Header cold water pipe open communication heat absorption heat exchanger and manufacturing process thereof

A technology of cold water pipes and heat exchangers, which is applied in the field of heat-absorbing heat exchangers connected to the open of header cold water pipes and its manufacturing process, which can solve the problems of poor heat absorption effect and heat exchange efficiency due to the inability of cold water pipes to be filled with acid solution for cleaning. Low-level problems, to achieve the effects of compact structure, reduced water leakage rate, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

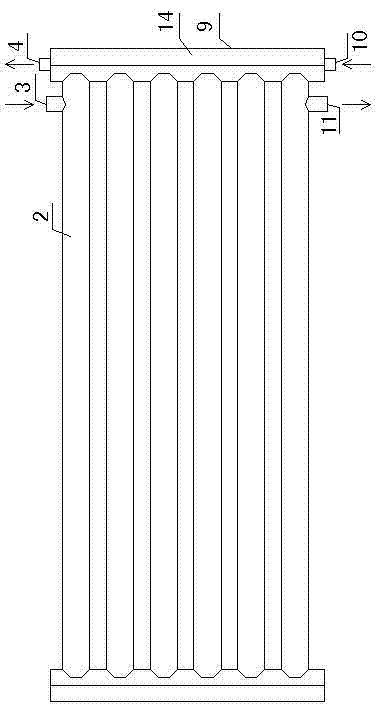

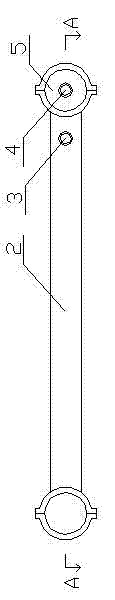

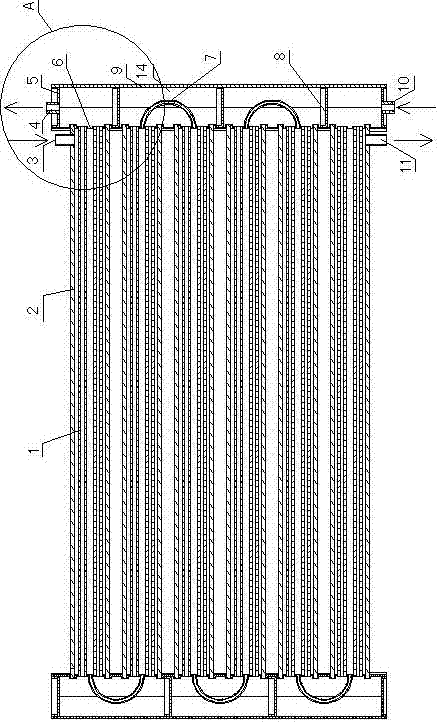

Embodiment 1

[0045] A header with cold water pipes open and connected to a heat-absorbing heat exchanger, including six heat supply pipes 2, the two ends of the heat supply pipes 2 are respectively welded with a circular pipe-shaped header 9, such as image 3 As shown, there is a terminal cover plate 5 at the end of the header 9, the heating inlet 3 and the heating outlet 11 are respectively arranged at both ends of the heating pipe to communicate with the heating pipe, and the cold water outlet 4 and the cold water inlet 10 are respectively arranged at the header 9 The end cover plate 5 communicates with the water storage Unicom shunt chamber 14 of the header; the inner orifice plate 6 is welded in the openings of the two ends of the heat supply pipe 2 respectively, and the inner orifice plate 6 is provided with two cold water pipe connection holes 12 ; The inner orifice plate 6 is also provided with a heat supply pipe connection hole 13; The heat supply pipes 2 are welded and connected i...

Embodiment 2

[0055] A header with cold water pipes open and connected to a heat-absorbing heat exchanger, including six heat supply pipes 2, with D-shaped headers 9 welded to both ends of the heat supply pipes 2, such as Figure 7 As shown, there is a terminal cover plate 5 at the end of the header 9, the heating inlet 3 and the heating outlet 11 are respectively arranged on the header 9 to communicate with the heat supply pipe 2, and the cold water outlet 4 and the cold water inlet 10 are respectively arranged on the end cover The plate 5 is in communication with the water storage Unicom shunt chamber 14 in the header 9; the inner orifice plate 6 is respectively welded in the mouth of the heat supply pipe 2, and two cold water pipe connection holes 12 are arranged on the inner orifice plate 6; The connecting pipe is a connecting straight pipe 15, and the connecting straight pipe 15 directly connects the adjacent heating pipes 2 sequentially; The hole wall of the connection hole 12 is weld...

Embodiment 3

[0064] A header with cold water pipes open and connected to a heat-absorbing heat exchanger, including two heat supply pipes 2, and the two ends of the heat supply pipes 2 are respectively welded with a circular header 9, such as Figure 11 As shown, there is a terminal cover plate 5 at the end of the header 9, the heating inlet 3 and the heating outlet 11 are respectively arranged on the header 9 to communicate with the heat supply pipe 2, and the cold water outlet 4 and the cold water inlet 10 are respectively arranged on the end cover The plate 5 is in communication with the water storage Unicom shunt chamber 14 of the header 9; the inner orifice plate 6 is respectively welded in the mouth of the heat supply pipe 2, and two cold water pipe connection holes 12 are arranged on the inner orifice plate 6; The connecting pipe is a connecting straight pipe 15, and the connecting straight pipe 15 directly connects the adjacent heat supply pipes 2 in sequence; two cold water pipes 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com