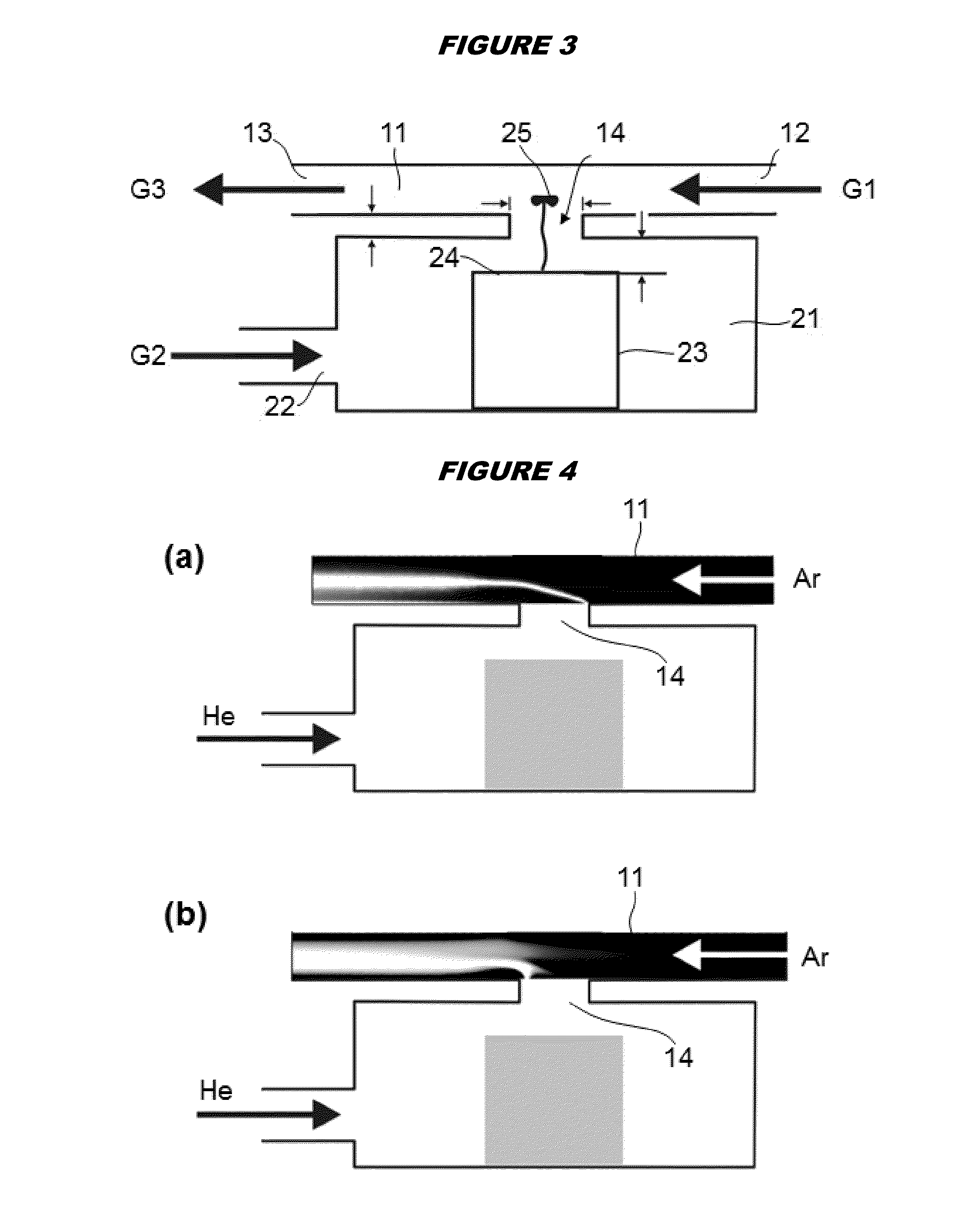

A laser ablation cell (1) comprises a flow channel (11) having an essentially constant cross-sectional area so as to ensure a strictly laminar flow in the flow channel. A sample chamber (21) is provided adjacent to a lateral opening (14) of the flow channel. A laser beam (41) enters the sample chamber (21) through a lateral window (16) and impinges on a surface (24) of a sample (23) to ablate material from the sample. The sample may be positioned in such a distance from the flow channel that the laser-generated aerosol mass distribution has its center within the flow channel. This leads to short aerosol washout times. The laser ablation cell is particularly well suited for aerosol generation in inductively coupled plasma mass spectrometry (ICPMS), including imaging applications.

Owner:ETH ZZURICH +1

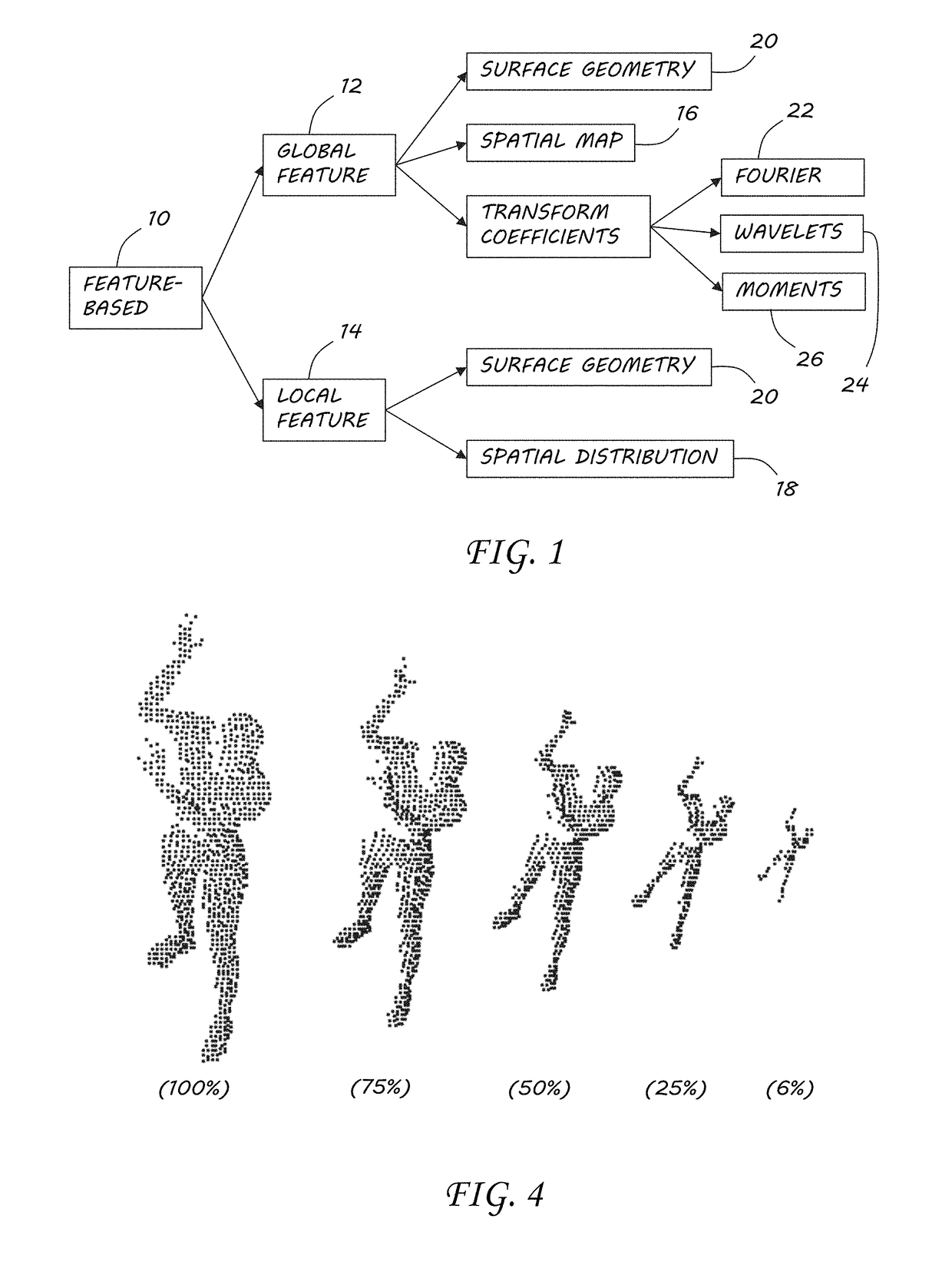

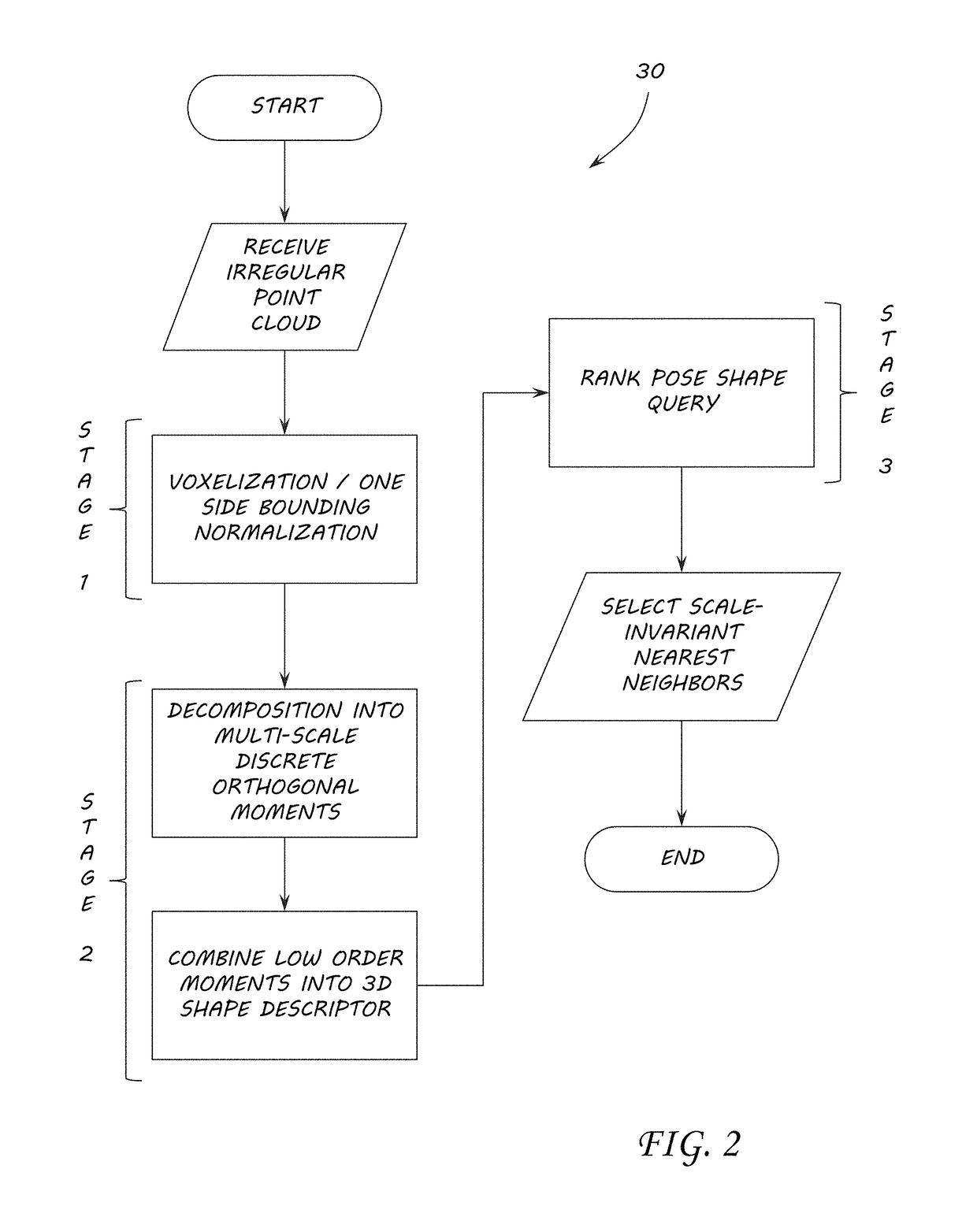

Tchebichef moment shape descriptor for partial point cloud characterization

A process and apparatus are provided to characterize low-resolution partial point clouds for object recognition or query. A partial point cloud representation of an object is received. Zero and first order geometric moments of the partial point cloud are computed. A location of a center of a point cloud mass is computed using the geometric moments. A cubic bounding box is generated centered at the location of the mass center of the point cloud, with one side of the box bounding the point cloud at its longest semi-axis. The bounding box is divided into a three dimensional grid. A normalized voxel mass distribution is generated over the three dimensional grid. Tchebichef moments of different orders are calculated with respect to the voxel mass distribution in the grid. Low-order moments are collected to form TMSDs. Similarity is compared between the TMSD of the point cloud with TMSDs of other point clouds.

