Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Reduce the probability of water leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

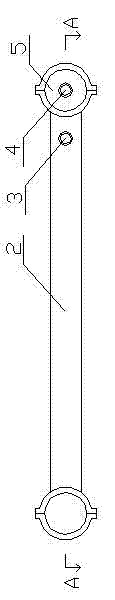

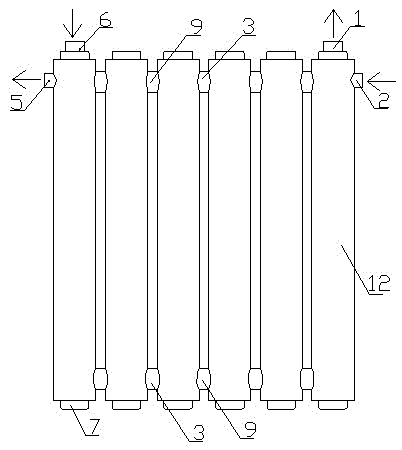

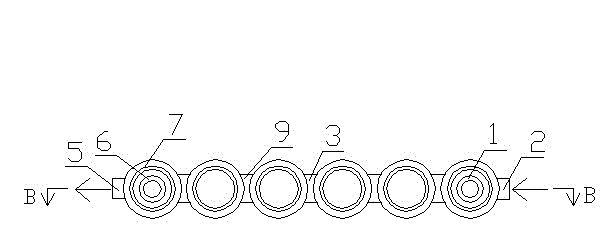

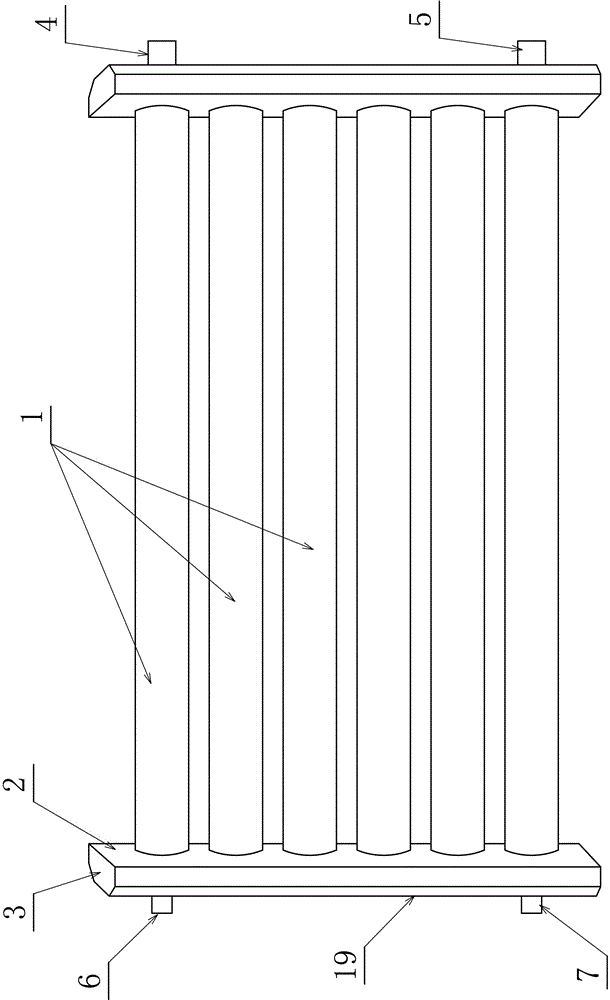

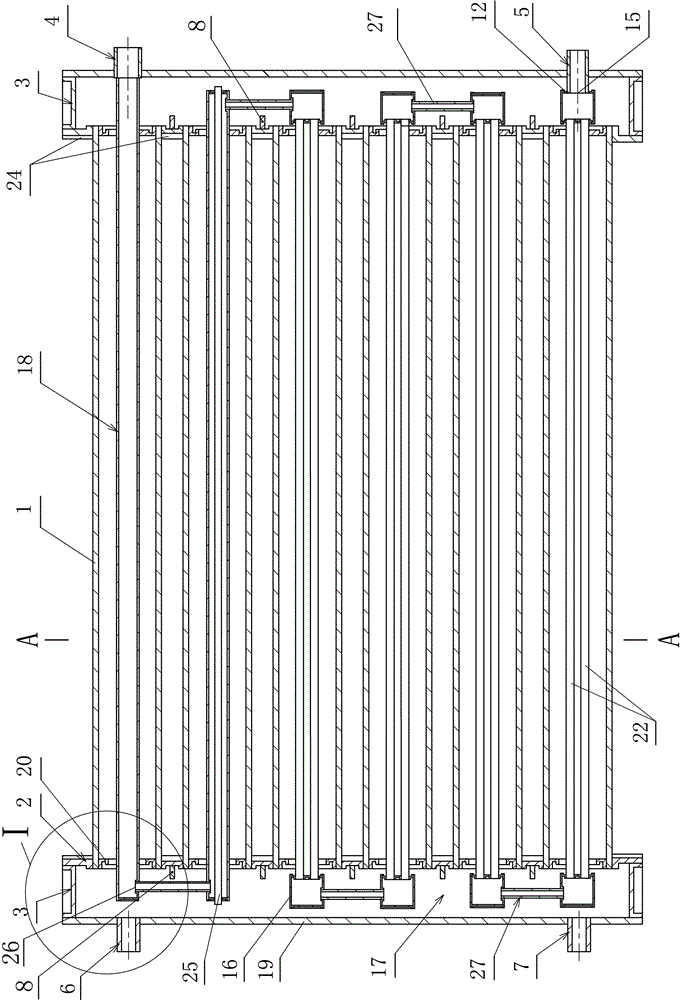

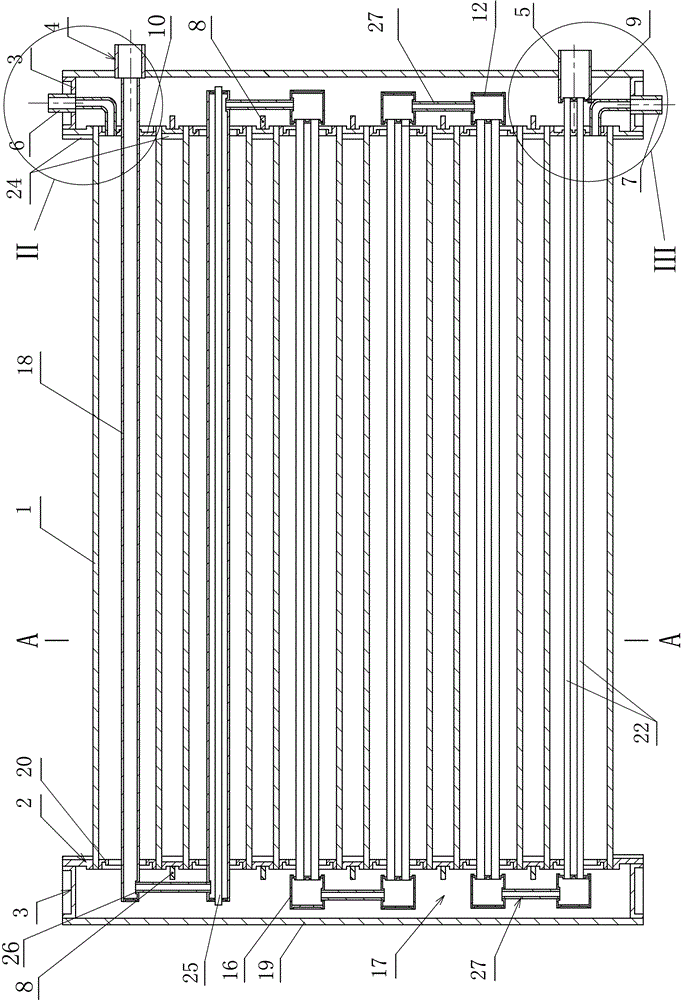

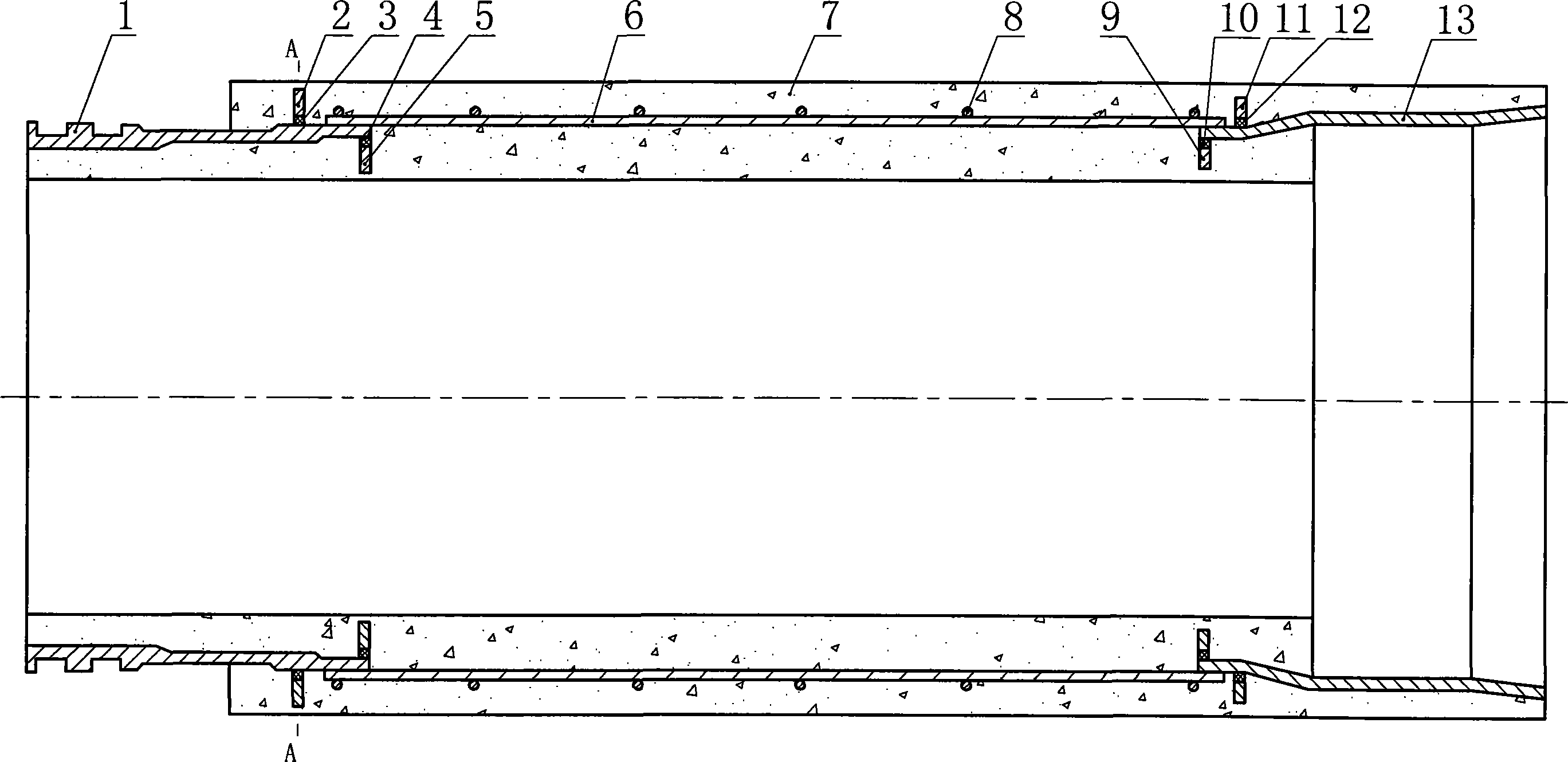

Pipe communication splice welding pressure-bearing type heat exchanger

InactiveCN102322754AIncrease heat transfer areaSolve the welding seam leakage rate is too highHeat exhanger sealing arrangementHeat exchanger casingsWater leakagePlate heat exchanger

The invention relates to a pipe communication splice welding pressure-bearing type heat exchanger, which comprises tap water heat absorption pipes. Heat supply pipes are arranged in the tap water heat absorption pipes. The tap water heat absorption pipes are communicated through tap water communication pipes. The heat supply pipes are communicated through heat supply pipe communication pipes. The seal heads of the tap water heat absorption pipes are outwardly flanged and embedded in the ports of the tap water heat absorption pipes. The flanges of the seal heads of the tap water heat absorption pipes and the port edges of the tap water heat absorption pipes are in splice bilateral alignment edge-kneading welding connection. The walls of the tap water heat absorption pipes are punched and inwardly flanged. The tap water communication pipes are inserted in the punches of the tap water heat absorption pipes. The port edges of the tap water communication pipes and the punched inward flanges of the tap water heat absorption pipes are in splice bilateral alignment edge-kneading welding connection. Heat supply pipe blocking plates are embedded in the ports of the heat supply pipes. The heat supply pipe blocking plates are outwardly flanged. The outward flanges of the heat supply pipe blocking plates and the port edges of the tap water heat absorption pipes are in splice alignment edge-kneading welding connection. According to the pipe communication splice welding pressure-bearing type heat exchanger disclosed by the invention, two technical defects of higher water leakage ratio of the welding line and incapability of continuously producing hot water of the original patent product can be solved; and the heat exchanger has the advantages of no leakage and continuous hot water production.

Owner:张伟

Header cold water pipe open communication heat absorption heat exchanger and manufacturing process thereof

ActiveCN102927604AReduce cloggingReduce heat lossLighting and heating apparatusSpace heating and ventilation detailsWater channelMetallic materials

The invention discloses a header cold water pipe open communication heat absorption heat exchanger and a manufacturing process of the header cold water pipe open communication heat absorption heat exchanger. The header cold water pipe open communication heat absorption heat exchanger at least comprises two heat supply pipes, wherein two ends of the heat supply heats are respectively welded with a header, at least one cold water channel is arranged inside a heat supply pipe cavity, ports at two ends of the cold water pipe channel are communicated in open cavity mode, and deposited scales in a cold water pipe can be conveniently cleaned by poured acid liquor. The cold water pipe stores water and absorbs heat, effective heat sources can be fully utilized, the heat is quickly absorbed through multiple dividing walls, the heat is transmitted in step mode, a heat absorption area is enlarged, and due to the fact that water is stored in the headers, the length of flow path of cold liquor is increased, the time of heat exchange is prolonged, heat loss is reduced, and heat exchange efficiency is improved. Longitudinal or transverse flexible installation is achieved by reasonable utilization of space, requirements of users can be met, materials are saved, and production cost is reduced. Product quality is stable and reliable, and service life is prolonged. The same kind of metal material is adopted, the weight is light, transportation is convenient, and logistics transportation cost is saved.

Owner:ZAOZHUANG LINENG WATER HEATER FACTORY

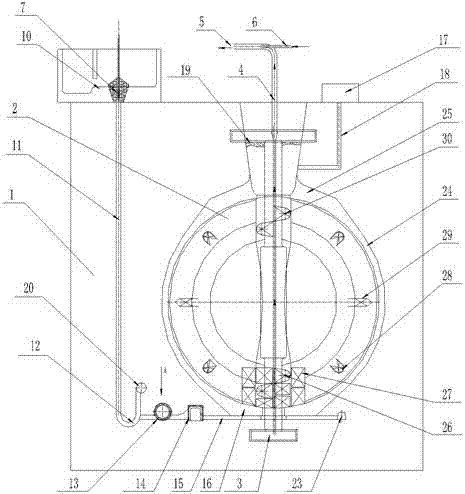

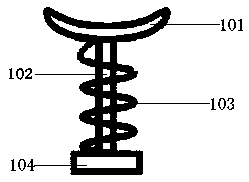

Humidifier

ActiveCN108413543APrevent leakageImprove securityLevel controlLighting and heating apparatusWater storageNebulizer

The invention provides a humidifier. The humidifier comprises a machine seat, a water tank, a water storage chamber, an atomizer, a mist-out channel and a water-out control device. The water tank is provided with a water outlet. The water storage chamber is arranged on the machine seat and is provided with the atomizer, and the mist-out channel discharges the mist generated by the atomizer out ofthe humidifier. The water-out control device is used for controlling opening and closing of the water outlet so that the water in the water tank can enter the water storage chamber. The humidifier further comprises an outer wrapping body, wherein the upper portion of the outer wrapping body is open to prevent the water from being leaked out, the water tank is separately arranged in the outer wrapping body, and the lowest point at the upper end of the outer wrapping body is higher than the highest water level of the water leaked out of the water tank. The humidifier has the following advantagesof being stable as a whole, being capable of preventing water leakage, convenient to detach and clean, high in fan efficiency, firm in structure, high in insurance, high in safety coefficient, convenient to operate, clean and tidy and high-end in appearance and optimal in performance.

