Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Simple detection principle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

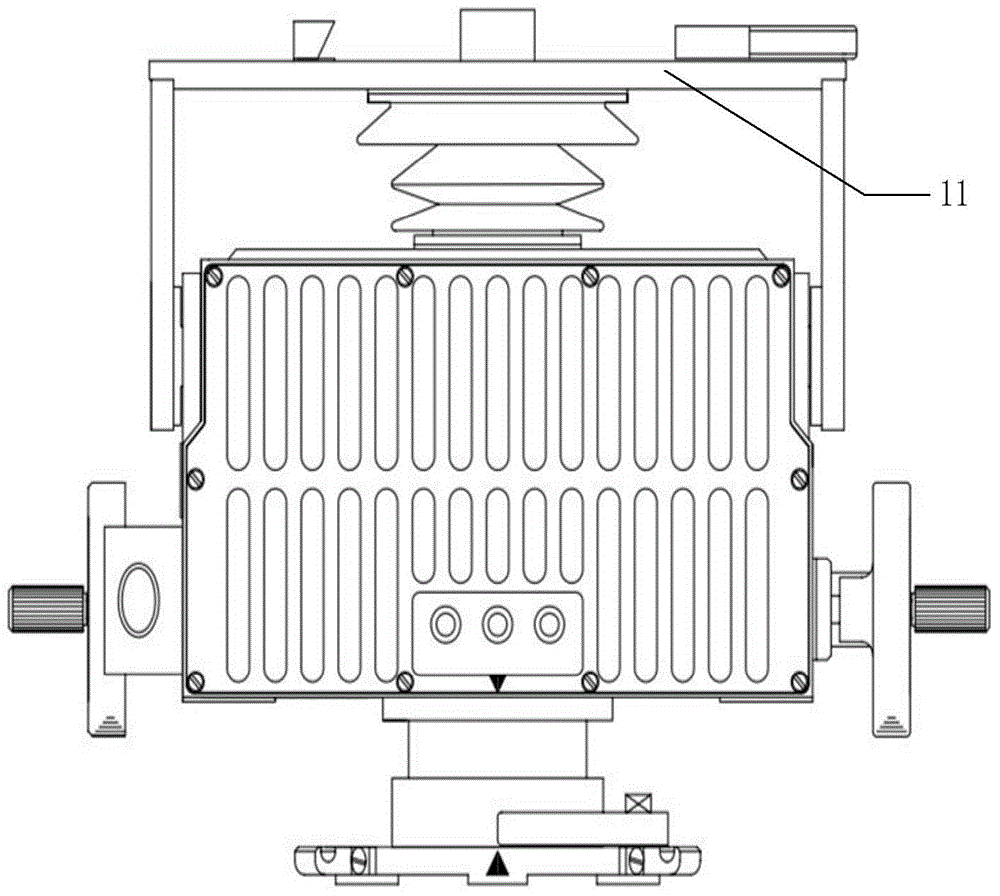

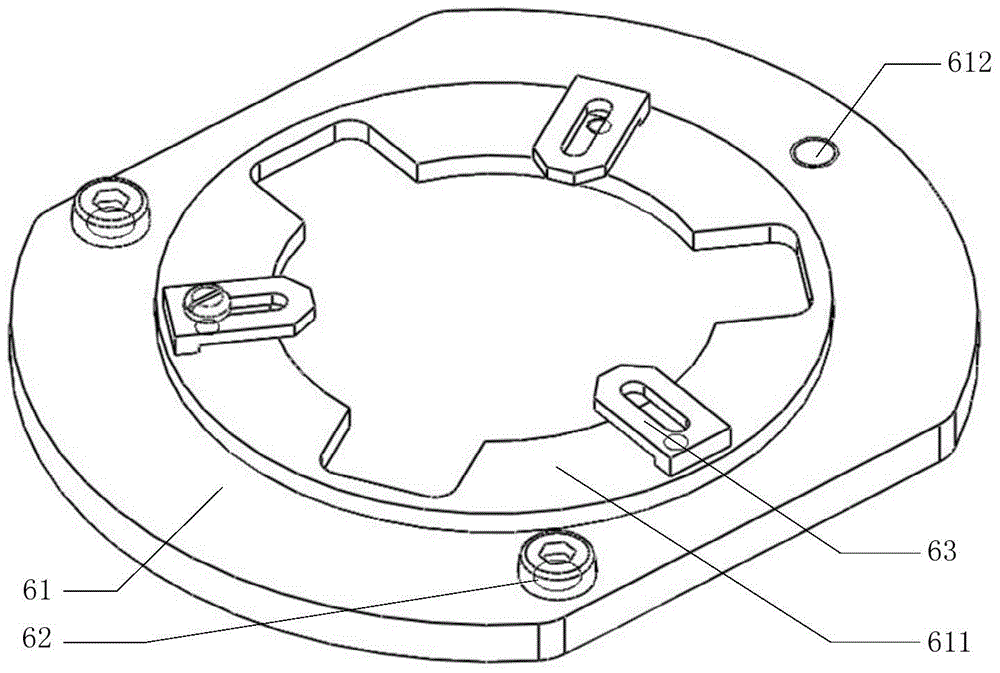

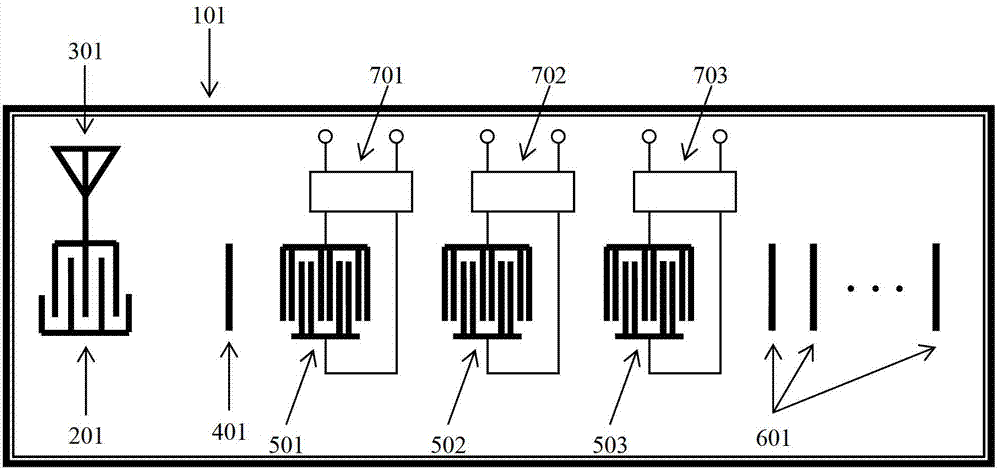

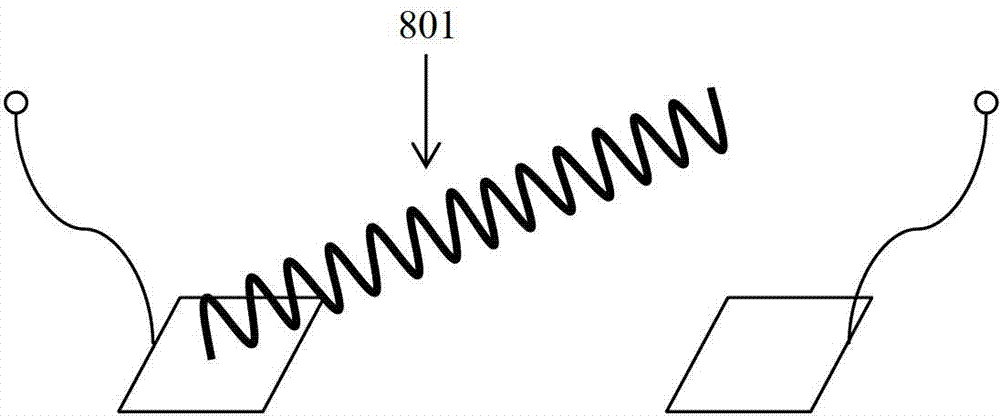

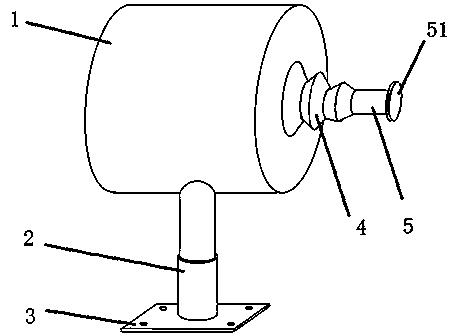

Vibration sensor based on surface acoustic wave radio frequency identification technology and application for vibration sensor

ActiveCN102889923AComplex structureSimple designVibration measurement in solidsAcceleration measurement using interia forcesGratingVibration acceleration

The invention relates to a vibration sensor based on a surface acoustic wave radio frequency identification technology and application for the vibration sensor. The vibration sensor can be used for identifying the identity of a measured object in a radio frequency manner, and can also be used for monitoring whether the vibration acceleration of the measured object exceeds a set threshold value or not and then recording the vibration acceleration of the measured object; a surface acoustic wave device comprises an antenna, a piezoelectric substrate, an interdigital transducer, reflecting gratings and an elastic element; radixes in the reflecting gratings are used for coding radio frequency tags; the 1-3 reflecting gratings are connected with the elastic element, and then a normally open loop is formed; when the vibration acceleration induced by the vibration sensor exceeds the set threshold value, the reflecting gratings, the elastic element and matched networks jointly form a closed loop; and features of echo signals reflected back to a reader are changed, so that the vibration sensor can alarm after the vibration acceleration in a superthreshold is recorded. Compared with the prior art, the vibration sensor has the characteristics that a measuring method is simple, multidimensional and multi-range measurement can be realized, the vibration sensor is wide in application, and the like.

Owner:SHANGHAI JIAO TONG UNIV

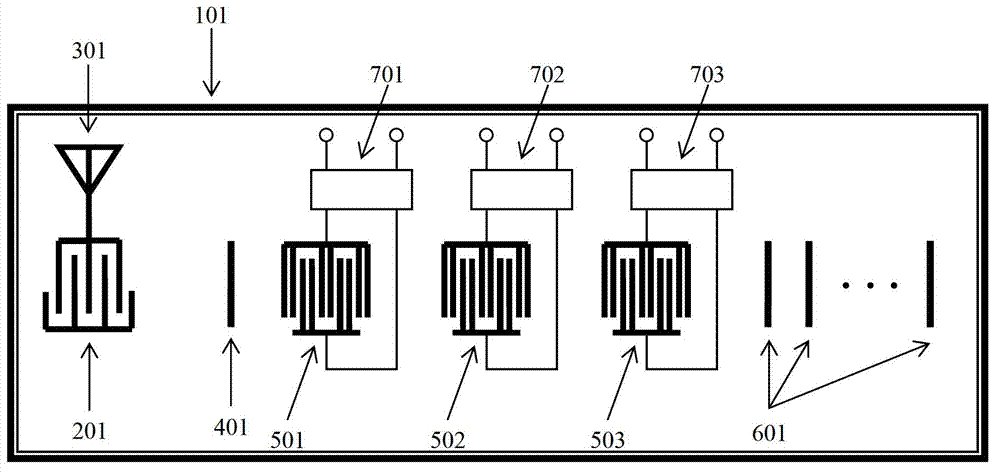

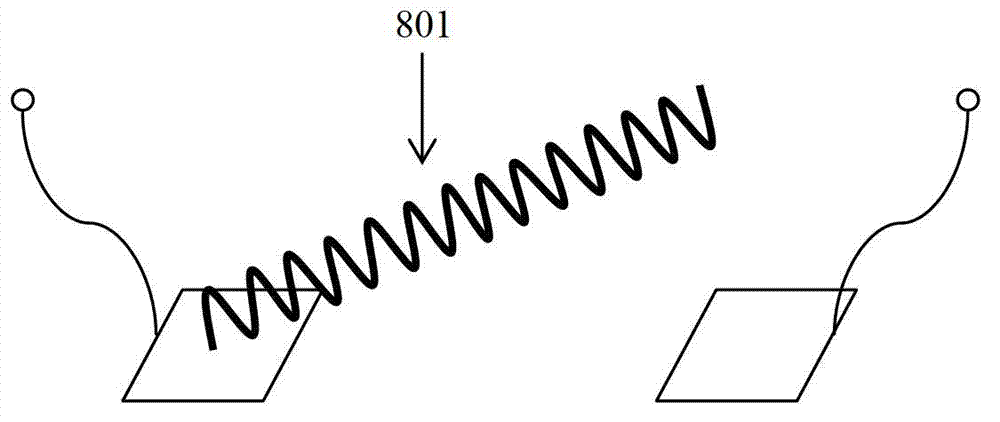

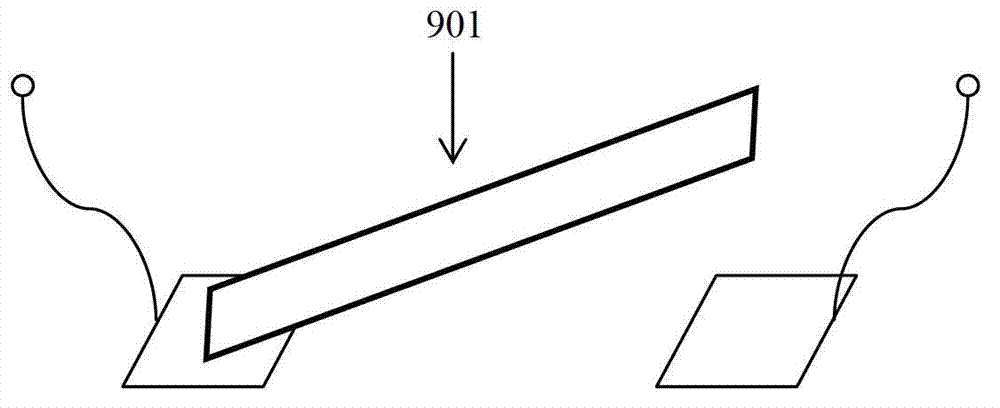

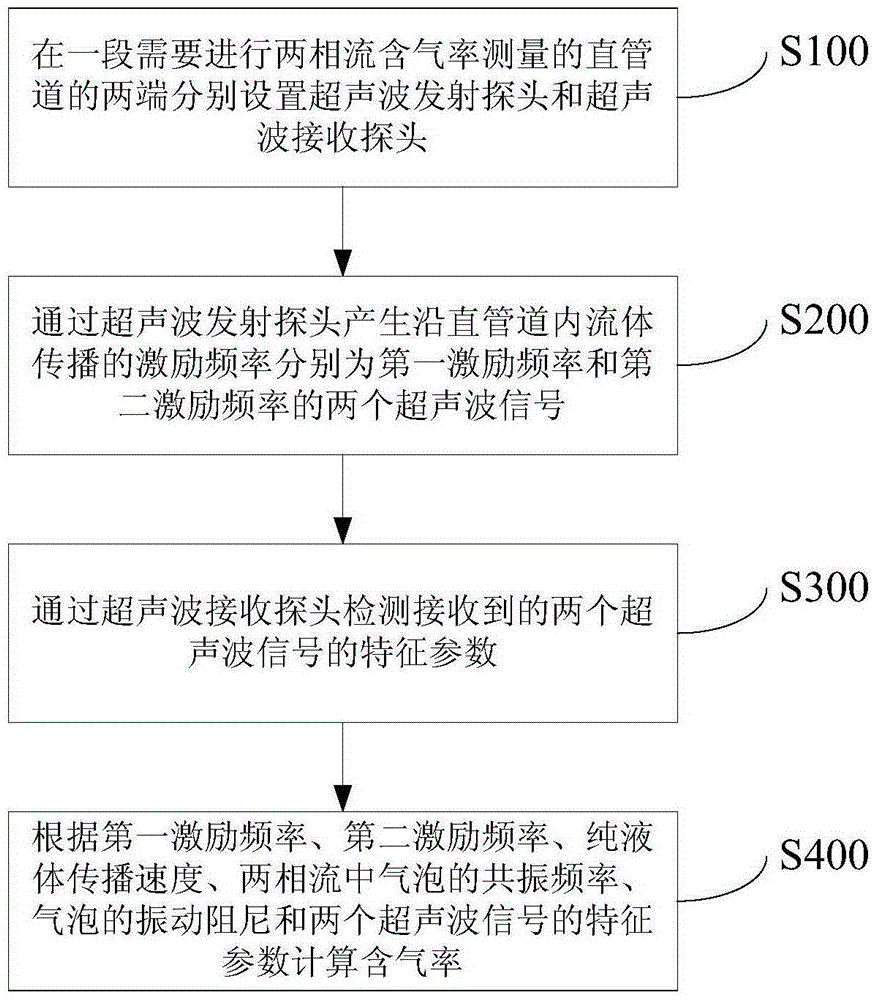

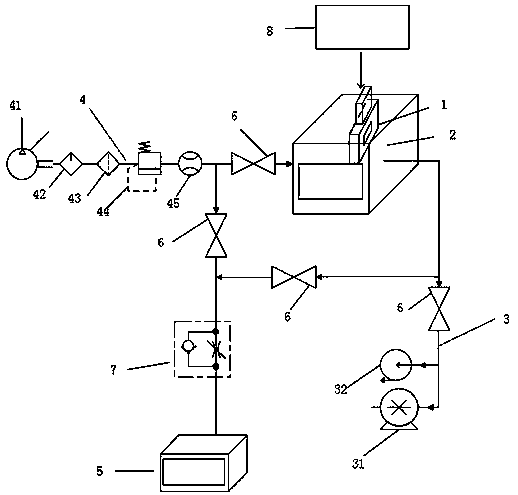

Method for measurement of two-phase flow gas holdup based on ultrasonic two-frequency signal

ActiveCN105181793ARealize non-contact measurementDoes not impede flowAnalysing fluids using sonic/ultrasonic/infrasonic wavesDouble frequencyMechanics

