Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Short cooling path" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

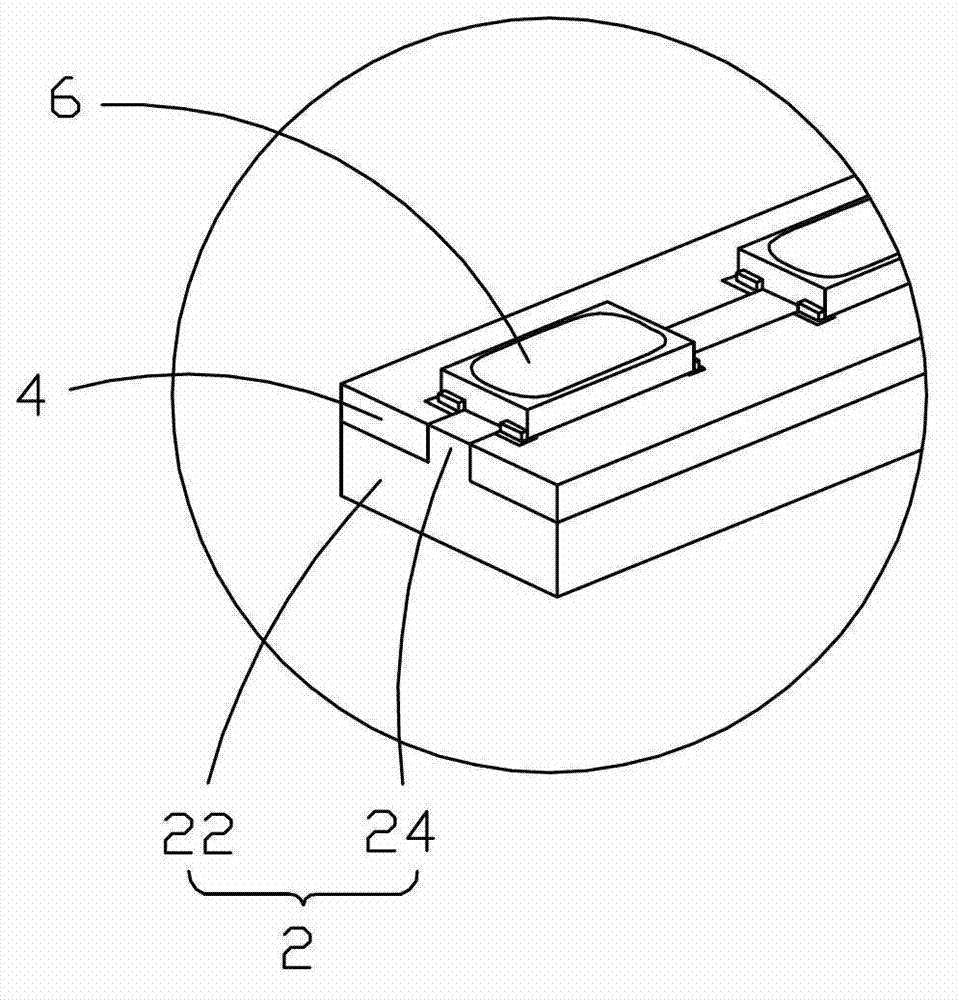

QFN surface-mounted RGB-LED encapsulation module and manufacturing method thereof

PendingCN106847800AQuick exportHigh resolutionSolid-state devicesIdentification meansSurface mountingEngineering

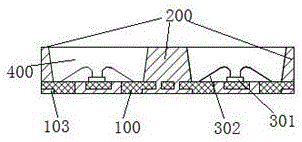

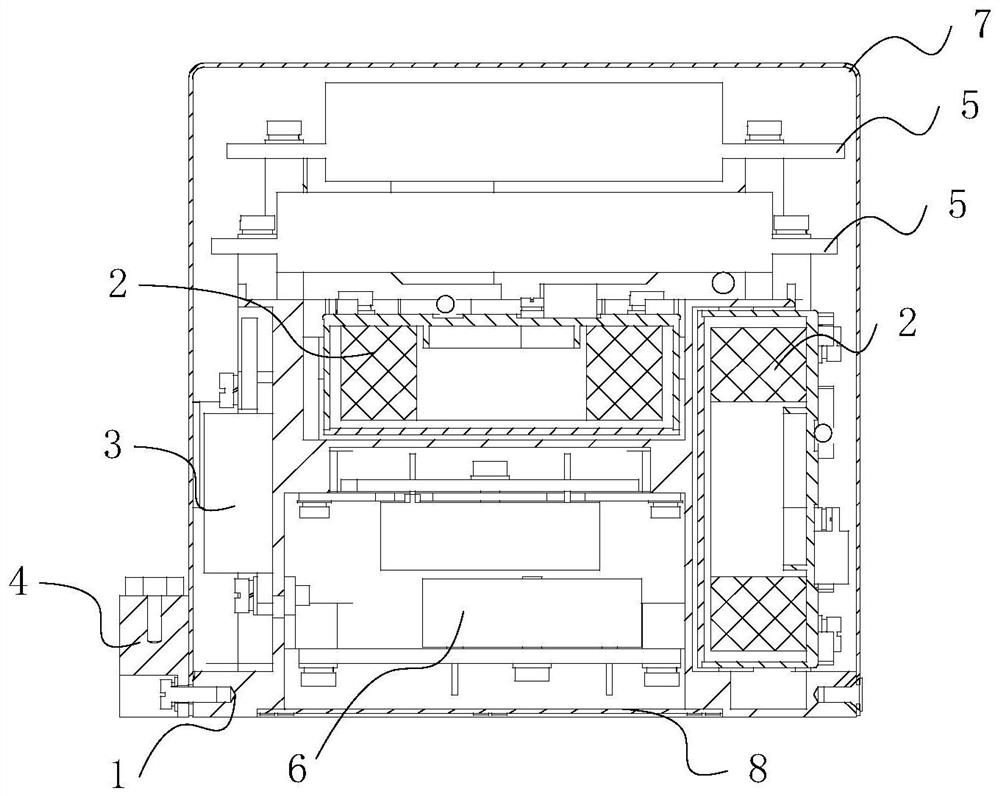

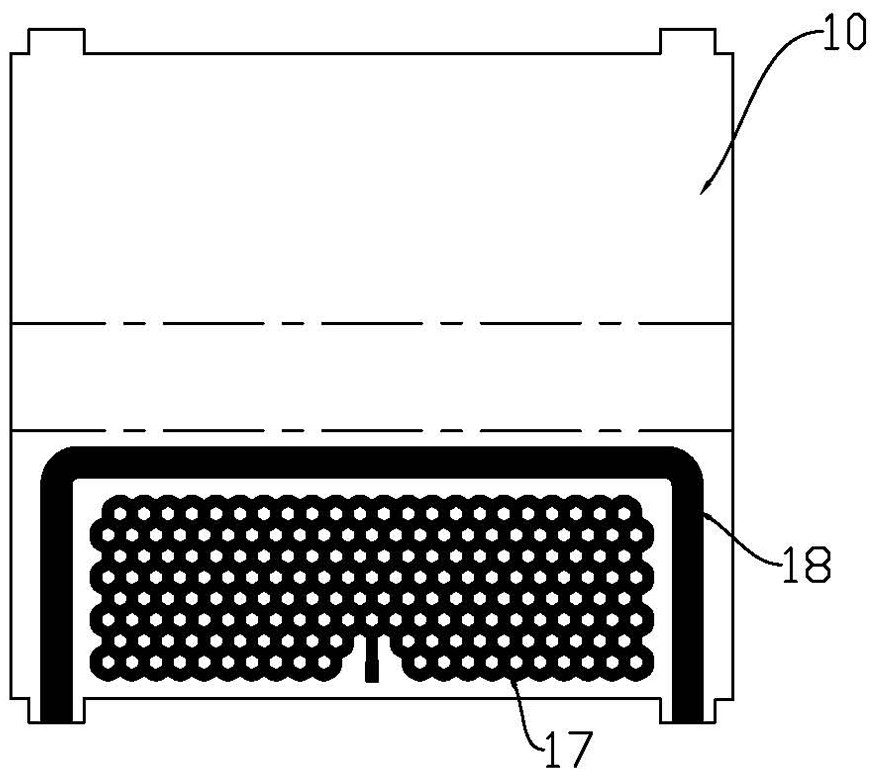

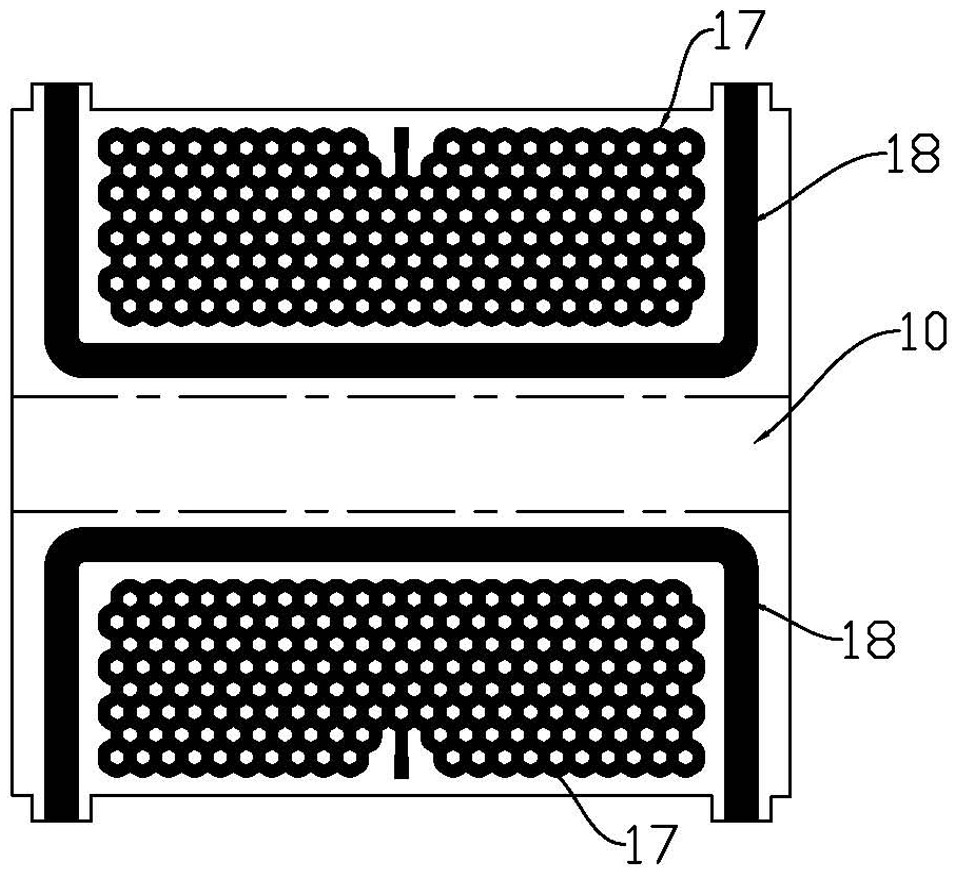

The invention provides a QFN surface-mounted RGB-LED encapsulation module and a manufacturing method thereof. The RGB-LED encapsulation module comprises an encapsulation bracket and light-emitting units arranged on the encapsulation bracket, wherein the number of the light-emitting units is at least two; the encapsulation bracket comprises a metal baseplate and an insulating frame; a bracket electrode for fixing crystal and bonding a wire is arranged at a region, where each light-emitting unit is located, by the metal baseplate; each light-emitting unit comprises an RGB-LED chip fixed on the metal baseplate and a bond and a wire for connecting the RGB-LED chip and a bracket electrode; a protective layer is arranged on each light-emitting unit; the bracket electrode is connected with an external circuit through a bonding pad arranged on the back of the metal baseplate. The encapsulation module is in direct contact with a PCB through the metal baseplate, so that chip heat can be quickly led out; a bowl-cup structure is formed on the front, so that a light-emitting surface is unique; the multiple light-emitting units are integrated on the one encapsulation module, so that the production efficiency is further improved.

Owner:SHANDONG JIERUNHONG OPTOELECTRONICS CO LTD

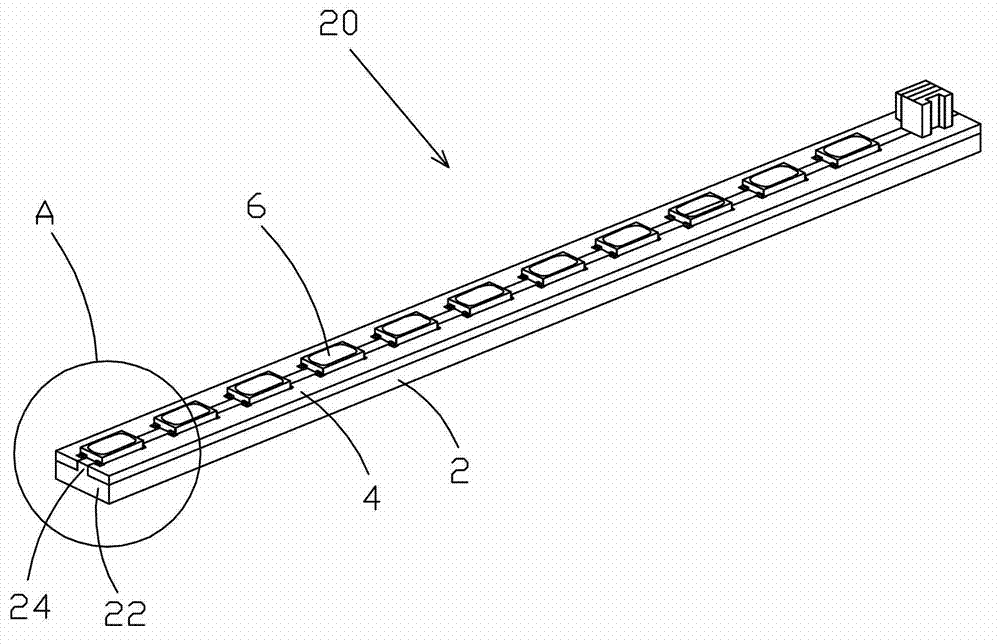

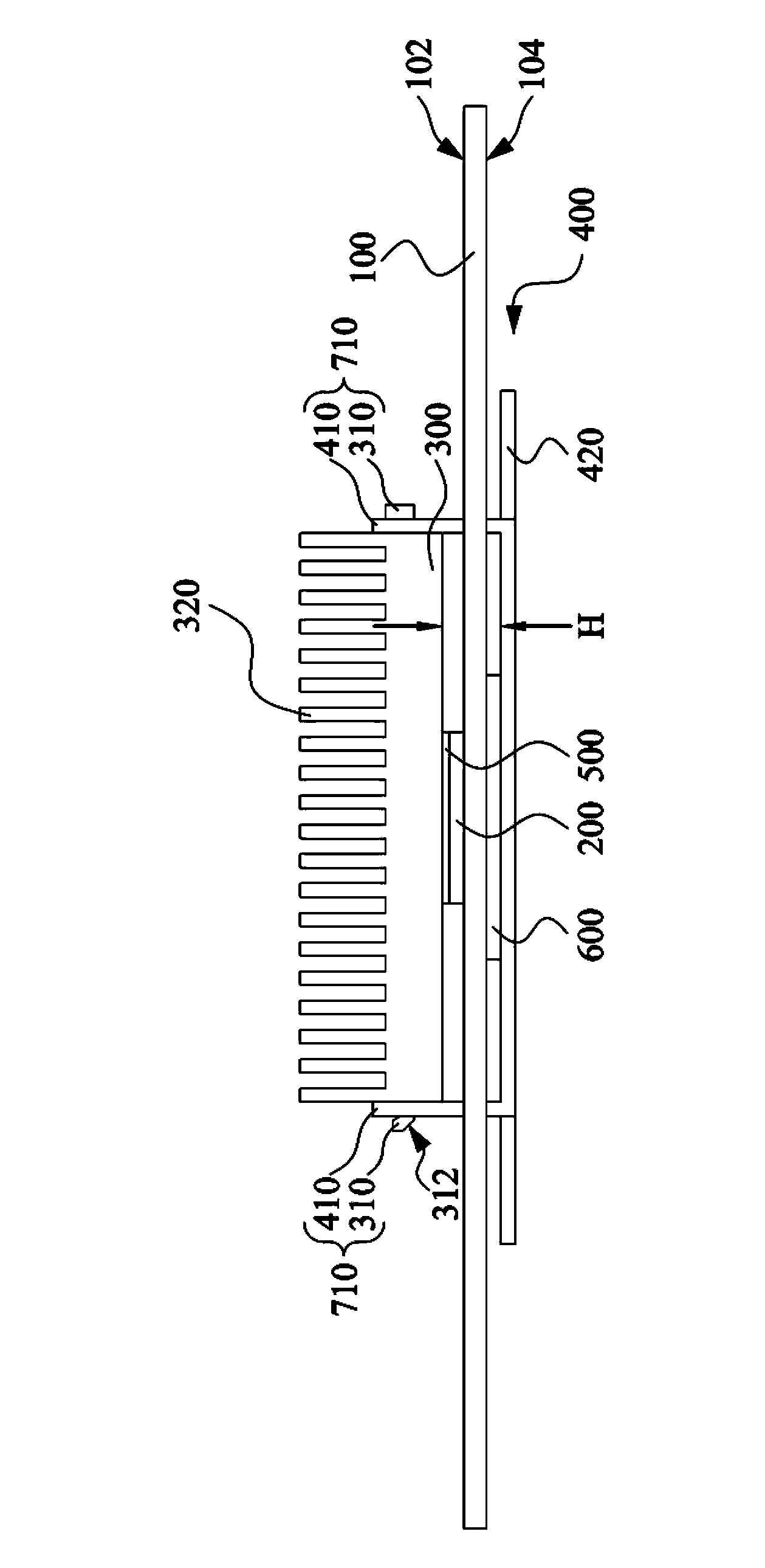

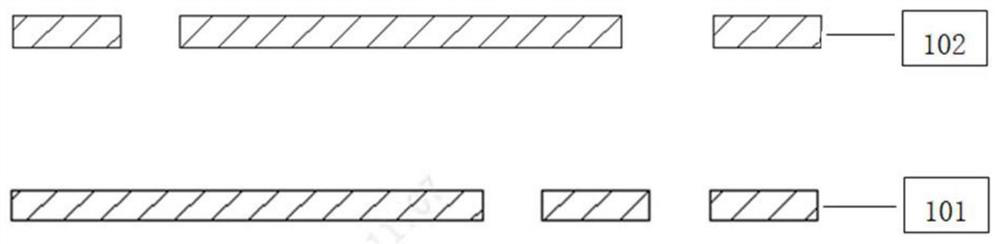

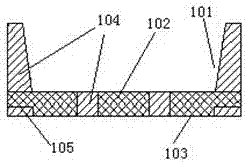

LED (Light Emitting Diode) lamp strip and backlight module employing same

InactiveCN102900989ASimple processShort cooling pathPoint-like light sourceLighting heating/cooling arrangementsEngineeringLED lamp

The invention provides an LED (Light Emitting Diode) lamp strip and a backlight module employing the same, wherein the LED lamp strip comprises a heat-radiating strip, a PCB (Printed Circuit Board) arranged on the heat-radiating strip, LED chips electrically connected with the PCB and arranged on the heat-radiating strip, and thermal interface material layers arranged between the LED chips and the heat-radiating strip. According to the LED lamp strip and the backlight module employing the same provided by the invention, by arranging the LED chips on the heat-radiating strip with good heat conduction effect, the process of heat transfer through the PCB with poorer heat radiation effect required in the prior art is avoided. The LED lamp strip and the backlight module employing the same has the advantages of simple process, shorter overall heat radiation path, realization of favourable heat radiation effect, and guarantee of backlight quality.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