Owner:GOVERNMENT OF THE UNITED STATES AS REPRESENTED BY THE SEC OF THE AIR FORCE

Polyethylene Molding Composition for Producing Blown Films Having Improved Mechanical Properties and Processability

InactiveUS20080199674A1Good drawing effectAdequate film bubble stabilitySynthetic resin layered productsCeramic shaping apparatusBlow moldingMolar mass distribution

The invention relates to a polyethylene molding composition having a multimodal molar mass distribution particularly suitable for blow molding films having a thickness in the range from 8 to 200 μm. The molding composition has a density at a temperature of 23° C. in the range from 0.948 to 0.953 g / cm3 and an MFR190 / 5 of the final product after extrusion in the range from 0.10 to 0.50 dg / min. The composition comprises from 30 to 60% by weight of a first ethylene polymer fraction made of a homopolymer A having a first molecular weight, from 22 to 40% by weight of a second ethylene polymer fraction made of a further homopolymer or first copolymer B of ethylene and at least one first comonomer from the group of olefins having from 4 to 8 carbon atoms, the first copolymer B having a second molecular weight higher than the first molecular weight, and from 10 to 30% by weight of a third ethylene polymer fraction made of a second copolymer C having a third molecular weight higher than the second molecular weight. The molding composition of the invention allows to produce films having a good balance between processability and mechanical properties.

Owner:BASELL POLYOLEFINE GMBH

Polyethylene Molding Composition for Producing Blown Films Having Improved Mechanical Properties

InactiveUS20080166535A1Improve bubble stabilitySynthetic resin layered productsPolymer scienceDrop impact

The invention relates to a polyethylene molding composition having a multimodal molar mass distribution particularly suitable for blow molding films having a thickness in the range from 8 to 200 μm. The molding composition has a density at a temperature of 23° C. in the range from 0.940 to 0.948 g / cm3 and an MFR190 / 5 of the final product after extrusion in the range from 0.10 to 0.50 dg / min. The composition comprises from 40 to 60% by weight of a first ethylene polymer fraction made of a homopolymer A having a first molecular weight, from 25 to 45% by weight of a second ethylene polymer fraction made of a first copolymer B of ethylene and at least one first comonomer from the group of olefins having from 4 to 8 carbon atoms, the first copolymer B having a second molecular weight higher than the first molecular weight, and from 10 to 30% by weight of a third ethylene polymer fraction made of a second copolymer C having a third molecular weight higher than the second molecular weight. The molding composition of the invention allows to produce thin films having improved mechanical properties, in particular in terms of dart drop impact strength, at a high take-off speed without impairing the film bubble stability.

Owner:BASELL POLYOLEFINE GMBH

Films having improved mechanical properties

A blown film having a thickness from 8 to 200 μm and dart drop impact DDI of more than 400 g, comprising a polyethylene molding composition having a multimodal molar mass distribution; a density from 0.940 to 0.948 g / cm3; an MFR190 / 5, from 0.10 to 0.50 dg / min; comprising:40 to 60% of an ethylene homopolymer A having a molecular weight;25 to 45% of a copolymer B of ethylene and at least one comonomer selected from the group of olefins having from 4 to 8 carbon atoms, said copolymer B having a molecular weight higher than said molecular weight of homopolymer A; and10 to 30% of a copolymer C of ethylene and at least one comonomer, said copolymer C having a molecular weight higher than said molecular weight of copolymer B,all percentages being based on the total weight of the molding composition.

Owner:BASELL POLYOLEFINE GMBH

Process for preparing a blown film from a polyethylene molding composition

InactiveUS20110171450A1Improve stabilityReduce pressureSynthetic resin layered productsBlow moldingMolar mass distribution

The invention relates to a polyethylene molding composition having a multimodal molar mass distribution particularly suitable for blow molding films having a thickness in the range from 8 to 200 μm. The molding composition has a density at a temperature of 23° C. in the range from 0.948 to 0.953 g / cm3 and an MFR190 / 5 of the final product after extrusion in the range from 0.10 to 0.50 dg / min. The composition comprises from 30 to 60% by weight of a first ethylene polymer fraction made of a homopolymer A having a first molecular weight, from 22 to 40% by weight of a second ethylene polymer fraction made of a further homopolymer or first copolymer B of ethylene and at least one first comonomer from the group of olefins having from 4 to 8 carbon atoms, the first copolymer B having a second molecular weight higher than the first molecular weight, and from 10 to 30% by weight of a third ethylene polymer fraction made of a second copolymer C having a third molecular weight higher than the second molecular weight. The molding composition of the invention allows to produce films having a good balance between processability and mechanical properties.

Owner:BASELL POLYOLEFINE GMBH

Wind-power blade preparation method capable of controlling mass distribution

ActiveCN105383074ASingle point counterweight avoid or reduceSingle point counterweight reductionDomestic articlesElectricityMolar mass distribution

The invention belongs to the technical field of nonmetallic composite material machining and forming and mainly relates to a wind-power blade preparation method capable of controlling mass distribution. The wind-power blade preparation method capable of controlling the mass distribution comprises the steps of preparation of a blade upper shell, preparation of a blade lower shell, preparation of a front edge web, preparation of a rear edge web, preparation of a girder and blade die assembly and adhesion forming. Control over the weight and mass distribution is conducted in the processes of the preparation of the blade upper shell, preparation of the blade lower shell, preparation of the front edge web, preparation of the rear edge web, preparation of the girder and blade die assembly and adhesion, and thus control over the mass distribution of the wind-power blade is achieved. The final mass distribution of the blade can be controlled within a certain range, later-stage single-point balance weight of the blade is avoided or reduced, and the quality and security risks of the single-point balance weight are reduced.

Owner:LUOYANG SUNRUI WIND TURBINE BLADE

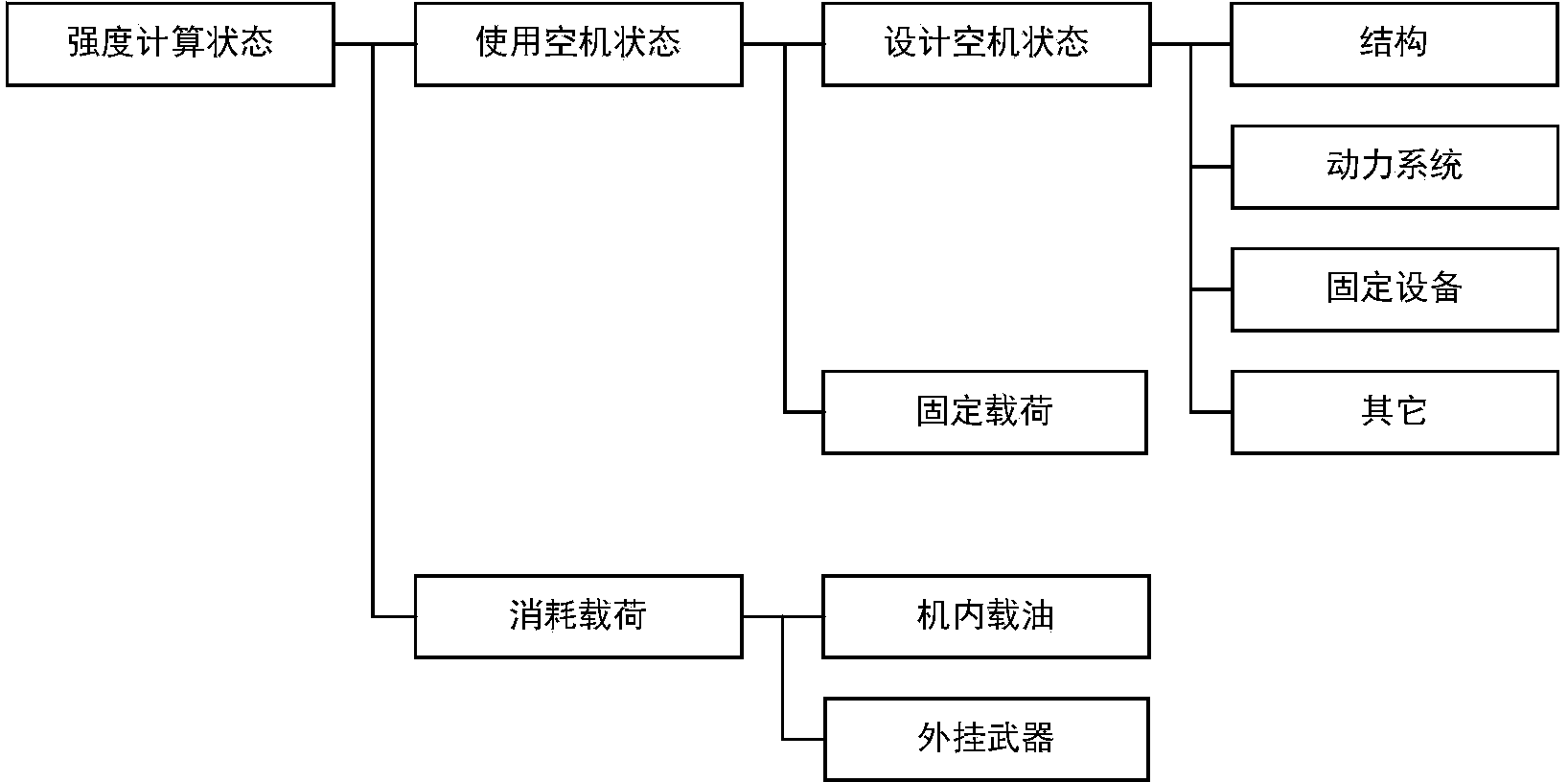

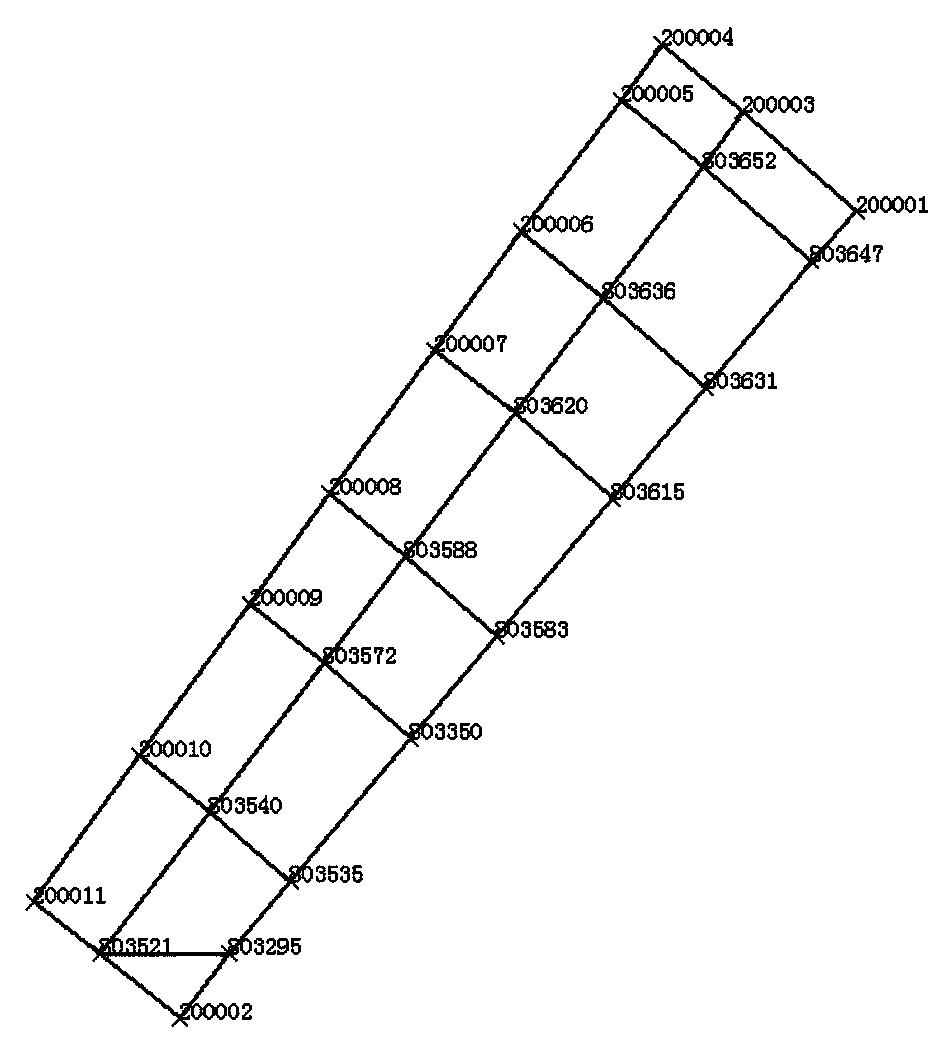

Computation method for mass distribution of aircraft

InactiveCN104166756ARealize digital engineering applicationsImprove calculation accuracySpecial data processing applicationsMolar mass distributionOriginal data

The invention provides a computation method for mass distribution of an aircraft, and belongs to the engineering field of aircraft weight. The computation method is characterized by comprising the steps of analysis of computation requirements, collection of original data, classified computation and summarization of the data. Data of mass distribution of the full aircraft can be obtained. The computation method has the advantages that digitization engineering application of computational analysis of mass distribution of the aircraft is achieved; the computational accuracy and the computational efficiency are greatly improved compared with a traditional method; the computation result does not rely on engineering application experience of engineers, and therefore influence of human factors on the computation data is reduced.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

Method for producing non-colored polyacrylate adhesive compounds with a narrow molar mass distribution

ActiveUS20140288242A1Increase response rateFully moistenedEster polymer adhesivesMolar mass distributionColor reaction

Method for producing polyacrylate adhesive compounds with a narrow molar mass distribution by radical polymerization and subsequent decolorization of colored reaction products resulting therefrom.