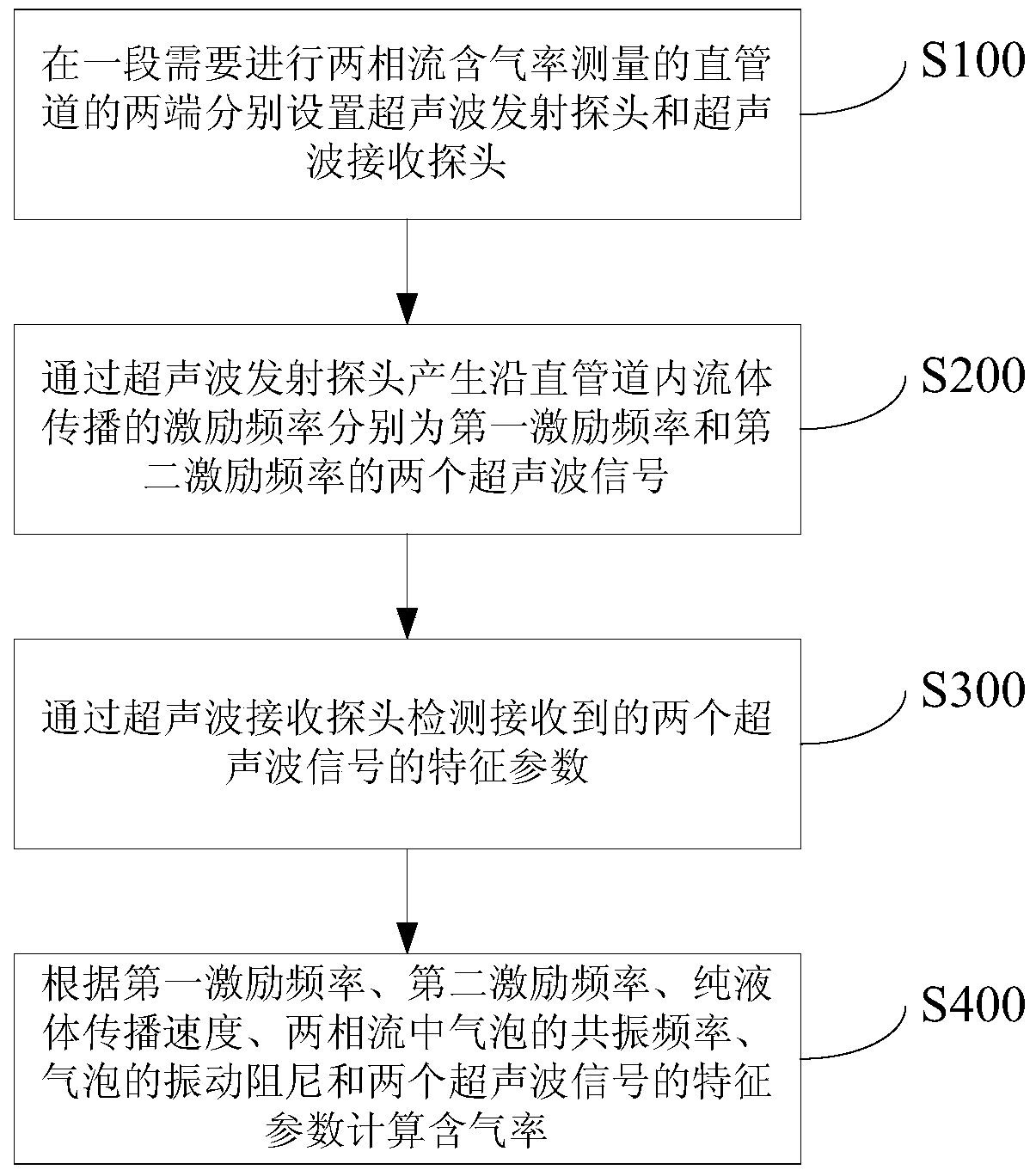

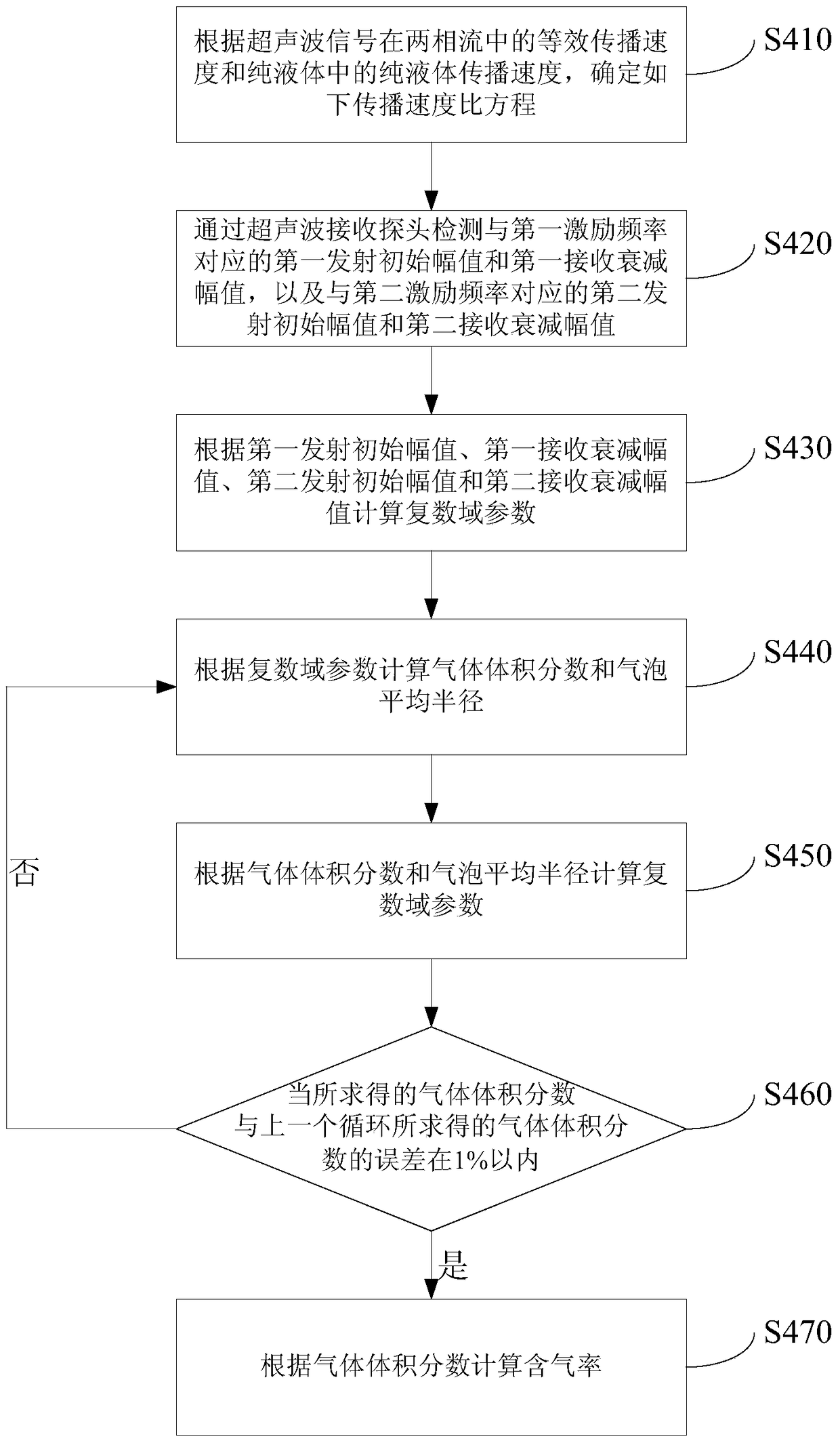

The invention discloses a method for measurement of two-phase flow gas holdup based on an ultrasonic two-frequency signal. The method comprises the steps of: arranging an ultrasonic transmitting probe and an ultrasonic receiving probe respectively at both ends of a section of straight pipeline needing two-phase flow gas holdup measurement; by means of the ultrasonic transmitting probe, generating two ultrasonic signals that are propagated along the fluid in the straight pipeline and have the excitation frequencies of a first excitation frequency and a second excitation frequency respectively; detecting the characteristic parameters of the received two ultrasonic signals by the ultrasonic receiving probe; and calculating the gas holdup according to the first excitation frequency, the second excitation frequency, the pure liquid propagation velocity, the resonant frequency of bubbles in the two-phase flow, the bubble vibration damping and the characteristic parameters of the two ultrasonic signals. The ultrasonic probes are installed on the outer wall of the straight pipeline, and are not needed to be arranged in the two-phase flow in the pipeline, thus realizing non-contact measurement of the two-phase flow gas holdup. The data processing amount is very small, and flow of the two-phase flow in the pipeline is not hindered in the measurement process.

Owner:NAT UNIV OF DEFENSE TECH

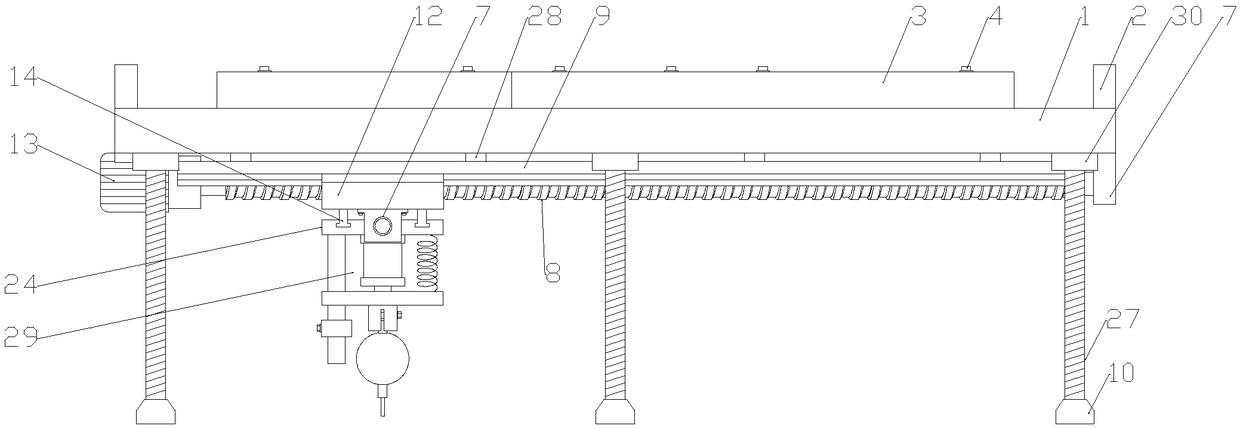

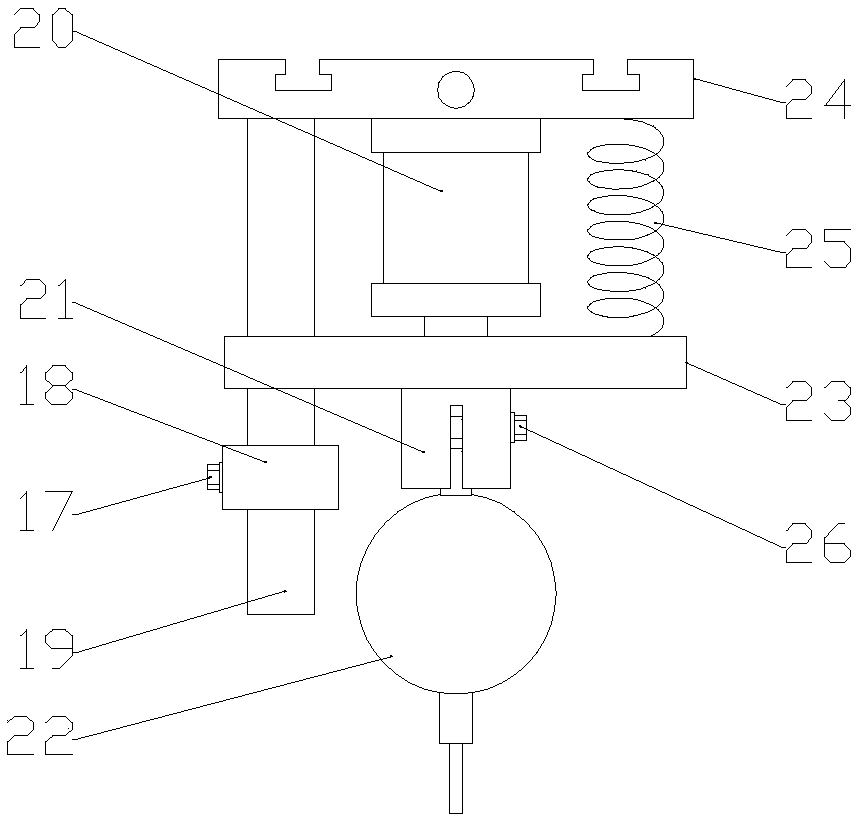

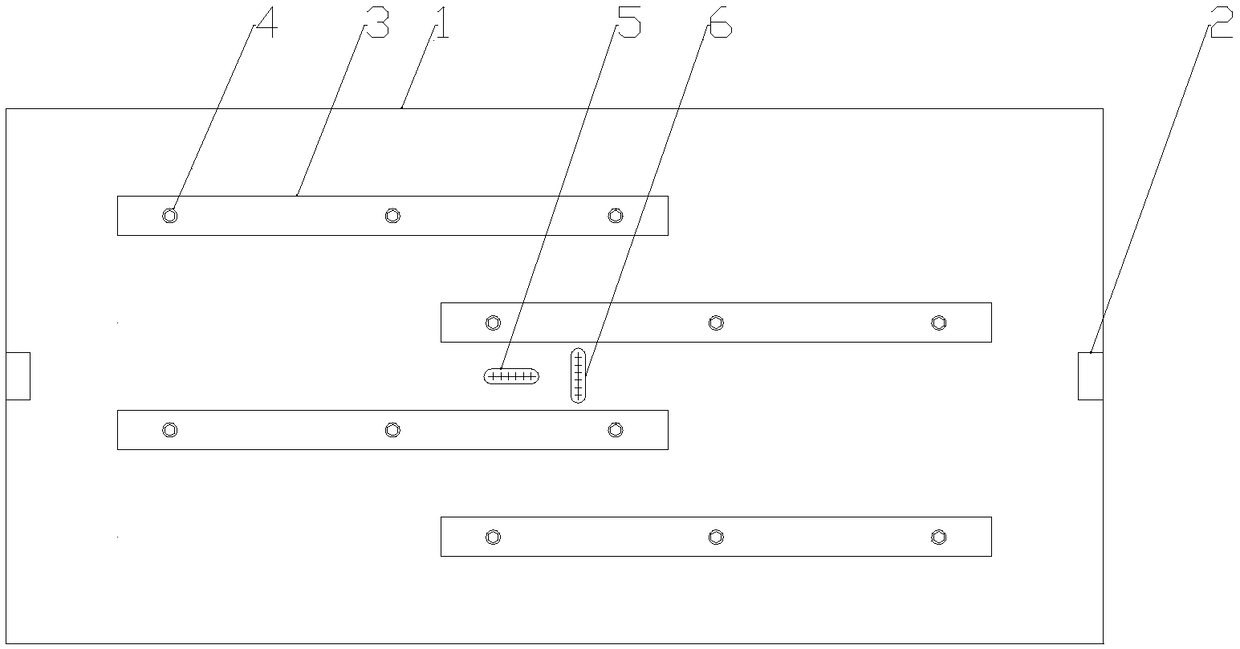

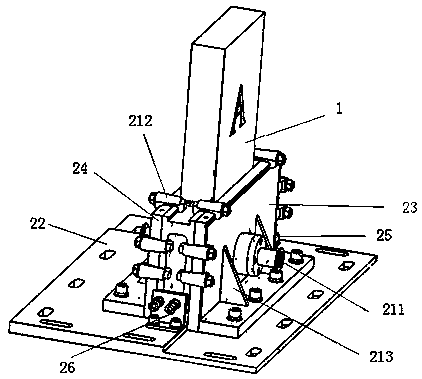

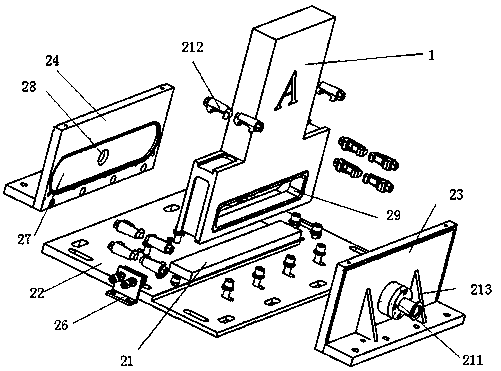

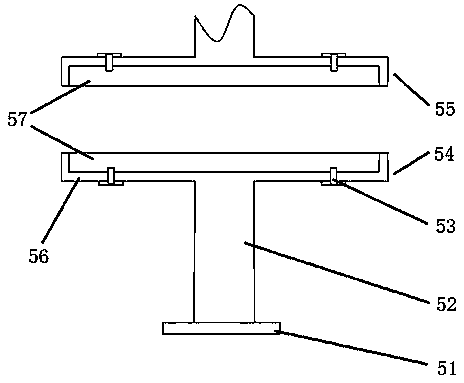

Workbench flatness detection device

InactiveCN109059743AGuaranteed levelImprove detection efficiencyMechanical roughness/irregularity measurementsScrew threadSymmetric axis

The invention discloses a workbench flatness detection device, comprising a flat plate, a horizontal pipe I and a horizontal pipe II which are vertical to each other are arranged at the middle part ofthe upper end of the flat plate, screws connected by virtue of a screw thread are arranged at four corners of the lower end of the flat plate and midpoints of long sides, a gear motor I and a bearingblock I are fixed at the lower ends of the two sides of the flat plate, a lead screw I is arranged at the output terminal of the gear motor I, the lead screw I is coincided with a symmetric axis in the length direction of the flat plate, sliding rails I are arranged at the two sides of the lead screw I in parallel, a strut is arranged at the upper end of each sliding rail I, the struts are fixedon the lower end face of the flat plate, the lead screw I is provided with a movable plate I connected by virtue of a screw thread, a gear motor II and a bearing block II are respectively fixed at thetwo ends of the movable plate I, a lead screw II is arranged at the output terminal of the gear motor II, a movable plate II connected by virtue of a screw thread is arranged on the lead screw II, and a detector is arranged at the lower end of the movable plate II. The workbench flatness detection device disclosed by the invention controls movement of the detection device in the horizontal direction by utilizing the gear motor I and the gear motor II, flatness is detected by virtue of a dial gauge, an operation method is simple, and detection precision is high.

Owner:安徽省临泉县智创精机有限公司

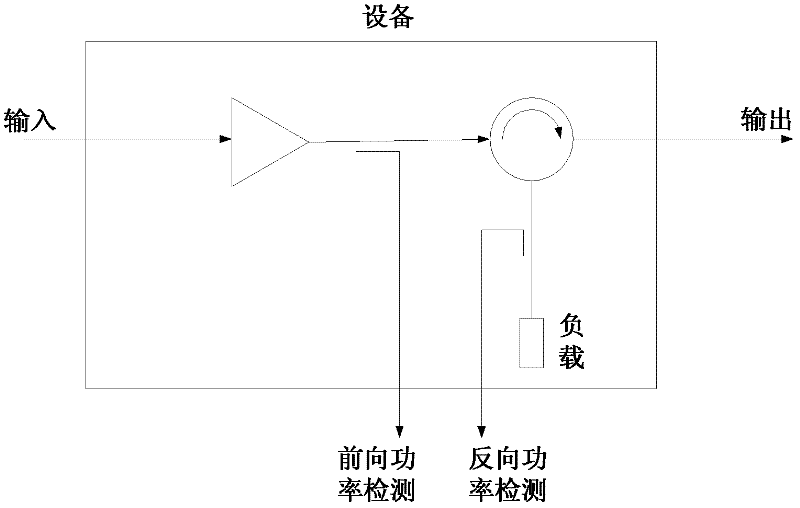

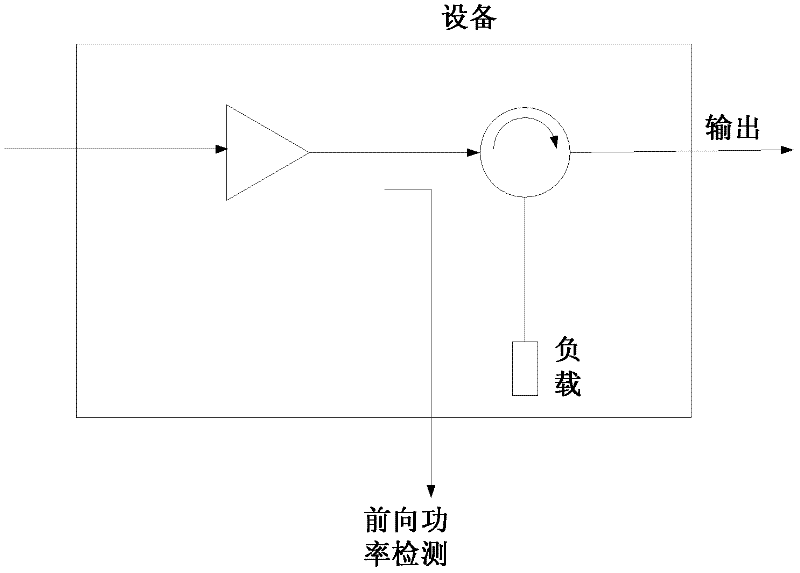

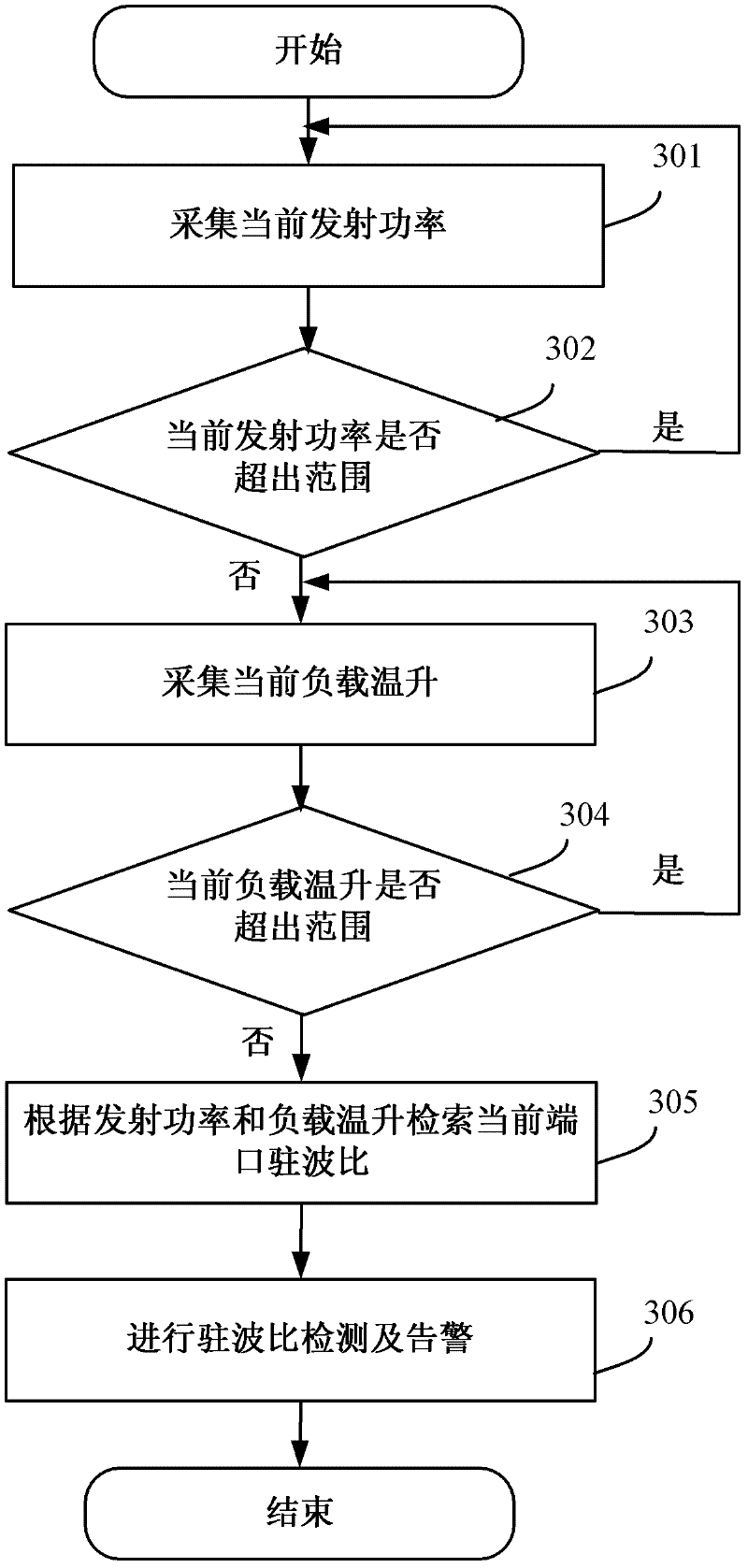

Standing wave ratio detection method, device and equipment of equipment output port