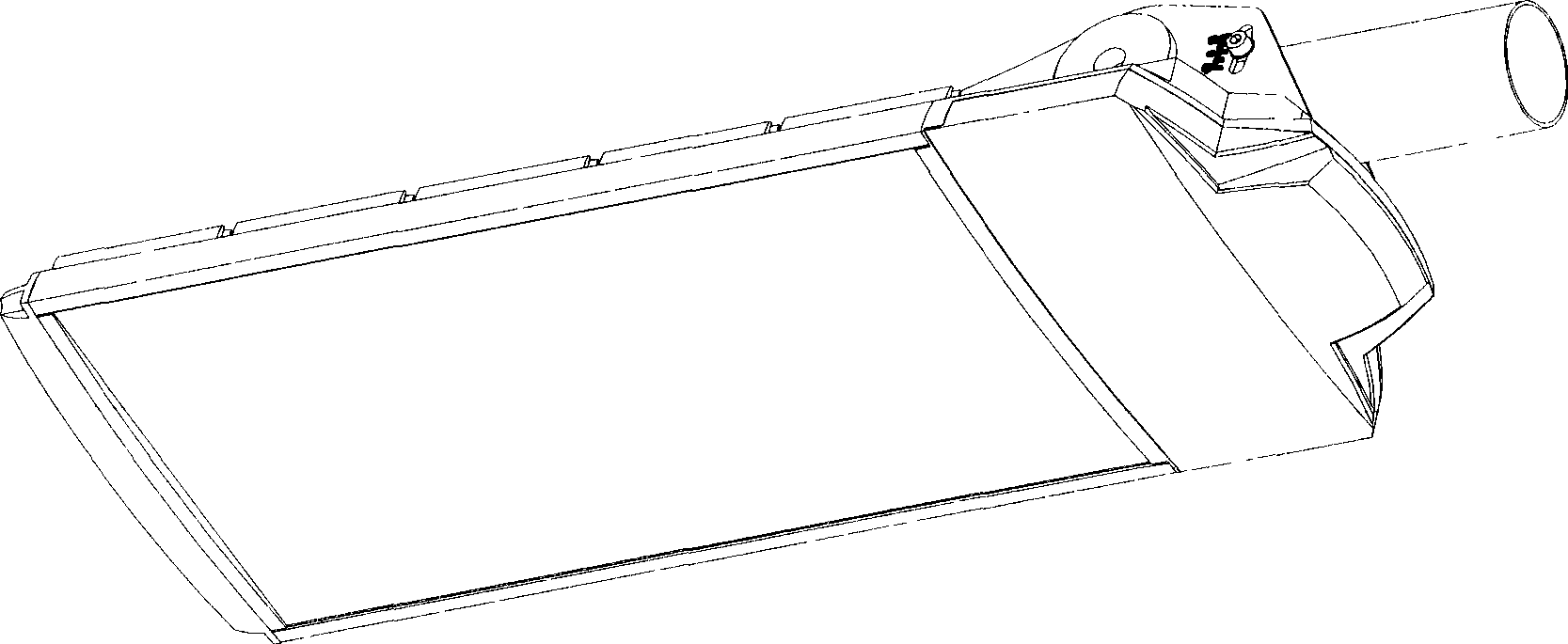

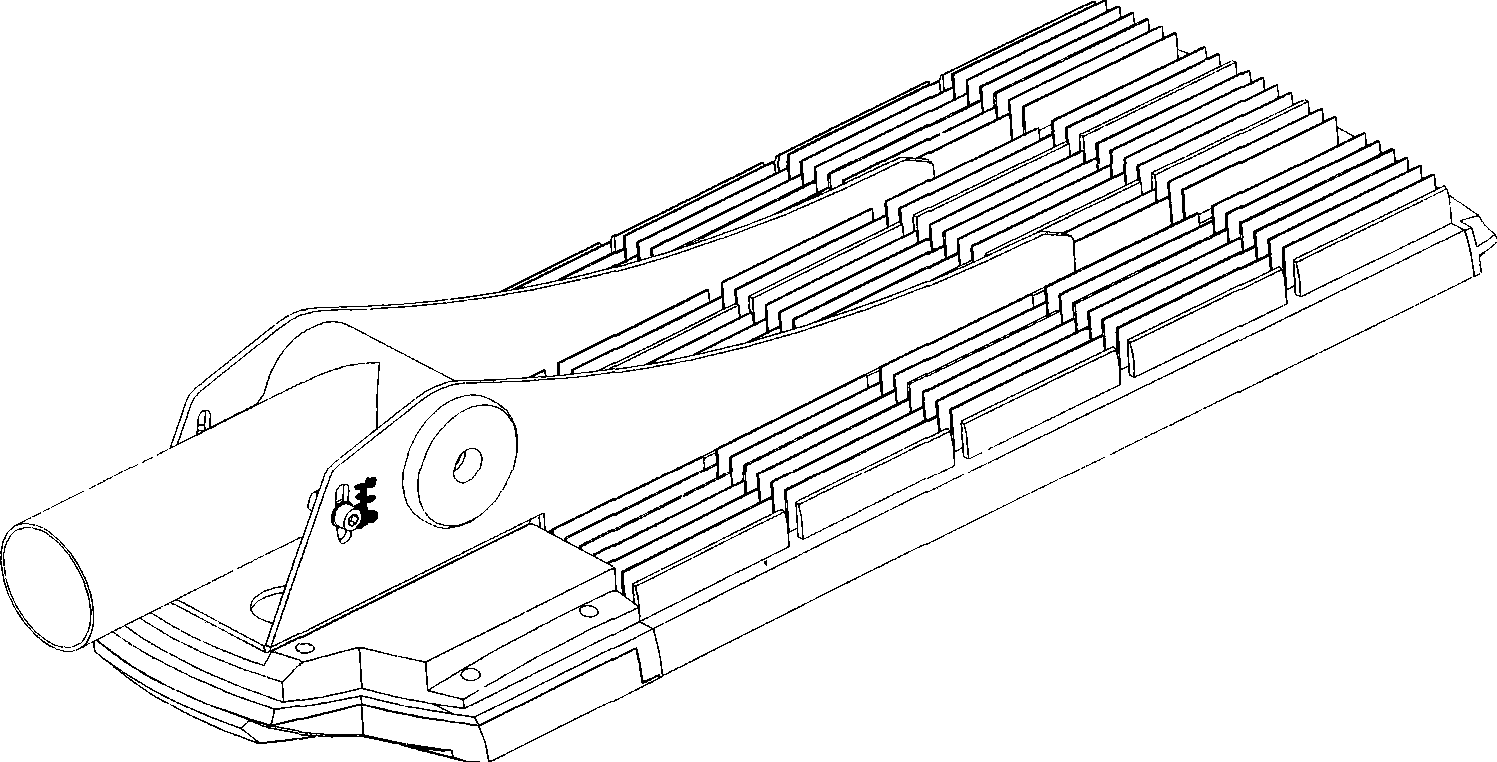

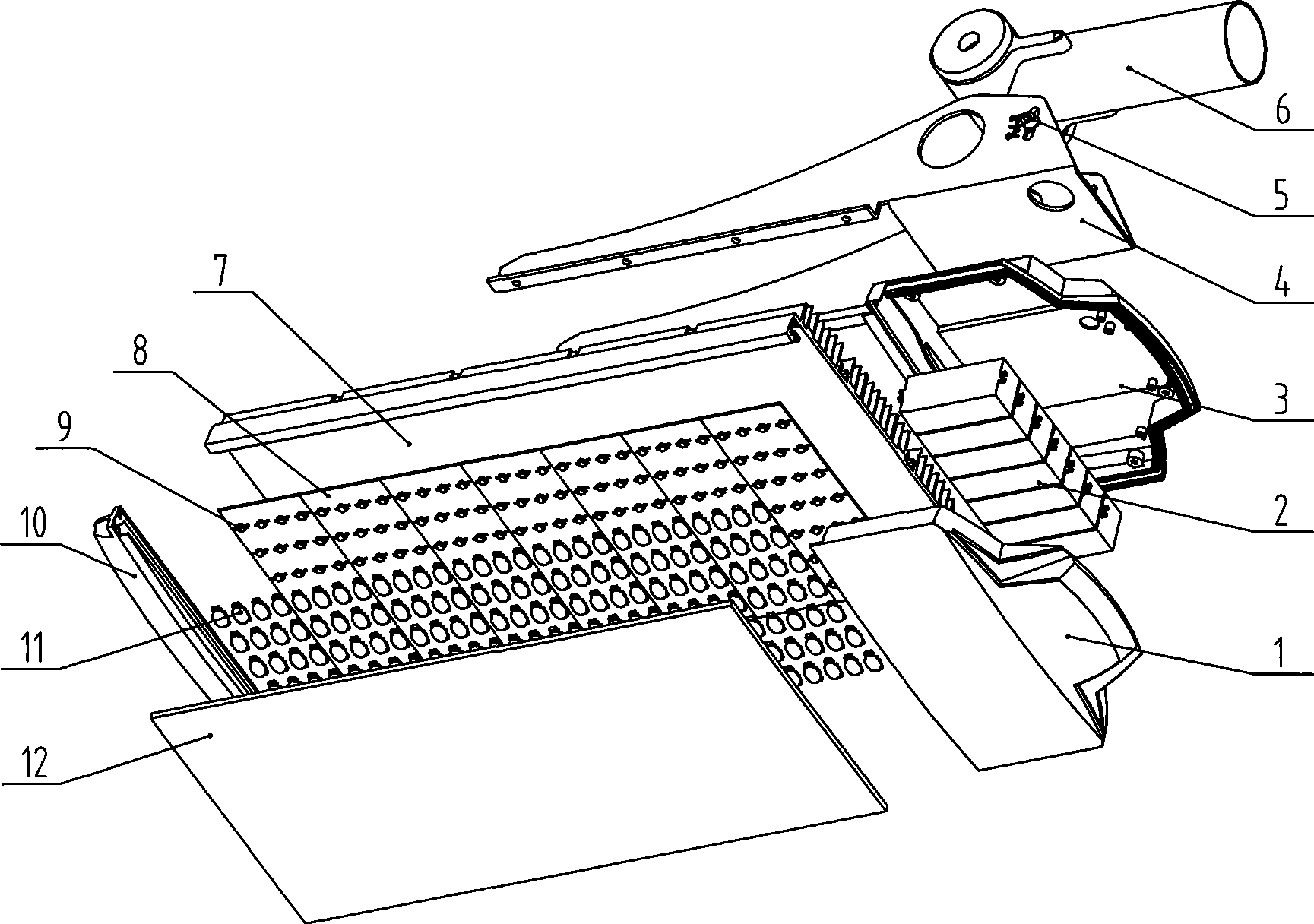

Irradiation angle-adjustable high-cooling property high-power LED road lamp cap

InactiveCN101487575ASolve the problem of high temperature heat dissipationGuaranteed service lifePoint-like light sourceLighting heating/cooling arrangementsHeat conductingEffect light

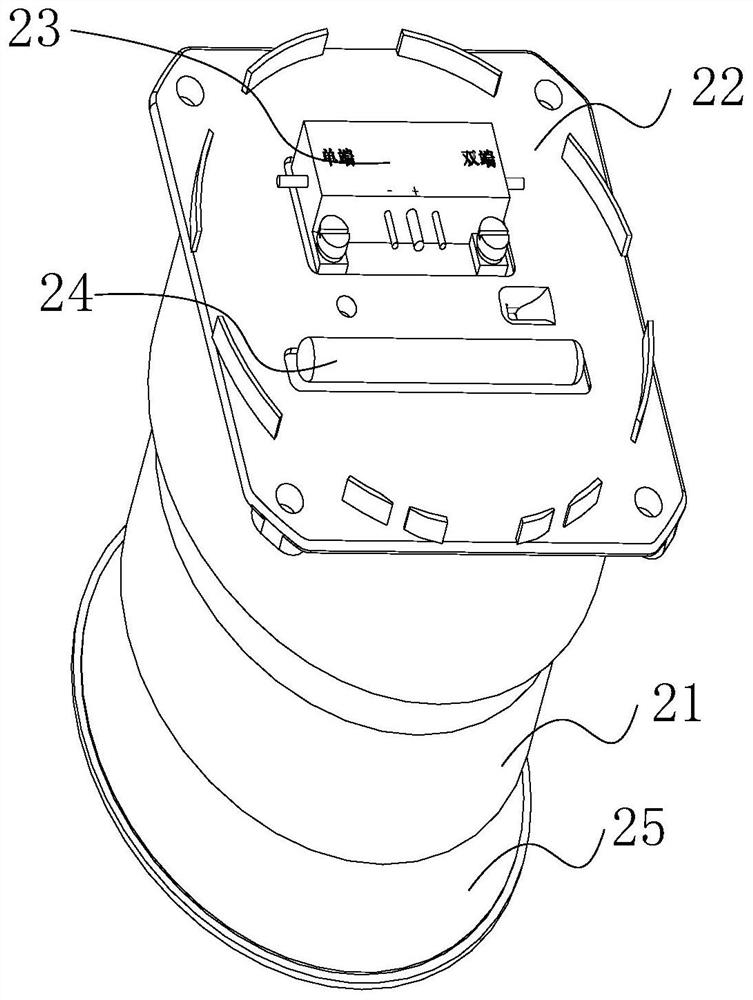

A high thermal diffusivity high-power LED street lamp cap with adjustable irradiation angles belongs to the technical field of semiconductor lighting. The LED street lamp cap comprises a lamp cap upper cover, a lamp cap lower cover, a supporting skeleton, a running rest, a lamp cap end closure, a radiator, a light manager, a light penetration panel, a plurality of LED light source drives, a plurality of LED light sources, and an LED breadboard. The lamp cap end closure is fixed on one end of the radiator. The light penetration panel is sealed on the uncovered part of the radiator by glue. The lamp cap upper cover and the lamp cap lower cover are folded, connected and fixed on the other end of the radiator. The radiator is hung on the base plane of the supporting skeleton which is fixed on the running rest. The LED light sources are arranged and encapsulated on the LED circuit board at regular intervals. The LED circuit board is arranged in a sealing space formed by the light lamp end closure, the radiator, the light penetration panel, the light cap upper cover and the like. The back of the LED circuit board is tightly attached to the inner wall of the radiator by a heat-conducting medium. The street lamp cap has good heat dissipation effect, adjustable illumination angle, good service performance and long service life.

Owner:史杰

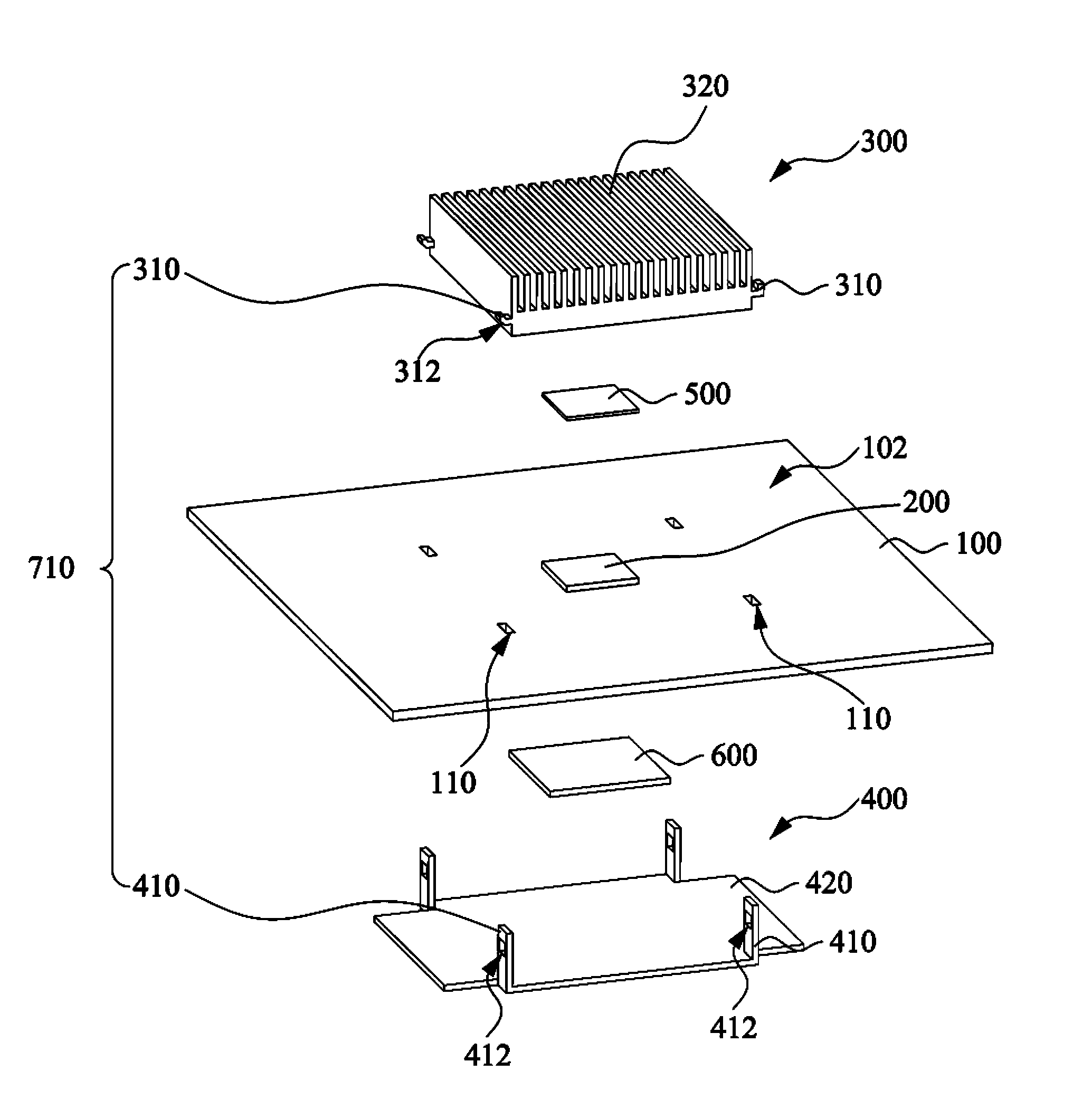

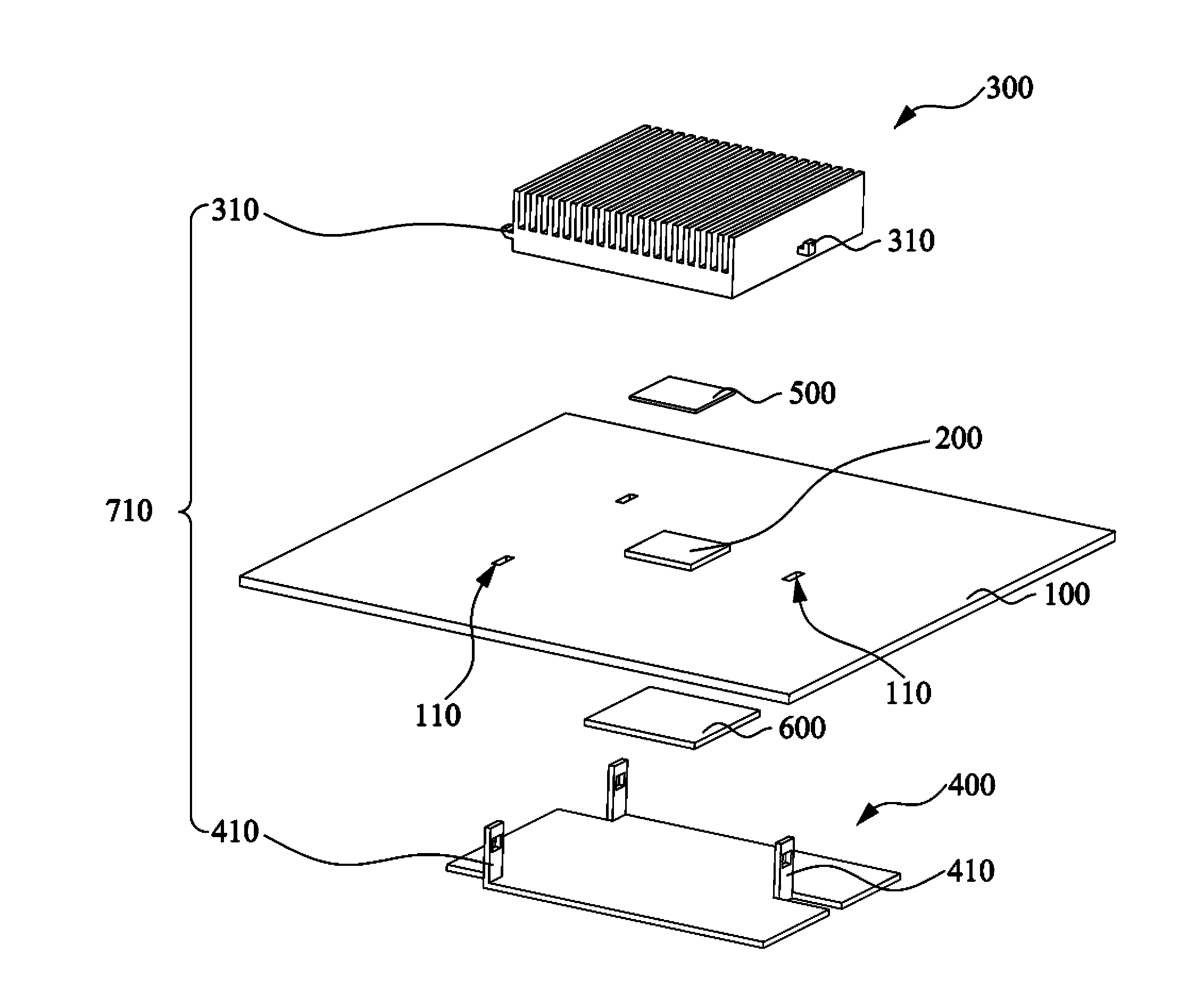

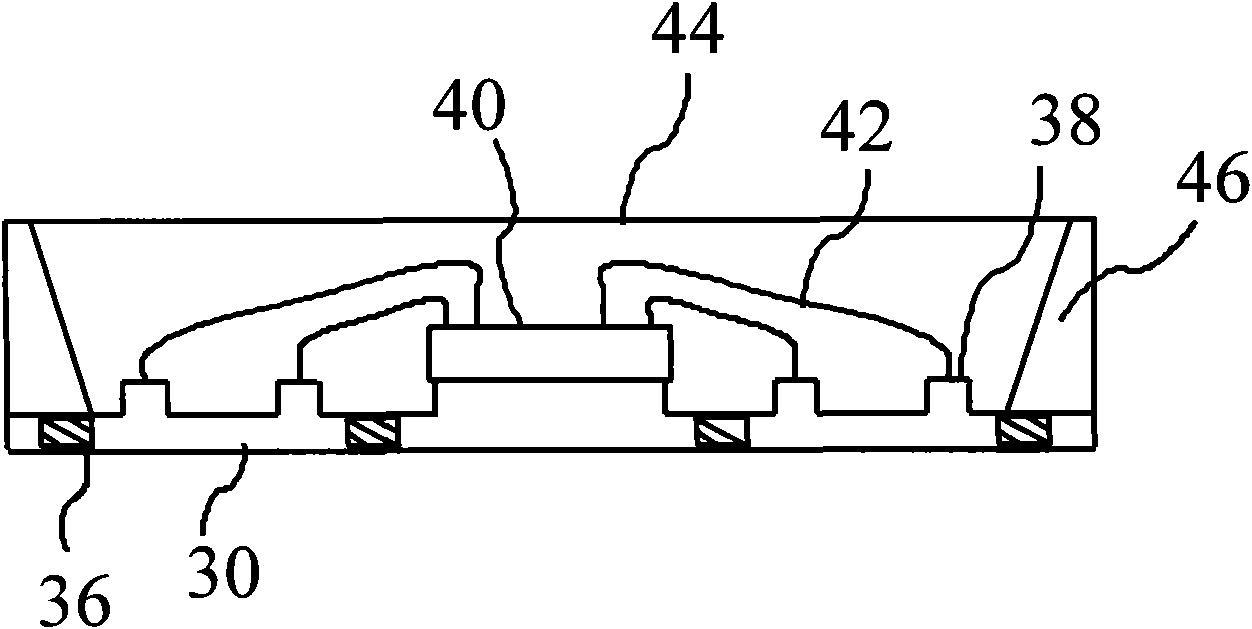

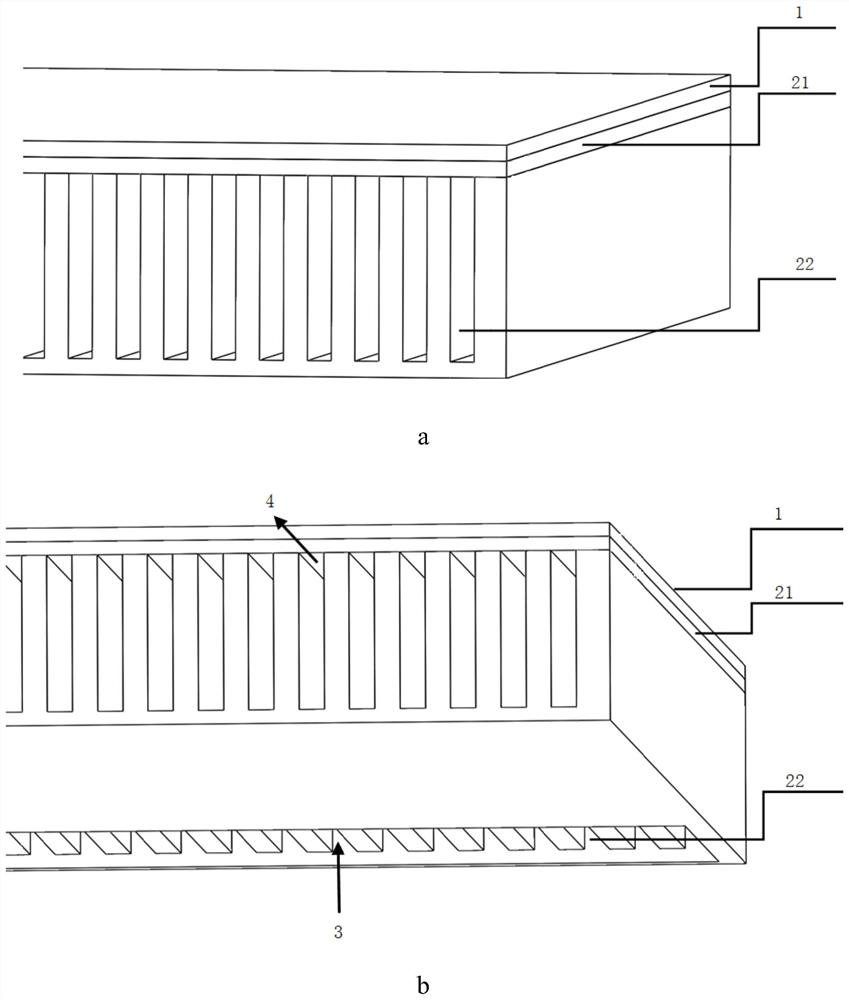

Heat dissipation assembly structure

InactiveCN104219928AUniform heat exchangeIncrease cooling areaCooling/ventilation/heating modificationsAssembly structureComputer engineering

The invention discloses a heat dissipation assembly structure which comprises a circuit board, a heat source, a first heat dissipation element, a second heat dissipation element, a first heat dissipation medium and a second dissipation medium, wherein the circuit board is provided with a first main surface, a second main surface and a plurality of through holes, the first main surface and the second main surface are opposite to each other, the heat source is fixed on the first main surface of the circuit board, the first heat dissipation element is arranged on the first main surface of the circuit board and comprises a plurality of first engagement parts, the second heat dissipation element is arranged on the second main surface of the circuit board and comprises a plurality of a second engagement parts, one of each first engagement part and each second bucked part are mutually engaged to form an engagement structure, the engagement structures respectively pass through the through holes of the circuit board, the first heat dissipation medium is arranged between the first heat dissipation element and the heat source, and the second heat dissipation element is arranged between the second heat dissipation element and the circuit board.