Owner:TESA SE

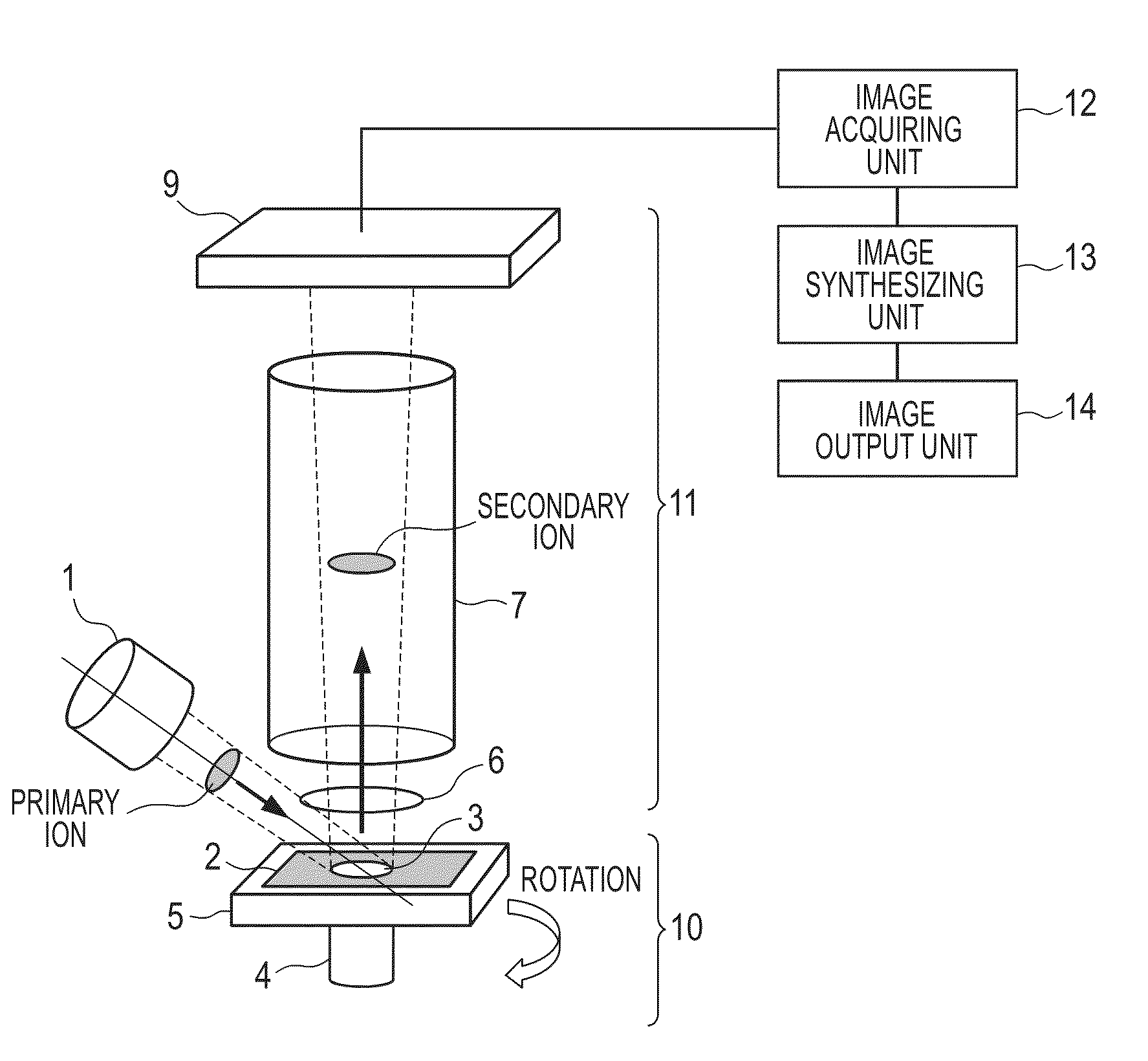

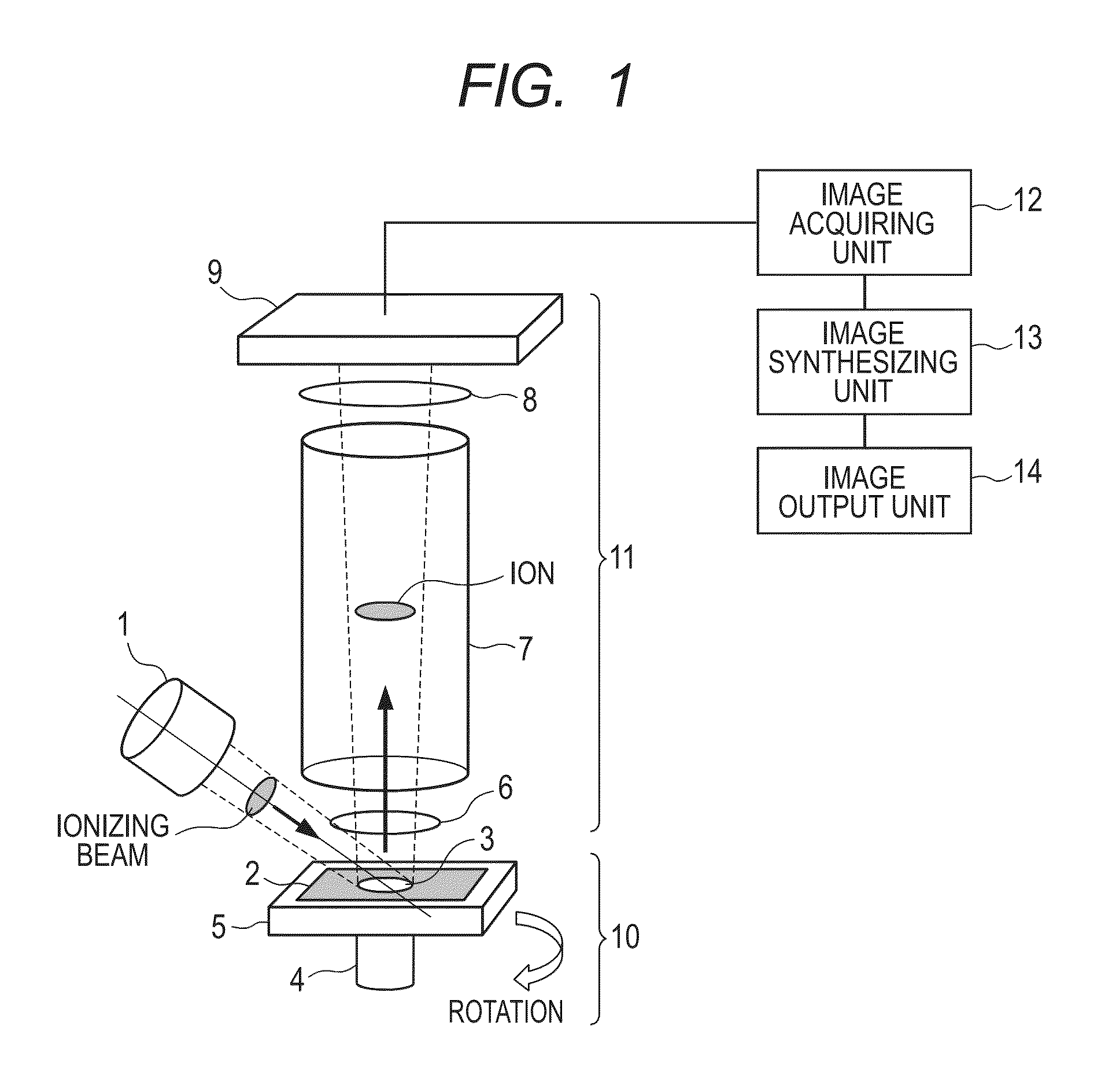

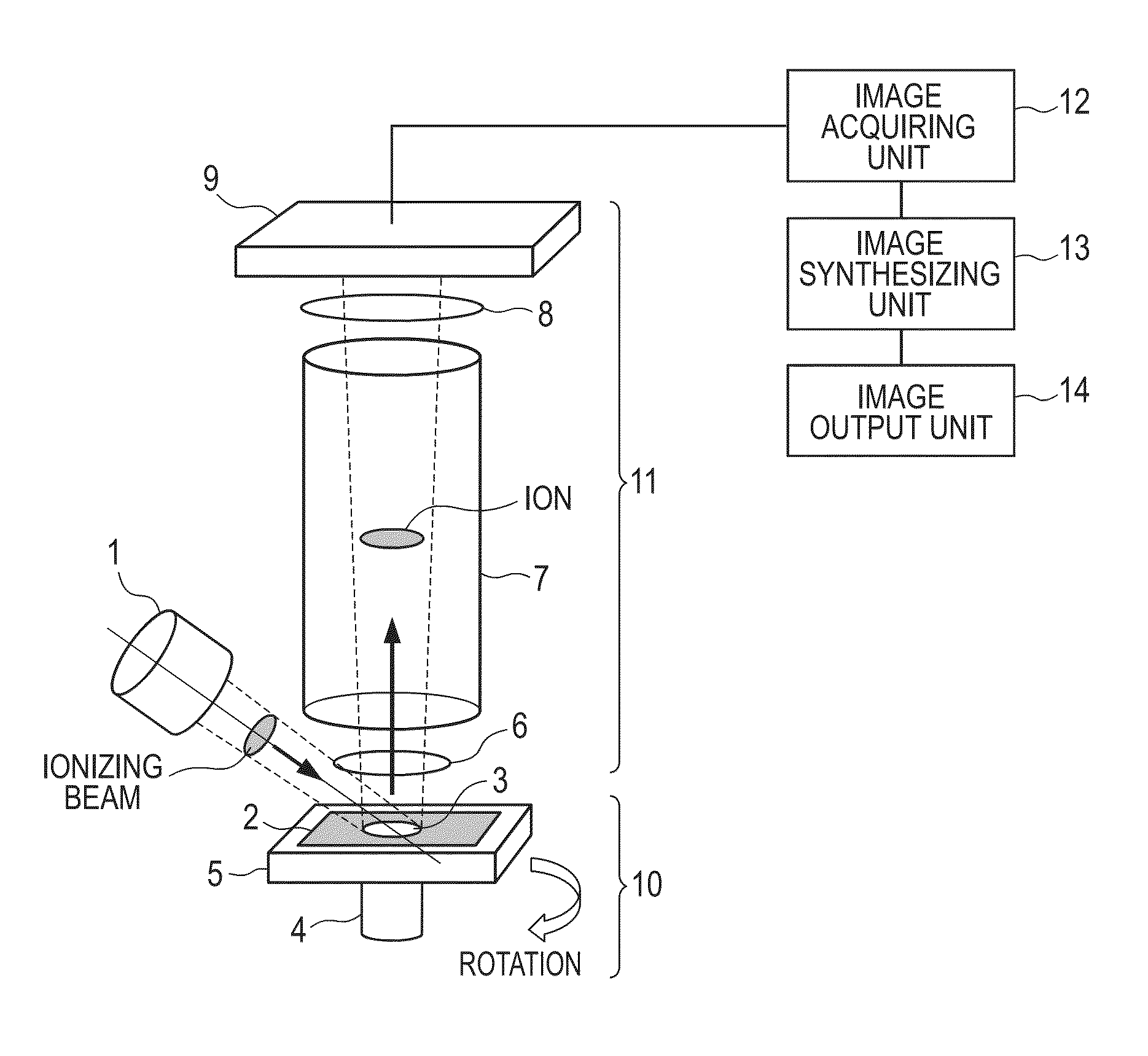

Mass distribution measuring method and mass distribution measuring apparatus

InactiveUS20130092831A1High affinityEasy to useIsotope separationImaging particle spectrometryMolar mass distributionMass Spectrometry-Mass Spectrometry

To provide a method that reduces an influence of dependence of an ionizing beam in an incident direction or uneven irradiation to a sample on a result of mass spectrometry, and can measure mass distribution with high reliability. A mass distribution measuring method according to the present invention includes: changing a direction of irradiating the ionizing beam to a sample surface; acquiring a plurality of mass distribution images in a plurality of incident directions; performing image transform of the mass distribution images according to an angle formed by an incident direction of the ionizing beam and a substrate surface; synthesizing the plurality of transformed images; and outputting the synthesized mass distribution images.