ActiveCN102332958ASimple detection principleEasy to implementTransmission monitoringWireless communicationCurrent loadEngineering

The invention provides a standing wave ratio detection method, device and equipment of an equipment output port, as well as a port standing wave ratio simulator, wherein the standing wave ratio detection method of the equipment output port comprises the following steps of: acquiring and storing the corresponding relationship between different standing wave ratios of the equipment output port and different temperature rises of an equipment load under different transmitting powers; and searching the corresponding relationship according to the acquired current transmitting power and the current load temperature rise of the equipment, and detecting the standing wave ratio of the equipment output port. The standing wave ratio detection method and device are easier to realize in the implementation difficulty level, and the standing wave ratio detection cost is lowered to a certain degree.

Owner:ZTE CORP

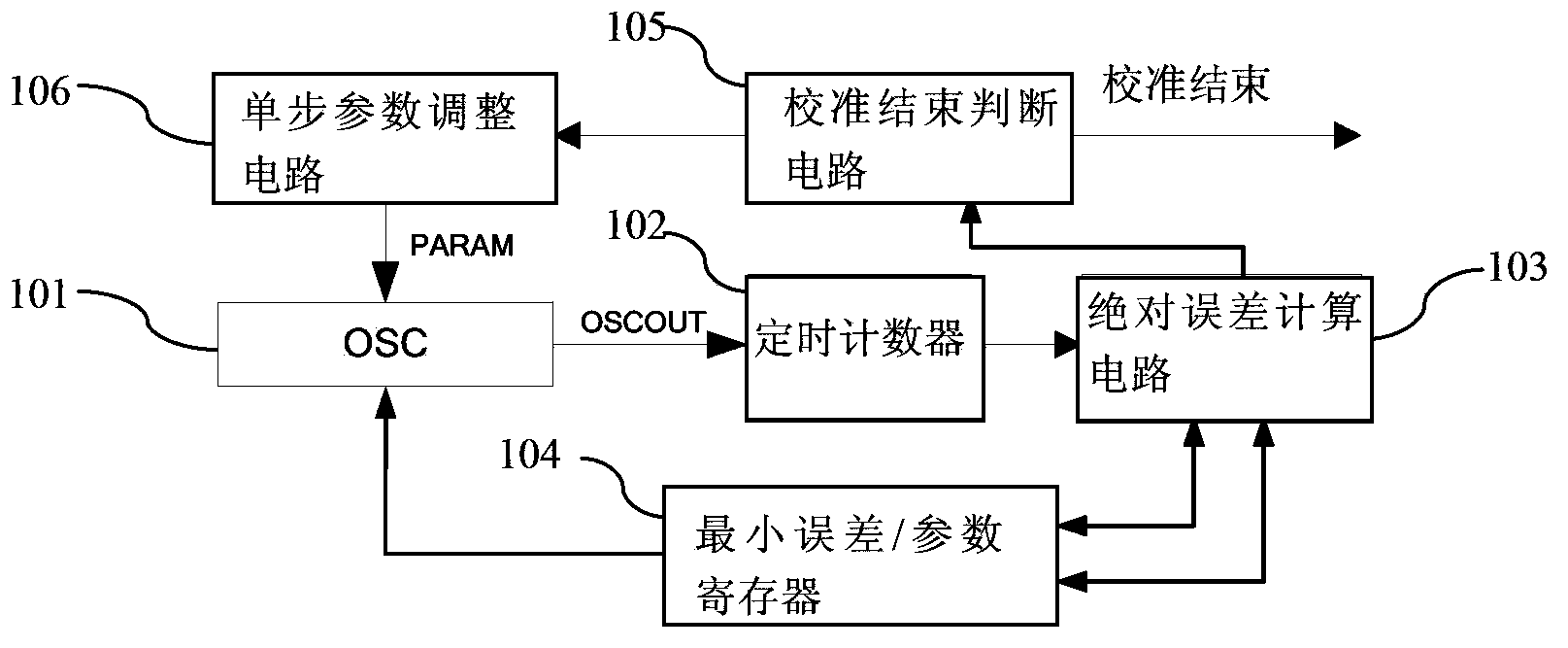

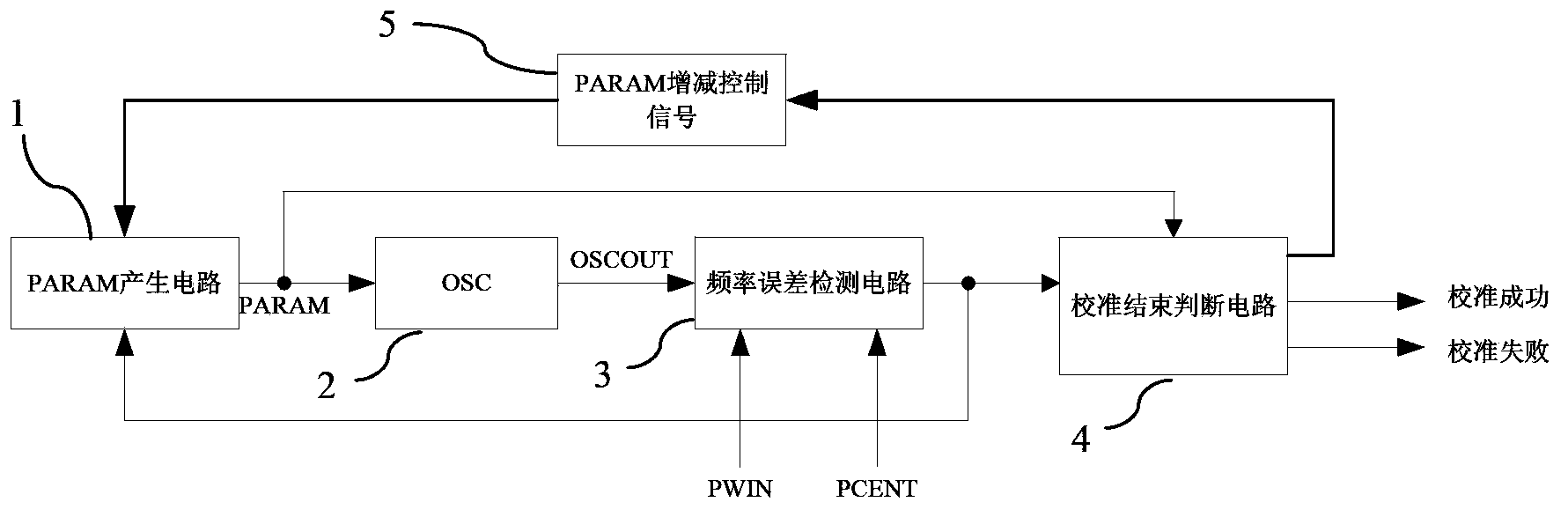

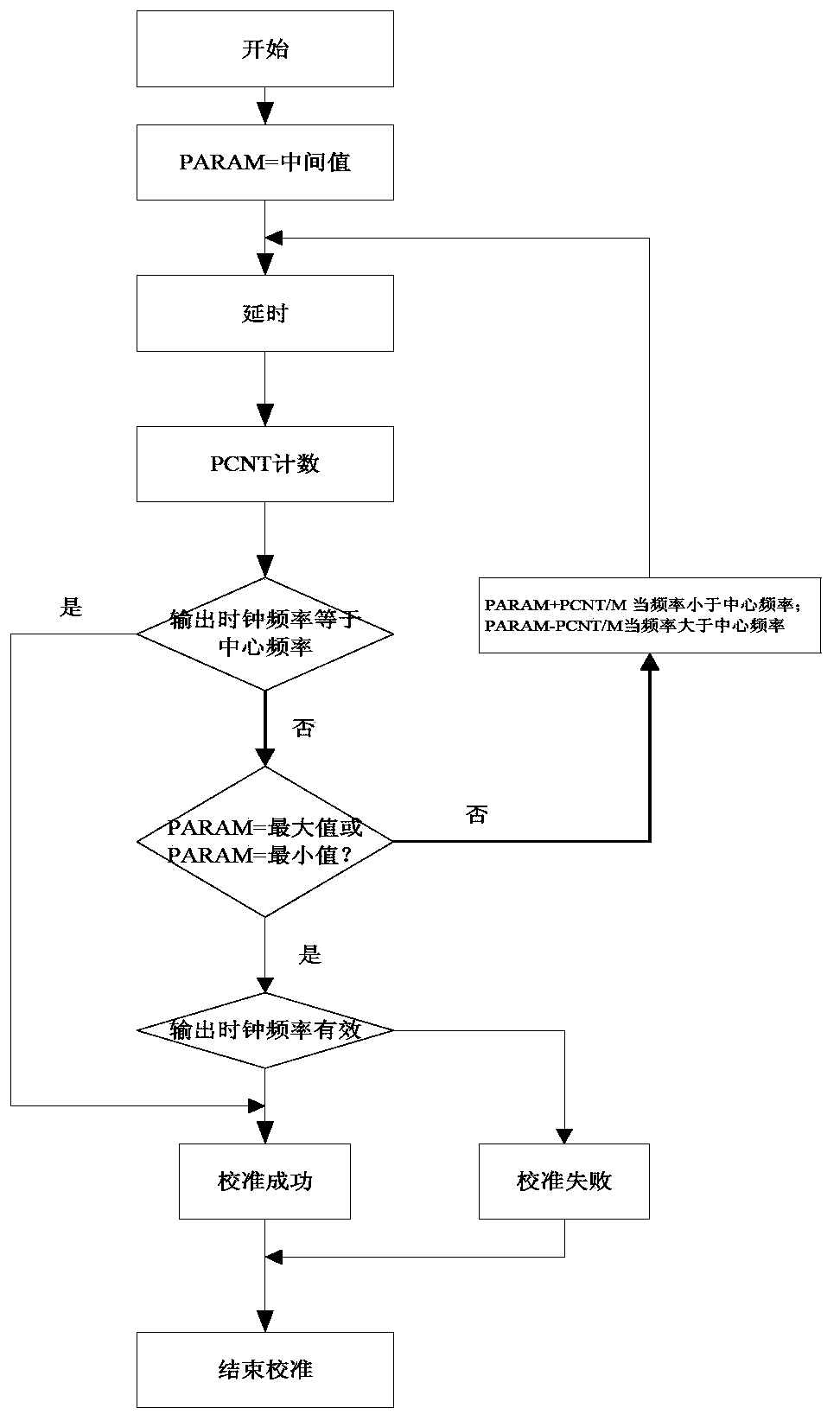

OSC frequency automatic calibration circuit and automatic calibration method

ActiveCN103634003ASimple detection principleReduce areaPulse automatic controlControl signalControl circuit

The invention discloses an OSC frequency automatic calibration circuit comprising a parameter generator, an OSC circuit, a frequency error detection circuit, a calibration ending judgment circuit and a parameter adding and subtracting control circuit. The frequency error detection circuit is connected with a reference time window signal and a center frequency indication signal, and frequency error detection is performed on a clock signal according to the reference time window signal and the center frequency indication signal, and a frequency error value is calculated. The calibration ending judgment circuit judges whether frequency automatic calibration is ended or not and whether frequency automatic calibration is successful or failed. When calibration is not ended, the parameter adding and subtracting control circuit outputs a parameter adding and subtracting control signal to the parameter generator and adjusts a control parameter, wherein the adjusting amplitude is directly proportional to the frequency error value. The invention discloses an automatic calibration method of the OSC frequency automatic calibration circuit. The circuit is simple in detection principle and small in circuit area. Parameter adjustment is directly proportional to the frequency error value so that calibration speed can be enhanced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Precision test method of two-freedom-degree tracking angle measurement device

ActiveCN104482940ABeneficial technical effectReduce mistakesAngle measurementMeasurement deviceLight pipe

The invention relates to a precision test method of a two-freedom-degree tracking angle measurement device. The two-freedom-degree tracking angle measurement device is installed on a biaxial-rate-position turntable plane, and the turntable plane is level; a hexagonal mirror block is installed on the top surface of the two-freedom-degree tracking angle measurement device. The rotation angle of the table-board azimuth of the biaxial-rate-position turntable plane is used as a true value, a self-collimating light pipe system is used as a benchmark, the two-freedom-degree tracking angle measurement device can rotate in opposite directions, and tests are repeatedly carried out to obtain the azimuth tracking angle precision. An electronic level instrument is installed on the two-freedom-degree tracking angle measurement device to be leveled. The pitching rotation angle of the biaxial-rate-position turntable plane is used as a true value, a display value of the electronic level instrument is used as the benchmark, the two-freedom-degree tracking angle measurement device can rotate in the opposite directions, and the tests are repeatedly carried out to obtain the pitching tracking angle precision. By adopting the method, the test precision is guaranteed, the detection principle is simple, the simplicity in operation is realized, and the precision detection efficiency for a system-stage two-freedom-degree angle measurement device can be effectively improved.

Owner:北京兴华机械厂有限公司

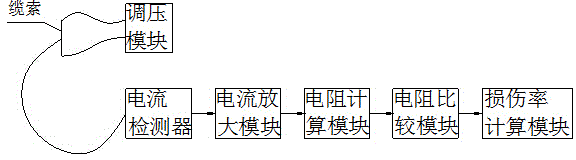

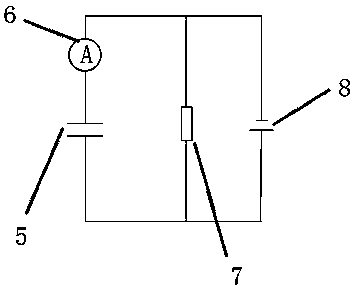

Bridge cable damage electric detecting device and detecting method

InactiveCN104458830ASimple detection principleEasy to operateMaterial resistanceElectricityElectrical resistance and conductance

The invention discloses a bridge cable damage electric detecting device and a bridge cable damage electric detecting method. The detecting device comprises a voltage regulating module, a voltage output guide wire, a current detector, a current amplifying module, a resistance calculating module, a resistance comparing module and a damage rate calculating module; the detecting method comprises the following steps: A, generating and detecting current; B, calculating the resistance; C, comparing the resistance; and D, calculating the damage rate. The resistance value is measured and calculated electrically, the area change value is determined according to the difference value between the measured resistance value and the theoretical resistance value, the detecting principle is simple; during specific detection, the voltage is only loaded to the two ends of the cable, so that only the current on the cable is needed to be measured; the specific operation steps are simple, during the measured result treatment, the measured current is amplified through a current amplifier for calculating the size of the resistance and amplifying the current value, so that the precise current value can be obtained, the calculating errors are small, and the calculated resistance value is relatively precise.

Owner:邢鹏达

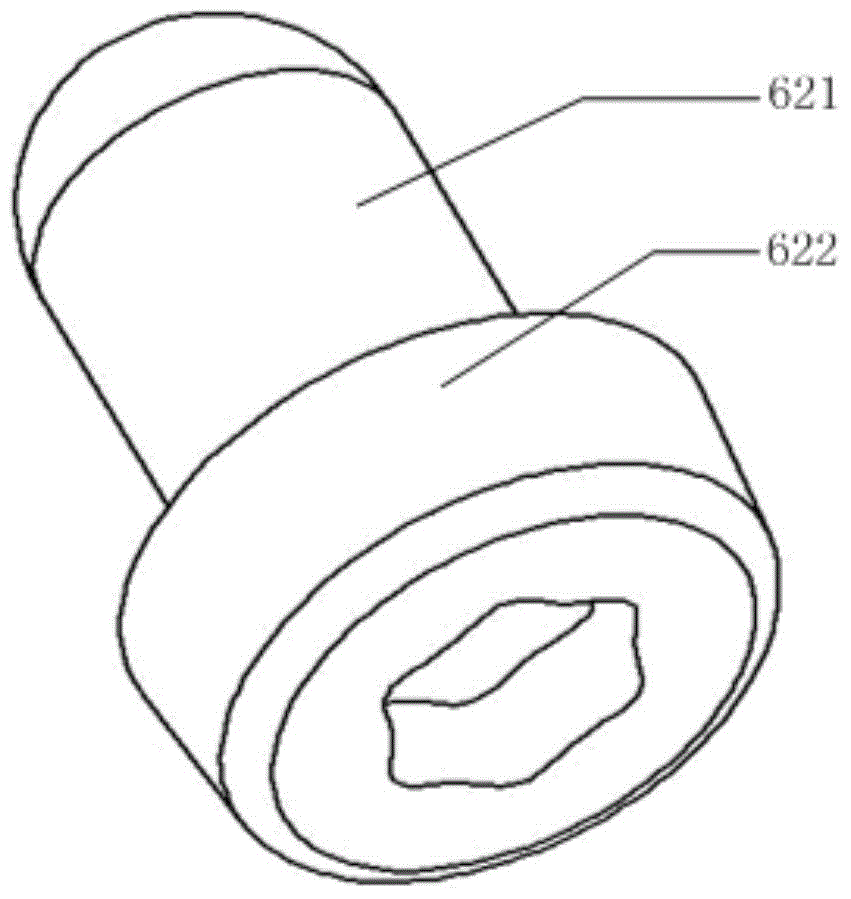

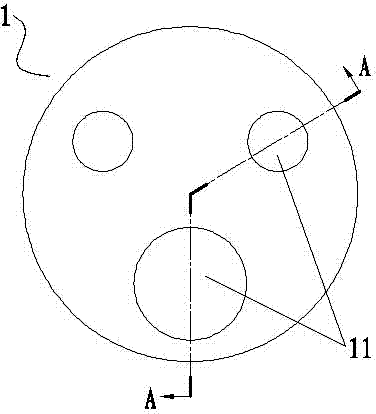

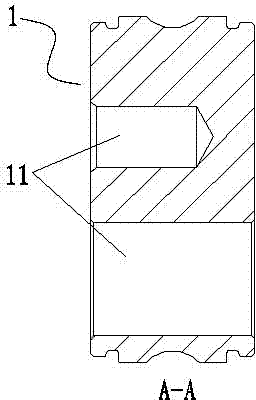

Combination gauge for abnormal bearing inner ring pore detection and detection method thereof