Owner:WISTRON NEWEB

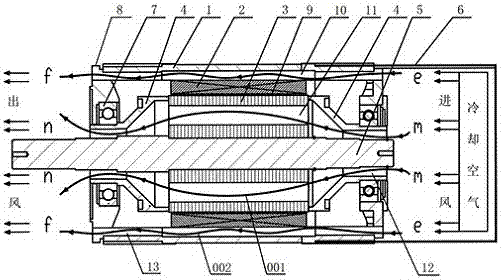

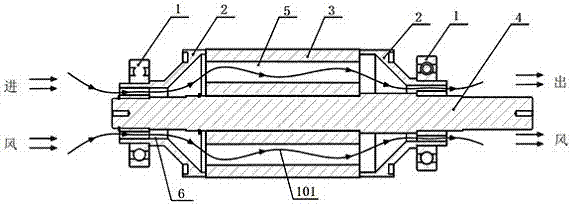

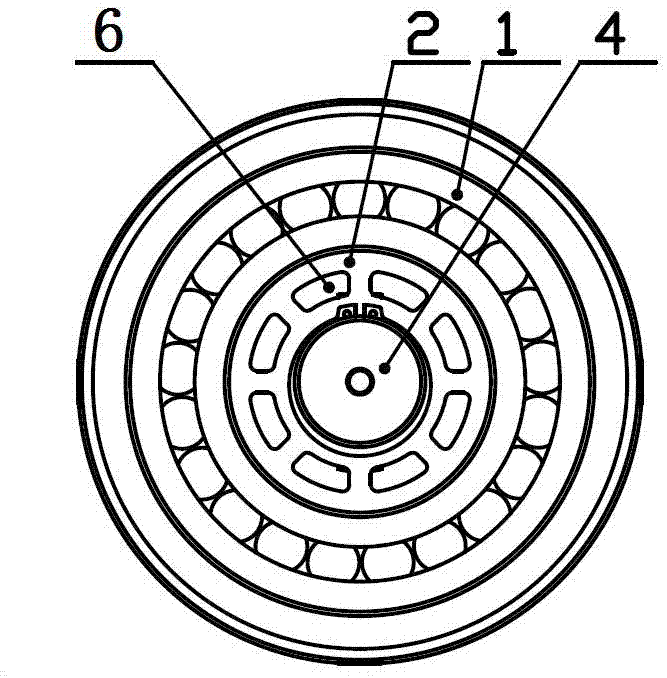

Highly efficient heat dissipation air cooling stator-rotor motor

PendingCN107086713AShort cooling pathRapid and efficient heat dissipationSupports/enclosures/casingsElectric machineEngineering

The invention discloses a highly efficient heat dissipation air cooling stator-rotor motor. The motor comprises a case and motor end covers arranged on two ends of the case. A stator and a rotor are arranged in the case. An air gap is left between the stator and the rotor. A spindle is arranged in the center of the rotor. Multiple case stator heat dissipation wind flow channels are arranged in a housing body of the case. A motor wind cover is arranged on one end of the case and used for injecting external cold wind. Multiple rotor heat dissipation wind flow channels are arranged in the rotor. Rotor wind covers are arranged on two ends of the rotor. Air passing flow channels are arranged between the rotor wind covers and the spindle. The air passing flow channels between the rotor wind covers and the spindle and rotor heat dissipation wind flow channels in the rotor form rotor heat dissipation wind channels. Multiple stator heat dissipation wind flow channels are arranged in the stator. Air holes are arranged in the motor end covers. Case stator heat dissipation wind channels are arranged between the air holes and case stator heat dissipation wind flow channels. According to the invention, the motor is capable of saving energy and reducing consumption and dissipating heat highly efficiently, simple in structure and long in service lifetime.

Owner:GUANGDONG LIANSU MACHINERY MFG

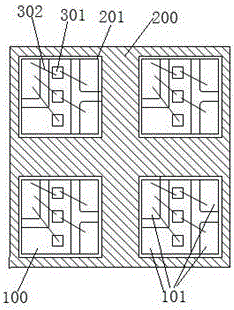

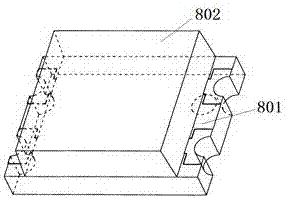

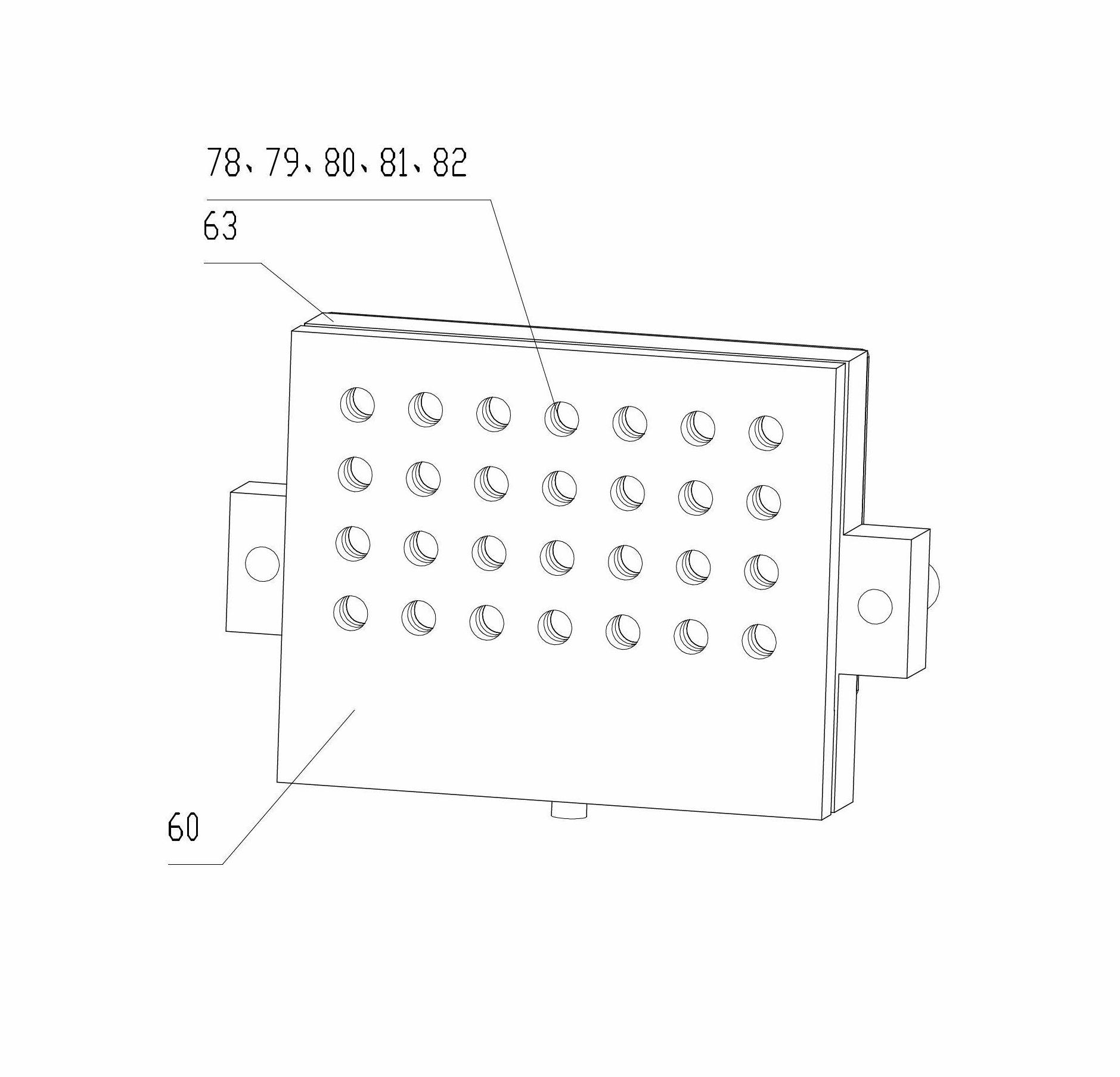

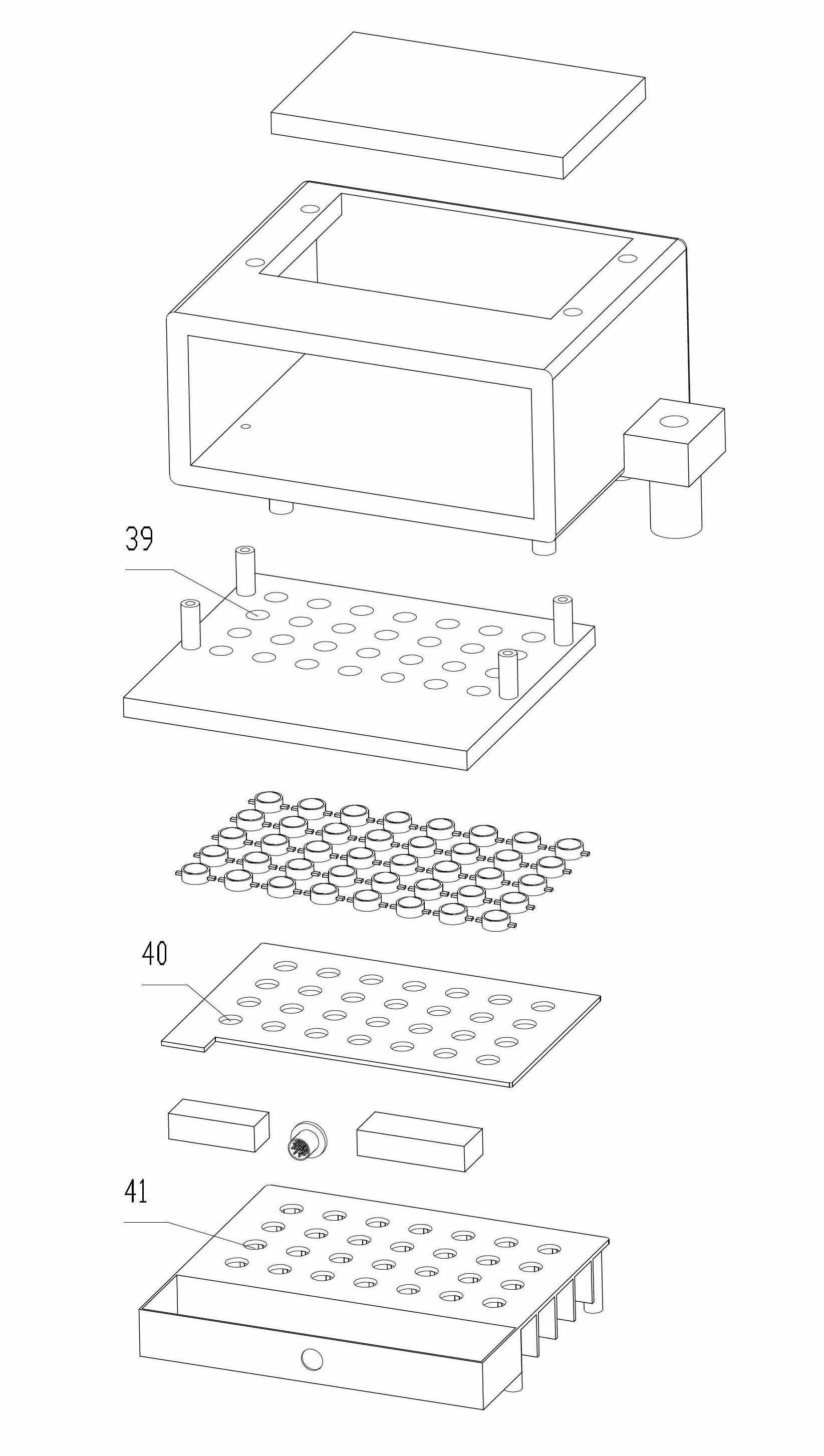

Integrated RGB-LED display

InactiveCN106876375AHigh resolutionExcellent light and dark contrastSolid-state devicesIdentification meansLED displayEngineering

The present invention provides an integrated RGB-LED display. The integrated RGB-LED display comprises a PCB board and a plurality of RGB-LED package modules welded to the PCB board; the package module comprises a package holder and a plurality of light emitting units arranged on the package holder; the number of light emitting units is at least two, and each set of light emitting units comprises a set of RGB-LED chips. According to the integrated RGB-LED display provided by the present invention, a plurality of light emitting units are integrated on a package module to further improve the production efficiency and reduce the production cost; and in addition, the plurality of light emitting units are integrated on a package module, so that overall resistance of the display to external mechanical strength is improved.

Owner:SHANDONG JIERUNHONG OPTOELECTRONICS CO LTD

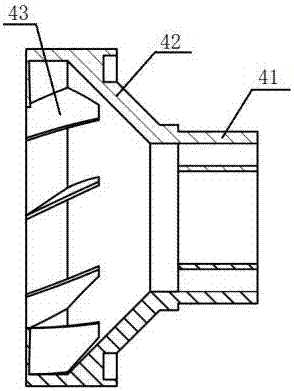

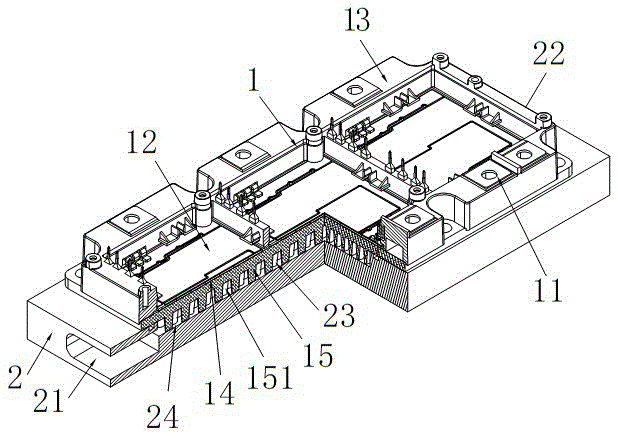

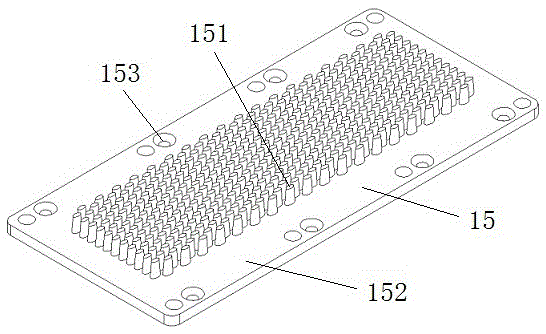

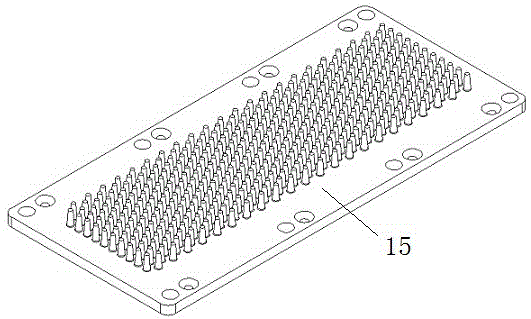

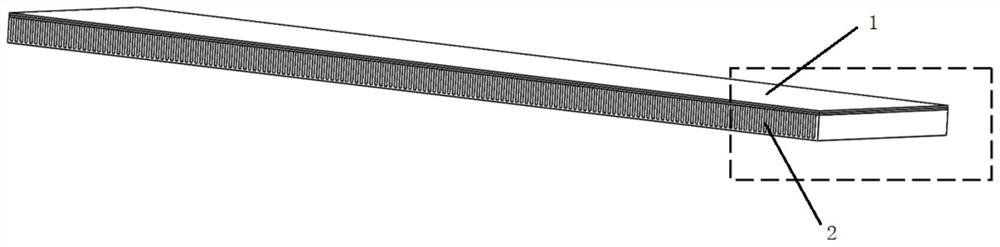

Integrated liquid cooling heat sink device of power module and bottom plate used by power module

InactiveCN105552049AShort cooling pathImprove cooling efficiencySemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitEngineering

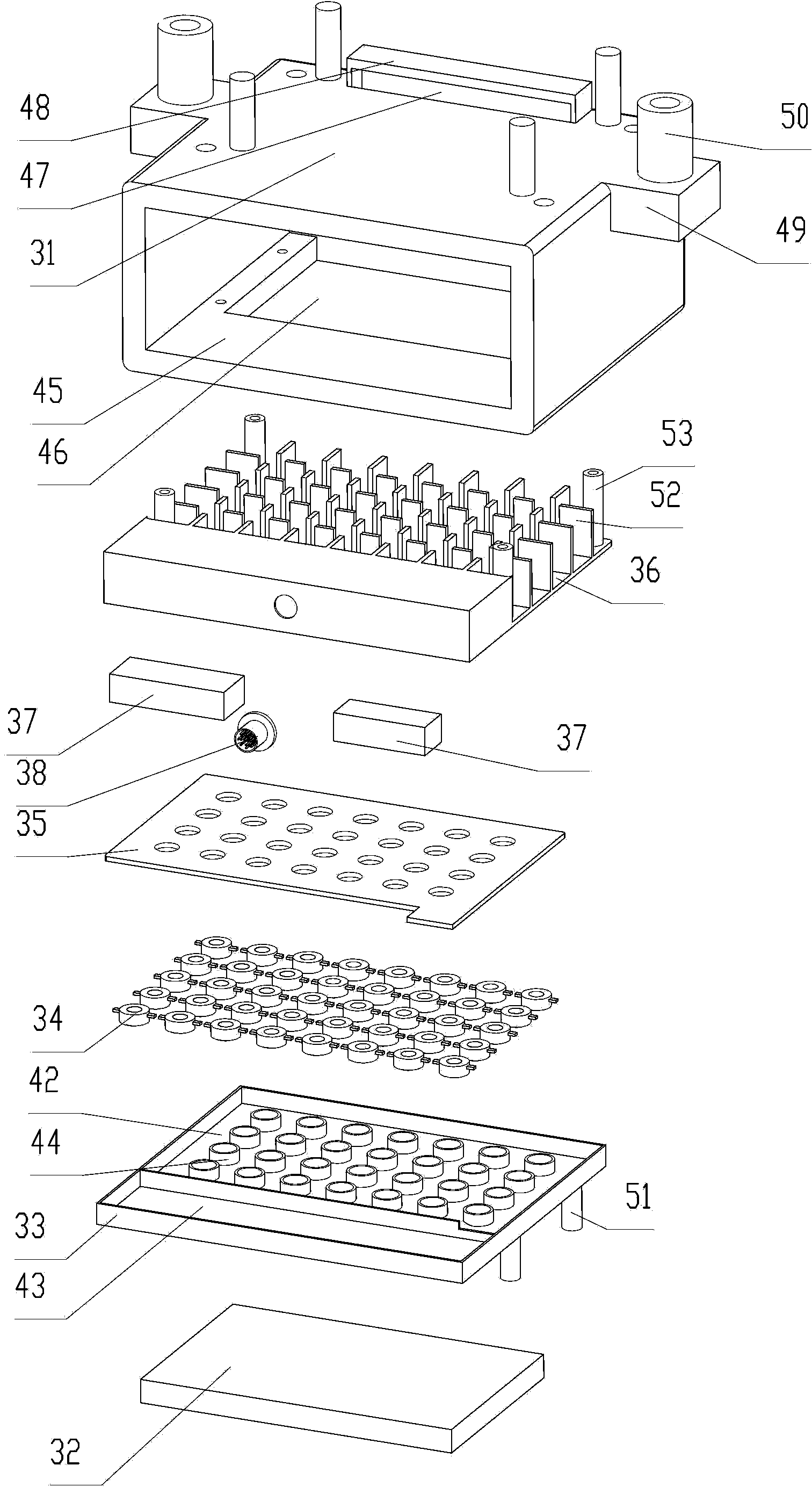

The invention discloses an integrated liquid cooling heat sink device of a power module and a bottom plate used by the power module. The integrated liquid cooling heat sink device is connected to the bottoms of a power chip, a copper cladding substrate and the bottom plate of the power module and comprises a square liquid cooling heat sink body, wherein the square liquid cooling heat sink body is fixedly connected to the bottom of the bottom plate, a liquid runner is arranged in the heat sink body and penetrates from left to right, a connection cut is arranged at the top position of the liquid runner, a plurality of staggered turbulence columns are arranged at the bottom of the bottom plate, and the staggered turbulence columns of the bottom plate partially pass through the connection cut and are bucked in the liquid runner. With the integrated liquid cooling heat sink device disclosed by the invention, a heat conductive silicon grease layer with poor heat conductivity is removed, the power module and a heat sink are integratedly designed, the heat sink is the bottom plate of the module, a cooling path is shorter, and the cooling efficiency of the power module is further improved; and moreover, the comprehensive structure of the integrated liquid cooling heat sink device is simplified, and the manufacturing cost is reduced.

Owner:南京银茂微电子制造有限公司

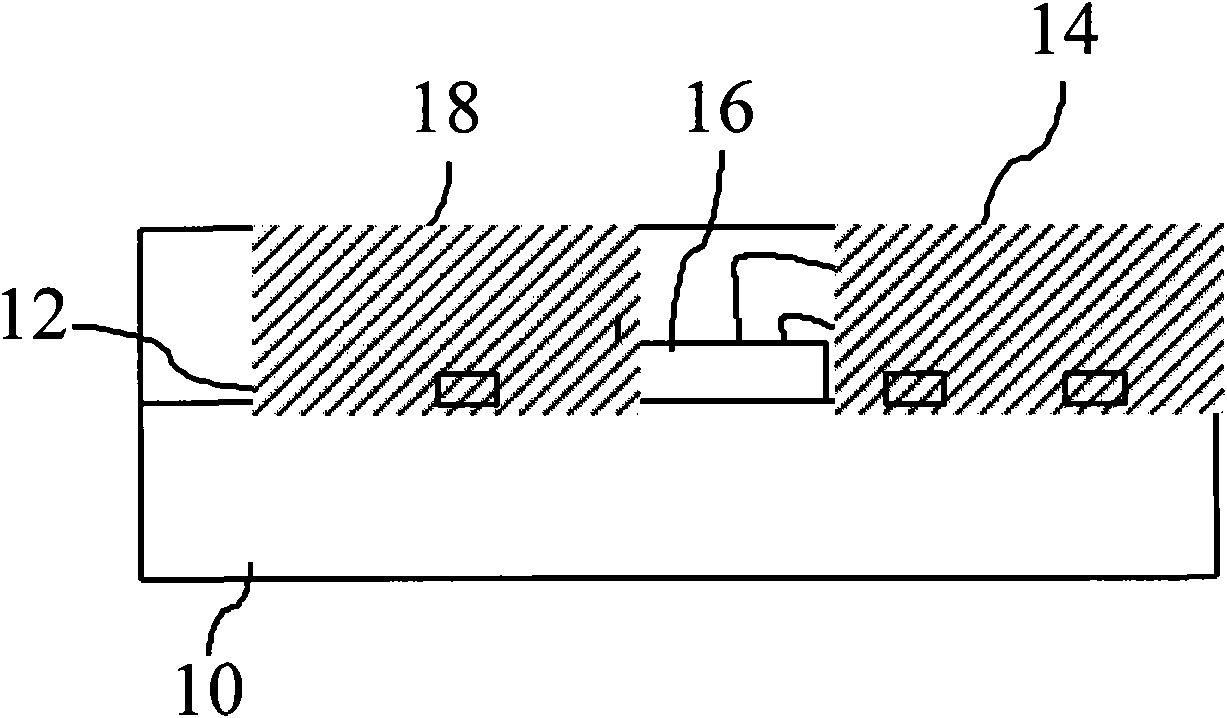

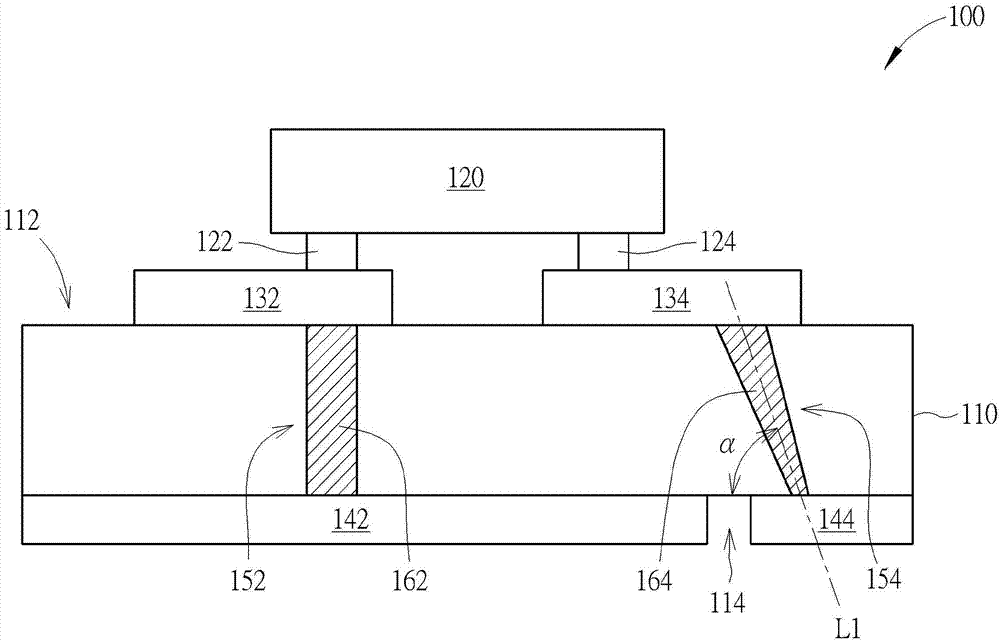

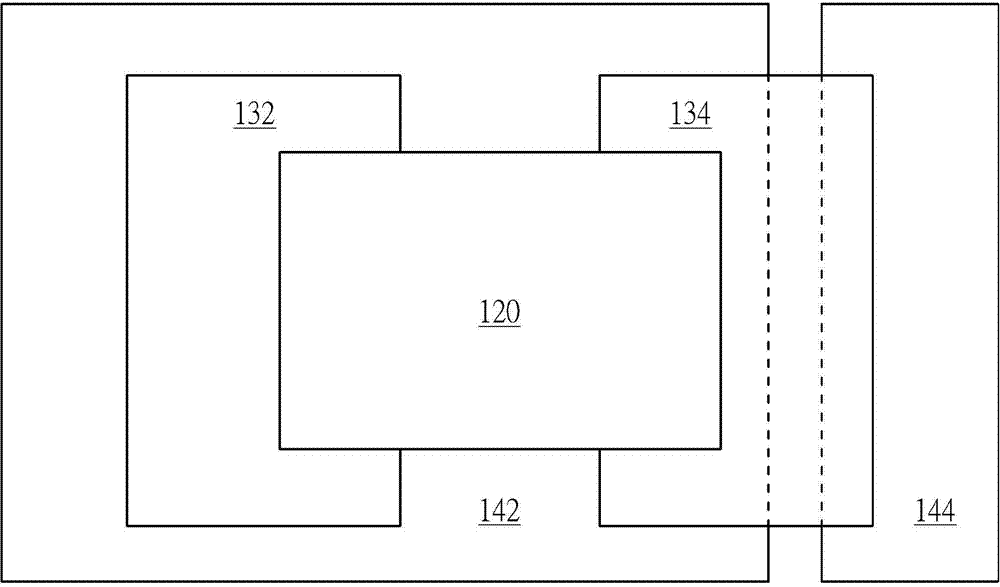

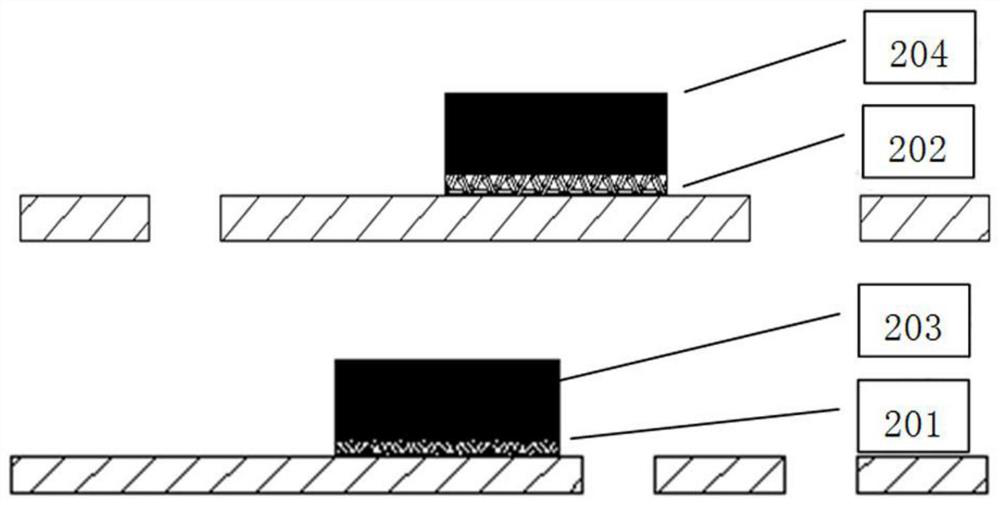

Heat-radiation packaging structure and packaging method

InactiveCN101685808AImprove heat transfer efficiencyShort cooling pathSemiconductor/solid-state device detailsSolid-state devicesColloidEngineering