Owner:CANON KK

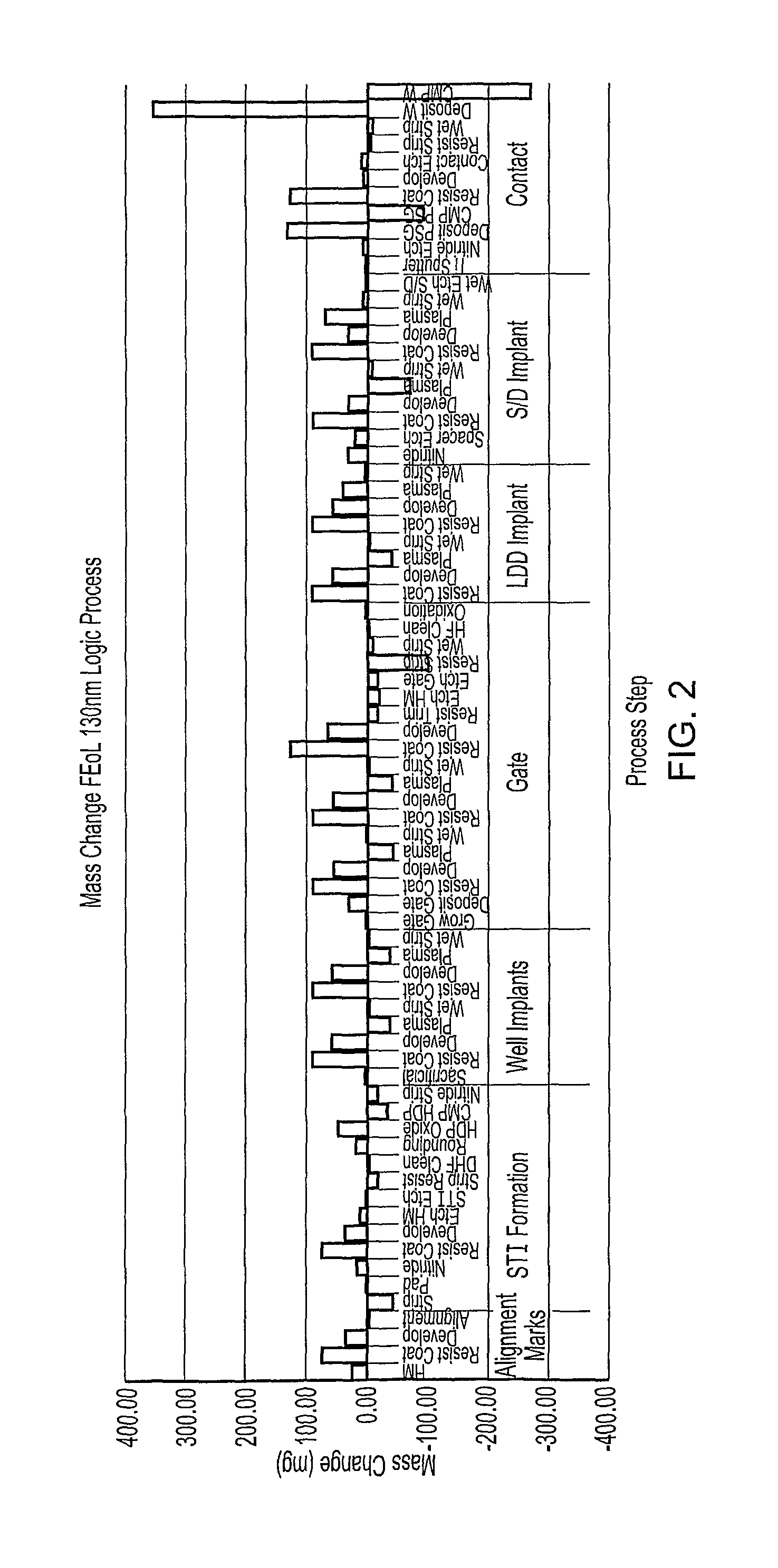

Method of controlling semiconductor device fabrication

ActiveUS8364302B2Information can be usedEasy to detectSemiconductor/solid-state device testing/measurementComputer controlMetrologyPower flow

A semiconductor wafer fabrication metrology method in which process steps are characterized by a change in wafer mass, whereby during fabrication mass is used as a measurable parameter to implement statistical process control on the one or more of process steps. In one aspect, the shape of a measured mass distribution is compared with the shape of a predetermined characteristic mass distribution to monitor the process. An determined empirical relationship between a control variable of the process and the characteristic mass change may enable differences between the measured mass distribution and characteristic mass distribution to provide information about the control variable. In another aspect, the relative position of an individual measured wafer mass change in a current distribution provides information about individual wafer problems independently from general process problems.

Owner:METRYX

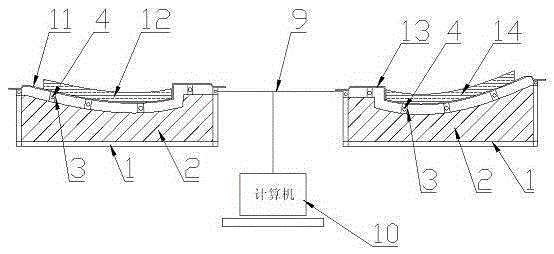

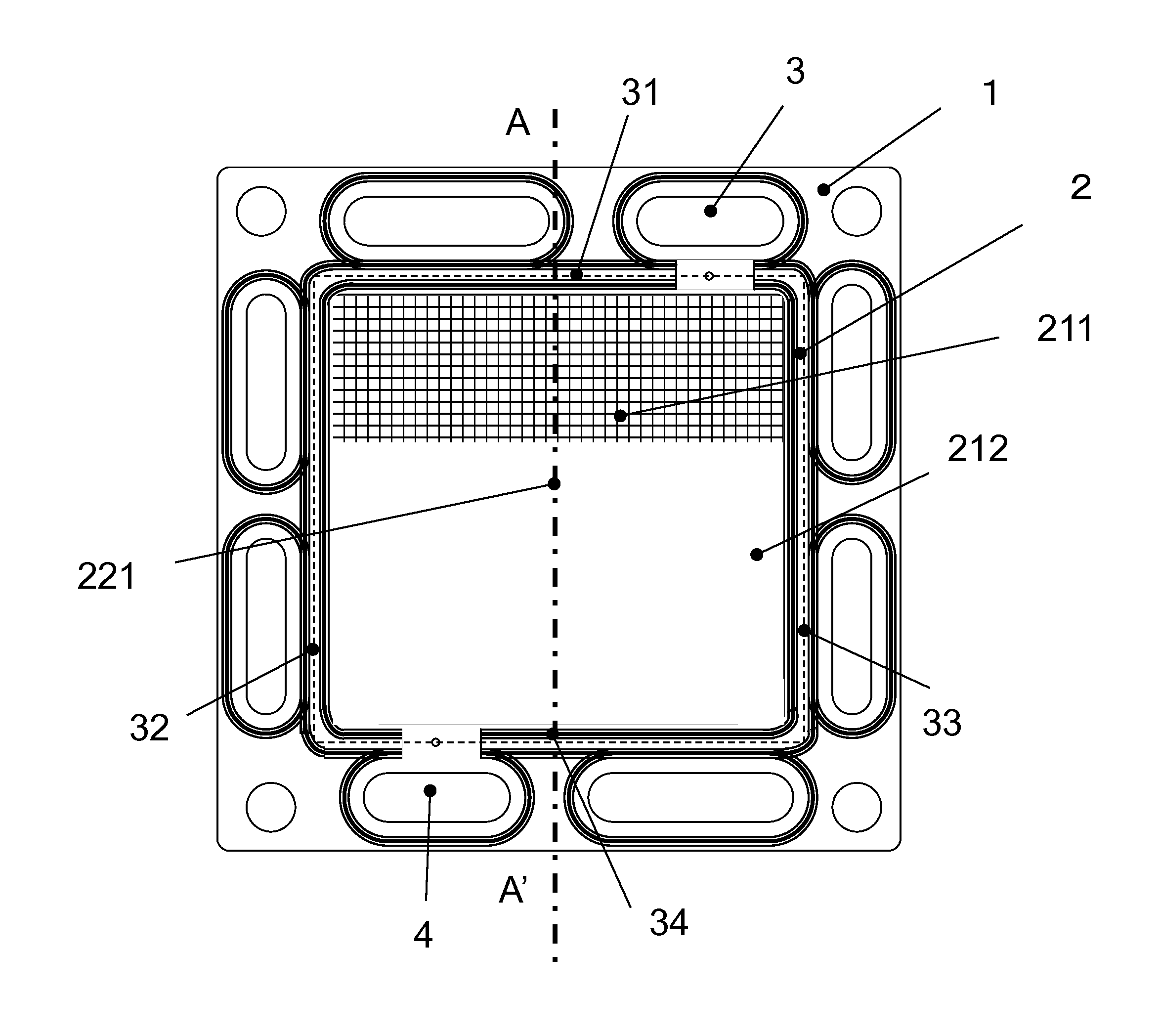

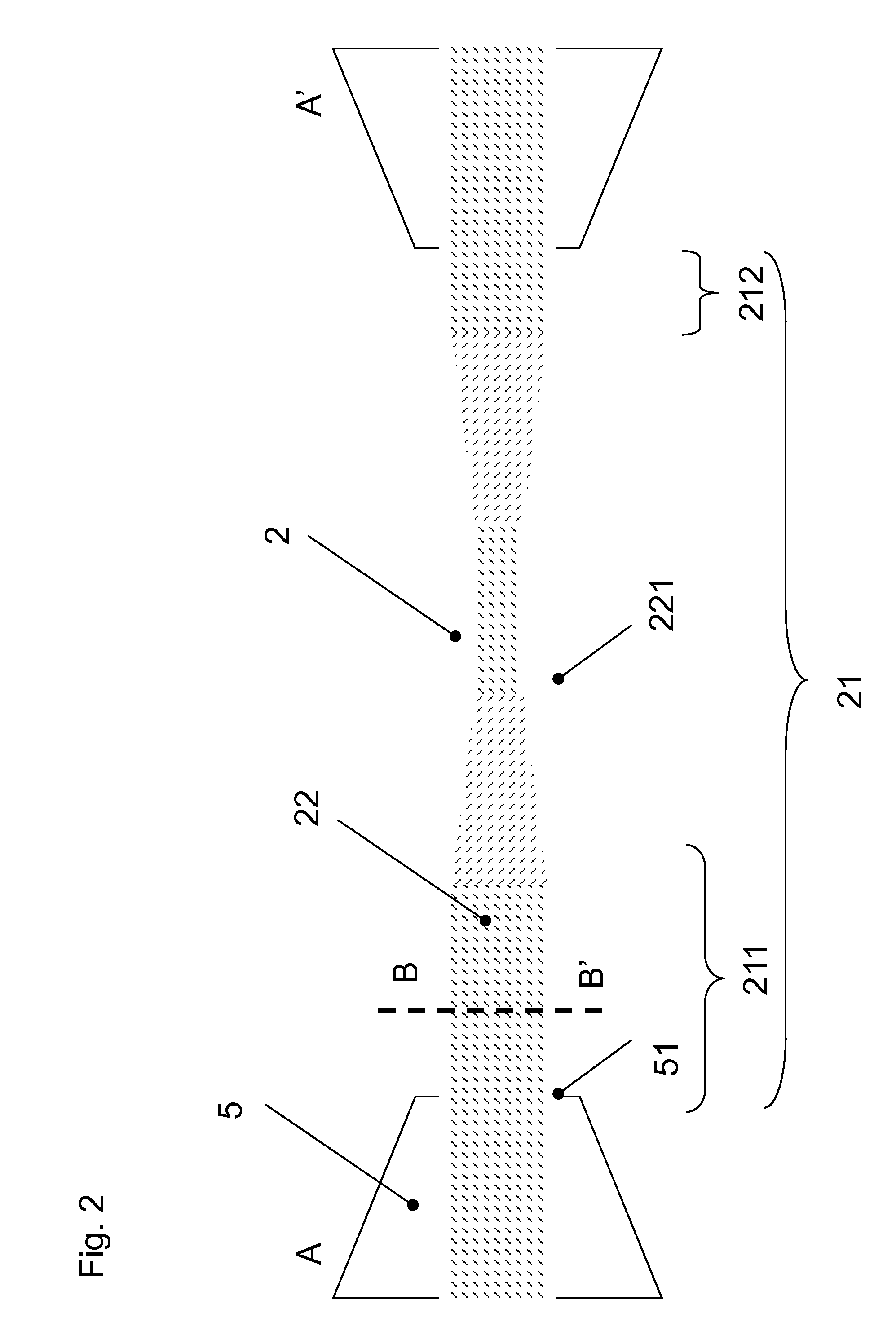

MEMS sensor-based fan blade vibration detection and control device

ActiveCN104898722AAvoid failurePrevent flutteringMechanical oscillations controlMolar mass distributionControl system

The invention provides an MEMS sensor-based fan blade vibration detection and control device, and consists of an MEMS sensor (1), a controller (2), a stepping motor (3), mass blocks (4), a slide rail (5) and a lead screw (6). The device changes the frequency of fan blades by controlling mass distribution of the mass blocks in the fan blades, thereby enabling the fan blades to be balanced, and achieving an effect of alleviating vibration. By adoption of a fan blade vibration active control system, blade vibration is effectively avoided, and preventing a fan failure from being caused.