Owner:FOSHAN JINXINGHUI ELECTRICAL APPLIANCE

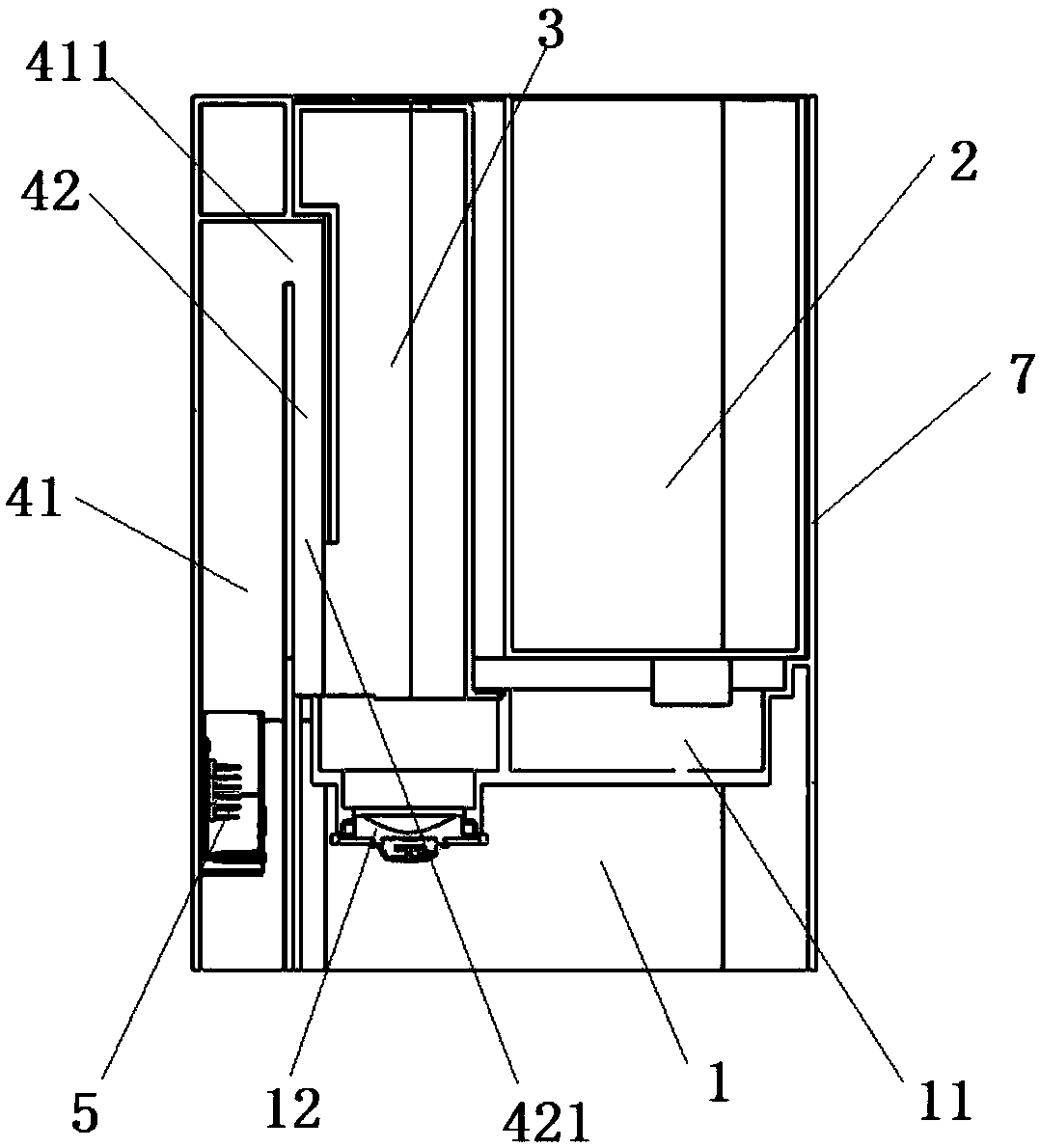

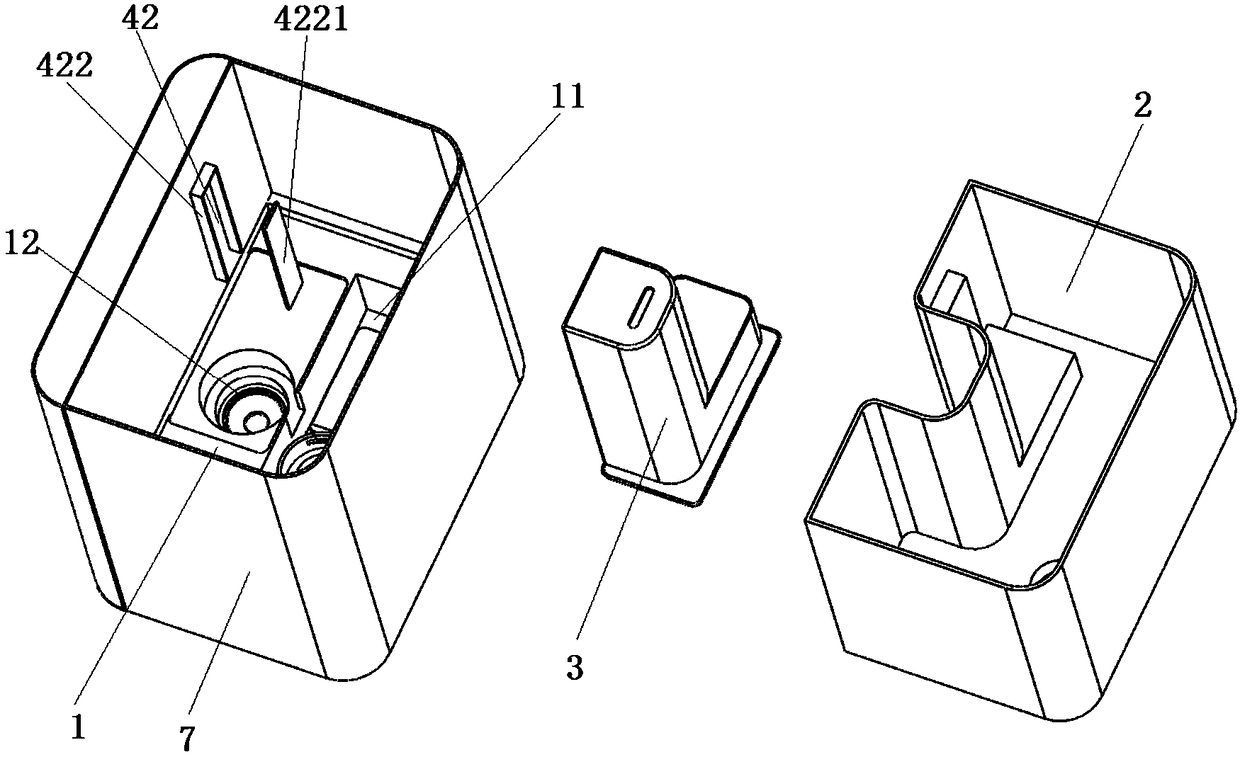

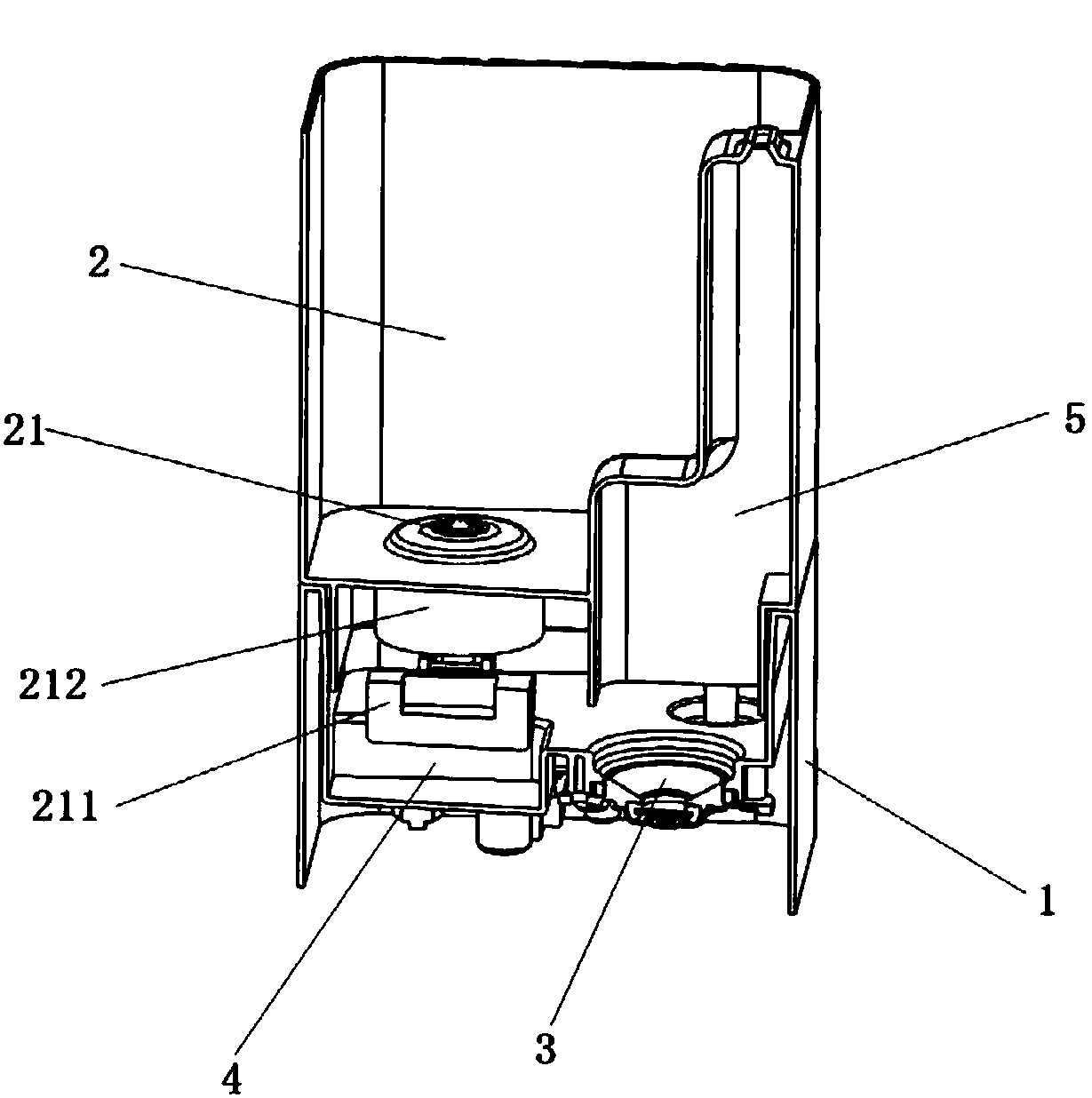

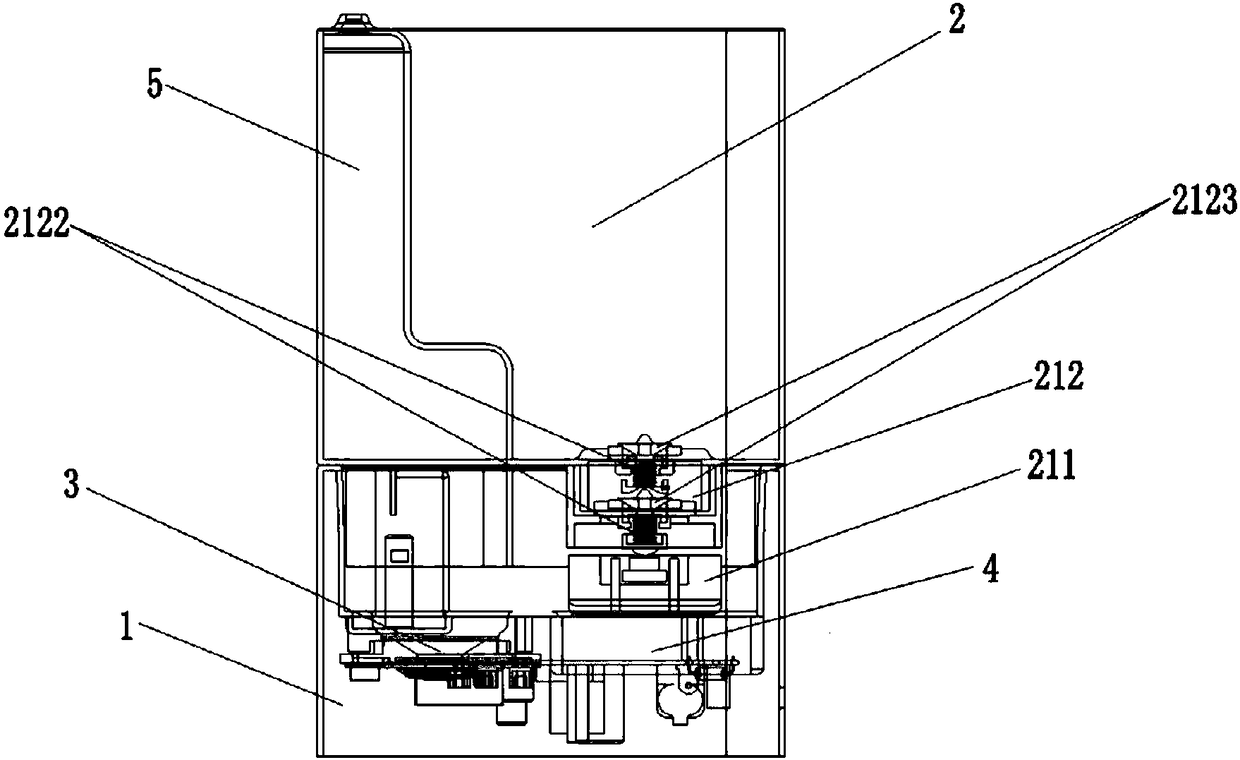

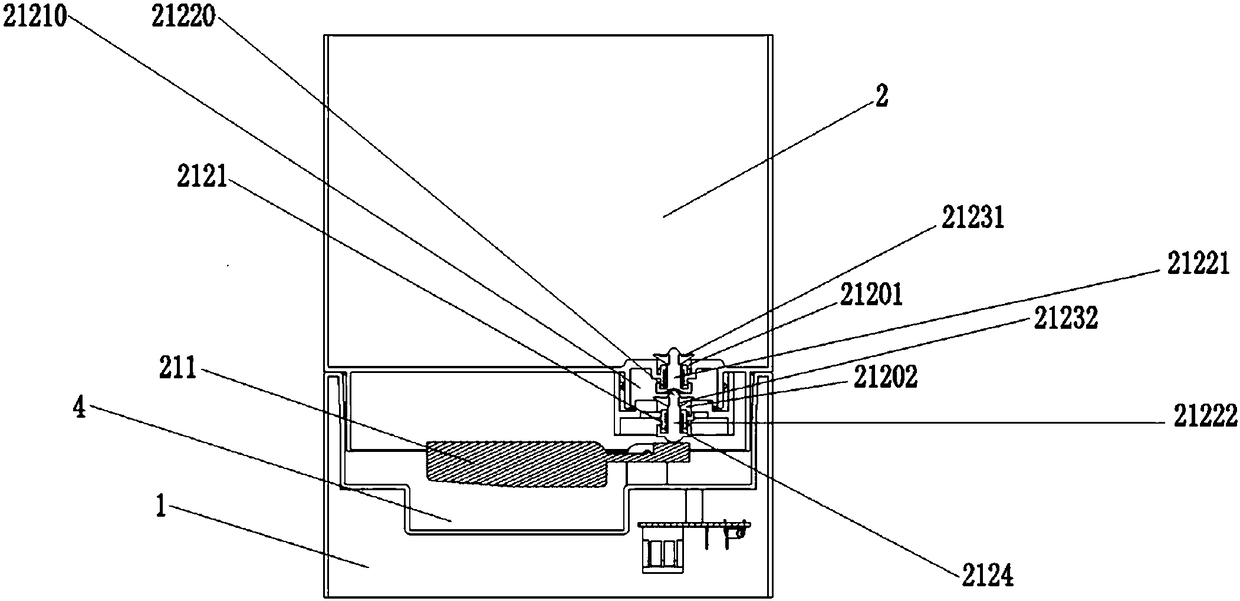

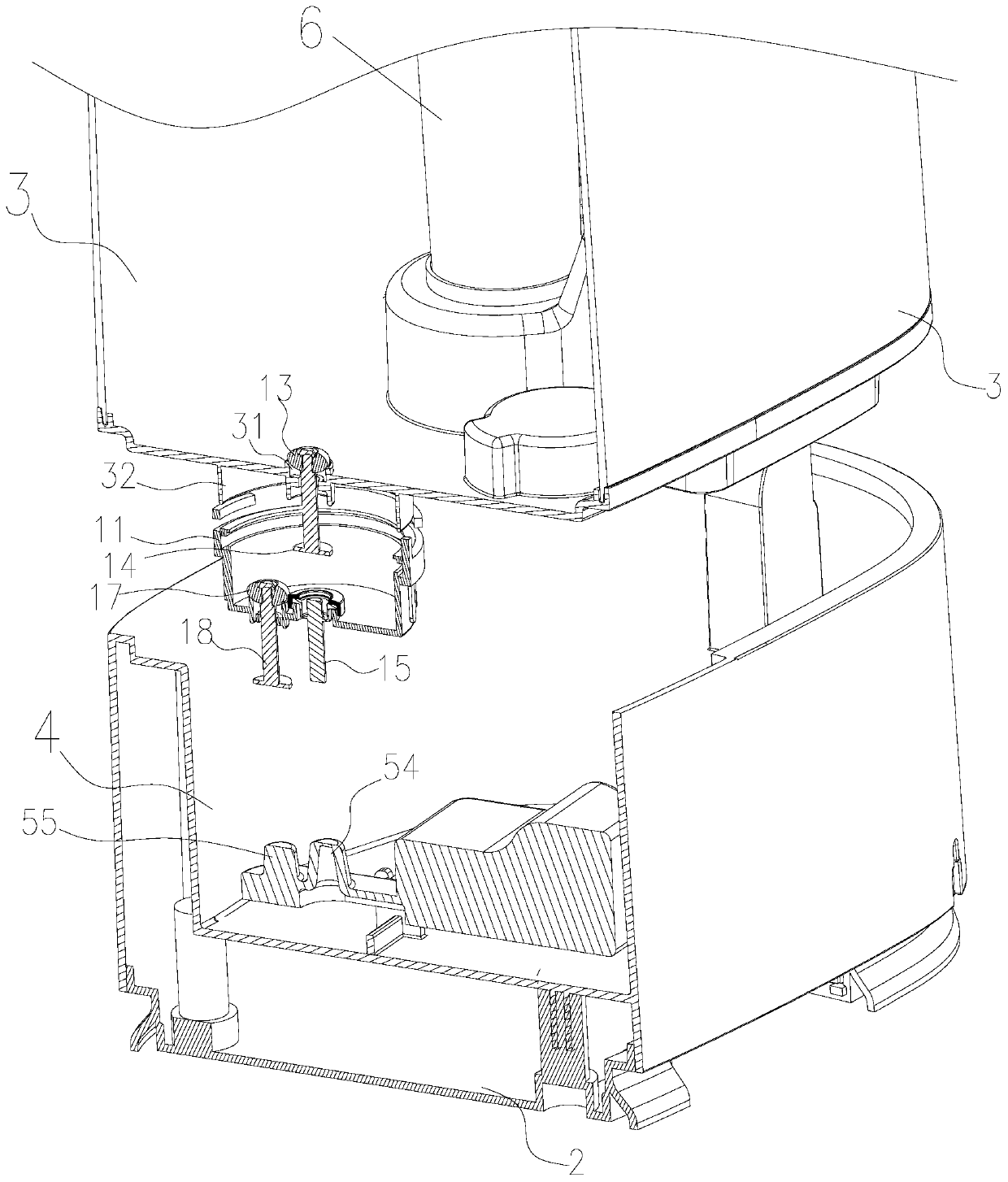

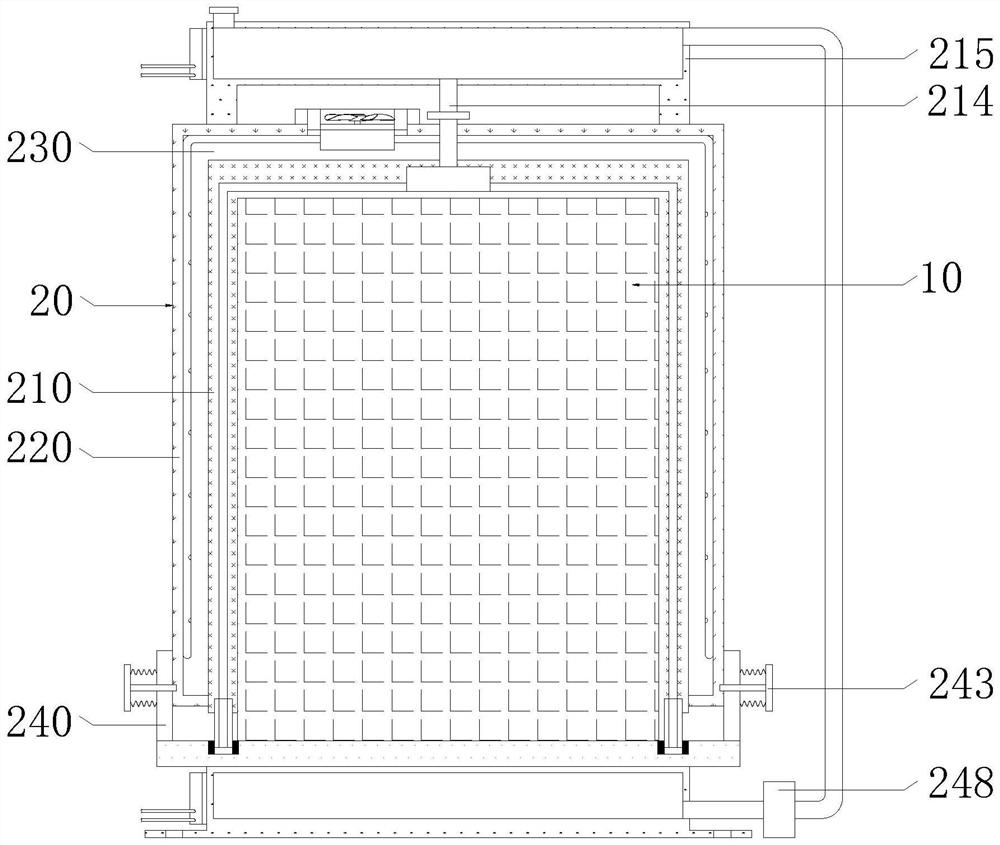

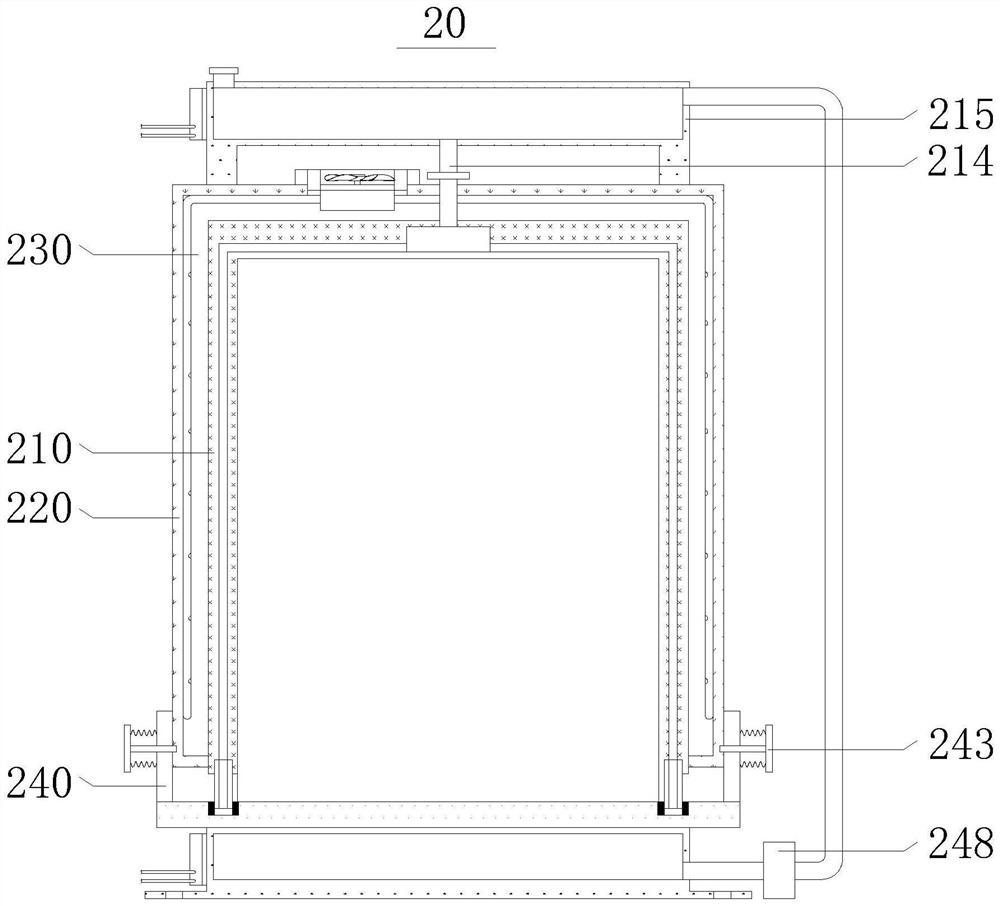

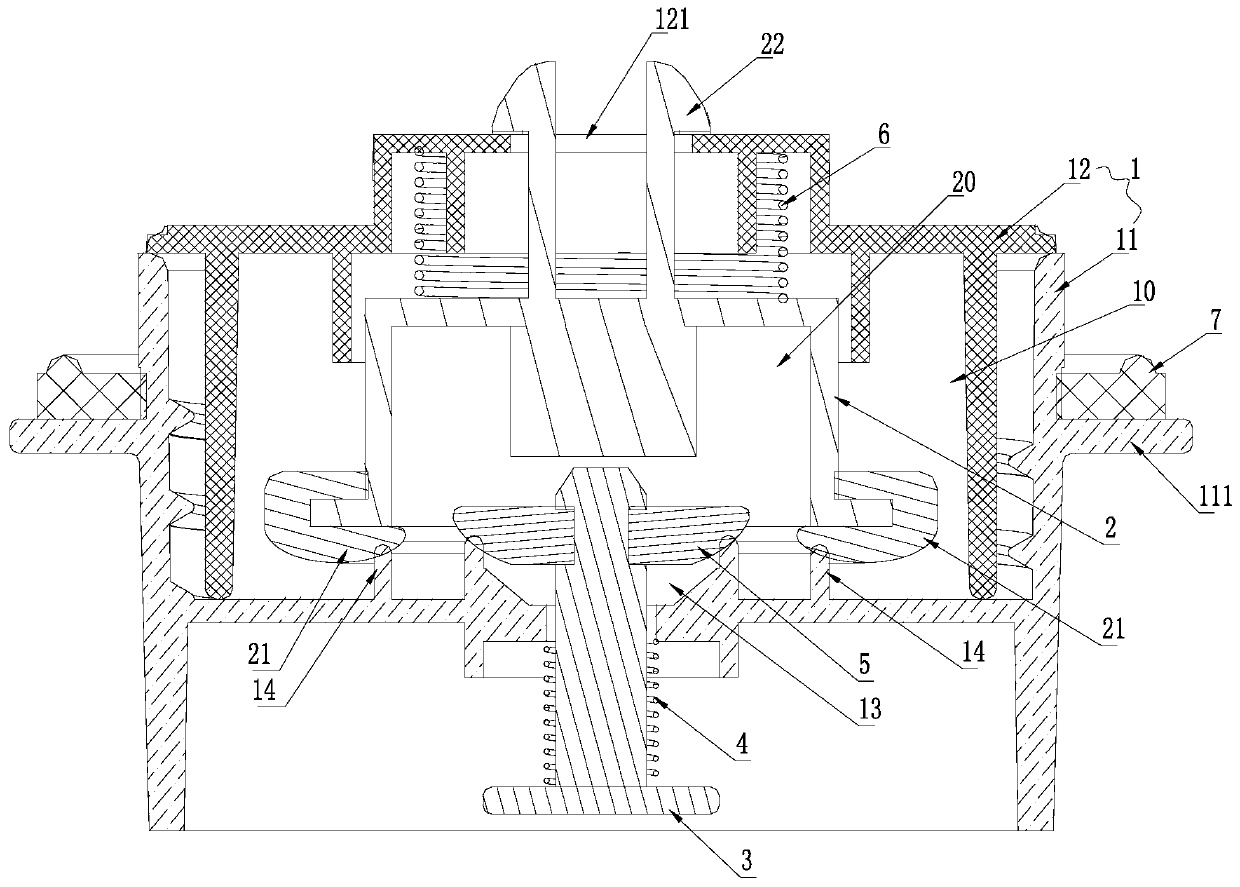

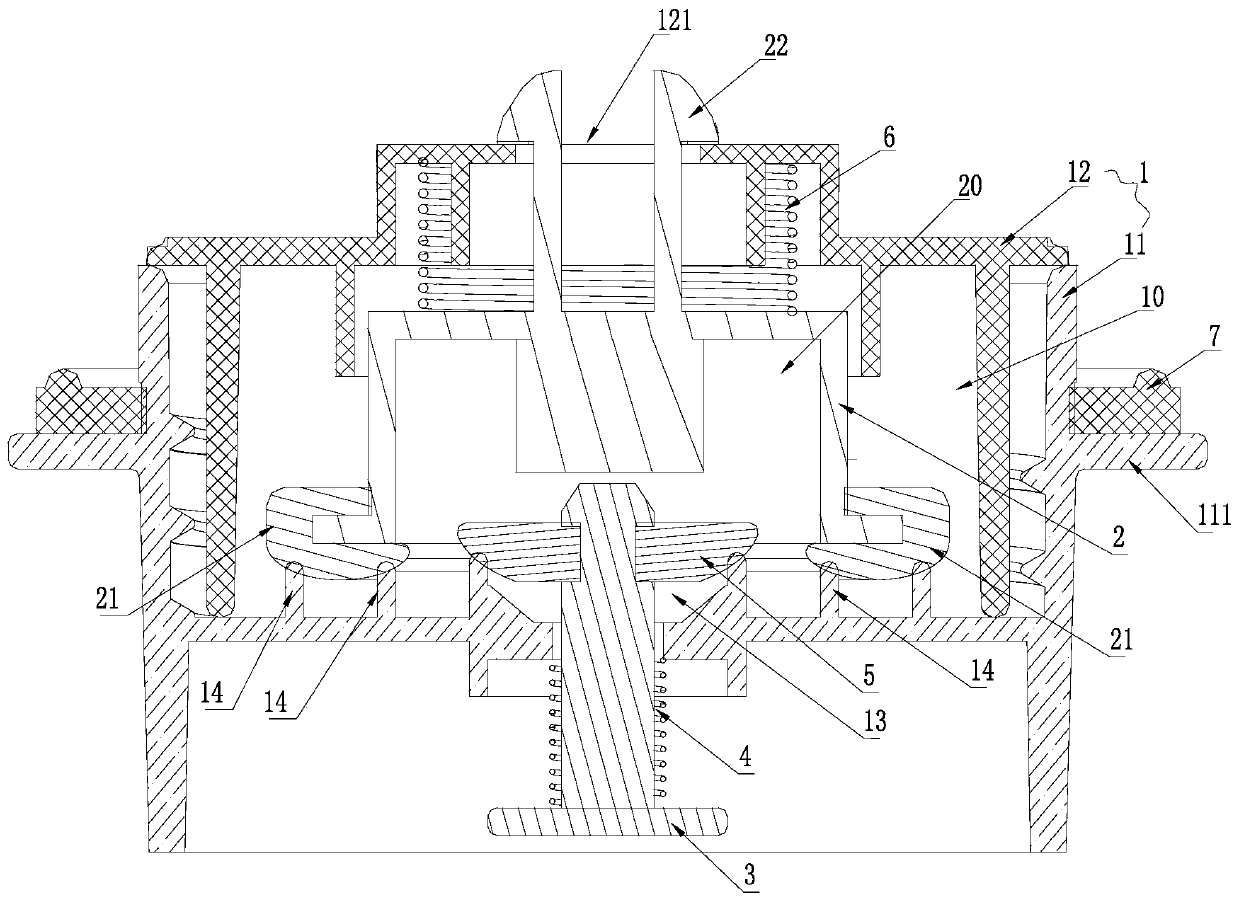

Humidifier with double-valve structure

ActiveCN108253572AReduce the probability of water leakageImprove securityLighting and heating apparatusEfficient regulation technologiesWater leakageWater discharge

A humidifier with a double-valve structure comprises a base, a water tank, an atomization device, a water accumulation chamber and a mist outlet channel. The water accumulation chamber is arranged onthe base and provided with the atomization device. Mist generated by the atomization device is discharged out of the humidifier through the mist outlet channel. A water discharging port is formed in the water tank and provided with a water discharging control device. The water discharging control device comprises a detection and drive mechanism and a water discharging part. The water discharging part is arranged at the position of the water discharging port. The water discharging part is provided with a first water outlet hole and a second water outlet hole which are connected in series. The first water outlet hole and the second water outlet hole are provided with valves correspondingly, the valves act according to signals generated by the detection and drive mechanism and open or close the first water outlet hole and the second water outlet hole, and the valves independently close the first water outlet hole and the second water outlet hole. Compared with the prior art, the providedhumidifier with the water discharging part structure has the following beneficial effects that the water leakage probability is reduced, security is high, the safety coefficient is high, and performance is better optimized.

Owner:FOSHAN JINXINGHUI ELECTRICAL APPLIANCE

Method for casting copper alloy butterfly valve plate

The invention relates to a method for casting a valve plate, and particularly relates to a method for casting a copper alloy butterfly valve plate, aiming at mainly solving the technical problems of shrinkage porosity and slag eye generation when vertical casting of the copper alloy butterfly valve plate is adopted in the prior art. The method comprises the following steps: firstly, plugging a graphite drawing plug for preparation, pouring copper water in a baffle-type pouring cup, then pulling the plug so that copper water enters a mold cavity of a casting body through a gate sprue, a U-shaped gate sprue base, a steel plate filter screen, a ceramic filter screen, a transverse sprue and a flow gate, turning a pouring ladle to a dead head sprue when the copper liquid flows to a position higher than the casting body by 80mm, covering with a heat preservation exothermal agent immediately after casting, loosening screws 10 hours after the casting to release part stress, and opening the box 20 hours after the casting to obtain the copper alloy butterfly valve plate.

Owner:浙江元鼎船舶设备有限公司

Heat exchanger with open-type, communicated and heat-absorbing cooling water pipe

ActiveCN102914187AReduce difficultySolve technical problems of fatigue lifeStationary conduit assembliesHeat exchanger casingsWater storageEngineering

The invention discloses a heat exchanger device with a open-type, communicated and heat-absorbing cooling water pipe, which can be used not only for heating and heat radiation, but also for replacing bathing hot water. The heat exchanger has a compact structure and is simple in manufacturing technique; water storage communicated flow splitting chambers are respectively arranged in sealing heads at two ends of each heating pipe; the inner chambers of the heating pipes and the water storage communicated flow-dividing chambers are isolated by welding separating walls; at least one cooling water pipe penetrates each heating pipe; mouths of two ends of each cooling water pipe are arranged on the corresponding separating walls and communicated with the water storage communicated flow-dividing chambers; the mouths of two ends of each cooling water pipe are communicated with the water storage communicated flow-dividing chambers in an open manner, so as to bring convenience for filling acid liquor to clean deposited dirt in the cooling water pipes; the cooling water pipes can be used for water storage and heat absorption, and the effective heat source can be fully utilized; dividing walls can quickly absorb heat; the heat is transferred in a stepped manner to increase the heat-absorbing area; and the cooling water, which is stored in the water storage communicated flow-dividing chambers, is used for heat absorption. According to the invention, as the water is stored in the device, the process length of the cold fluid is increased, the heat exchange time is prolonged, the heat loss is reduced, the heat exchange efficiency is improved, and the manufacturing cost is reduced.

Owner:ZAOZHUANG LINENG WATER HEATER FACTORY

Solar flat-plate collector adopting electric tracing bands for auxiliary heating

InactiveCN105135704ARealize the heating effectHeating up fastSolar heating energySolar heat devicesWater leakageInsulation layer

The invention discloses a solar flat-plate collector adopting electric tracing bands for auxiliary heating. The solar flat-plate collector comprises a casing, wherein heat insulation layers are arranged in the casing, a light-transmitting cover plate is arranged on the casing, a cavity is formed between the light-transmitting cover plate and the heat insulation layers, a heat collecting plate is arranged in the cavity, a pipe bank is arranged on the heat collecting plate, the heat collecting plate comprises a front side and a back side, the front side of the heat collecting plate faces the light-transmitting cover plate, a coating absorbing solar energy is arranged on the surface of the font side of the heat collecting plate, and the electric tracing bands are arranged on the back side of the heat collecting plate. The electric tracing bands are arranged on the back side of the heat collecting plate and have the fast heating effect, and water in the pipe bank of the heat collecting plate can be rapidly heated through heat transmission; holes in a water storage tank or the pipe bank are not needed, so that the water leakage probability of the equipment is reduced, and meanwhile, the safety problem caused by electric leakage of the equipment is reduced; the heat collecting plate or the pipe bank is directly heated, the problem that water in the pipe bank is frozen and expands in cold weather to damage the pipe bank can be effectively solved, and the solar flat-plate collector adopting the electric tracing bands for auxiliary heating has the advantages of simplicity in operation, safety and reliability in use and long service life.