The invention discloses a heat-radiation packaging structure and a packaging method which utilize a metal basal plate. The metal basal plate is provided with a plurality of conductive joints, a plurality of insulators, at least one chip, at least one light reflecting mirror and a packaging colloid, wherein the insulators are positioned in the metal basal plate and are arranged between the conductive joints; the chip is installed at the surface of the metal basal plate and is electrically connected with the conductive joints by a plurality of leading wires, and heat energy generated by the chipis dispersed by the metal basal plate; the light reflecting mirror is arranged at the periphery of the metal basal plate and increases the reflection efficiency of a light source; and the packaging colloid covers and protects the metal basal plate. The invention can maintain a favorable heat-radiation effect, simplify the packaging structure and the manufacturing procedure, and lower the production cost.

Owner:何昆耀

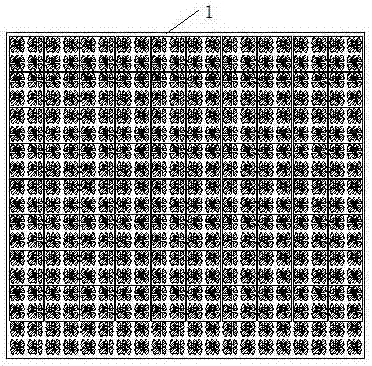

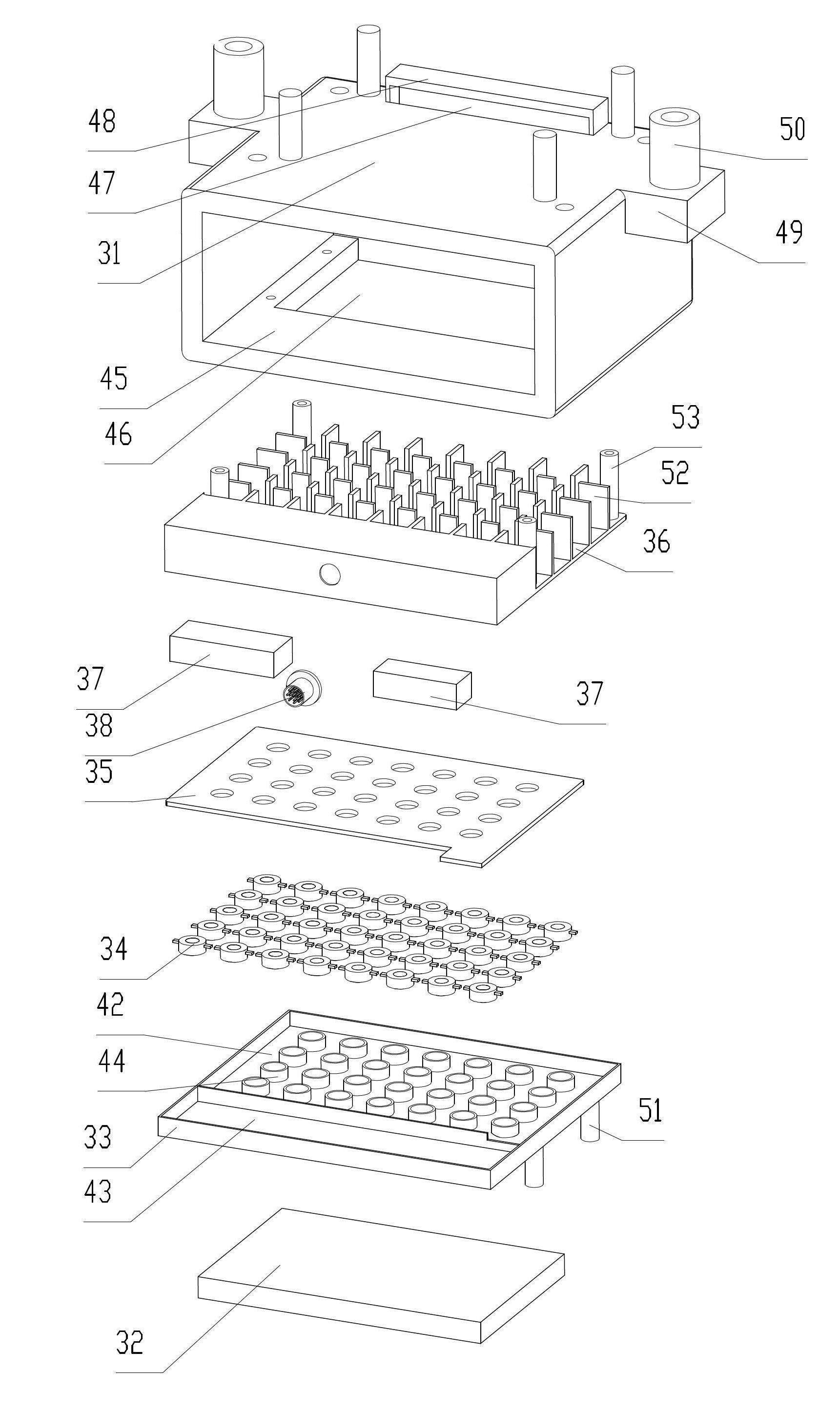

LED (Light Emitting Diode) dot matrix display screen and combined dot matrix display screen

InactiveCN102682673AHigh junction temperatureImprove cooling effectCooling/ventilation/heating modificationsIdentification meansElectricityDot-matrix display

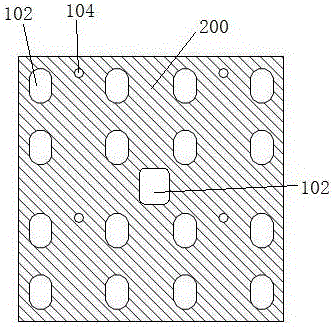

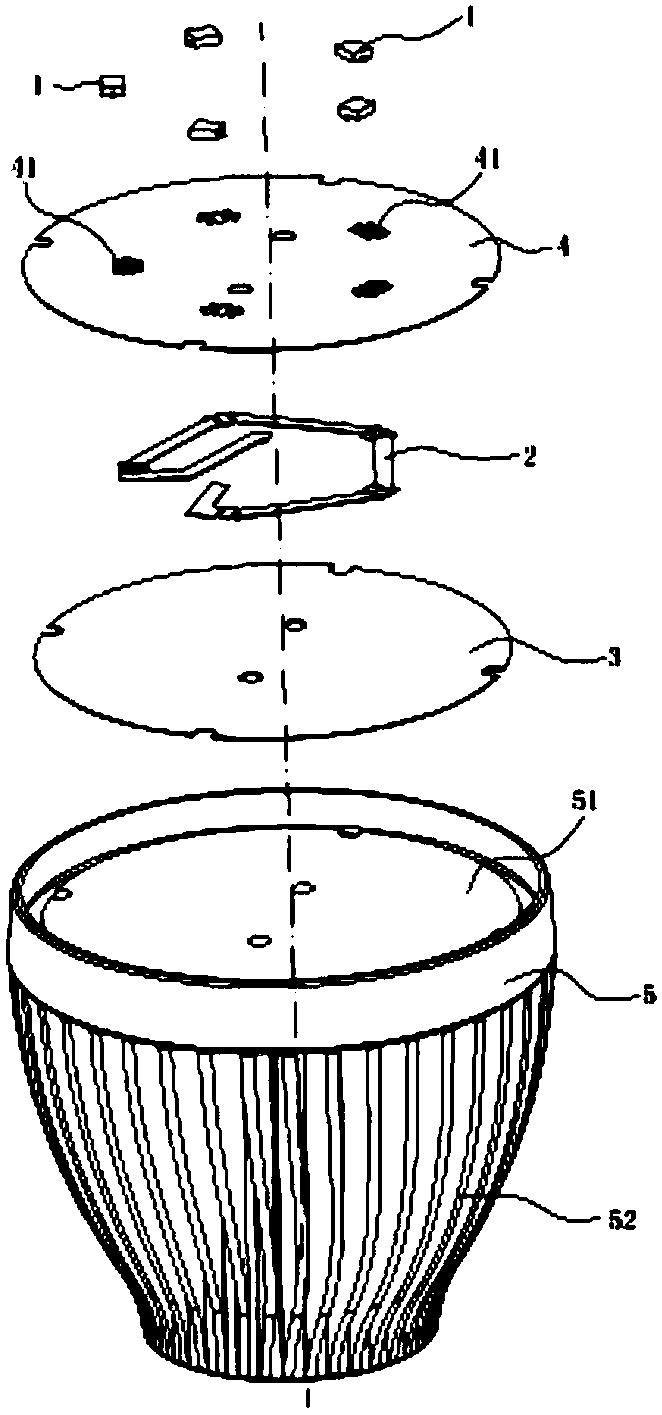

The invention relates to an LED (Light Emitting Diode) dot matrix display screen which comprises a radiating base, uniformly arrayed LED illuminating units and an imaging controller, wherein layout circuit conductive layers electrically connected with the LED illuminating units are arranged on one side of the radiating base facing to the LED illuminating units; each of the LED illuminating units is independently in electric connection with the imaging controller through each of the layout circuit conductive layers; the LED dot matrix display screen further comprises a runner shell which is arranged on the other side of the radiating base deviating from the LED illuminating units; a radiating through hole is formed in the central position of each four adjacent LED illuminating units; each of the LED illuminating units is adjacent to the radiating through hole; the radiating through hole passes through the radiating base and the runner shell; an outer runner side wall and an inner runner side wall which is arranged on the periphery of the radiating through hole are arranged between the runner shell and the radiating base; and a circulating cooling runner is formed by the runner shell, the outer runner side wall, the inner runner side wall and the radiating base. The LED dot matrix display screen has the advantage of excellent radiating effect.

Owner:杨东佐

LED (light-emitting diode) dot matrix display screen

InactiveCN102682672AHigh junction temperatureImprove cooling effectCooling/ventilation/heating modificationsIdentification meansDot-matrix displayEngineering

The invention discloses an LED (light-emitting diode) dot matrix display screen which comprises a heat-dissipating substrate, LED light-emitting units, an imaging controller and a layout circuit conducting layer, wherein the LED light-emitting units are uniformly arrayed; each LED light-emitting unit is separately electrically connected with the imaging controller through the layout circuit conducting layer; the LED light-emitting units are fixed on the heat-dissipating substrate; the central position of every four adjacent LED light-emitting units is provided with a straight heat-dissipating through hole, each LED light-emitting unit is adjacent to the straight heat-dissipating through hole, and the straight heat-dissipating through hole passes through the heat-dissipating substrate; the LED dot matrix display screen also comprises a display-screen outline border, and the display-screen outline border is provided with an accommodating cavity (the bottom surface thereof is provided with an opening); and a position (facing to each LED light-emitting unit) on the front surface of the display-screen outline border is provided with a through hole for covering the LED light-emitting unit, the through hole is provided with a light-pervious seal plate, a position (close to the upside of the display-screen outline border) on the back face of the display-screen outline border is provided with heat-dissipating holes, and the back face of the display-screen outline border is also convexly provided with a rain cover for preventing rainwater from entering the accommodating cavity. The LED dot matrix display screen has the advantages of good heat dissipation and waterproof properties.

Owner:JIANGMEN JUNDA OPTOELECTRONICS TECH

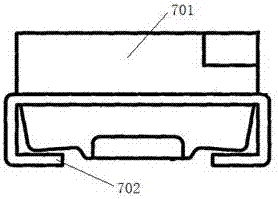

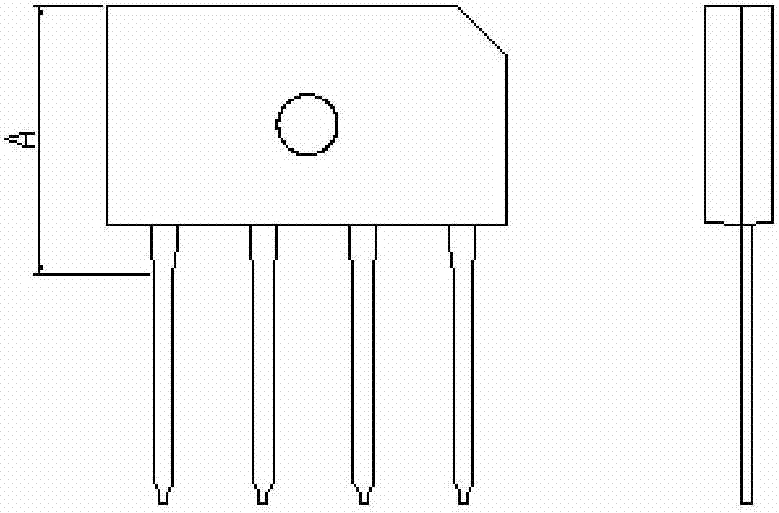

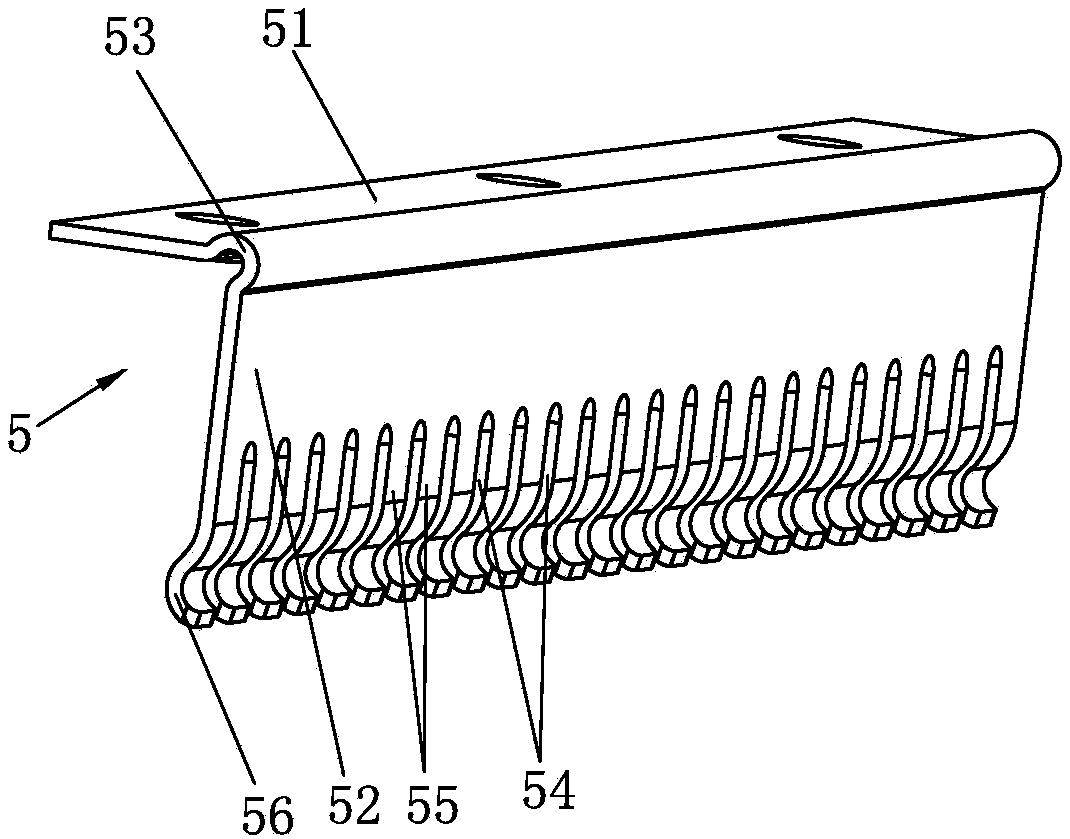

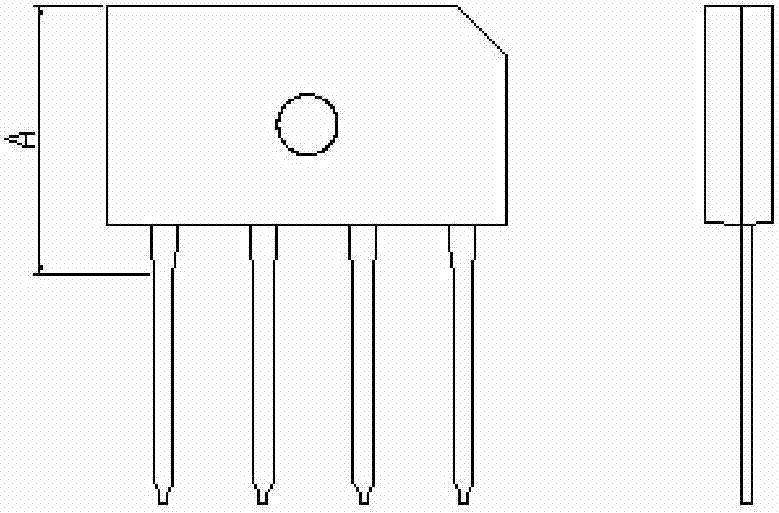

Radiating fin structure surface-mount rectifier bridge device

ActiveCN105185757AShort cooling pathMake full use of cooling capacitySemiconductor/solid-state device detailsSolid-state devicesMetal stripsSurface mounting

The invention discloses a radiating fin structure surface-mount rectifier bridge device. The radiating fin structure surface-mount rectifier bridge device comprises a first diode chip, a second diode chip, a third diode chip, a fourth diode chip and a cathode metal strip all coated by an epoxy packaging body, and a first metal substrate, a second metal substrate and an E-shaped metal substrate are respectively located at left side and right side of the bottom of the epoxy packaging body; a first connecting sheet, a second connecting sheet, a third connecting sheet and a fourth connecting sheet are arranged in parallel along a front-to-back direction; the front end of the cathode metal strip, located between the first metal substrate and the E-shaped metal substrate, comprises a bending part, and the bottom of the bending part and the bottom of each of the first metal substrate, the second meal substrate and the E-shaped metal substrate are in the same horizontal plane and are all naked outside the epoxy packaging body; the first metal substrate and the second metal substrate are used as alternating current input ends, the cathode metal strip is used as a direct current cathode end, and the E-shaped metal substrate is used as a direct current anode end. According to the invention, a radiating path between the chips and a PCB is shortest, radiating fins are metal material and have excellent heat conductivity coefficient, own radiating capacity of the PCB is used fully, and defects of the existing product, such as poor epoxy heat conduction capability caused by radiating through air convection in a case, are avoided.