ActiveCN103615950AThe overall structure is simpleSimple detection principleMechanical diameter measurementsEngineeringSmall hole

Owner:BH TECH GRP CO LTD

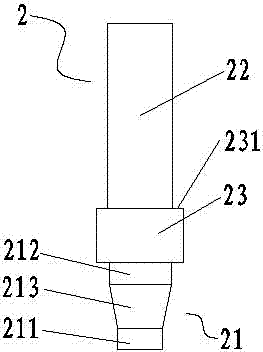

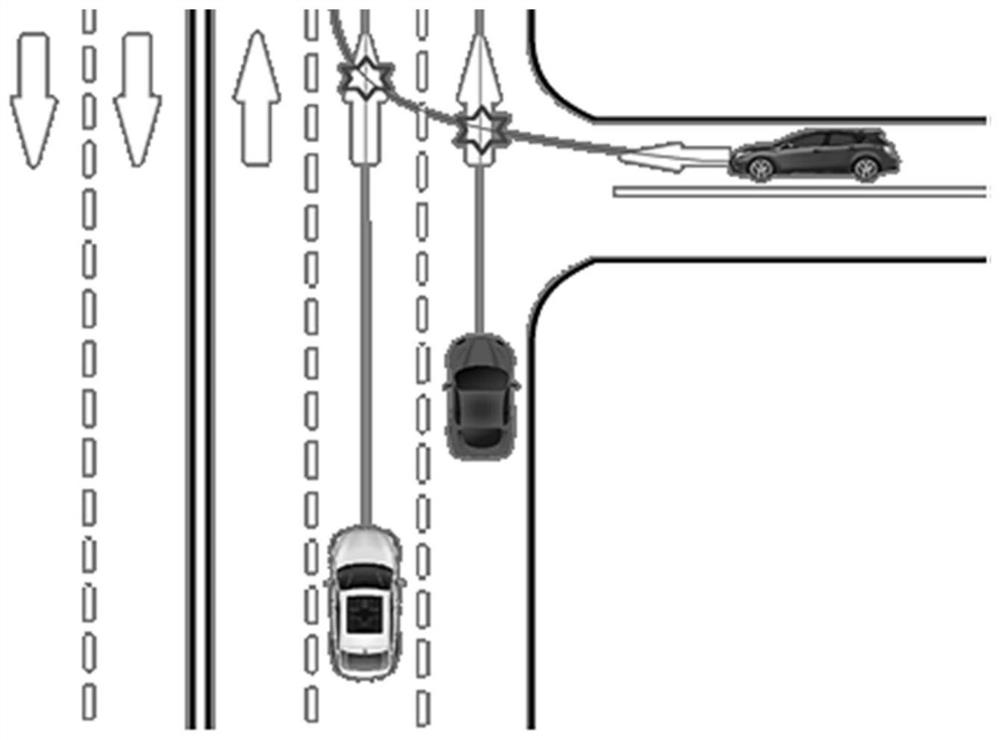

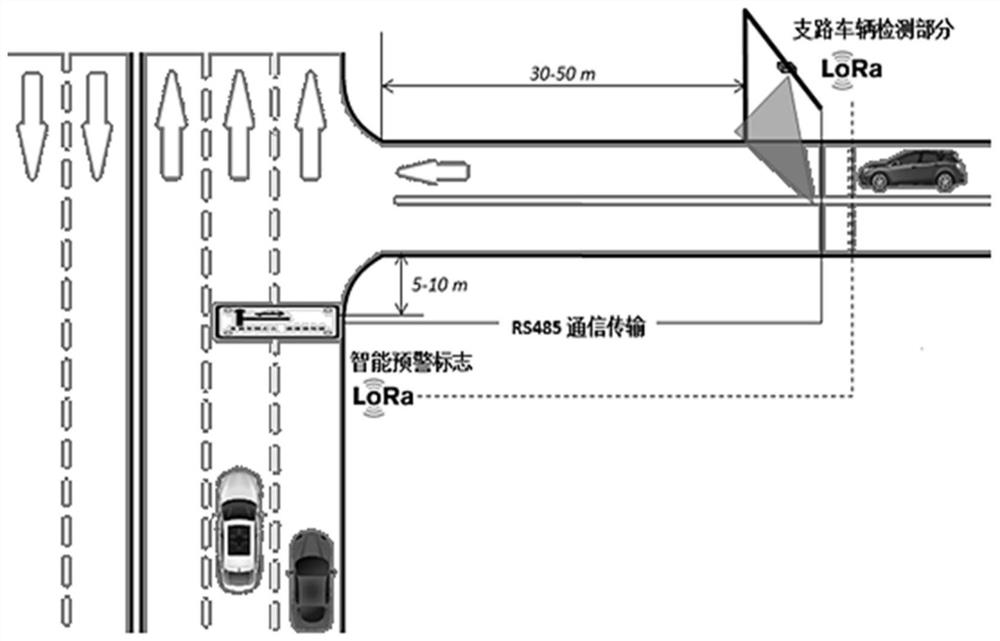

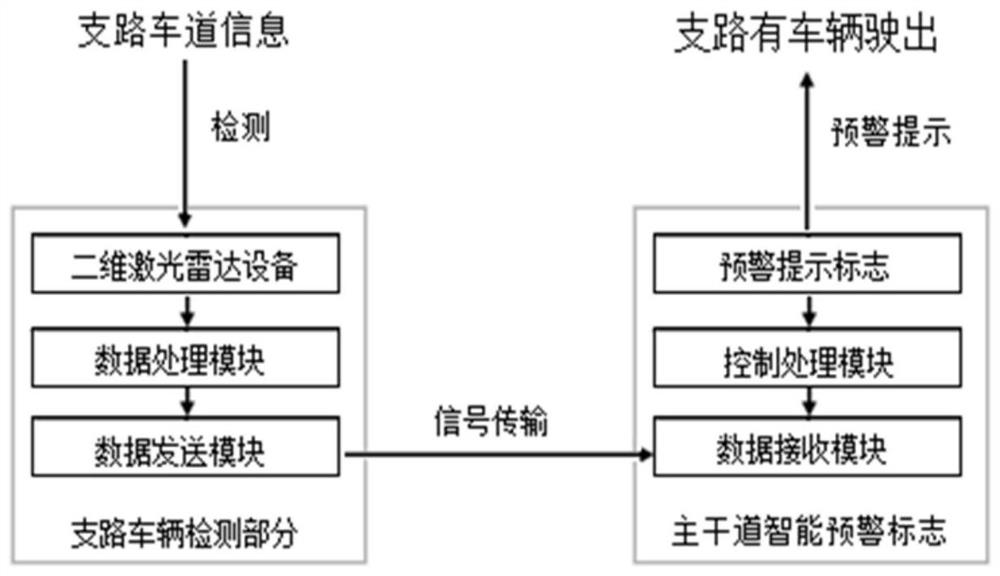

Branch vehicle afflux early warning system for vehicles coming and going on main road

ActiveCN111815949ATimely and effective early warning reminderSolving Detection ErrorsDetection of traffic movementTraffic signalsEarly warning systemVehicle detection

The invention relates to a branch vehicle afflux early warning system for vehicles coming and going on a main road. The system comprises a branch vehicle detection system used for detecting branch vehicle appearance information through two-dimensional laser radar detection equipment, and a main road intelligent early warning sign used for prompting a main road driving vehicle through a detection result. The branch road vehicle detection system is arranged at the edge of a branch road and is 30-50 meters away from a branch road intersection, the two-dimensional laser radar detection equipment is vertically downward, and is installed facing a road, the main road intelligent early warning sign is arranged on a main road, is about 5-10 meters away from the branch road intersection and is arranged facing the direction of coming vehicles of the main road, and the branch road vehicle detection system is in real-time communication with the main road intelligent early warning sign in wired andwireless transmission modes. Compared with the prior art, the system has the advantages of stable, accurate, efficient and all-weather detection and the like.

Owner:TONGJI UNIV +1

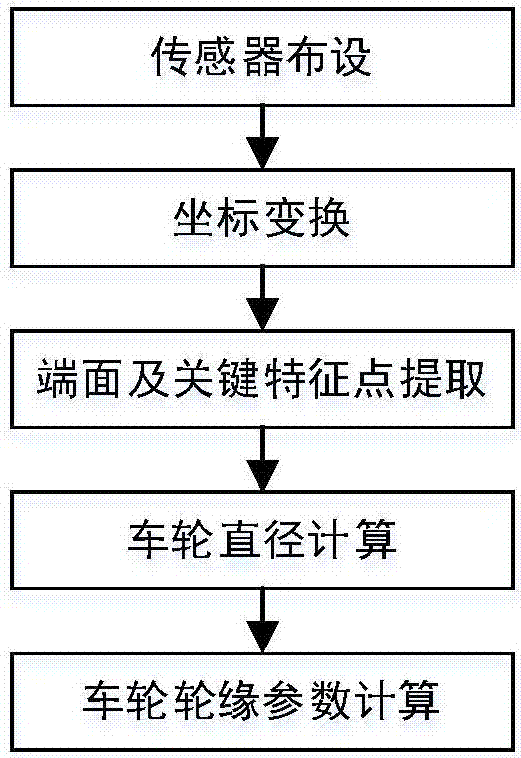

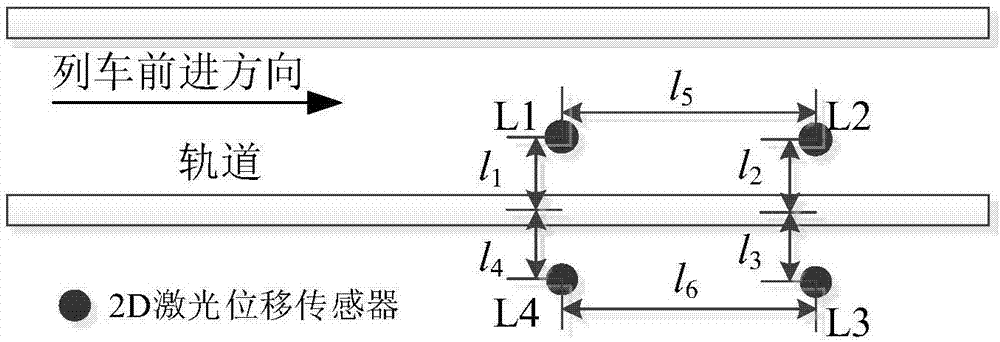

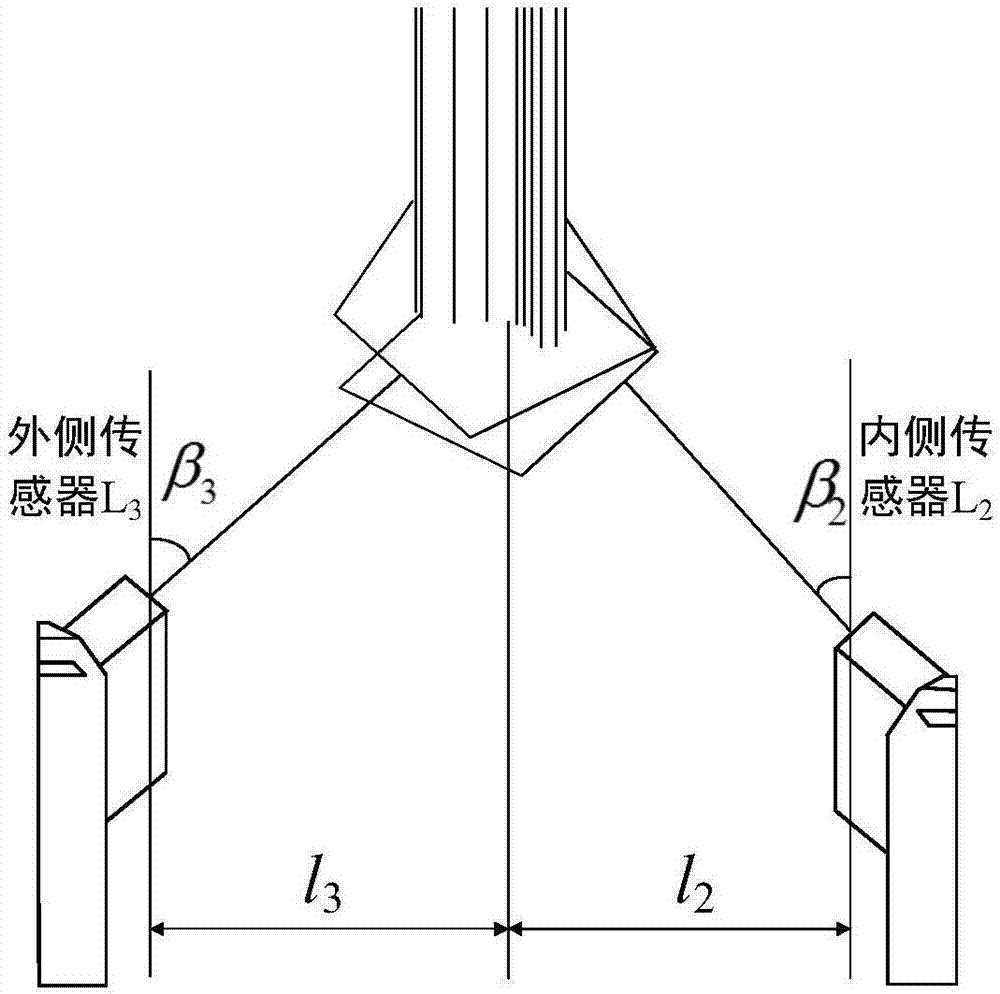

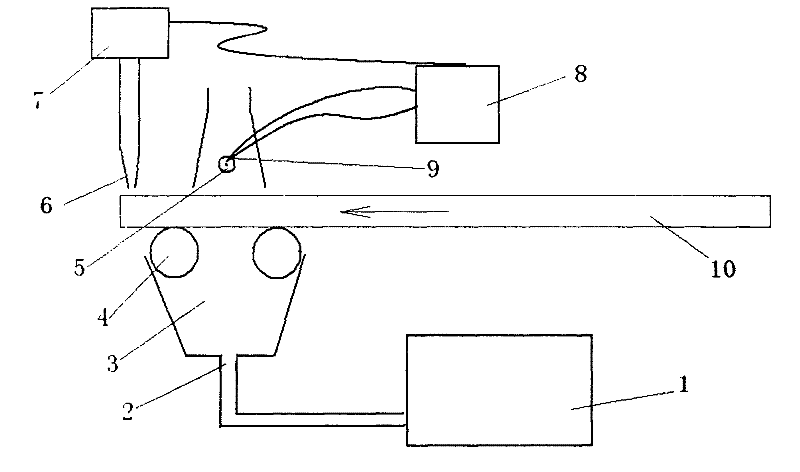

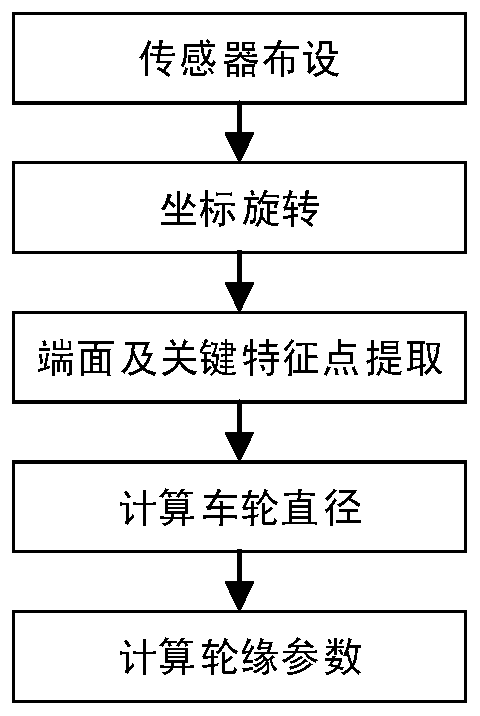

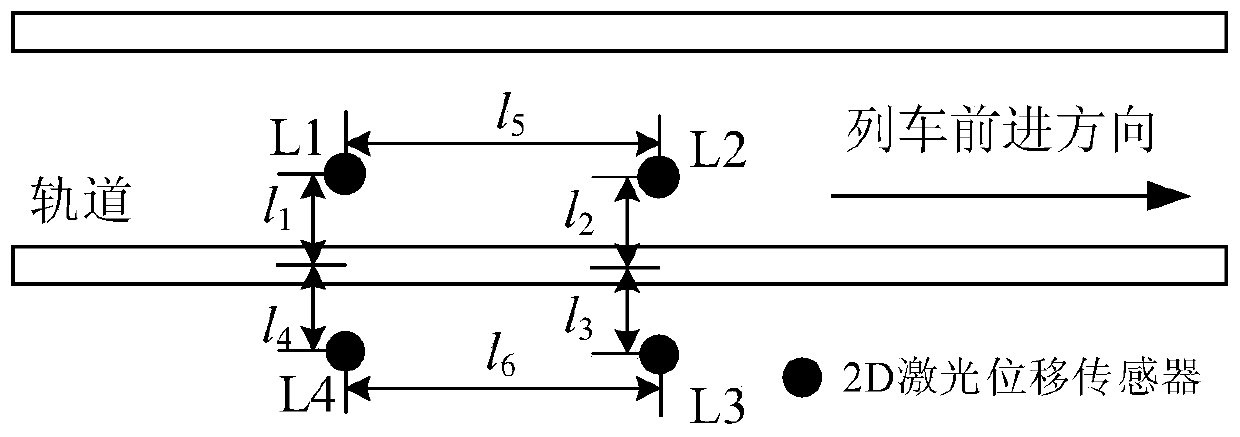

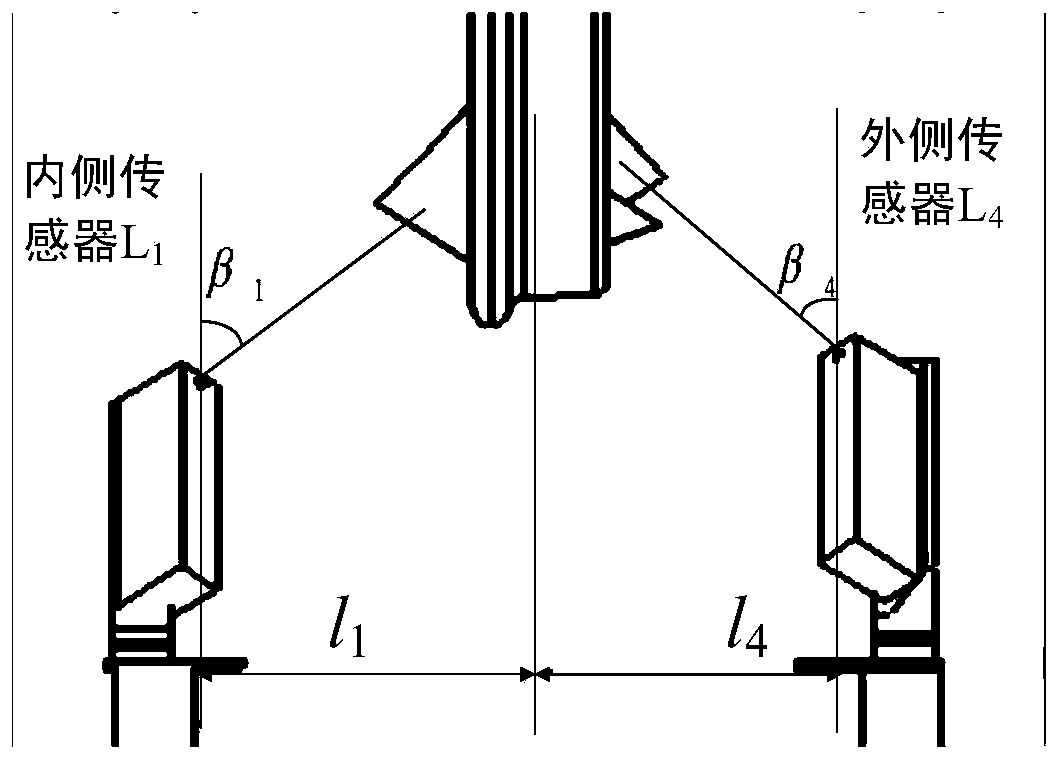

Non-contact type on-line wheel-set profile detection method based on laser displacement sensor

InactiveCN107139967ASimple detection principleLow costWheel-rims surveying/measuringUsing optical meansContact typeFlange

The invention discloses a non-contact type on-line wheel-set profile detection method based on laser displacement sensors. The method comprises the following steps: sequentially setting a first laser displacement sensor and a second laser displacement sensor along the inner side of a track in a train advancing direction, and sequentially setting a fourth laser displacement sensor and a third laser displacement sensor on the outer symmetric side of the track, wherein laser sources of the first laser displacement sensor and the second laser displacement sensor are both on a same plane with the upper surface of the track; performing coordinate transformation on data points output from the laser displacement sensors, and extracting end surfaces and key feature points; measuring the distance between the laser displacement sensors and a tire tread when the circle center of a wheel is on central lines of the first laser displacement sensor and the second laser displacement sensor, and calculating the diameter of the wheel according to geometric relationships; and acquiring outlines of two tire treads through data fusion, and further acquiring a mean value of two groups of wheel flange parameters. The method has the advantages of being simple in structure, high in precision and high in stability.

