Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Solve inherent problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

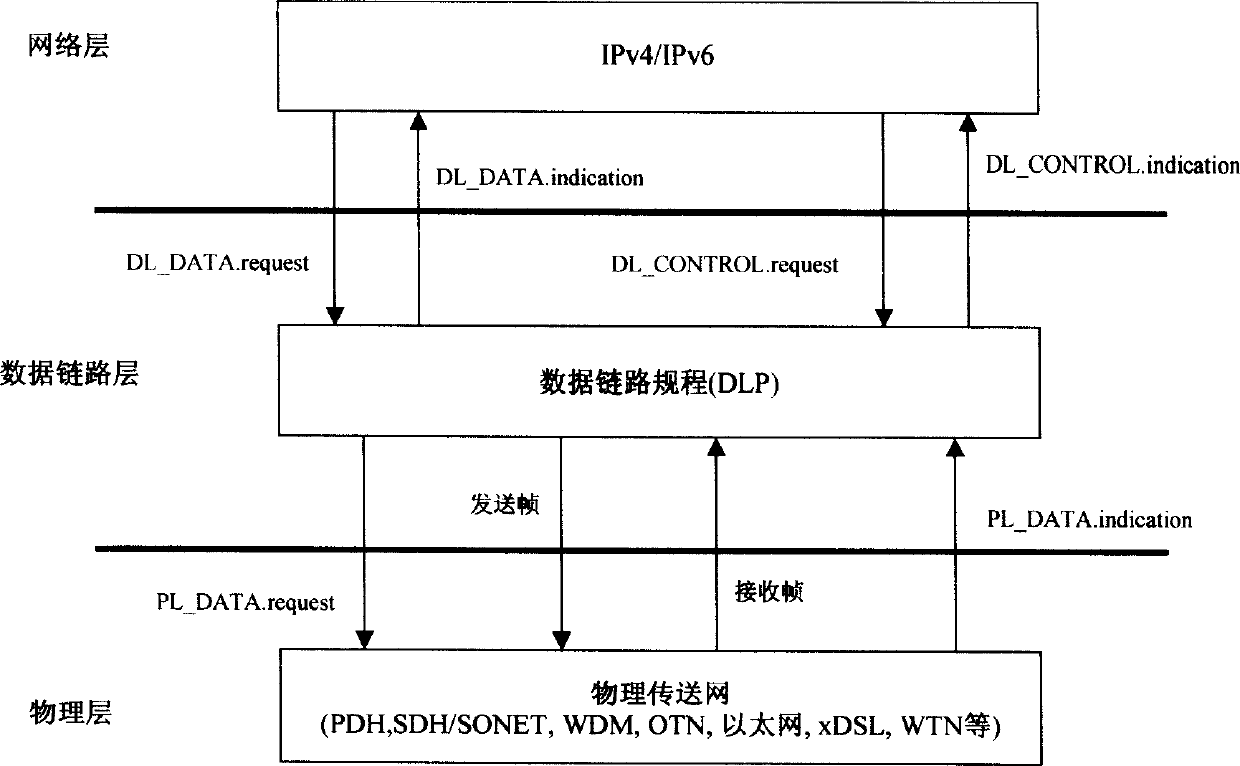

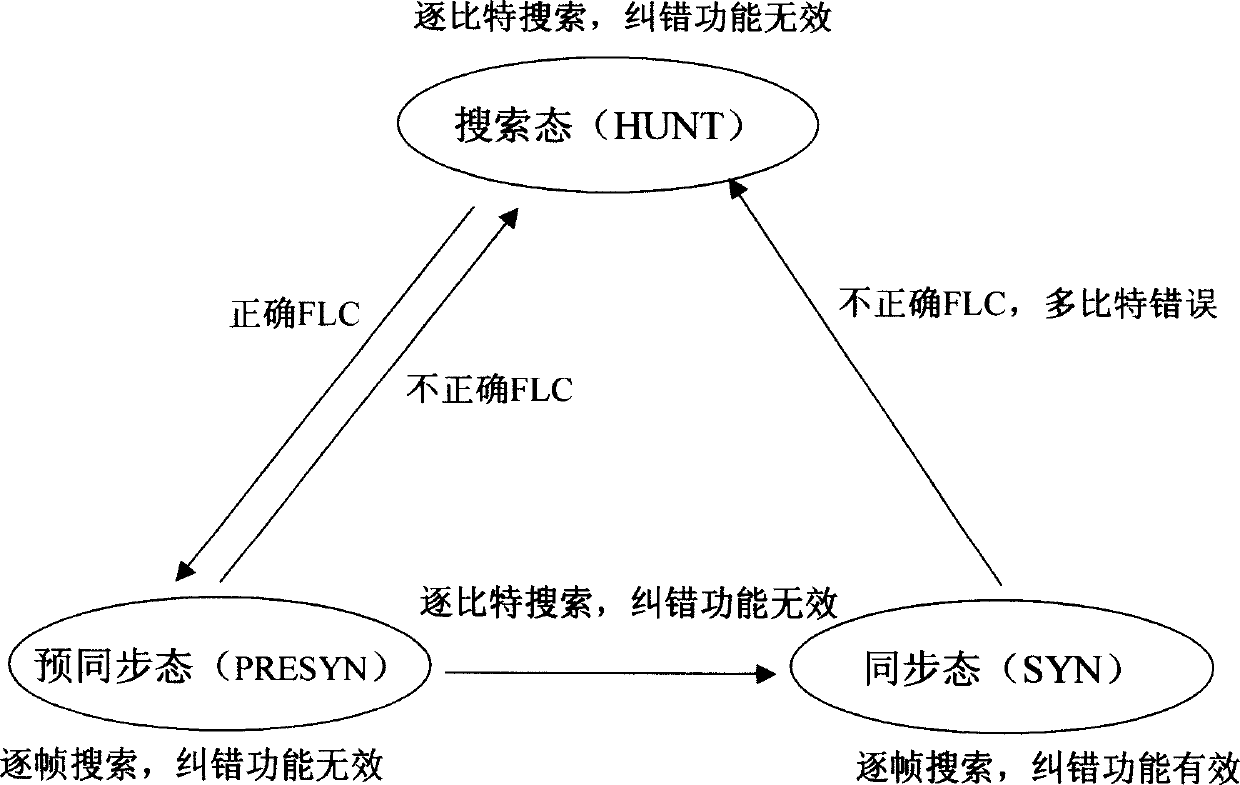

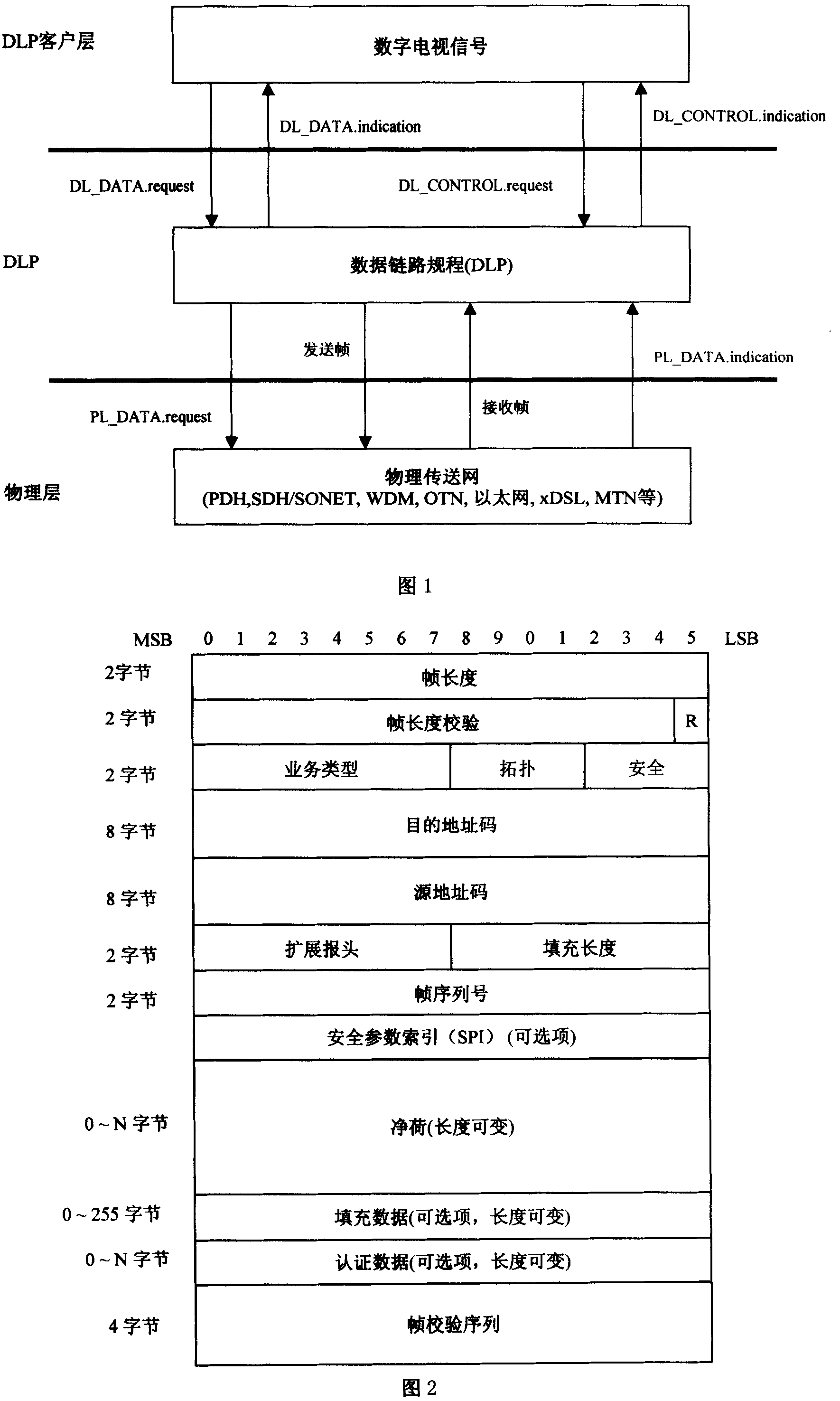

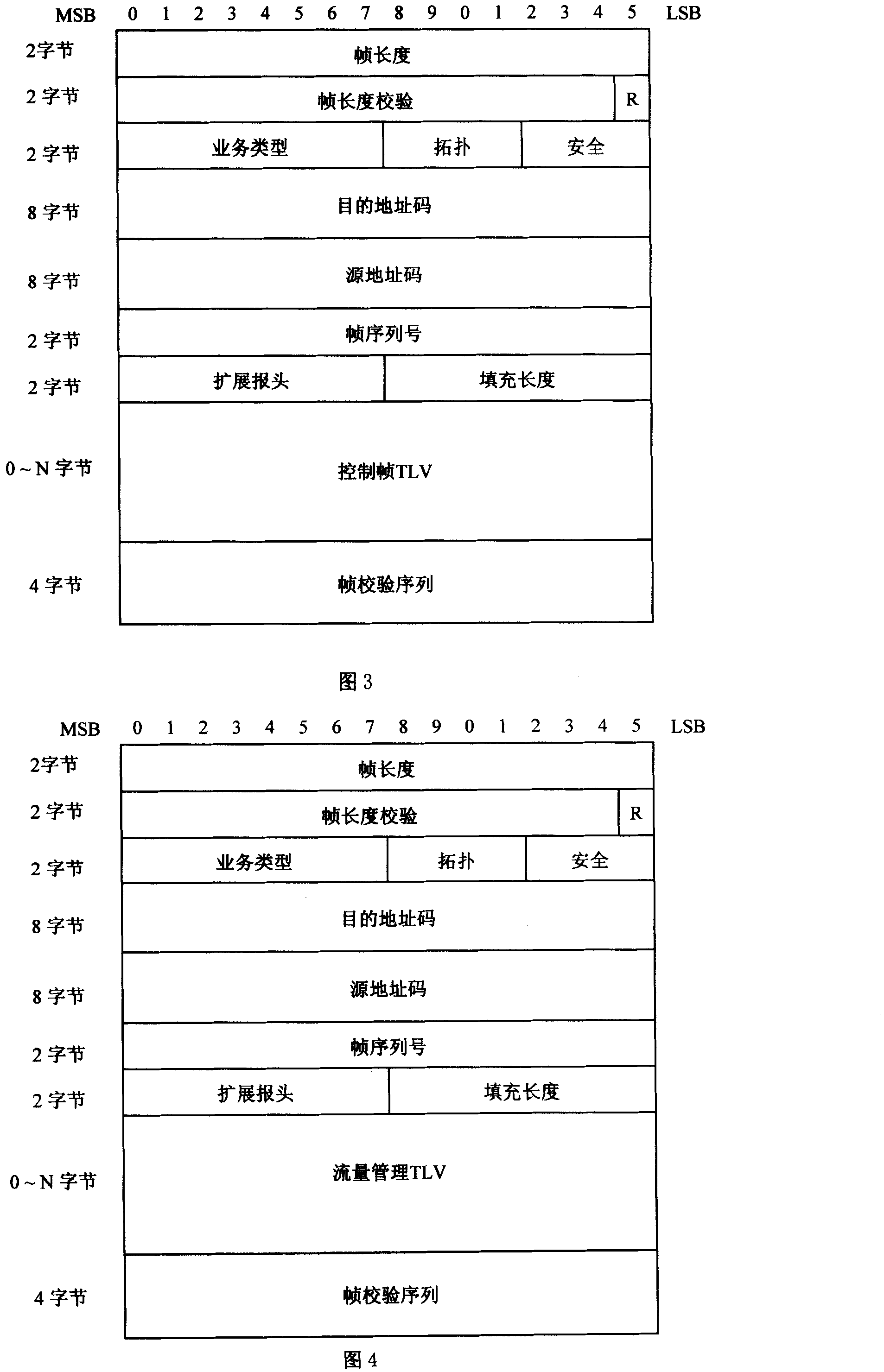

Method for transmtitig digital video

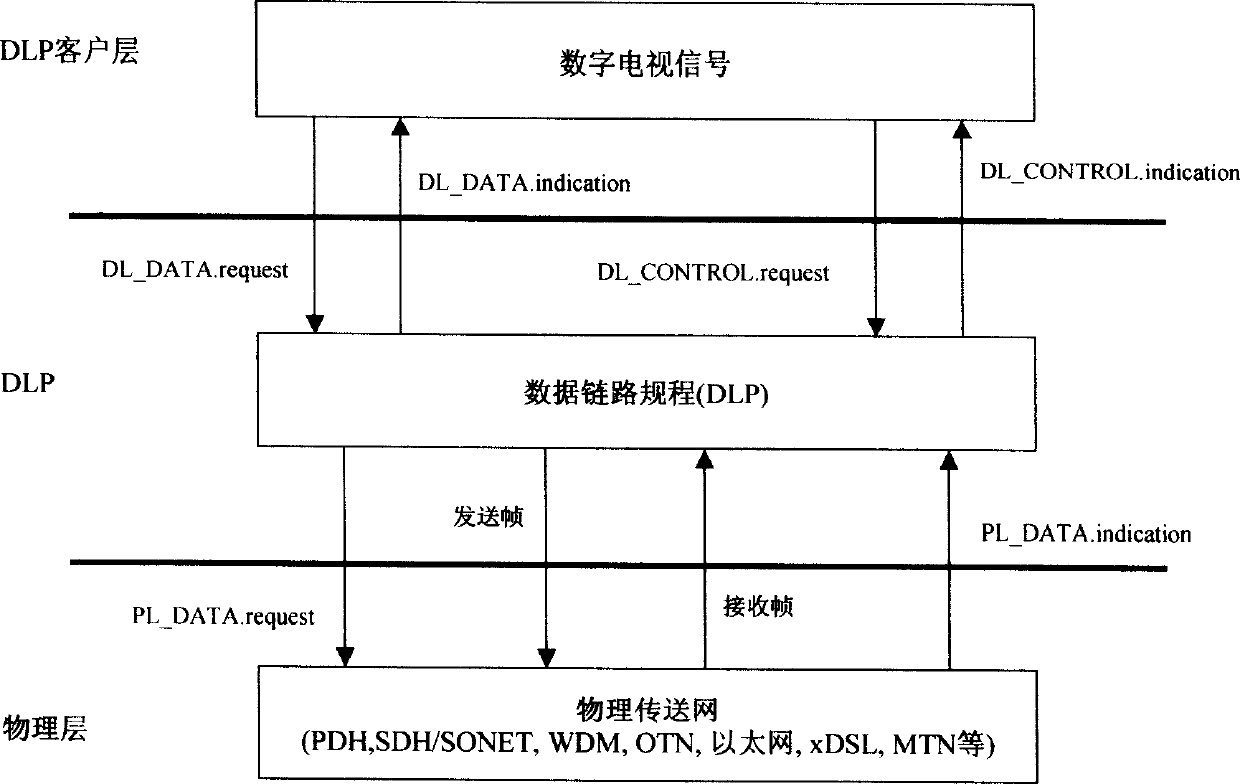

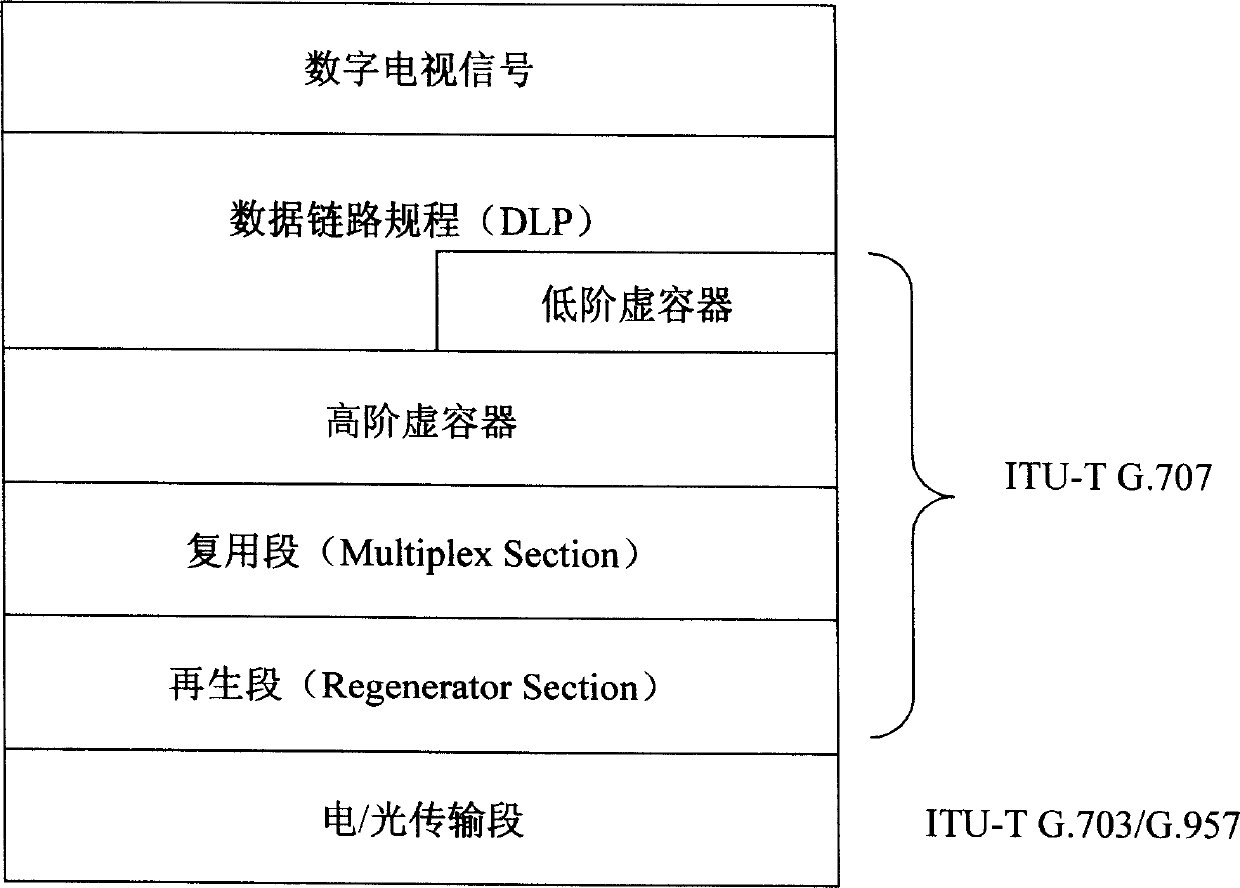

InactiveCN1728713ARealize triple playReduce networking costsTransmissionDigital videoNetwork management

Using packet switching, the disclosed digital video transmission method can be applicable to united public network in next generation. New layer of data link layer protocol - data link procedure (DLP) is introduced between digital video service layer and each physical layer. Using DLP protocol defined destination address code and source address code compatible to current telephone number system as addresses of sending end and receiving end of digital video signal realizes forwarding and exchanging digital video signal in two layers, as well as realizes purpose compatible between packet voice network and IP network. Using safety mechanism, network control management mechanism, flow management mechanism provided by DLP realizes network management control function such as two layer protected rearrangement in two layers, performance management, fault management etc. The method makes current communication network transits to united public network in next generation smoothly.

Owner:邓里文

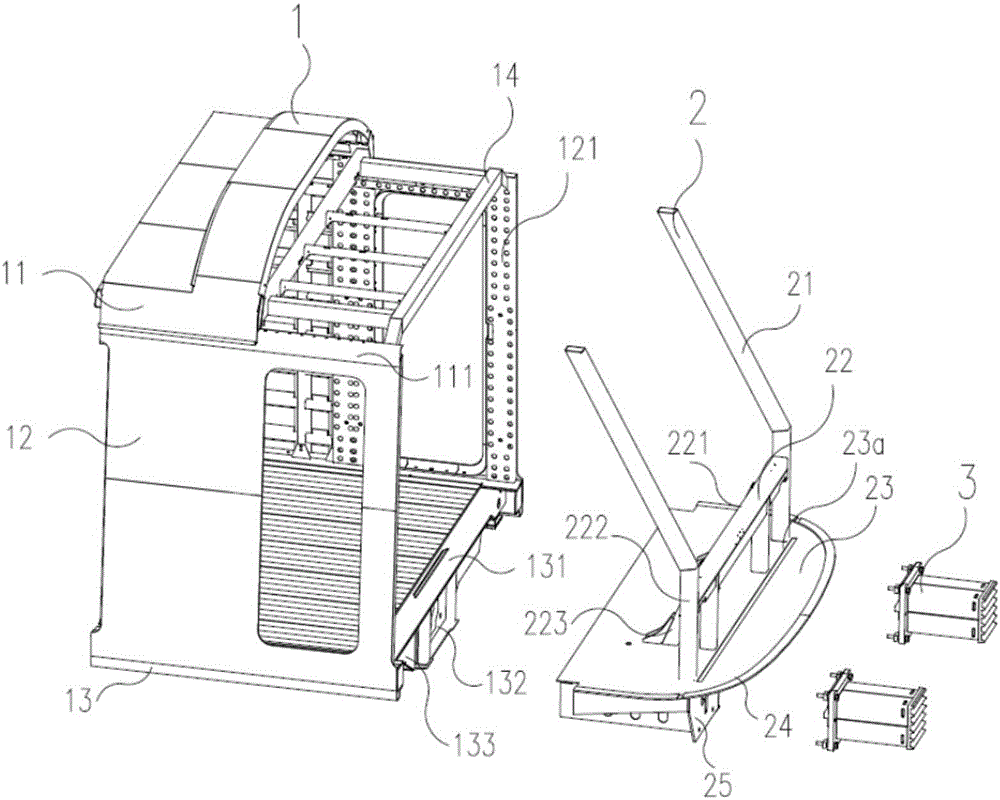

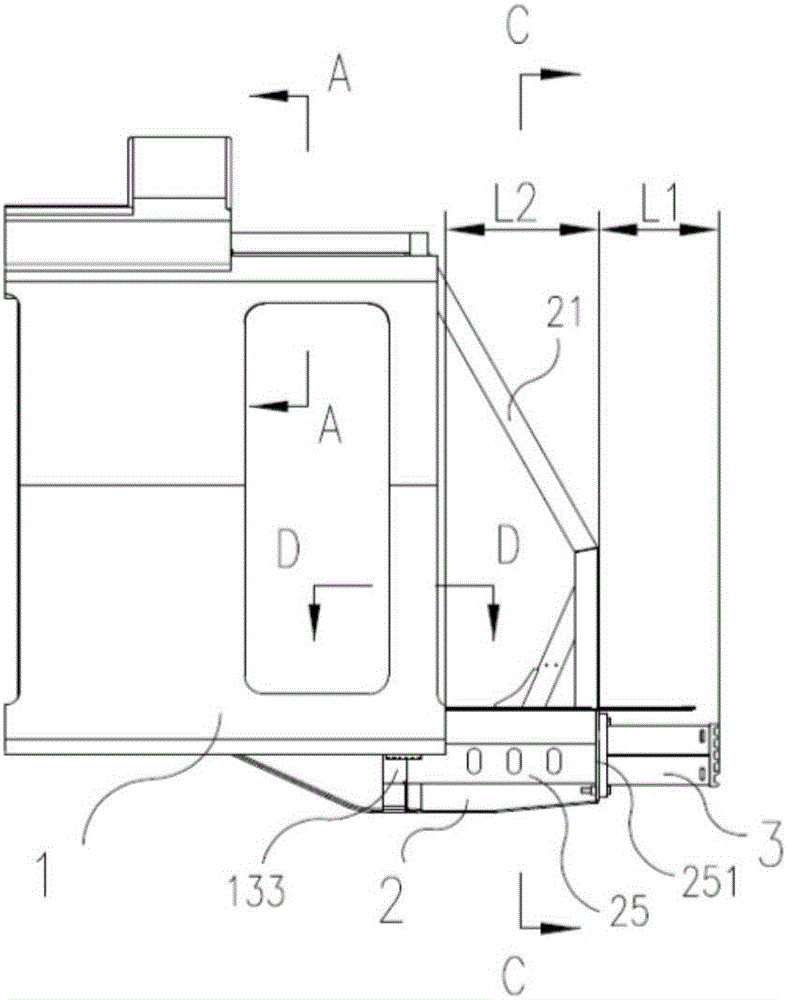

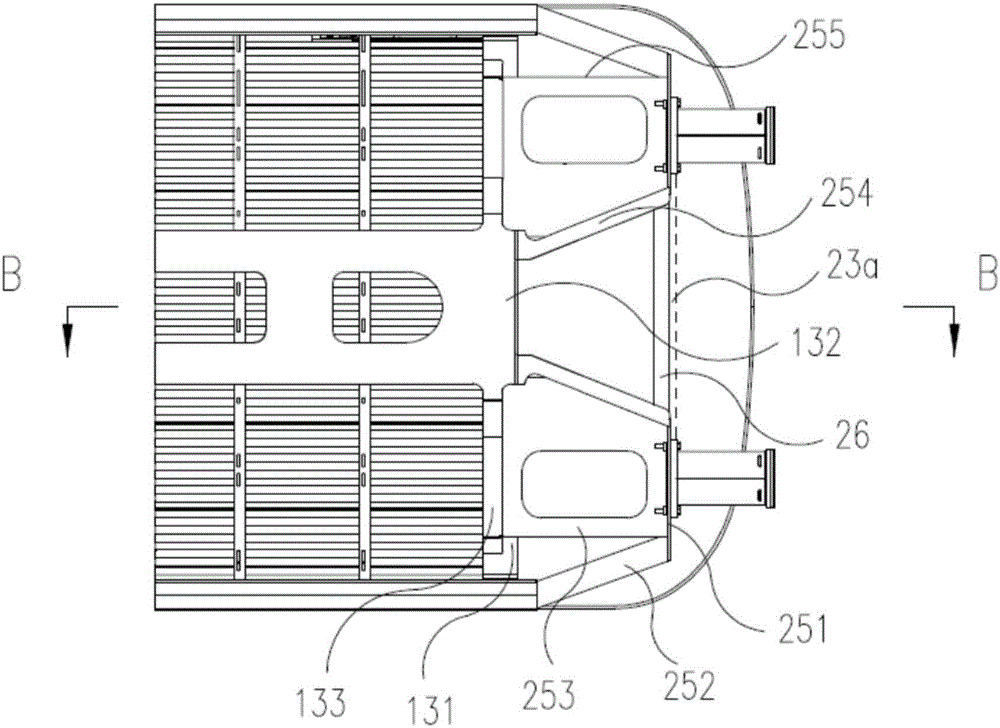

Railway vehicle head structure

ActiveCN106240587AEasy to replaceImprove carrying capacityBuffer carsRailway wheel guards/bumpersAbsorbed energySafety zone

The invention discloses a railway vehicle head structure. The railway vehicle head structure comprises a vehicle body main structure, a vehicle head anti-collision structure and an anti-creeper. A vehicle head is divided into a safety zone of which the longitudinal load strength is decreased progressively in a gradient mode, a