Owner:SUZHOU GOODARK ELECTRONICS CO LTD

High-reliability rectifier bridge device

ActiveCN107887353AShort cooling pathMake full use of cooling capacitySemiconductor/solid-state device detailsSolid-state devicesMetal stripsAlternating current

Owner:SUZHOU GOODARK ELECTRONICS CO LTD

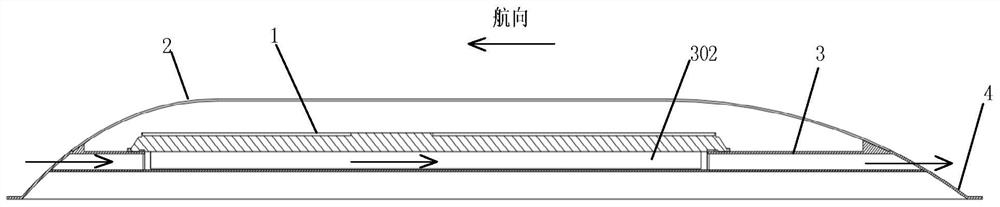

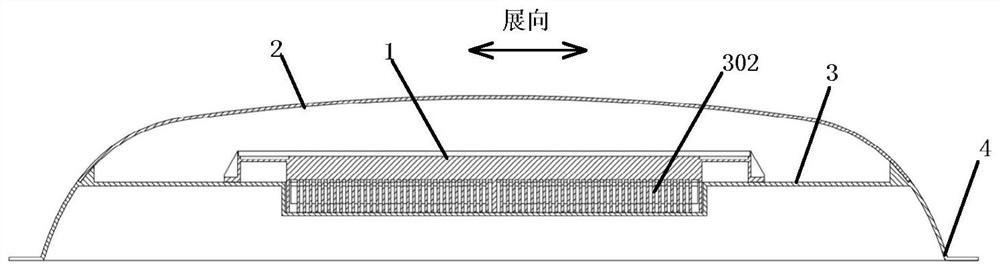

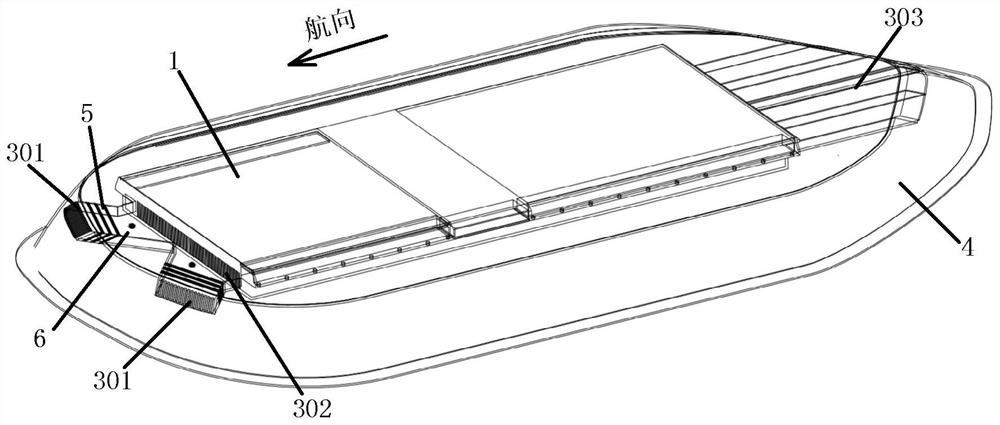

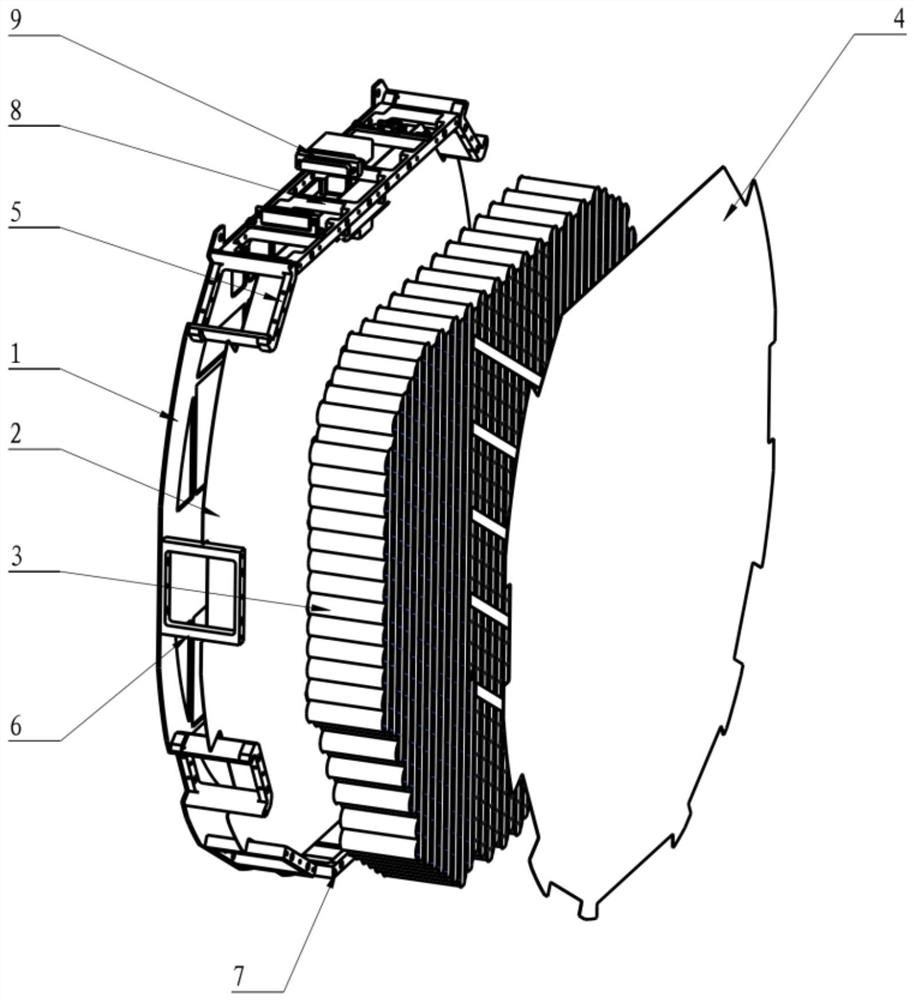

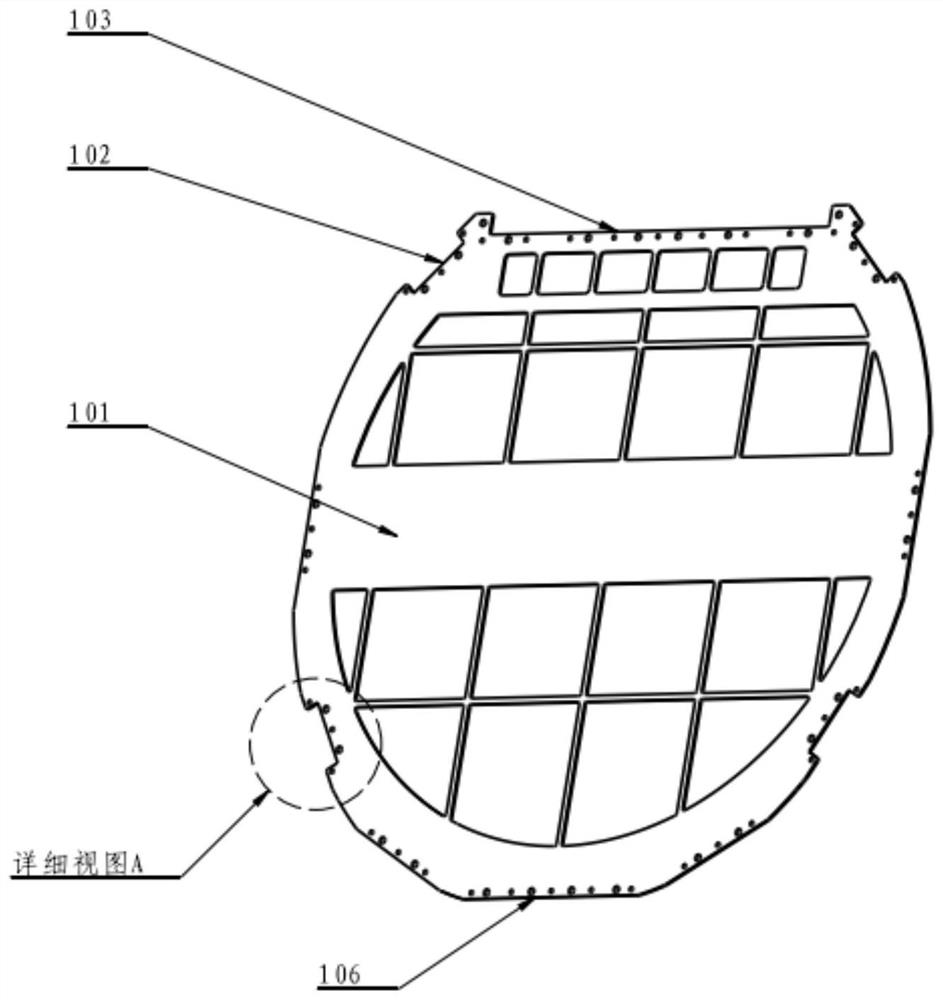

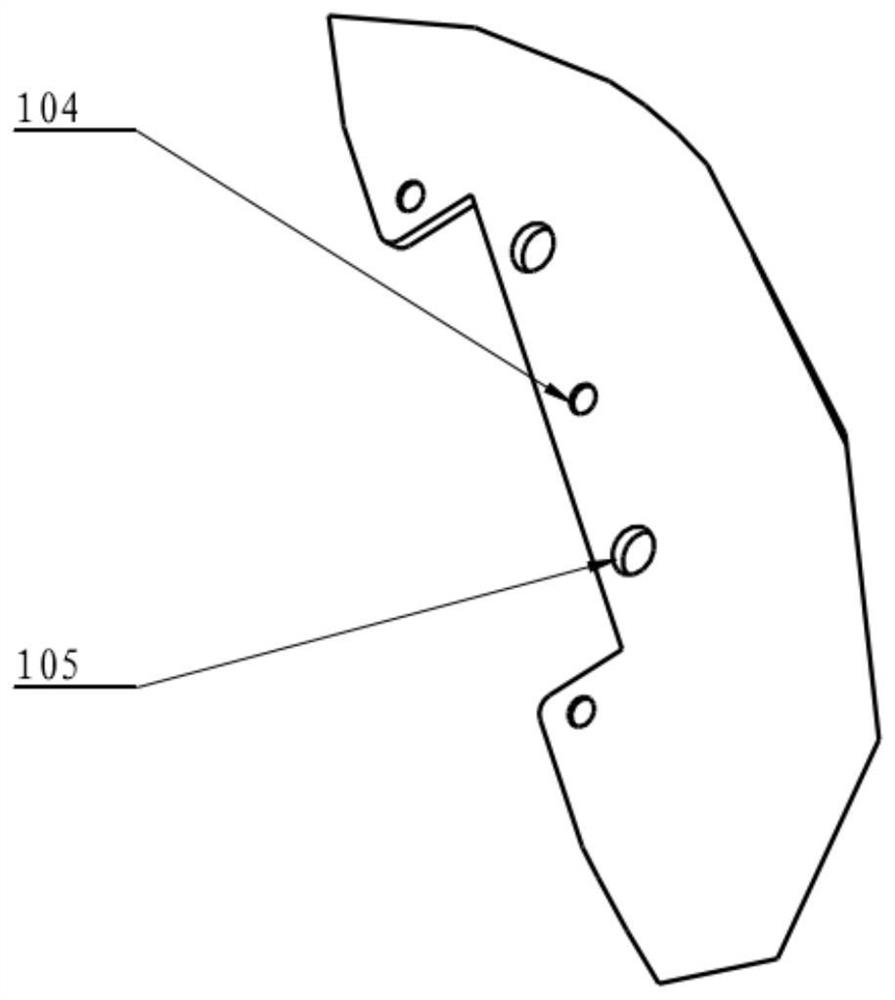

High-speed airflow through type air-cooled heat dissipation airborne antenna

ActiveCN113782940AProtection of enclosed spacesHigh ability to resist harsh environmentAntenna adaptation in movable bodiesRadiating element housingsCold airEngineering

A high-speed airflow through type air-cooled heat dissipation airborne antenna disclosed by the invention is resistant to a severe environment and high in heat dissipation efficiency. According to the technical scheme, a fairing and a radome define a closed space for protecting an antenna body, and the fairing is in smooth transition connection with the radome through an outer wall ring of a carrier plate; an air inlet area is designed at the front end of the carrier plate along the heading direction, and the antenna body is embedded in the rectangular concave cavity of the carrier plate through a middle rectangular concave cavity and a rear end air exhaust area and is buckled on the upper surface of the concave cavity of the carrier plate to form a heat dissipation functional area; and an antenna body is embedded into the concave cavity of the carrier plate and is provided with strip-shaped heat dissipation teeth along the course, heat generated by the antenna is conducted to the heat dissipation teeth of the antenna, the heat is taken away by blowing airflow generated in the high-altitude flight process of an aerial carrier, and high-speed cold air entering from air inlets in the left side and the right side of the inclined front end of the course converges at the rear end of the air inlet area, flows through the heat dissipation air channel and is discharged from the air outlet, and the air directly blows the surfaces of the heat dissipation teeth to discharge the heat dissipated by the antenna to the atmosphere.

Owner:10TH RES INST OF CETC

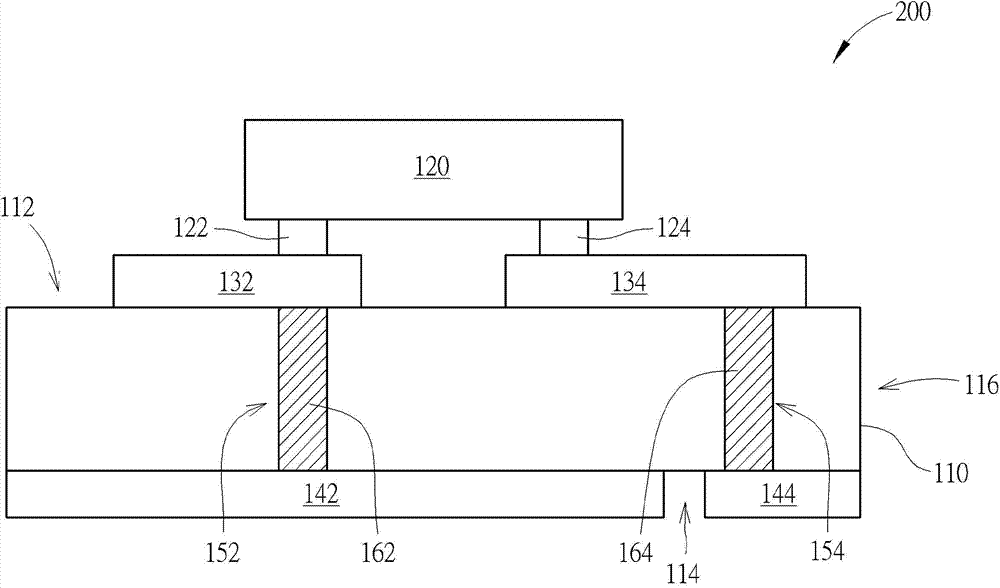

Package Structure Of Light Emitting Diode

InactiveCN104733602ASolve the cooling problemImprove cooling efficiencySolid-state devicesSemiconductor devicesLight-emitting diodeDiode

A package structure of light emitting diode includes a substrate and a light emitting diode die. The substrate has an upper surface and a lower surface opposite to each other. Two upper metal pads without mutual conduction are arranged on the upper surface. Two lower metal pads without mutual conduction are arranged on the lower surface. The light emitting diode die is disposed across the two upper metal pads. The light emitting diode die has a first electrode and a second electrode electrically connected to the two upper metal pads respectively. Wherein an orthographic projection area of one of the lower metal pads is greater than or equal to an orthographic projection area of the light emitting diode die, and the orthographic projection area of the light emitting diode die is totally located within the orthographic projection area of one of the lower metal pads.

Owner:GENESIS PHOTONICS

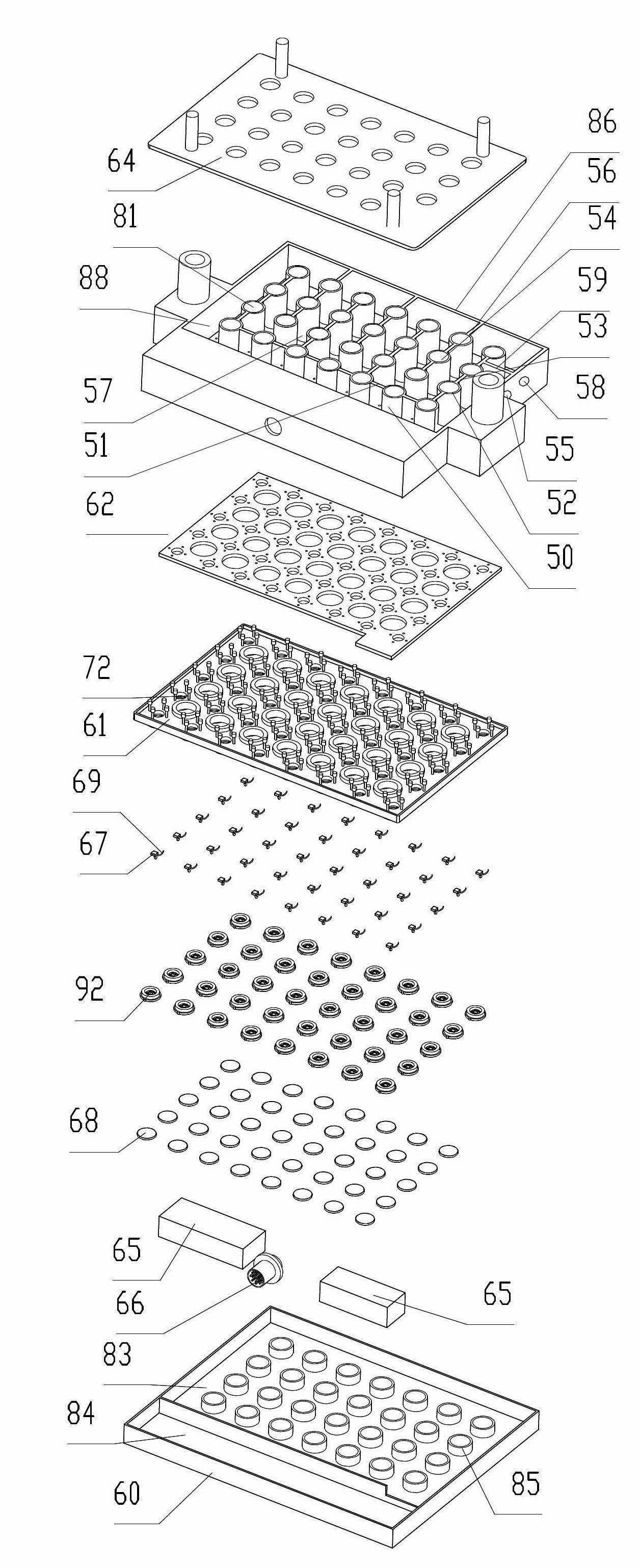

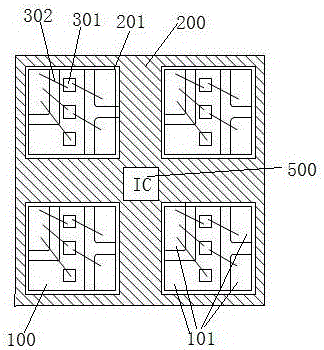

Surface mounting type RGB-LED (Red, Green and Blue-Light Emitting Diode) packaging module integrating IC (Integrated Circuit)

ActiveCN106847803ASimple circuit designImprove the ability to resist external mechanical strengthSolid-state devicesIdentification meansElectricitySurface mounting

The invention provides a surface mounting type RGB-LED (Red, Green and Blue-Light Emitting Diode) packaging module integrating an IC (Integrated Circuit). The surface mounting type RGB-LED packaging module comprises a packaging bracket, and light emitting units arranged on the packaging bracket; at least two light emitting units are arranged; the packaging bracket is integrated with an IC driving module; the light emitting units are electrically connected with the IC driving module. According to the surface mounting type RGB-LED packaging module integrating the IC, provided by the invention, the plurality of light emitting units are integrated on one packaging module, so that the production efficiency is improved and the production cost is reduced. Furthermore, the plurality of light emitting units are integrated on one packaging module and the whole outside mechanical strength resisting capability of a display screen can be effectively improved. Meanwhile, the packaging module is integrated with the IC and the plurality of light emitting units on the module are controlled, so that a subsequent circuit design of a PCB (Printed Circuit Board) is simplified and a production process is simplified.