Owner:吕延成

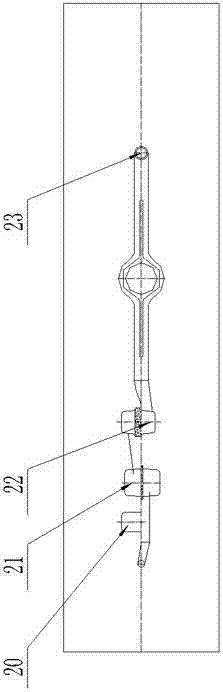

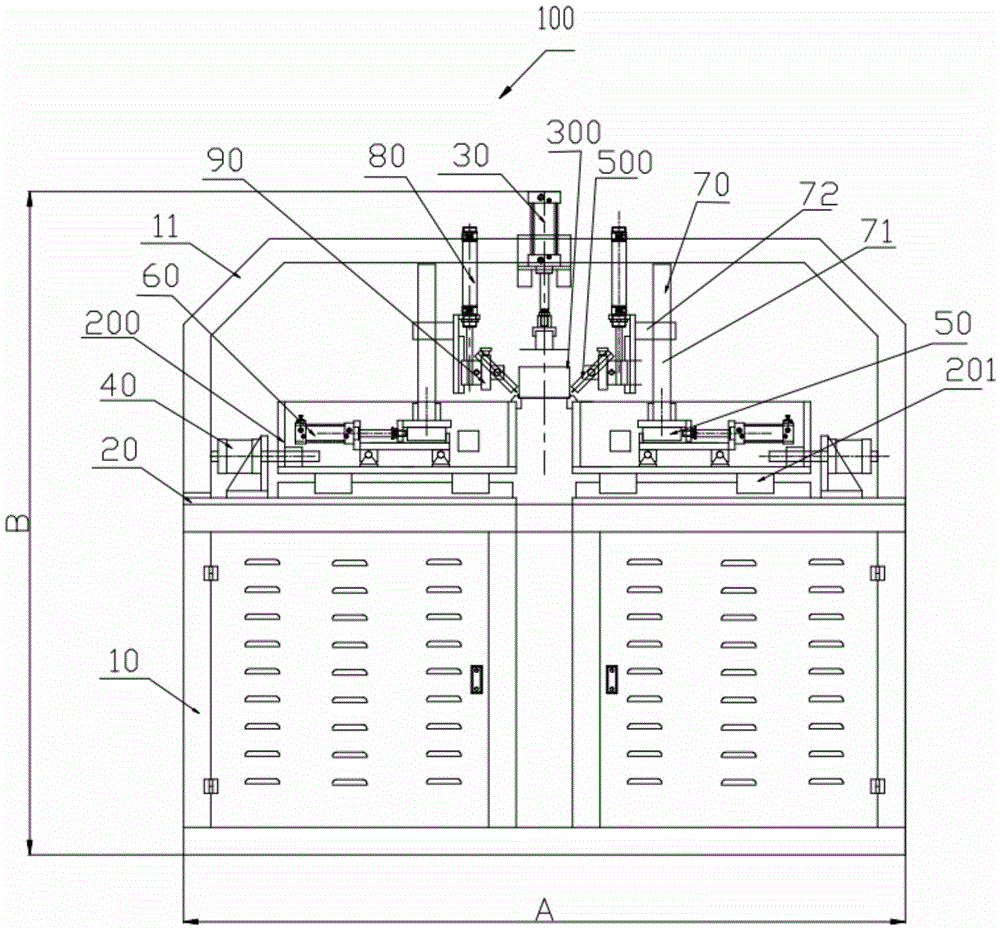

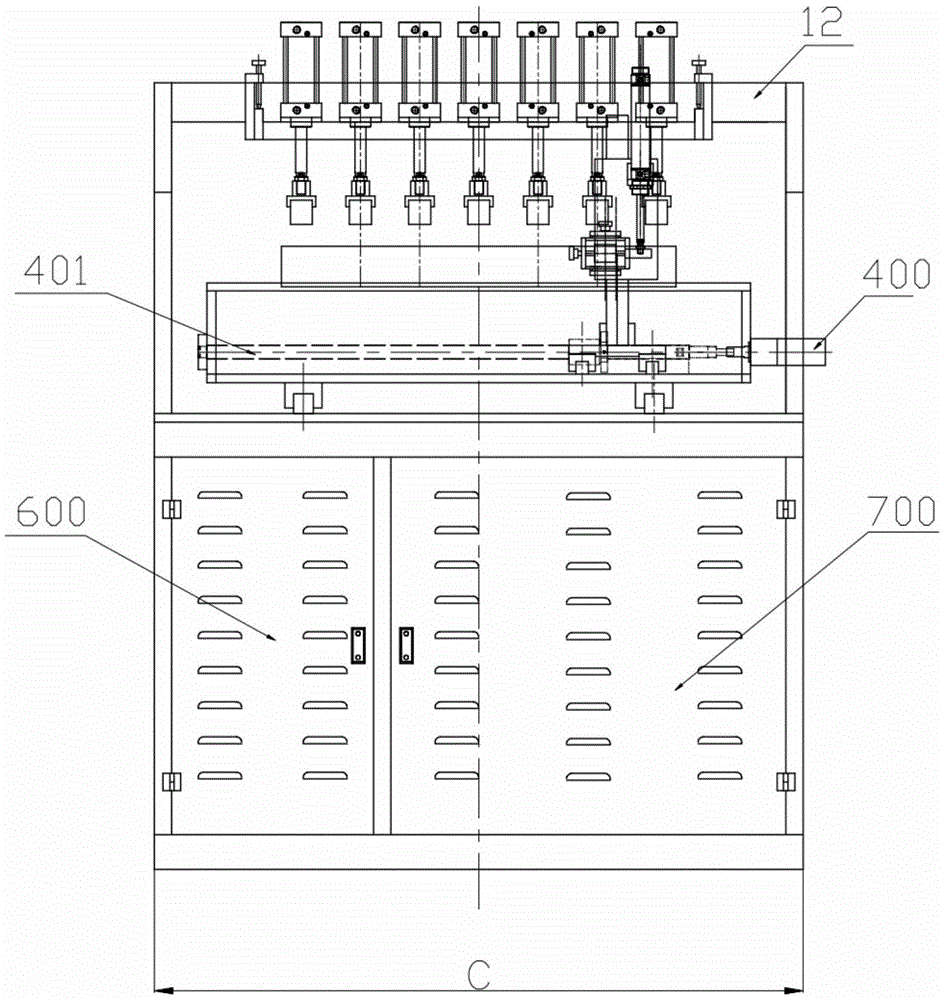

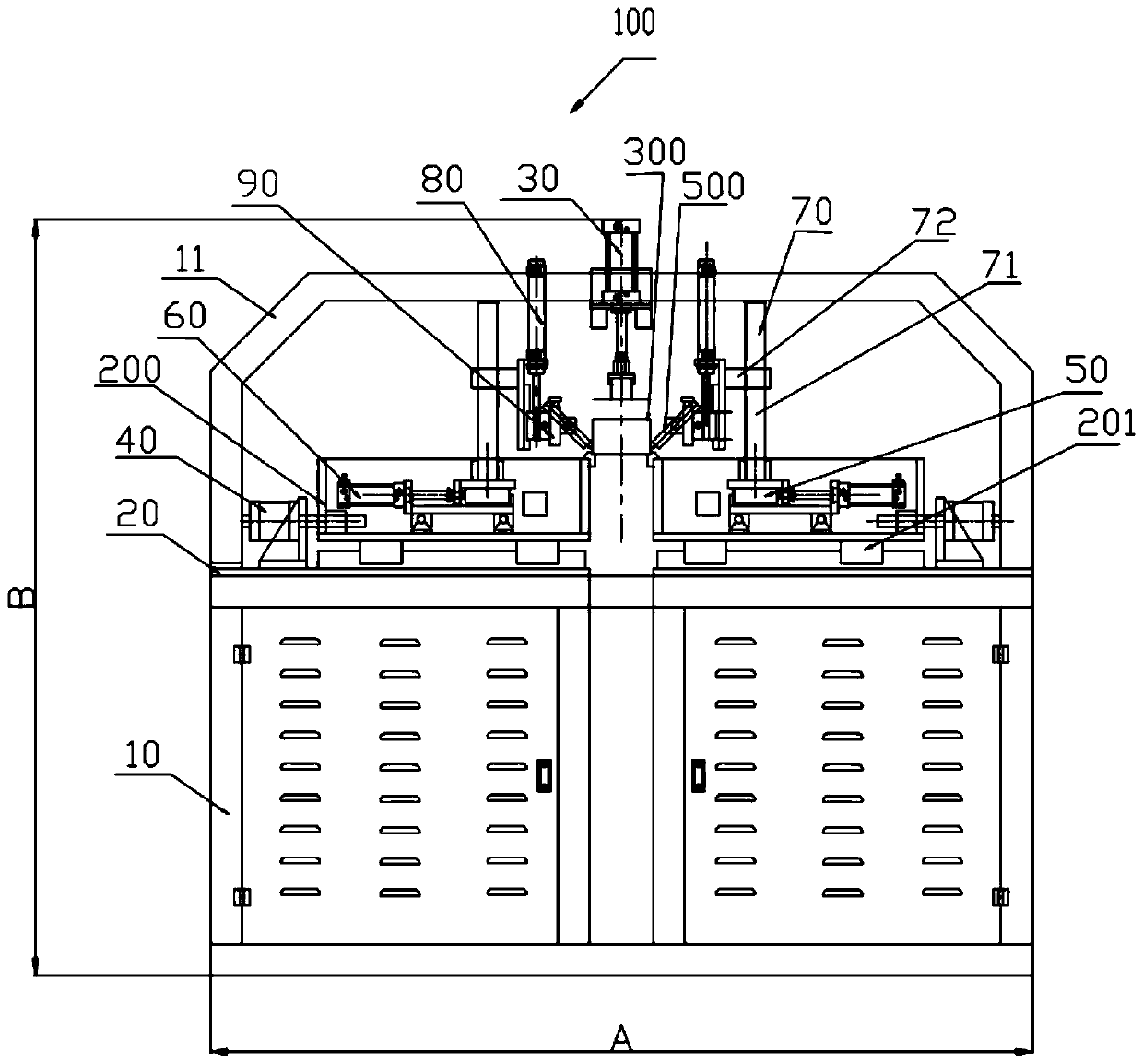

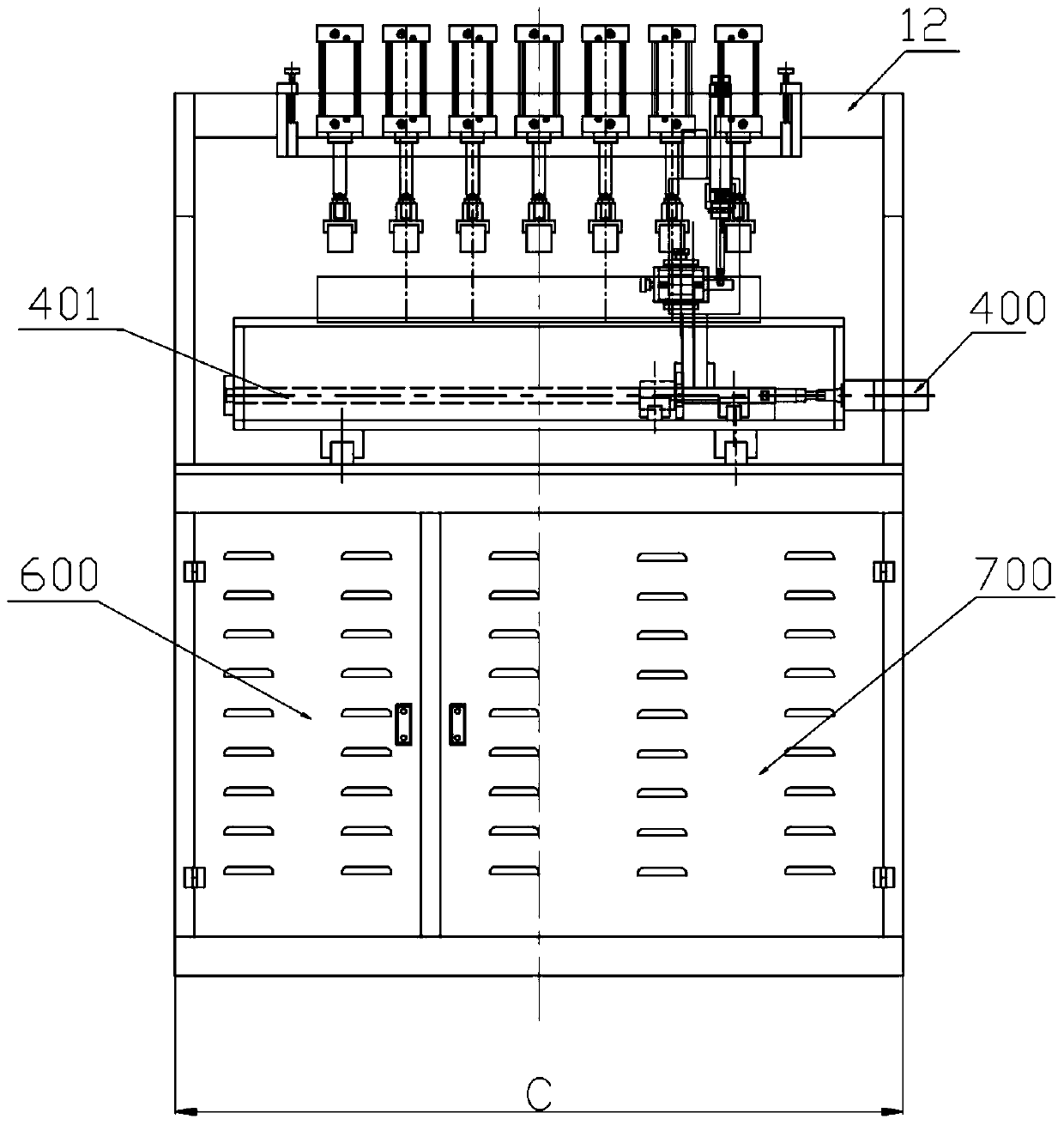

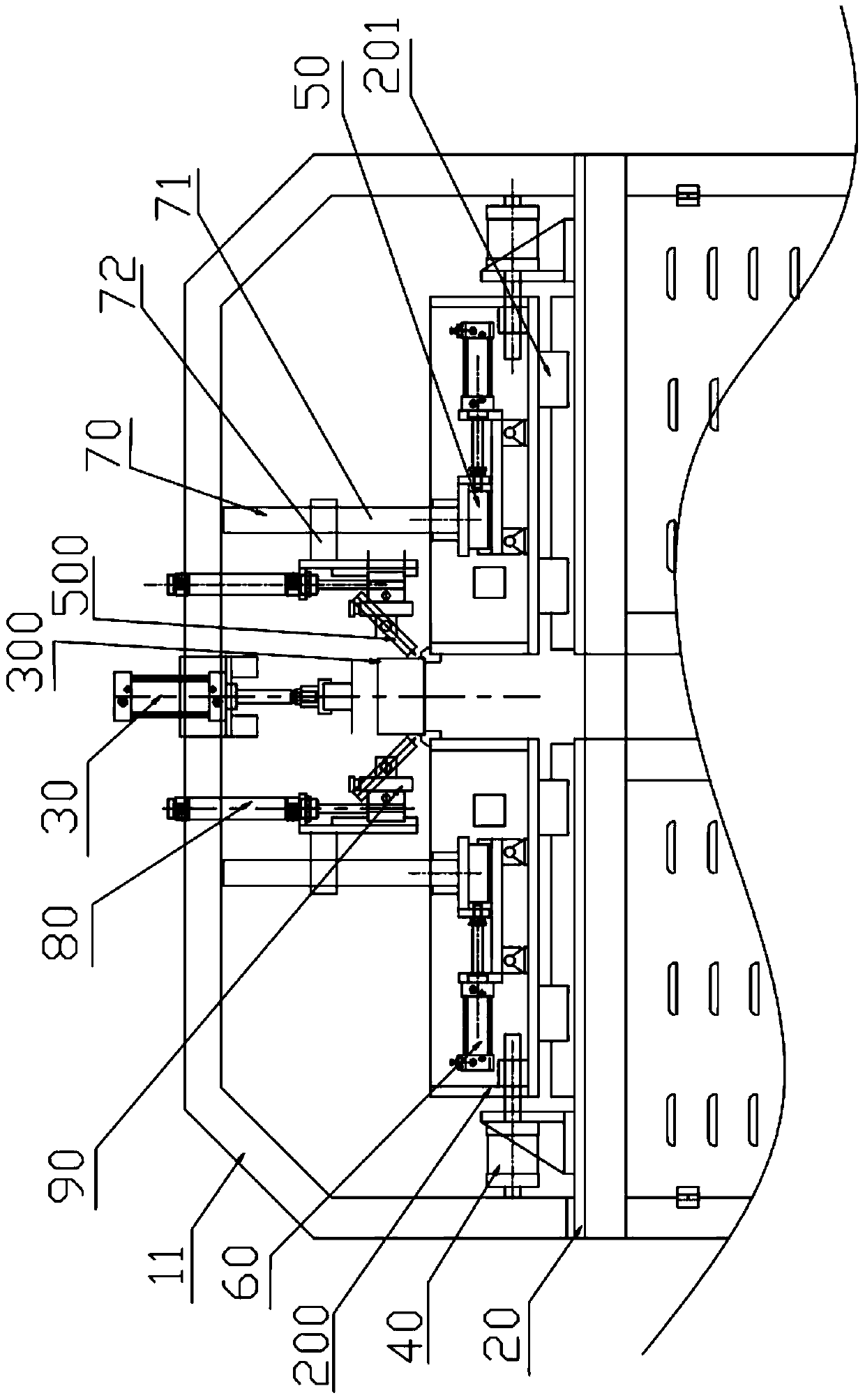

Welding device

ActiveCN105458468AReduce the probability of water leakageImprove welding efficiencyWelding/cutting auxillary devicesElectrode holder supportersEngineeringElectric control

The invention discloses a welding device which comprises a machine frame. The machine frame is provided with an electric control cabinet and an operation table arranged at the top end. The top side of the operation table is fixedly provided with a first positioning cylinder for positioning a first workpiece to be welded. The two sides of the operation table are each provided with a guide rail which extends in the longitudinal direction and is used for containing a second workpiece to be welded. The outer side of each guide rail is provided with a second positioning cylinder for positioning the second workpiece to be welded. The two guide rails are each provided with a shifting guide rail capable of moving in the longitudinal direction. A welding gun fixing support is arranged at the top end of each shifting guide rail. A welding gun is fixed to each welding gun fixing support. When the shifting guide rails move in the longitudinal direction at the certain speed according to set parameters of the electric control cabinet, the welding gun fixing supports drive the welding funs to move longitudinally, and then the welding guns weld the first workpiece to be welded and the second workpiece to be welded according to the set parameters of the electric control cabinet. The welding device is provided with the two welding guns, so that welding of radiators is performed at the same time, the welding efficiency and quality are improved, welding beads are uniform, and the appearance is attractive.

Owner:JIANGXI XINTIAN AUTO IND

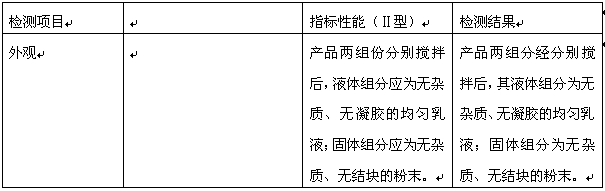

II-type polymer cement waterproof coating and preparation method thereof

InactiveCN108409262AExcellent tensile strengthExcellent elongation at break indexEmulsionNational standard

The invention discloses an II-type polymer cement waterproof coating and a preparation method thereof. The coating comprises mixed liquid and mixed powder according to the weight part ratio of 90-110:140-160, the mixed liquid comprises the following raw materials in parts by weight: elastic waterproof emulsion, water, a defoamer and a sterilizing agent according to the weight ratio of 90-110: 8-18: 0.15-0.25: 0.08-0.16; and the mixed powder comprises the following raw materials in parts by weight: 32.5 cement, 800-mesh ground calcium carbonate, 40-120-mesh silica sand and a water reducing agent according to the weight part ratio of 90-110: 90-110: 90-110: 0.8-2. Fifteen physical and mechanical properties of a polymer cement waterproof coating as claimed in an embodiment of the invention totally pass all stipulations of GB / T23445-2009, and are much higher than the national standard, and after the II-type polymer cement waterproof coating is soaked in water, heated and subjected to alkali treatment, the tensile strength, the index of elongation at break, bonding force and anti-permeability actual measurement index are much higher than those of the product in the prior art.

Owner:马官友

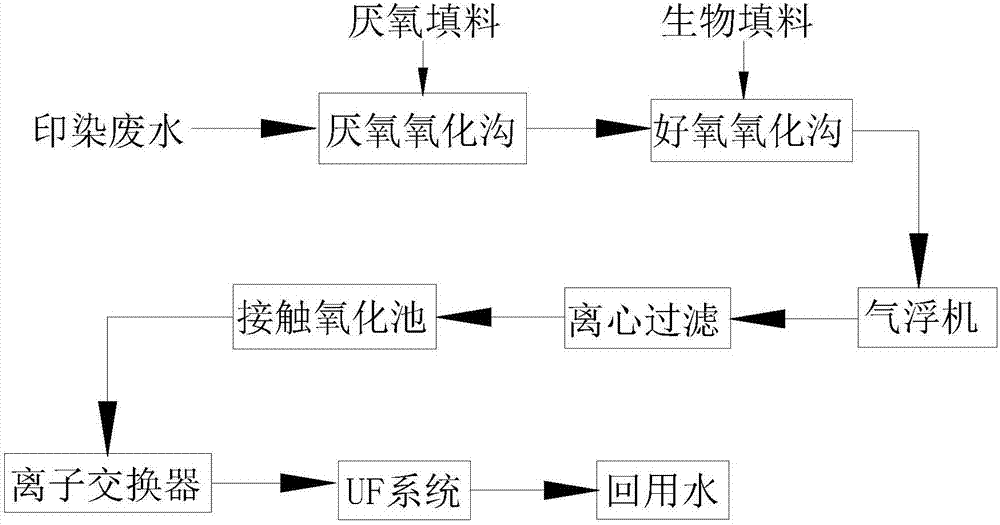

Advanced treatment and reuse method of printing and dyeing waste water

InactiveCN107352740AImprove liquidityReduce dead space porosityWater/sewage treatment by centrifugal separationWater treatment parameter controlFiltrationWater quality

The invention discloses an advanced treatment and reuse method of printing and dyeing waste water. The printing and dyeing waste water sequentially passes an anaerobic oxidation ditch, an aerobic oxidation ditch, an air flotation machine, a centrifugal filtering tank, a contact oxidation tank, an ion exchanger and a UF reaction tank for recovery treatment; when the printing and dyeing waste water enters the anaerobic ditch, anaerobic filler is injected into the anaerobic oxidation ditch, an aeration device in the anaerobic ditch acts for 3-5 h, and the mixture is left to stand for 5-8 h to facilitate biofilm culturing of the anaerobic filler and discharged into the aerobic oxidation ditch. An ozone generator in the UF reaction tank can kill bacteria, no energy is consumed in the ultra-filtration process, bacteria, colloid and other substances can be separated, the fault rate and the water leaking probability are relatively low, the structure is simple, the price is low, the printing and dyeing waste water deep treatment problem is effectively solved, indexes including the COD value of water, the pH value, the chroma, SS, total hardness and the like all reach the recycled water reuse standard in the printing and dyeing industry, the investment cost of an enterprise for waste water treatment is reduced, and the burden on the enterprise is reduced.

Owner:张家港市双盈印染有限公司

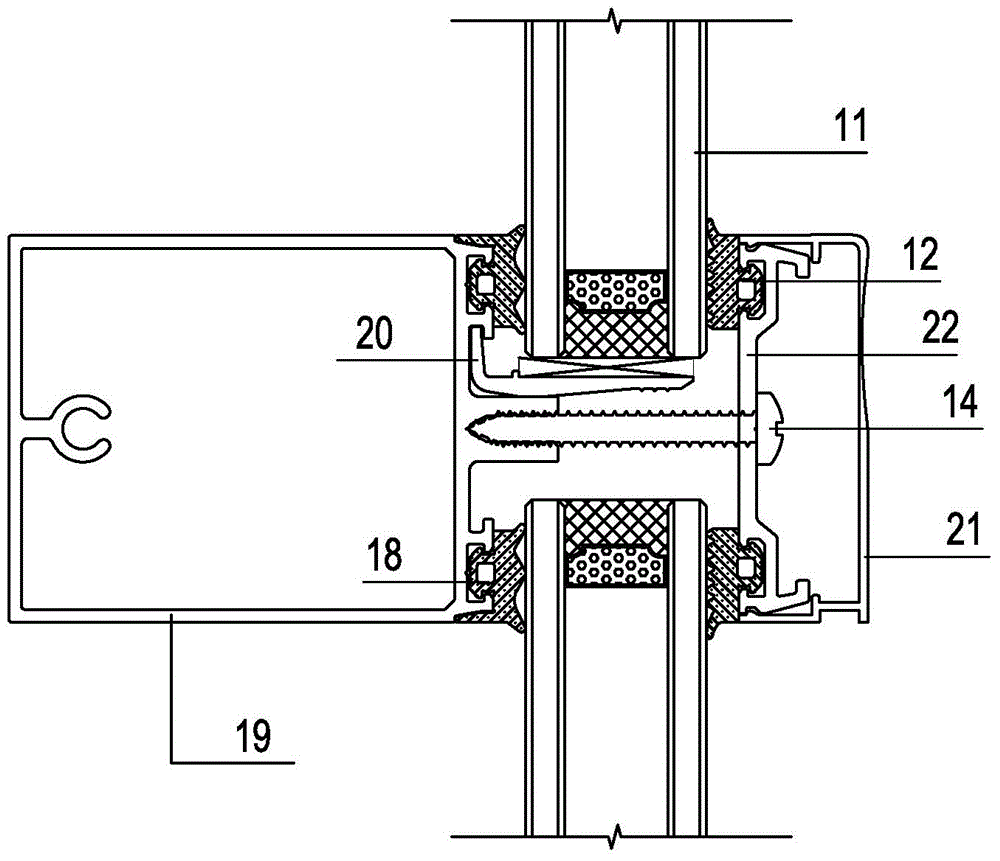

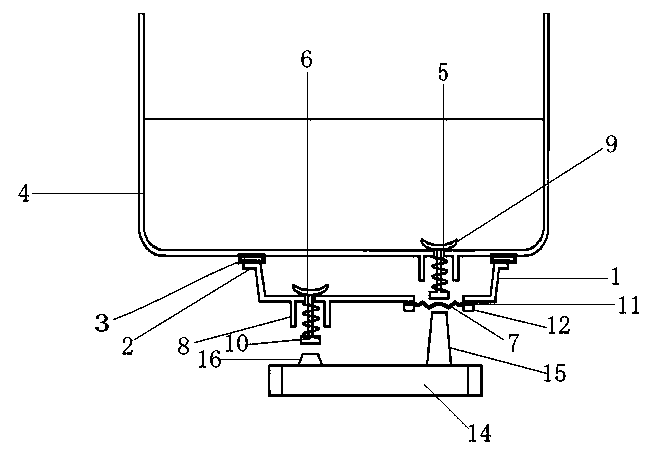

Water tank with dual water valve and humidifier

PendingCN109764465AReduce the probability of water leakageSimple structureMechanical apparatusLighting and heating apparatusEngineeringWater tanks

The invention discloses a water tank with a dual water valve and a humidifier. The water tank comprises a water storing cavity, a first water valve, a water draining cavity, a second water valve and aforce transmission mechanism; the cavity bottom of the water storing cavity is provided with a first water draining channel; the first water is arranged in the first water draining channel; the waterdraining cavity communicates with the first water draining channel, and the cavity bottom of the water draining cavity is provided with a second water draining channel arranged to be not coaxial to the first water draining channel; the second water valve is arranged in the second water draining channel; and the force transmission mechanism is used for controlling a first valve element of the first water valve to enable the first water valve to be opened after the second water valve and closed before the second water valve, and the force transmission mechanism is arranged under the first valveelement. According to the water tank with the dual water valve and the humidifier, the dual water valve structure is adopted, therefore, the dual water draining protection effect can be truly achieved, the water draining sealing effect is greatly improved, and the water leakage probability is extremely low.