secondary deformation zone and a main deformation zone according to the longitudinal direction of a railway vehicle. The safety zone is the vehicle body main structure and comprises a passenger room zone and a driver seat zone. The secondary deformation zone is a zone from a cab front door to an anti-creeper installation plate and comprises the vehicle head anti-collision structure and an anti-creeper installation structure. The main deformation zone comprises a cab floor located in front of the anti-creeper installation plate and the anti-creeper. A first-stage stopping structure is arranged between the secondary deformation zone and the main deformation zone. A second-stage stopping structure is arranged between the safety zone and the secondary deformation zone. According to the railway vehicle head structure, a vehicle body deforms and absorbs energy in a controllable and orderly mode, and the good safety performance is obtained.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

Method for mutual communication between IPv4 network and IPv6 network

InactiveCN1728714AIncrease the level of processingIncrease overheadTransmissionTraffic capacityForwarding equivalence class

New layer of data link layer protocol - data link procedure (DLP) is introduced between IP of network layer and each physical layer in the invention in order to overcome shortage of current method of intercommunication between IPv4 network and IPv6 network. Using DLP defined destination address code and source address code expresses forwarding equivalence class of IP address and source address of IP packet. Using forwarding equivalence class of IP packet as addresses in data link layer realizes forwarding and exchanging IP packets in two layers so as to realize intercommunication between IPv4 network and IPv6 network in data link layer. Features are: high efficiency of forwarding IP packets, safety and reliability, flux engineering capability, 50 ms protected rearrangement function, compatible to packet voice network. The method makes current IP network transits to united telecom public network in next generation smoothly.