Owner:SHANDONG JIERUNHONG OPTOELECTRONICS CO LTD

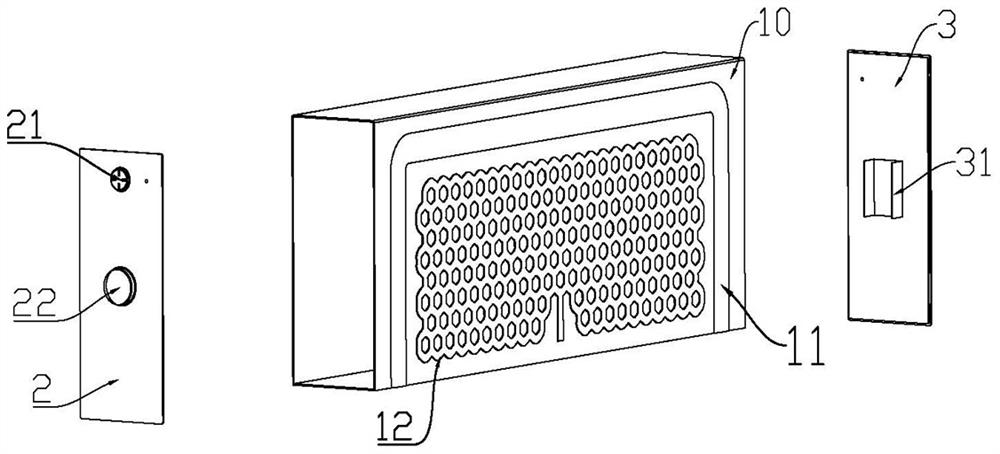

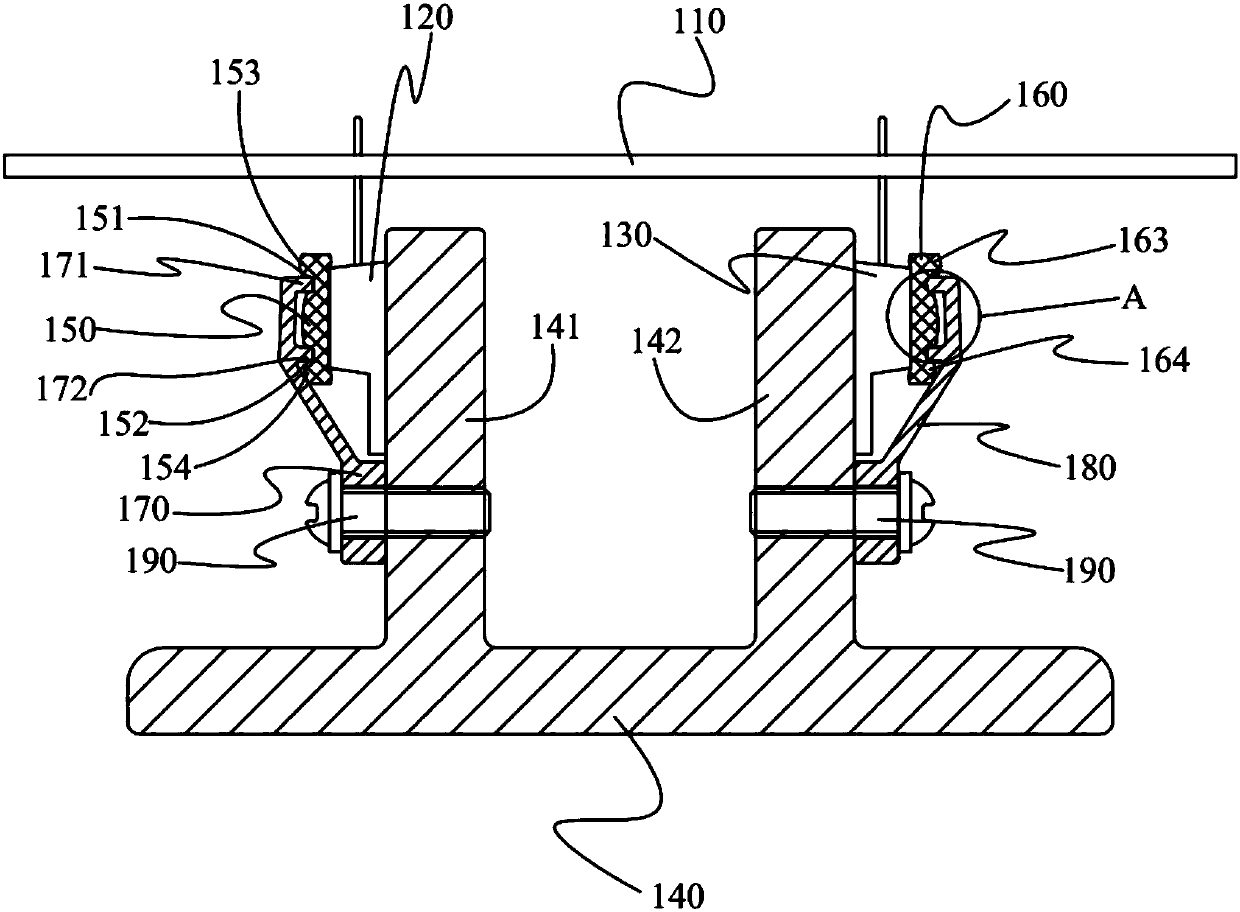

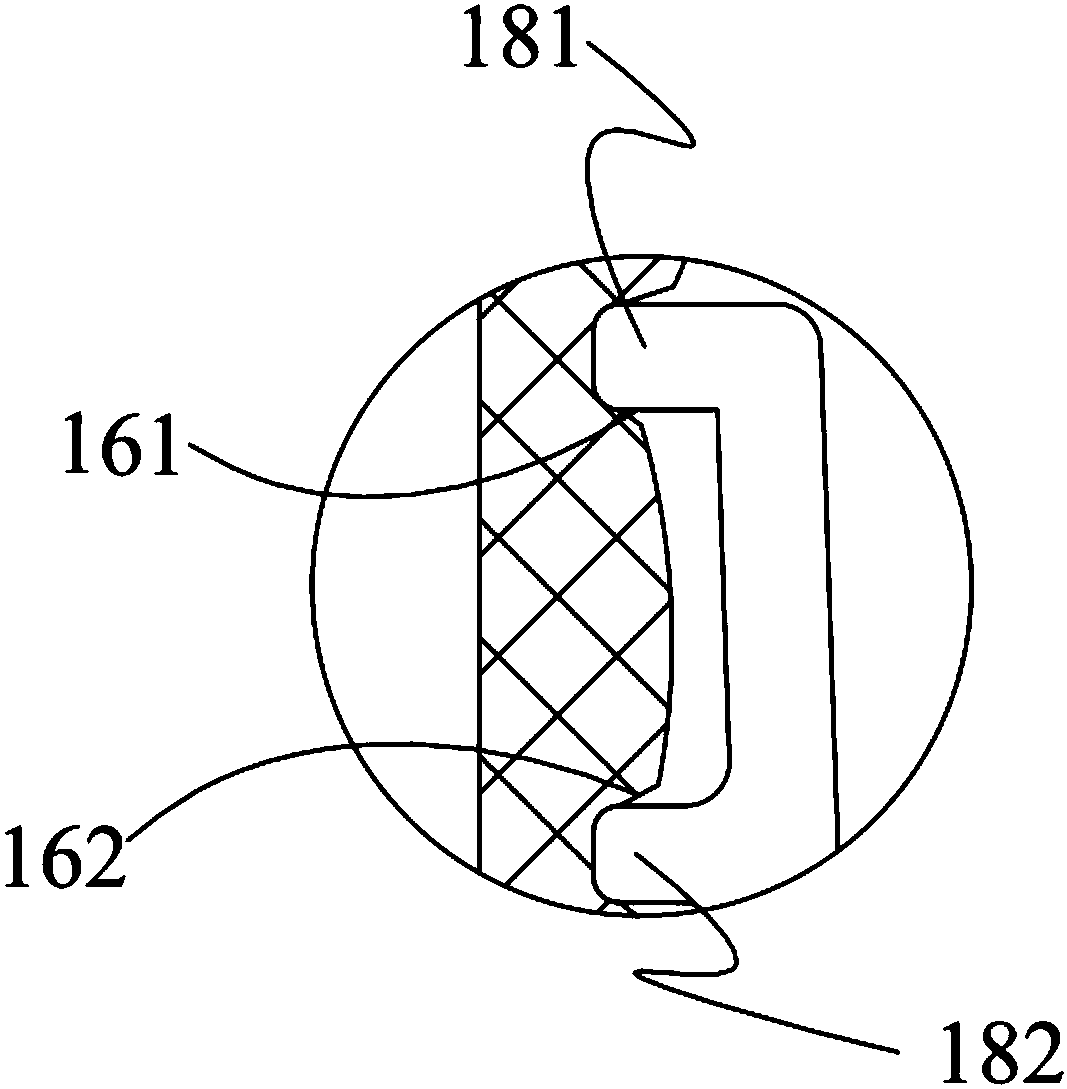

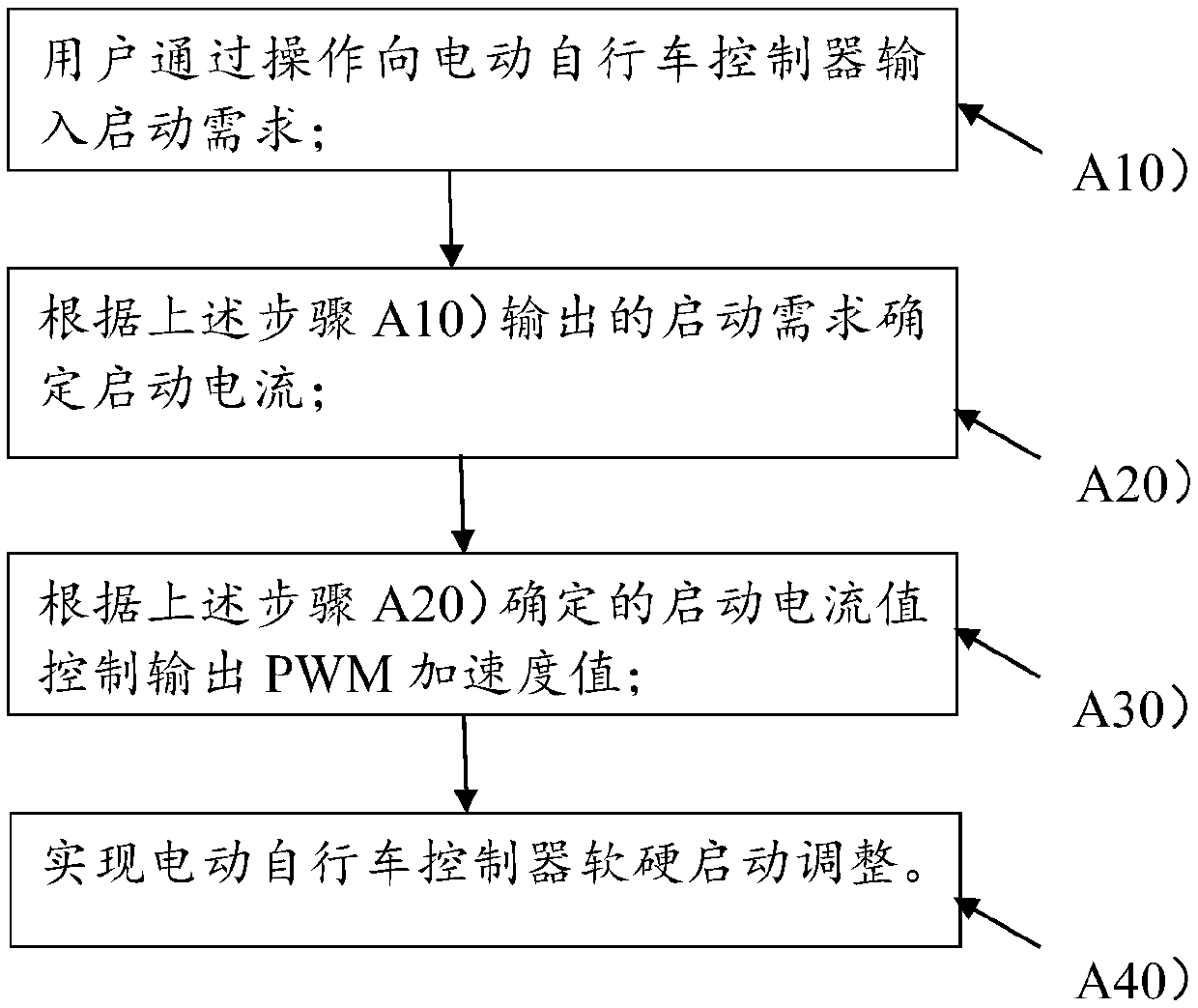

An elastically fixed electric vehicle controller cooling device

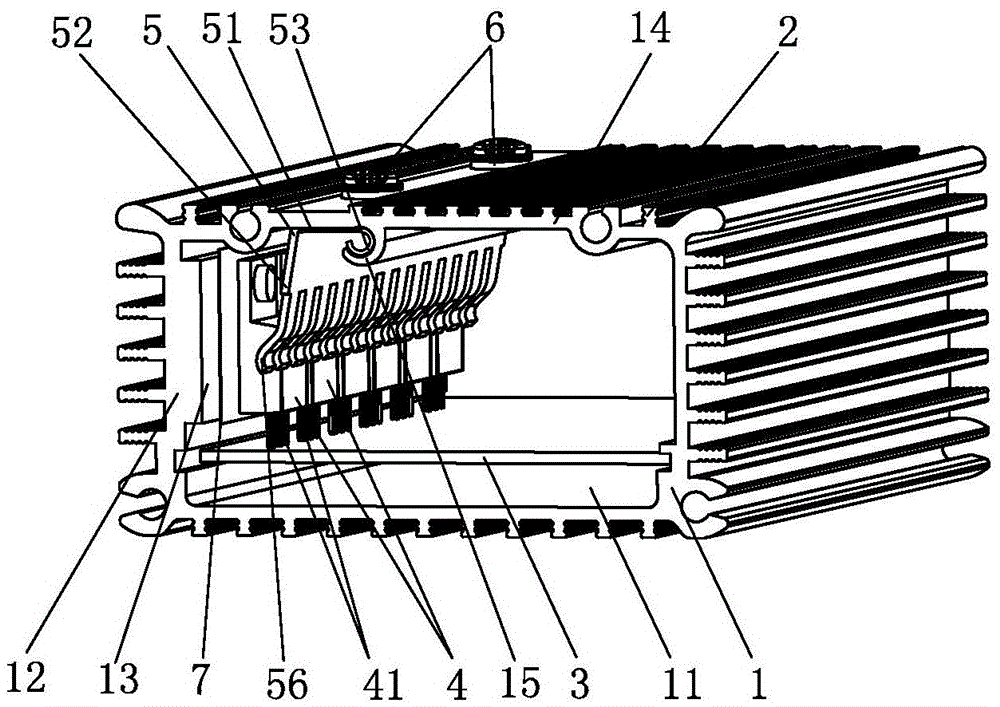

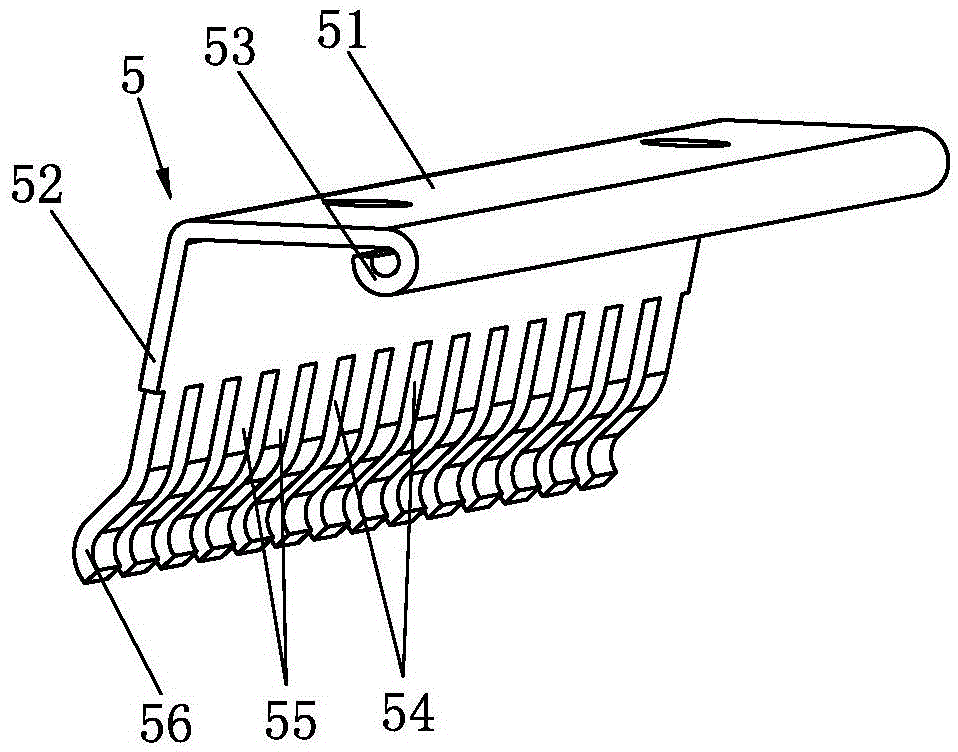

ActiveCN103619147BDistribute quicklyThe connection is tight and firmCooling/ventilation/heating modificationsElectricityElectric vehicle

The invention relates to the technical field of electric vehicle accessories, in particular to an elastically fixed radiator for an electric vehicle controller; On the upper top surface of the cavity, the outer side of a spring pressing edge is elastically pressed on the row of power switch tubes, so that the power switch tubes are pressed on the installation plane of the hollow inner cavity, and there is no need to install aluminum strips and power switch tubes one by one. The characteristics of convenient and fast installation, simplified production process, and reduced production cost; the present invention does not require bolts to pass through the power switch tube, avoiding the heat sink of the traditional heat sink due to the short creepage distance between the bolt and the power switch tube, which cannot fully meet the high voltage resistance The problem of insulation resistance requirements occurs; the heat dissipation path is shorter than the traditional heat sink, so that the heat can be dissipated faster, greatly reducing its overheating damage rate, and enhancing its service life.

