Drainage hopper for exposed frame curtain wall

A technology for exposed frame curtain walls and drainage buckets, which is applied in the direction of roof drainage, walls, building components, etc., can solve the problems of increasing the risk of water leakage and affecting the service life of exposed frame curtain walls, etc., to reduce the probability of water leakage, easy to operate, Enhanced sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

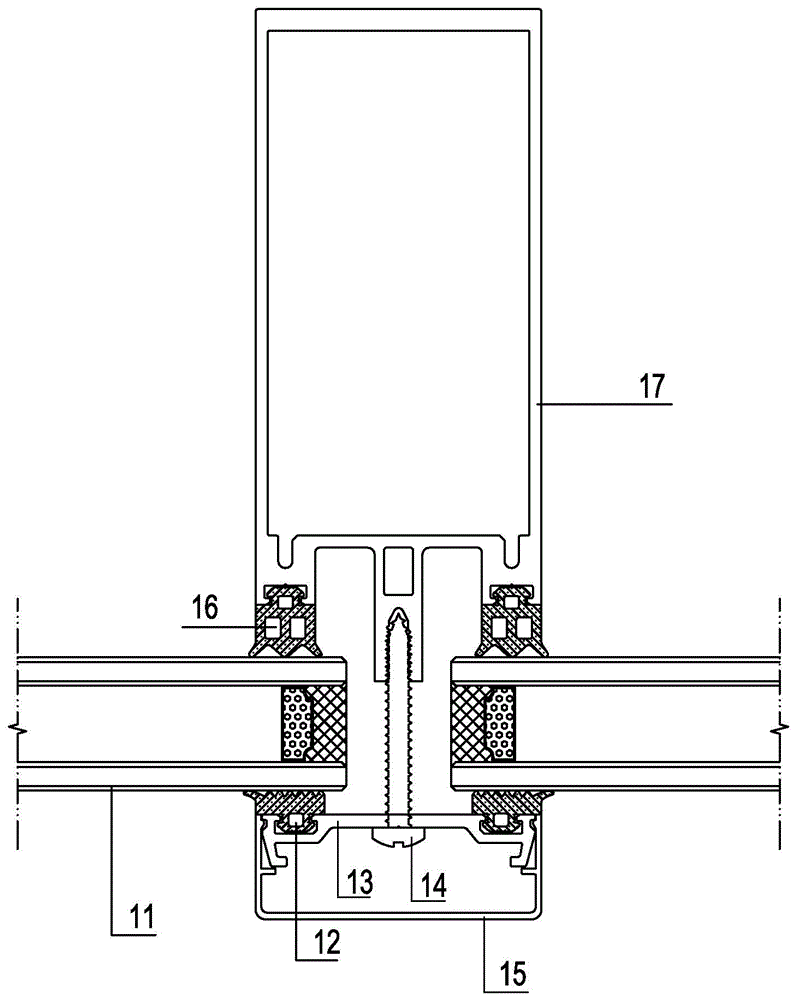

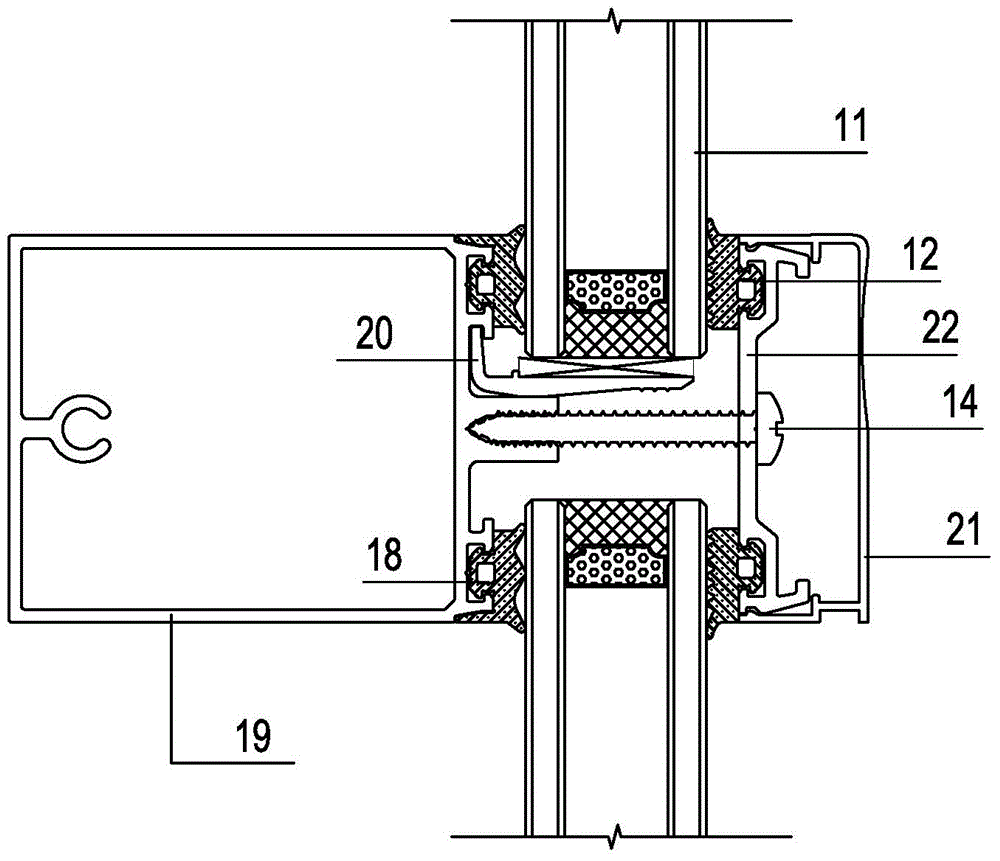

[0024] Such as Figure 3 to Figure 9 As shown, the drainage bucket 30 for the bright frame curtain wall of the present invention includes a main body 31 with a Y-shaped cross section and three ends. The three ends of the main body 31 are two water inlets 33 and one water outlet 34. On the upper surface of 31, from each water inlet end 33 to outlet end 34 concaves, be provided with the flowing water groove 32 that groove depth gradually becomes darker, and flowing water groove 32 forms water inlet groove 331 at water inlet end 33, and flowing water groove 32 is at water outlet end 34. Form the water outlet 341 that can make the water flow down, that is to say, the flow tank 32 is from the water inlet 331 to the water outlet 341, the depth of the groove is from shallow to deep, and the bottom of the groove is inclined, so that the water falling into the water inlet 331 can smoothly flow to the water outlet 341 flows and flows out, the main body 31 is provided with a positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com