Owner:邓里文

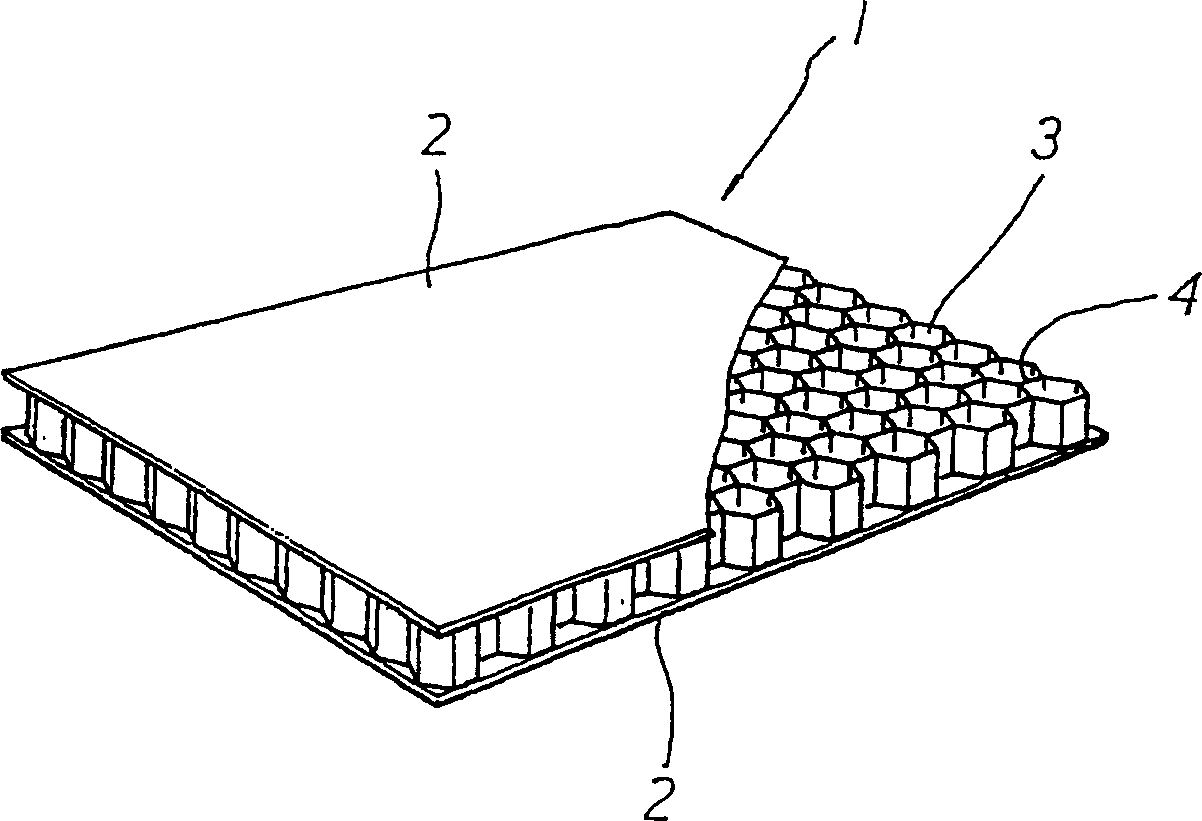

Stainless sheet honeycomb panel and method for mfg. thereof

InactiveCN1443112ASolve inherent problemsSolve the problem of flakingSoldering apparatusBuilding componentsAdhesiveMetallurgy

The present invention relates to a stainless steel honeycomb structural panel for external or internal finishing of house construction, and this panel can be used semi-permanently, the present invention particularly relates to a stainless steel honeycomb structural panel and its manufacturing method and device, the honeycomb The structural panels are made of stainless steel, which is durable, does not rust and does not detach in any external environment. Conventional stainless steel honeycomb panels are manufactured by placing honeycombs between stainless steel plates and fixing them by using an adhesive. However, this method has a disadvantage that separation tends to occur due to external temperature and humidity, and thus has limitations when used as exterior finishing of construction. In the present invention, the stainless steel honeycomb structure plate is manufactured in such a way that the solder sheet coated with flux on both sides is superimposed on one side of the stainless steel plate, the honeycomb is inserted between the stainless steel plates, and while being pressed with a pressing device Directly or indirectly heat both sides of the stainless steel structural plate at a temperature of 200°C to 300°C.

Owner:БМЕК ЭНД ВООЦЗИНЬ ЭТС КО., ЛТД

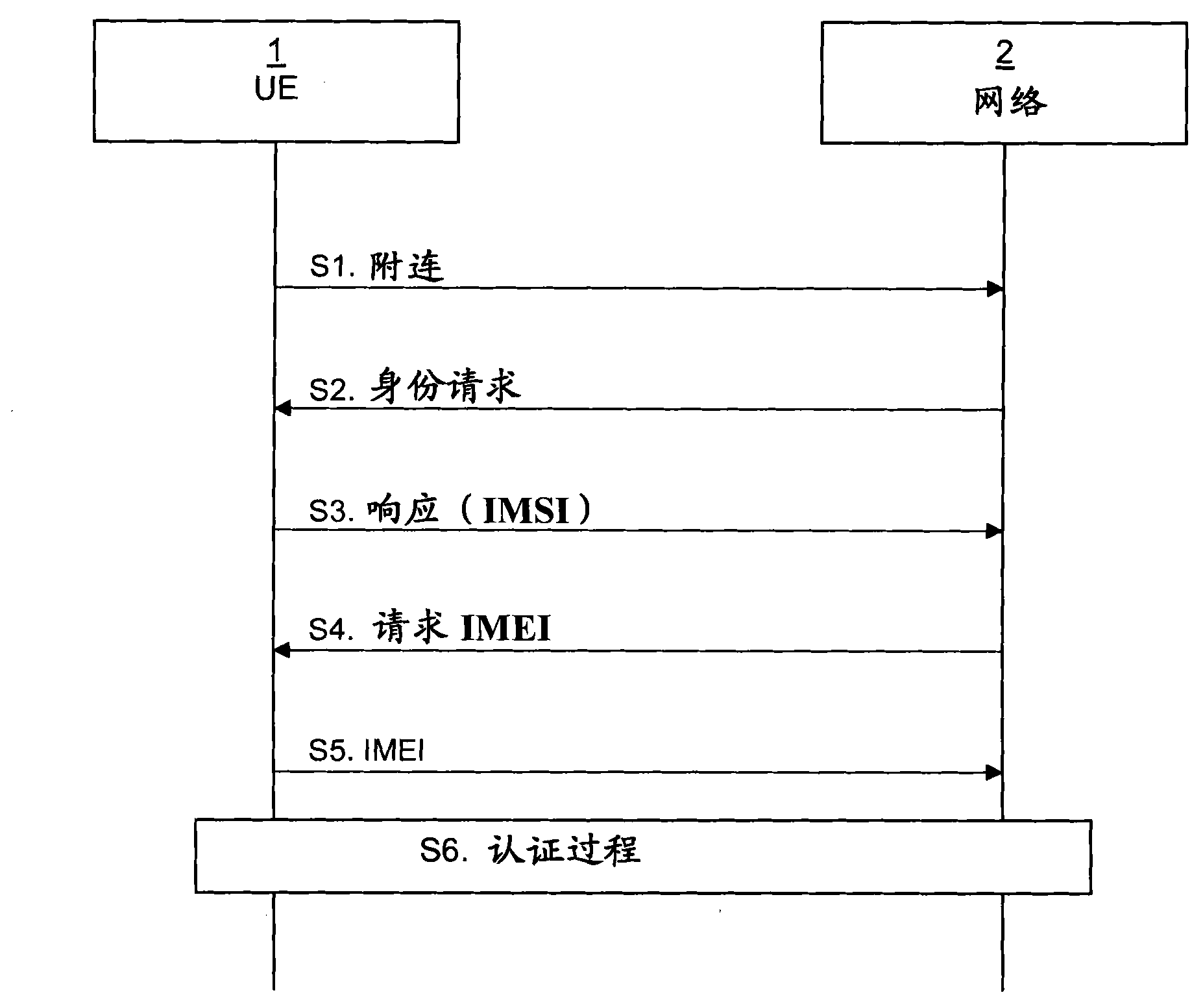

Terminal identifiers in a communications network

ActiveCN102714791AIncrease the lengthSolve inherent problemsSecurity arrangementNetwork data managementGPRS core networkComputer terminal

A method and apparatus for allocating an identifier to a terminal in a communications network. A core network controlling node, such as a Mobility Management Entity (MME) receives an International Mobile Subscriber Identity (IMSI) and an International Mobile Equipment Identity (IMEI) from the terminal. Subscription information is determined using both the IMSI and the IMEI. A temporary identifier that can be used to identify the terminal is then allocated to the subscription information.

Owner:TELEFON AB LM ERICSSON (PUBL)

Method for preparing high-magnetic induction and high-strength non-oriented silicon steel based on thin strip continuous casting

The invention discloses a method for preparing high-magnetic induction and high-strength non-oriented silicon steel based on thin strip continuous casting, and belongs to the technical field of metallurgy. The method comprises the following steps: (1) molten steel is smelted according to set components, and comprises the following components in percentage by weight: 0.001-0.005% of C, 2.4-3.5% of Si, 0.2-2% of Mn, 0.35-1.0% of Alt, 0.4-3% of Ni, 0.5-4% of Cr, 0.02-0.2% of Sn, O not more than 0.005%, S not more than 0.005%, N not more than 0.005%, P not more than 0.005%, and the balance of Fe; (2) the molten steel is cast in a double-roller thin strip continuous casting device for continuous casting; (3) a cast strip is secondarily cooled to reach room temperature, and is hotly rolled by singly gate; (4) the cold rolling is performed after acid washing; and (5) finally, the annealing treatment is performed; an insulation coating layer is coated online; and the winding is performed at last. The method can exert inherent advantages of thin strip continuous casting to the greatest extent, improves the magnetic performance and the mechanical performance of thin strip continuous casting electrical steel products, and is simple in preparation, environment-friendly and energy-saved in production process, low in investment cost and high in production efficiency.

Owner:NORTHEASTERN UNIV

Nitrogen-doped carbon-based metal monoatomic catalyst as well as preparation method and application thereof

InactiveCN110124722AIncrease loadHigh activityPhysical/chemical process catalystsWater treatment compoundsIn situ polymerizationHigh activity

The invention provides a nitrogen-doped carbon-based metal monoatomic catalyst as well as a preparation method and application thereof. A hard template method is selected to prepare the metal monoatomic catalyst, an amino-containing organic body and a chlorine-containing organic body are used as polymerization monomers, a transition metal salt is used as a metal source, a ratio relationship of a template, the organic monomers and the metal salt and reaction conditions are precisely regulated and controlled, so that in-situ polymerization of the organic monomers on the surface of the template and simultaneous chelating of transition metal ions can be realized to prepare the highly exposed monoatomic metal catalyst. The preparation method of the catalyst provided by the invention can ensurethe load capacity of the monoatomic metal to the greatest extent, and the condition that a nitrogen-doped carbon material wraps a metal oxide can be avoided through reasonable regulation and control of reparation conditions; and in addition, the Fenton catalyst prepared by the method has the advantages of high activity, a low metal loss rate and strong regeneration ability.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

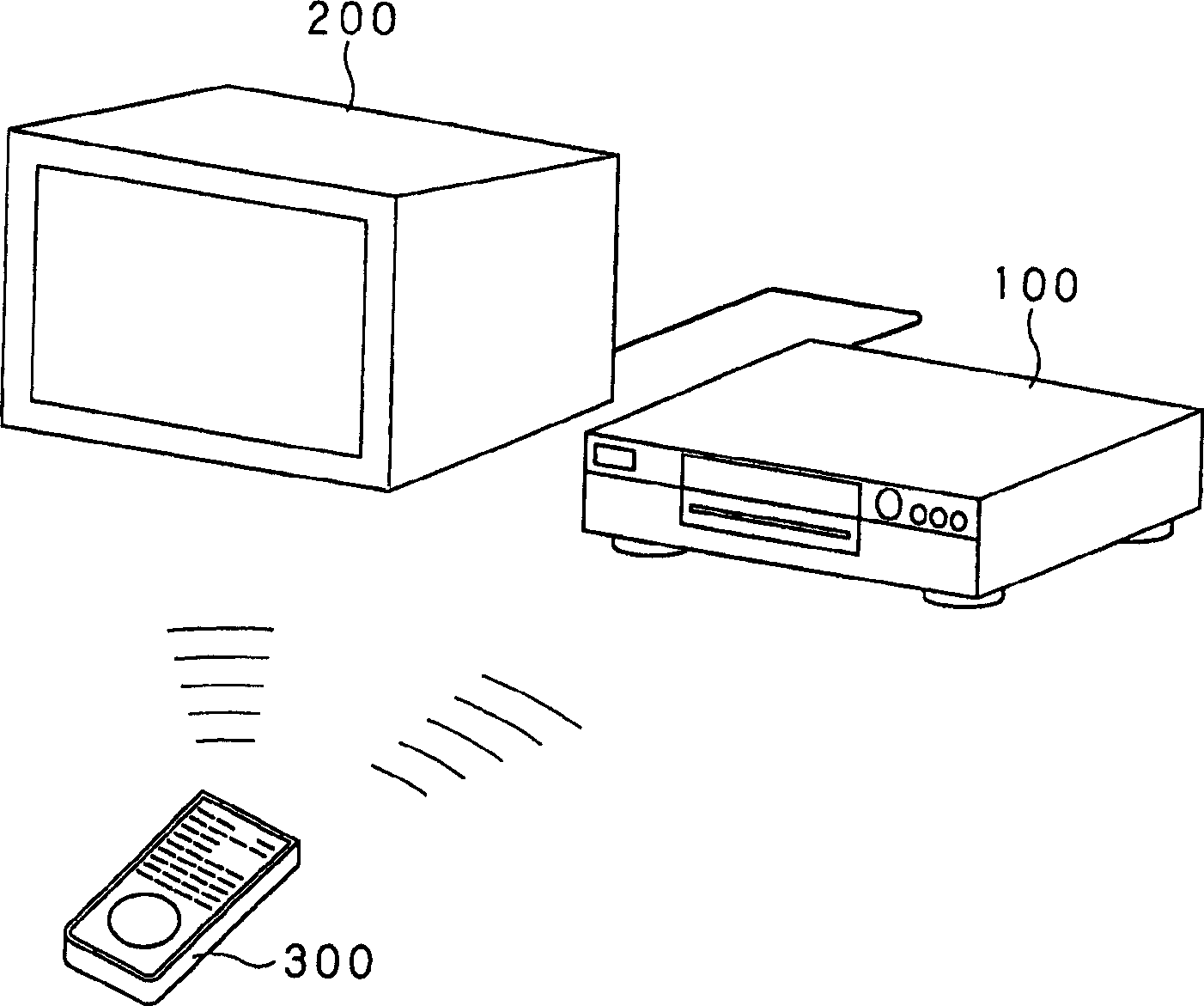

Decoding device and decoding method

InactiveCN1545808ASolve inherent problemsNovel decoding deviceTelevision system detailsTelevision system scanning detailsStreaming dataDecoding methods

Disclosed is a decoding apparatus for performing decoding processing in keeping with multi-view broadcast. The decoding apparatus includes a picture stream data storage unit (31) for allocating a storage area for each picture stream data and storing the storage area, a picture stream data readout (14) for time-divisionally reading out the picture stream data stored in the storage area, a decoding unit (33) for decoding the read-out picture stream data into a picture frame, a picture frame storage unit (34) for storing the picture frame, a management table storage unit (15) for storing a management table for supervising the state-of-use information indicating the state of use of the picture frame storage unit (34), a first decision unit (host CPU) (14) for determining whether or not a picture frame is storable in a picture frame storage unit (34), based on the state-of-use information supervised by the management table, and an allowance unit (host CPU) (14) for allowing readout of the picture stream data from a picture stream data storage unit (31) of the picture stream data readout unit (host CPU) (14).