Owner:广东高标智能科技股份有限公司

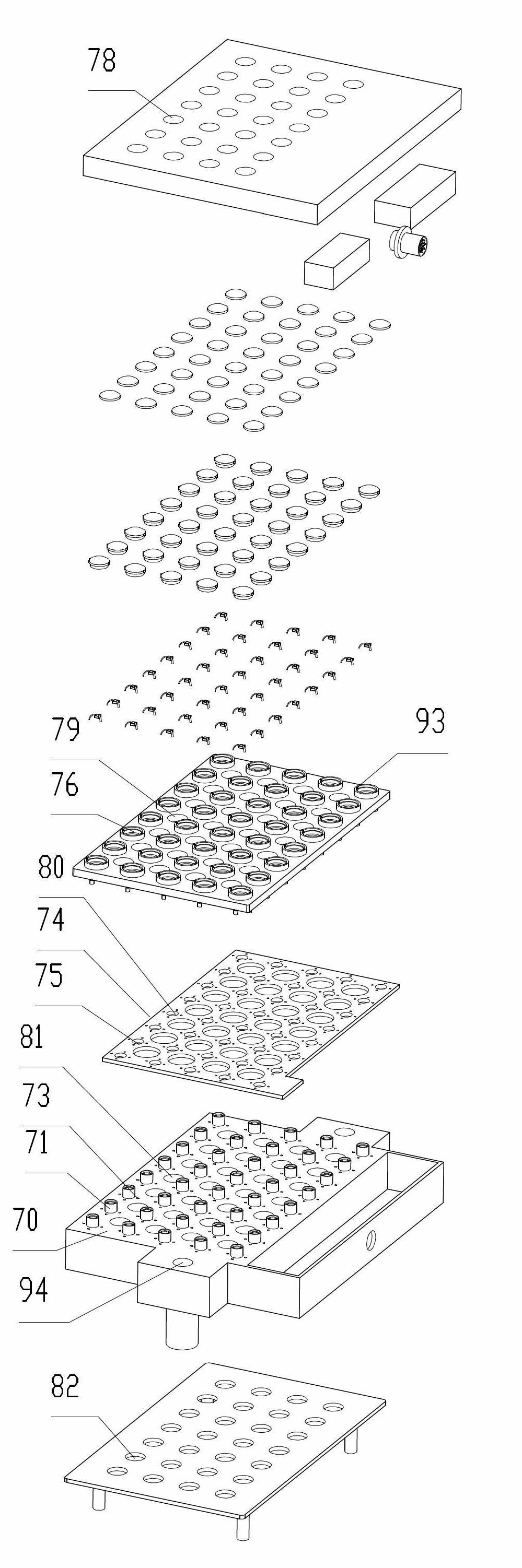

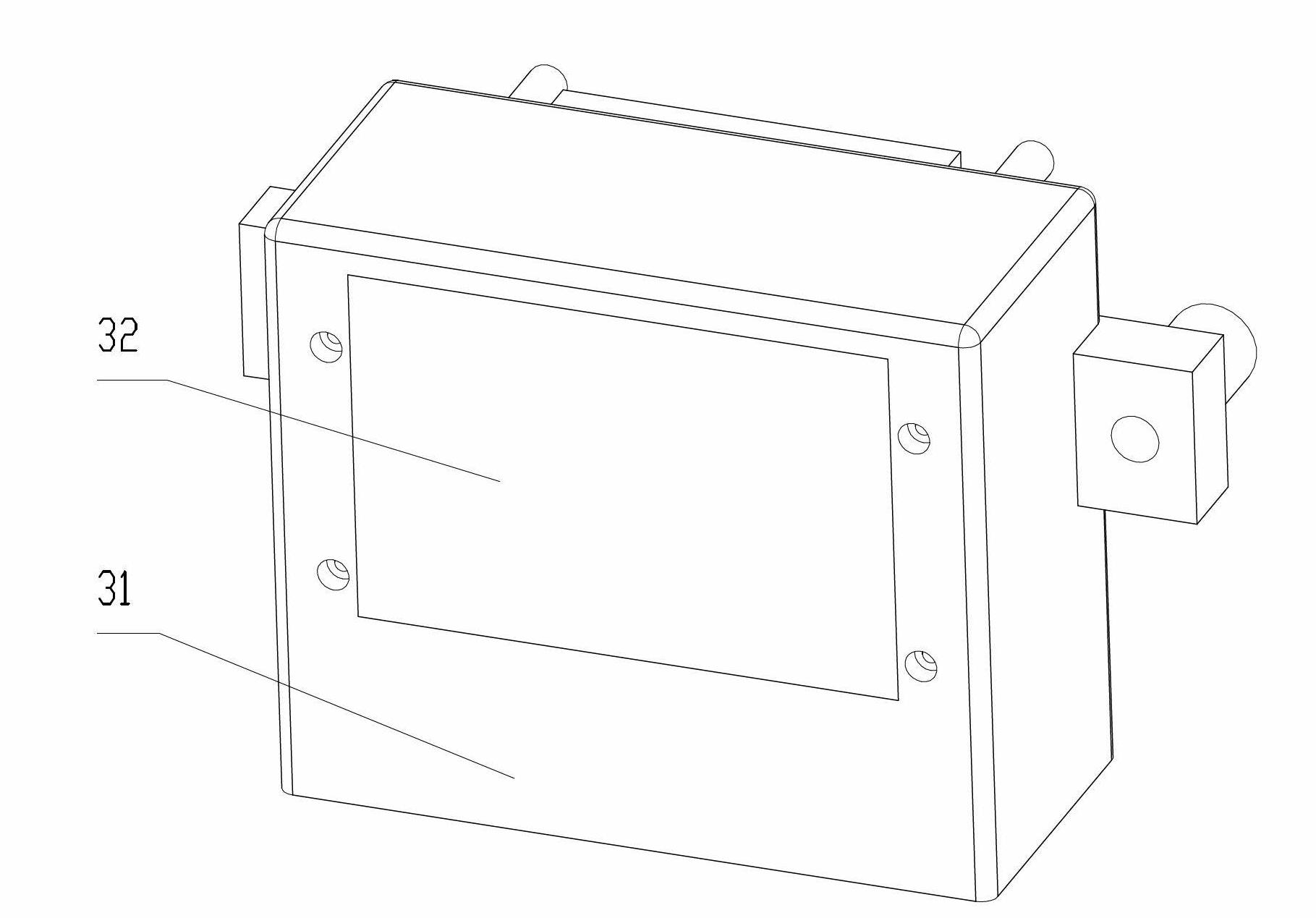

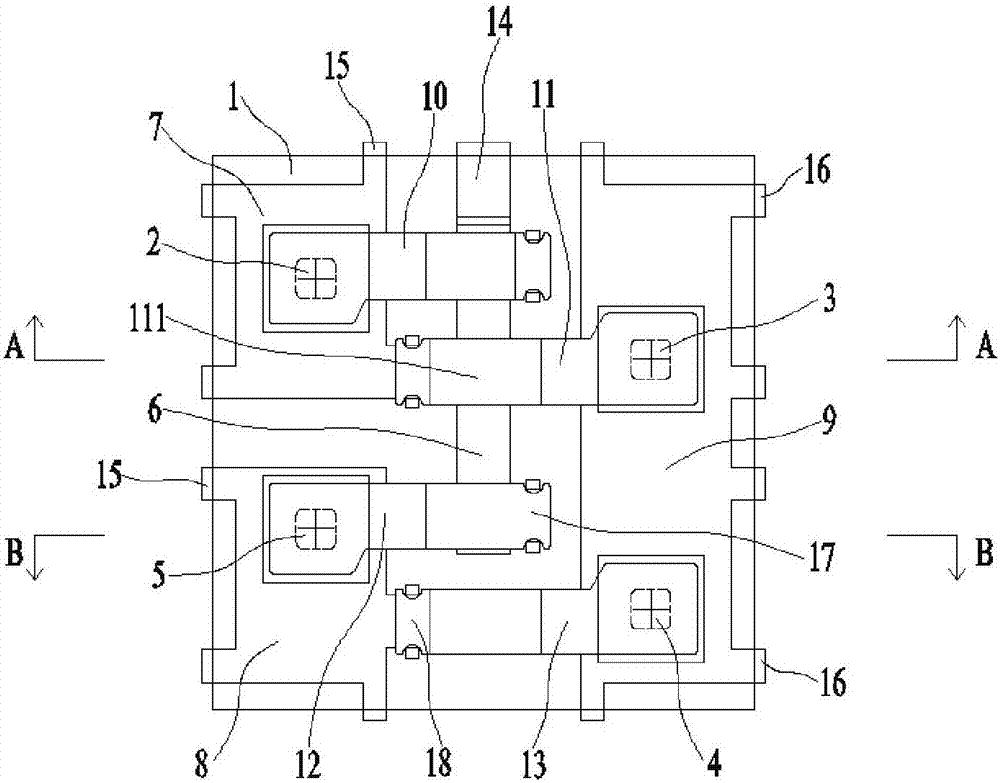

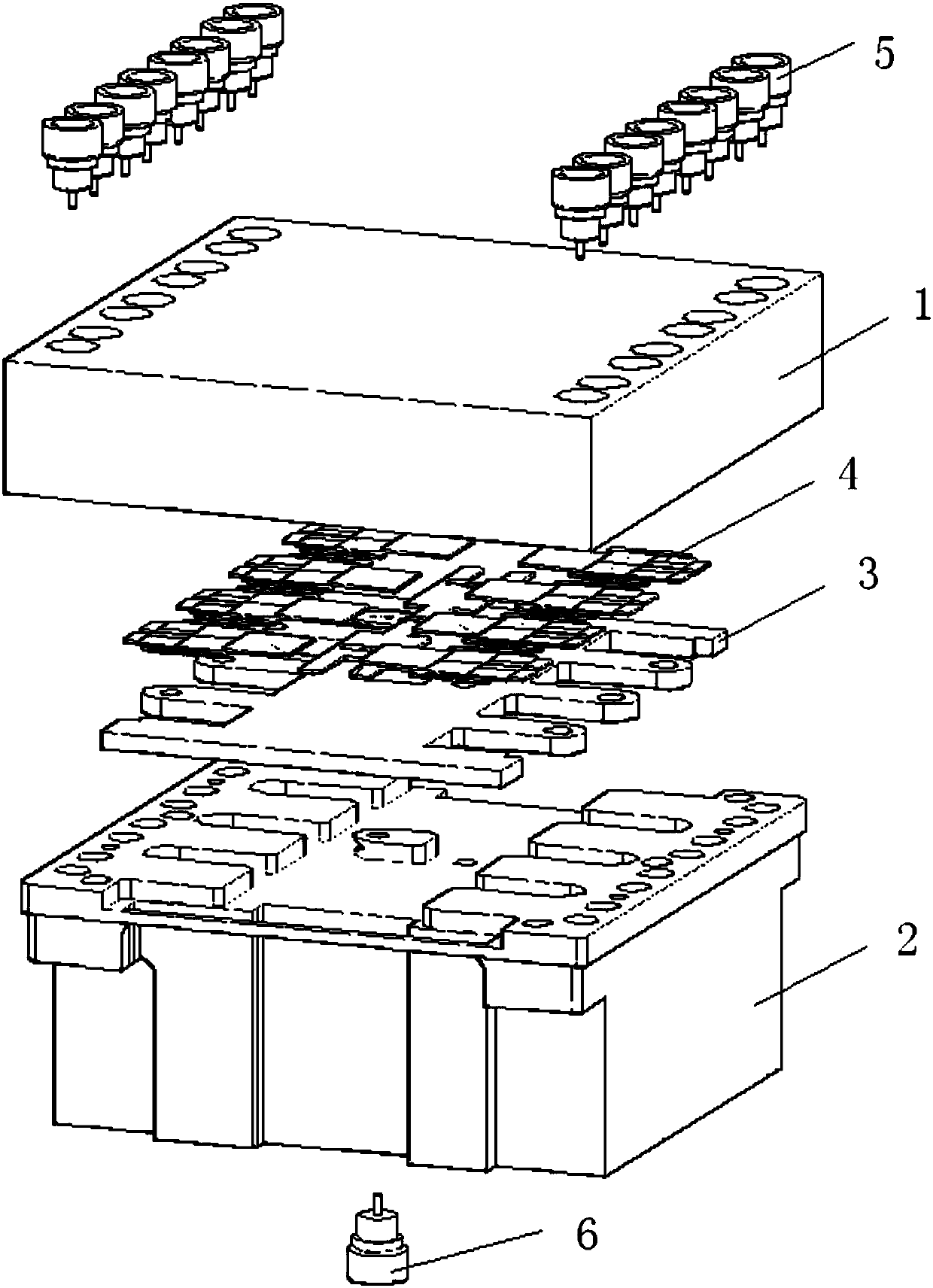

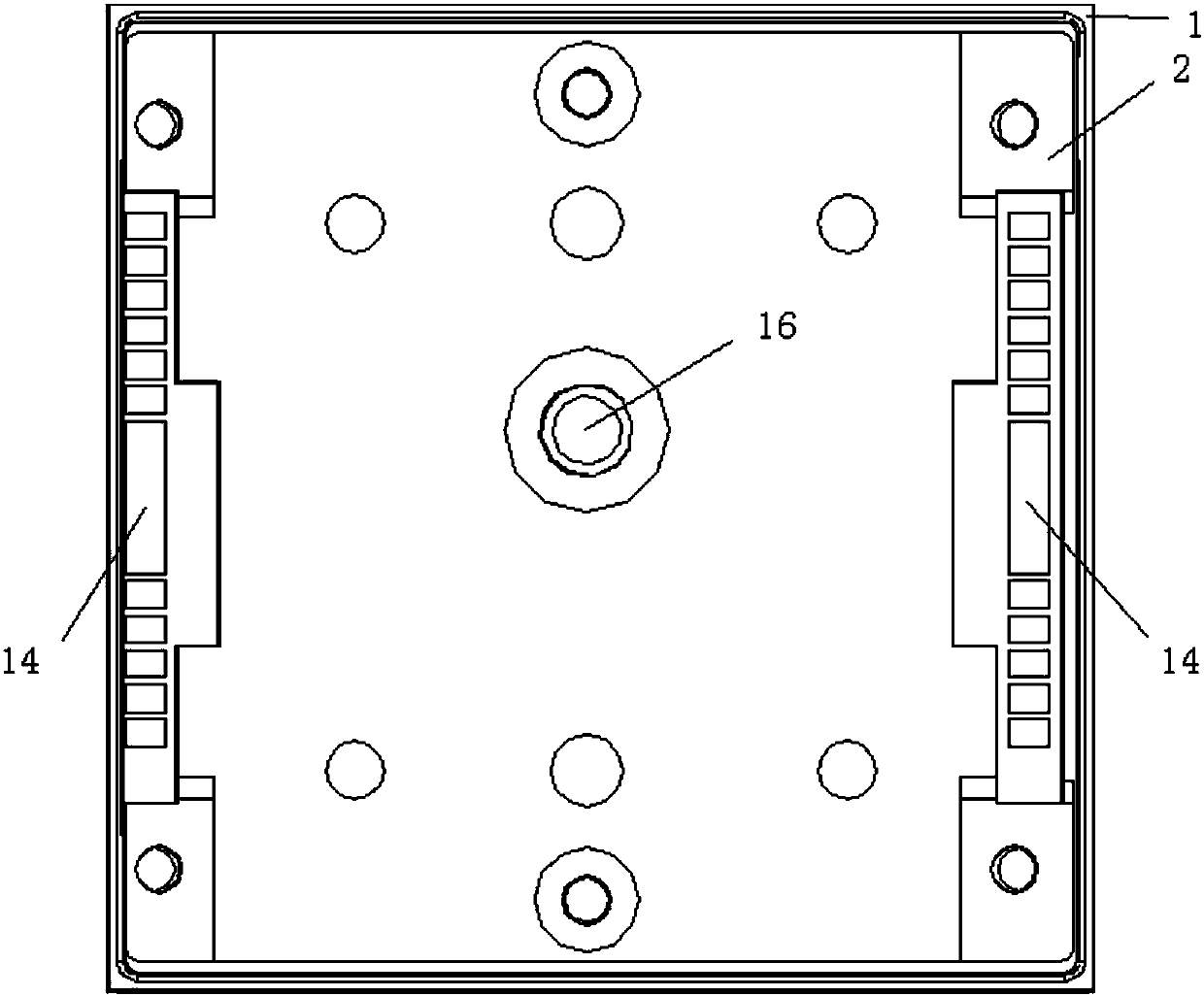

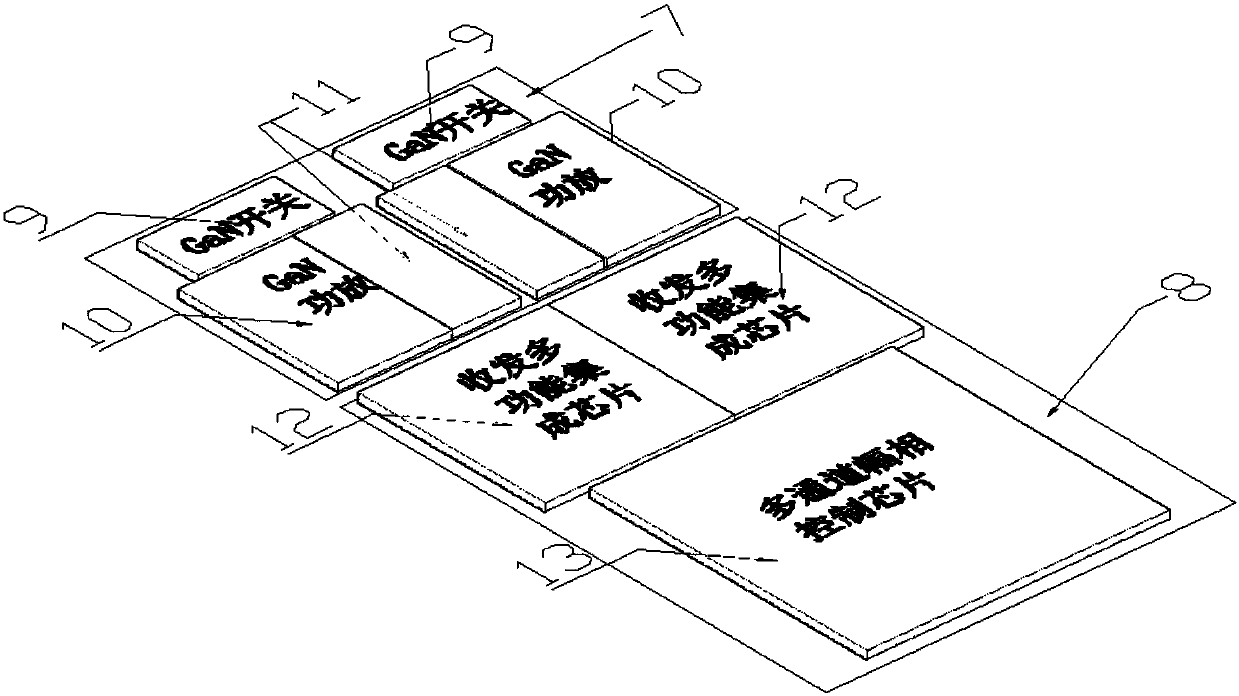

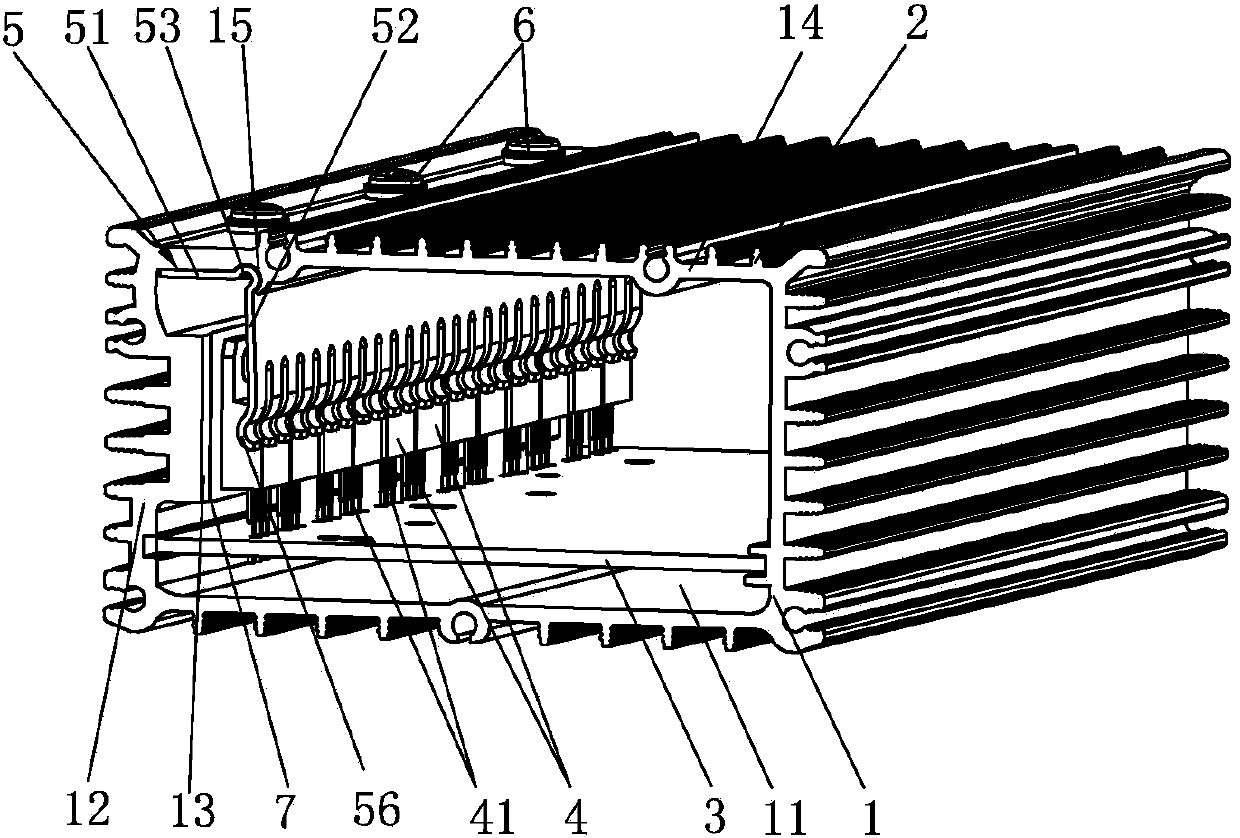

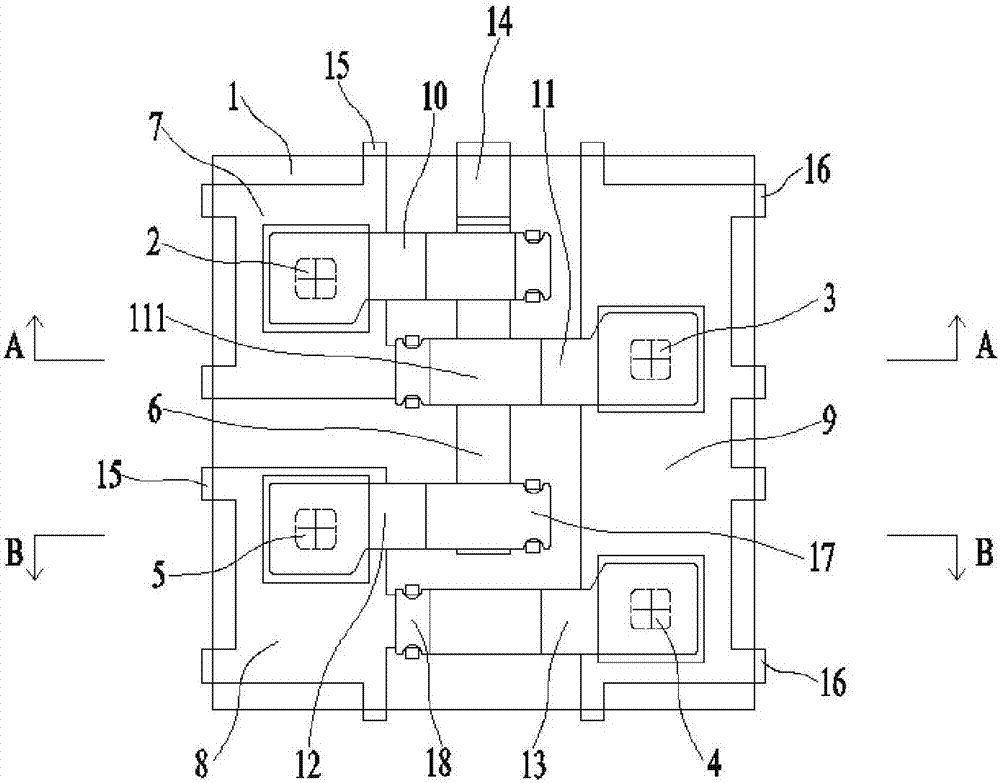

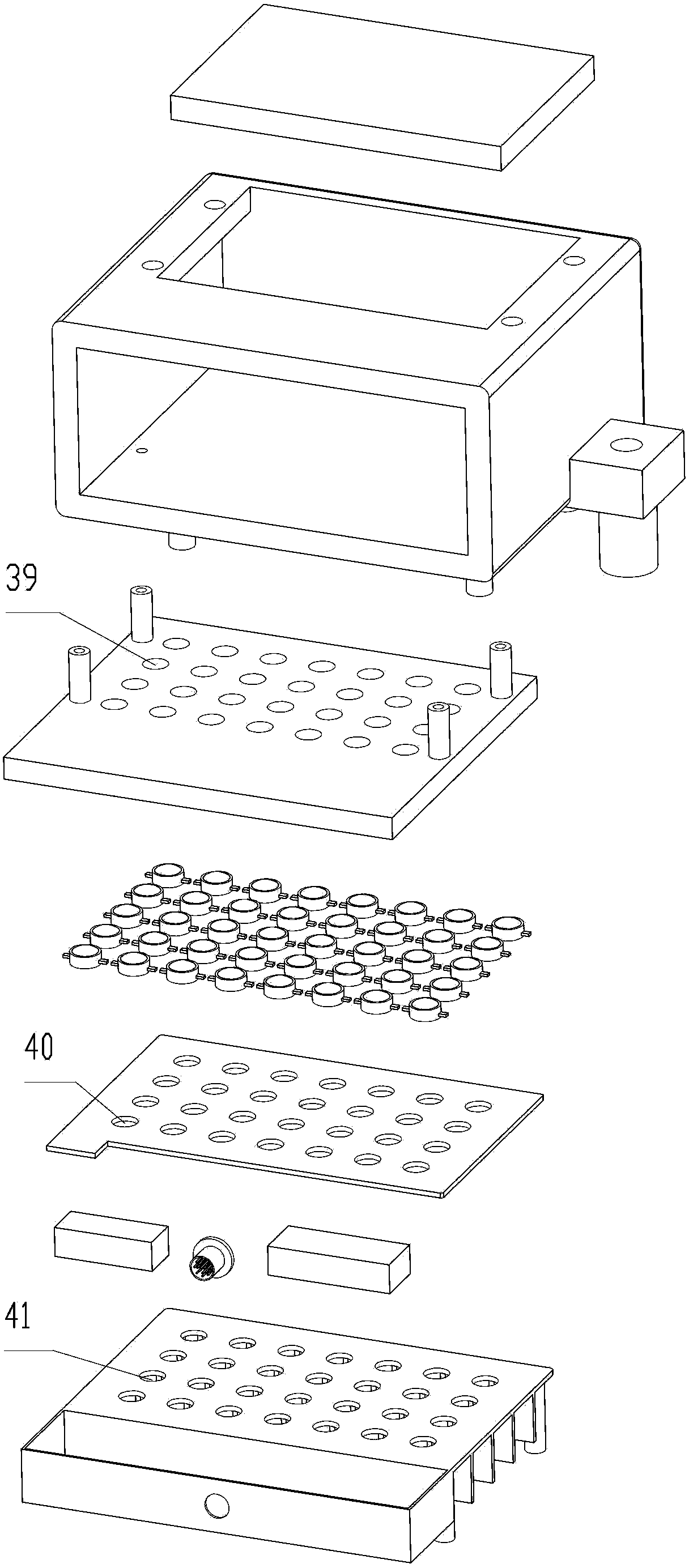

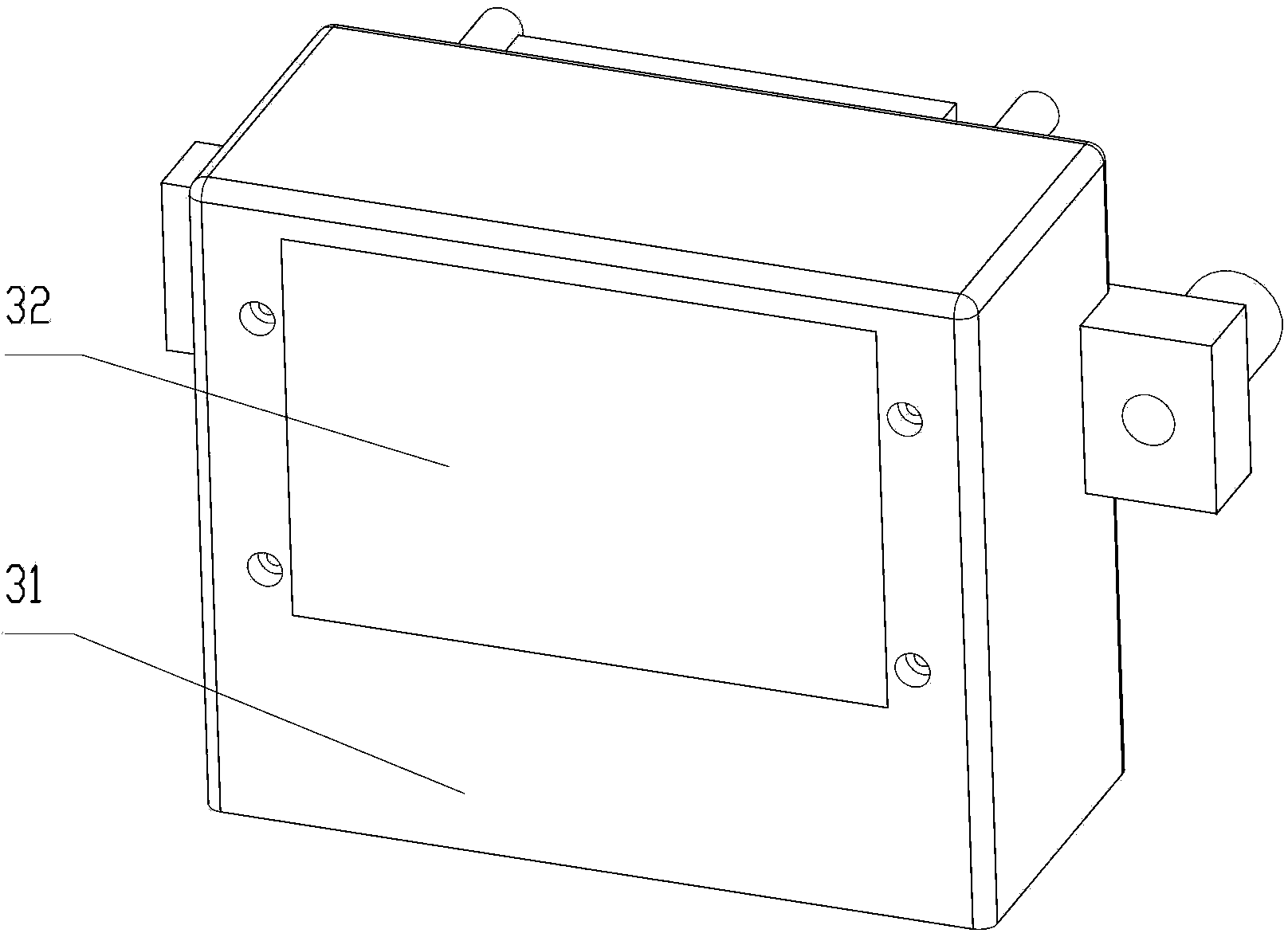

Millimeter wave tile-type phased array antenna tr component

ActiveCN105514566BTo achieve the purpose of high-density integrationImprove regularityAntenna supports/mountingsModular arraysAntenna gainActive phase

The invention relates to a millimeter wave tile-type phased-array antenna TR module, and the invention aims at providing a TR module realization scheme with advantages of high reliability, low cost and high density integration for a millimeter wave frequency range high-power active phased-array antenna (APAA). The millimeter wave tile-type phased-array antenna TR module can be realized by the following scheme: a radio-frequency signal is fed from a radio-frequency vertical interconnection interface of a common port of the lower cavity bottom of the TR module, after the radio-frequency signal is performed the power distribution through a power divider mounting on the surface of a multi-layer circuit board and the like, the radio-frequency signal is fed in a multichannel amplitude-phase control chip connected with every transmit-receive channel, after the radio-frequency signal is performed the second power distribution by the multichannel amplitude-phase control chip, the amplitude-phase information of each channel radio-frequency signal is adjusted according to the state of the external control code and is outputted to a TR multi-function chip, the signal is amplified and outputted to the final power amplifier until saturation, the signal is outputted to a power switch, the emission access is gated, and the signal is transmitted to antenna radio-frequency vertical interconnection interfaces arranged on two ends of the cavity on the TR module; when the TR module receives a work, the radio-frequency signal passes through the TR module in a reverse direction.

Owner:10TH RES INST OF CETC

A cooling device for electric vehicle controllers fixed by shrapnel

ActiveCN103619148BDistribute quicklyThe connection is tight and firmCooling/ventilation/heating modificationsElectric carsElectric vehicle

Owner:广东高标智能科技股份有限公司

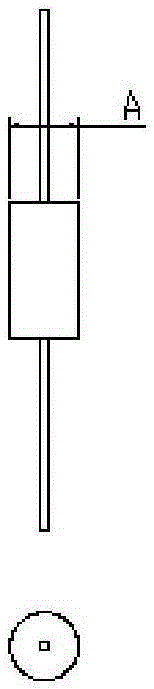

Self-cooling semiconductor laser

PendingCN113948959APerformance is not affectedAchieve coolingLaser detailsSemiconductor lasersHeat sinkSemiconductor

The invention provides a self-cooling semiconductor laser, which overcomes the problems of long heat transfer path, large thermal resistance, large volume and the like of a laser semiconductor adopting an existing heat dissipation structural form. The self-cooling semiconductor laser comprises a semiconductor laser working area and a substrate, wherein the semiconductor laser working area grows on the substrate, and the substrate is divided into a first substrate and a second substrate which are stacked up and down; the upper surface of the first substrate is in contact with the semiconductor laser working area and is a current diffusion flow-through area; a cooling flow channel is formed in the second substrate and is used for cooling the semiconductor laser working area; heat generated by the semiconductor laser working area is conducted to the second substrate through the first substrate and exchanges heat with a refrigerant flowing in the cooling flow channel in the second substrate, so that the path between a hot spot and the refrigerant is shortened, the thermal resistance is reduced, and the purpose of improving the overall heat exchange effect is achieved; and meanwhile, an external cooling heat sink is not needed, the overall size of the device is reduced, and integrated design is facilitated.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Miniature bridge rectifier

ActiveCN107887367AMake full use of cooling capacityShort cooling pathSemiconductor/solid-state device detailsSolid-state devicesElectricityMetal strips

The invention relates to a miniature bridge rectifier. According to the miniature bridge rectifier, a first metal substrate, a second metal substrate and an E-shaped metal substrate are located at thebottom of an epoxy packaging body and are distributed at the left side and right side of the epoxy packaging body; a negative pole metal strip is located between the first metal substrate, the secondmetal substrate and the E-shaped metal substrate; two ends of a first connecting sheet are electrically connected with the negative pole end of a first diode chip and the upper surface of the negative pole metal strip respectively; and the middle portion of a second connecting sheet is provided with a protruding portion which is isolated from the negative pole metal strip through the epoxy packaging body; a second positioning mechanism is composed of protruding points at two sides of the first metal substrate and two sides of the second metal substrate, and recessed portions at two sides of the tail end of the second connecting sheet and two sides of the tail end of a fourth connecting sheet, wherein the protruding points are embedded into the recessed portions; the thickness of the epoxypackaging body is smaller than 2 mm; and an end surface of the E-shaped metal substrate, which is located at the edge of the epoxy packaging body, is provided with four second pin outward-protrudingportions. An existing product dissipates heat through air convection in a chassis, as a result, the area of heat dissipation sheets can be 50% of the length*width area of the product, while, with theminiature bridge rectifier adopted, such kind of situation in the prior art can be avoided.

