Motion characteristic detection method based on built-in sensor signal of industrial robot

An industrial robot and sensor signal technology, applied in the field of robotics, can solve problems such as complicated operation, high price, and inability to apply in a large range, and achieve the effect of simple detection principle, easy implementation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

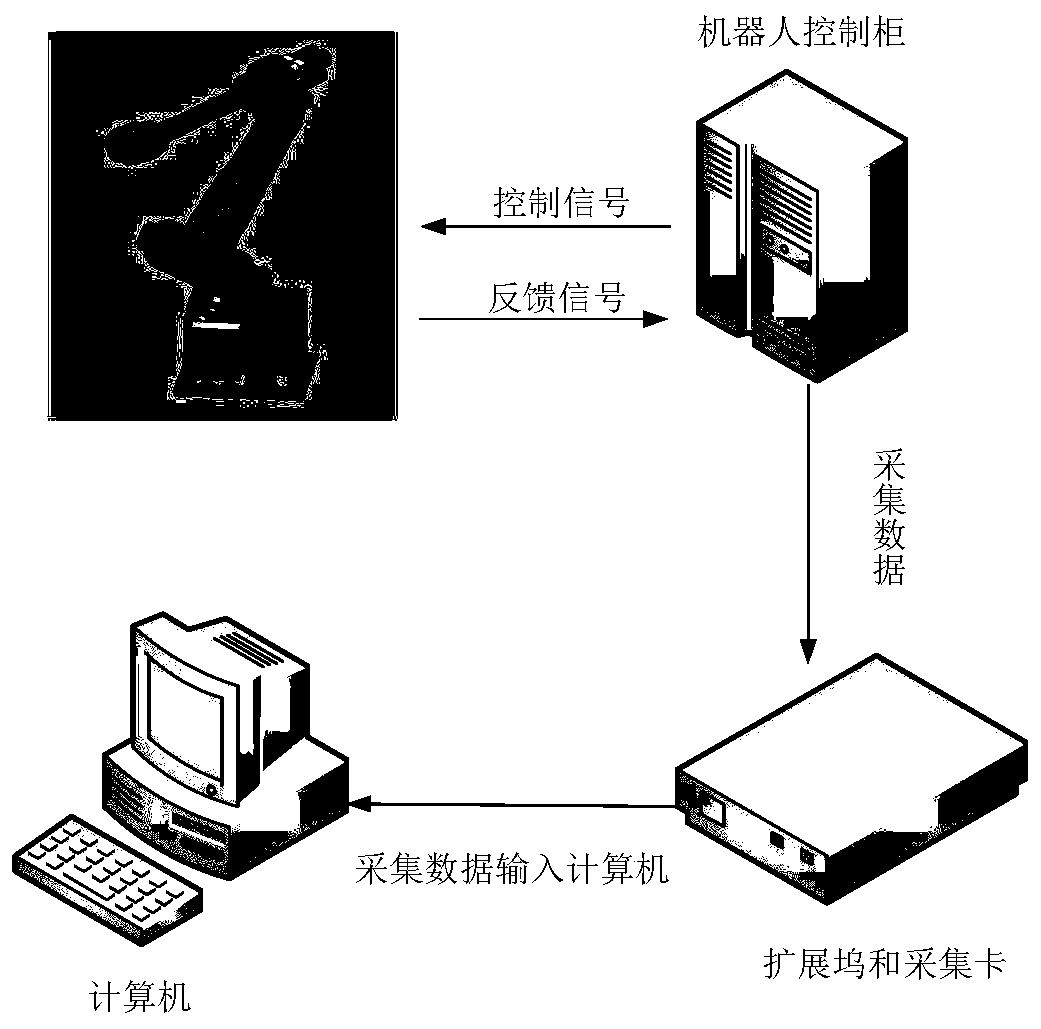

[0034] A motion characteristic detection method based on a built-in sensor signal of an industrial robot, comprising the following operations:

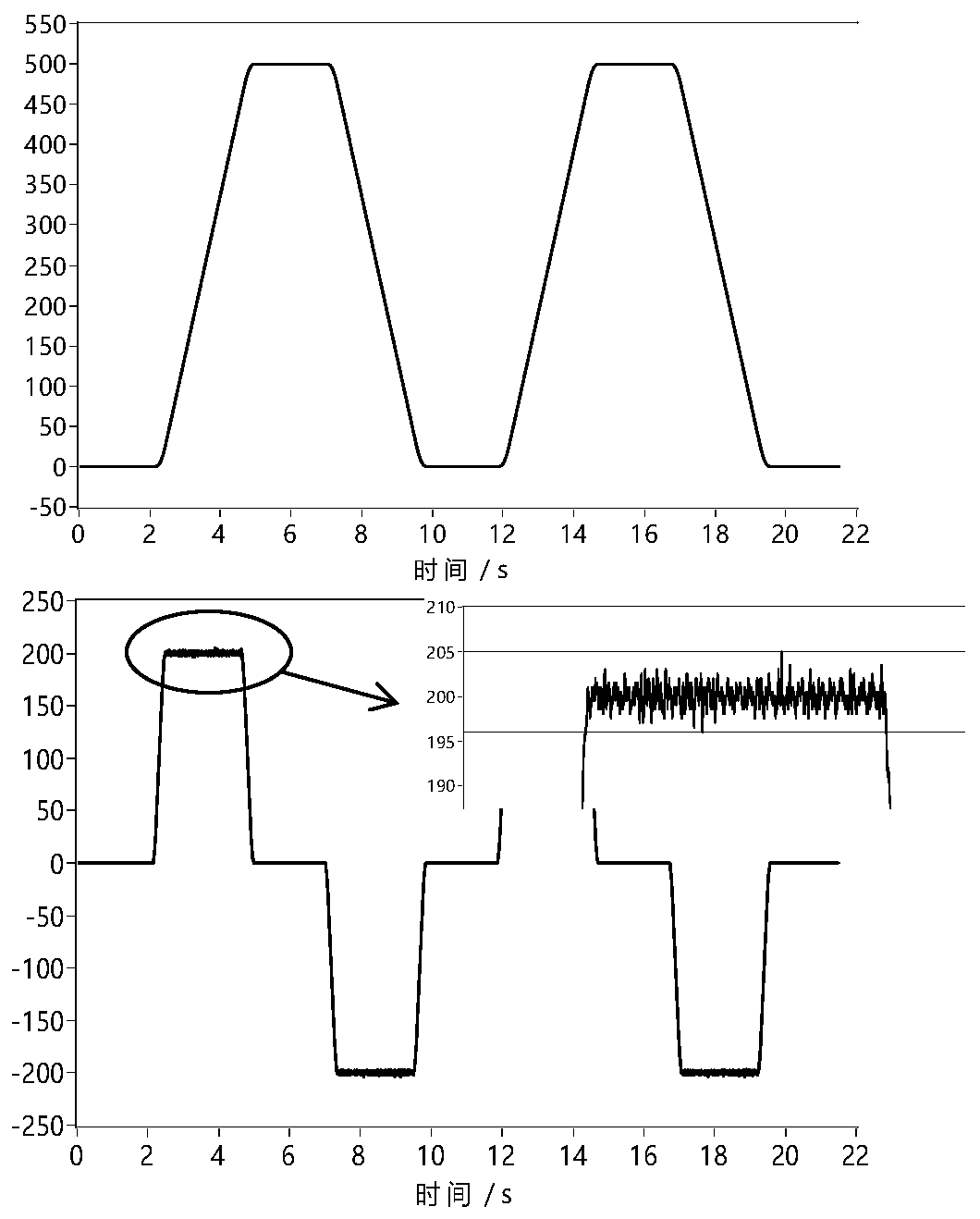

[0035] 1) When the industrial robot moves according to the control command sent by the robot control cabinet, the data acquisition board collects the signal of the encoder of the servo motor of each joint of the industrial robot, and reads the number of position feedback pulses sent by the joint servo motor to the robot control cabinet; The data acquisition board sends the collected signal to the calculation processing unit for processing, obtains the motor rotation angle through the number of position feedback pulses, and then obtains the rotation angle and joint motion information of each joint through the reduction ratio of the motor rotation angle and the joint rotation angle, and restores the Motion information of each joint of the industrial robot including position and speed;

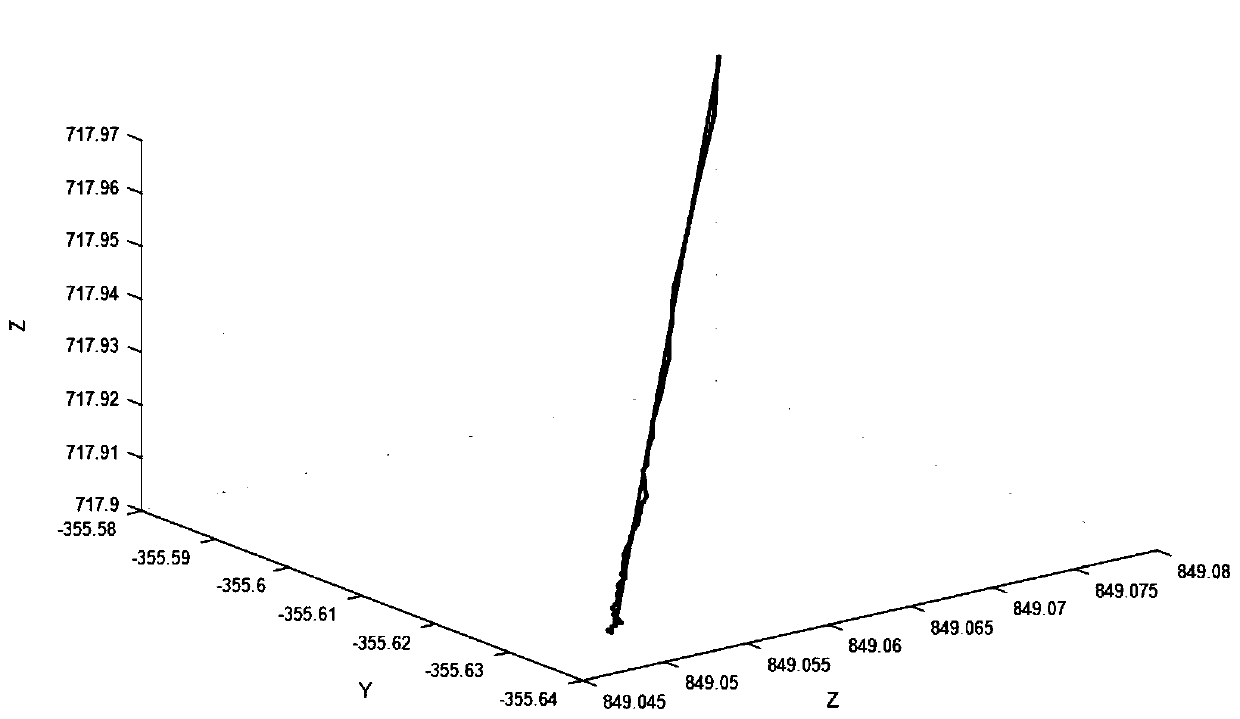

[0036] 2) According to the robot kinematics D-H mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com