Owner:SONY CORP

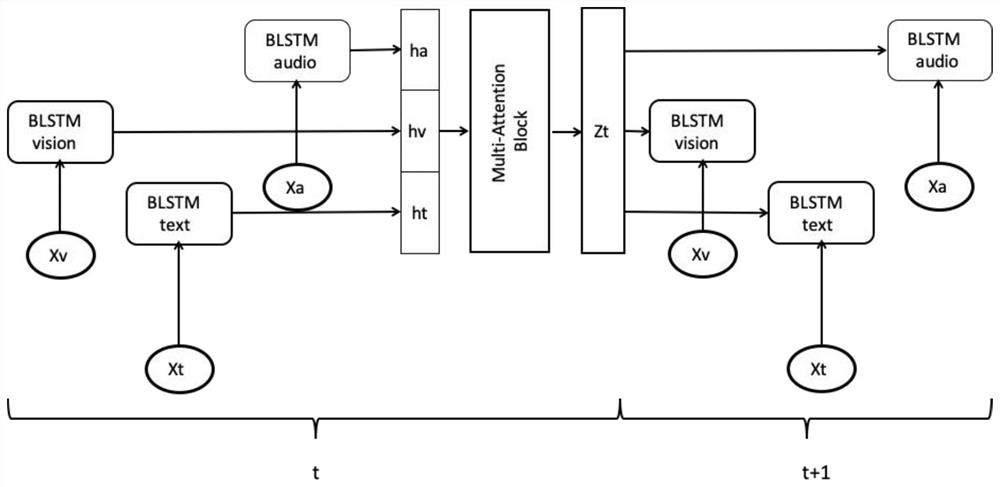

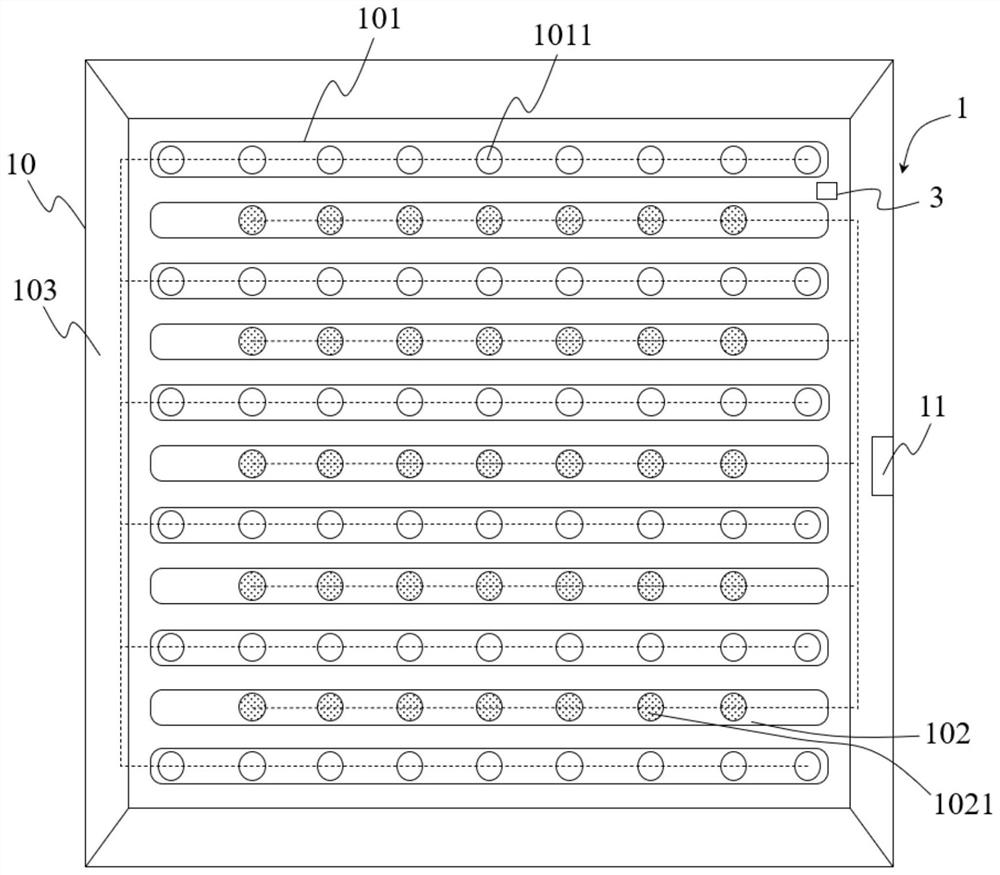

Rapid intelligent emotion evaluation and analysis method based on voice and expressions

PendingCN112133407ASolve inherent problemsMedical communicationSpeech analysisFacial expressionHuman–computer interaction

The invention discloses a rapid intelligent emotion evaluation and analysis method based on voice and expressions. The method is characterized by comprising the following steps: recording and analyzing time of a testee for each question during online scale testing, and analyzing and discovering answer characteristics of the testee for different questions; adopting an innovative mode of voice questioning and answering to provide diversified test means for the testee, capturing voiceprint features of the testee, performing psychological emotion analysis, collecting and analyzing voice of the testee, and converting into text features by adopting open voice dialogue; and capturing the facial expressions of the testee in the test process, and timely analyzing the expressions of the testee by adopting a latest deep learning technology. Finally, the multi-dimensional and multi-modal emotion evaluation and analysis method integrating scale, voice and expression analysis is formed.

Owner:田文洪 +5

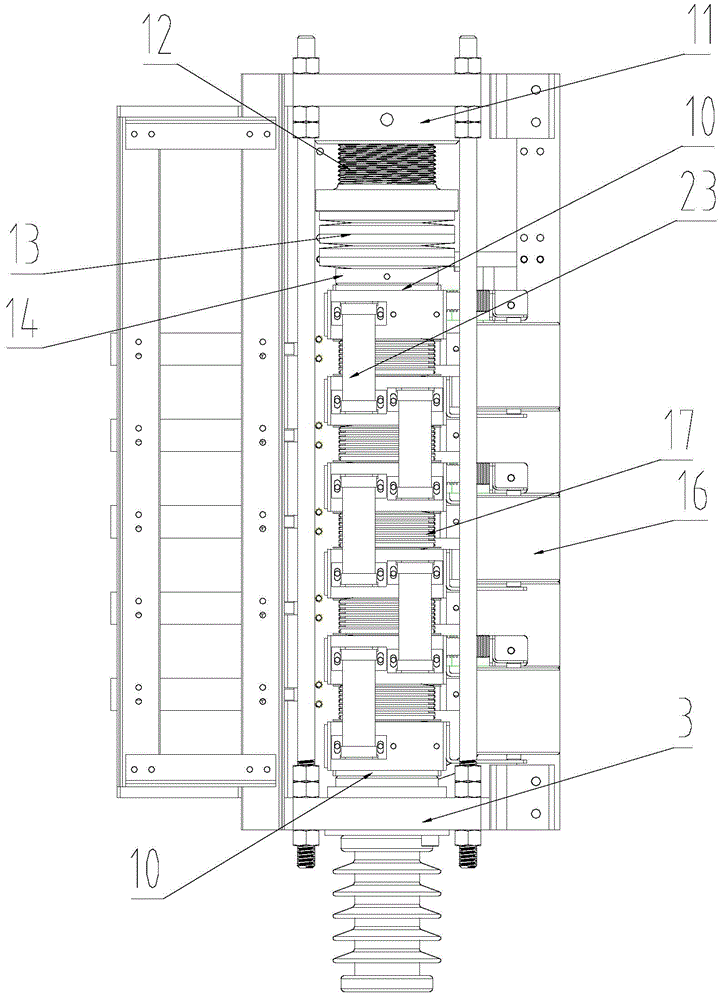

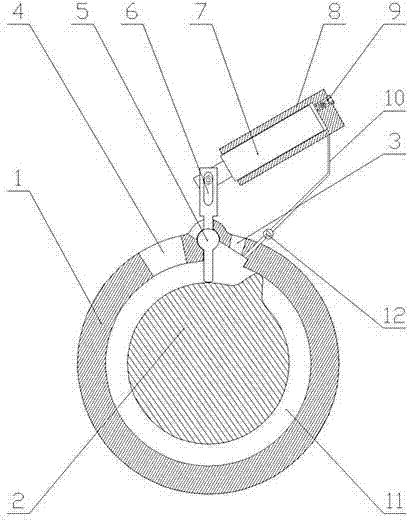

Intelligent solid state transfer switch, processing method thereof and transfer switch control system

ActiveCN103560774ACompact structureStructuredElectronic switchingElectrical resistance and conductanceSquare waveform

The invention provides an intelligent solid state transfer switch and a transfer switch control system adopting the intelligent solid state transfer switch. Two sets of thyristors connected in parallel are fixed between an upper end plate and a lower end plate, each set of thyristors comprises a plurality of thyristors connected in series, the number of the thyristors in the two sets of thyristors is equal, and each pair of corresponding thyristors of the two sets of thyristors are connected in an anti-parallel mode; each pair of thyristors is further connected with a static state equalizing resistor and a dynamic equalizing unit in parallel; all static state equalizing resistors are in serial connection in sequence, and all dynamic equalizing units are in serial connection in sequence; multiple TE plates are respectively connected with and control gate poles of each thyristor of each pair of thyristors; each TE plate is connected with an energy-gaining coil; AC square wave is output by a high-frequency energy-sending power source through a high-voltage energy-sending cable, and trigger drive energy is provided for the TE plates through induction of the energy-gaining coils. The intelligent solid state transfer switch is compact in structure and reasonable in arrangement, and turning-on, turning-off and quick switching of 10KV electric system lines can be achieved. The intelligent solid state transfer switch has the advantages of being intelligent and free of arc, noise and mechanical fatigue, and self-diagnosis, soft turning-on and soft turning-off can be achieved.

Owner:TIANJIN HONGCHENGTAI TECH DEV

Power equipment state diagnosis method based on temperature rise load performance, electronic equipment and storage medium

PendingCN112507510AImprove accuracyImprove reliabilityForecastingDesign optimisation/simulationEquipment temperatureControl engineering

The invention provides a temperature rise load performance-based power equipment state diagnosis method, and the method comprises the steps of physical mathematical modeling, equipment temperature rise load performance index calculation, equipment fault state judgment, equipment temperature rise load performance index feature definition, temperature rise load performance index feature curved surface transition diagram diagnosis, temperature rise load performance index feature parameter diagnosis, and temperature rise load performance index characteristic parameter change trend diagnosis. The invention relates to electronic equipment and a storage medium, which are used for executing the method. According to the invention, the load current and temperature relation model is applied to the monitoring and diagnosis of the power equipment, thereby greatly promoting the development of the state monitoring and diagnosis technology of the power equipment, improving the accuracy and reliabilityof the monitoring and diagnosis of the power equipment, and well solving the inherent problems in the state monitoring and diagnosis of the power equipment; the method is an important means for realizing state maintenance management of power equipment and improving the lean level of power production operation management.

Owner:ZHUHAI YADO MONITORING TECH CO LTD

Manufacturing process of tea

InactiveCN103918805ANo side effectsFragrant tastePre-extraction tea treatmentTea flavoringSide effectAdditive ingredient

The invention relates to the new technology fields of manufacturing process and processing method of tea, and particularly relates to a manufacturing process of cold beauty tea. The manufacturing process comprises three steps of picking, sorting and steamed smoking, wherein the picking step needs to follow five selection principles, the sorting step needs to follow eight discarding principles, and the steaming smoking process is divided into eighteen procedures. The cold beauty tea prepared by the manufacturing process has a health-preserving efficacy without addition of any substance, does not has any side effect, is good for both young and old, has no drug taste and other miscellaneous tastes, is fresh in mouthfeel, and has a long-term storage characteristic; and the cold beauty tea can be brewed with both cold water and hot water, and shows two quite different tea tastes, aromas and mouthfeels with cold brewing and hot brewing. The manufacturing process solves the problems that health-care and health-preserving tea in markets all has inappropriate crowds and various side effects and is heavier in medicinal material taste and poor in mouthfeel, has a need of addition of other ingredients to play health-care and health-preserving efficacies, has the shelf life of 12 months to 24 months, and cannot be stored for a long time.