Owner:SHENYANG INST OF ENG

Polyethylene and catalyst composition for its preparation

InactiveCN101935369AEfficient mixingReduce consumptionThin material handlingMolar mass distributionPolymer science

The invention relates to a polyethylene and catalyst composition for its preparation. Polyethylene which comprises ethylene homopolymers and / or copolymers of ethylene with 1- alkenes and has a molar mass distribution width MW / Mn of from 3 to 30, a density of from 0.945 to 0.965 g / cm3, a weight average molar mass Mw of from 50 000 g / mol to 200 000 g / mol, a HLMI of from 10 to 300 g / 10 min and has from 0.1 to 15 branches / 1000 carbon atoms, wherein the 1 to 15 % by weight of the polyethylene having the highest molar masses have a degree of branching of more than 1 branch of side chains larger than CH3 / 1000 carbon atoms, a process for its preparation, catalysts suitable for its preparation and also injection moldings in which this polyethylene is present.

Owner:BASELL POLYOLEFINE GMBH

Colloid particle size-mass distribution measurement technology

ActiveUS20180284005A1Reducing of degreeSmall sizeNanoparticle analysisParticle size analysisMolar mass distributionNebulizer

A system and method for measuring particle mass distributions as a function of particle diameter. The system includes a nebulizer, a particle size classifier and a particle detector. The system may include a dilution module. It may also include a particle mass classifier. The system and method are useful for distinguishing particle populations of similar size and different densities as well as determining the interaction between materials (binding) in mixed colloid systems with varying material ratios. The system and method are also useful for determining particle density in both homogeneous and heterogeneous colloids.

Owner:KANOMAX FMT INC

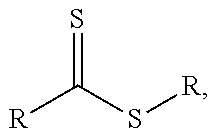

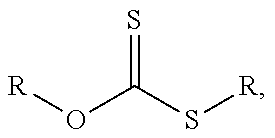

Functionalized polymers or contact adhesive masses

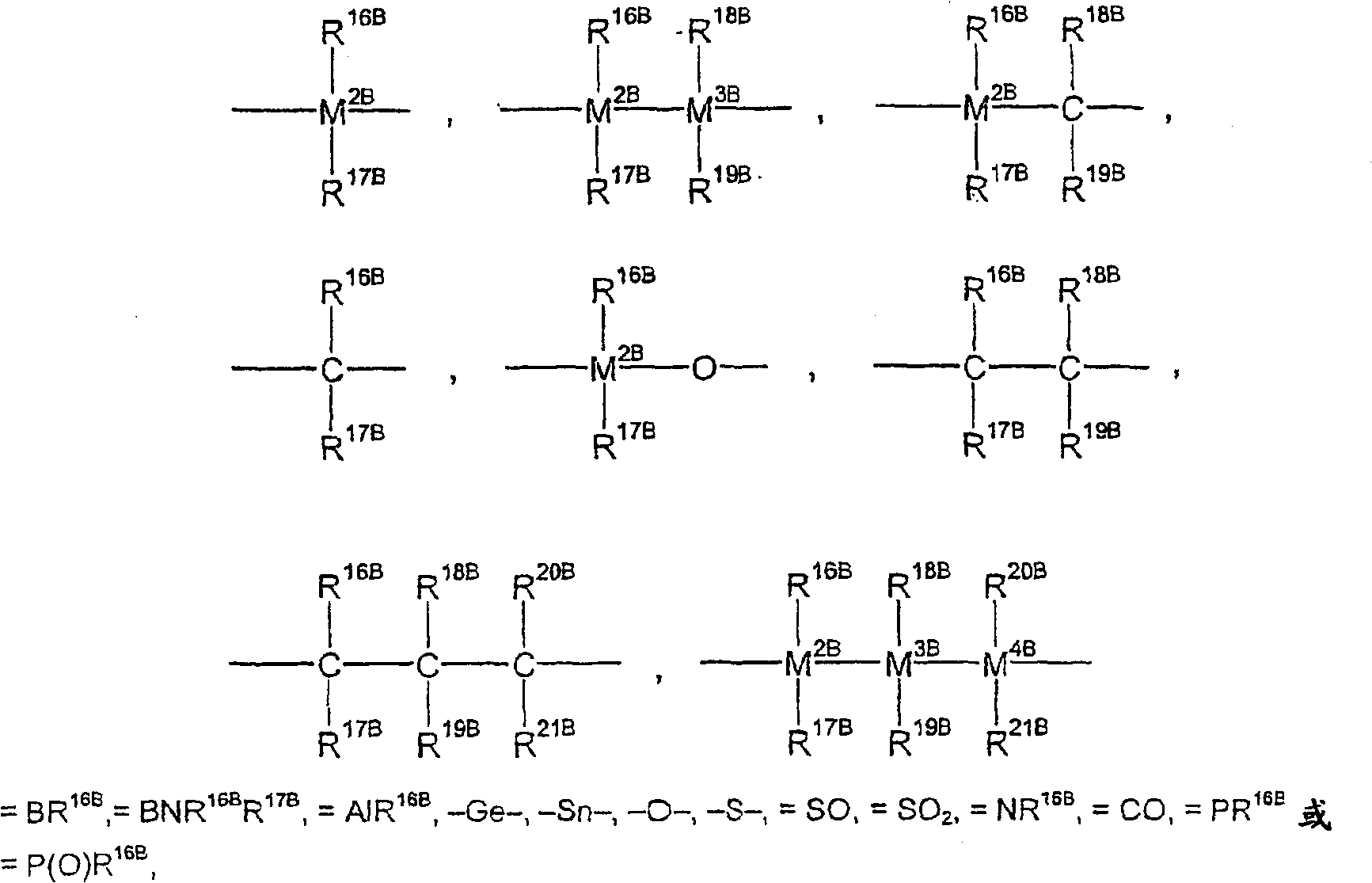

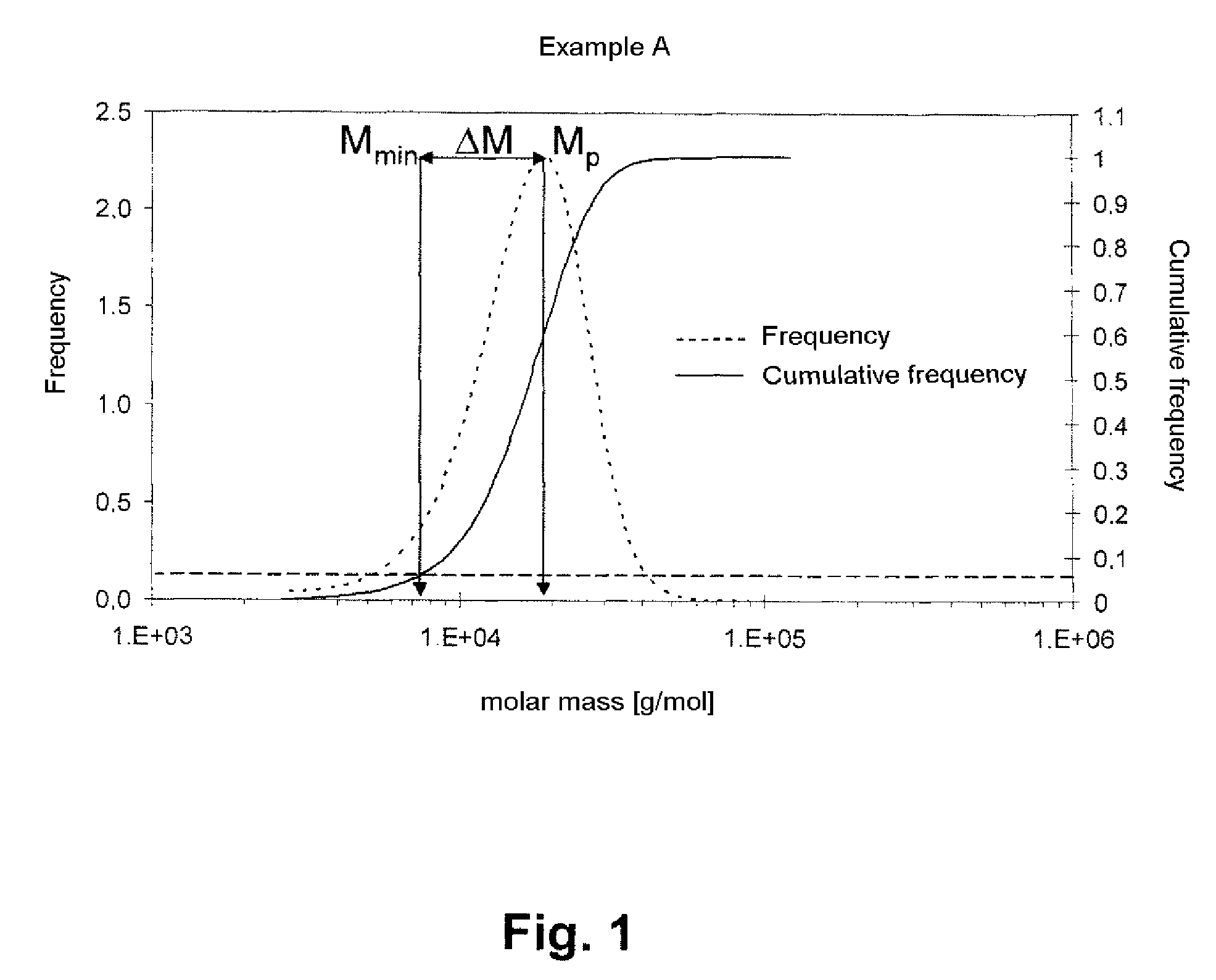

Pressure-sensitive adhesives containing at least one functionalized polymer or block polymer having a weight average of the molar mass distribution of between 5,000 g / mol and 200,000 g / mol and a difference between Mp and Mmin which is lower than 25,000 g / mol, where Mp represents the peak molar mass of a monomodal polymer or the peak molar mass of the smallest mode in a bimodal or multimodal polymer and Mmin represents the lowest molar mass in the molar mass distribution, defined at each point where the cumulative frequency of the molar mass distribution has a value of 0.05, the functionalized polymer or block polymer carries at least one type of functionalization that can be used for a subsequent cross-linking and the at least one type of functionalization of the functionalized polymer results from the use of at least one type of functionalized monomer during the production of the functionalized polymer.

Owner:TESA SE

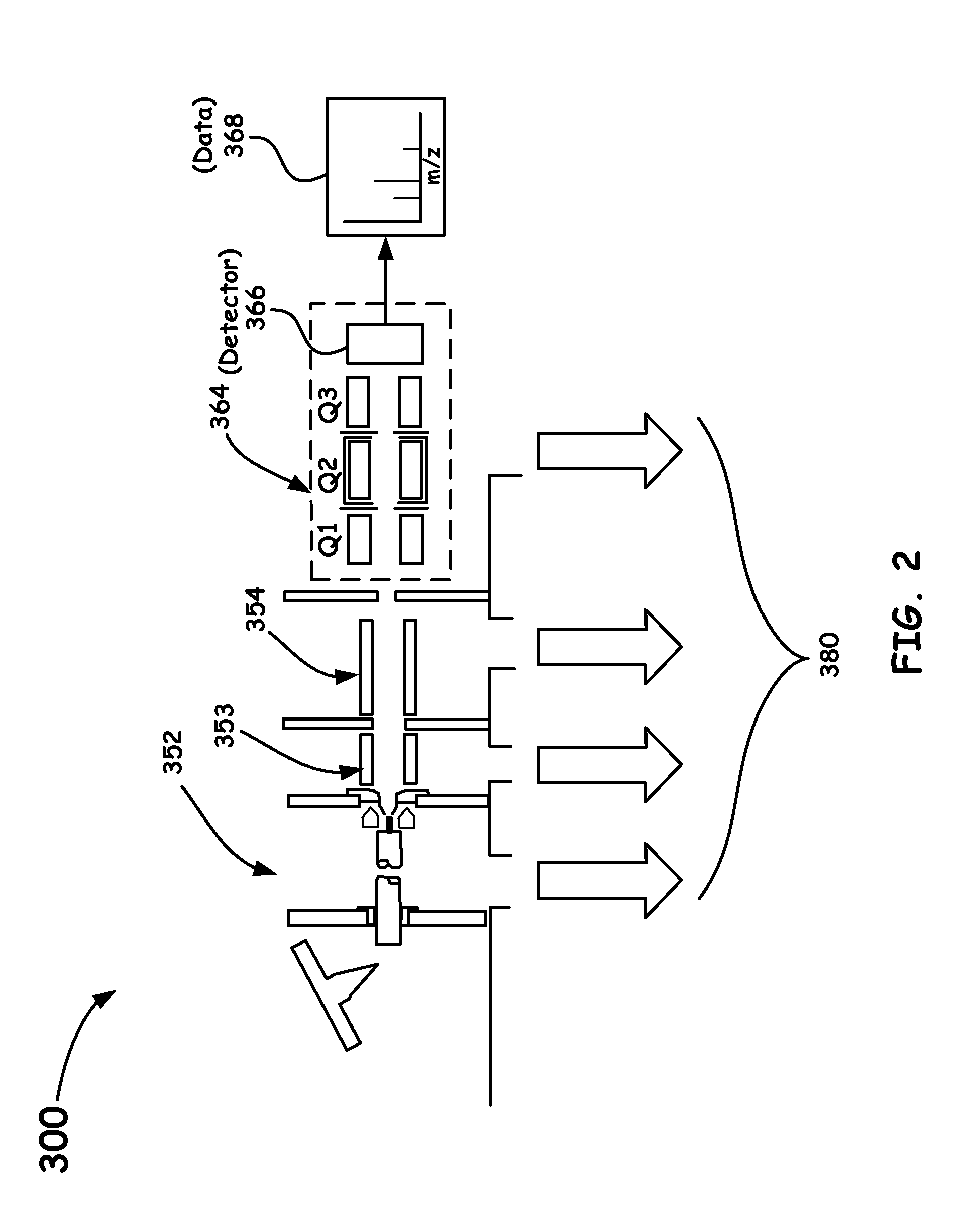

Exponential Scan Mode for Quadrupole Mass Spectrometers to Generate Super-Resolved Mass Spectra

