Welding device

A technology of welding equipment and welding torch, which is applied in the field of welding equipment for welding automobile radiators. It can solve the problems of long welding hours, ugly appearance, and weld scars on finished products, and achieve the effects of improving welding efficiency, beautiful appearance, and uniform weld scars.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

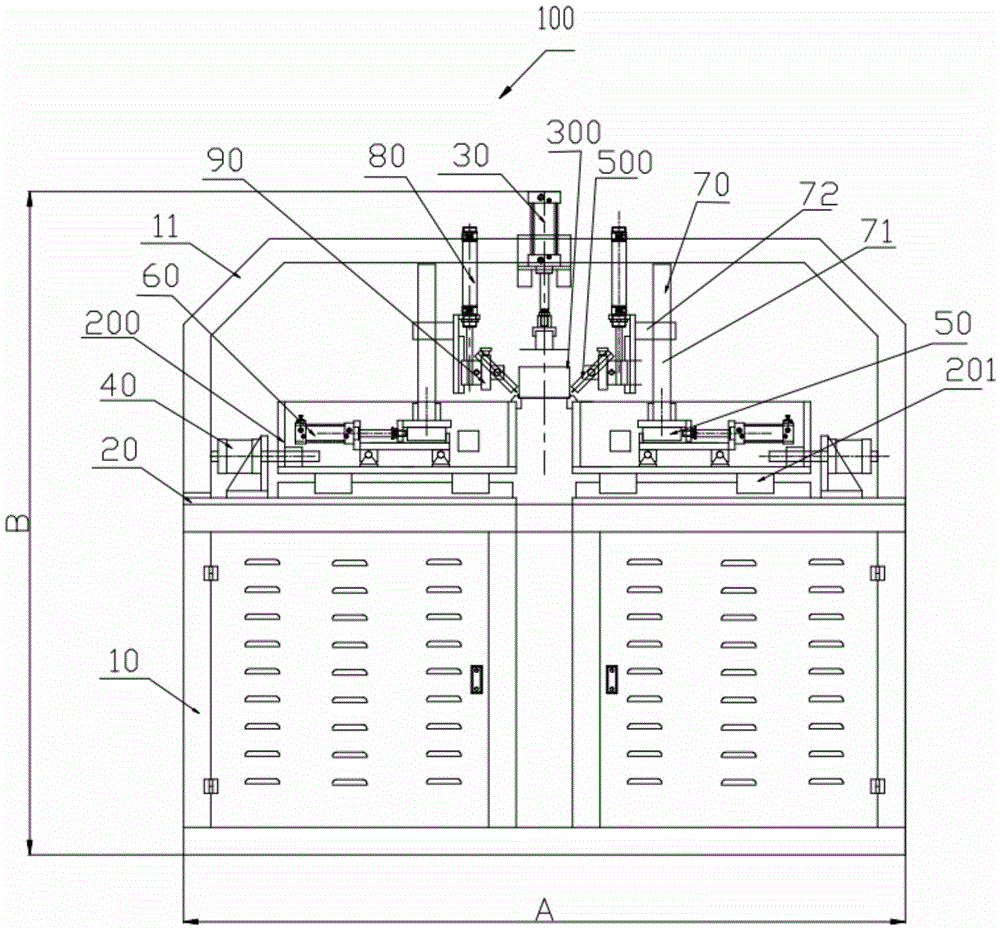

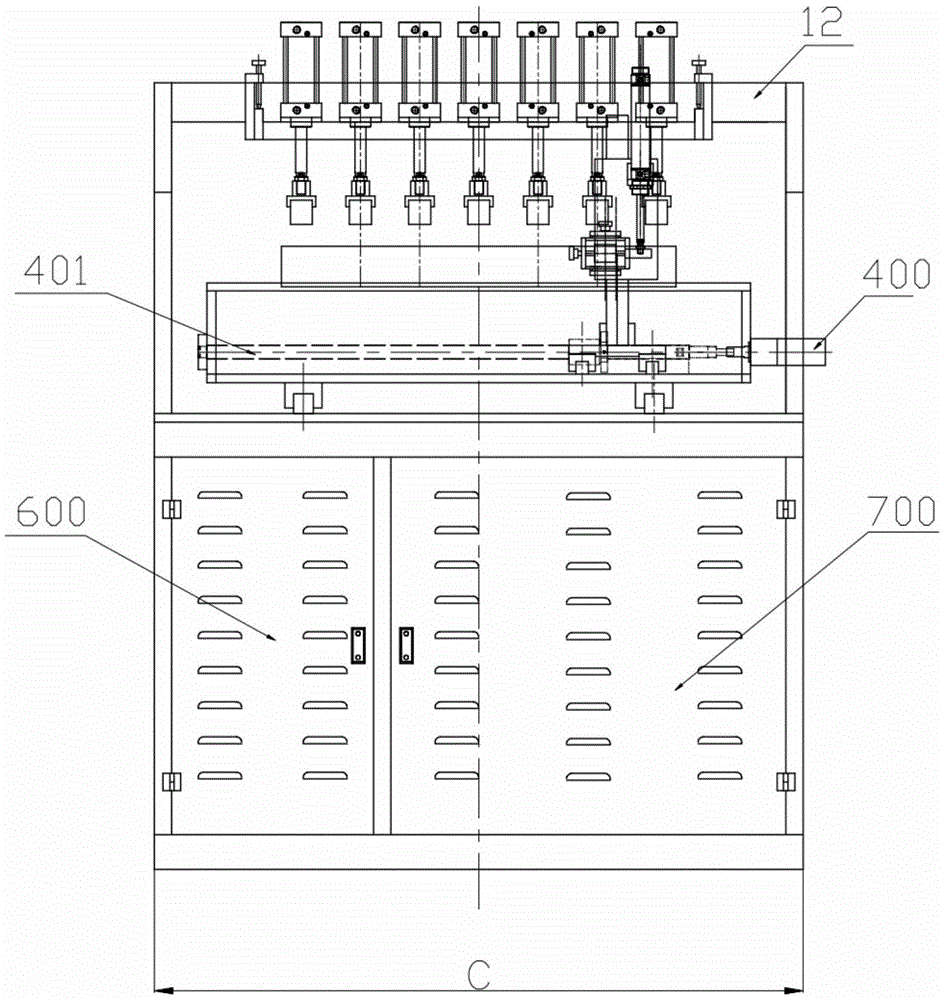

[0021] see Figure 1 to Figure 4 , the welding equipment 100 of the present invention is used for welding the water chamber 200 and the heat dissipation core 300 of the automobile radiator. The welding device 100 includes a frame 10 . The top of the frame 10 is provided with a console 20 . The operating platform 20 includes two parallel and opposite beams 11 arranged on its front and rear sides and a vertical beam 12 vertically connecting the two beams 11 . A plurality of first positioning cylinders 30 are arranged on the longitudinal beam 12 f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com