Owner:董骥

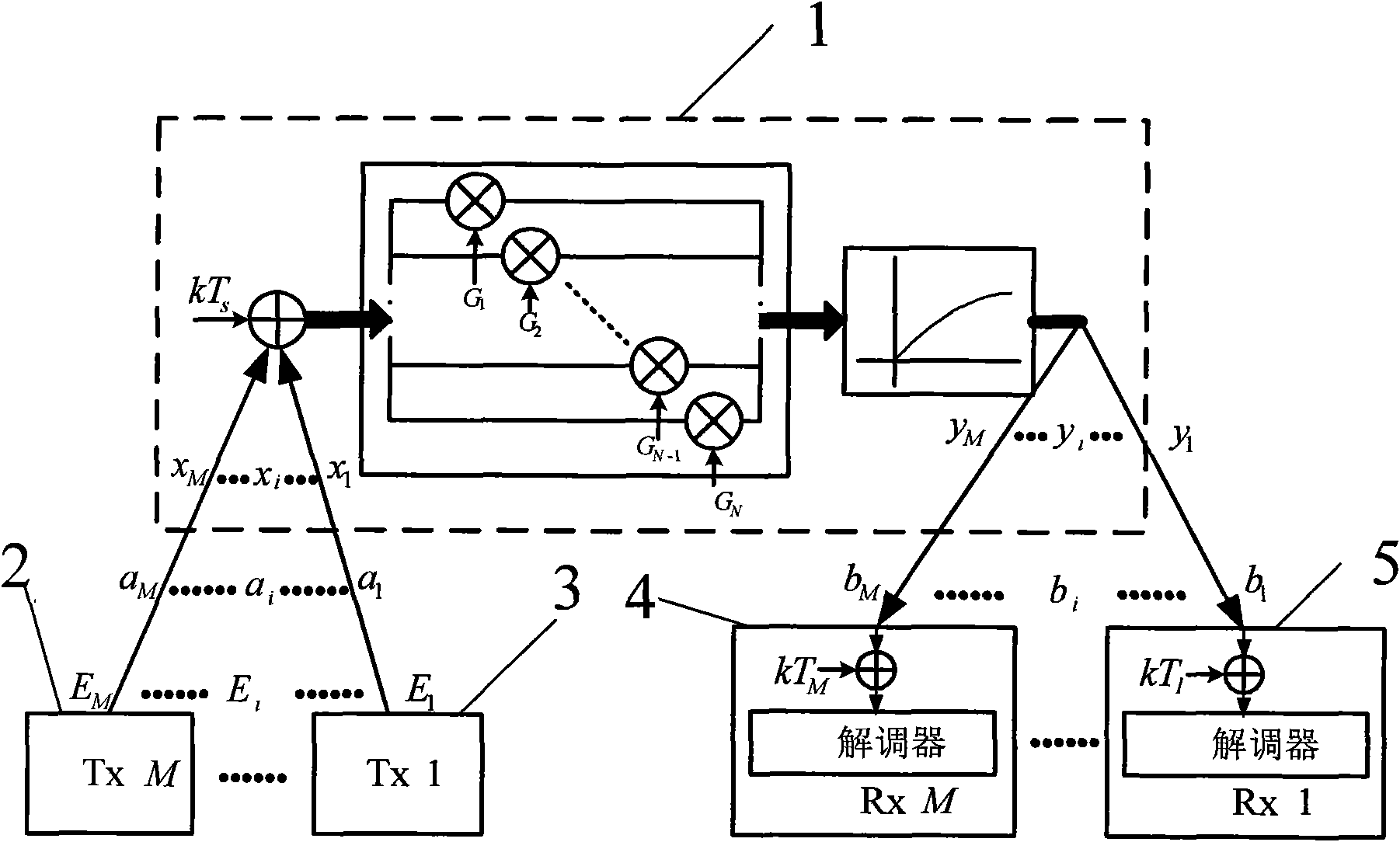

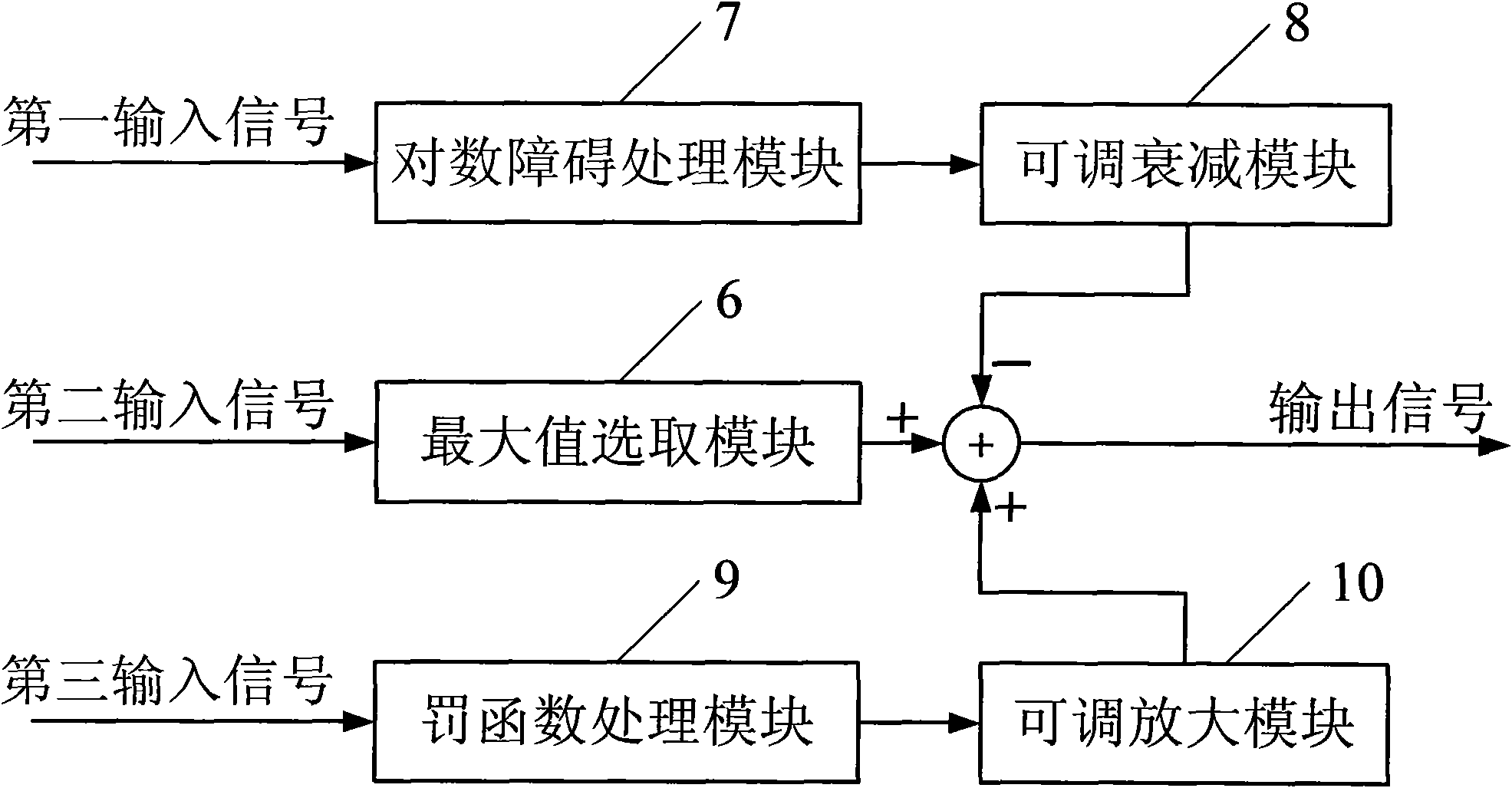

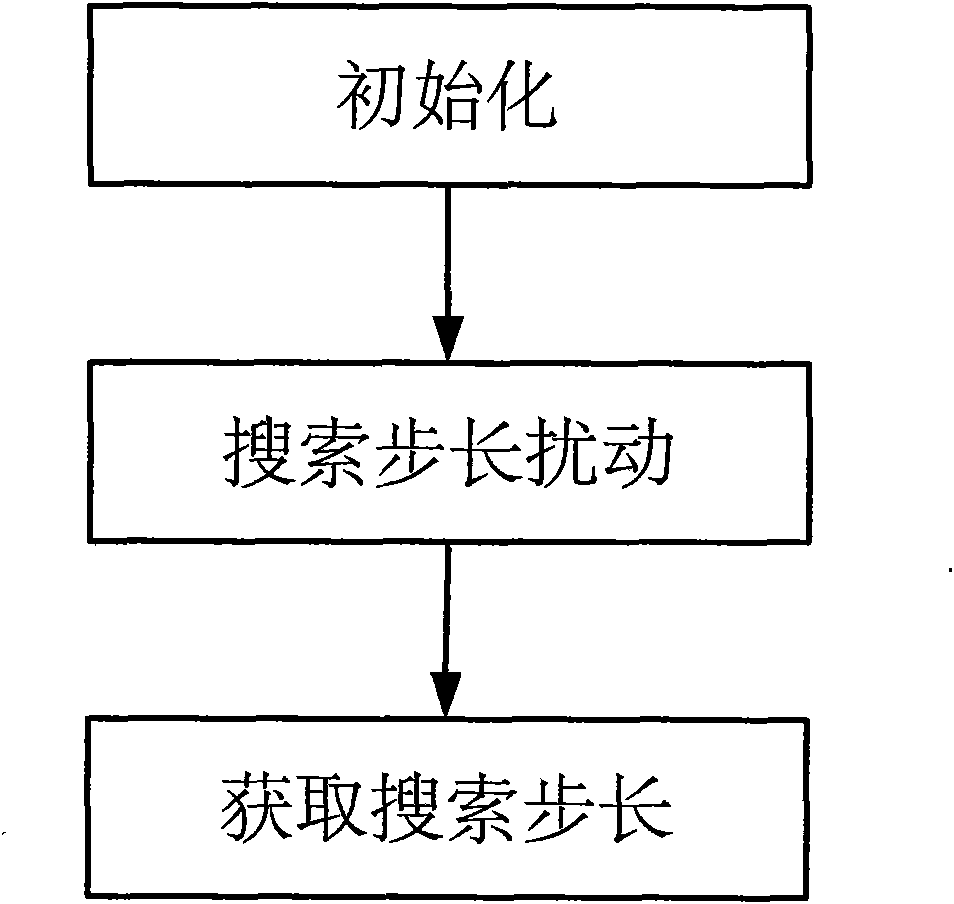

Satellite communication link supportable system and optimization method thereof

InactiveCN101610105AAvoid unevennessImprove power utilizationDiversity/multi-antenna systemsCarrier signalSatellite

The invention discloses a satellite communication link supportable system and an optimization method thereof. The system consists of five modules of a maximum value selection module, a logarithmic barrier processing module, an adjustable attenuation module, a penalty function processing module and an adjustable amplifier module. The optimization method firstly carries out initialization, then sequentially selects an initial neighbourhood, obtains a new point in the initial neighbourhood, carries out local research and finally carries out neighborhood change. The application of the link supportable system and the optimization method thereof can effectively solve the difficult problem of co-exist of big and small carriers in a multi-carrier satellite communication system, improves the capacity of the system and the power utilization rate of a transponder and has very important theoretical guiding significance and engineering practical value for the design of the satellite communication system.

Owner:BEIHANG UNIV

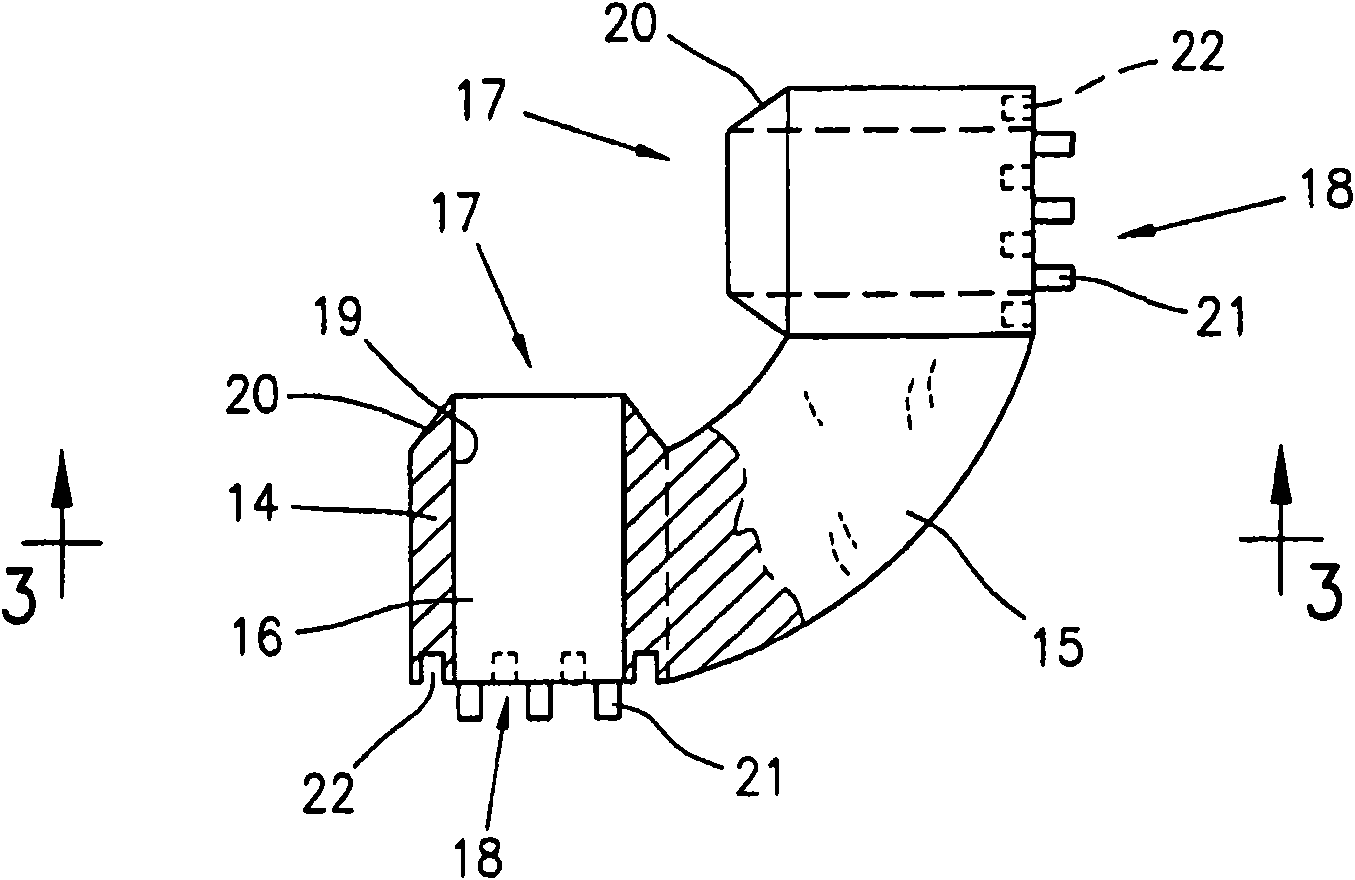

A joining device and system for a rigid connection between magnetically anchorable bar-shaped elements