Owner:BEAR ELECTRICAL APPLIANCE CO LTD

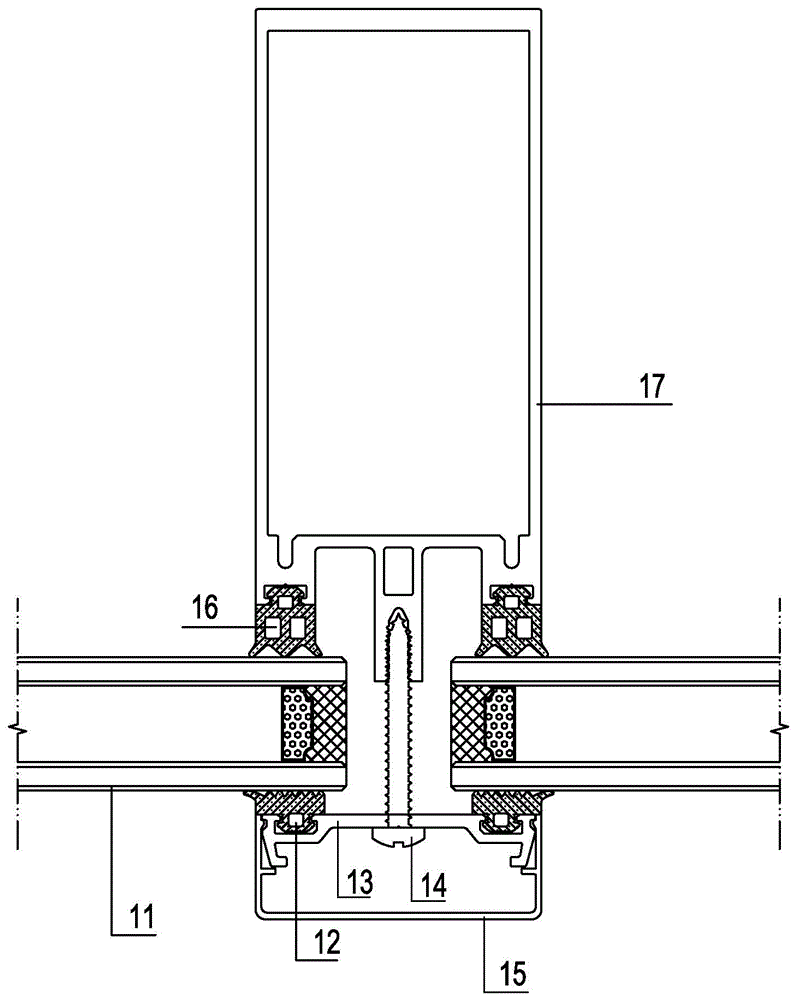

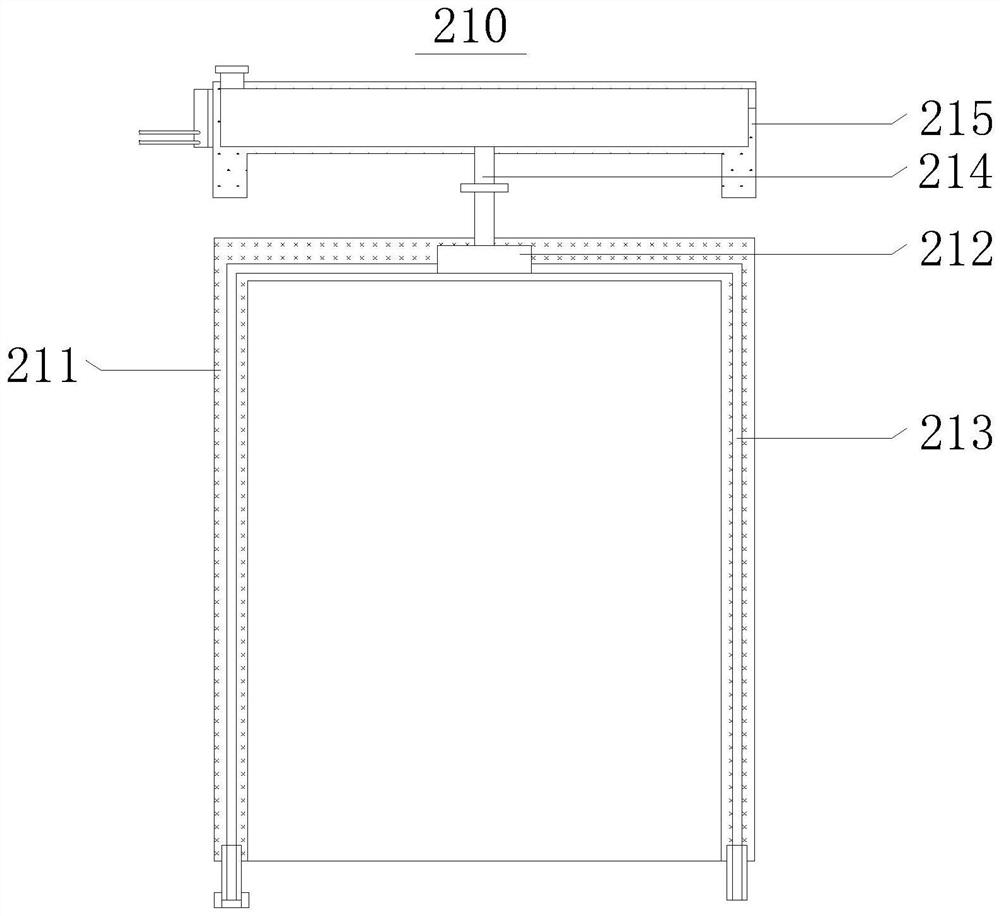

Drainage hopper for exposed frame curtain wall

InactiveCN104878882AExtended service lifeReduce the risk of water leaksWallsRoof drainageWater leakageWater flow

The invention discloses a drainage hopper for an exposed frame curtain wall. The drainage hopper comprises a main body which has a Y-shaped transverse section and is provided with three end parts, wherein the three end parts of the main body include two water inlet ends and one water outlet end; on the upper surface of the main body, a water flow groove which is deepened gradually is formed from each water inlet end to the water outlet end in a depressing way; the water flow grooves form water inlet grooves in the water inlet ends; the water flow grooves form a water outlet through which water can flow downwards in the water inlet end; the main body is provided with a positioning part provided with a positioning hole; the main body is provided with a glue groove; sealing glue injected into the glue groove is filled into a gap between the drainage hopper on a vertical column and the vertical column to enhance the air tightness. By adopting the drainage hopper, water falling from the upper part of the vertical column can be effectively drained outwards, the water leakage risk is lowered, and the service life of the exposed frame curtain wall is prolonged.

Owner:BEIJING JANGHO CURTAIN WALL SYST ENG +1

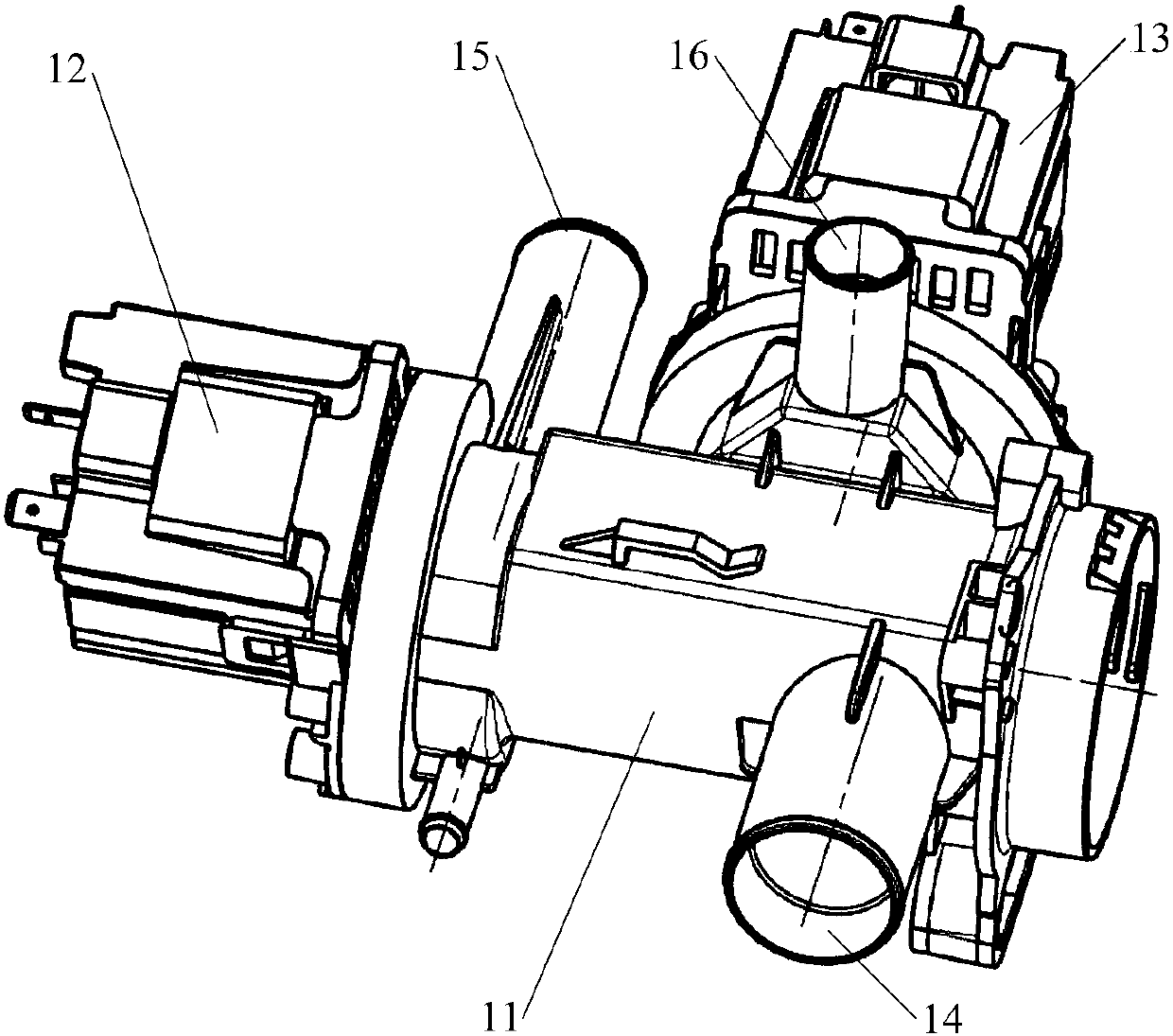

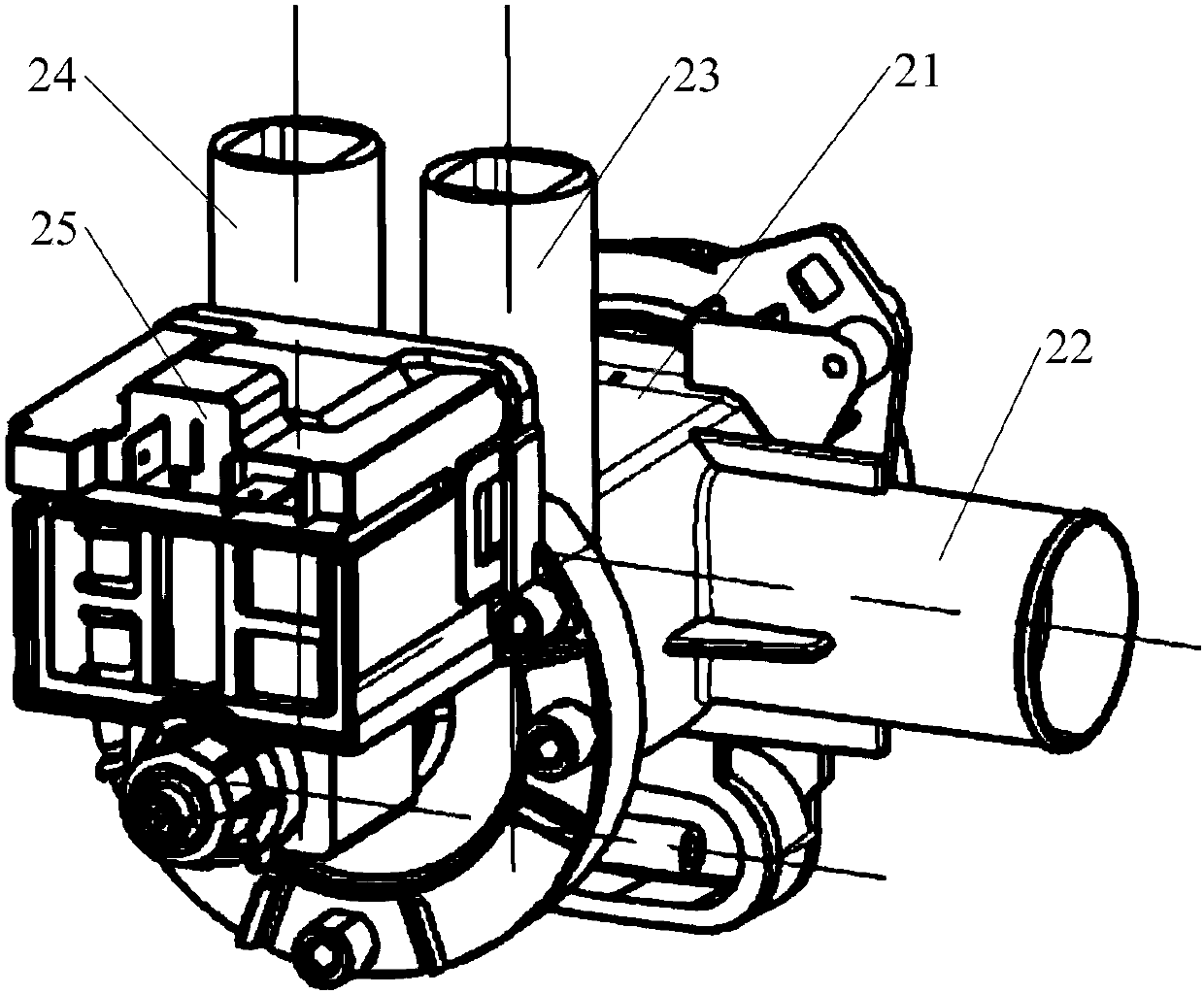

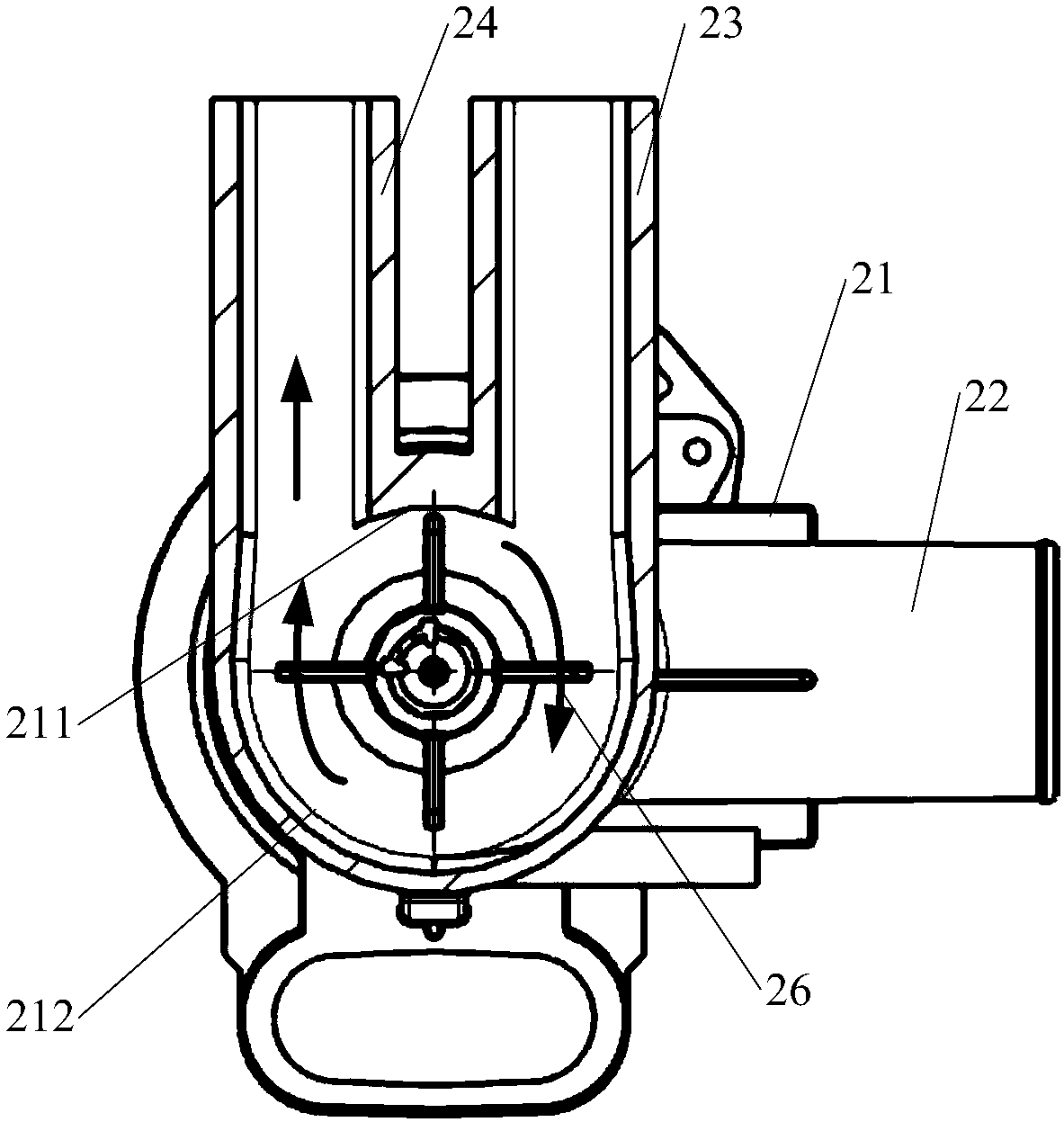

Delivery pump and washing machine

PendingCN107816436ARealize deliveryAchieve net functionPump componentsOther washing machinesImpellerWater leakage

The invention discloses a delivery pump and a washing machine. The delivery pump comprises a pump body, an impeller and a driving part. The pump body is provided with a pump cavity, a water inlet, a water outlet and a circulation water gap, wherein the water inlet, the water outlet and the circulation water gap both communicate with the pump cavity. The impeller is located in the pump cavity. Thedriving part can drive the impeller to rotate forwardly and reversely. When the impeller rotates forwardly, the water inlet, the pump cavity and the circulation water gap are sequentially connected. When the impeller rotates reversely, the water inlet, the pump cavity and the water outlet are sequentially connected. According to the delivery pump disclosed by the invention, drainage of the washingmachine and delivery of circulation water can be achieved through the matching of the impeller and the pump cavity as well as the forward and reverse rotation of the impeller; and due to the fact that only one driving part is required in the delivery pump, cost is effectively reduced compared with the mode that two motors are needed for driving in the prior art. Meanwhile, the size of the whole delivery pump is reduced, so that transportation is facilitated and space occupancy is reduced. The number of positions needing to be sealed is also reduced, the probability of water leakage is loweredand the assembly of the washing machine is correspondingly simplified.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

Engine with heat dissipation and cooling mechanism

PendingCN114562360AReduce water leakageReduce the probability of water leakageInternal combustion piston enginesEngine cooling apparatusThermodynamicsEngineering

The invention provides an engine with a heat dissipation and cooling mechanism, and belongs to the technical field of engines. The engine with the heat dissipation and cooling mechanism comprises an engine body and a heat dissipation and cooling assembly. The heat dissipation and cooling assembly comprises a water-cooled cooling part and an air-cooled cooling cover part, the water-cooled cooling part is attached to the outer wall of a shell of the engine body, the air-cooled cooling cover part is connected to the outer portion of the water-cooled cooling part, and an air draft cavity is formed by the air-cooled cooling cover part and the water-cooled cooling part; the bottom of the air-cooled heat dissipation cover piece is detachably connected with an installation piece. More comprehensive and effective water-cooling heat dissipation can be carried out on the engine body through cooperation of the water-cooled cooling part and the mounting part, and heat dissipation of the engine body can be accelerated through cooperation of the air-cooled heat dissipation cover part and the water-cooled cooling part and the mounting part; and through cooperation of the air-cooled heat dissipation cover piece and the air draft cavity, circulation of air around the engine body can be reduced, and the preheating time of the engine body is shortened.