Owner:NANJING UNIV OF SCI & TECH

Respiration monitoring device capable of recognizing respiration state

InactiveCN111281390AImprove detection accuracySimple structureRespiratory organ evaluationSensorsRespiration monitoringIntensive care medicine

The invention relates to a respiration monitoring device capable of recognizing a respiration state. The respiration monitoring device is divided into a daytime monitoring module and a night monitoring module, and is more suitable for actual medical application; and during daytime patient activities, the patient can wear the daytime monitoring module, which does not influence the activities, and the device is multiple in monitoring items and high in detection accuracy; when the night module is used at night, on one hand, respiration of a patient can be monitored, on the other hand, the monitoring device is simple in structure and light, sleep is not affected, the monitoring and alarming functions are achieved, and an alarm can be given in time no matter under the conditions of dyspnea, transient respiratory arrest and the like. A unique daytime detection module is designed, multiple indexes of respiration can be detected by only using one light detection means, the monitoring effect isgood, and the cost is low; and the night monitoring module uses a capacitance detection method, the detection principle is simple, the detection effect is good, the cost is low, and even disposable use can be realized.

Owner:孙爱玲

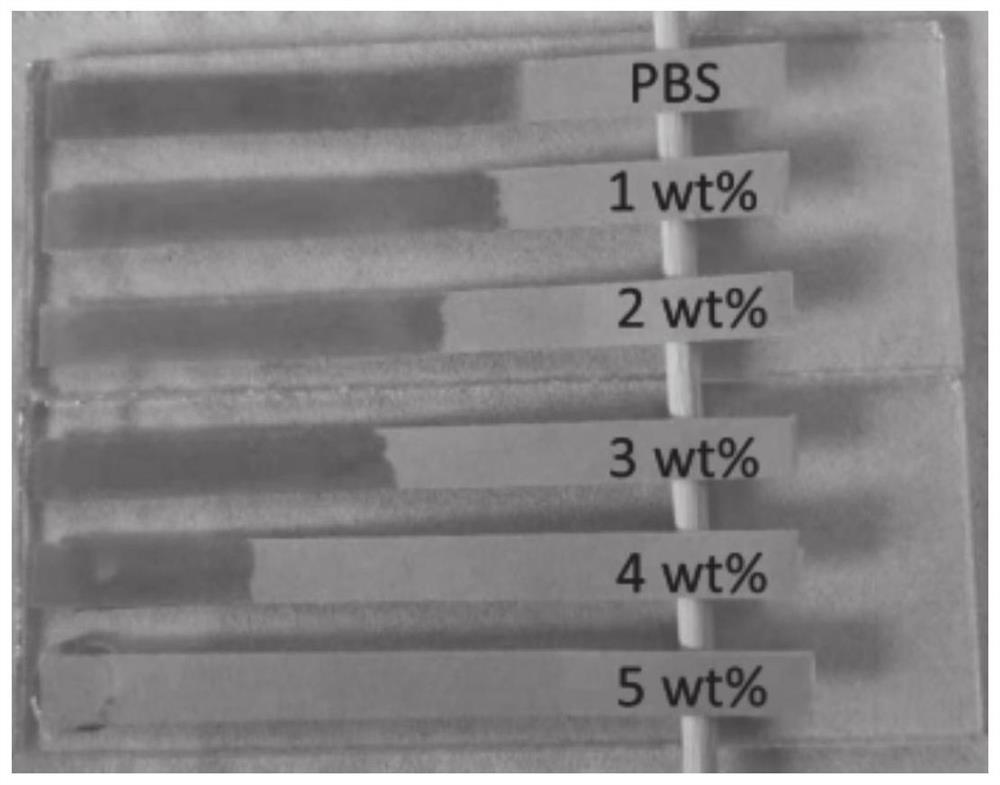

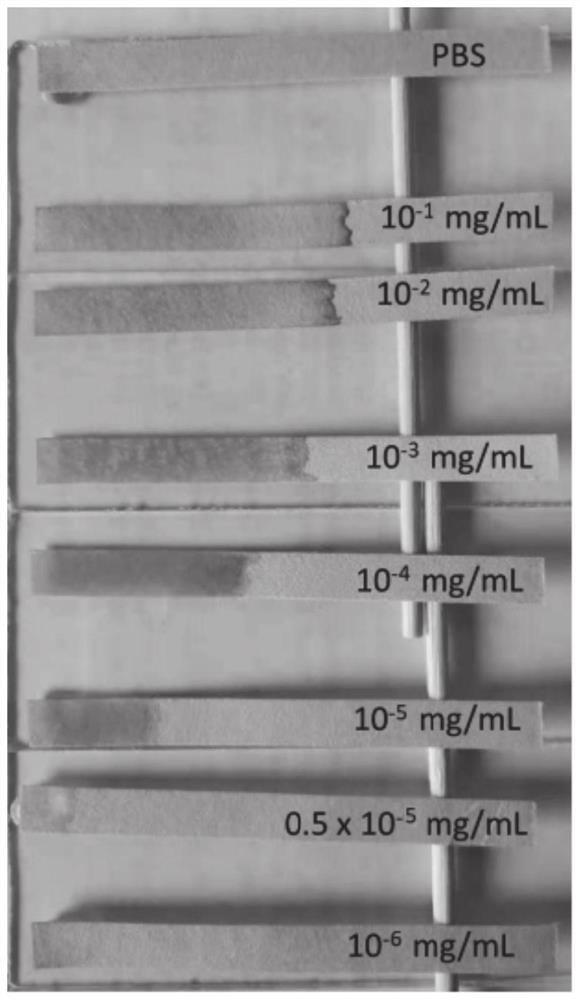

Detection method of biomolecules and inhibitor molecules

PendingCN113552122ALow costAvoid interferenceMaterial analysis by observing effect on chemical indicatorHydrolysisTest strips

The invention belongs to the technical field of analysis and detection, and particularly provides a detection method of biomolecules and inhibitor molecules. The detection method of biomolecules and inhibitor molecules comprises the following steps: mixing an object to be detected with a viscous solution or hydrogel to form a mixed solution, placing the mixed solution at one end of an indicating test strip, and enabling different quantities of target detection objects to cause different hydrolysis degrees of the viscous solution or the hydrogel, so that the contents of water released by the viscous solution or the hydrogel through decomposition are different, the pH sensor can move on the pH test strip at different distances, and the target detection object can be detected according to the length of the moving distance. The problems that a common biomolecule detection method in the prior art is tedious in operation steps, needs to train professionals to operate related equipment, is long in detection time and low in efficiency, causes resource waste and cost increase, and influences the detection sensitivity due to environment background factors such as matrixes exist are solved.

Owner:SHANDONG ANALYSIS & TEST CENT

Vibration sensor based on surface acoustic wave radio frequency identification technology and application for vibration sensor

ActiveCN102889923BSimple structureSimple designVibration measurement in solidsAcceleration measurement using interia forcesGratingVibration acceleration

Owner:SHANGHAI JIAOTONG UNIV

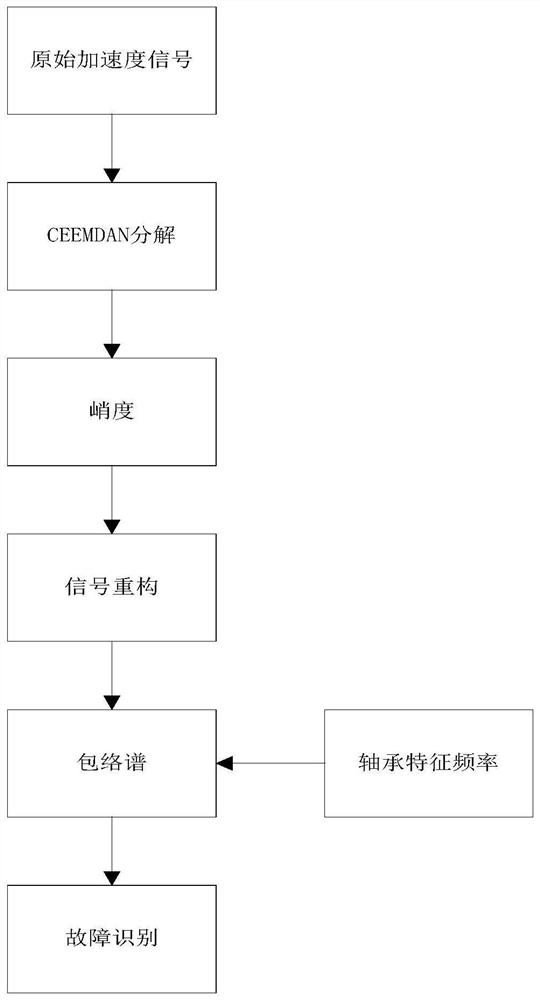

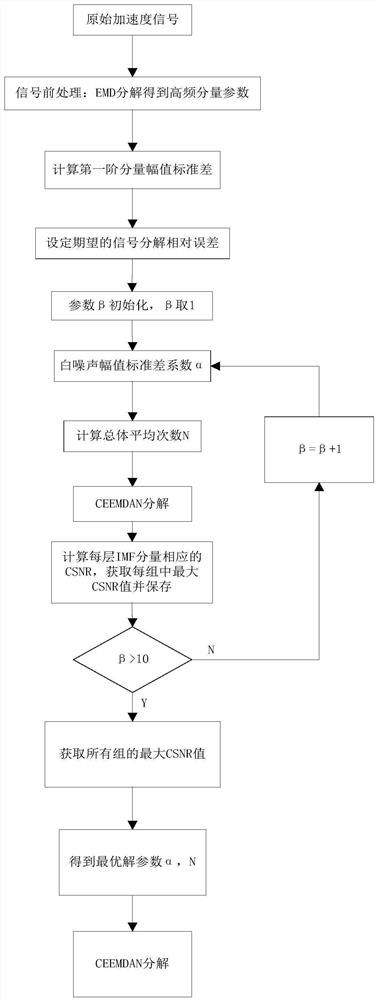

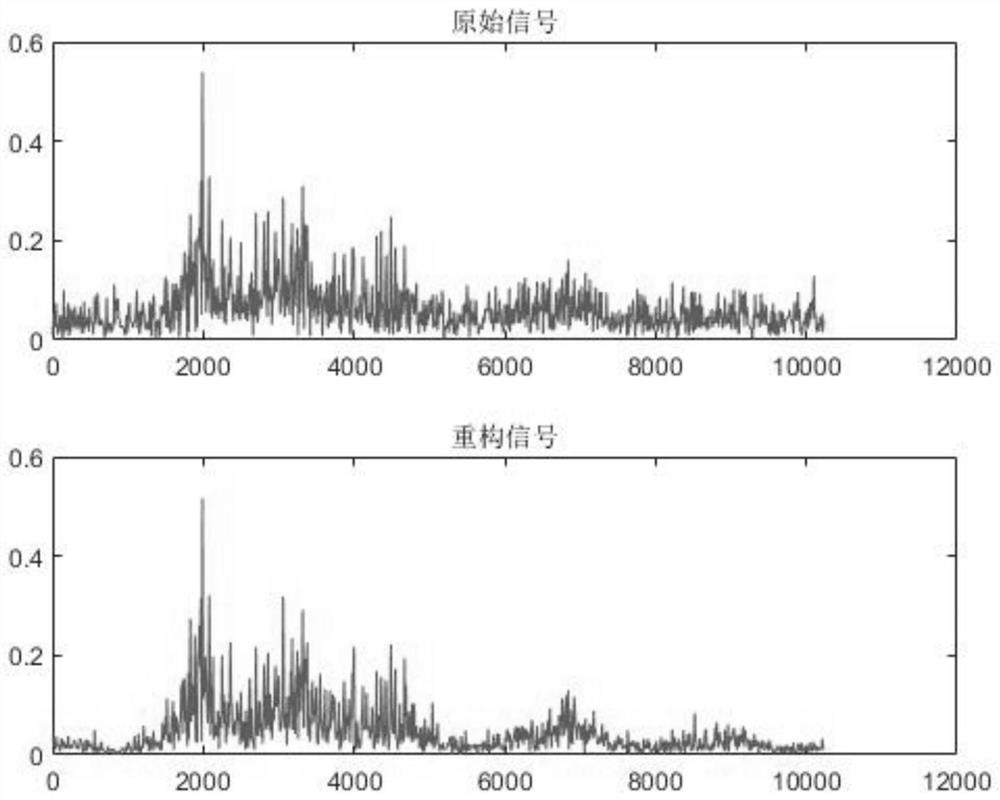

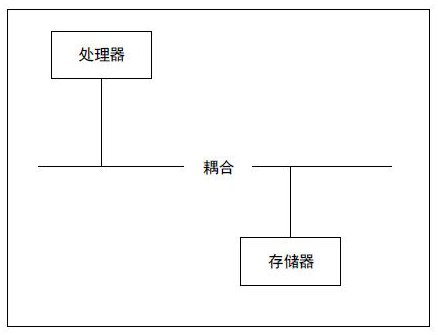

Method for judging bearing fault based on CEEMDAN decomposition, electronic equipment and storage medium

The invention discloses a method for judging a bearing fault based on CEEMDAN decomposition, electronic equipment and a storage medium, and the method comprises the steps: carrying out the CEEMDAN decomposition of an original acceleration signal of a bearing, and obtaining an intrinsic mode function component; calculating the kurtosis K of the intrinsic mode function component of each layer, and adding the corresponding values of the intrinsic mode function components of each layer with the kurtosis K greater than a set value to obtain a reconstructed acceleration signal; performing envelope demodulation on the reconstructed acceleration signal to obtain an envelope spectrum; calculating a bearing characteristic frequency according to the bearing signal and the rotating speed; and checking the amplitude of the characteristic frequency of the bearing in the envelope spectrum, and if the amplitude of a certain characteristic frequency exceeds an envelope threshold value, determining that the bearing part corresponding to the characteristic frequency has a fault. According to the invention, the signal resolution can be effectively improved, the interference of noise and other vibration signals can be weakened, and the loss and mode overlapping of fault signals can be avoided. The detection capability of weak fault characteristic signals is obviously improved, and the fault part of the bearing can be effectively identified.

Owner:南京凯奥思数据技术有限公司

Method for measuring gas fraction of two-phase flow based on ultrasonic dual-frequency signal

ActiveCN105181793BRealize non-contact measurementDoes not impede flowAnalysing fluids using sonic/ultrasonic/infrasonic wavesDual frequencyMechanics

The invention discloses a method for measurement of two-phase flow gas holdup based on an ultrasonic two-frequency signal. The method comprises the steps of: arranging an ultrasonic transmitting probe and an ultrasonic receiving probe respectively at both ends of a section of straight pipeline needing two-phase flow gas holdup measurement; by means of the ultrasonic transmitting probe, generating two ultrasonic signals that are propagated along the fluid in the straight pipeline and have the excitation frequencies of a first excitation frequency and a second excitation frequency respectively; detecting the characteristic parameters of the received two ultrasonic signals by the ultrasonic receiving probe; and calculating the gas holdup according to the first excitation frequency, the second excitation frequency, the pure liquid propagation velocity, the resonant frequency of bubbles in the two-phase flow, the bubble vibration damping and the characteristic parameters of the two ultrasonic signals. The ultrasonic probes are installed on the outer wall of the straight pipeline, and are not needed to be arranged in the two-phase flow in the pipeline, thus realizing non-contact measurement of the two-phase flow gas holdup. The data processing amount is very small, and flow of the two-phase flow in the pipeline is not hindered in the measurement process.

Owner:NAT UNIV OF DEFENSE TECH

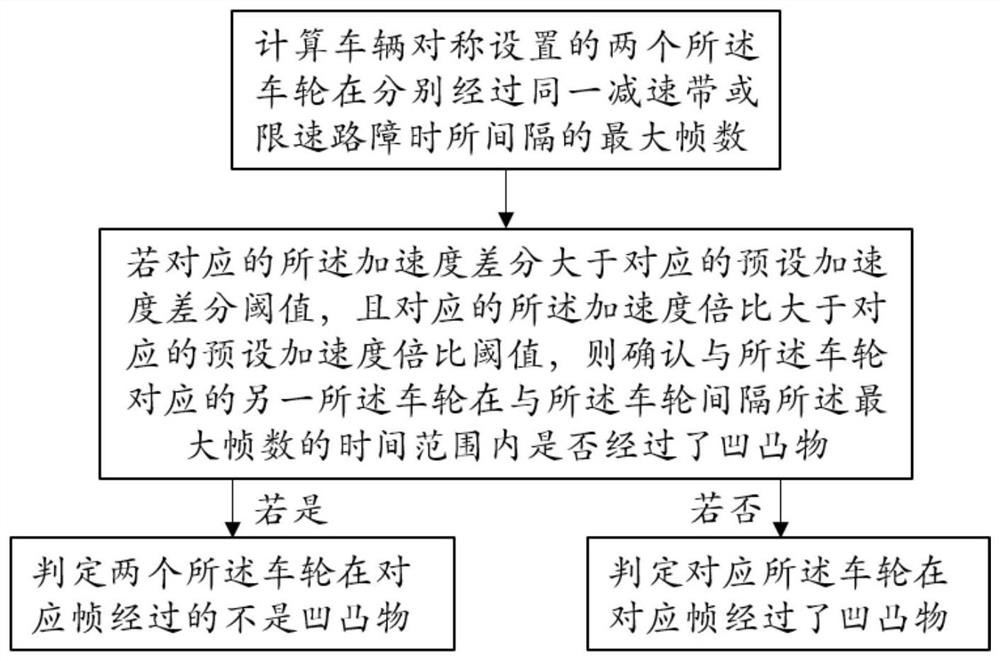

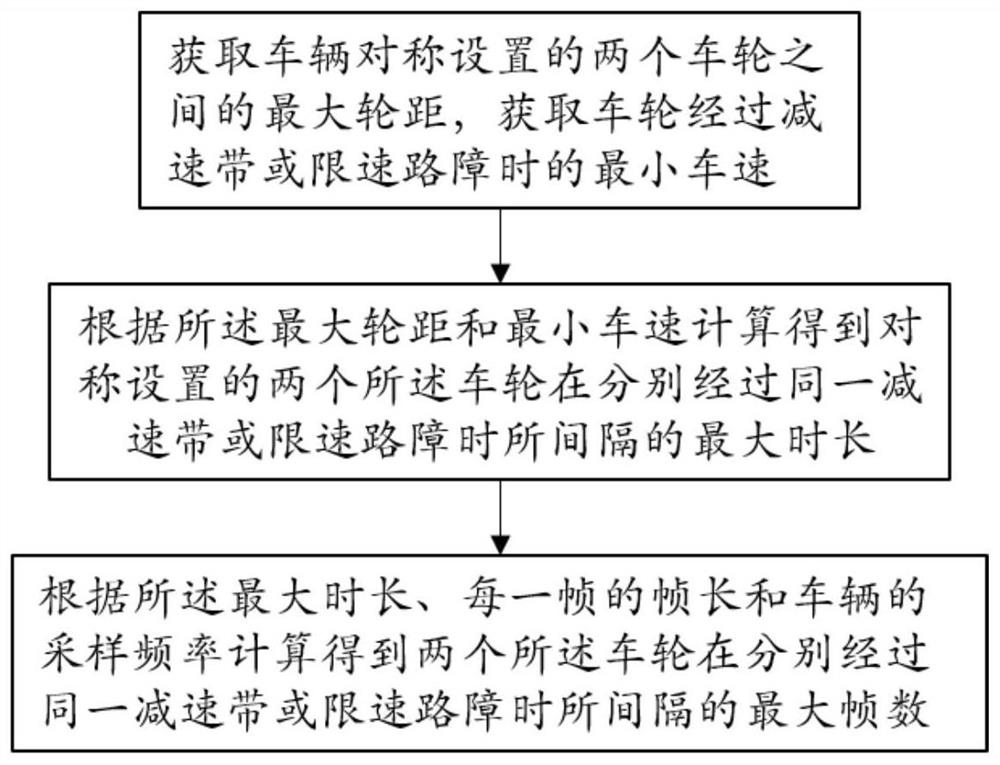

Road concave-convex object detection method and device

PendingCN114154533ASimple detection principleImprove accuracyCharacter and pattern recognitionData informationSimulation

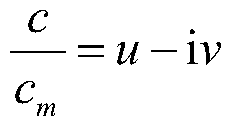

The invention relates to a road concave-convex object detection method and device, and relates to the technical field of intelligent traffic. The method comprises the following steps: firstly, acquiring an acceleration signal of each wheel of a vehicle, carrying out framing processing on the acceleration signal, and respectively calculating an acceleration difference and an acceleration multiple ratio of each frame of acceleration signal of each wheel; if the corresponding acceleration multiple ratio is larger than the corresponding preset acceleration multiple ratio threshold value, it is judged that the corresponding wheel passes through the concave-convex object in the corresponding frame, data information of each concave-convex object passed by the vehicle is obtained, and the data information of all the concave-convex objects is transmitted to a traffic department server; and the traffic department server evaluates each concave-convex object by using the data information of the concave-convex objects and the vehicle information of the corresponding vehicle. According to the road concave-convex object detection method provided by the invention, the problems that the detection effectiveness of the concave-convex object on the road is poor, the accuracy of the detection structure is low and the overall efficiency needs to be improved in the related technology are solved.