Owner:克劳迪奥维琴泰利

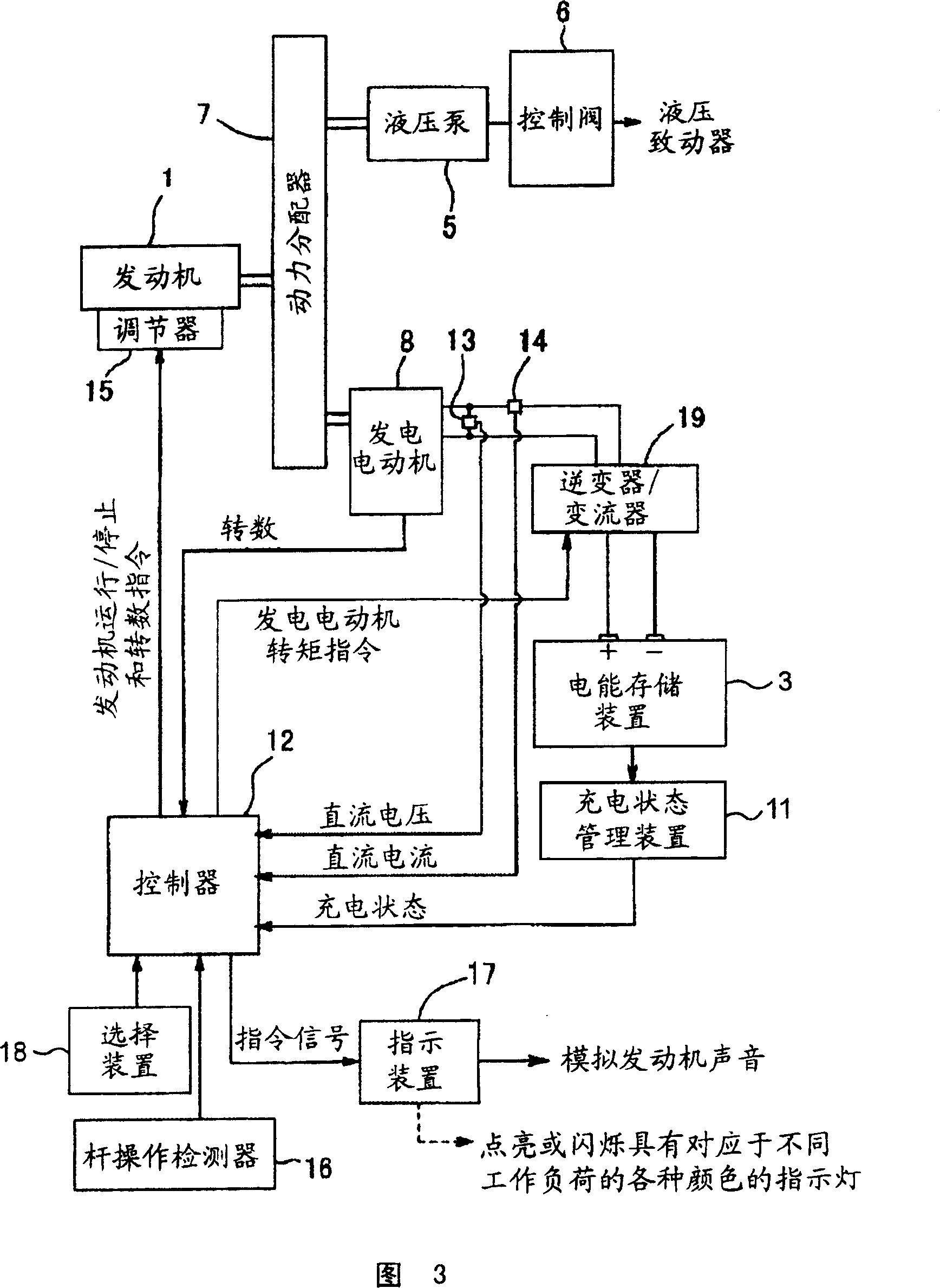

Construction machine

InactiveCN1955382ASolve inherent problemsImprove securitySoil-shifting machines/dredgersDisplay deviceEngineering

In a hybrid construction machine, its display device displays, toward an operator, an artificial engine sound serving as load information according to a magnitude of a workload, instead of an engine sound. Furthermore, the display device issues an alarm sound to surrounding workers when performing an operation by only stored electrical power of an electrical energy storage device without using an engine. In this hybrid construction machine, in addition to the issuing of alarm from the display device during the operation without using the engine, the display device issues an advance notice sound for engine restart when at least one value out of the workload and a charge amount of the electrical energy storage device has become an advance notice set value close to a set value of engine restart.

Owner:KOBELCO CONSTR MASCH CO LTD

Conveying line device with function of retaining workpieces temporarily

The invention discloses a conveying line device with a function of retaining workpieces temporarily. A tradition structure with friction strips and friction furrow wheels is abandoned and replaced by an annular friction disc and an idle gear meshed with a chain. A round turning disc is disposed at one end of a drive shaft of a frame to enable the conveying line device to be more reliable and smooth in turning. Profiling blocks matched with pins disposed on the turning disc are disposed on two sides of a support frame. Turning of the support frame is realized by inserting pins into turning holes on the profiling blocks. The conveying line device with the function of retaining workpieces temporarily is simple in structure, ingenious in design, and reasonable in layout. A damping (spring) structure is used for driving the support frame to move, the pins and turning holes are used for driving the support frame to turn, and accordingly moving is more reliable, and operation complexity caused by frequent replacing of friction strips can be avoided.

Owner:大连奥托股份有限公司

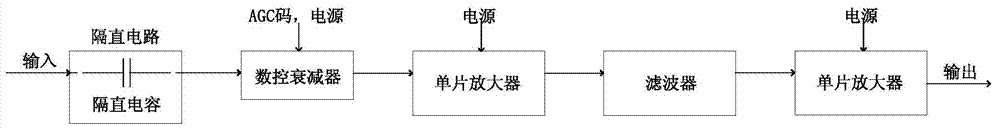

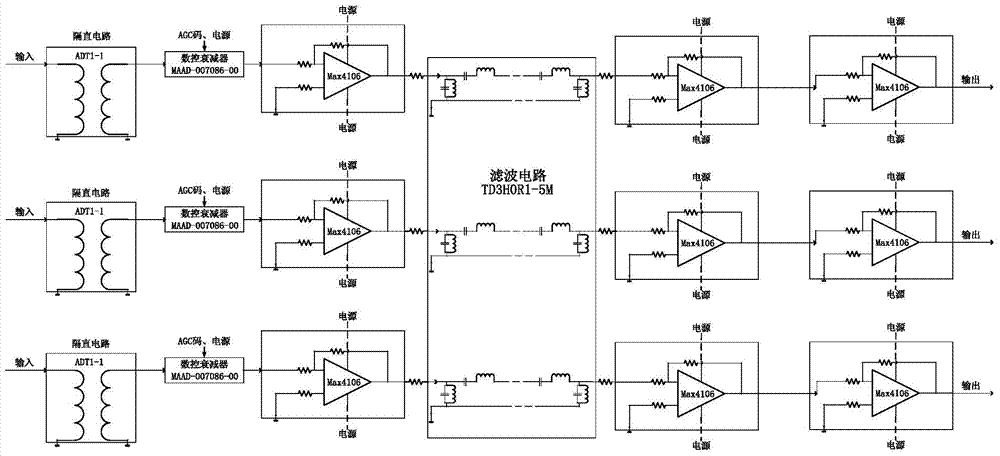

Multichannel radar video receiving machine based on operational amplifier

InactiveCN103501417ALarge dynamic rangeMeet UWBMultiple-port networksTelevision system detailsNumerical controlLow noise

The invention relates to a multichannel radar video receiving machine based on an operational amplifier. The multichannel radar video receiving machine based on the operational amplifier is characterized in that the input ends of the receiving machine are blocking circuits, the blocking circuits are connected with numerical control attenuators, the output ends of the numerical control attenuators are connected with first-stage negative feedback amplifier circuits, the output ends of the first-stage negative feedback amplifier circuits are connected with filter circuits, and the output ends of the filter circuits are sequentially connected with second-stage negative feedback amplifier circuits and third-stage negative feedback amplifier circuits through 50omega resistors. The multichannel radar video receiving machine based on the operational amplifier solves the inherent problems existing in a self-mixing system receiving machine, and also meets the requirements for miniaturization, the high integration level, the low cost, low noise, the ultra wide band and the like. On the premise that the low noise requirement is met, the negative feedback amplifier circuits formed based on the operational amplifier can conveniently adjust the gain of the amplifier circuits, and therefore gain distribution can be readjusted until the designed video receiving machine meets the system requirements when the video receiving machine is debugged.

Owner:CNGC INST NO 206 OF CHINA ARMS IND GRP

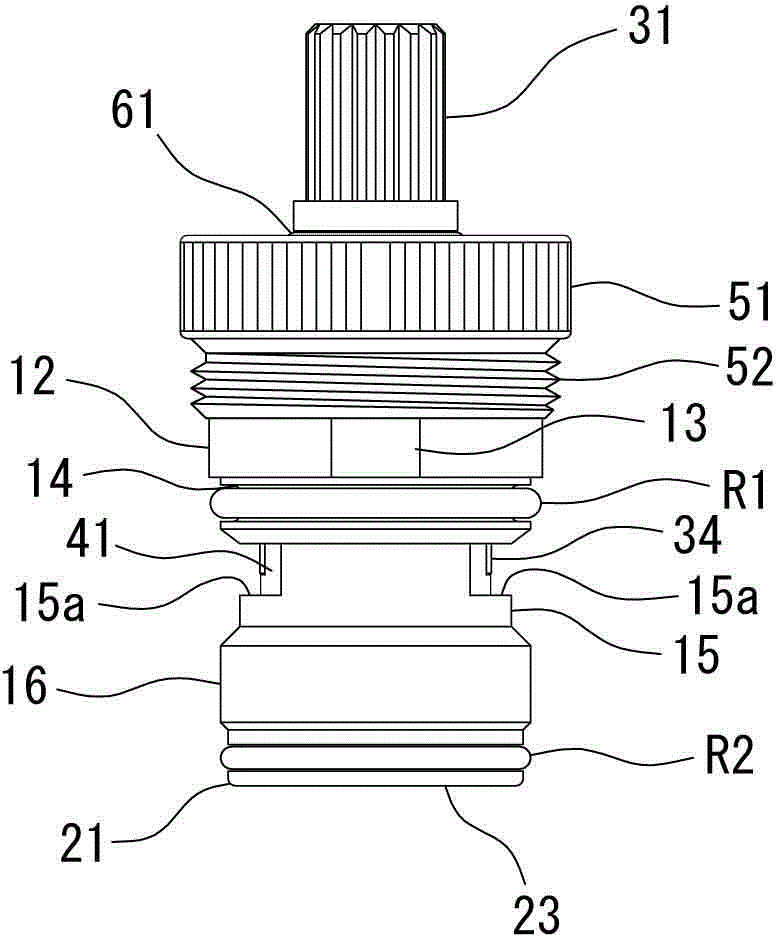

Resin Stop Water Valve Cylinder, Installation Structure Of Resin Stop Water Valve Cylinder, And Water Stop Structure Of Water Tap

InactiveCN104061344ASolve inherent problemsReduce weightOperating means/releasing devices for valvesMultiple way valvesWhole bodyEngineering

The invention relates to a resin stop water valve cylinder. The resin stop water valve cylinder can be completely made of and formed by a synthetic resin material, so weight reduction brought by synthesis resinificatin can be realized, and inherent problems of a brass material in the past are solved. A whole body of a housing (10), a supporting cover (20), a plunger rod (30) and a fixing cover (50) are formed by synthetic resin. The fixing cover (50) is mounted on a top end side of the housing (10) in a forward and reverse rotation manner. In the housing (10), a pair of embedded protrusions (13) are formed in extending manner in the axial direction nearby a position of the fixing cover (50). The embedded protrusions (13) of the housing (10) are embedded in a tap main body (100), and the housing (10) cannot move relative to a valve receiving part (120) through embedded buckling between the embedded protrusions (13) and the tap main body (100), so the fixing cover (50) is screwed into the valve receiving part (120) to perform installation.

Owner:MIZSEI MFG

Omnidirectional mobile equipment

ActiveCN111645778ASolve inherent problemsImprove adaptabilityResilient suspensionsWheelsClassical mechanicsEngineering

The invention provides omnidirectional mobile equipment. The equipment comprises a walking system which comprises 2N groups of Mecanum wheel mechanisms, a body frame, and an elastic suspension mechanism; 2N groups of Mecanum wheel mechanisms are symmetrically mounted on the body frame through the elastic suspension mechanism, and N is greater than or equal to 2; when the 2N groups of Mecanum wheelmechanisms continuously operate, the elastic suspension mechanism is used for allowing the 2N groups of Mecanum wheel mechanisms to relatively move on a mechanical degree of freedom given by the elastic suspension mechanism so as to absorb vibration generated in the operation process of the Mecanum wheel mechanisms; and a task load cabin is arranged on the walking system, a LiDAR laser radar is installed in the cabin body, and the LiDAR laser radar is driven by the walking system to move in a guide-rail-free mode. The inherent problems of a traditional Mecanum wheel mobile platform are solved, an optimally designed elastic suspension system and a unique wheel set arrangement method are adopted, the adaptability of the chassis to topographic relief is enhanced, and meanwhile mechanical vibration generated when the chassis operates is remarkably reduced.