Owner:广西玉柴船电动力有限公司

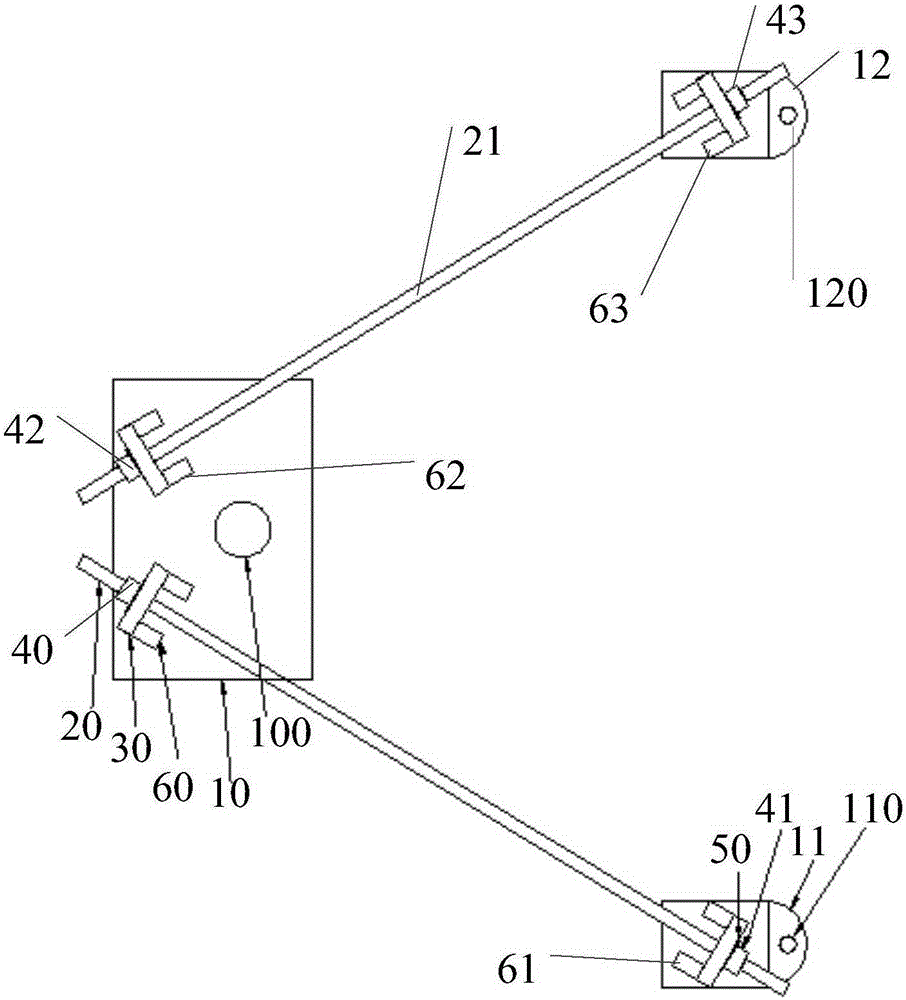

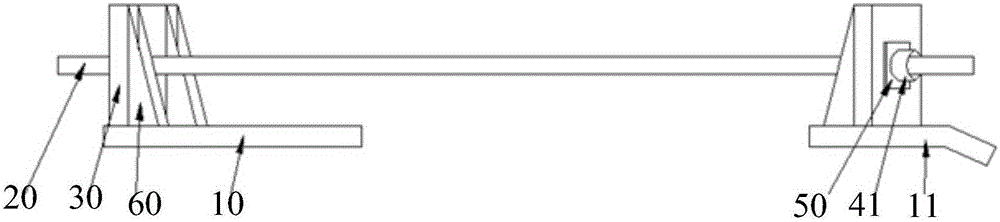

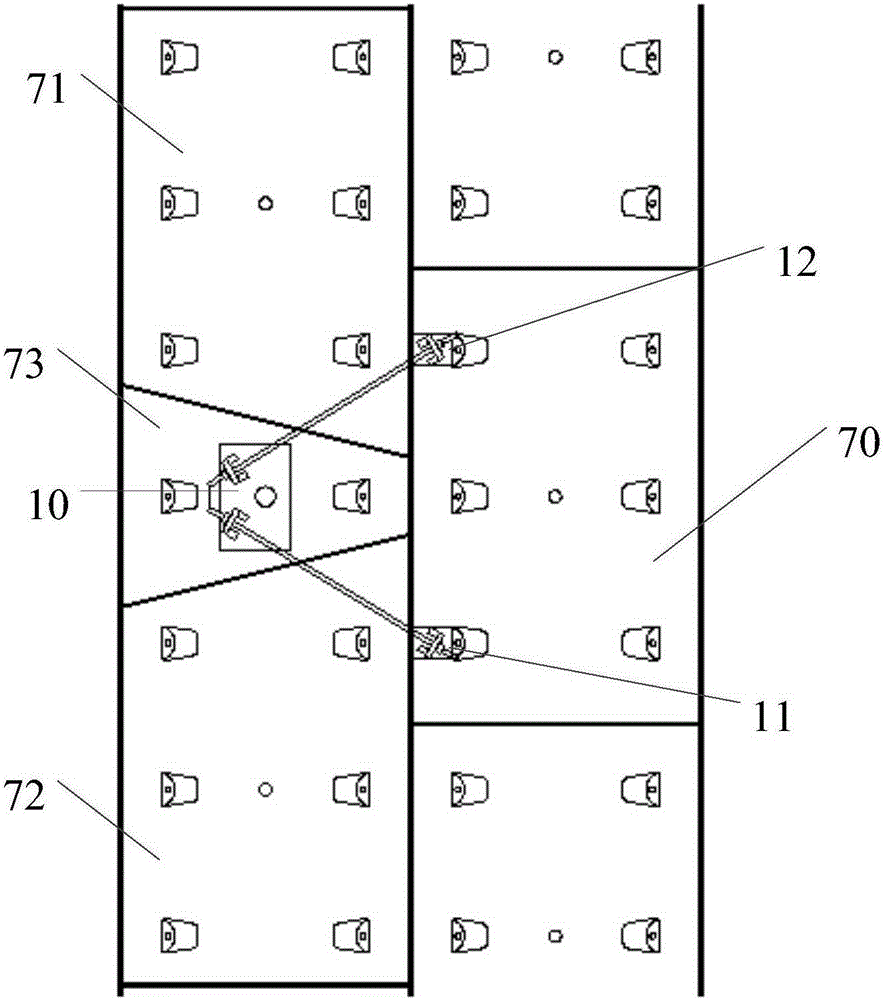

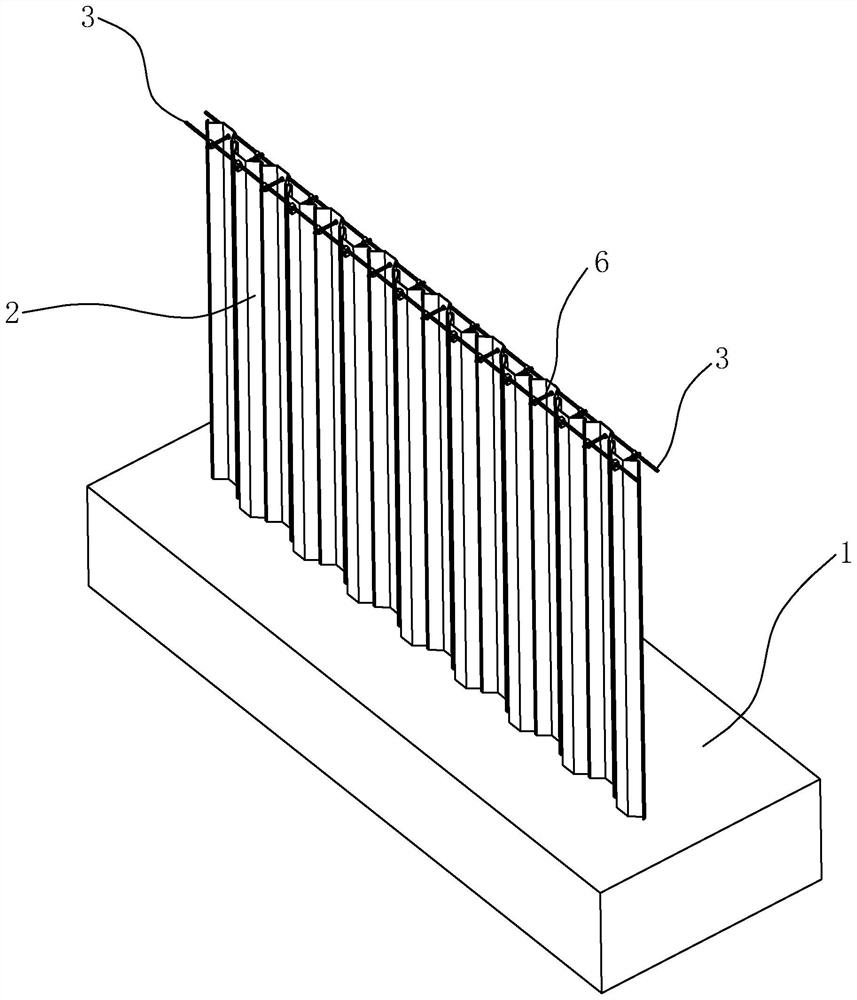

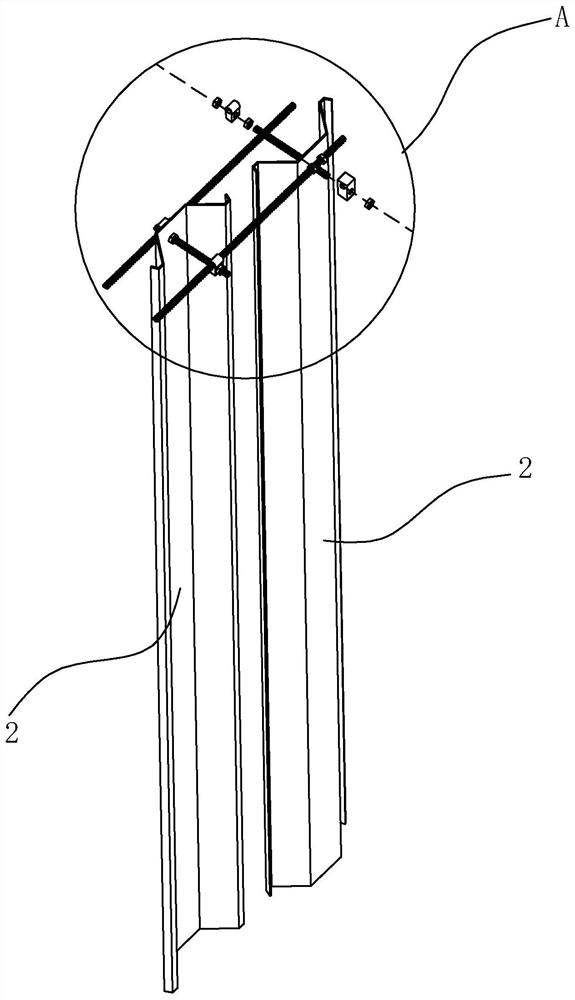

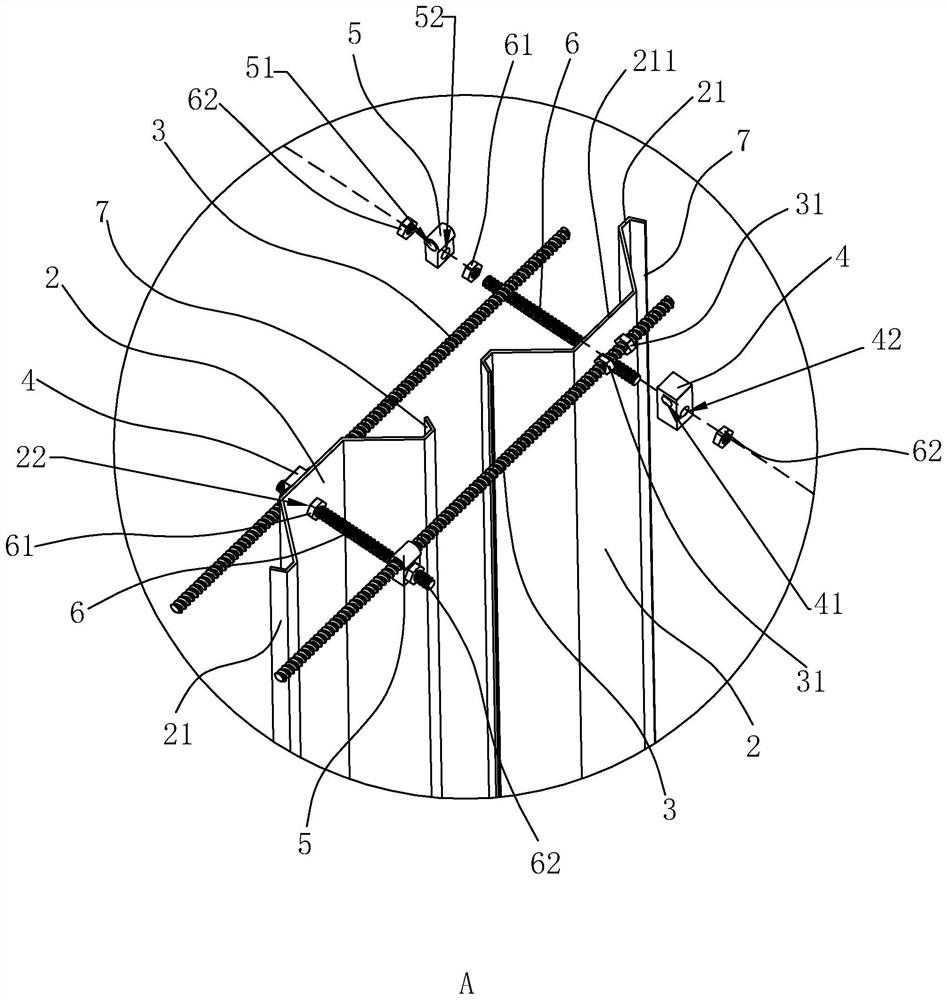

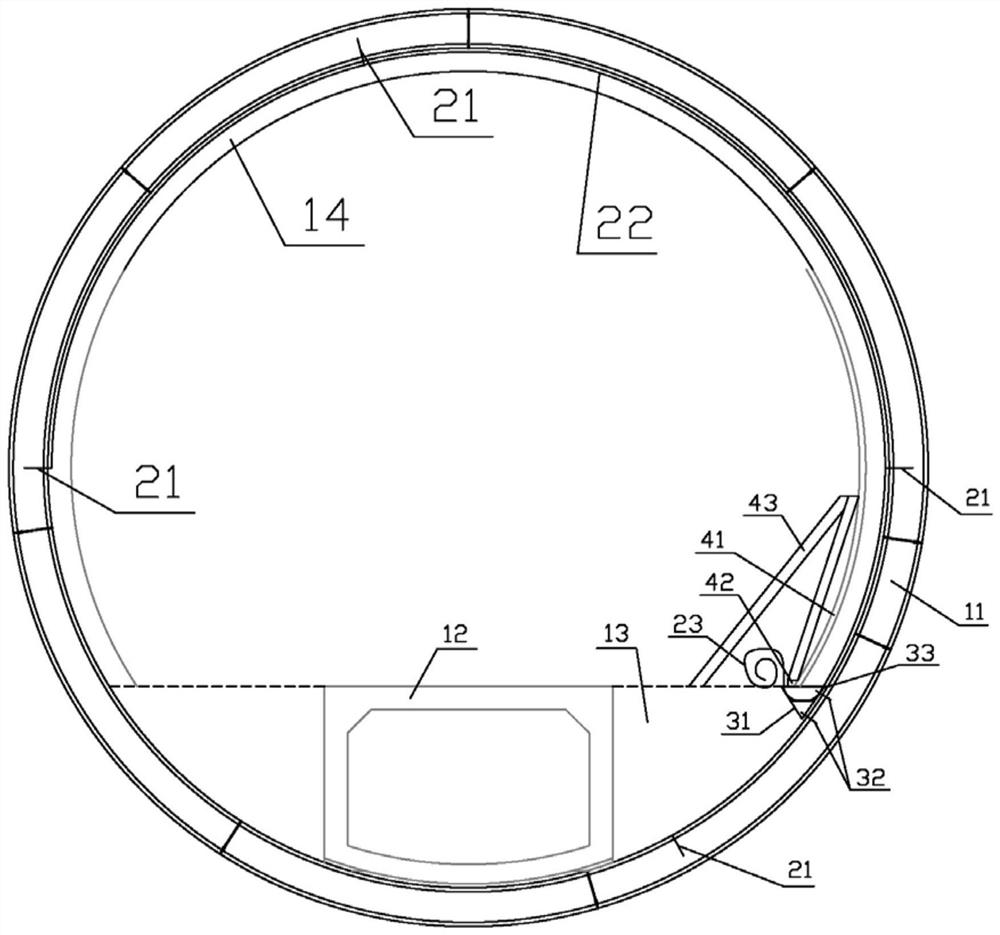

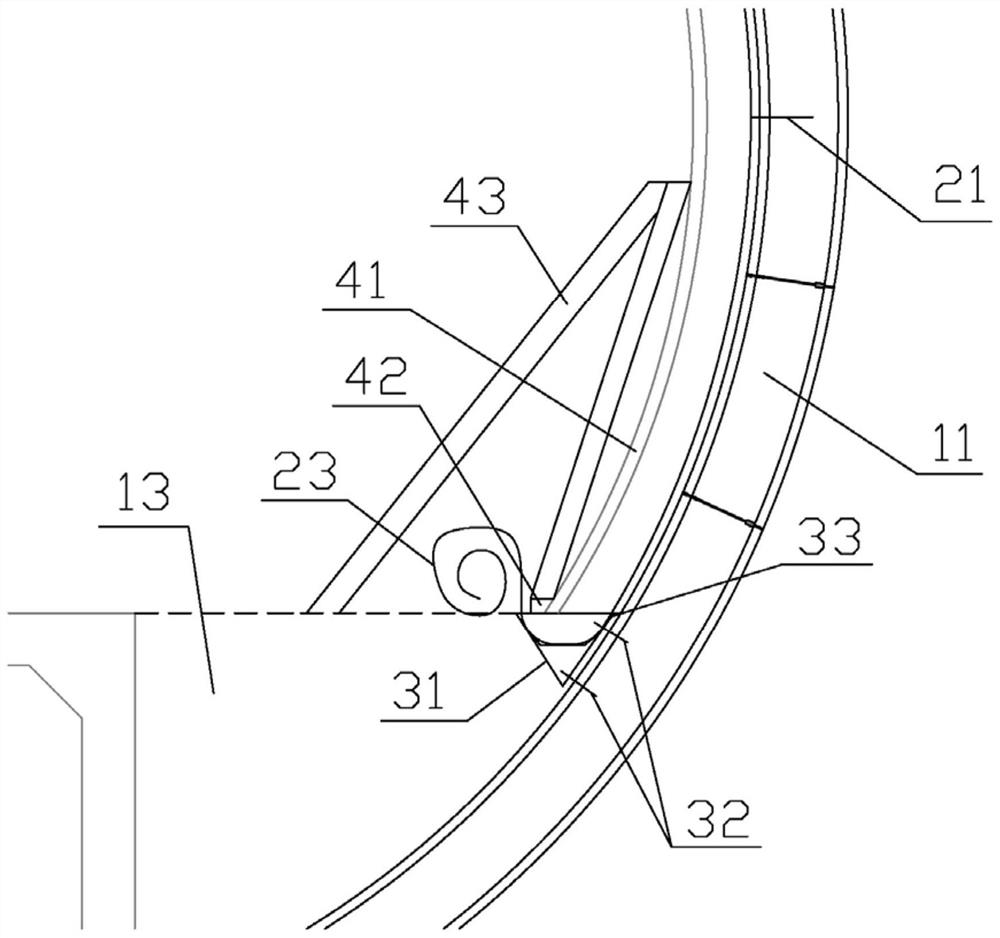

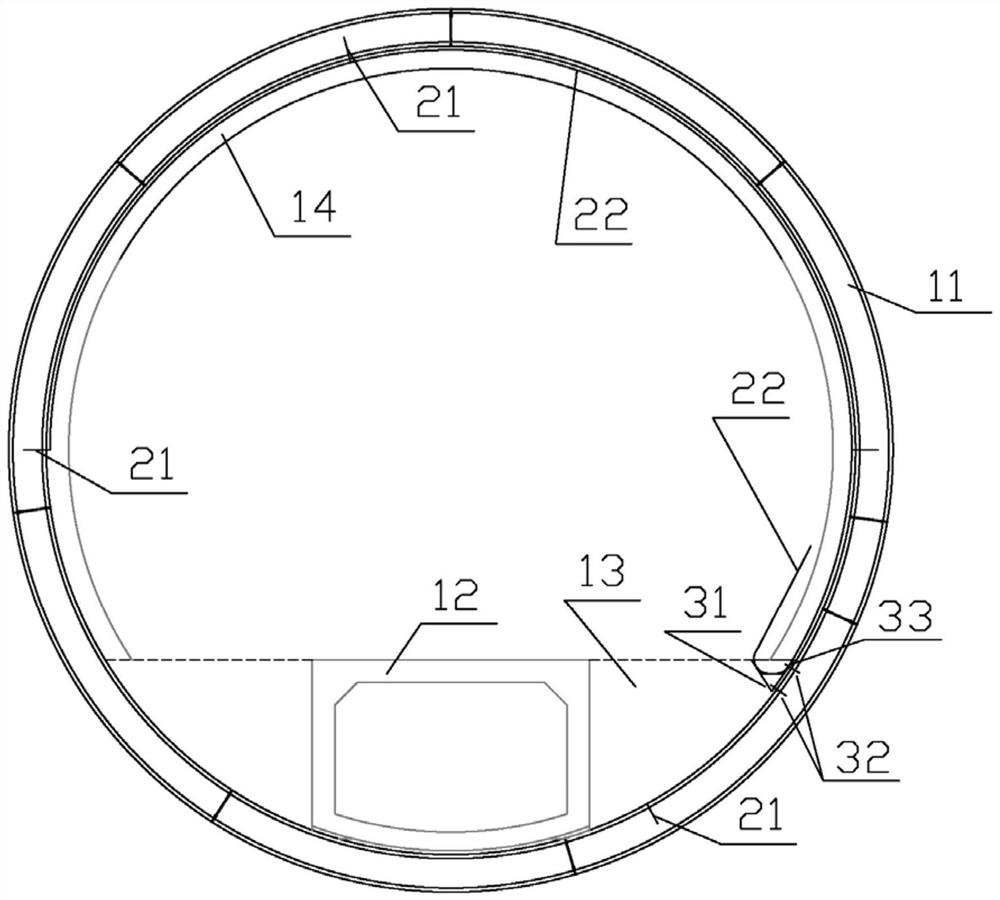

Locking device for tunnel segment

ActiveCN105178984AReduce the amount of backlashImprove assembly qualityUnderground chambersTunnel liningWater leakEngineering

The invention discloses a locking device for a tunnel segment. The locking device for the tunnel segment comprises a first baffle, a second baffle, a first lead screw, a first locking component, a second locking component and a third locking component, wherein the first baffle is fixed on a front-end bottom plate; the second baffle is fixed on a first rear-end bottom plate; the first lead screw penetrates in the first baffle and the second baffle; the first lead screw is fixed on the first baffle by the first locking component, and is fixed on the second baffle by the second locking component; the front-end bottom plate is fixed on a K-shaped segment of a tunnel segment; and the first rear-end bottom plate is fixed on an A-shaped segment by the third locking component. By the locking device for the tunnel segment, the retreating amount of the K-shaped segment retreating towards a tunneling direction in a construction process can be reduced, the probability of water leaking from gaps due to the fact that gaps among segments are over large is reduced, and assembling quality of shield segments is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Steel sheet pile cofferdam connecting structure for hydraulic engineering construction

InactiveCN113802585AReduce gapImprove compactnessArtificial islandsProtective foundationWater leakageVertical edge

The invention relates to a steel sheet pile cofferdam connecting structure for hydraulic engineering construction. The steel sheet pile cofferdam connecting structure comprises two sets of first threaded rods, and channel steel is integrally formed on the vertical edges of the two sides of a steel sheet pile; first connecting blocks are fixed to the vertical end faces of the sides, deviating from notches, of the groove bottoms of all the sets of steel sheet piles, horizontally-formed first through holes are formed in all the sets of first connecting blocks in a penetrating mode, the axes of the first through holes are parallel to the plane where the groove bottoms of the steel sheet piles are located, and all the sets of first threaded rods are jointly inserted into all the sets of first through holes; the first threaded rods are in threaded connection with a plurality of sets of first nuts, every two sets of first nuts are distributed in one set, and the two sets of first nuts abut against and are fixed to the vertical end faces of the two sides of each set of the first connecting blocks; and wing plates of the two sets of channel steel close to each other of any two adjacent sets of steel sheet piles are kept attached. According to the steel sheet pile cofferdam connecting structure for hydraulic engineering construction, gaps between the steel sheet piles are reduced, so that the overall compactness of a cofferdam is improved, and the probability of water leakage caused by the gaps between the steel sheet piles is reduced.

