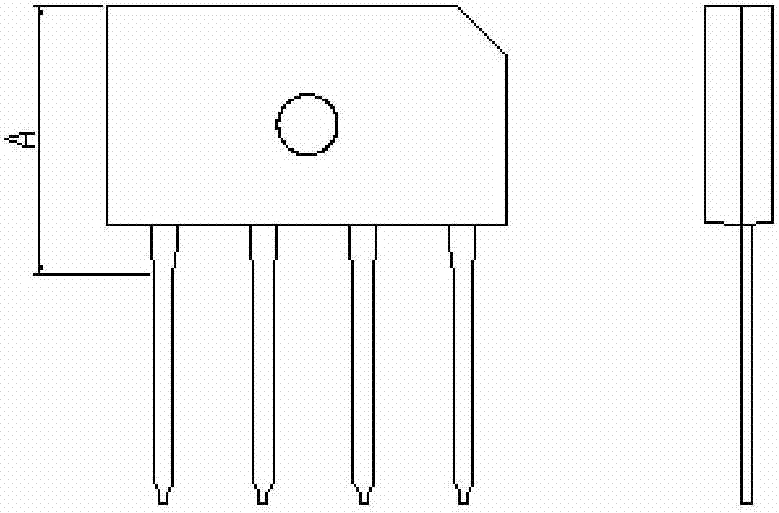

High-reliability rectifier bridge device

A rectifier bridge stack, reliability technology, applied in the direction of electric solid devices, semiconductor devices, semiconductor/solid state device components, etc., can solve the problems of device damage, large heat generation of end products, unfavorable energy saving and environmental protection, etc., to improve the installation accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

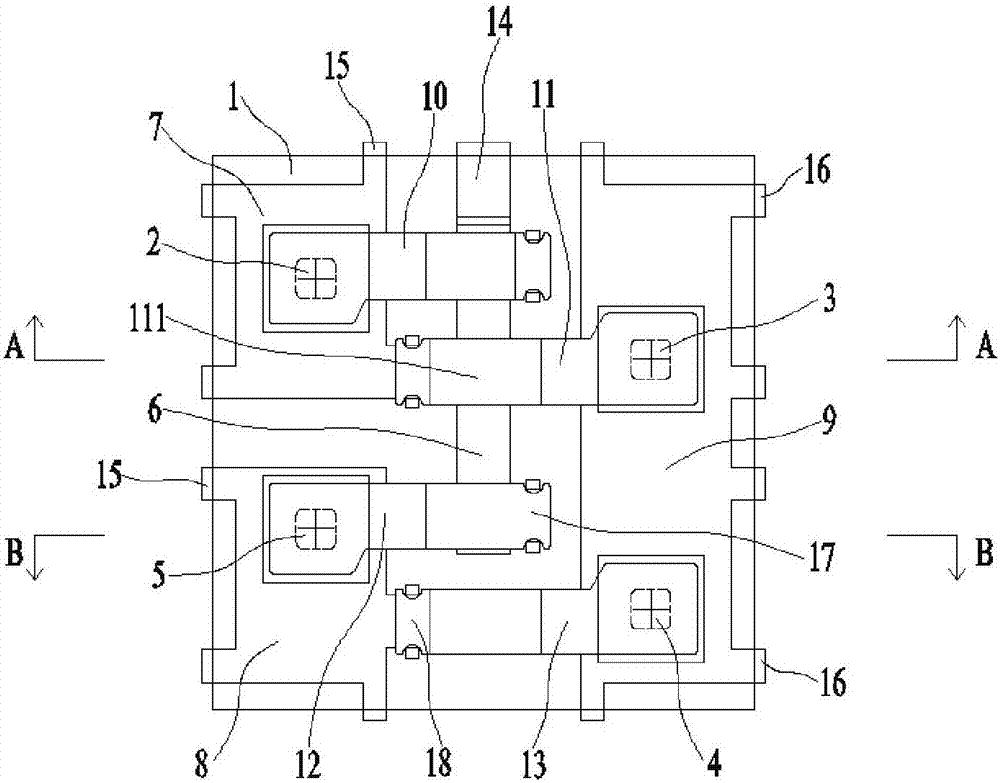

[0025] Embodiment: A high-reliability rectifier bridge stack device, including: first, second, third, fourth diode chips 2, 3, 4, 5 and negative metal strips covered by epoxy package 1 6. First and second metal substrates 7, 8 and E-shaped metal substrates 9 are respectively fixed on the bottom of the epoxy package 1 and on the left and right sides, and the negative electrode metal strip 6 is located on the first and second Between the metal substrates 7, 8 and the E-shaped metal substrate 9;

[0026] The positive terminal of the first diode chip 2 is electrically connected with the upper surface of the first metal substrate 7, the negative terminal of the second diode chip 3 is electrically connected with the upper surface of one end of the E-shaped metal substrate 9, and the third diode The negative end of the chip 4 is electrically connected to the upper surface of the other end of the E-shaped metal substrate 9, and the positive end of the fourth diode chip 5 is electrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com