Owner:SYMG SHANGHAI INTELLIGENCE SYST CO LTD

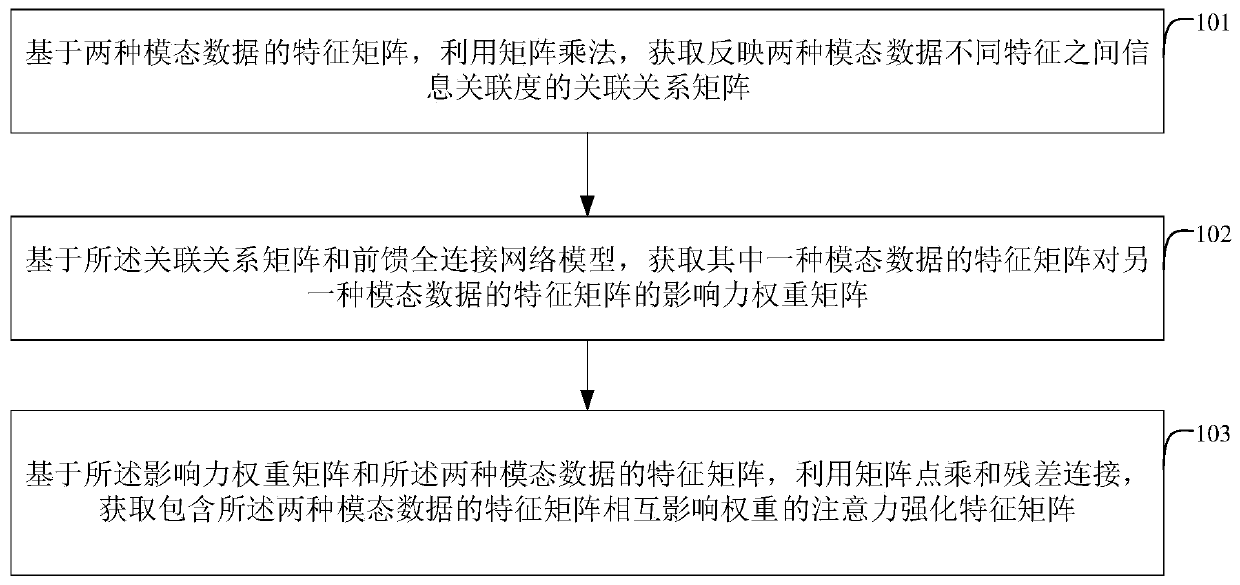

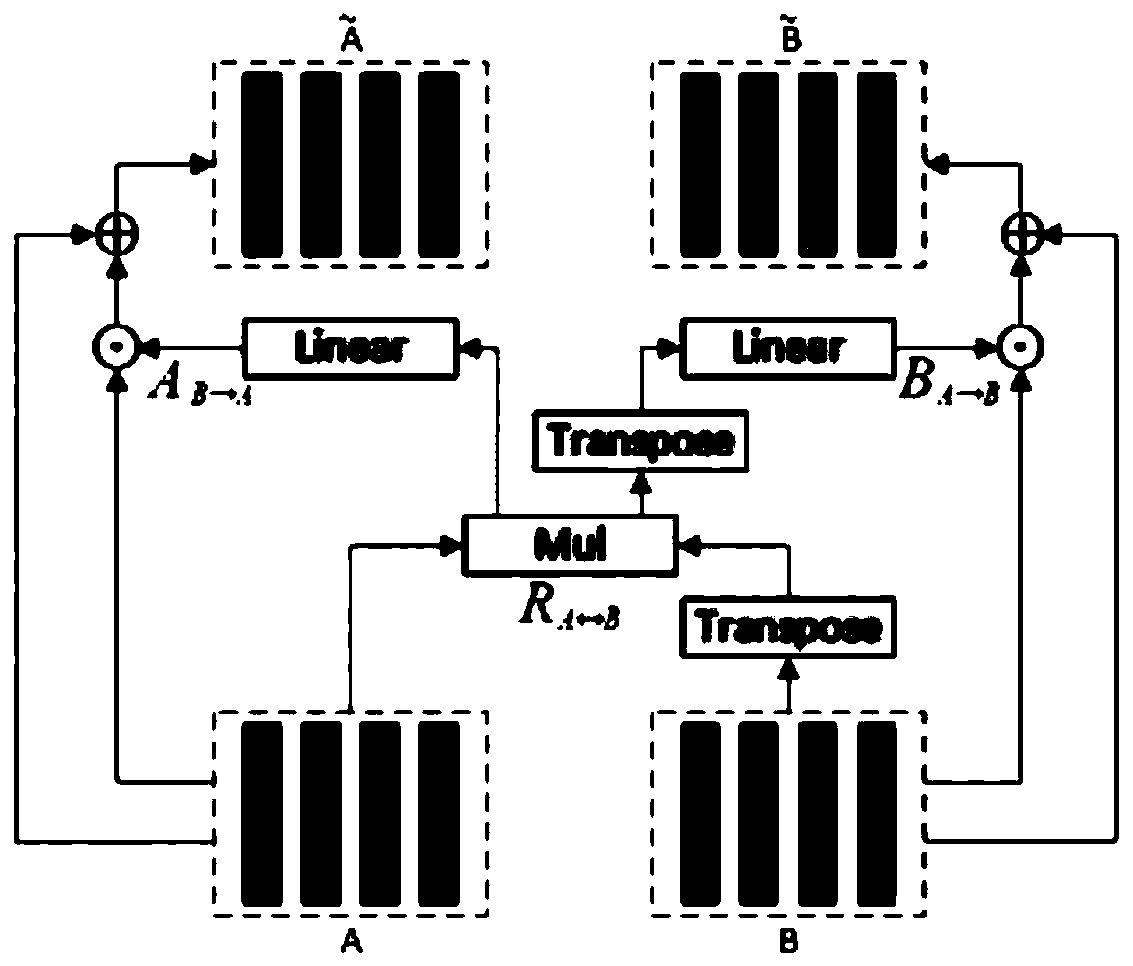

Multi-modal fusion method and device for psychological stress detection

ActiveCN110301920BSolve inherent problemsSolve the window period of psychological testingSensorsPsychotechnic devicesPattern recognitionData graph

The embodiments of the invention provide a multi-modal fusion method and device for psychological stress detection. The multi-modal fusion method is based on an attention-enhanced feature matrix of physiological data->text, physiological data->pictures, text->physiological data, text->pictures, pictures->physiological data and pictures->text, based on a feedforward fully-connected neural network,a fusion feature matrix of the text, the pictures and the physiological data is obtained; then based on importance weights of the text, the pictures, and the physiological data and the fusion featurematrix of the text, the pictures and the physiological data, a fusion representation matrix of three modes is obtained; and finally, based on the fusion representation matrix of the three modes and the feedforward fully-connected network, a pressure classification vector reflecting the psychological stress problem is obtained. By merging text picture data and physiological related data, not only the deficiencies caused by the subjectivity of text and picture data are compensated, but also certain inherent problems of physiological related data are solved.

Owner:TSINGHUA UNIV

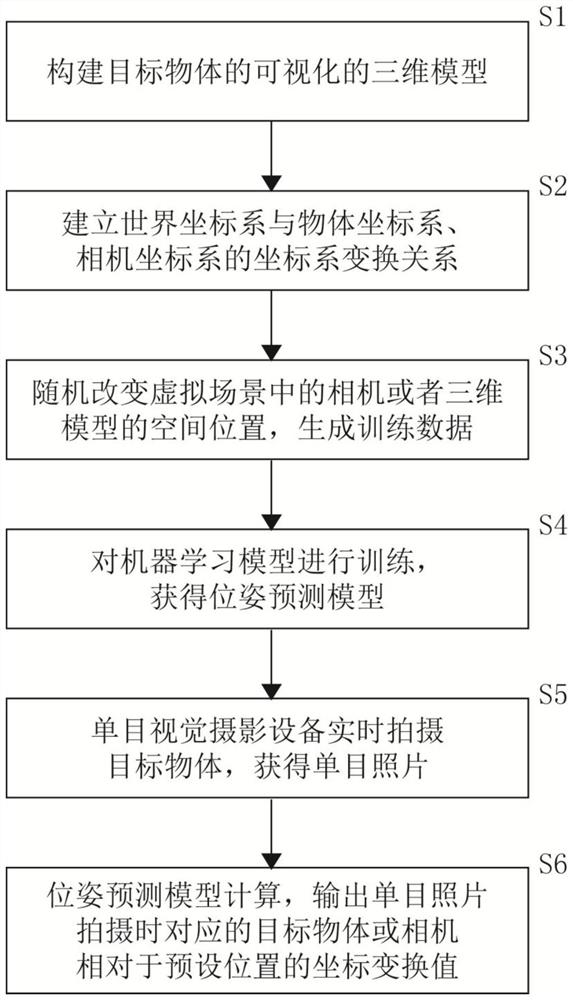

Three-dimensional target automatic positioning and attitude determination method based on monocular optical photography and application thereof

PendingCN114519742ASolve inherent problemsHigh precisionImage enhancementImage analysisComputer graphics (images)Radiology

The invention provides a three-dimensional target automatic positioning and attitude determination method based on monocular optical photography. The method comprises the following steps: constructing a visual three-dimensional model of a target object; presetting the positions of the three-dimensional model and the camera in the world coordinate system, and establishing a coordinate system transformation relation among the world coordinate system, the object coordinate system and the camera coordinate system; randomly changing the spatial position of the camera or the three-dimensional model in the virtual scene, and recording corresponding image and spatial position transformation information; training the machine learning model to obtain a pose prediction model; the object monocular picture of the target object is input into the pose prediction model, and the pose prediction model outputs the coordinate transformation value of the corresponding target object or the camera relative to the preset position. According to the invention, accurate spatial position and attitude evaluation can be carried out on the target object shot by a traditional monocular vision imaging device, and no additional marker or camera needs to be added, or no calibration and processing are carried out on the target object on the spot.

Owner:CAPITAL UNIVERSITY OF MEDICAL SCIENCES

Continuous oscillation flow pipe type cooling crystallization method of erythritol

PendingCN106866367AImprove liquidityGood conditionVibration crystallizationHydroxy compound separation/purificationRetention timeEngineering

The invention relates to a continuous oscillation flow pipe type cooling crystallization method of erythritol. The technical scheme is as follows: feeding erythritol crystallization mother liquor into a multi-stage serial sleeve type crystallizer, and axially arranging a circular damper along a center in each sleeve, axially reciprocating and oscillating along the center in the tube through the circular damper, thereby obviously improving the fluid flowing and micromixing state near the continuous sleeve type crystallizer pipe wall, and enabling the crystal particles in the crystallization mother liquor to uniformly suspend; the plug flow type RTE (retention time distribution) can be approximately achieved even under low flow velocity, and the inherent chronic disease restricting the traditional tubular continuous crystallizer industrial application is effectively solved, such as the following technical problems that the heat transfer efficiency is obviously lowered since the crystallizer wall is easy to deposit / separate the crystal to form the crystal scale, the radial temperature-concentration gradient is larger, and the local oversaturation is higher since a pipe wall retention layer is thick under the low shearing rate. The method disclosed by the invention has the advantages of being continuous in production, capable of effectively lowering the crystallization production cost of the erythritol.

Owner:WUHAN UNIV OF SCI & TECH

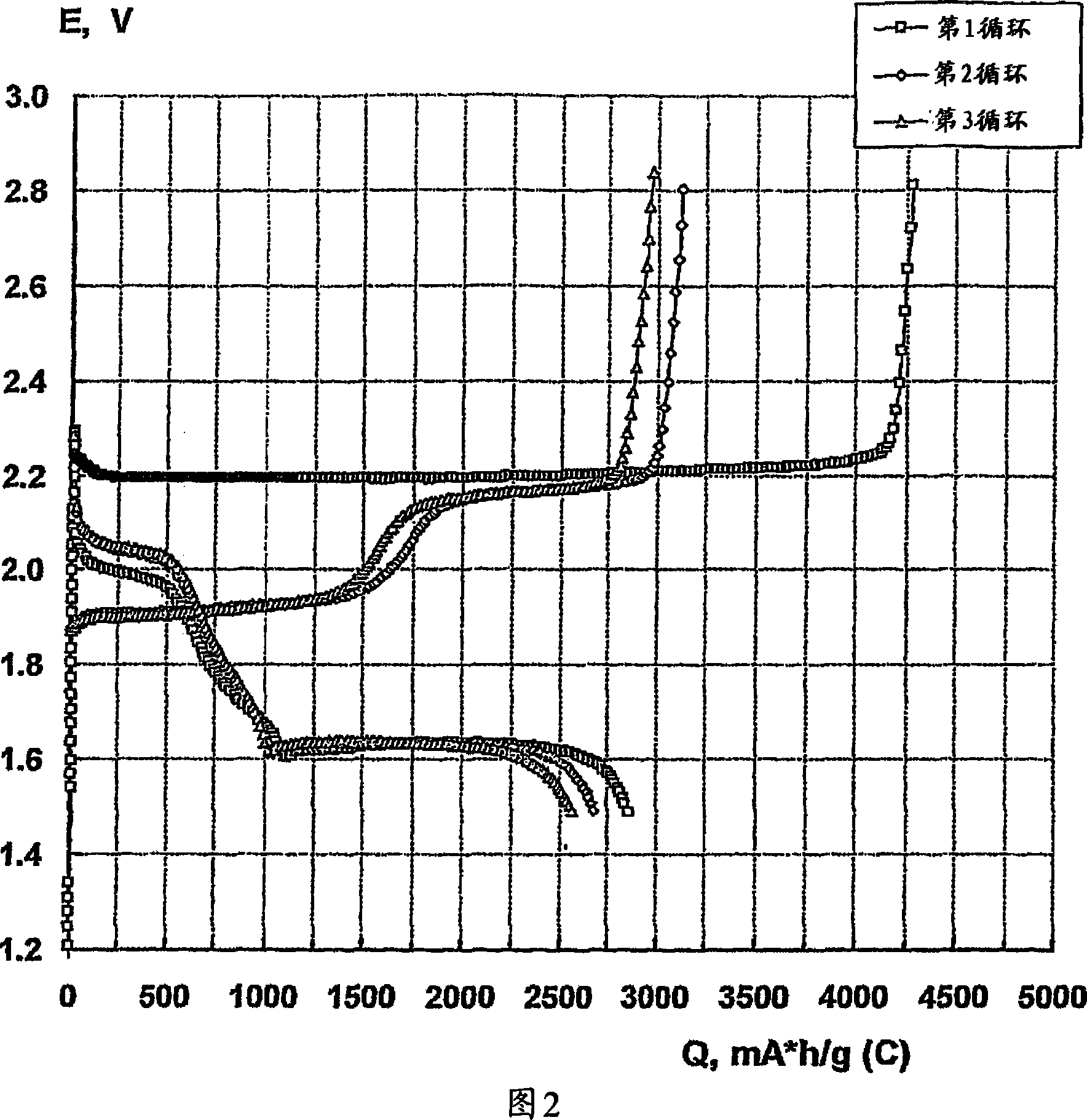

Lithium sulphide battery and method of producing the same

There is disclosed a chemical source of electrical energy comprising a positive electrode (cathode) made of an electrically conductive material, a mixture of lithium sulphide and sulphur, a permeable separator or membrane, and a negative electrode (anode) made of an electrically conductive material or a material that is able reversibly to intercalate lithium ions, wherein an aprofic electrolyte comprising at least one lithium salt in at least one solvent is provided between the electrodes.

