Steel sheet pile cofferdam connecting structure for hydraulic engineering construction

A technology for steel sheet pile cofferdams and water conservancy projects, applied in water conservancy projects, underwater structures, sheet pile walls, etc., can solve the problems of difficult precise control of position accuracy, water leakage of cofferdams, inconvenience of cofferdam construction, etc. Improved compactness, reduced water leakage, and improved overall compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is attached Figure 1-3 The application is described in further detail.

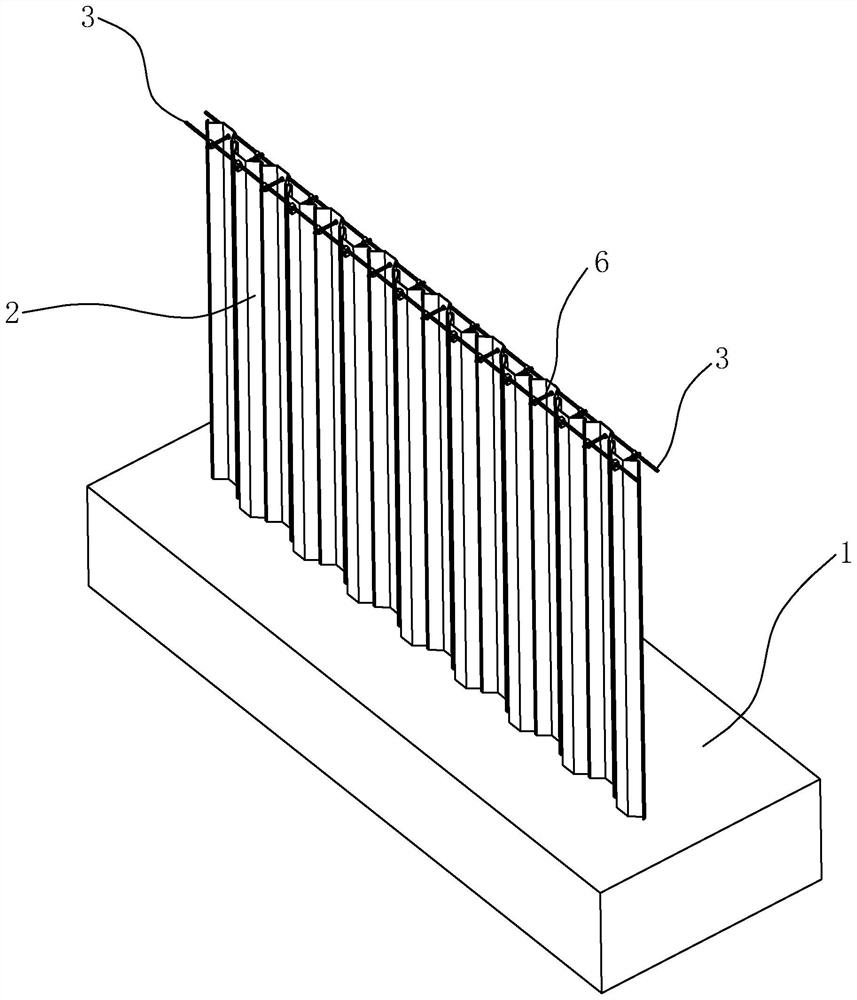

[0028] The embodiment of the present application discloses a steel sheet pile cofferdam connection structure for hydraulic engineering construction. refer to figure 1 The cofferdam construction needs to be carried out before the construction of the water conservancy project. The river bed 1 of the river course is set horizontally. The cofferdam is formed by assembling several groups of steel sheet piles 2 of the same specification, and each group of steel sheet piles 2 is prefabricated. This cofferdam connection structure includes two groups of first threaded rods 3 installed on each group of steel sheet piles 2 , the two groups of first threaded rods 3 are distributed in parallel, and each group of steel sheet piles 2 is inserted vertically on the river bed 1 .