Owner:DONGFENG MOTOR GRP

Method for detecting the number of fallen particles during working process of valve

ActiveCN109406133AUnderstand qualityAvoid the impact of product qualityMachine valve testingIndividual particle analysisParticle counterMechanical engineering

The invention discloses a method for detecting the number of fallen particles during the working process of a valve. The method comprises firstly making a cavity vacuum; then opening and closing the valve until the number of opening and closing times of the valve reaches the actual working number of times of the valve to be tested, wherein the particles fallen during the working process of the valve fall into the cavity; then counting the fallen particles by a particle counter, wherein the calculation principle of the particle counter is to blown the fallen particles into the particle counterby a gas, then to blow a gas of the same flow into the particle counter, and to compare the two numbers so as to obtain the number of the fallen particles. The method can detect the number of fallen particles during the working process of the valve, so that a manufacturer and a purchaser of the vacuum valve can accurately understand the number of the fallen particles of the vacuum valve, thereby solving the problem that the quality of a semiconductor or photovoltaic module is affected because the number of the fallen particles of the vacuum valve does not meet a requirement.

Owner:SICHUAN JIUTIAN VACUUM TECH CO LTD +1

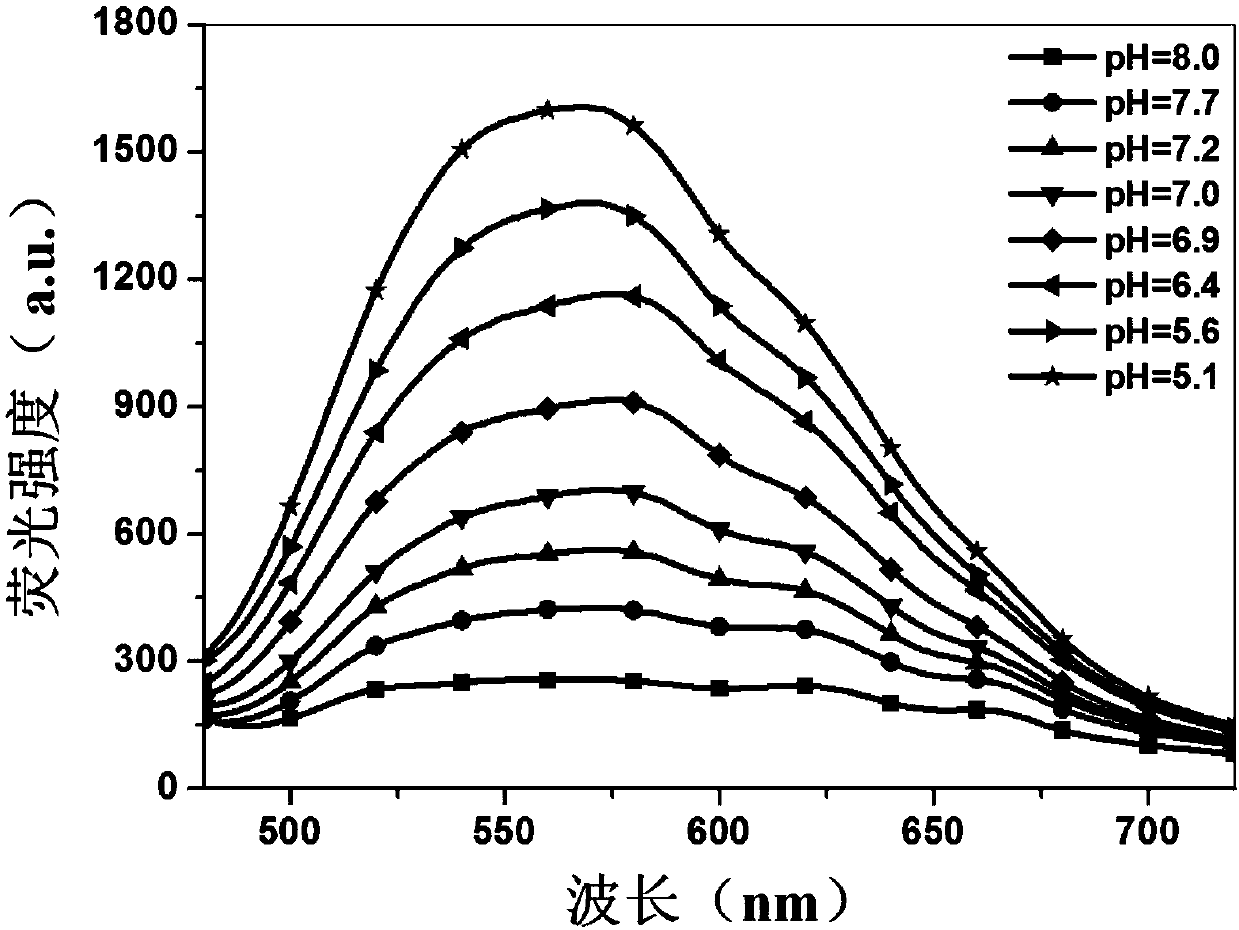

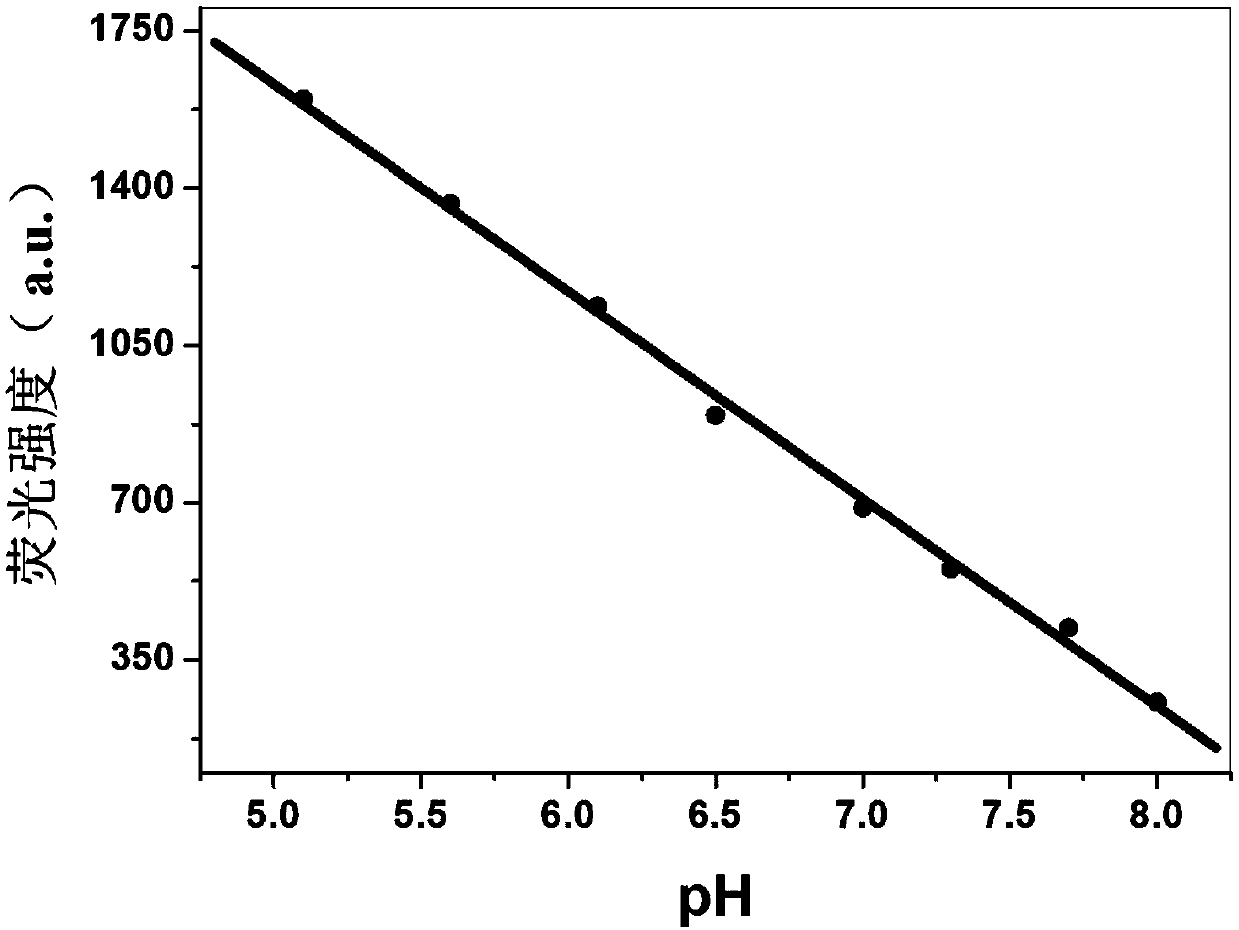

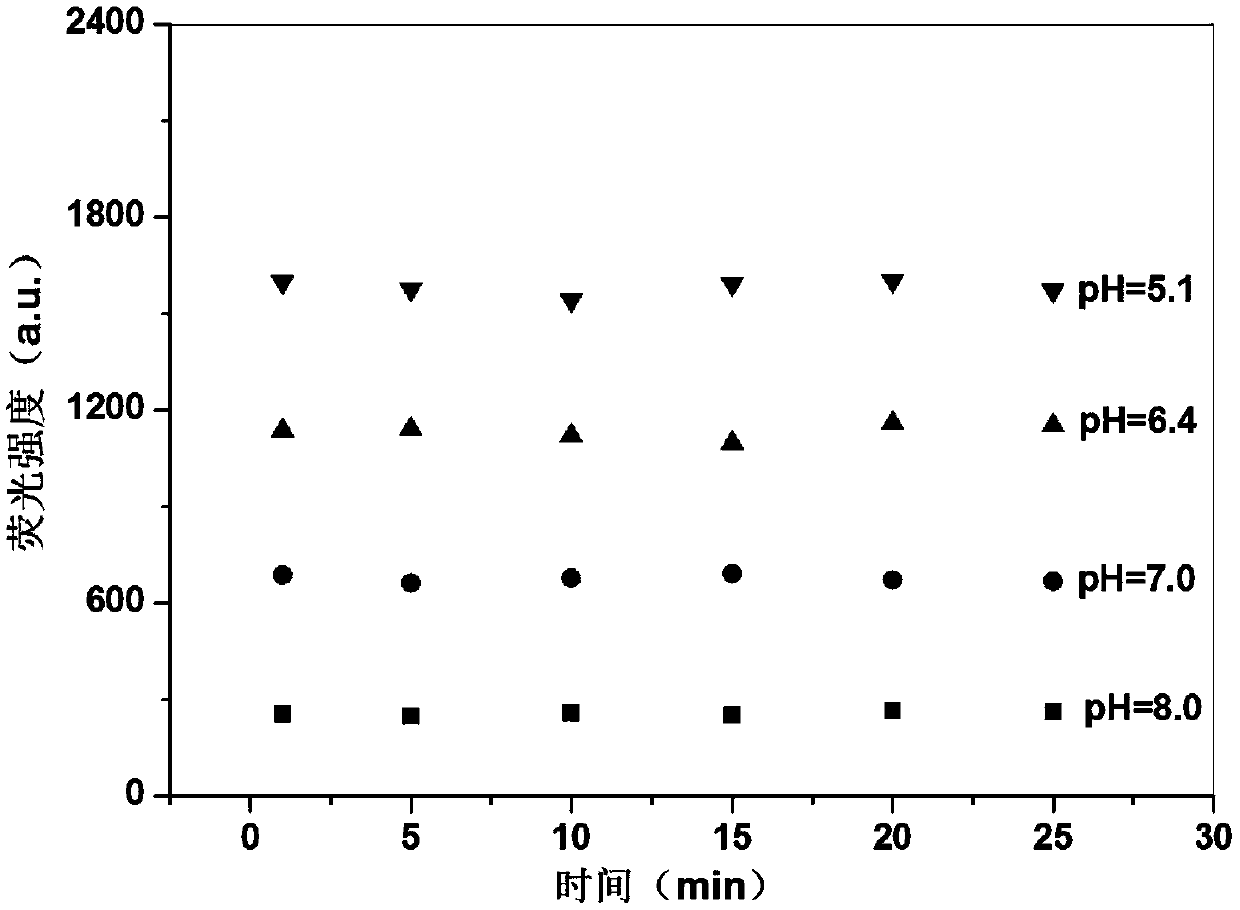

PH-responsive conjugated polymer nanoparticles, preparation method and applications thereof

ActiveCN111138639AGood biocompatibilityHigh fluorescence intensityFluorescence/phosphorescenceLuminescent compositionsCompatibilizationTumor cells

The invention discloses pH-responsive conjugated polymer nanoparticles, a preparation method and applications thereof. The preparation method comprises the following steps: uniformly mixing ultrapurewater and anhydrous acetonitrile to obtain a mixed solution; keeping the mixed solution in an ultrasonic state at a temperature of 20-35 DEG C, adding a mother liquor into the mixed solution in a dropwise manner, and continuously carrying out ultrasonic treatment for 1-2 hours after dropwise adding is completed to obtain a solution M, wherein the preparation method of the mother liquor comprises the following steps: dissolving a polythiophene derivative in chloroform to obtain a polythiophene derivative mother liquor with a concentration of 1-2 mg / mL; and introducing nitrogen into the solutionM, and removing chloroform and acetonitrile to obtain the pH-responsive conjugated polymer nanoparticle aqueous solution. The pH-response conjugated polymer nanoparticle has the characteristics of good biocompatibility, high fluorescence intensity, low toxicity and the like, can be used for accurately measuring the weakly acidic pH value in an aqueous solution, and can also be used for sensitivedetection and fluorescence imaging of tumor cell microenvironment response.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Method and device for detecting flow field gangue coal of dense-medium shallow-slot sorting machine

ActiveCN112129668ASimple detection principleThe detection effect is accurateMaterial capacitanceSpecific gravity measurementProcess engineeringCoal

The invention provides a method for detecting flow field gangue coal of a dense-medium shallow-slot sorting machine. The method is characterized by comprising the following steps of: acquiring the density of a gangue coal seam mixed solution, comparing the density with a density threshold value of the gangue coal seam mixed solution when a gangue coal seam is in a blocked state, and judging that the gangue coal seam is in the blocked state when the density of the gangue coal seam mixed solution is greater than the threshold value. According to the detection method and the detection device, theblocked state is reflected by utilizing the density change of the gangue coal seam, the detection principle is simple, the detection effect is accurate, the real-time property is high, an alarm signal can be timely sent when the density exceeds the threshold value when the gangue coal seam is accumulated more and more, and the blockage of the whole flow field is avoided.

Owner:ZHUZHOU TIANQIAO SHUNCHEN COAL PREPARATION MACHINERY

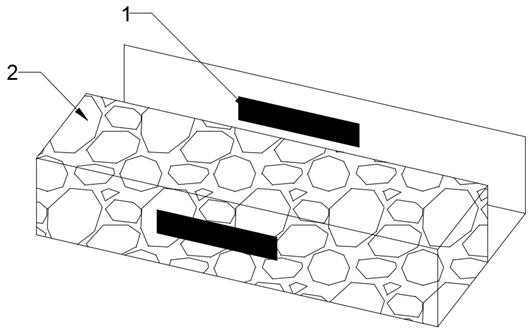

Method and device for detecting forming evenness of recombinant material slab

InactiveCN101566557BSimple processSolve the problem of uneven pavingUsing mechanical meansMaterial analysisProduction lineEngineering

The invention discloses a method and a device for detecting the forming evenness of a recombinant material slab. The device consists of an air blowing part, a detection part and a marking part. Compressed air is blast into the recombinant material slab which is transferred forward, a wind speed sensor is used to detect the wind speed difference at different positions, and a marker is spray-coatedat the position where the wind speed has obvious change. The device for detecting the recombinant material slab can be used with a recombinant material slab forming machine and slab processing equipment by matching. The method and the device for detecting the recombinant material slab have the advantages that: (1) the method and the device can finish the detection and marking on production lines,and have a simple process; and (2) the method and the device have a simple detection principle and reliable equipment, and can effectively solve the problem of uneven slab forming.

Owner:NORTHWEST A & F UNIV

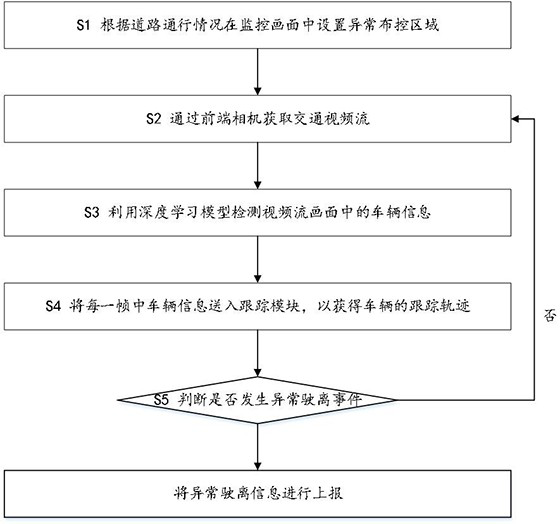

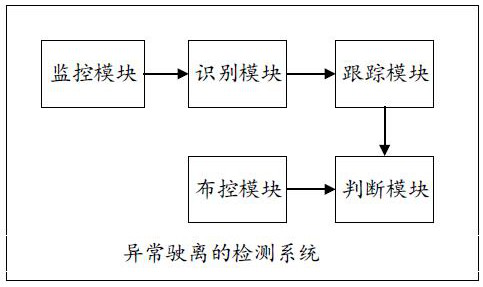

A detection method, system, electronic device and storage medium for abnormal departure

ActiveCN112507993BSimple detection principleImprove real-time detectionCo-operative working arrangementsCharacter and pattern recognitionSimulationMonitor equipment

The application provides a detection method, system, electronic equipment and storage medium for abnormal driving away, which belong to the field of detection technology, and the method includes: S1, setting an abnormal control area in the monitoring screen according to the road traffic conditions; S2, obtaining through the front-end camera Traffic video stream; S3, use the deep learning model to detect vehicle information in the video stream screen; S4, send the vehicle information in each frame to the tracking module to obtain the tracking track of the vehicle; S5, judge based on the tracking track and abnormal control area Whether the vehicle has an abnormal departure event, if so, report the abnormal departure information; if not, return to step S2. Compared with the use of embedded coils and light sensors in the prior art, or the use of RFID technology for abnormal departure detection, the solution of this application does not need to lay out expensive infrastructure, and can be realized based on existing road monitoring equipment. Moreover, the detection principle is simple, which can ensure high detection real-time performance and accuracy.