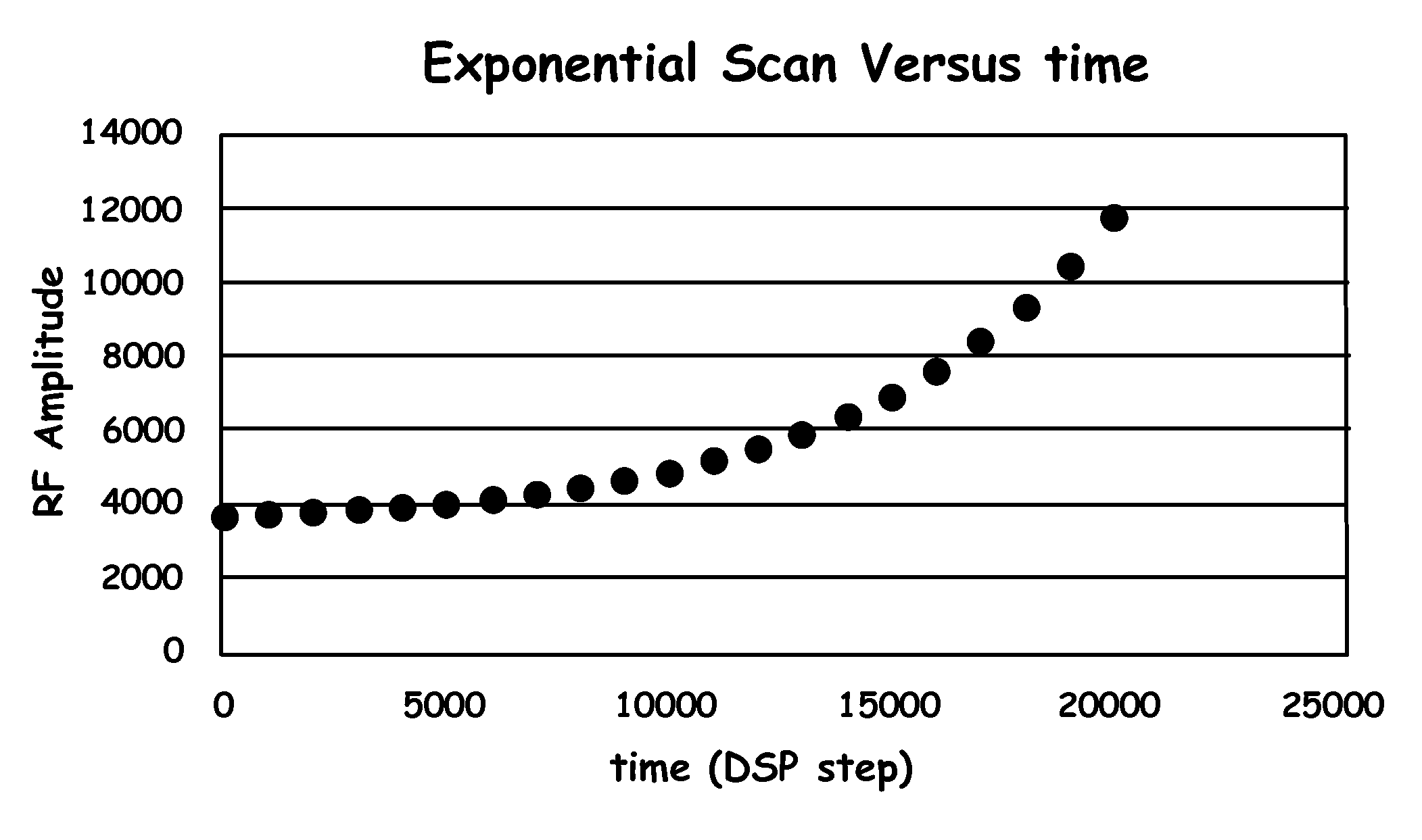

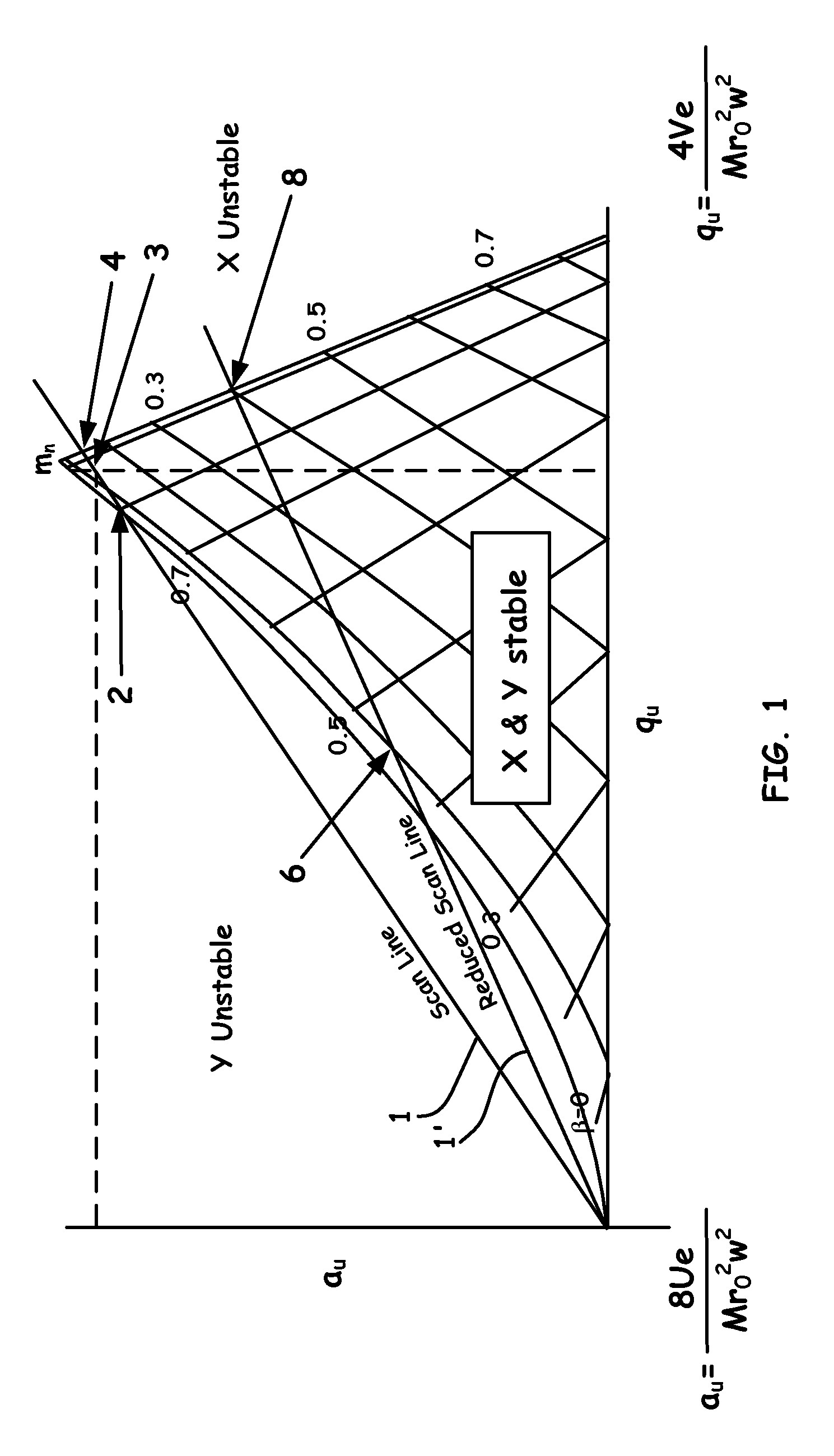

ActiveUS20140151544A1Improve performanceLittle additional hardware costStability-of-path spectrometersMaterial analysis by electric/magnetic meansOperation modeMass analyzer

A novel scanning method of a mass spectrometer apparatus is introduced so as to relate by simple time shifts, rather than time dilations, the component signal (“peak”) from each ion even to an arbitrary reference signal produced by a desired homogeneous population of ions. Such a method and system, as introduced herein, is enabled in a novel fashion by scanning exponentially the RF and DC voltages on a quadrupole mass filter versus time while maintaining the RF and DC in constant proportion to each other. In such a novel mode of operation, ion intensity as a function of time is the convolution of a fixed peak shape response with the underlying (unknown) distribution of discrete mass-to-charge ratios (mass spectrum). As a result, the mass distribution can be reconstructed by deconvolution, producing a mass spectrum with enhanced sensitivity and mass resolving power.

Owner:THERMO FINNIGAN

Polyetheylene moulding compound suitable as a pipe material with excellent processing properties

InactiveCN1466608AMeet internal pressure long-term toleranceMeets stress crack resistanceHeat exhanger conduitsRigid pipesPolymer scienceMolar mass distribution

The invention relates to a polymeric molding compound made from a first ethylene polymer (A) and from a second ethylene polymer (B) which is particularly suitable for producing thick-walled large-caliber pipes, wherein the molding compound comprises an amount in the range from 55 to 75% by weight of the first ethylene polymer (A) and an amount in the range from 25 to 45% by weight of the second ethylene polymer (B), based in each case on the total weight of the molding compound, where the first ethylene polymer (A) is a copolymer of ethylene with a 1-olefin having a total number of carbon atoms in the range from 4 to 10 as comonomer, and with a proportion of from 0.2 to 5% by weight of comonomer, based on the weight of the first ethylene polymer (A), and with a wide bimodal molar mass distribution, and where the second ethylene polymer (B) is a copolymer made from ethylene units and from a 1-olefin having a number of carbon atoms in the range from 4 to 10, which has a bimodal molar mass distribution differing from that of the first ethylene polymer (A). The invention further relates to a high-strength pipe made from this molding compound, and to its use for the transport of gas or water.