Owner:广东平润建设工程有限公司

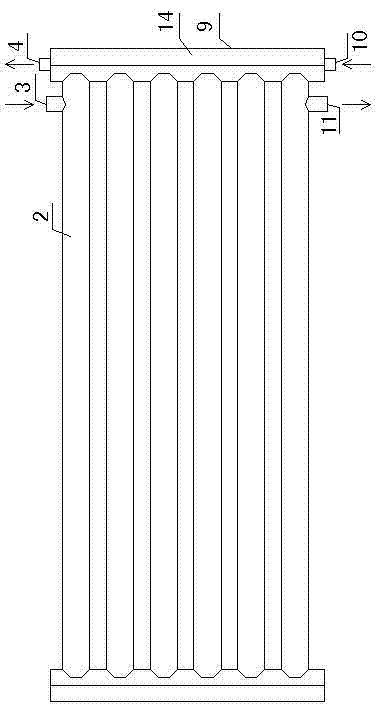

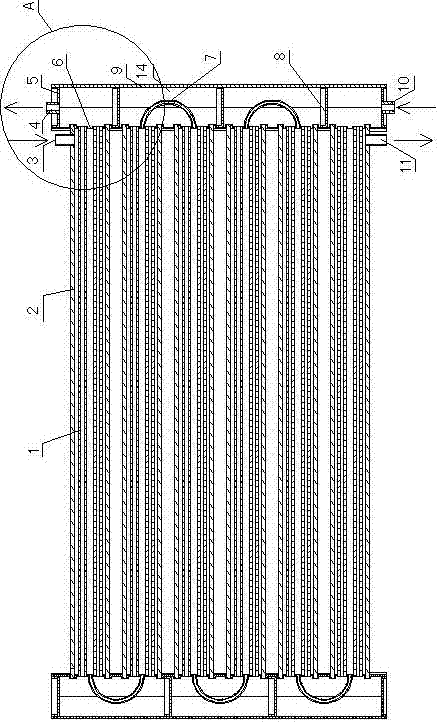

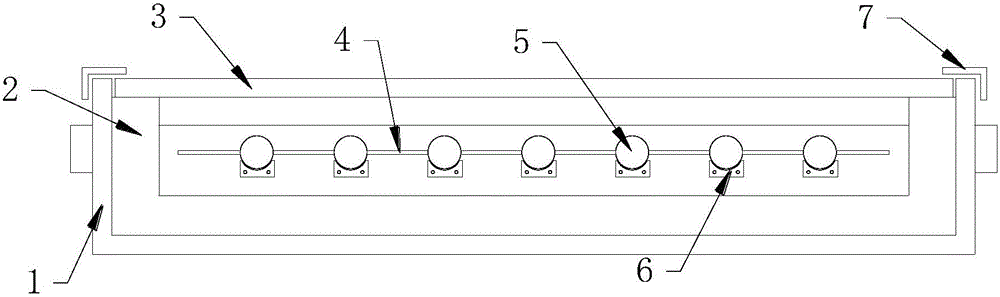

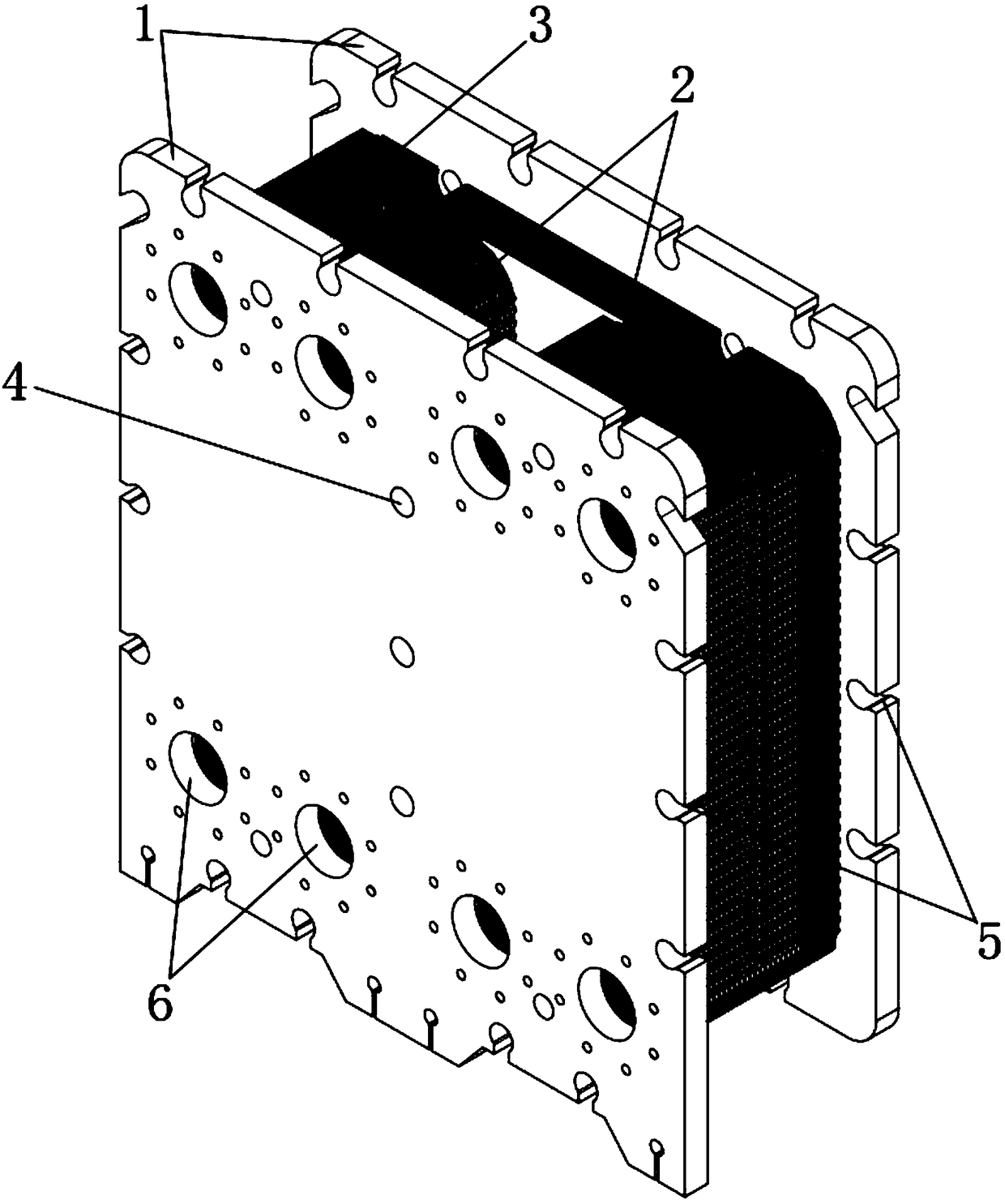

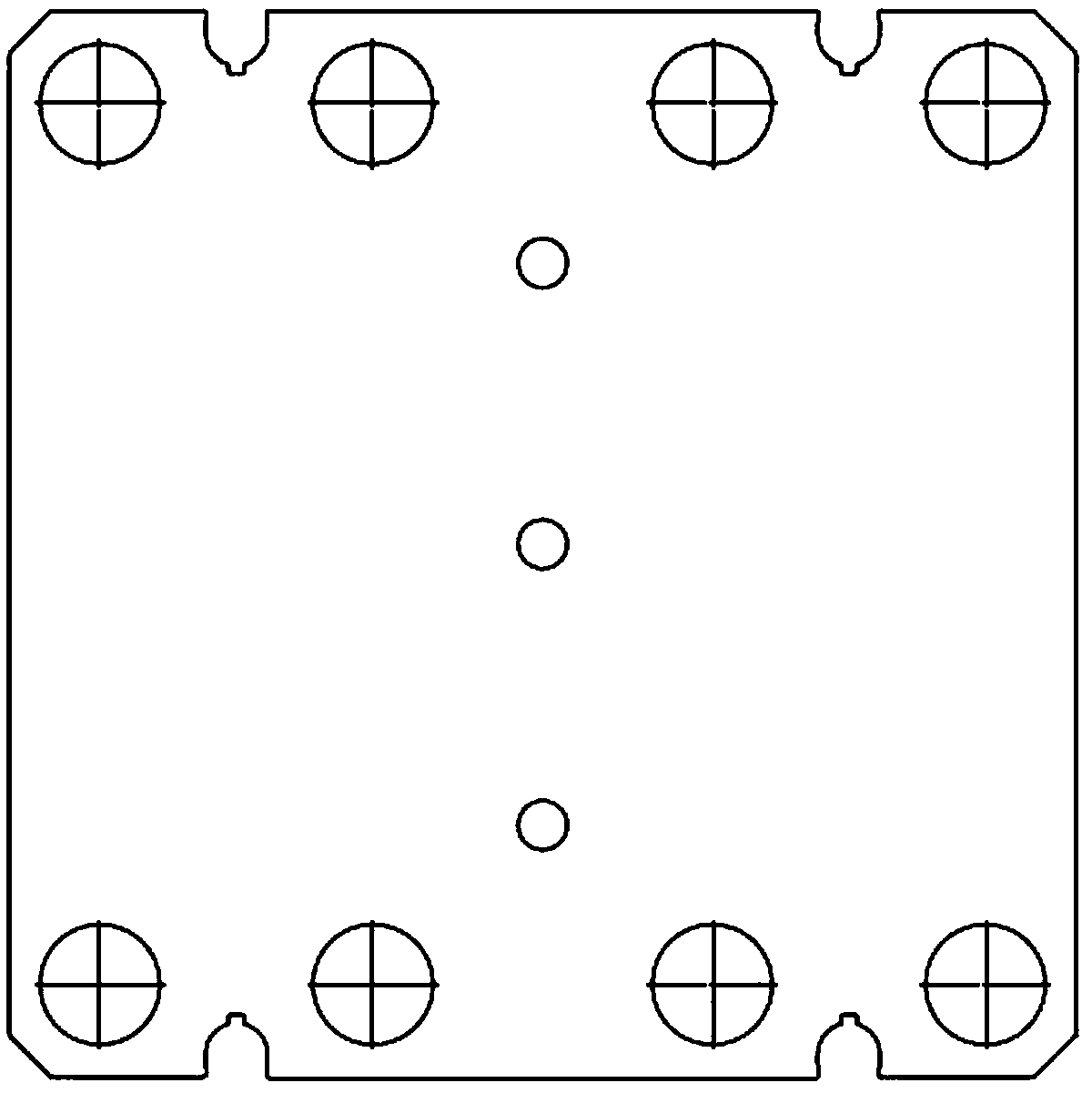

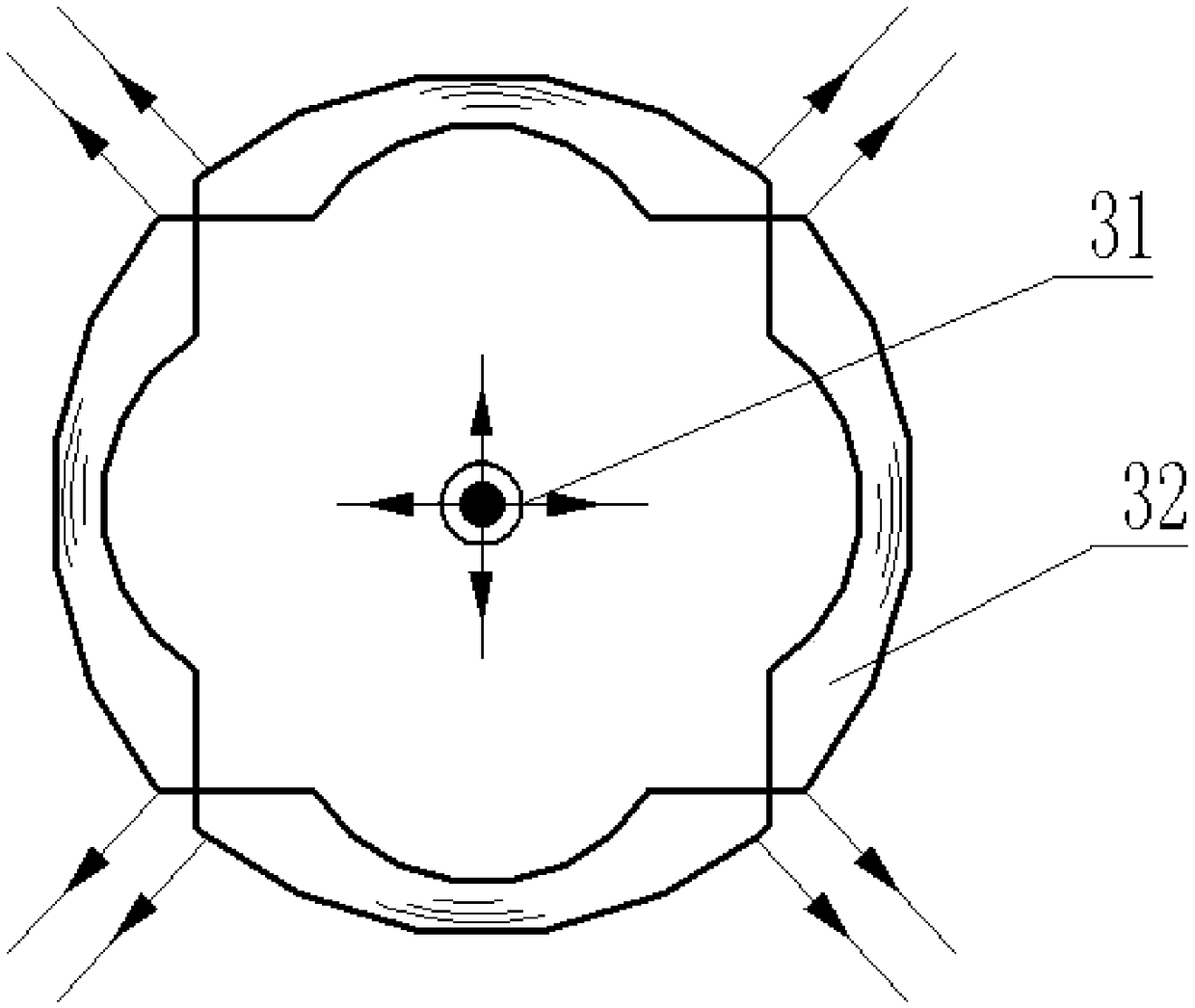

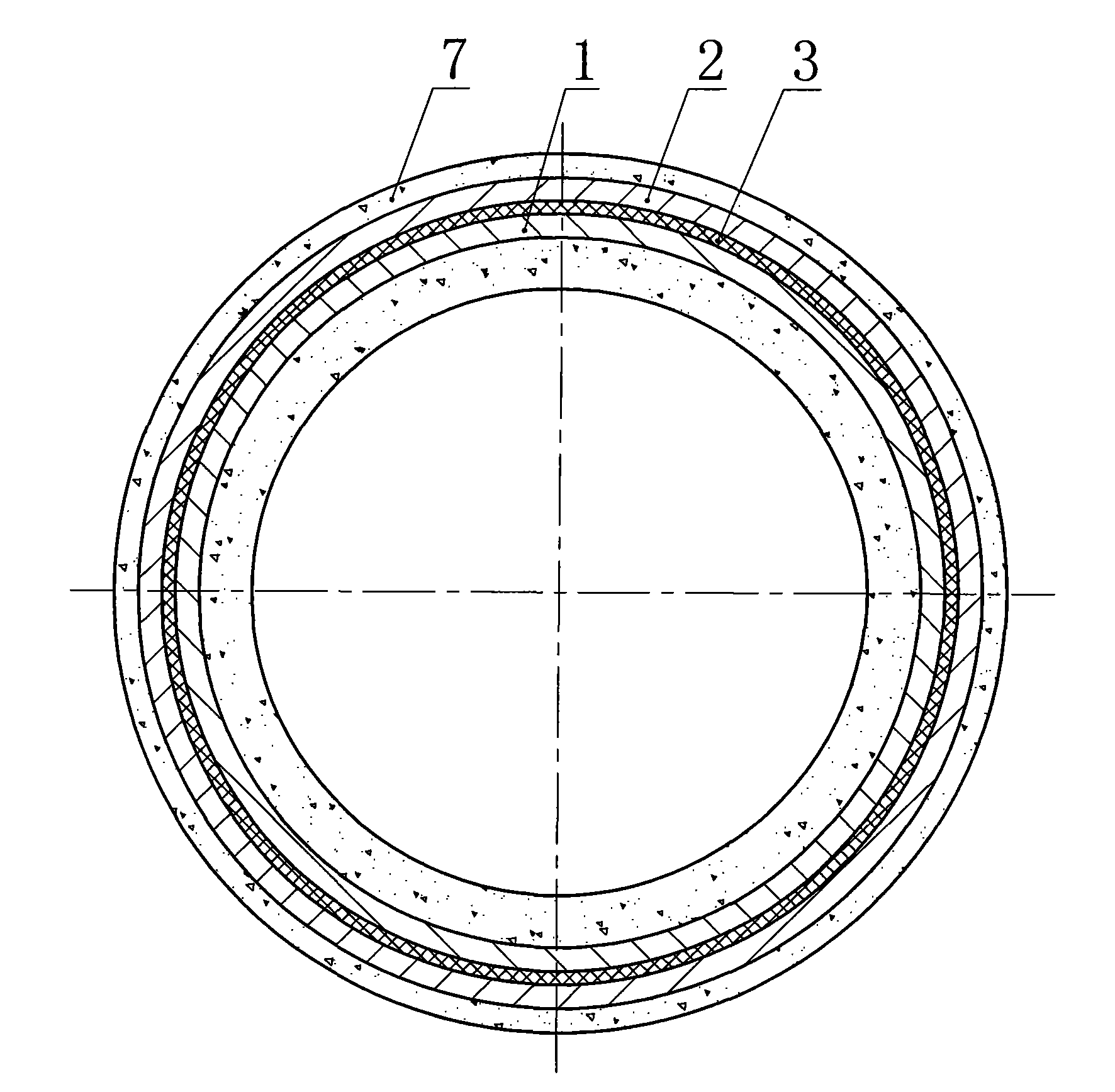

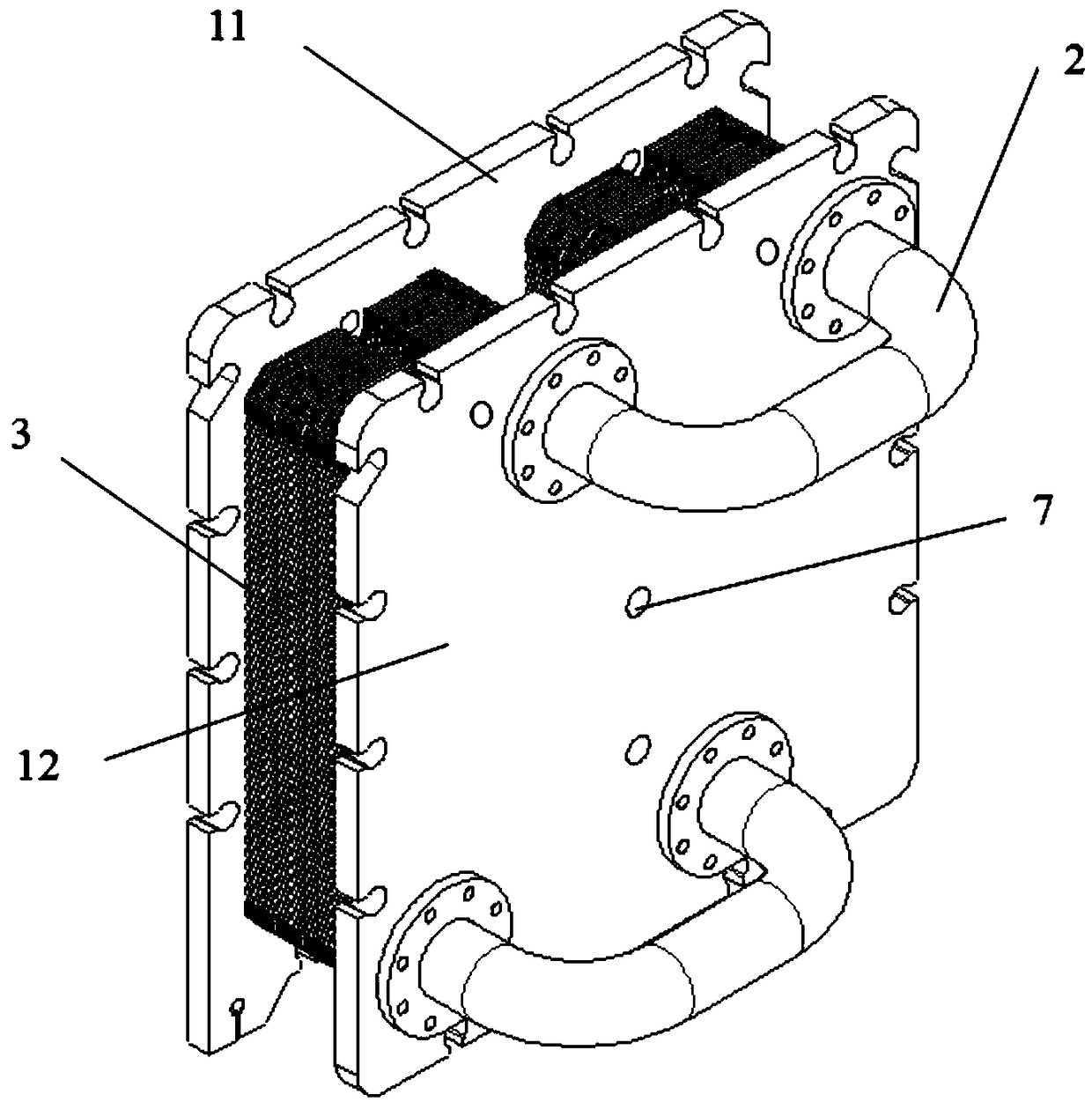

Plate-connected plate heat exchanger

PendingCN109186294AImprove connectivityExtended service lifeHeat exhanger sealing arrangementStationary plate conduit assembliesWater leakageEngineering

The invention relates to a plate-connected plate heat exchanger. The plate-connected plate heat exchangercomprises end pressing plates and heat exchange plate bundles, and the heat exchange plate bundlesare disposed between the end pressing plates.The plate-connected plate heat exchanger further comprises communication plate bundles. The heat exchange plate bundles are arranged at intervals between the end pressing plates. The plurality of sets of heat exchange plate bundles are connected to each other in a series, parallel or parallel serial manner by the communication plate bundles, and theheat exchange plate bundles and the communication plate bundles are clamped and fixed by the end pressing plates.According to the plate-connected plate heat exchanger, the problem that the large heatexchange plate is easy to be deformed and water leakage occurs can be overcome, the maintenance workload and cost reduction are facilitated, the service life of the heat exchanger is prolonged, heat exchange efficiency is high, and combination is flexible. A matching custom function is realized according to the requirements, installation environment and other needs, the structure is compact, the space is small, and the transportation is more convenient.

Owner:SHANGHAI PANDA MACHINEGRP CO LTD

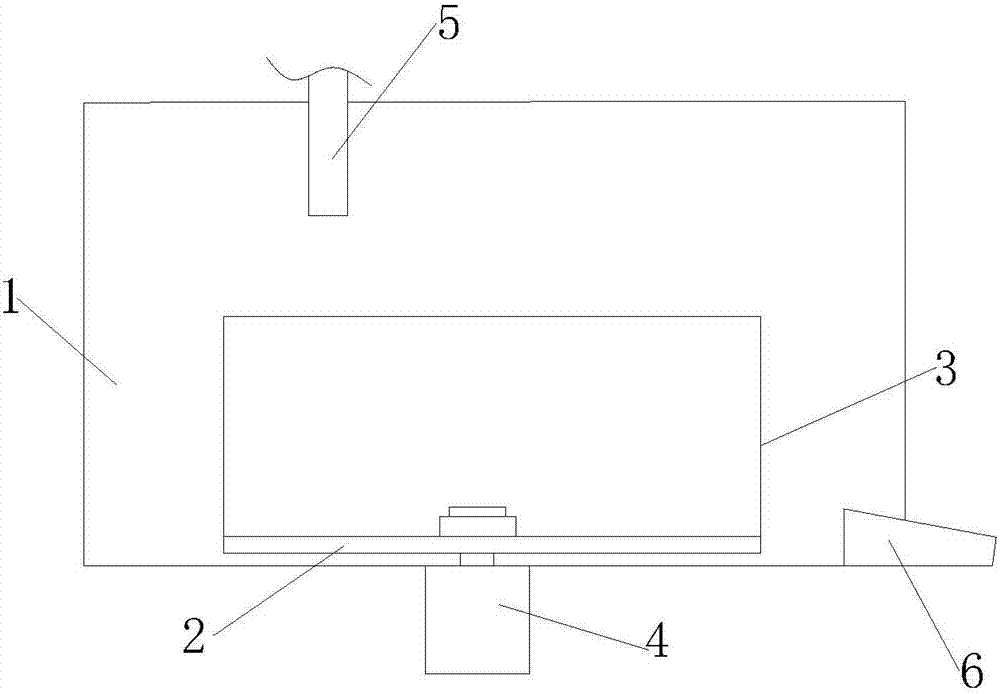

Photoelectric separation type sterilizing system and sterilizing method

PendingCN109319878AAchieve disinfectionNo installation and debuggingWater/sewage treatment by irradiationSpecific water treatment objectivesUltraviolet lightsEngineering

The invention discloses a photoelectric separation type sterilizing system which is used for sterilizing water. The photoelectric separation type sterilizing system comprises an ultraviolet generationsource, a spreading optical fiber and a sterilizing part, wherein the spreading optical fiber is connected between the ultraviolet generation source and the sterilizing part. The invention further discloses a sterilizing method using the system. The photoelectric separation type sterilizing system disclosed by the invention is provided with the ultraviolet generation source, the spreading opticalfiber and the sterilizing part, the principle that ultraviolet light can sterilize is utilized to achieve photoelectric separation type sterilization, ultraviolet light emitted by an ultraviolet lampsource is gathered to a receiving optical fiber by a lens assembly and is spread into the sterilizing part by the spreading optical fiber, the ultraviolet light is spread to water to be sterilized through a lens ball of the sterilizing part, and water sterilization is realized; in addition, the whole set of system is a finished product, installation and debugging are avoided, a complex constructing, reserving and embedding technology is avoided, the system can be distributed without professional workers, and the technology is favorable for being applied and popularized.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

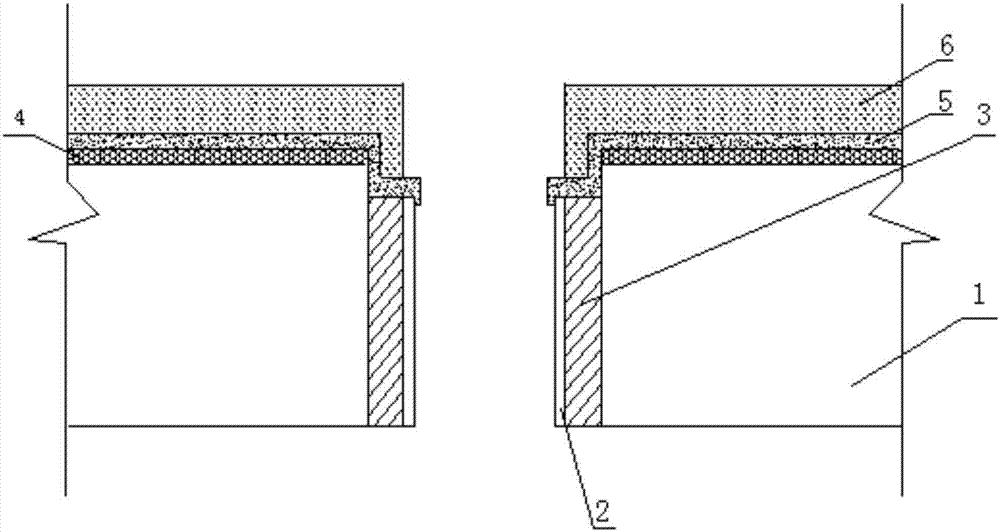

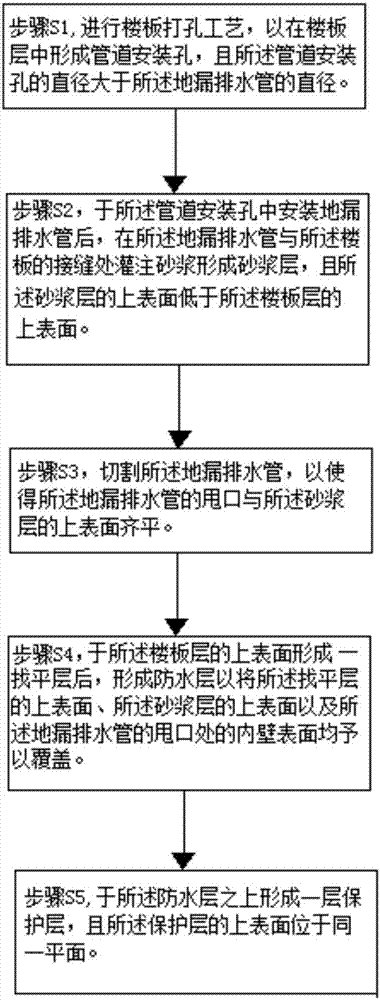

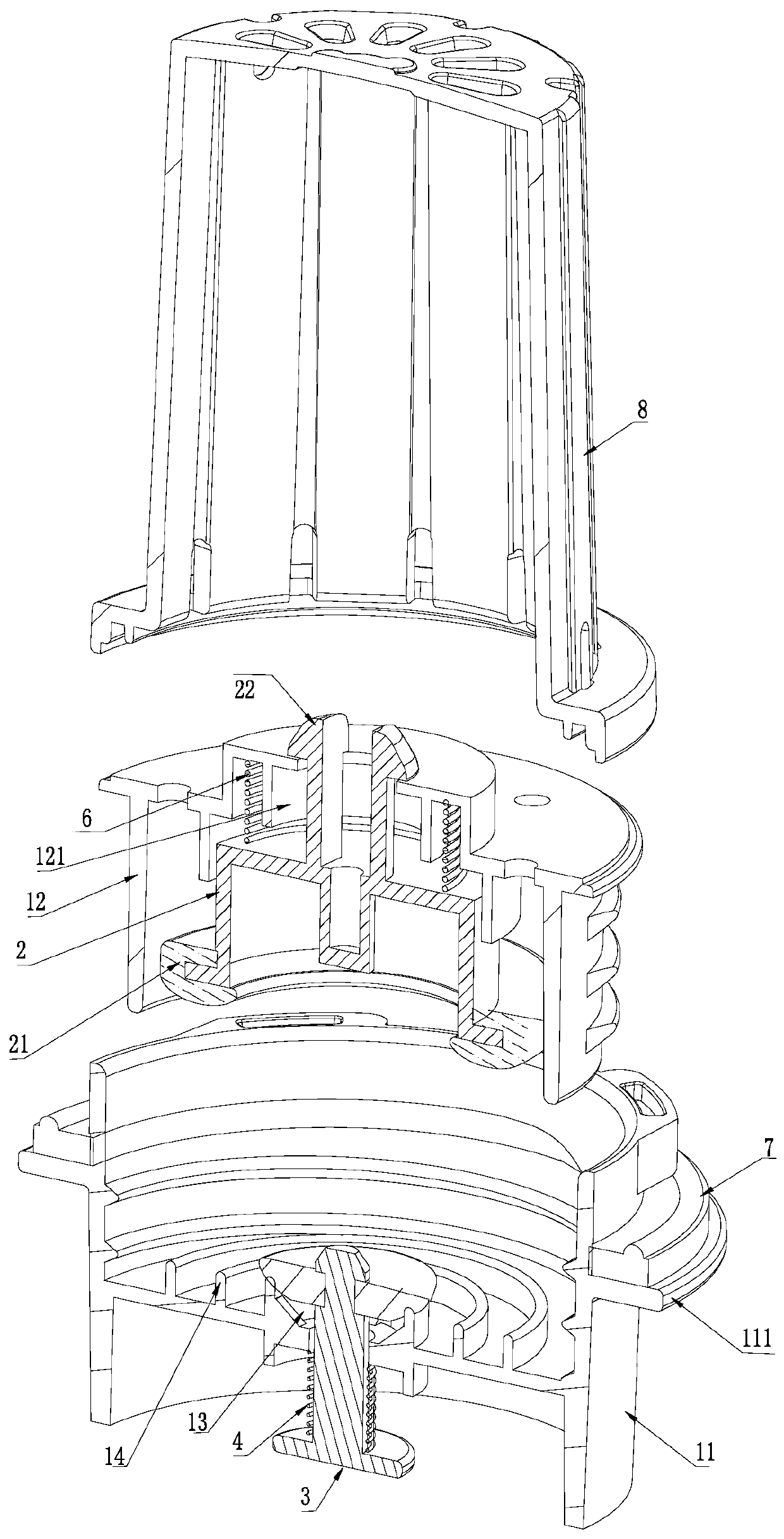

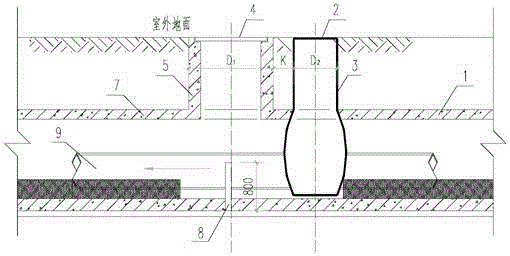

Ground leakage drain pipe structure and manufacture method thereof

InactiveCN106996139APromote excretionReduce the probability of water leakageSewerage structuresSewer pipelinesLeaking waterFloor slab

The invention relates to the technical field of ornament and decoration, in particular to a ground leakage drain pipe structure and a manufacture method thereof. By enabling the reserved connector position of a ground leakage drain pipe to be lower than the upper surface of a floor slab layer so as to form a ladder groove between the ground leakage drain pipe and the floor slab layer, leaked water can flow in a drain pipe through the ladder groove, and then water hidden on a waterproof layer is convenient for draining accordingly, thereby reducing the water leaking probability.

