Propeller manufacturing technique

A manufacturing process and propeller technology, which is applied in the field of air propeller manufacturing process, can solve the problems of propeller dynamic unbalance, affecting distribution balance and structural strength, and inconvenient operation, so as to meet the strength and mass distribution and reduce the phenomenon of unbalanced motion , Simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

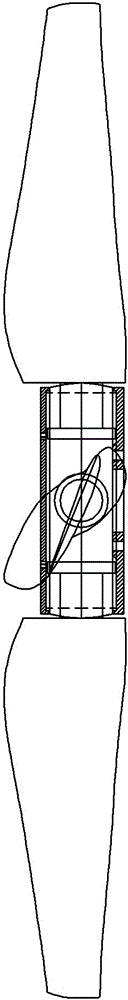

Image

Examples

Embodiment Construction

[0013] A manufacturing process for a propeller, comprising the following steps: first, making the upper piece 1 and the lower piece 2 of each blade; Cloth, the third layer of carbon fiber cloth, the fourth layer of carbon fiber cloth, the fifth layer of carbon fiber cloth, the sixth layer of uniaxial fiber cloth and the seventh layer of fiber grid cloth are laid in order, and then polyethylene resin is used as the The matrix is made by vacuum infusion molding process for resin infusion, demoulding after curing, and trimming; the bottom sheet is the first layer of fiber grid cloth, the second layer of uniaxial fiber cloth, and the third layer from bottom to top. The carbon fiber cloth, the fourth layer of carbon fiber cloth, the fifth layer of carbon fiber cloth, the sixth layer of uniaxial fiber cloth and the seventh layer of fiber grid cloth are laid up in order, and then polyethylene resin is used as the matrix. The infusion molding process carries out resin infusion, rele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com