Owner:BASELL POLYOLEFINE GMBH

Mass distribution measuring method and mass distribution measuring apparatus

InactiveUS8637808B2High affinityEasy to useIsotope separationImaging particle spectrometryMolar mass distributionMass Spectrometry-Mass Spectrometry

Owner:CANON KK

Propeller manufacturing technique

ActiveCN104985827AReduce movement imbalanceMeet the intensityDomestic articlesMolar mass distributionPropeller

Disclosed is a propeller manufacturing technique. Blades of a propeller are completed in a multi-layer manufacturing manner, the mass distribution of the propeller can be controlled better, product precision is improved, and the motion unbalance phenomenon caused by uneven weight gravity center distribution to the propeller is effectively reduced. The blades of the propeller are spliced in a foam perfusion manner after being completed, the technique is simple and effective, the requirements for the strength and mass distribution of the propeller can be met, and operation is easy and convenient.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Electrolyte membrane for solid polymer fuel cells, membrane electrode assembly having said electrolyte membrane, and solid polymer fuel cell

ActiveUS20130273455A1Improve fuel cell performanceDecreased proton conductivityConductive materialSolid electrolyte fuel cellsFiberMolar mass distribution

An electrolyte membrane for solid polymer fuel cell includes a reinforce membrane made of nonwoven fibers and an electrolyte provided in a space among the nonwoven fibers. The nonwoven fibers have a non-uniform mass distribution in a plane of the electrolyte membrane. A mass of the nonwoven fibers per unit area in a region corresponding to at least part of a peripheral portion of a fuel cell-use gasket frame is greater than a mass of the nonwoven fibers per unit area in a region corresponding to a center portion of the gasket frame. The electrolyte membrane for solid polymer fuel cell is attached to the fuel cell-use gasket frame.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

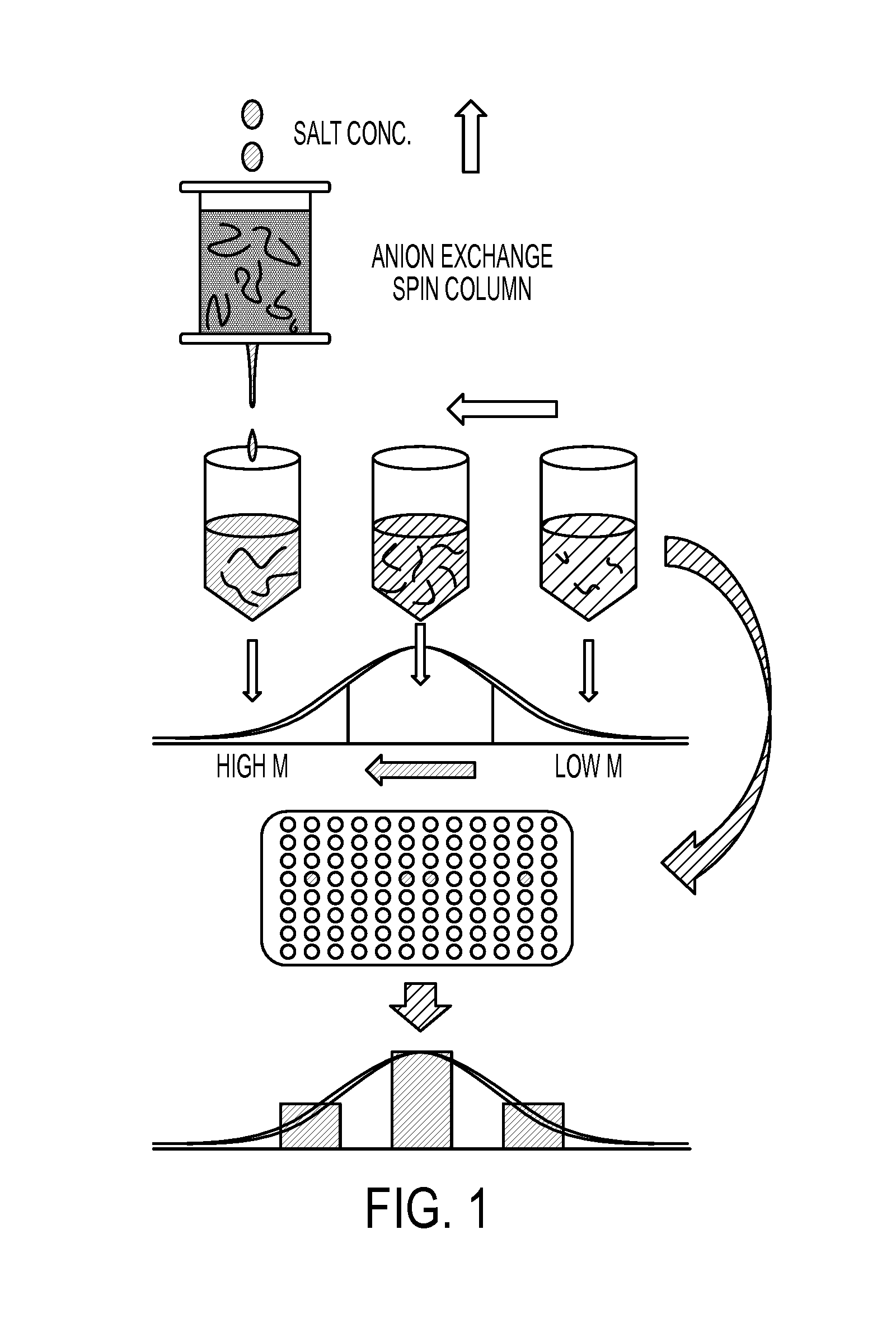

Method for separating hyaluronan and quantifying its molecular mass distribution in biological samples

ActiveUS20160347869A1Biological material analysisBiological testingMolar mass distributionFractionation

The present invention provides a facile method for separation (fractionation) of HA in a sample over a broad M range, including low M HA, by ion exchange (IEX) chromatography. The present invention also provides an assay method for quantifying in a sample the presence of low M HA in total HA isolated from a biological source. The method involves HA fractionation according to M by use of IEX separation, followed by HA-specific assay of HA size range fractions.

Owner:NEW YORK UNIV

Metallocene catalyst supported by hybrid supporting means, process for producing same, polymerization process for producing an ethylene homopolymer or copolymer with broad or bimodal molar mass distribution, use of the supported metallocene catalyst and ethylene polymer with broad or bimodal molar mass distribution

ActiveUS20150274852A1Easy to processReduce processing costsOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer scienceMolar mass distribution

The present invention relates to a metallocene catalyst based on a transition metal of group 4 or 5 of the periodic table, supported on a hybrid catalytic support provided with aliphatic organic groups.One also describes a process for supporting metallocene on said hybrid catalytic support of aliphatic organic groups.The supported metallocene catalyst of the present invention exhibits, as its main advantage, the fact of producing an ethylene polymer with broad or bimodal molar mass distribution, by using only one type of metallocene complex on the support. As a result, on obtains, better processability of the resin obtained and, therefore, a potential reduction of the processing cost.

Owner:BRASKEM SA +1

Polyethylene molding composition for producing blown films having improved processability

The invention relates to a polyethylene molding composition having a multimodal molar mass distribution particularly suitable for blow molding films having a thickness in the range from 8 to 200 μm. The molding composition has a density at a temperature of 23° C. in the range from 0.953 to 0.960 g / cm3 and an MFR190 / 5 of the final product after extrusion in the range from 0.10 to 0.50 dg / min. The composition comprises from 30 to 60% by weight of a first ethylene polymer fraction made of a homopolymer A having a first molecular weight, from 22 to 40% by weight of a second ethylene polymer fraction made of a further homopolymer or first copolymer B of ethylene and at least one first comonomer from the group of olefins having from 4 to 8 carbon atoms, the first copolymer B having a second molecular weight higher than the first molecular weight, and from 10 to 30% by weight of a third ethylene polymer fraction made of a second copolymer C having a third molecular weight higher than the second molecular weight. The molding composition of the invention allows to produce thin films having improved processability without impairing the mechanical properties.

Owner:BASELL POLYOLEFINE GMBH

Exponential scan mode for quadrupole mass spectrometers to generate super-resolved mass spectra

ActiveUS8921779B2Improve performanceIncreased complexityStability-of-path spectrometersMaterial analysis by electric/magnetic meansMass analyzerOperation mode

A novel scanning method of a mass spectrometer apparatus is introduced so as to relate by simple time shifts, rather than time dilations, the component signal (“peak”) from each ion even to an arbitrary reference signal produced by a desired homogeneous population of ions. Such a method and system, as introduced herein, is enabled in a novel fashion by scanning exponentially the RF and DC voltages on a quadrupole mass filter versus time while maintaining the RF and DC in constant proportion to each other. In such a novel mode of operation, ion intensity as a function of time is the convolution of a fixed peak shape response with the underlying (unknown) distribution of discrete mass-to-charge ratios (mass spectrum). As a result, the mass distribution can be reconstructed by deconvolution, producing a mass spectrum with enhanced sensitivity and mass resolving power.

Owner:THERMO FINNIGAN

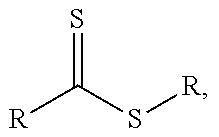

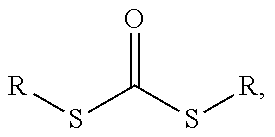

Method for producing non-colored polyacrylate adhesive compounds with a narrow molar mass distribution

ActiveUS9540458B2Fully moistenedLack of interactionEster polymer adhesivesMolar mass distributionCompound (substance)

Method for producing polyacrylate adhesive compounds with a narrow molar mass distribution by radical polymerization and subsequent decolorization of colored reaction products resulting therefrom.