Owner:MCC5 GROUP CORP SHANGHAI

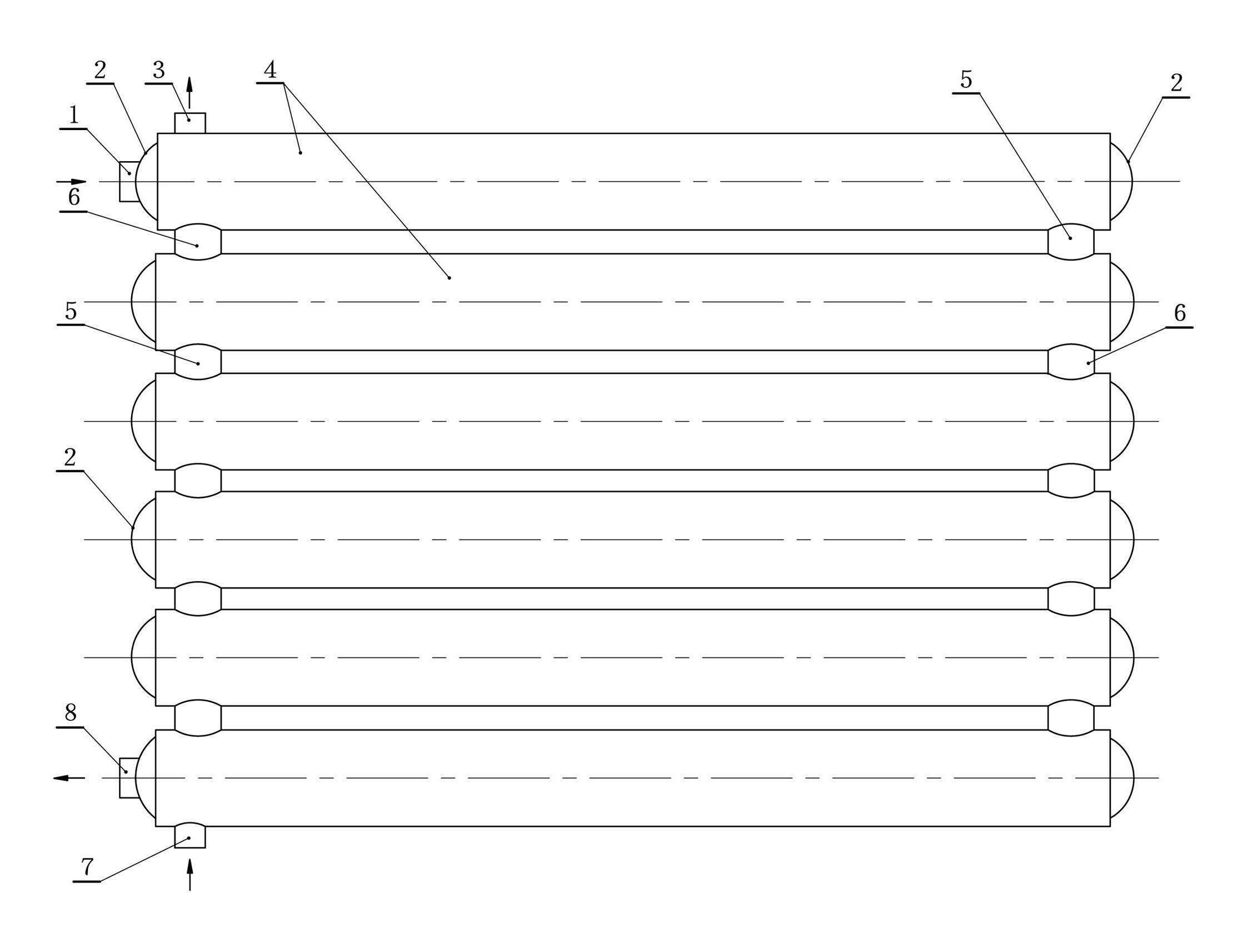

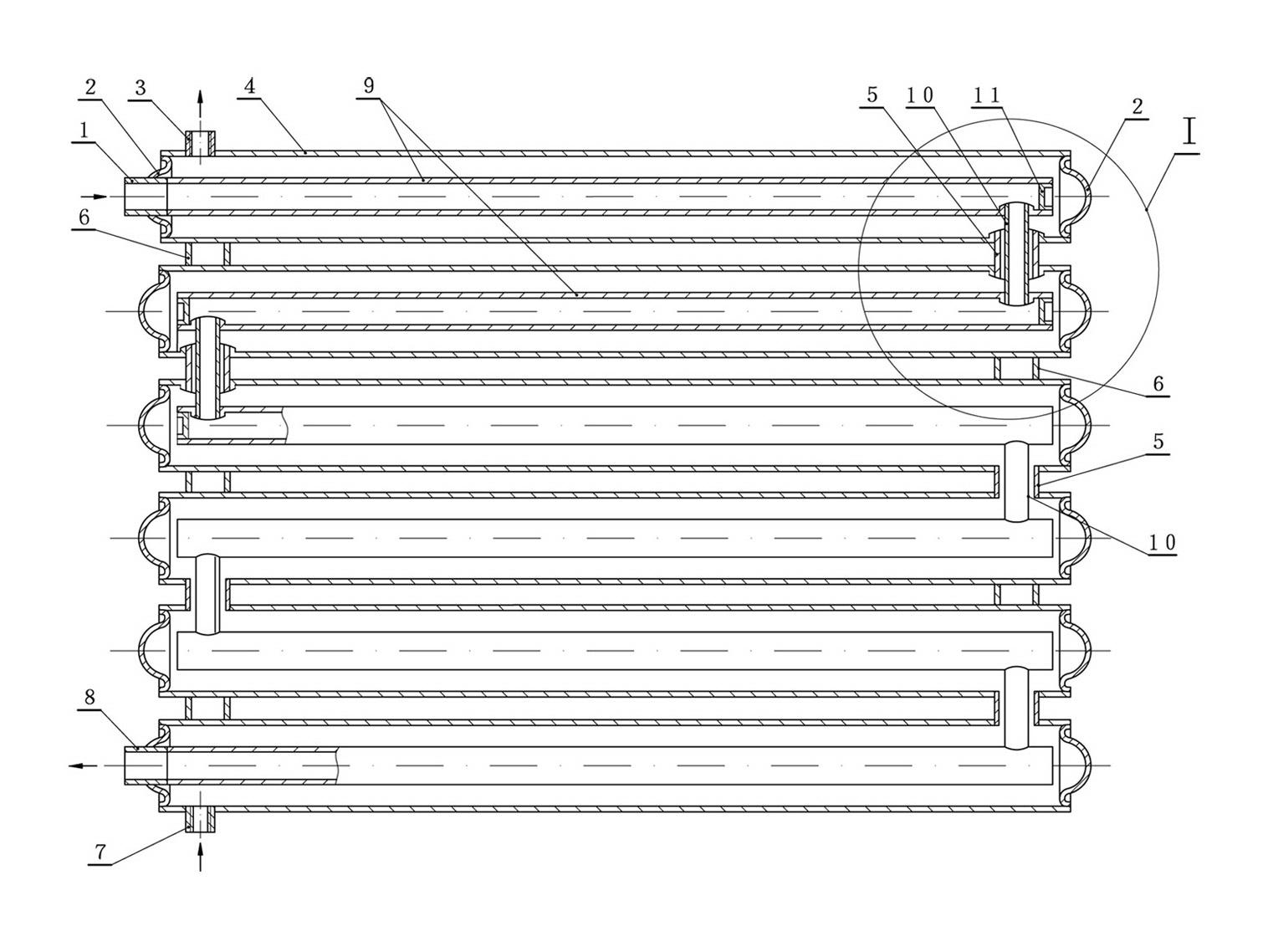

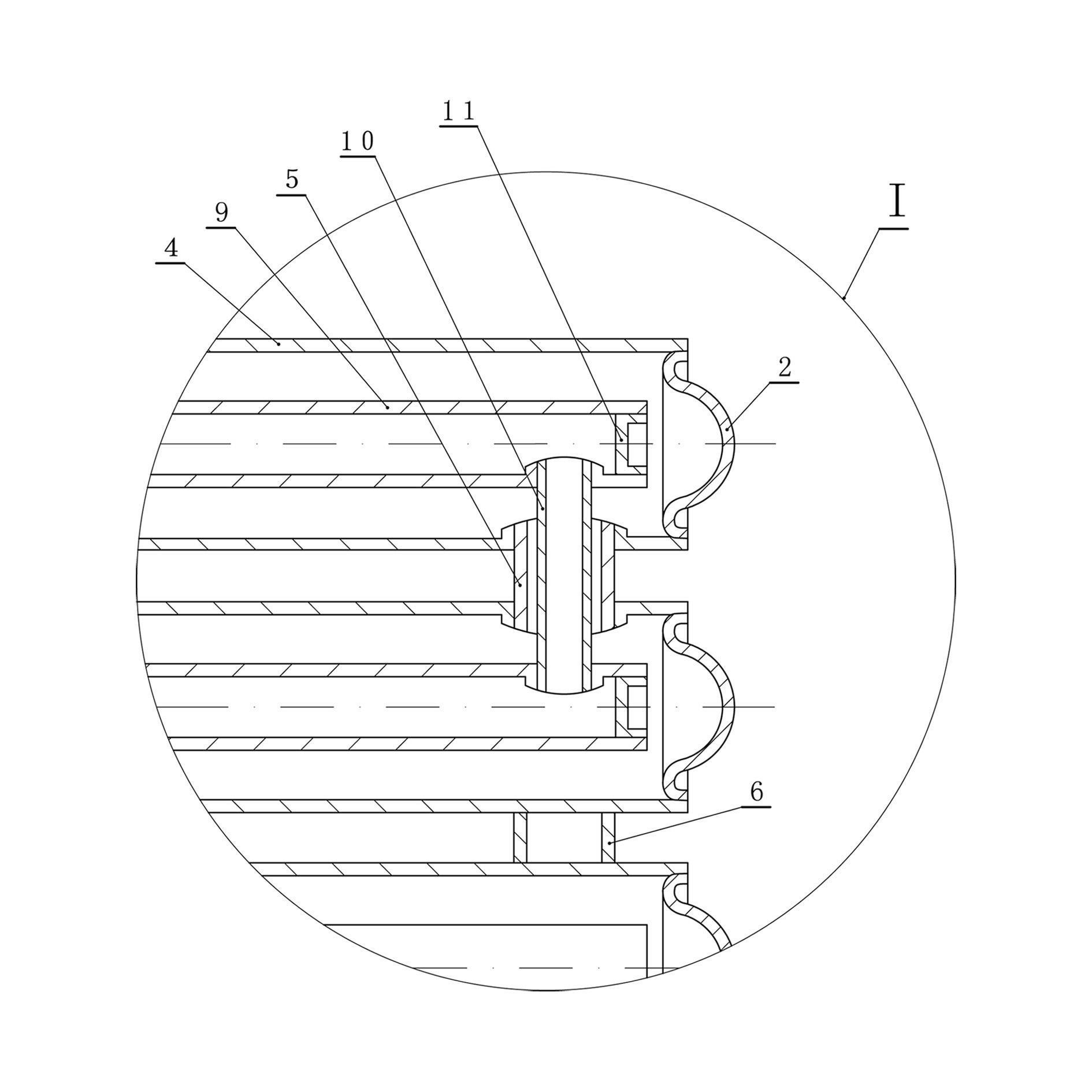

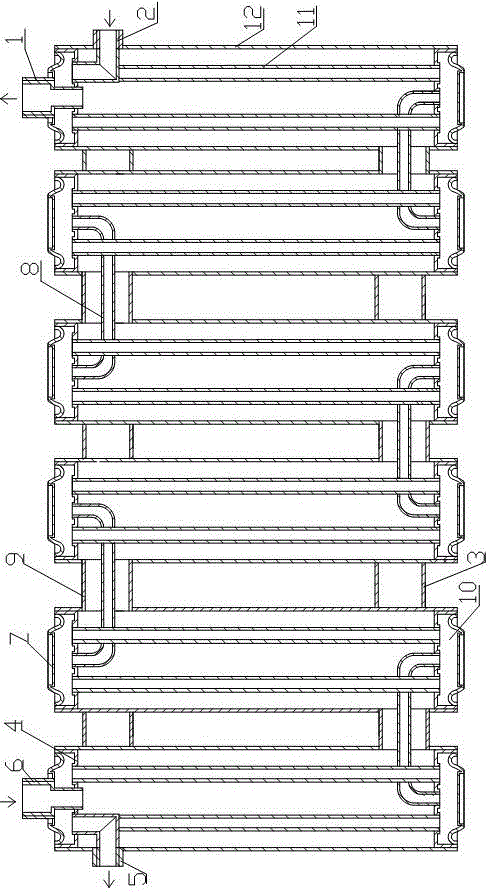

Header body shell tube communication pressure-bearing heat exchanger

ActiveCN105423777AHigh strengthImprove rigidityHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerHeat transmission

The invention discloses a header body shell tube communication pressure-bearing heat exchanger. The header body shell tube communication pressure-bearing heat exchanger comprises two header bodies. Stiffening objects are arranged on the spacing board faces between header inner side pore plates and pipe holes of a plurality of shell circular pipes or / and circular ring stiffening plates are arranged in pipe openings of the multiple shell circular pipes. The stiffening objects are transversely welded to the header inner side pore plates to form T-shaped stiffening ribs. At least one pipe heat exchanging pipe or a combined heat exchanging pipe is arranged in each pipe cavity of the multiple shell circular pipes. The heat exchanging pipes or the combined heat exchanging pipes are held to bent pipes in inner cavities of headers to be communicated or be communicated by welding communication pipes. The inlet ends and the outlet ends of the heat exchanging pipes or the inlet ends and the outlet ends of the combined heat exchanging pipes are communicated by welding third pipe connectors and fourth pipe connectors to form pipe pass fluid circulation heat-transmission flowing channel. Two medium fluid in a heat exchanger passes through pipe passes of the heat exchanging pipes or the pipe passes of the combined heat exchanging pipes and / or the shell passes of the inner cavities of the headers and the shell passes of the multiple shell circular pipes to conduct heat exchanging. According to the header body shell tube communication pressure-bearing heat exchanger, the heat exchanging area is large, the header body shell tube communication pressure-bearing heat exchanger efficiency is high, and installation materials are saved.

Owner:山东利能换热器有限公司

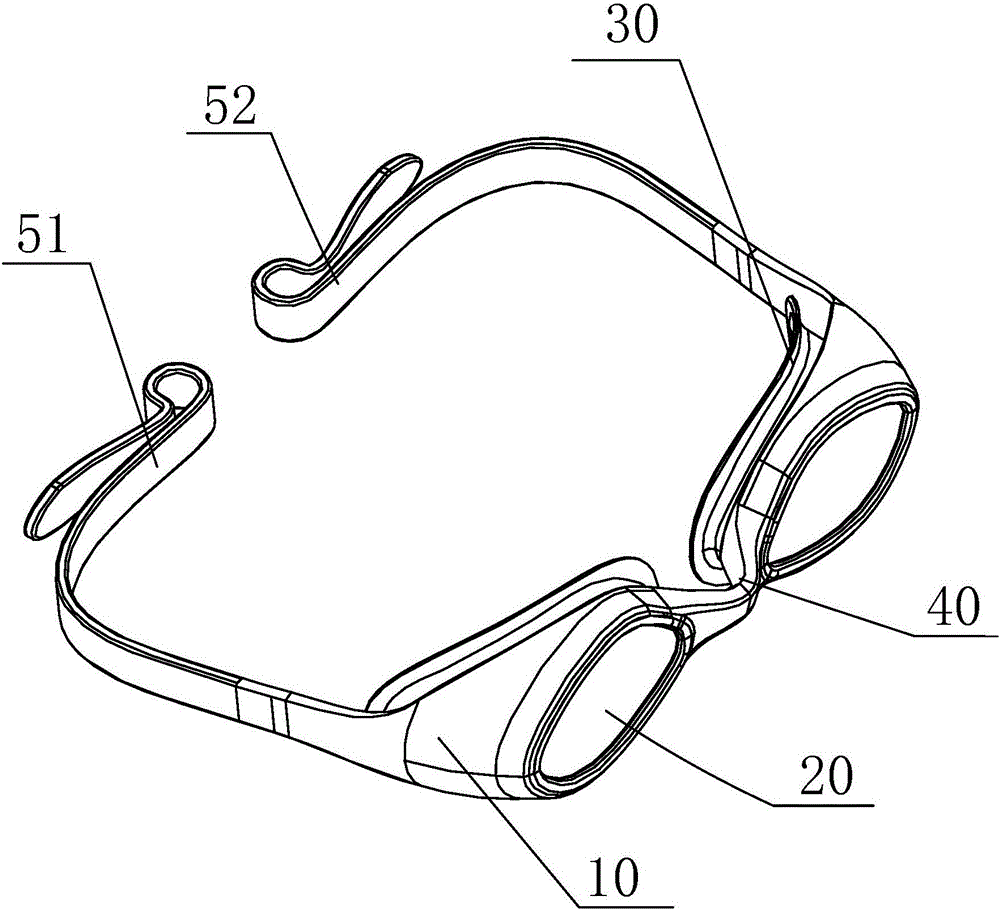

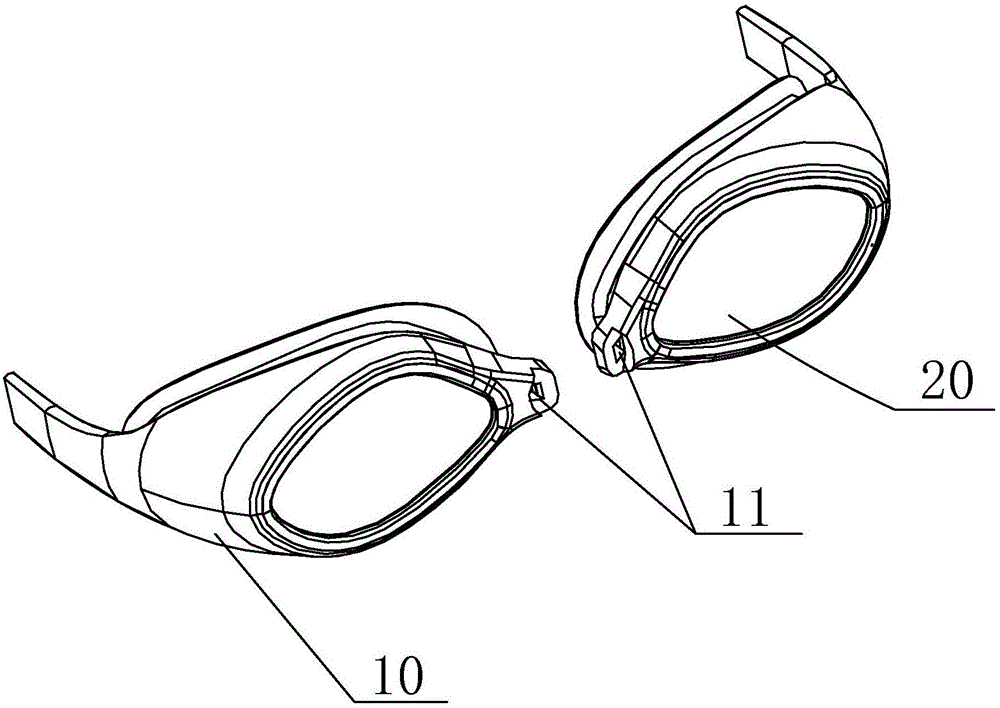

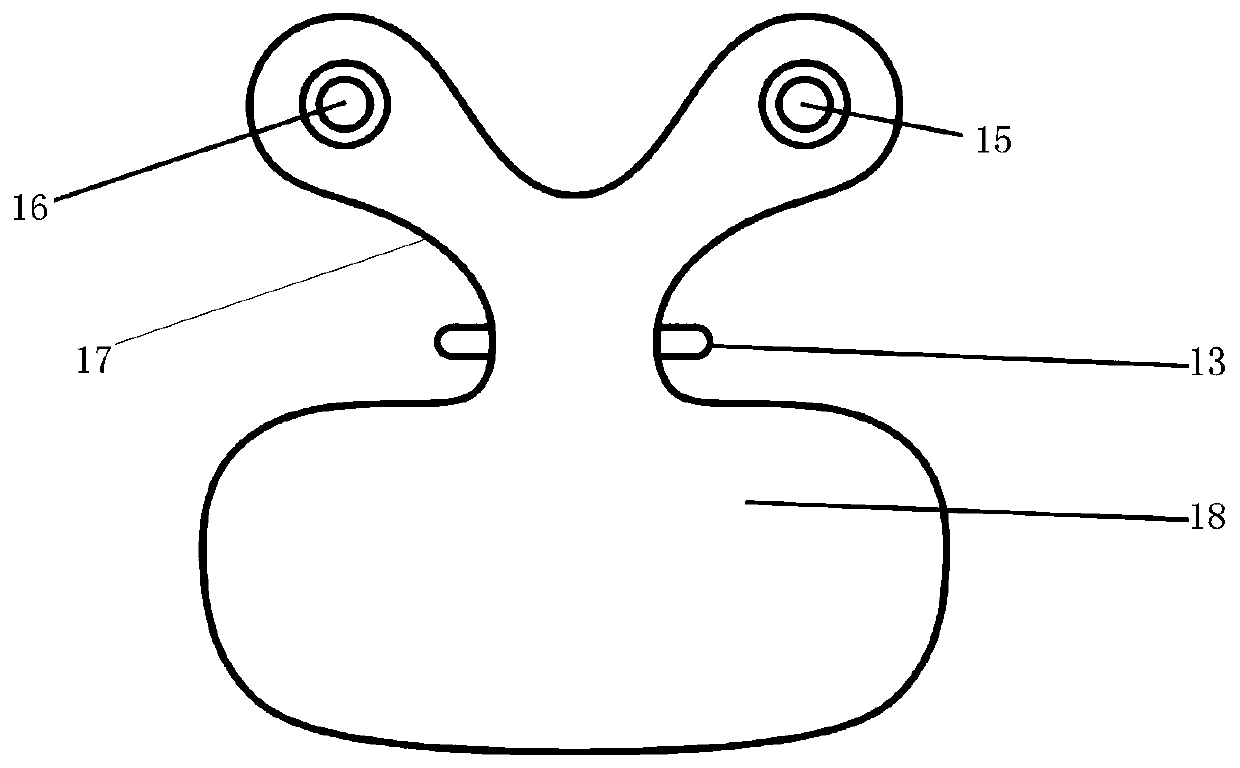

Diving goggles

InactiveCN105963933AExtended service lifeConnect evenly and tightlySwim capsWater leakUltimate tensile strength

The invention discloses a diving goggle, which comprises a lens and a sealing gasket, and the lens and the sealing gasket are integrally formed with the same material. The lens and the sealing gasket are integrally formed with the same material, and the lens and the sealing gasket are integrated, so that there is no need to use glue for bonding, avoiding the situation of inconsistent bonding strength that may occur when using glue bonding, and making the gap between the lens and the sealing gasket The connection between them is uniform and tight, which greatly reduces the possibility of water leakage between the lens and the gasket, reduces the probability of water leakage, and improves the service life of the diving goggles.

Owner:SHENZHEN ZHIHUISHIFANG TECH

welding equipment

ActiveCN105458468BReduce the probability of water leakageImprove welding efficiencyWelding/cutting auxillary devicesElectrode supporting devicesWelding torchSoldering gun

Owner:JIANGXI XINTIAN AUTO IND

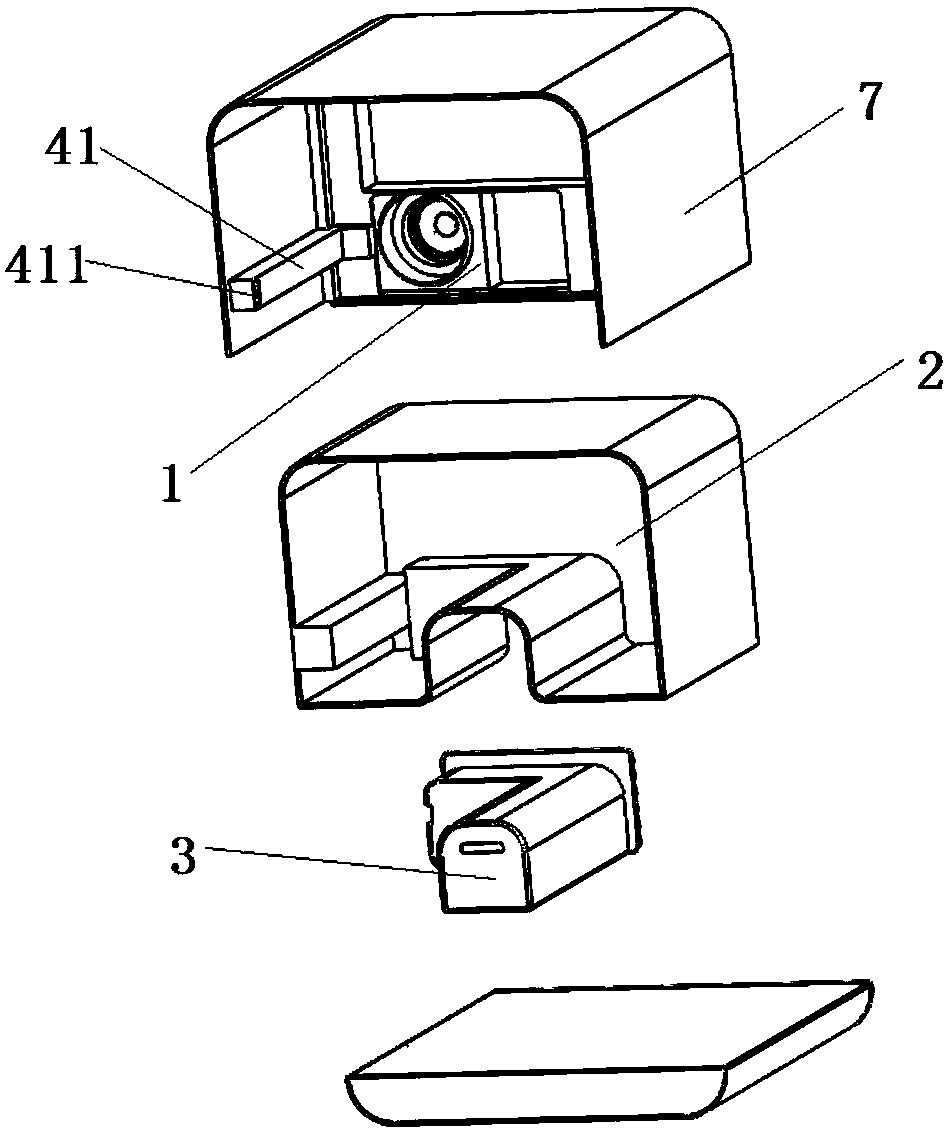

Water outlet valve assembly, water tank using water outlet valve assembly and humidifier

PendingCN109780232AImprove the water sealing effectReduce the probability of water leakageOperating means/releasing devices for valvesLighting and heating apparatusWater tanksVALVE PORT

The invention discloses a water outlet valve assembly, a water tank using the water outlet valve assembly and a humidifier. The water outlet valve assembly comprises a water draining portion, a valvebody, an ejection rod, a first elastic portion and an isolator; the water draining portion is provided with a first water outlet flow channel; the valve body is arranged at a water outlet of the firstwater outlet flow channel; the ejection rod and the first elastic portion are fixedly connected with the valve body; and the isolator is arranged in the first water outlet flow channel and provided with a second water outlet flow channel, when the isolator is not subjected to the action of the ejection rod, the isolator is located at the first position, the second water outlet flow channel does not communicate with the first water outlet flow channel, and when the isolator is subjected to the action of the ejection rod after moving on the ejection rod for a preset distance, the isolator is located at the second position, and the second water outlet flow channel communicates with the first water outlet flow channel. According to the water outlet valve assembly, the water tank using the water outlet valve assembly and the humidifier, the water outlet valve assembly provides multiple water outlet protection, is simple in structure and can be disassembled to be cleaned, the water leakageprobability is extremely low, and then the reliability is improved.

