Method for casting copper alloy butterfly valve plate

A technology of copper alloy and disc valve, which is applied in the field of valve plate casting, can solve problems such as uneven wall thickness, insecure quality, and imperfect technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

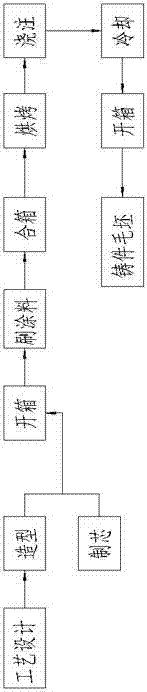

[0033]Embodiment: The copper alloy disc valve plate casting method of this example, the pouring weight of this piece is 800KG, and the pouring temperature is 1165-1170°C, such as figure 1 , whose steps are:

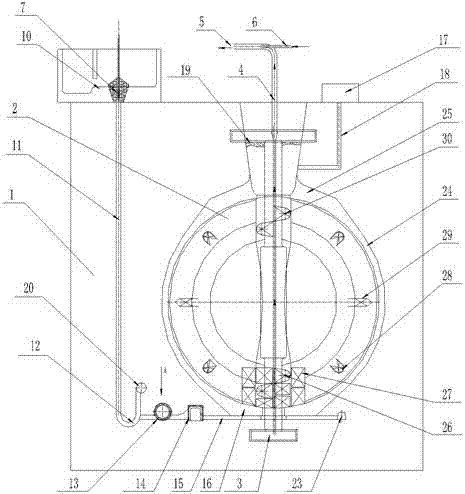

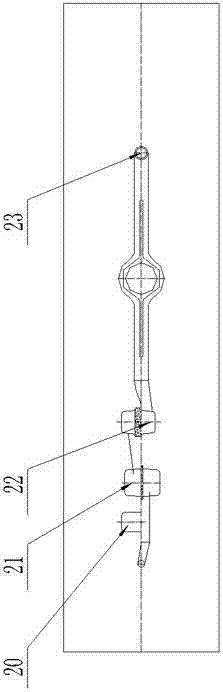

[0034] a. Castings are molded by resin sand real sample wood mold, such as figure 2 , image 3 Place the mud core 2 in the sand box 1, the lower end of the mud core is provided with the first cold iron 26, the second cold iron 27, the middle part of the mud core is distributed with the third cold iron 28, the fourth cold iron 29, the mud core The upper end of is provided with the fifth cold iron 30, and all cold irons are separated in half, stays 3mm interval in the middle, puts chrome ore at the interval after the two half cold irons are closed. The inner ring of the cavity of the sand box is provided with a slag collection groove 24 and an exhaust groove 25. The mud core is suspended by two T-shaped mud core heads 3. The mud core forms the shape of the inner wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com