Owner:TESA SE

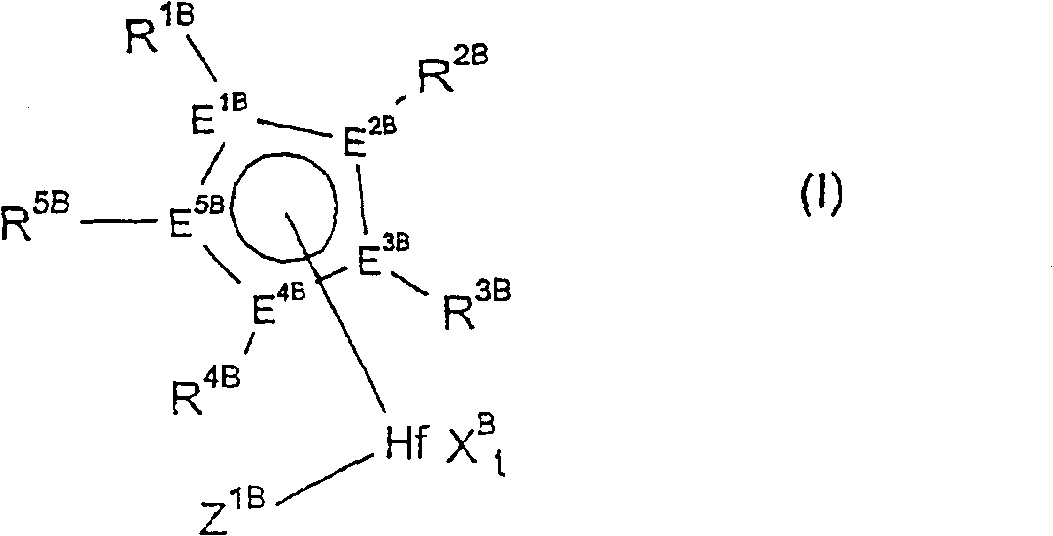

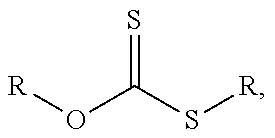

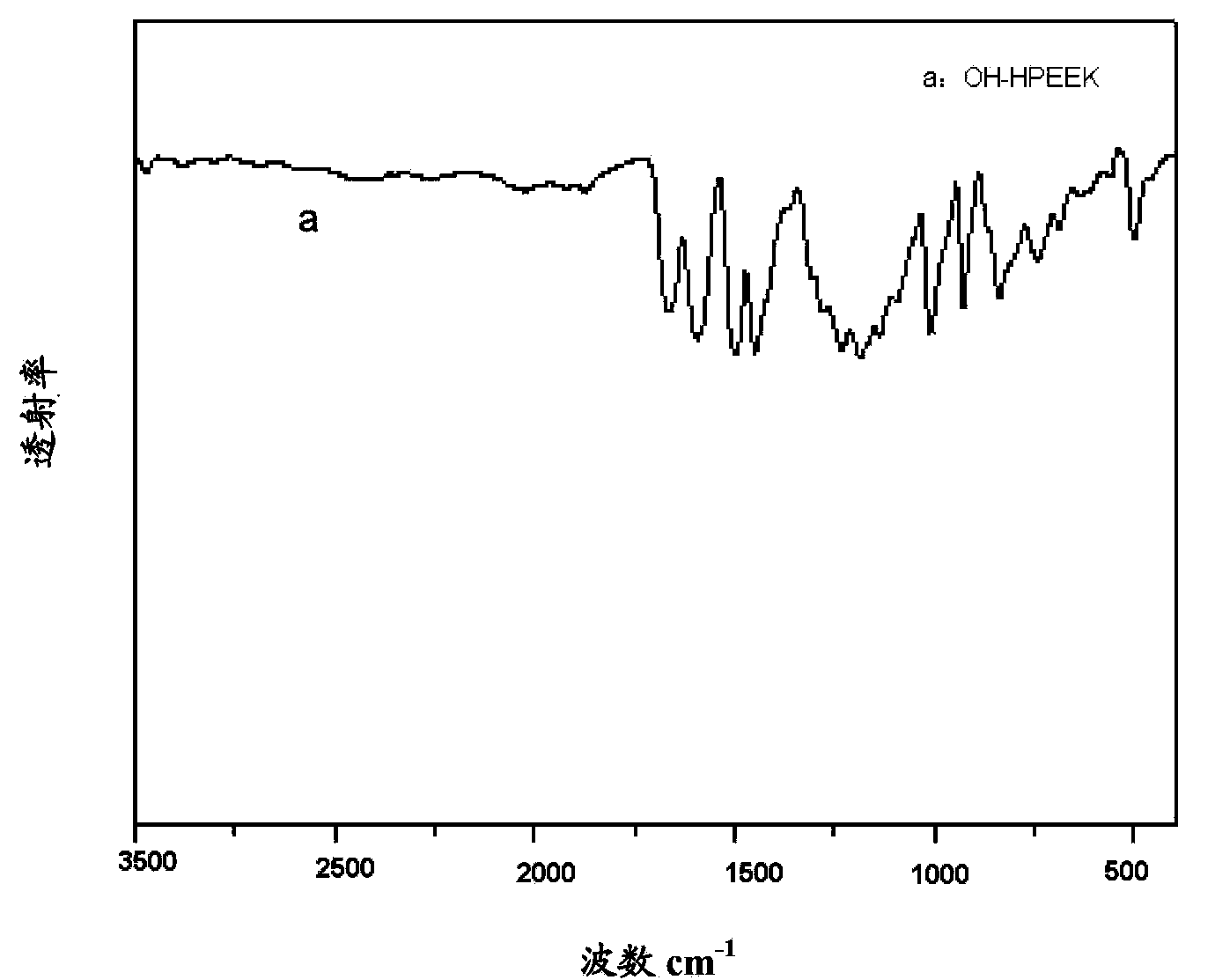

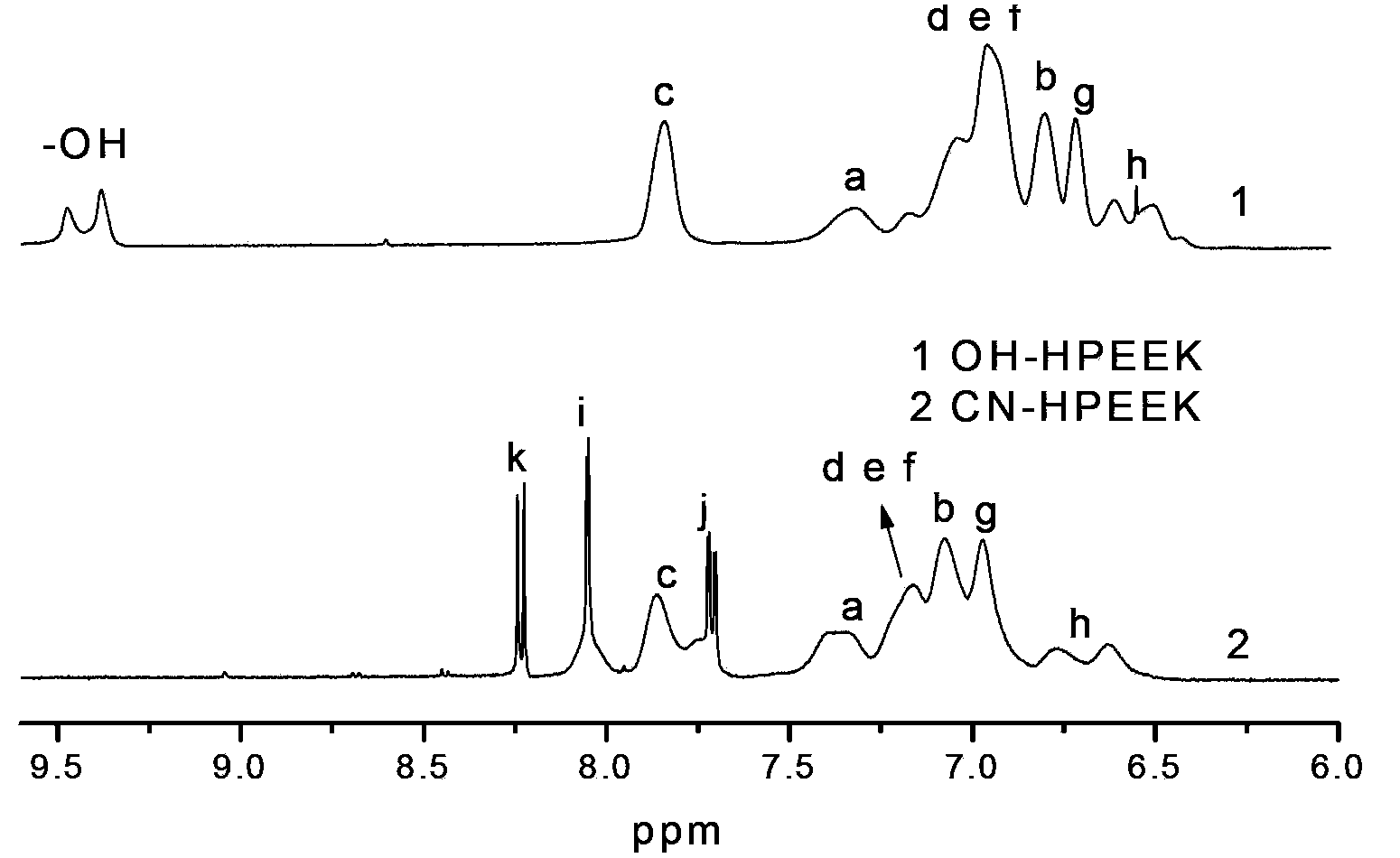

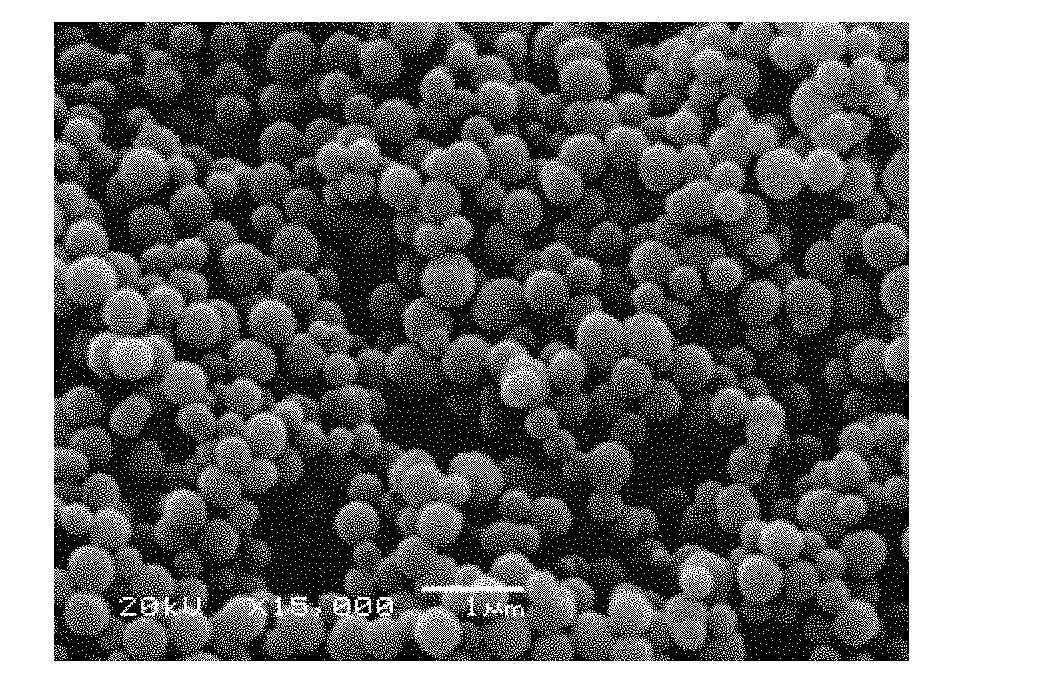

Hyperbranched polyaryletherketone, preparation method and application thereof

InactiveCN102731771BImprove solubilityGood film formingNon-linear opticsCrystallographyMolar mass distribution

A hyperbranched polyaryletherketone, a preparation method for same, and an application thereof. The hyperbranched polyaryletherketone comprises a compound as represented by formula (I) and having a number average molecular mass between 27,500 and 45,000 and a molar mass distribution between 1.45 and 1.84, where R is either -OH or formula (II). The hyperbranched polyaryletherketone can be used in preparing a liquid crystal alignment film. The hyperbranched polyaryletherketone has a structure of increased similarity to liquid crystal molecules and provides an enhanced force between the liquid crystal molecules and the liquid crystal alignment film.

Owner:BOE TECH GRP CO LTD +1

Metallocene catalyst supported by hybrid supporting means, process for producing same, polymerization process for producing an ethylene homopolymer or copolymer with broad or bimodal molar mass distribution, use of the supported metallocene catalyst and ethylene polymer with broad or bimodal molar mass distribution

The present invention describes a metallocene catalyst based on a transition metal of group 4 or 5 of the periodic table, supported on a hybrid catalytic support provided with aliphatic organic groups, and a process for supporting metallocene on the hybrid catalytic support. The supported metallocene catalyst provides an ethylene polymer with broad or bimodal molecular weight distribution, in the presence of only one metallocene complex on the support.

Owner:BRASKEM SA +1

Rubber mixture and vehicle tires

ActiveCN106232701AImprove featuresGood handling characteristicsMolar mass distributionPolymer science

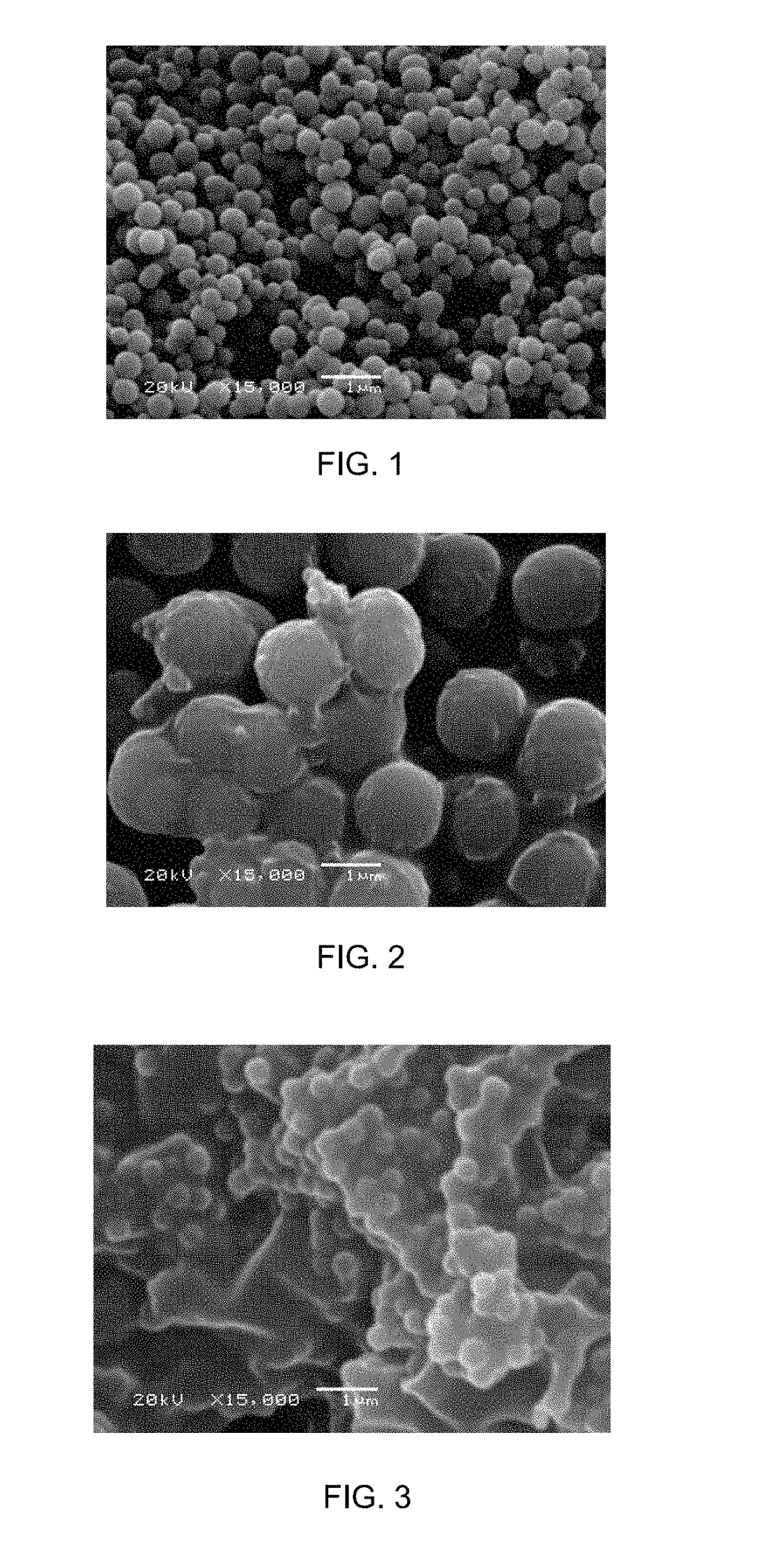

The invention relates to a rubber mixture, in particular for treads of vehicle tires and to vehicle tires. The rubber mixture contains at least the following components: at least one diene rubber and 30 to 150 phr of at least one soot which has a DBP number of 130 to 200 ml / 100 g according to ASTM D 2414, an iodine adsorption number of 40 to 75 g / kg according to ASTM D 1510, and a distribution index DI of 1.00 to 1.10. DI is calculated from the particle size distribution (mass distribution by the Stokes diameter) determined by means of DCP (disk centrifuge photosediometer) according to formula I): I) DI = DW / Dmode. The rubber mixture exhibits an improved rolling resistance behavior and an improved abrasion behavior. The vehicle tire contains the rubber mixture in at least one component, preferably in the tread.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com