Owner:上海闪马智能科技有限公司

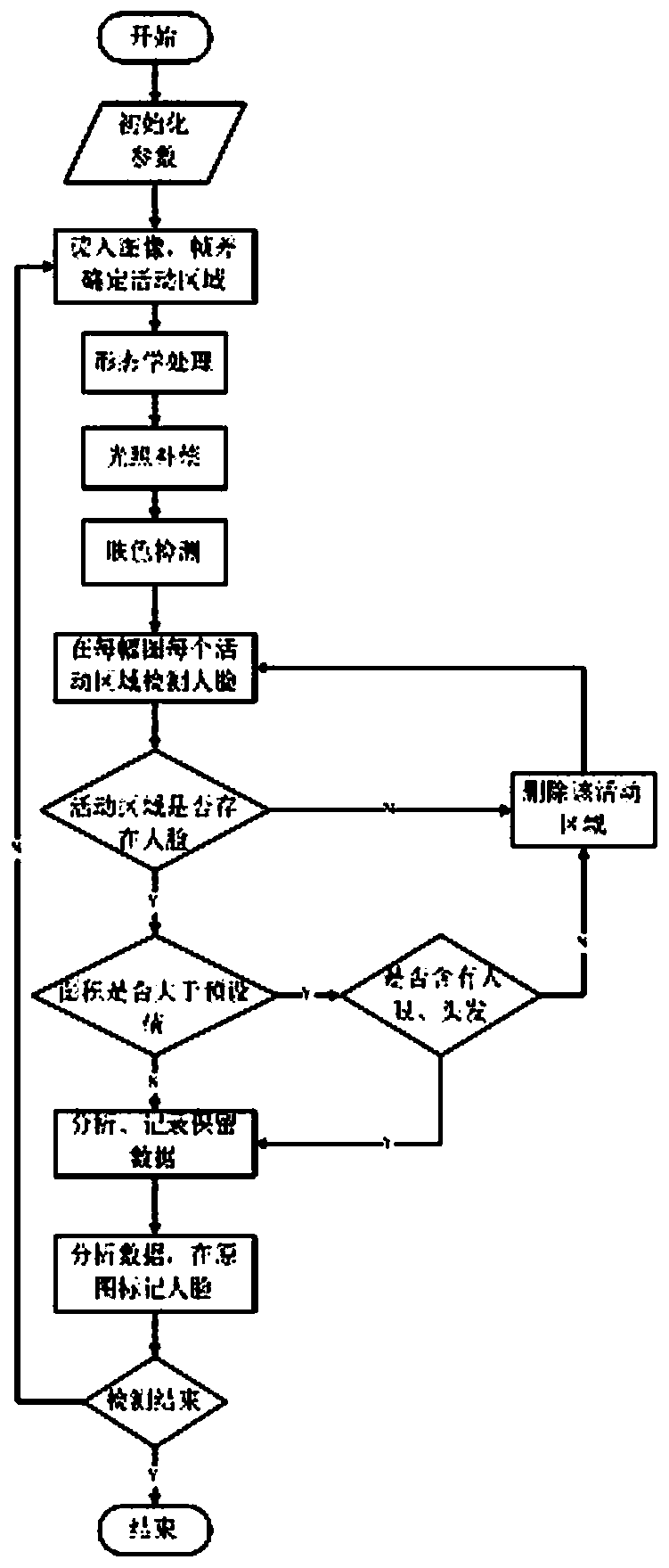

A method for detecting and locating standing faces in an intelligent recording and broadcasting system

ActiveCN107480607BImprove accuracyClever designImage enhancementTelevision system detailsFace detectionSkin colour

The invention belongs to the field of intelligent recording and broadcasting systems, and relates to a method for detecting and locating standing human faces in an intelligent recording and broadcasting system. value, and then perform morphological operations on the image, mark the active area and retain it with the smallest circumscribed rectangle, and perform light compensation on it, and then filter out the interfering active area through skin color detection, and classify it according to the proportion of the face area Screening and exclusion of skin-colored but no-face areas, and finally data analysis based on the processed data to mark faces. This method is ingenious in design, simple in detection principle, easy to operate and use, and can complete standing with only one camera. Face detection and positioning, low equipment requirements, high accuracy of detection results, friendly application environment, and broad market prospects.

Owner:QINGDAO UNIV

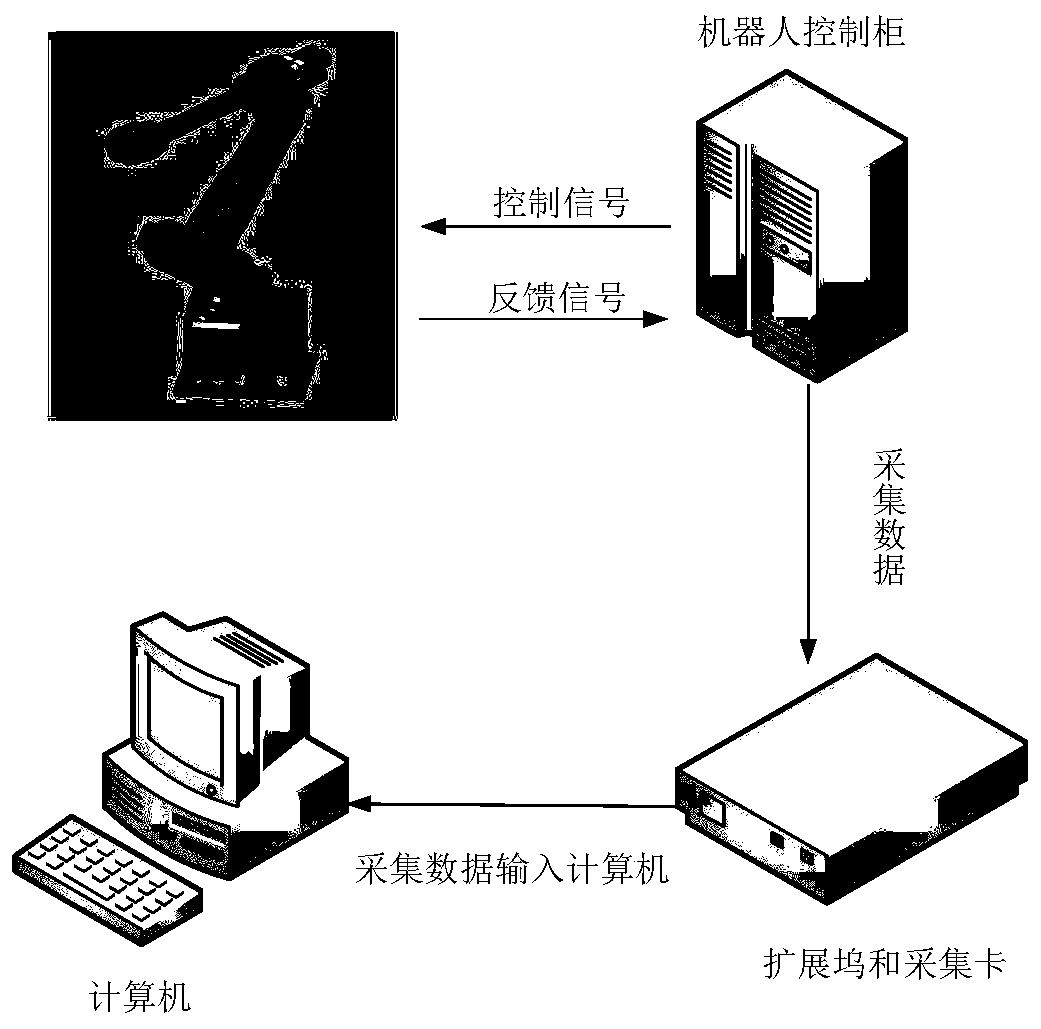

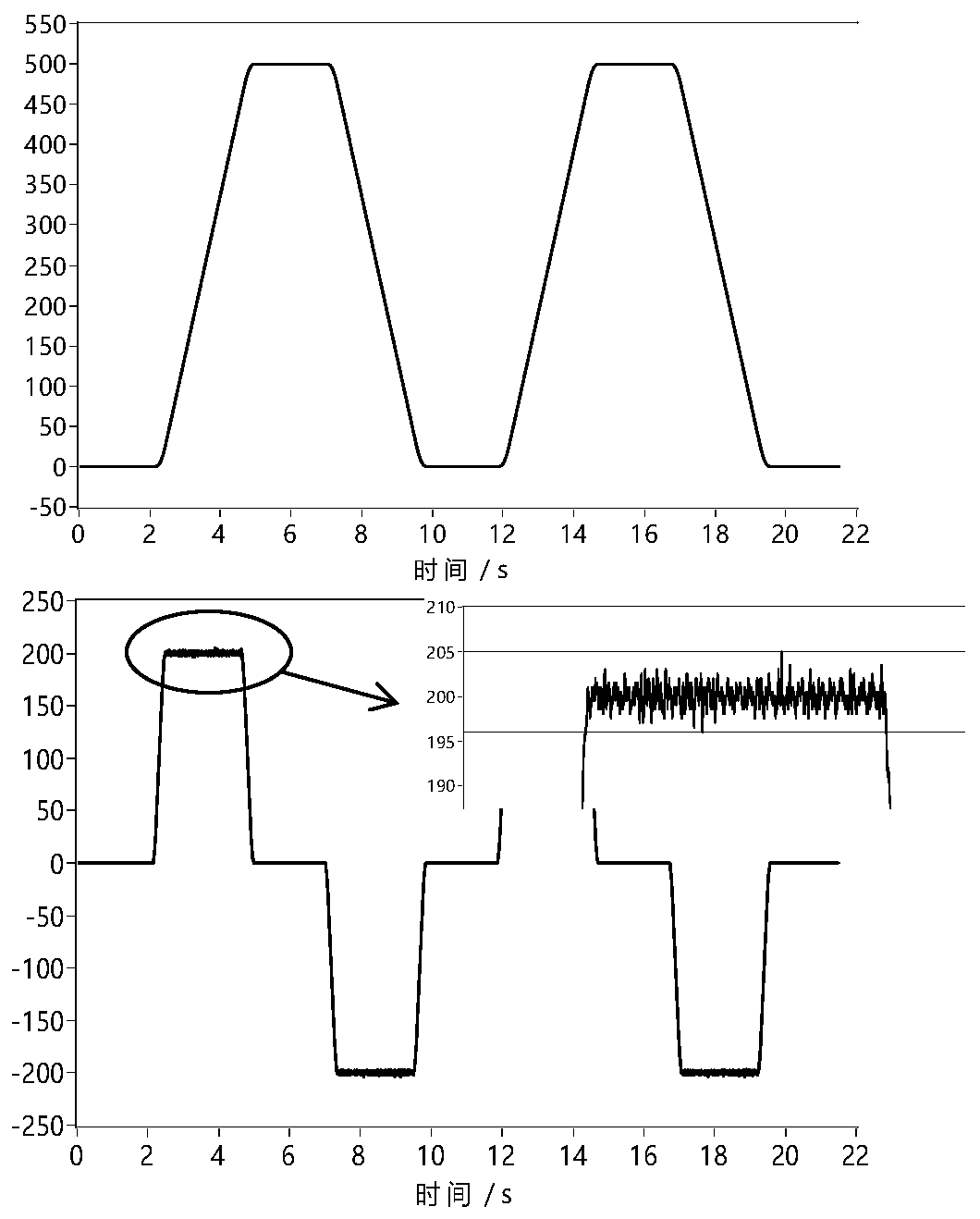

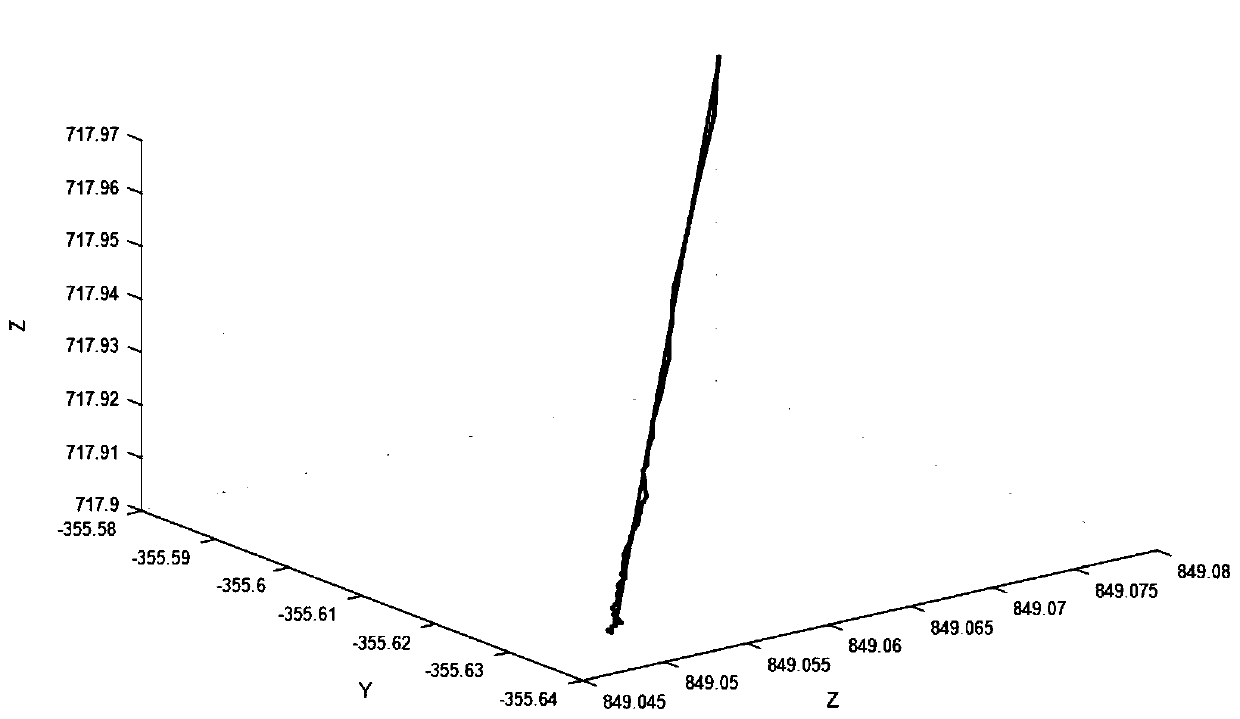

Motion characteristic detection method based on built-in sensor signal of industrial robot

The invention discloses a kinetic characteristic detecting method based on a built-in sensor signal of an industrial robot. The kinetic characteristic detecting method comprises the following steps that: a data acquisition board acquires a signal of each joint servo motor coder of the industrial robot, and reads position feedback pulse count, sent to a robot control cabinet, of a joint servo motor of the industrial robot; a calculating processing unit performs coordinate conversion computation of a joint conversion matrix in a D-H model on kinetic information of each joint of the industrial robot according to the robot kinetic D-H model to obtain a coordinate value and motion track, under a base coordinate system of the industrial robot, of real-time point location of the industrial robot end, and a calculating processing unit performs three-dimensional space real-time display on the coordinate value and the motion track through the display screen; and theoretical point location of the industrial robot end is compared with the obtained coordinate value to given position precision information. The kinetic characteristic detecting method is simple in detecting principle and is easy to realize, has the advantages of being convenient, quick and capable of real-time detection; and a measuring device does not need to be additionally arranged on the robot end, so that cost is greatly reduced.

Owner:XI AN JIAOTONG UNIV

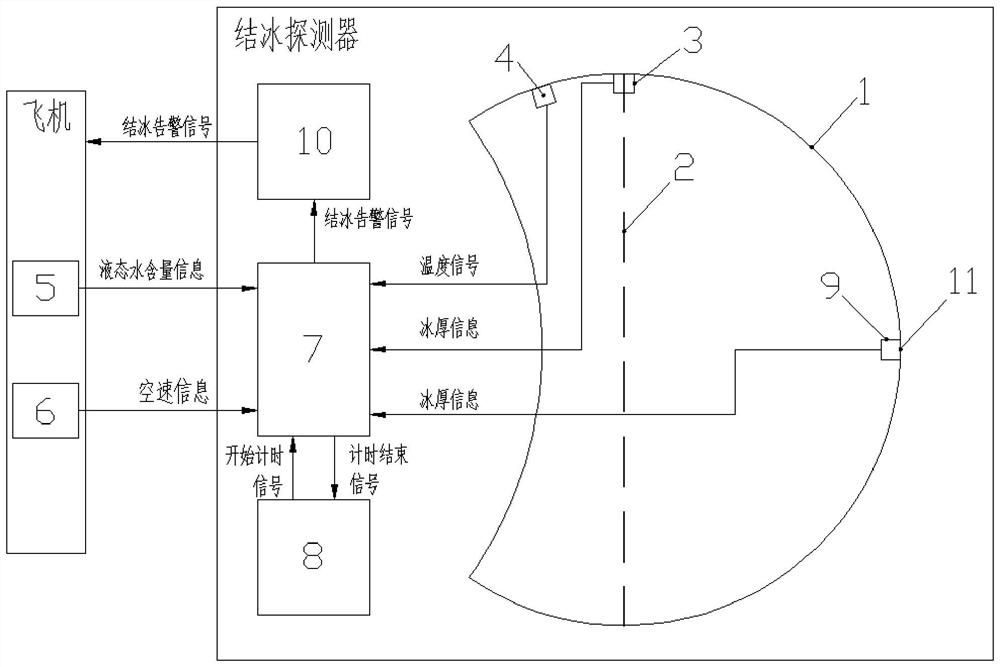

SLD icing detection method based on ice shape growth and icing detector

PendingCN112498697ASimple structureNot easy to freezeDe-icing equipmentsSpherical probeAtmospheric sciences

The invention discloses an SLD icing detection method based on ice shape growth and an icing detector. The method is carried out according to the following steps: S1 carrying out simulation to obtainsimulation icing time required for icing the maximum annular wall (2) of the windward side of a spherical probe (1) to a preset thickness; S2 collecting the actual icing thickness on the maximum annular wall (2) of the windward side of the spherical probe (1) in flight within the simulated icing time; and S3 comparison operation processing: comparing and operating the preset thickness and the actual thickness, and outputting an operation result. The icing detector has the advantages of being simple in structure, convenient to machine, low in cost and high in detection precision.

Owner:WUHAN AVIATION INSTR

A non-contact urban rail vehicle wheel set size online detection method

ActiveCN107607063BRealize dynamic online high-precision measurementImprove detection accuracyUsing optical meansEngineeringMechanical engineering

The invention discloses a non-contact type urban rail vehicle wheel set size on-line detection method. The method includes the following steps: successively arranging a first laser displacement sensorand a second laser displacement sensor on the inner side of a track in a train forwarding direction and successively arranging a fourth laser displacement sensor and a third laser displacement sensoron the outer side of the track, the first and fourth laser displacement sensors being symmetrical about the track and the second laser displacement sensor and the third laser displacement sensor being symmetrical about the track; carrying out coordinate rotation and transverse plane and feature point extraction on two-dimensional data points collected by the laser displacement sensors, and obtaining distances between the laser displacement sensors and a tread side of a vehicle wheel when the circle center of the vehicle wheel is in the central lines of the first and second laser displacementsensors and is in the central lines of the third and the fourth laser displacement sensors; solving two sets of diameters according to geometrical relations, and obtaining an average value of the diameter of the vehicle wheel; and obtaining two sets of vehicle wheel tread side contours through data fusion, and obtaining an average value of parameters of the rim of the vehicle wheel. The method hasthe advantages that the structure is simple, the precision is high and the stability is high.