Owner:BEAR ELECTRICAL APPLIANCE CO LTD

Leakage detection ditch for building protection in large-thickness collapsible loess area

InactiveCN106638695AReduce the probability of water leakageEasy to installArtificial islandsUnderwater structuresLeaking waterPipeflow

The invention provides a leakage detection ditch for building protection in a collapsible loess area. By the adoption of the leakage detection ditch, water leakage of laid drainage buried pipelines can be effectively found and eliminated. A leakage detection well is arranged every 100-120 m or so, and each leakage detection well is built close to the closest drainage inspection well or water supply valve within the range of 100-120 m and located in the downstream position. Pipeline faults can be found rapidly, and the leakage detection range is effectively shortened. The leakage detection ditch is provided with water collecting pits which are 300 mm deep, wherein each water collecting pit is arranged at the bottom of the corresponding leakage detection well with a certain slope and orientation (should be larger than 0.02), and the pits are used for collecting water leaked from the pipelines. As for an area where the water collecting pits cannot be arranged due to site condition limitation, a water fender used for blocking water flow can be arranged in the position where each water collecting pit should be arranged originally, the end face of one side of each water fender is attached to the ditch wall of the leakage detection ditch, and the interval H between the end face of the other side of each water fender and the ditch wall of the leakage detection ditch is 200-300 mm. In the leakage detection process of the leakage detection ditch, an operator can observe whether water flow exists in the notch or not from the position above the leakage detection well so as to judge whether the upstream pipeline leaks water or not.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

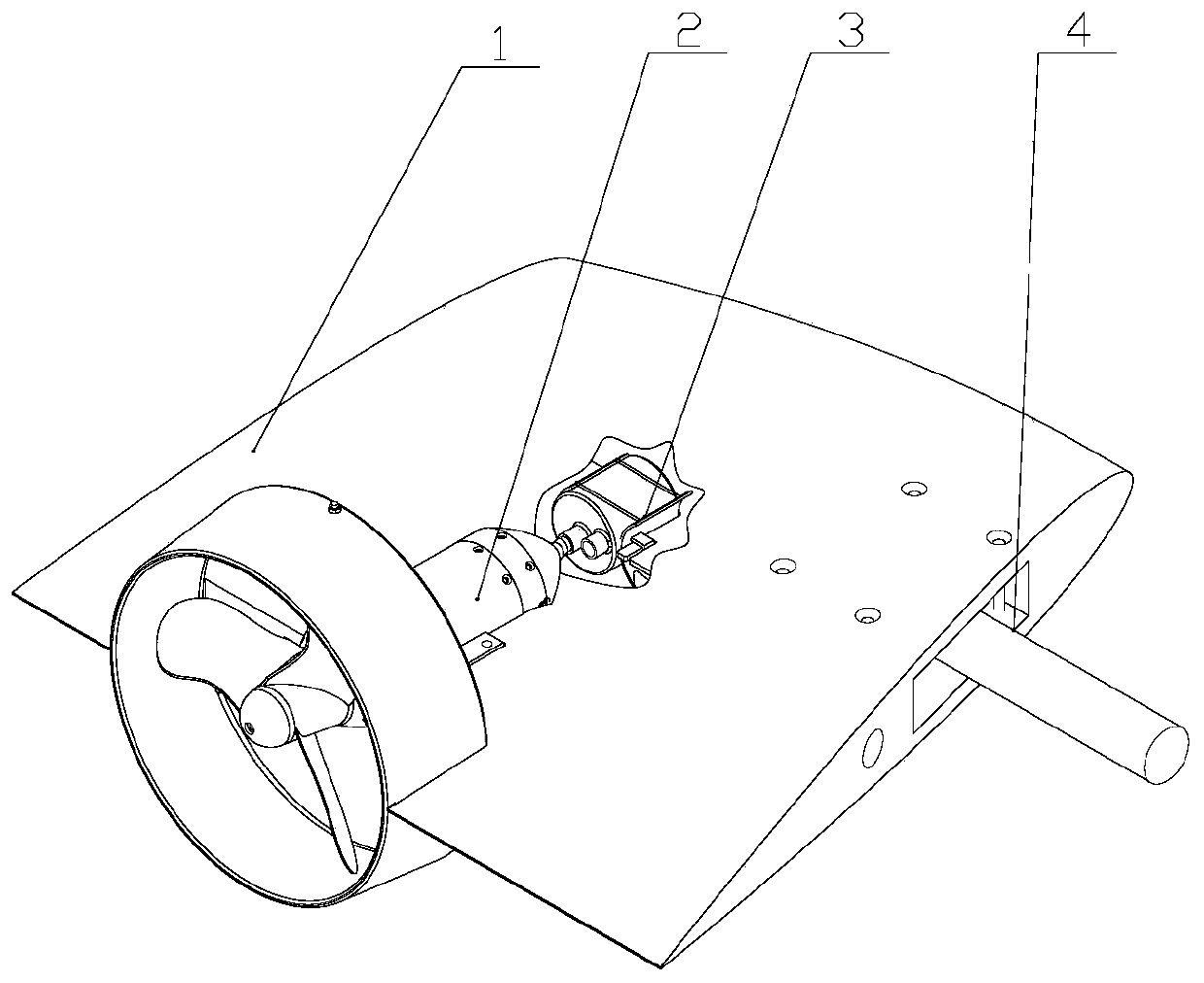

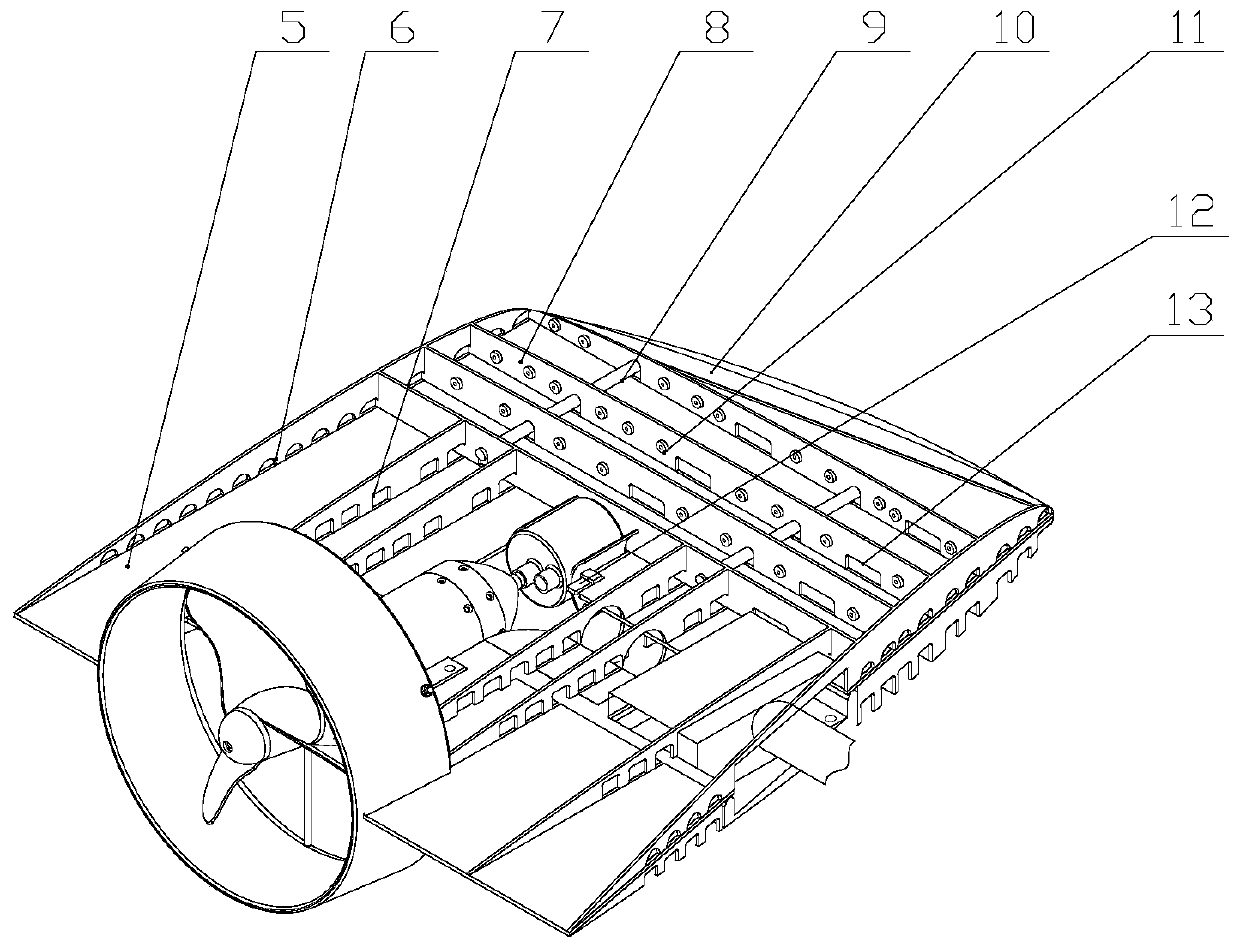

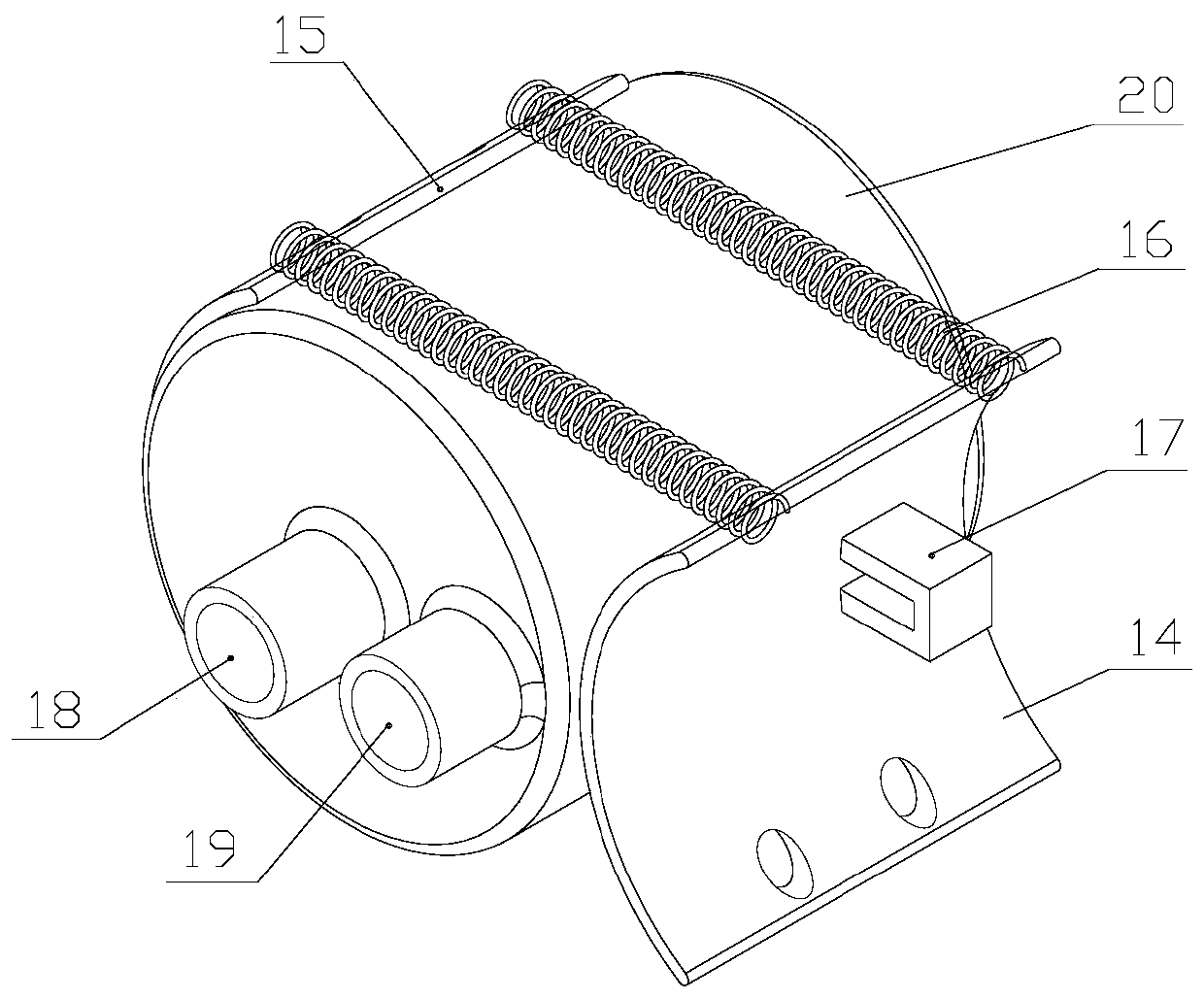

Light-weight rudder plate system

ActiveCN110588927AReduce quality problemsGuaranteed Outer Contour SurfaceUnderwater vesselsUnderwater equipmentPropellerFlow curve

The invention relates to the technical field of underwater robots, in particular to a light-weight rudder plate system. The light-weight rudder plate system comprises rudder plate skin, a rudder plateskeleton plate, a main propeller, an active compensator, a rudder plate connecting shaft and a rudder plate incident flow curved surface. Rib plate structures are symmetrically arranged on two sidesof the rudder plate skeleton plate. The rudder plate incident flow curved surface is arranged in the front portion of the rudder plate skeleton plate. The main propeller and the active compensator arearranged in the stern of the rudder plate skeleton plate. The main compensator is connected with the main propeller and used for conducting active compensation on the main propeller. The rudder plateskin is arranged on the outer sides of the rib plate structures. The rudder plate connecting shaft is arranged on the side face of the rudder plate skeleton plate. The light-weight rudder plate system is wide in the application range, high pressure resistant, high temperature and low temperature resistant, corrosion resistant, adjustable in the gravity center of design and high in reliability; and in addition, the function of active compensation is added.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

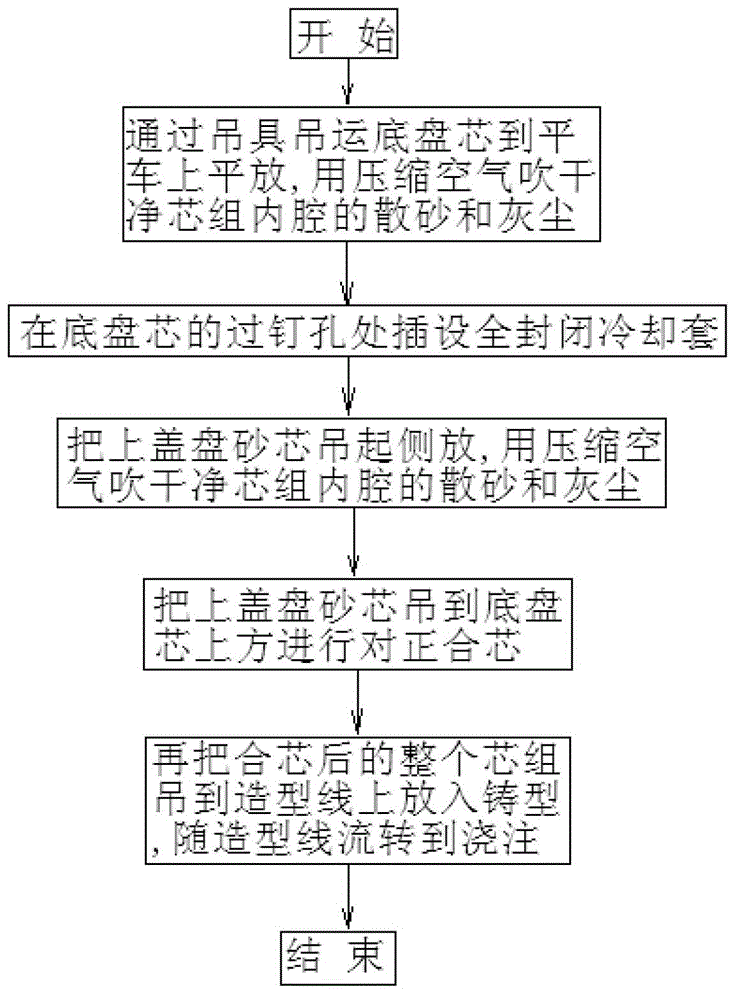

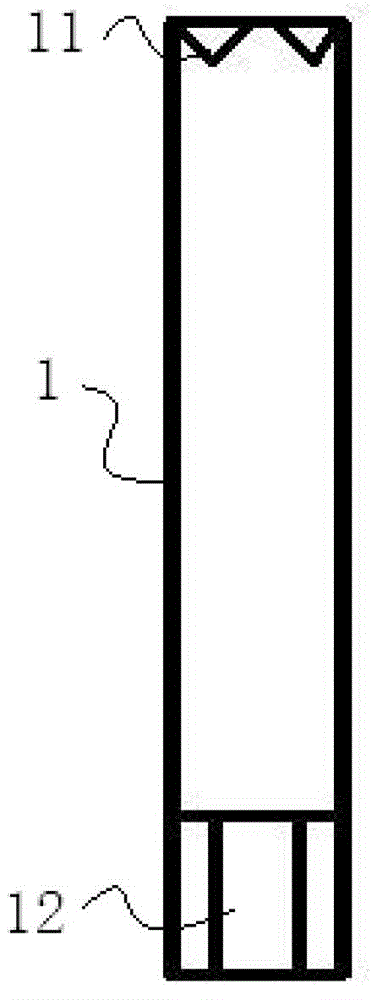

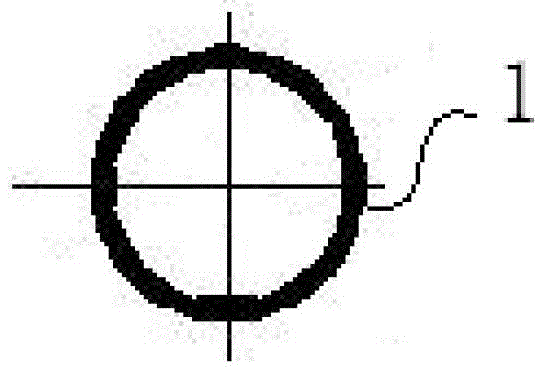

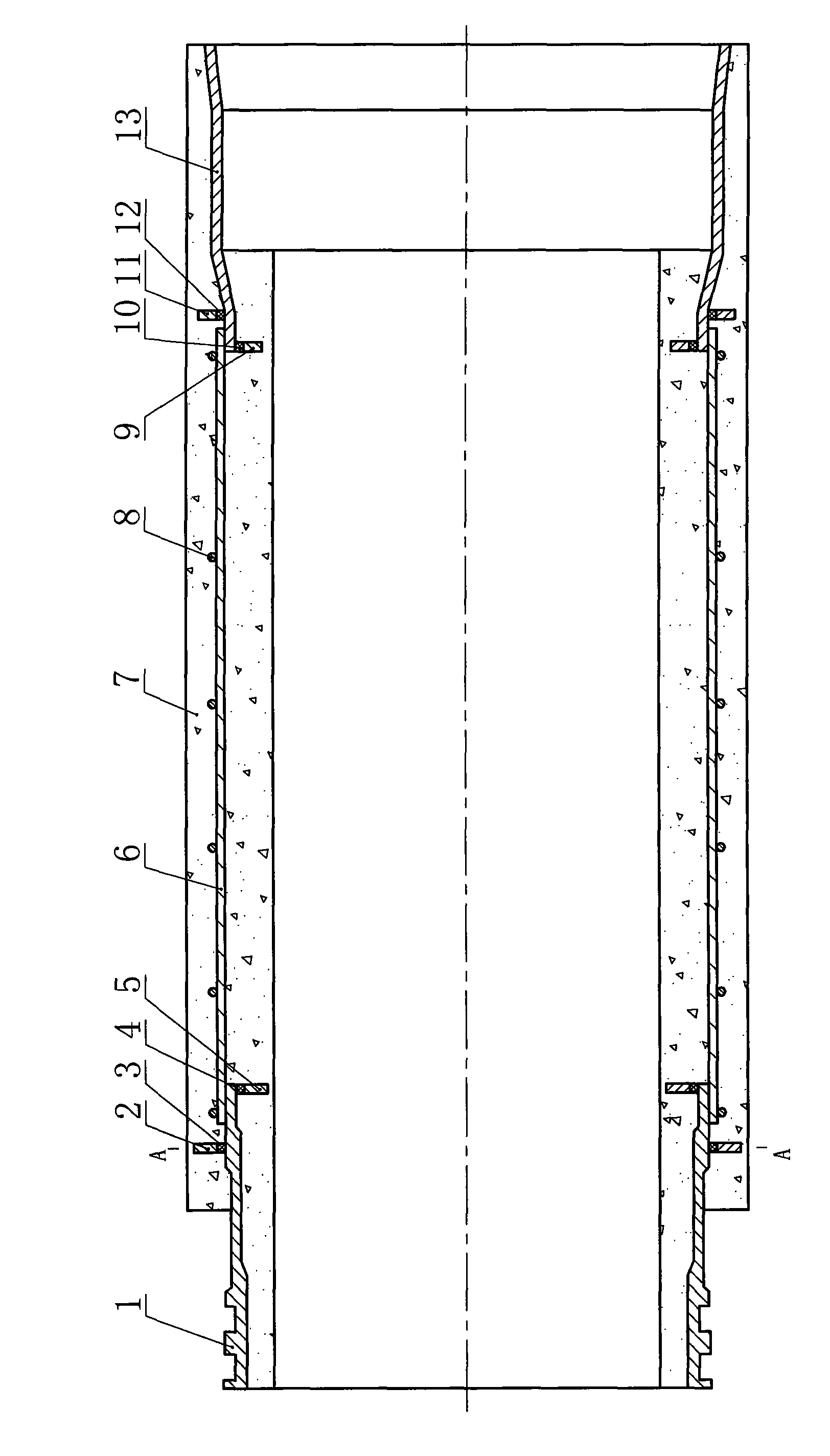

Diesel Engine Cylinder Head Casting Process

ActiveCN103909229BLow shrinkageReduce the probability of water leakageFoundry mouldsFoundry coresWater leakageCylinder head

The invention discloses a diesel engine cylinder cover casting process including the following steps: step 1, using a sling to sling a chassis core onto a flatcar to flatwise place, blowing loose sand and dust in a core group inner chamber away with compressed air; step 2, inserting a full closed cooling jacket at a nail through hole position of the chassis core; step 3, slinging an upper cover plate sand core to place laterally, and blowing the loose sand and dust in the core group inner chamber away with the compressed air; step 4, slinging the upper cover plate sand core to a place above the chassis core for aligned core combination; and step 5, slinging the whole combined core group onto a molding line to put in to cast, and flowing with the molding line to pour. According to the diesel engine cylinder cover casting process, the full closed cooling jacket is arranged at the nail through hole position of the sand core, so that molten iron at the nail through hole can be quenched and simultaneously cooled for solidification, the effects of full fusion of the molten iron and blockage of water leakage and gas leakage can be achieved, production of shrinkage cavities of a casting can be reduced, the water leakage rate of a cylinder cover casting can be reduced, and cylinder cover casting quality and operation performances of an assembled engine can be improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

Leakproof seal type steel bell and spigot concrete pipe

InactiveCN101936428AImprove water retentionPrevent seepageSleeve/socket jointsRigid pipesSpot weldingSealant

The invention relates to a leakproof seal type steel bell and spigot concrete pipe. Two ends of a concrete pipe are respectively and fixedly provided with a bellmouth steel ring ad a spigot steel ring, wherein the bellmouth steel ring and / or the spigot steel ring are / is radially welded and fixedly connected with a bellmouth water-resisting ring and a spigot water-resisting ring, a waterproof sealant is packaged in a gap between the bellmouth water-resisting ring and the bellmouth steel ring, a waterproof sealant is packaged in a gap between the spigot water-resisting ring and the spigot steel ring, and the bellmouth water-resisting ring and the spigot water-resisting ring are respectively fixedly arranged on the bellmouth steel ring and the spigot steel ring inside the concrete pipe. The provided leakproof seal type steel bell and spigot concrete pipe in the invention has the advantages of strong structural leakage resistance, simple manufacture, and shortened production time, and can effectively enhance the integral sealing property of a pipeline and guarantee the water supply pressure.

Owner:TIANJIN WATERLINE PIPELINE ENG CO LTD

Parallel type lower water valve structure of humidifier and combined use mode thereof

ActiveCN111089380AImprove securityGuaranteed to workLighting and heating apparatusSpace heating and ventilation detailsEngineeringStructural engineering

The invention discloses a parallel type lower water valve structure of a humidifier and a combined use mode thereof. The structure comprises valve boxes; multiple valve boxes can be provided; the multiple valve boxes are arrayed and laminated; a floater is arrayed with valve ejecting columns corresponding to lower water ports in number; the heights of the valve ejecting columns are reduced in sequence from right to left; and when two adjacent valve boxes are laminated, the valve boxes on the lower sides totally cover second lower ports of the valve boxes on the upper sides thereof, and first lower water ports of the valve boxes on the upper sides are exposed beyond the covering range of the valve boxes on the lower side.

Owner:BEIJING YADU ENVIRONMENTAL PROTECTION TECH

Method for large-diameter shield tunnel segment monitoring cable to pass through second lining

PendingCN114017062AThe overall impact is smallReduce the probability of water leakageMining devicesUnderground chambersGeotechnical engineeringStructural engineering

The invention provides a method for large-diameter shield tunnel segment monitoring cable to pass through a second lining, on the premise that the second lining is subjected to staged pouring construction, before pouring of backfilled concrete on the two sides of an opening piece, the cable penetrates through the backfilled position of the opening piece through a support and a cable guide groove and is fixed to a specific position, so that a sensor cable is wound out to the outer side of the second lining concrete steel formwork, after second lining concrete is poured, the cable is fixed to the surface of the second lining concrete, and cable fixing is completed. Holes can be prevented from being formed in the second lining concrete structure, the overall influence on the second lining concrete structure is reduced, and meanwhile the probability of water leakage of the pipeline is reduced. By means of the method, monitoring can be conducted in all stages before secondary lining concrete pouring, in pouring and after pouring, the monitoring interruption time is short, and the continuity of the monitoring time is guaranteed. The whole cable can be connected to the acquisition instrument at a time, cable joints are reduced, and signal loss caused by the cable joints is avoided.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO +1

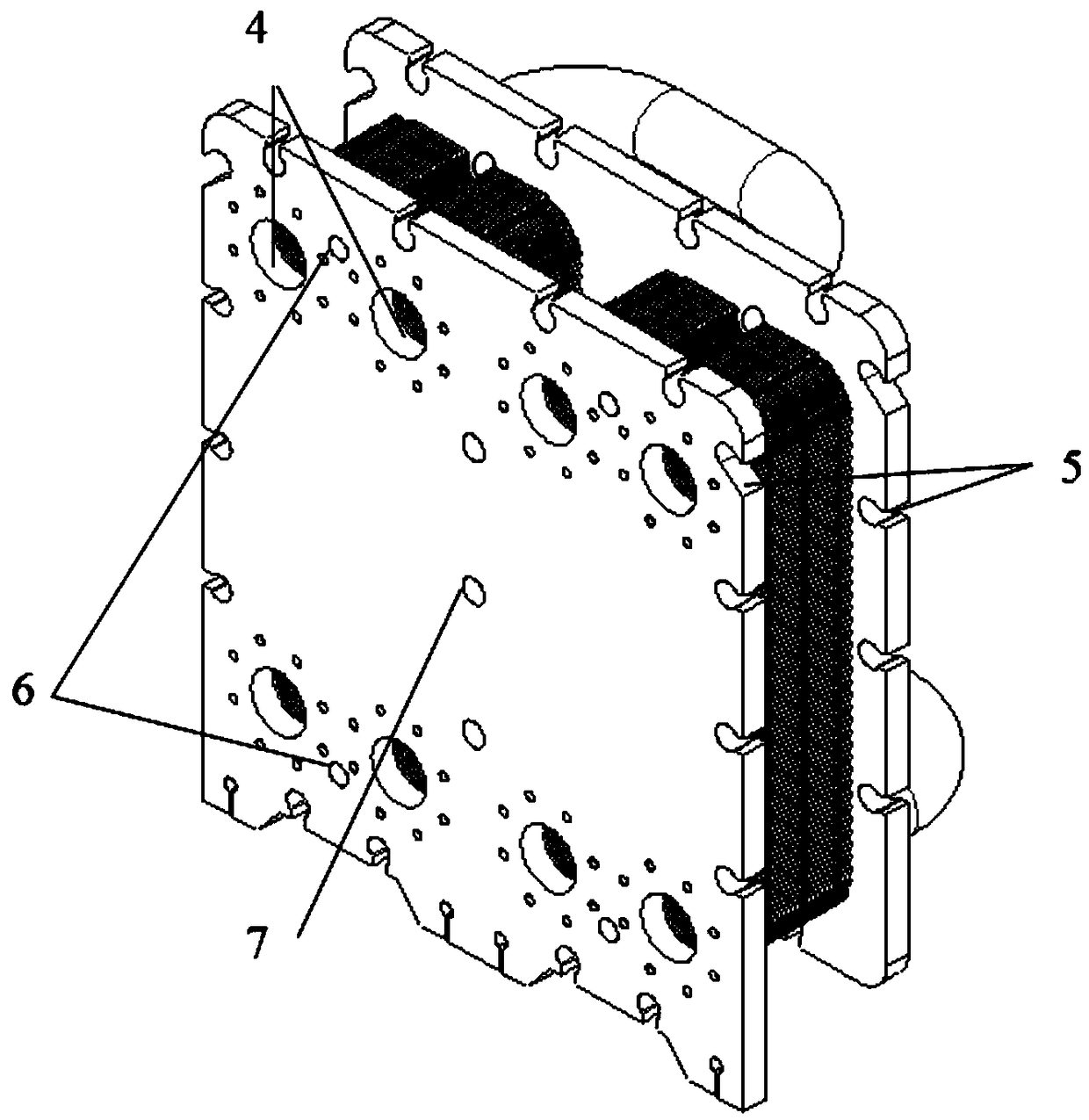

Combined plate heat exchanger with external communicating passage

PendingCN109141081AEven by forceReduce deformation rateLaminated elementsStationary plate conduit assembliesPlate heat exchangerWater leakage

The invention relates to a combined plate heat exchanger with an external communicating passage. The combined plate heat exchanger comprises end pressing plates, heat exchange plate bundle units and outer pipes. The end pressing plates comprise a fixed pressing plate and a movable pressing plate, and the fixed pressing plate and the movable pressing plate are vertically arranged side by side. Theheat exchange plate bundle units are evenly mounted between the fixed pressing plate and the movable pressing plate. A plurality of mounting locating holes corresponding to the ends of the heat exchange plate bundle units are arranged on the end pressing plates, and every two mounting locating holes form a group. The end pressing plates and the heat exchange plate bundle unit are connected and fixed by every group of mounting locating holes through fixing devices. A plurality of inlet and outlet hole sets corresponding to the ends of the outer pipes are formed in the fixed pressing plate or the movable pressing plate. The combined plate heat exchanger has the beneficial effects that the use ranges of the heat exchanger is widened, the flow capacity of the heat exchanger is guaranteed, andtherefore the heat exchange efficiency is improved; and the phenomenon of water leakage caused by plate deformation is avoided, and manual assembling is convenient.

Owner:SHANGHAI PANDA MACHINEGRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com