Owner:SUZHOU GOODARK ELECTRONICS CO LTD

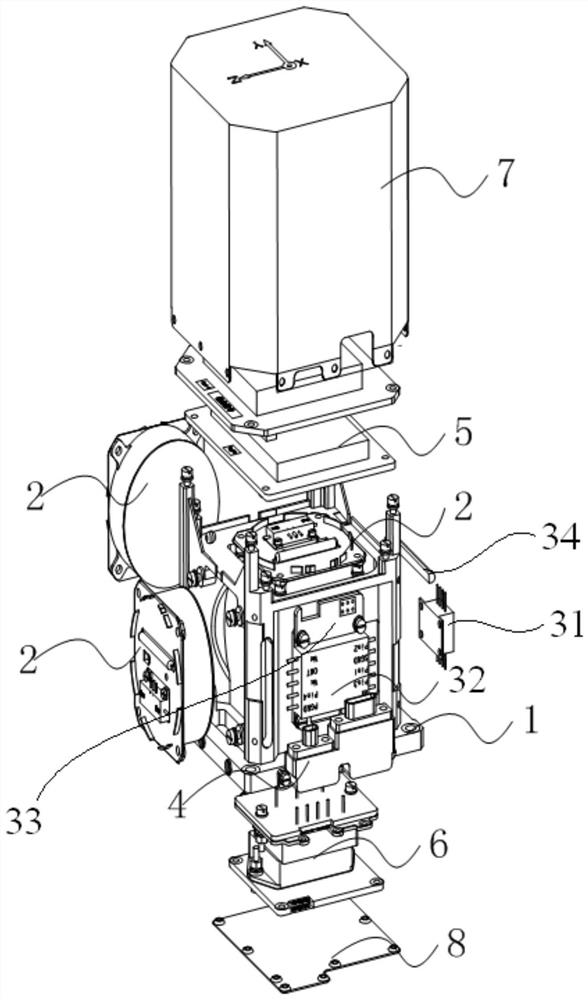

A fiber optic gyro combination device for satellite attitude control

ActiveCN111121775BImprove mechanical propertiesAchieve high integrationNavigation by speed/acceleration measurementsSagnac effect gyrometersGyroscopeComputational physics

A fiber optic gyro combination device used for satellite attitude control, innovatively designed the system body in the structural form of H-shaped longitudinal section and mouth-shaped cross-sectional connection surface connecting four support columns. The system body is the main structure supporting each component, while ensuring three orthogonal mounting surfaces for the three orthogonal optical path components; in order to ensure the stable operation of the device, it provides an independent working area for the secondary power circuit components; the present invention It has a good heat dissipation design to ensure the accuracy and reliability of the equipment during the satellite's working process; the invention has sufficient structural natural frequency and good mechanical resistance. The present invention optimizes materials and processing methods for non-load-bearing parts (outer cover, bottom cover), and realizes light weight and low cost. The invention has good processability in designing and assembling, and modularizes components with relatively independent functions, and belongs to the technical field of structural design of optical fiber gyro devices.

Owner:INNOVATION ACAD FOR MICROSATELLITES OF CAS +1

LED base plate with high power and high heat dissipation efficiency

InactiveCN109140261AImprove luminous performanceLight attenuation is smallLighting heating/cooling arrangementsSemiconductor devices for light sourcesJunction temperatureEngineering

The invention discloses an LED base plate with high power and high heat dissipation efficiency. The LED base plate comprise an LED light emitting chip, a circuit board, a rubber insulating layer and aheat dissipation device. The LED base plate is characterized in that the circuit board and the rubber insulating layer are directly solidified on the installation end surface of the heat dissipationdevice, namely the rubber insulating layer is arranged on the installation end surface of the heat dissipation device, the circuit board is arranged on the rubber insulating layer, and the LED light emitting chip is arranged in the circuit board. The LED light emitting chip, the circuit board and the rubber insulating layer are directly solidified on the installation end surface of the heat dissipation device, compared with a traditional structure, and the structure omits the structure of a base plate body and only has a two-layer structure; and no gap exists between the rubber insulating layer and the installation end surface of the heat dissipation device, so that an air layer cannot be formed; a heat dissipation path is short, so that the heat dissipation effect is greatly improved, theluminous efficiency of the LED light-emitting chip is improved, the light attenuation is small, the heat conduction and heat convection of the LED photoelectric base plate are enhanced, the defect ofexcessively high junction temperature of an LED is thoroughly overcome, and the service life of an LED light source is prolonged.

Owner:河南时事通医疗产业有限公司

LED (light-emitting diode) dot matrix display screen

InactiveCN102682672BHigh junction temperatureImprove cooling effectCooling/ventilation/heating modificationsIdentification meansDot-matrix displayEngineering

Owner:JIANGMEN JUNDA OPTOELECTRONICS TECH

Multi-chip packaging structure and manufacturing method thereof

ActiveCN113035724ASimple structureShort electrical pathSemiconductor/solid-state device detailsSolid-state devicesMiniaturizationDie bonding

The invention discloses a multi-chip packaging structure and a manufacturing method thereof. According to the multi-chip packaging structure and the manufacturing method thereof of the invention, multi-core module packaging is completed through the technological processes of copper substrate patterning, die bonding and conducting layer connection, dielectric material or top conducting layer manufacturing, dielectric patterning and hole opening, hole metallization, dielectric metal patterning, middle dielectric layer manufacturing, overall hole machining, hole metallization or dielectric filling, upper / lower surface metal patterning and the like. The whole technological process is completely compatible with PCB equipment and technologies; an obtained multi-core module is simple in structure, short in electrical path and short in heat dissipation path, has the excellent low-resistance characteristic and heat dissipation effect, and can achieve the effects of miniaturization, lightness and thinness.

Owner:FUDAN UNIV

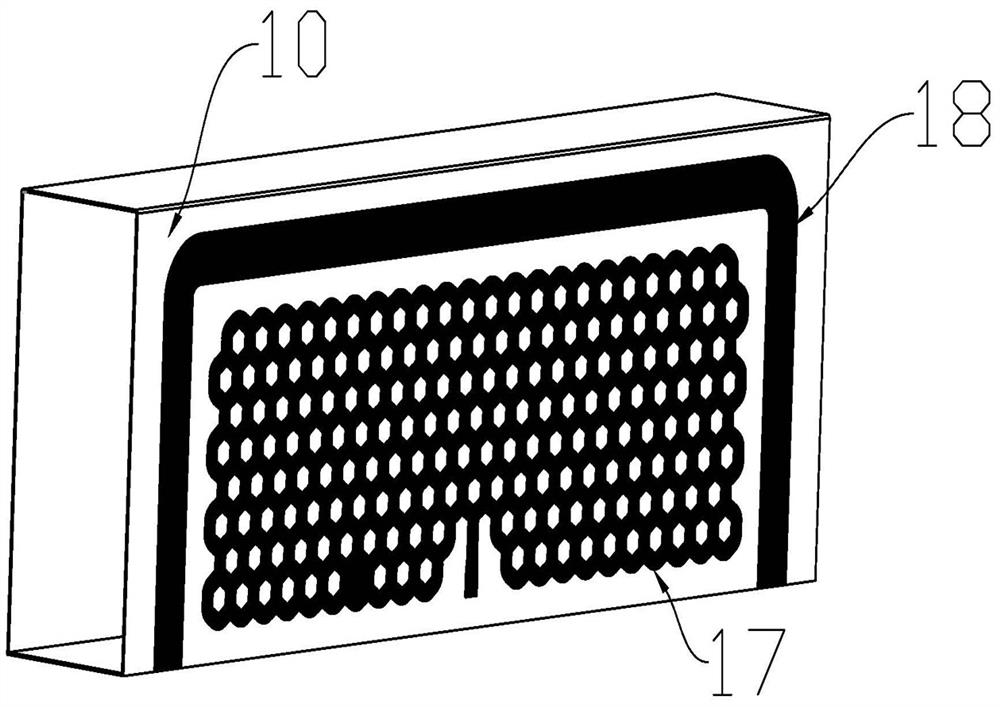

Battery shell manufacturing method, battery shell and battery

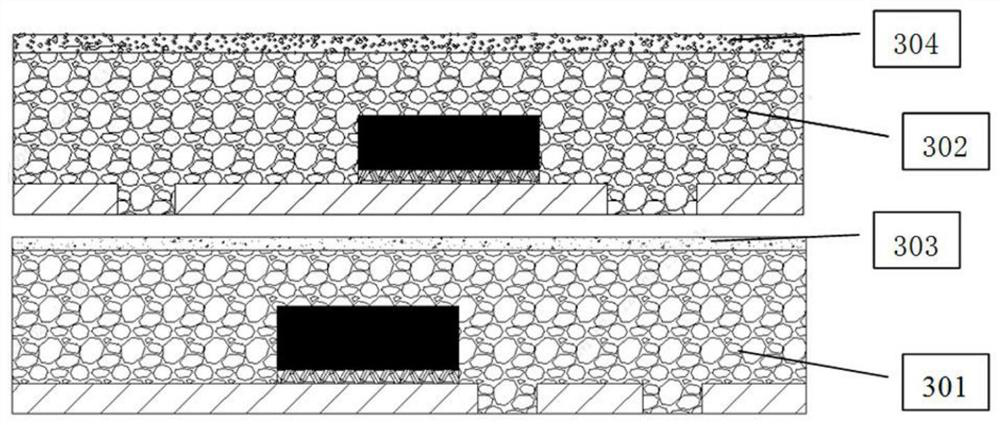

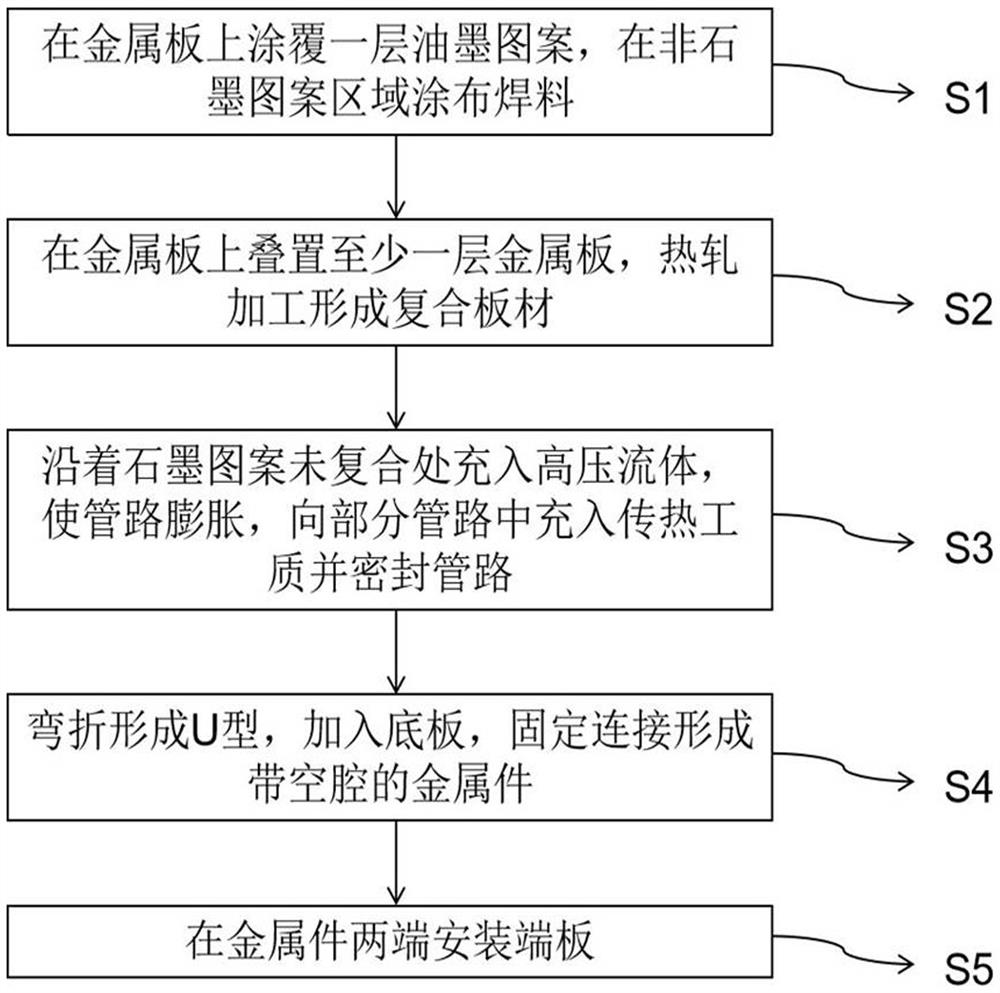

PendingCN114082854AImproved heat uniformity and heat dissipationShort cooling pathSecondary cellsCell component detailsElectrical batteryProcess engineering

The invention aims to provide a battery shell manufacturing method, a battery shell and a battery. The battery shell manufacturing method comprises: S1, coating a layer of ink pattern on a metal plate, and coating solder on a non-graphite pattern area; S2, stacking at least one layer of metal plate on the metal plate, and performing hot rolling to form a composite plate; S3, filling high-pressure fluid along a non-compounded part of the graphite pattern to expand the pipeline, filling a heat transfer working medium into part of the pipeline, and sealing the pipeline; S4, performing bending to form a U shape, adding a bottom plate, and conducting fixed connection to form a metal piece with a cavity; and S5, installing end plates at the two ends of the metal piece. According to the battery shell manufacturing method, the soaking capacity and the heat dissipation capacity of the battery shell are greatly improved, the heat dissipation path is short, the heat dissipation efficiency is improved, the heat dissipation cost is reduced, and the requirement for efficient heat control of the electric core level is met.

Owner:重庆三峡时代能源科技有限公司

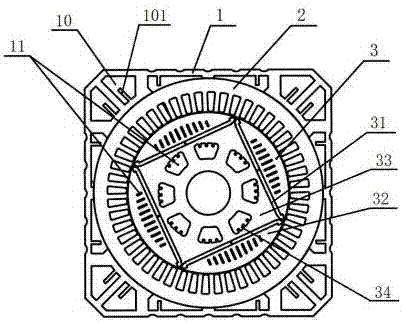

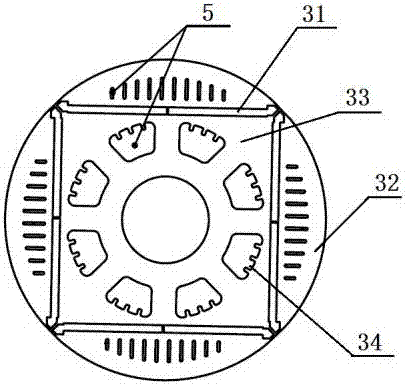

Highly efficient heat dissipation motor rotor structure

PendingCN107086690AEffective coolingPrevent clogged air gapMagnetic circuit rotating partsElectric machineEngineering

The invention discloses a highly efficient heat dissipation motor rotor structure. The structure comprises a rotor and a spindle arranged in the center of the rotor. Multiple rotor heat dissipation wind flow channels are arranged in the rotor. Rotor wind covers are arranged on two ends of the rotor. Air passing flow channel are arranged between the rotor wind covers and the spindle. The air passing flow channels between the rotor wind covers and the spindle and the rotor heat dissipation wind flow channels in the rotor form rotor heat dissipation wind channels. According to the invention, energy is saved; consumption is reduced;, heat is highly efficiently radiated; the structure is simple; and service lifetime of the motor can be prolonged.

Owner:GUANGDONG LIANSU MACHINERY MFG

Lightweight lithium-ion battery module for underwater device and manufacturing method

ActiveCN110277522BEasy to shapeEasy to processFinal product manufactureBattery isolationEngineeringElectrical connector

A lightweight lithium-ion battery module for an underwater device and a manufacturing method thereof. The overall structure of the module is an open structure with single-sided bonding and suspension support, including a panel, a first insulating plate, a battery stack, a second insulating plate, Guide supports, side supports, bottom supports, top supports, and electrical connectors. The first insulating board and the panel are respectively coated with silicone rubber and the silicone rubber is bonded together and cured for more than one day. The battery stack and the first insulating board are respectively coated with silicon rubber and bonded together and cured for more than five days. The second insulating board Installed to the other side of the battery stack for insulation without support. The guide support, the side support, the bottom support and the top support are not in contact with the battery stack. The invention adopts the one-sided adhesive suspension and flexible interconnection technology of the lithium-ion battery combination, which significantly reduces the specific gravity of the structural parts of the lithium-ion battery module and ensures its reliability at the same time.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

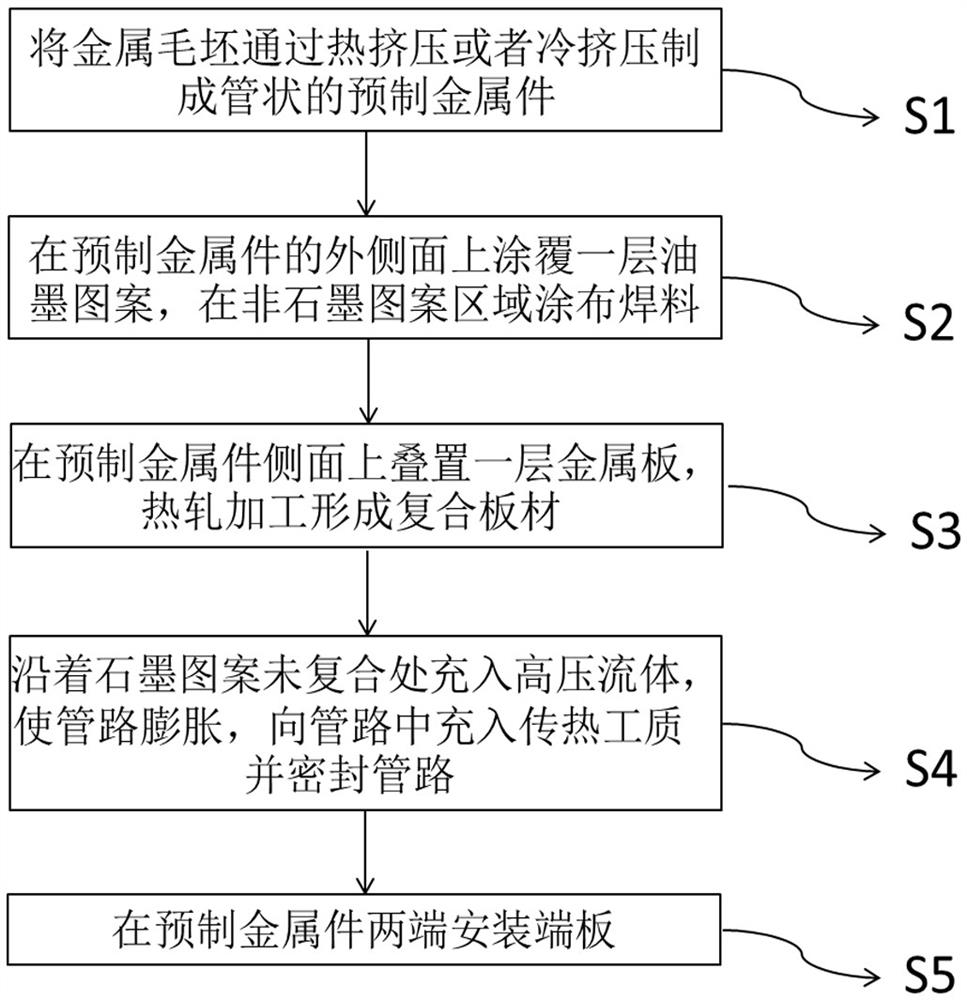

Manufacturing method of battery shell, battery shell and battery

PendingCN114069109AImproved heat uniformity and heat dissipationShort cooling pathSecondary cellsCell component detailsPhysicsEngineering

The invention aims to provide a manufacturing method of a battery shell, the battery shell and a battery. The manufacturing method of the battery shell comprises the following steps that S1, a metal blank is manufactured into a tubular prefabricated metal part through hot extrusion or cold extrusion; s2, the outer side face of the prefabricated metal part is coated with a layer of ink pattern, and a non-graphite pattern area is coated with welding flux; s3, a layer of metal plate is stacked on the side face of the prefabricated metal part, and a composite board is formed through hot rolling; s4, high-pressure fluid is injected along the non-compounded part of a graphite pattern to expand the pipeline, a heat transfer working medium is injected into the pipeline, and the pipeline is sealed; and S5, end plates are installed at the two ends of the prefabricated metal part. According to the manufacturing method of the battery shell, the soaking capacity and the heat dissipation capacity of the battery shell are greatly improved, the heat dissipation path is short, the heat dissipation efficiency is improved, the heat dissipation cost is reduced, and the requirement for efficient heat control of the electric core level is met.

Owner:重庆三峡时代能源科技有限公司

Fixing structure of controller MOS transistors, controller and electric vehicle

PendingCN107706162AAchieve fixationMeet fixedSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectric vehicle

The invention discloses a fixing structure of controller MOS transistors, a controller and an electric vehicle. The arrangement number of MOS transistors is two rows or more, the fixing structure of the controller MOS transistors includes a heat radiation pedestal, silica gel strips and heat radiation installation parts, heat radiation walls extend from the heat radiation pedestal, the number of the heat radiation walls is equal to the arrangement number of the MOS transistors, and each heat radiation wall and one side of each row of MOS transistors are in corresponding insulated contact connection; and the other side of each row of MOS transistors is in contact connection with the silica gel strip, and the silica gel strips are fixed on the heat radiation walls through the heat radiationinstallation parts. The fixing structure provided by the invention is stable and effective, a heat radiation path is rapid, adopted fixing part processing and installation processes are very simple, the production cost is low, the production efficiency is high, and the fixing structure can meet the requirement of fixing of a controller having a plurality of rows of MOS transistors, and is very suitable for batch production application.

Owner:WUXI SINE POWER TECH CO LTD

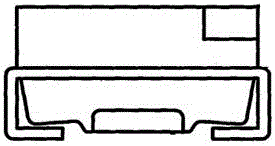

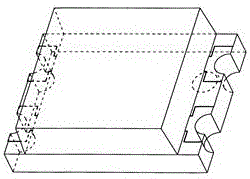

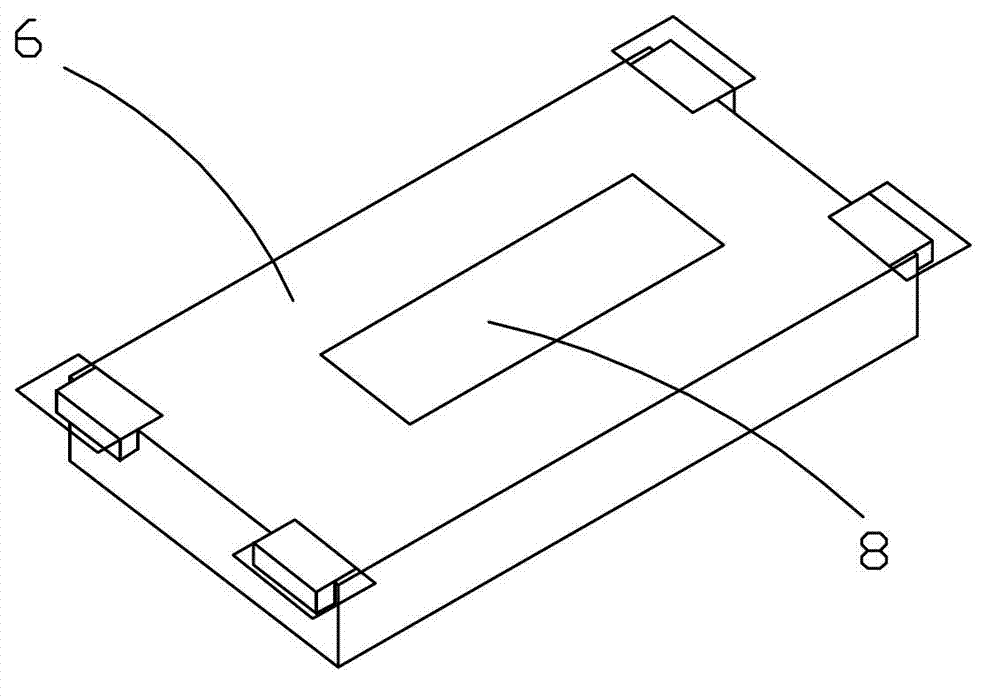

QFN (Quad Flat No-leadPackage) surface mounted RGB-LED packaging support and manufacturing method thereof

PendingCN107017329AGuaranteed stabilityQuick exportSolid-state devicesSemiconductor/solid-state device manufacturingImage resolutionSurface mounting

The invention provides a QFN (Quad Flat No-leadPackage) surface mounted RGB-LED packaging support, which comprises a metal bottom plate and an insulating frame, and is characterized in that the obverse side of the metal bottom plate is provided with light emitting areas, each light emitting area is divided into four regions, the regions are connected by the insulating frame, the insulating frame forms bowls at the obverse side of the metal bottom plate, and the reverse side of the metal bottom plate is provided with bonding pads used for being connected with an external circuit. The invention further provides a manufacturing method of the packaging support, which comprises the steps of making the metal bottom plate into a conductive circuit, manufacturing bonding pads at the reverse side of the metal bottom plate, manufacturing steps at the obverse side and / or the reverse side of the metal bottom plate, wrapping the metal bottom plate with rubber, leaving out metal electrodes for die bonding and wire welding, and forming a bowl-shaped insulating frame. According to the invention, light is concentrated through the bowl structure, the light emitting surface is enabled to be unique, and thus a manufactured display screen is enabled to be more excellent in resolution; and the tightness in combination with the insulating frame and the stability of the packaging support are ensured through manufacturing the steps on the metal bottom plate.

Owner:SHANDONG JIERUNHONG OPTOELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com