Owner:JOHNSON MATTHEY PLC

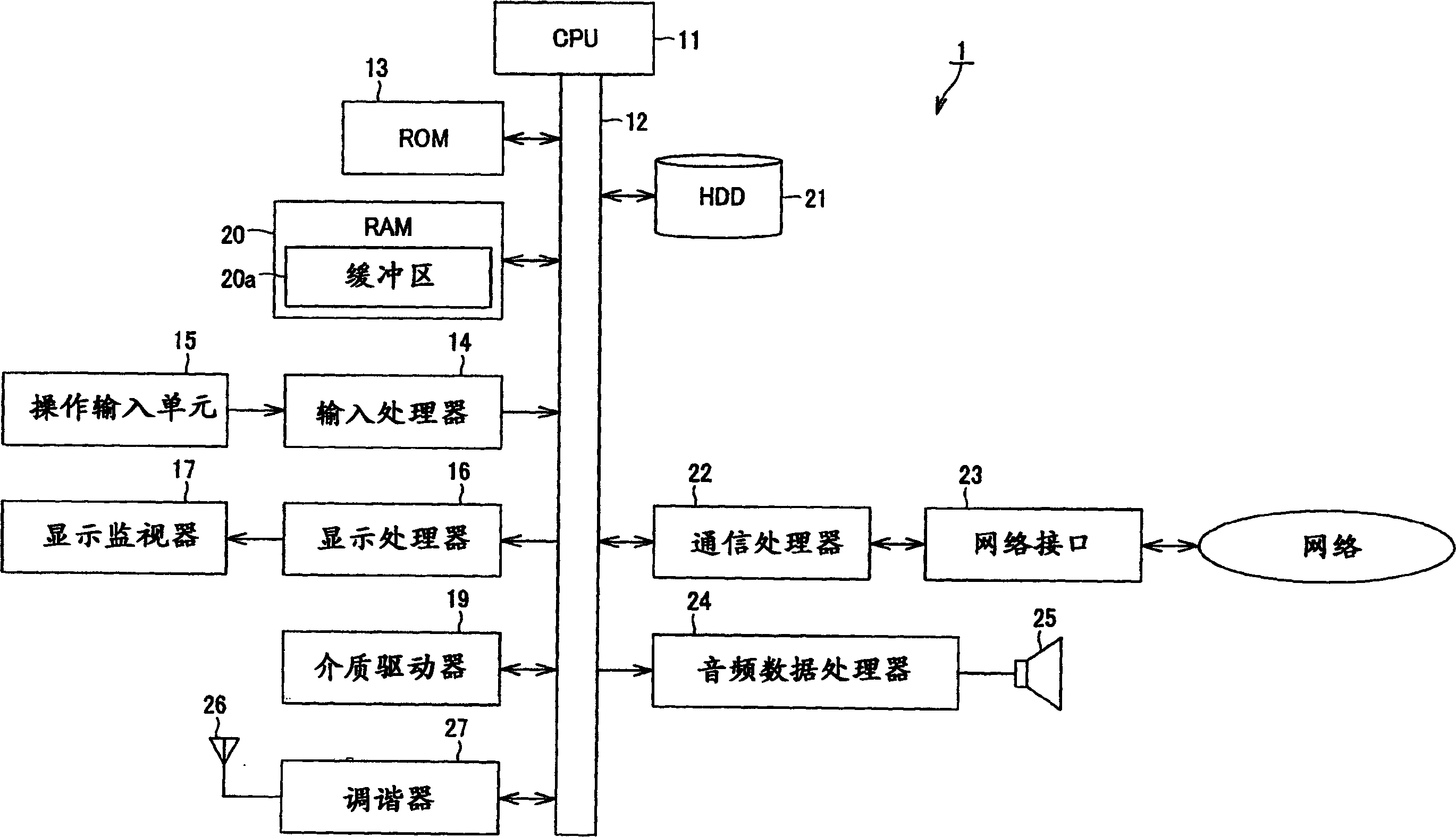

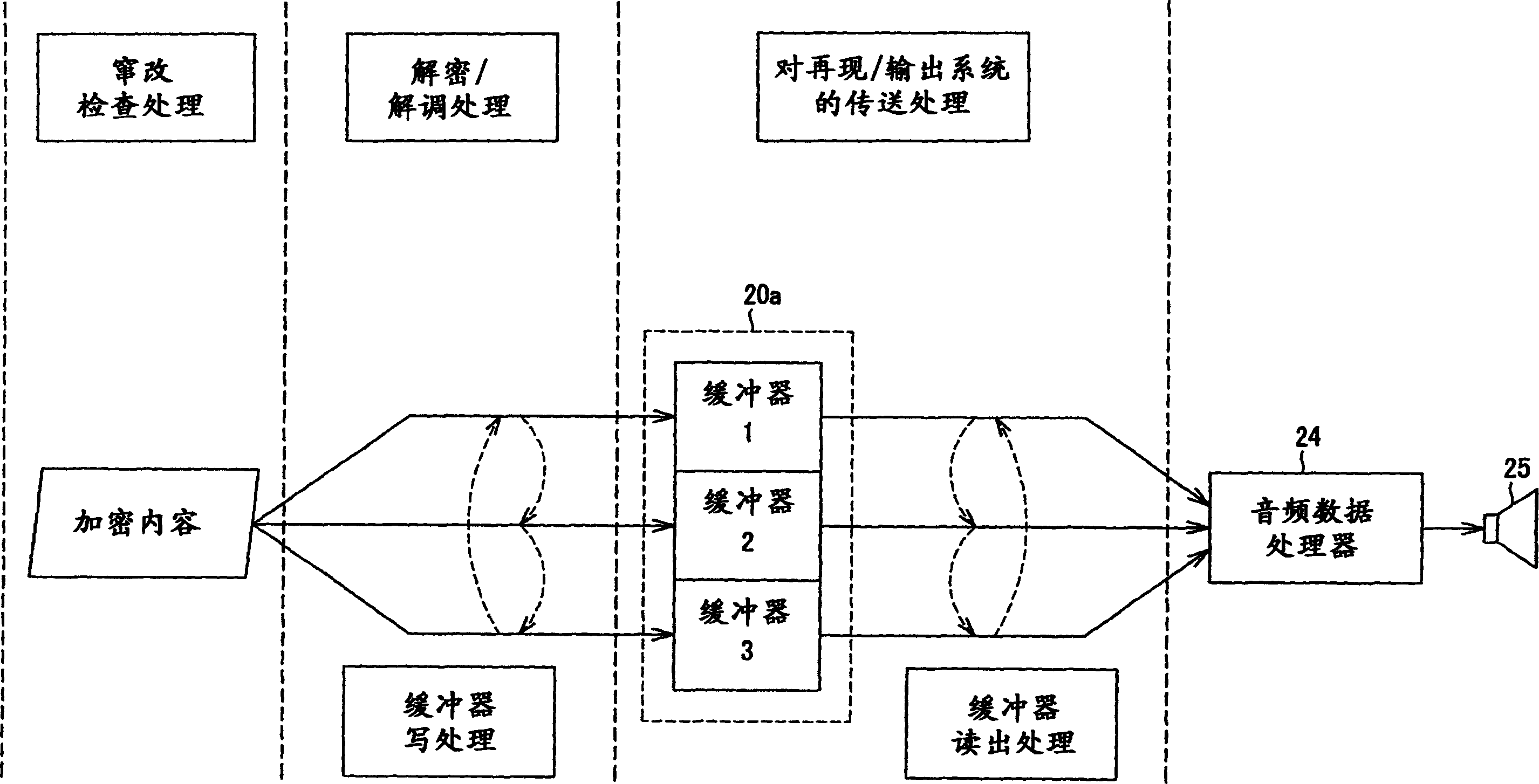

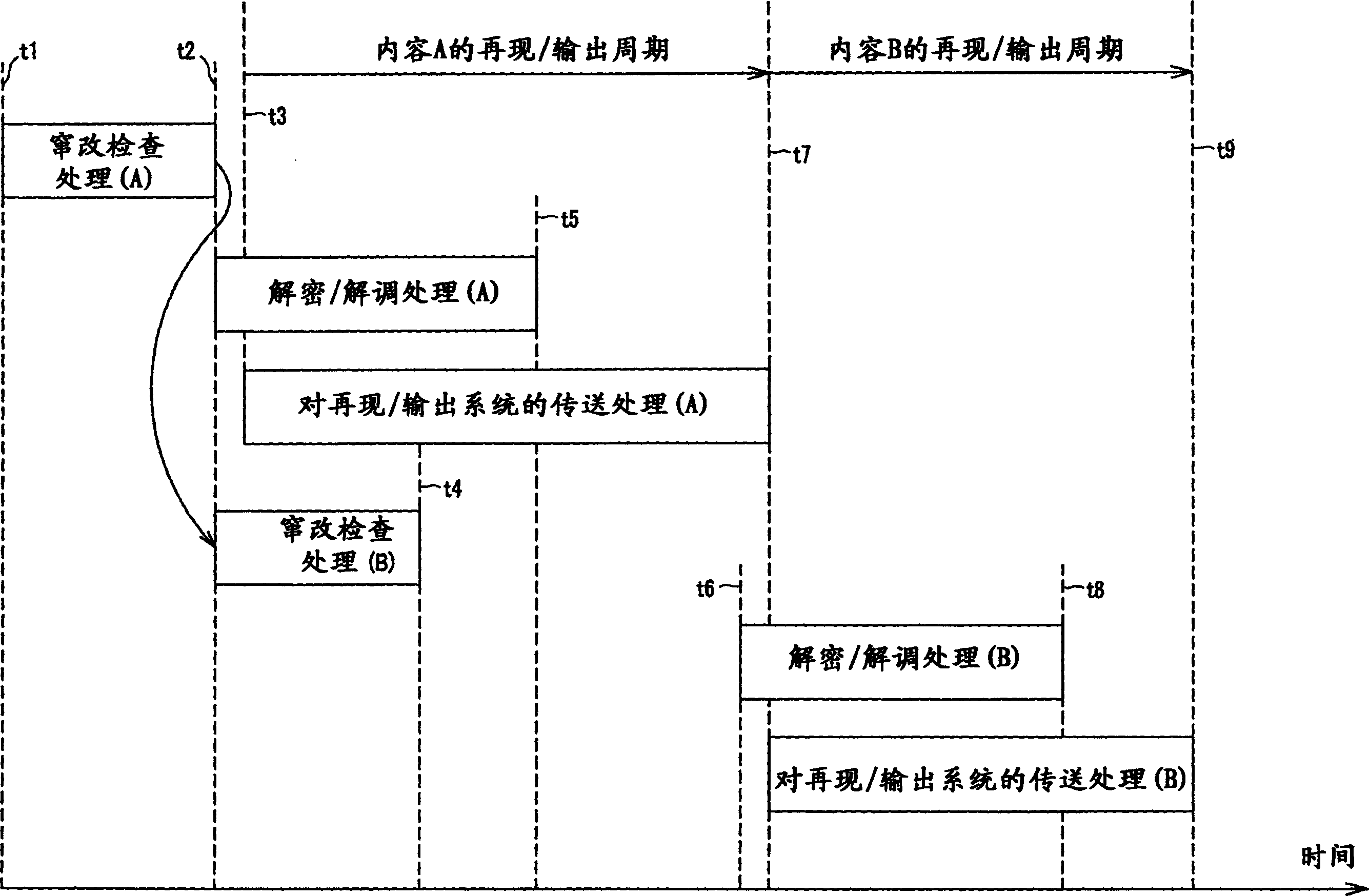

Information processing device and information processing method

InactiveCN1777947ASolve inherent problemsSpeech analysisUnauthorized memory use protectionInformation processingComputer hardware

The present invention relates to an information processing device and method, and specifically discloses an information processing method for performing processing on unit data in which one content is processed as one unit. In order to continuously reproduce and output content data, after the decryption / demodulation process of the current content data is terminated, the falsification checking process is started for the next content data reproduced after the current content data being reproduced. This eliminates the time interval when the decryption / demodulation process of the current content data and the falsification check process of the next content data are simultaneously performed, thus preventing an increase in processing load caused by the simultaneous execution of the falsification check process and the decryption / demodulation process.

Owner:SONY CORP

Method for transmtitig digital video

InactiveCN1728713BRealize triple playReduce networking costsTransmissionDigital videoNetwork management

Using packet switching, the disclosed digital video transmission method can be applicable to united public network in next generation. New layer of data link layer protocol - data link procedure (DLP) is introduced between digital video service layer and each physical layer. Using DLP protocol defined destination address code and source address code compatible to current telephone number system as addresses of sending end and receiving end of digital video signal realizes forwarding and exchanging digital video signal in two layers, as well as realizes purpose compatible between packet voice network and IP network. Using safety mechanism, network control management mechanism, flow management mechanism provided by DLP realizes network management control function such as two layer protectedrearrangement in two layers, performance management, fault management etc. The method makes current communication network transits to united public network in next generation smoothly.

Owner:邓里文

A method for preparing non-oriented silicon steel with high magnetic induction and high strength based on thin strip continuous casting

A method for preparing high magnetic induction and high strength non-oriented silicon steel based on thin strip continuous casting, which belongs to the field of metallurgical technology and is carried out according to the following steps: (1) Smelting molten steel according to the set composition, whose composition contains C 0.001~0.005% by weight. , Si 2.4~3.5%, Mn 0.2~2%, Alt 0.35~1.0%, Ni 0.4~3%, Cr 0.5~4%, Sn 0.02~0.2%, O≤0.005%, S≤0.005%, N≤0.005 %, P≤0.005%, the balance is Fe; (2) Pour into the double-roller thin strip continuous casting device for continuous casting; (3) The cast strip is cooled to room temperature twice, and single-pass hot rolling; (4) Pickling After cold rolling; (5) Final annealing treatment, insulating coating on line, and finally coiling. The method of the invention can maximize the inherent advantages of thin strip continuous casting, improve the magnetic properties and mechanical properties of thin strip continuous casting electrical steel products, has a simple preparation method, is environmentally friendly and energy-saving in the production process, has low investment cost and high production efficiency.

Owner:NORTHEASTERN UNIV LIAONING

Illuminating lamp system with function of automatically switching disinfection and sterilization

ActiveCN113237042ARegulate securitySolve inherent problemsElectric circuit arrangementsLighting elementsInfraredMicrocontroller

Owner:许武一

Gas engine capable of automatically adjusting expansion ratio

InactiveCN102305104ASimple structureIngenious designRotary piston enginesEngineeringAtmospheric pressure

The invention discloses a gas engine capable of automatically adjusting an expansion ratio. The gas engine comprises an engine shell in which a cam piston is arranged, wherein a gas inlet and a gas outlet are formed on the engine shell; the gas engine is characterized in that: a rotary blade valve is hinged with the engine shell between the gas inlet and the gas outlet; a sliding slot is formed at the upper end of the rotary blade valve; a buffering plug which is connected with the sliding slot and capable of sliding relative to the sliding slot is arranged in a buffering sleeve; a buffering check valve is arranged at the end of the buffering sleeve; a buffering cavity in the buffering sleeve is communicated with an inner cavity of the engine through a buffering pipeline; and a check valve is arranged on the buffering pipeline. The gas engine has the advantages of automatically adjusting the expansion ratio according to gas pressure in the cavity of the engine, reducing or even avoiding exhaust power consumption, effectively reducing friction resistance and the like, along with simple structure and ingenious design.

Owner:DALIAN SANGTER AUTOCAR ELECTRONICS +1

Apparatus and method of releasing disk in optical disk player

InactiveCN1747025ASolve inherent problemsReduce the numberRecord information storageRecord carrier contruction detailsControl theoryPower loss

Disclosed are an apparatus and method of releasing a disk. The disk releasing apparatus includes a first unit operating in cooperation with the second pivot plate to selectively couple the slider to the transmission unit, and a second unit operating in cooperation with the slider to release the second pivot plate from the disk. It can reduce the number of components, and decrease a power loss generated at the transmission.

Owner:SAMSUNG ELECTRONICS CO LTD

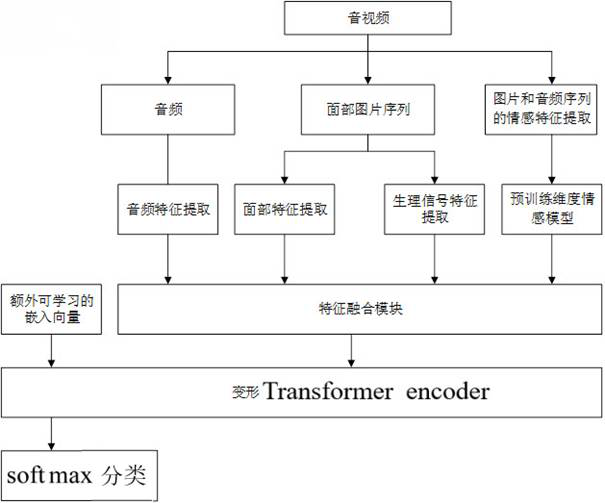

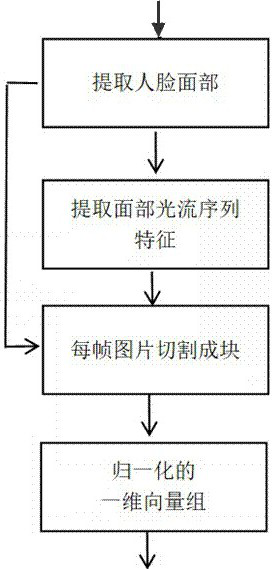

Psychological stress analysis method of multimodal fusion

ActiveCN113255635BSolve inherent problemsMake up for the lack of subjectivitySpeech analysisMental therapiesFrame sequenceFeature extraction

The present invention provides a multi-modal fusion psychological stress analysis method, including: cutting long audio and video into short audio and video with faces and voices, and performing frame processing on the short audio and video to obtain image sequences and voice signals; Perform facial feature extraction on the image sequence to obtain a facial frame sequence; apply the optical flow method to extract optical flow from adjacent frames of the facial frame sequence to obtain an optical flow sequence; fuse the facial frame sequence and the optical flow sequence to perform linear Mapping to obtain the facial embedding vector; extracting the region of interest from the image sequence to obtain the sequence of interest, performing linear mapping to obtain the physiological signal embedding vector; extracting the basic acoustic features of the speech signal in units of frames, and performing linear mapping to obtain the acoustic embedding vector; Emotional features are extracted from speech signals and image sequences; the above features are fused according to the time sequence of the frame sequence to obtain a spatiotemporal feature vector; the spatiotemporal feature vector is input into the model, and then the psychological stress level is obtained through softmax classification.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com