Owner:NANJING UNIV OF SCI & TECH

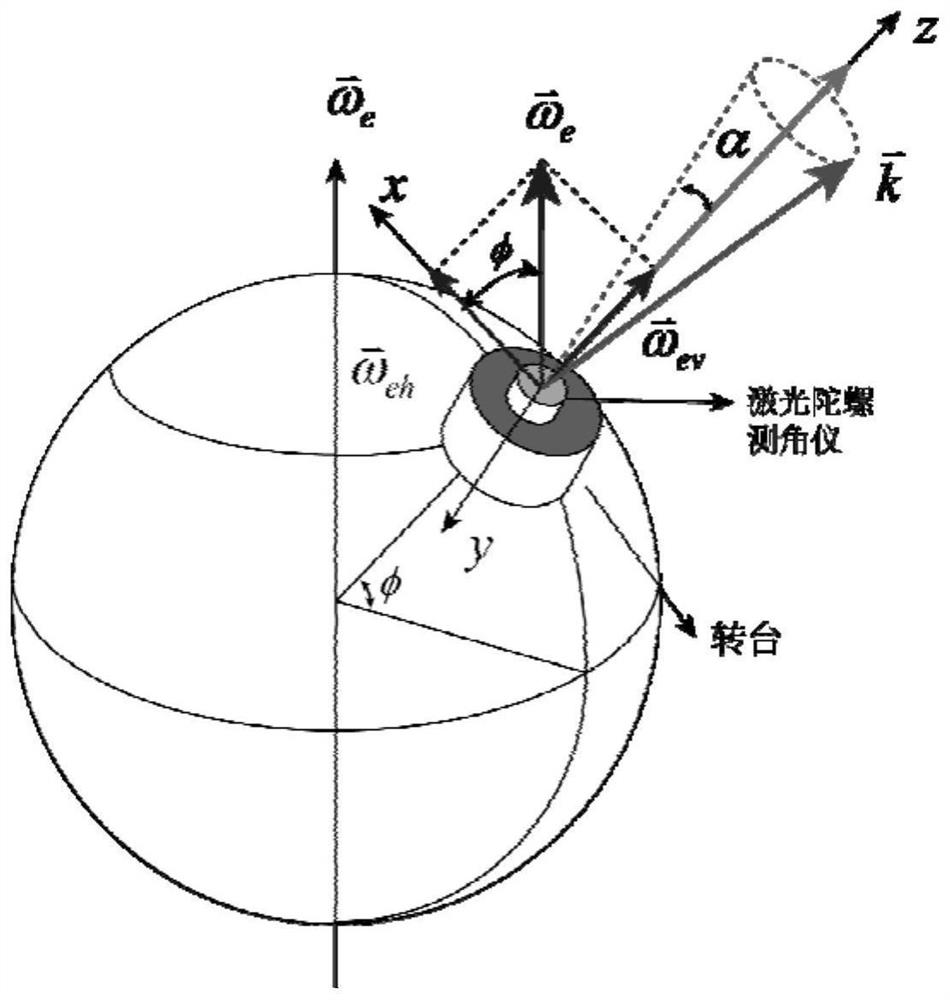

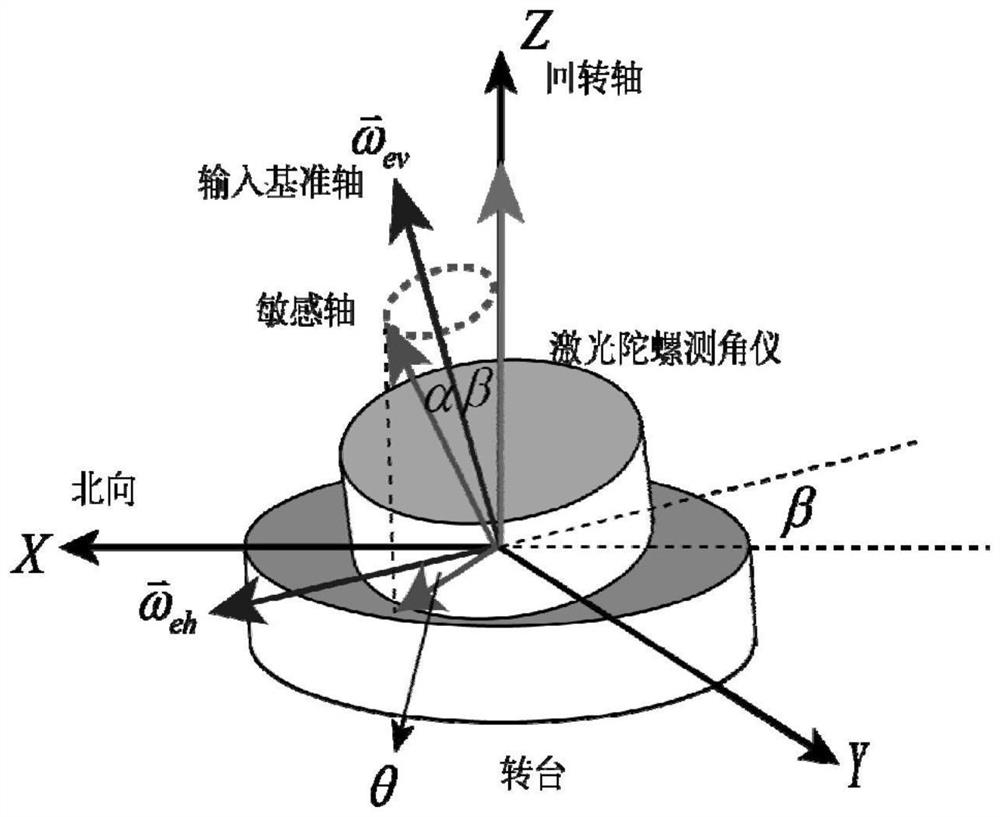

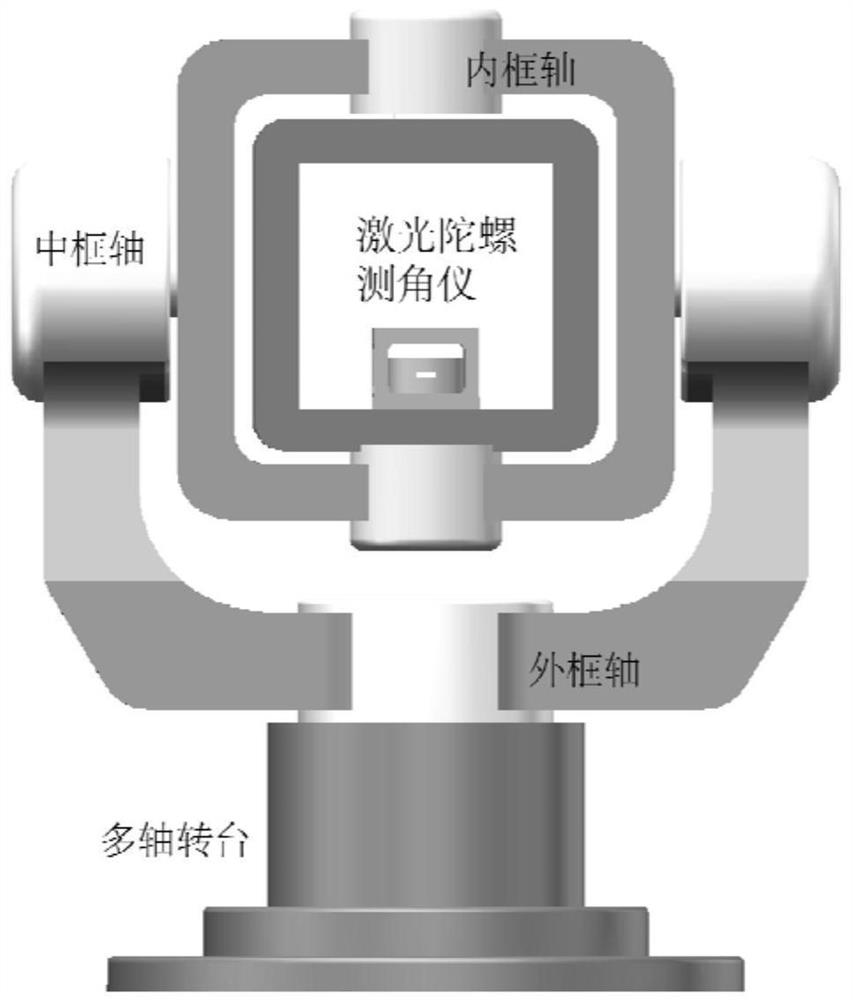

Multi-axis turntable angle positioning error detection method based on single-axis laser gyro goniometer

ActiveCN113899323AThe detection device is simpleSimple detection principleSagnac effect gyrometersUsing optical meansGoniometerPulse number

The invention discloses a multi-axis turntable angle positioning error detection method based on a single-axis laser gyro goniometer, wherein the method comprises the steps: electrifying the single-axis laser gyro goniometer, preheating for 30 minutes, mounting the single-axis laser gyro goniometer mounted in a fixture on a working table surface of a multi-axis turntable, and calibrating an offset value B0 of the single-axis laser gyro goniometer; rotating the measured shaft of the multi-shaft turntable, and enabling the single-shaft laser gyro goniometer to output corresponding pulses and count the output pulses; according to the scale coefficient K of the single-axis laser gyro goniometer and the output pulse number corresponding to the measured shaft, calculating an angle measurement value [theta]i of the measured shaft measured by the single-axis laser gyro goniometer; performing sine curve fitting on the angle measurement error value [delta][theta]i according to the angle measurement value [theta]i of the measured shaft, and calculating the angle measurement error value [delta][theta]i introduced by earth rotation according to the projection angle of a sensitive shaft of the single-shaft laser gyro goniometer; and eliminating the angle measurement error value [delta][theta]i introduced by earth rotation, and calculating an angle positioning error of the measured shaft.

Owner:NAT INST OF METROLOGY CHINA

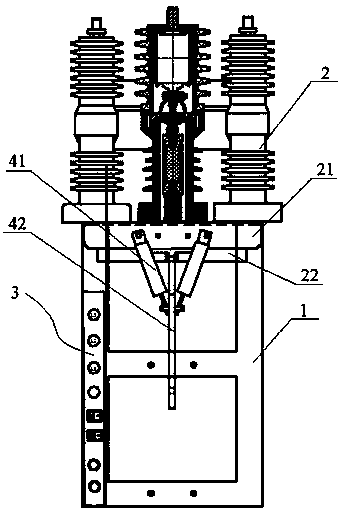

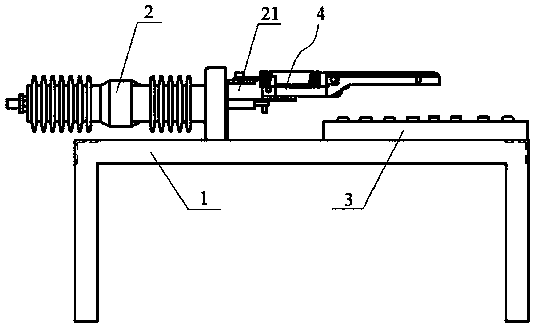

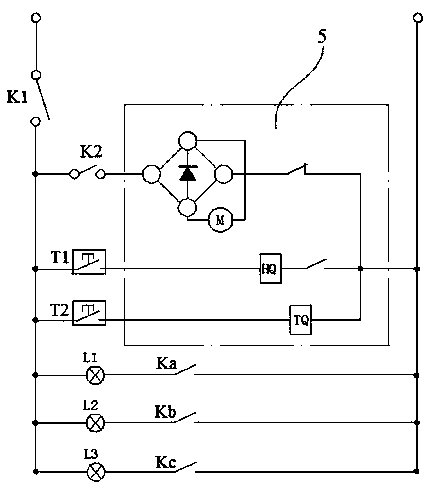

Spring operating mechanism detection device

ActiveCN105572583BEasy to set up and useGuaranteed performanceCircuit interrupters testingCircuit breakerHigh voltage

The invention discloses a spring operating mechanism detection device comprising a test support. One end of the test support is provided with an arc-extinguishing component via an arc-extinguishing chamber fixing rod box. The other end of the test support is provided with a tested spring operating mechanism. The arc-extinguishing component and the tested spring operating mechanism are connected via a connecting mechanism. The test support is also provided with a test mechanism used for detecting the tested spring operating mechanism. The spring operating mechanism to be detected and the arc-extinguishing component of a circuit breaker are matched through circuit connection so that simulation of the real use state of the high-voltage circuit breaker can be realized, one-to-one detection can be realized, the overall product performance of the finished high-voltage circuit breaker can be fully guaranteed, yield rate of the product can be enhanced and repair rate and quality accidents of the product can be reduced.

Owner:保定市水木电器设备有限公司

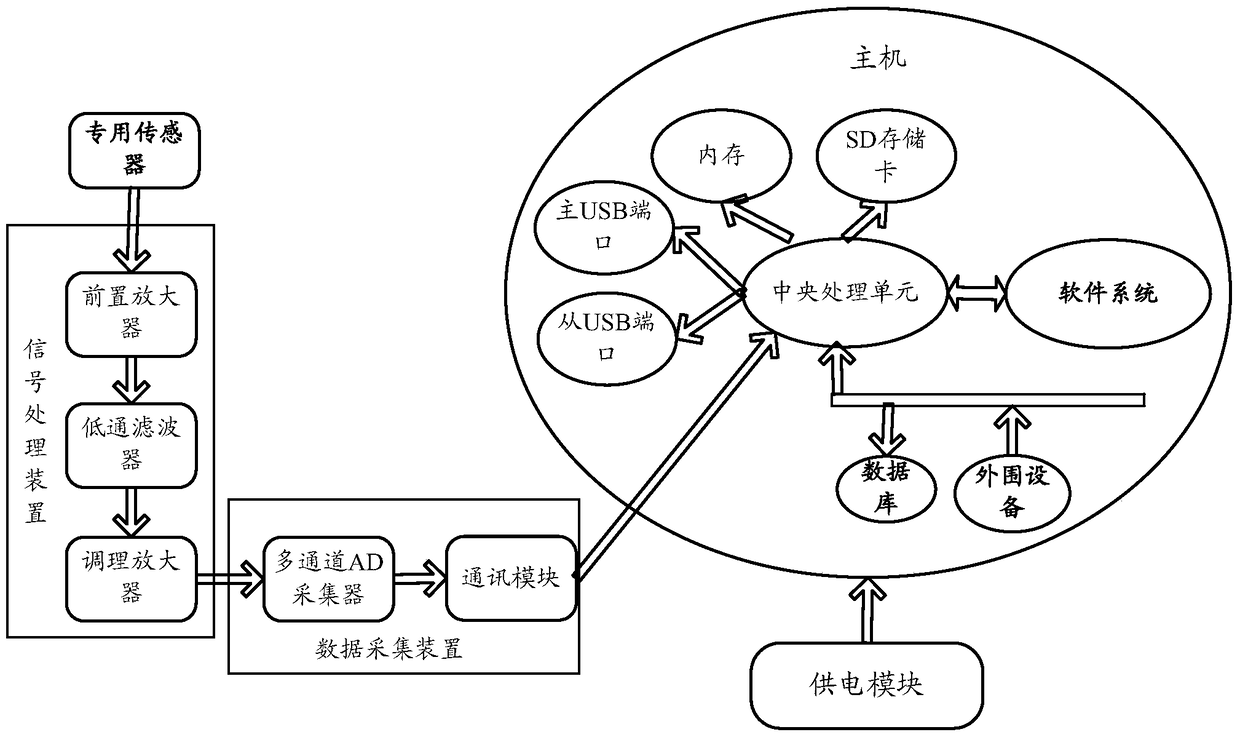

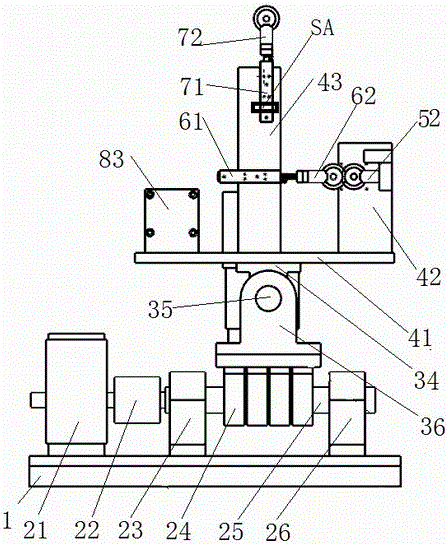

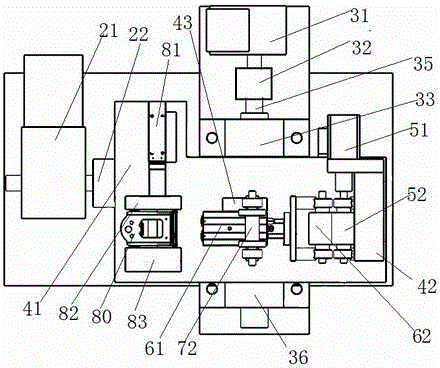

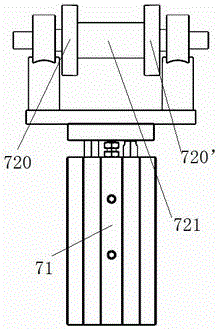

Quantitative detection method and detection instrument for scale accumulation in pipeline

ActiveCN105092691BSimple detection principleEasy to carryMaterial magnetic variablesSignal processingMagnetic field

The invention provides a quantitative detection method and a detector for detecting the accumulated oxide scales in the pipelines. The quantitative detection method comprises the following steps: arranging a special sensor on a primary detection point on the surface of a pipeline to be detected, moving the special sensor along the axial direction of the pipeline, wherein the special sensor can generate a stable, constant, and strong magnetic field on each detection points of the pipeline; exciting and magnetizing the oxides on the detection points in the pipeline through the strong magnetic fields, wherein the oxides can generate primary magnetic field signals after being excited and magnetized; receiving the primary magnetic field signals by the special sensor, processing the signals, sending the processed signals to a host computer; continuously analyzing the digital magnetic field signals by the host computer, and finally obtaining the accumulated oxide scale amount in each detection point of the pipeline by combining the primary detection point coordinate and the moving distance of the special sensor in the pipeline. The detection method and detector have the advantages of simple detection principle, portability, high sensitivity, and low cost, can be used to measure the accumulated oxide scale in stainless pipelines in a power plant, and have a good application prospect.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

Technological process for detecting quality of seat belt components

ActiveCN106323606AMeet the practical needs of acceleration performance testingMeet real needsMachine part testingEngineeringMechanical engineering

The present invention discloses a technological process for detecting quality of seat belt components. The process is characterized by successively comprising a process is followed by a device initialization step, a receiver fixing step, a seat belt wiring step, a seat belt clamping step, a seat belt pulling step, a seat belt acceleration step, an observation detection step and a detection completion step. The process overcomes the defects of the existing seat belt component acceleration measuring device is complex in structure, inconvenient in operation, high in cost and low in detection efficiency. The process realizes high-efficiency and low-cost detection of the seat belt acceleration performance.

Owner:CHUZHOU VOCATIONAL & TECHN COLLEGE

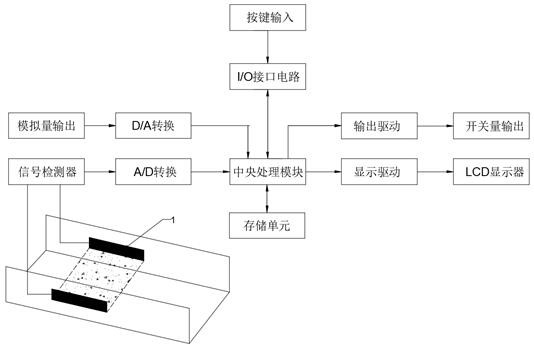

Online detection system for vibration of elevator traction motor

ActiveCN111537061AEasy to disassembleReduce maintenance costsSubsonic/sonic/ultrasonic wave measurementVibration signatureReliability engineering

The invention provides an online detection system for vibration of an elevator traction motor, which is characterized by comprising a sensor, a signal processing module, a data processing module, an alarm device, a motor control device and a power supply, wherein the power supply provides electric energy for all electrical components of the detection system; the sensor is used for collecting a vibration signal of the traction motor; the signal processing module is used for acquiring and amplifying data acquired by the sensor; the data processing module is used for storing, analyzing, displaying and judging the processed signal data; and the data processing module is in signal connection with the alarm device and the motor control device. The beneficial effects of the invention are that bymeans of fixing external equipment at a to-be-detected point of the motor, the detection equipment is convenient to disassemble, and the maintenance cost is low; and through information acquisition and analysis of regular change of current flowing through a capacitor line, the fact that the motor works abnormally is discovered at the first time, and the detection principle is simple.

Owner:JIANGSU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com