Advanced treatment and reuse method of printing and dyeing waste water

A printing and dyeing wastewater and advanced treatment technology, which is applied in water/sewage treatment, water treatment parameter control, flotation water/sewage treatment, etc., can solve the problems of increasing the burden on enterprises, increasing costs, and high costs, so as to improve filtration efficiency , saving resources and increasing liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The decolorizing agent is a flocculation decolorizing agent;

[0027] The air flotation machine is a super-efficient shallow air flotation machine;

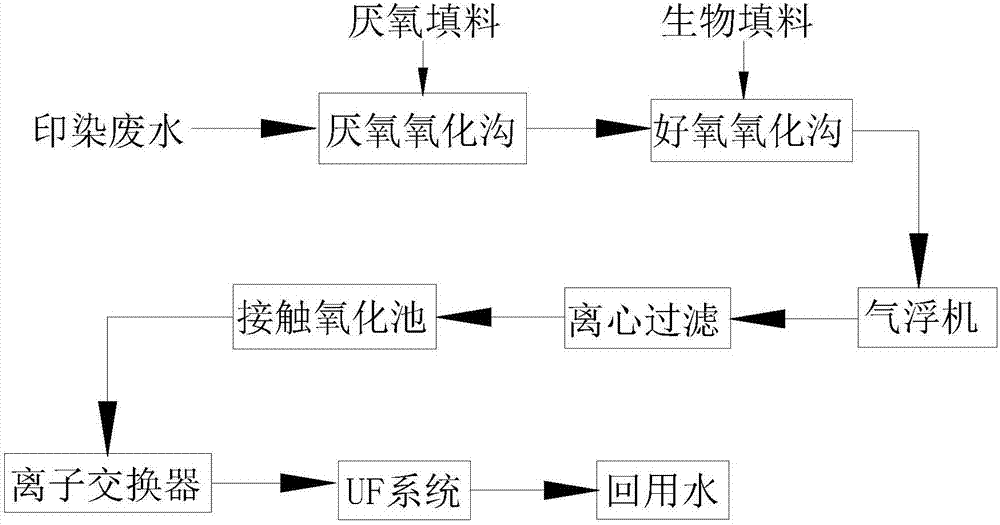

[0028] refer to figure 1 , a method for advanced treatment and reuse of printing and dyeing wastewater, wherein the printing and dyeing wastewater is recycled through an anaerobic oxidation ditch, an aerobic oxidation ditch, an air flotation machine, a centrifugal filter tank, a contact oxidation tank, an ion exchanger and a UF reaction tank in sequence;

[0029] The specific operation of the printing and dyeing wastewater from the anaerobic oxidation ditch to the air flotation machine is as follows: when the printing and dyeing wastewater enters the anaerobic oxidation ditch, anaerobic filler is put into the anaerobic oxidation ditch, and the aeration device in the anaerobic oxidation ditch acts for 3 hours, and then stands still 5h, it is convenient for the anaerobic filler to hang the film, and then discharged into the...

Embodiment 2

[0035] The decolorizing agent is an oxidation decolorizing agent;

[0036] The air flotation machine is a vortex concave air flotation machine;

[0037] refer to figure 1 , a method for advanced treatment and reuse of printing and dyeing wastewater, wherein the printing and dyeing wastewater is recycled through an anaerobic oxidation ditch, an aerobic oxidation ditch, an air flotation machine, a centrifugal filter tank, a contact oxidation tank, an ion exchanger and a UF reaction tank in sequence;

[0038]The specific operation of the printing and dyeing wastewater from the anaerobic oxidation ditch to the air flotation machine is as follows: when the printing and dyeing wastewater enters the anaerobic oxidation ditch, anaerobic filler is put into the anaerobic oxidation ditch, and the aeration device in the anaerobic oxidation ditch acts for 3 hours, and then stands still 6h, it is convenient for the anaerobic filler to hang the film, and then discharged into the aerobic oxi...

Embodiment 3

[0044] The decolorizing agent is an adsorption decolorizing agent;

[0045] The air flotation machine is an advection air flotation machine;

[0046] refer to figure 1 , a method for advanced treatment and reuse of printing and dyeing wastewater, wherein the printing and dyeing wastewater is recycled through an anaerobic oxidation ditch, an aerobic oxidation ditch, an air flotation machine, a centrifugal filter tank, a contact oxidation tank, an ion exchanger and a UF reaction tank in sequence;

[0047] The specific operation of the printing and dyeing wastewater from the anaerobic oxidation ditch to the air flotation machine is as follows: when the printing and dyeing wastewater enters the anaerobic oxidation ditch, anaerobic filler is put into the anaerobic oxidation ditch, the aeration device in the anaerobic oxidation ditch acts for 4 hours, and then it is left standing 7h, it is convenient for the anaerobic filler to hang the film, and then it is discharged into the aero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com