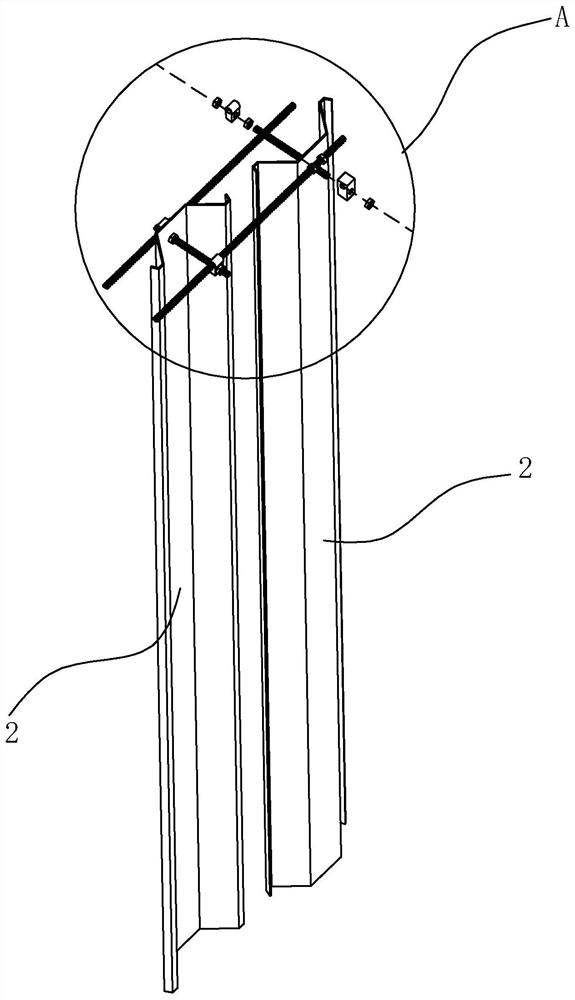

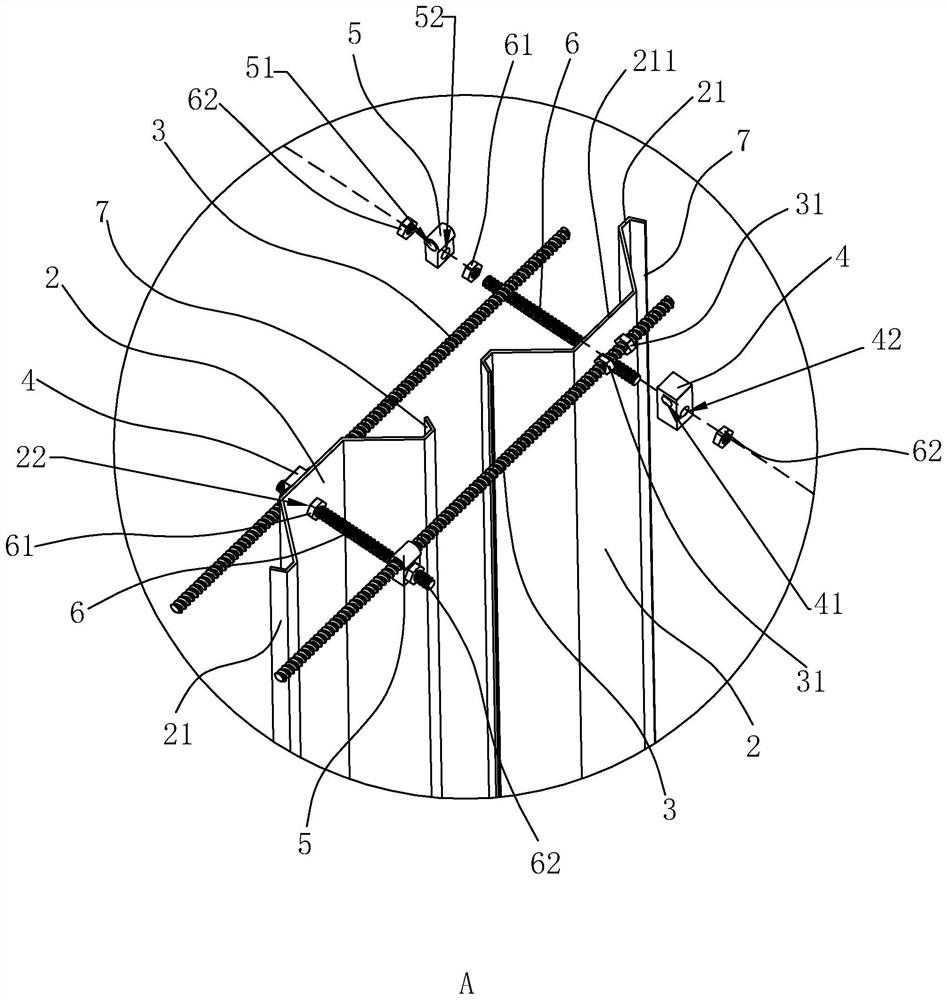

[0029] refer to figure 2 and image 3 , the steel sheet pile 2 includes a groove bottom 211, and after each group of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com