Header body shell tube communication pressure-bearing heat exchanger

A heat exchanger and box technology, applied in the field of HVAC, can solve the instability of the welded connection structure of the heat exchanger of the cold fluid header, the inflexible setting and manufacture of the shell-side channel and the tube-side channel, and the inability to install vertically To achieve the effect of improving product quality, enhancing strength and rigidity, and facilitating vertical or horizontal installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

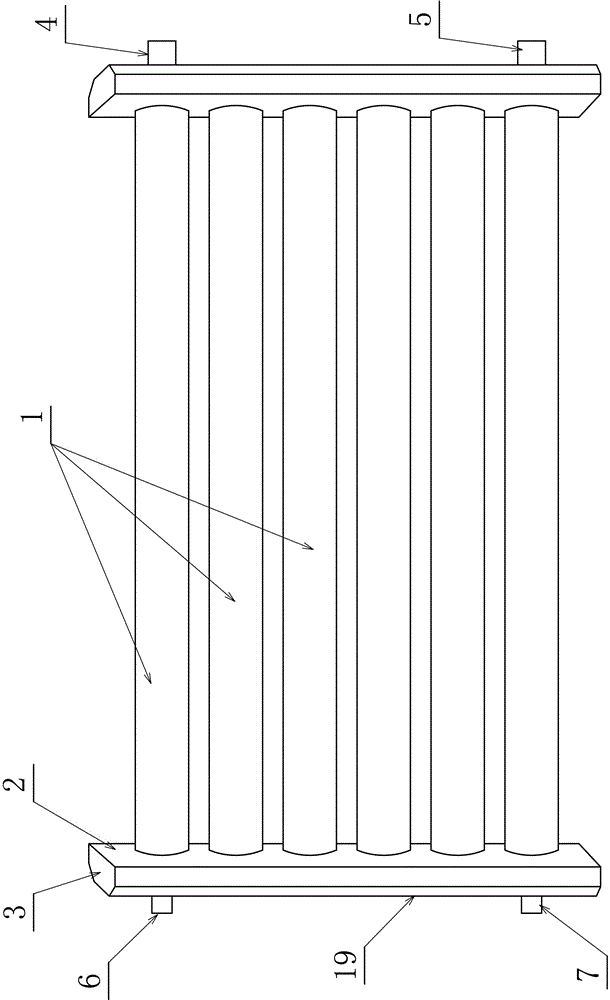

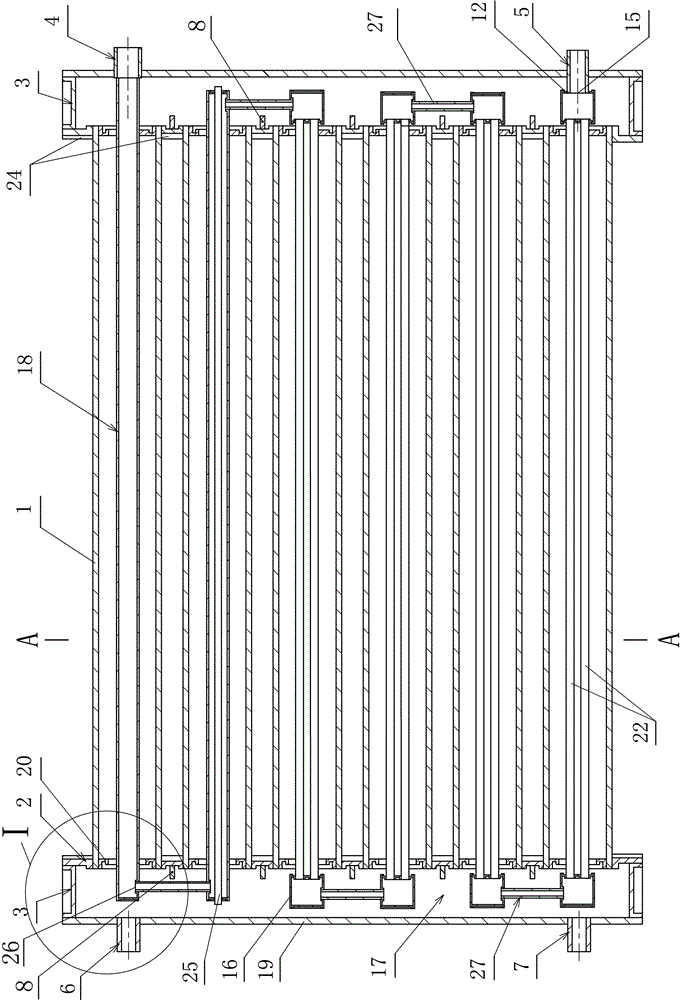

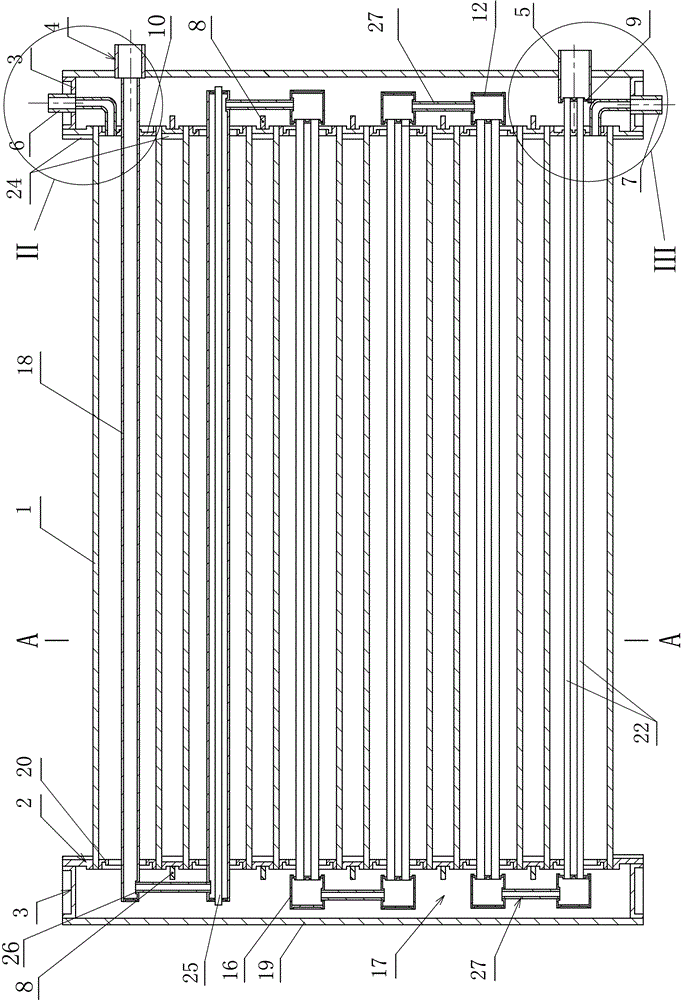

[0039] 1. A pressure-bearing heat exchanger connected by a header body shell tube of the present invention, such as Figure 1 to Figure 24 shown. It includes two header bodies, and the header body parts include: header inner orifice plate 2, header outer plate 19 and end cover plate 3; pipe joint installation holes 21 are opened on some parts of the header body, or the header body Pipe joint installation holes 21 are not opened on some components; pipe joints I7, pipe joints II6, pipe joints III4, and pipe joints IV5 are provided on some parts of the header body; Constitute a fluid circulation heat transfer flow channel; the space where the inner orifice plate 2 of the header is welded and combined with the outer plate 19 of the header is the inner chamber 17 of the header; the end cover plate 3 is sealed and welded to block the port of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com