Heat exchanger with open-type, communicated and heat-absorbing cooling water pipe

A technology of cold water pipes and heat exchangers, applied in the field of heat exchangers, which can solve problems such as difficult manufacturing, low heat exchange efficiency, and poor heat absorption effect, and achieve the effects of saving materials, improving heat exchange efficiency, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

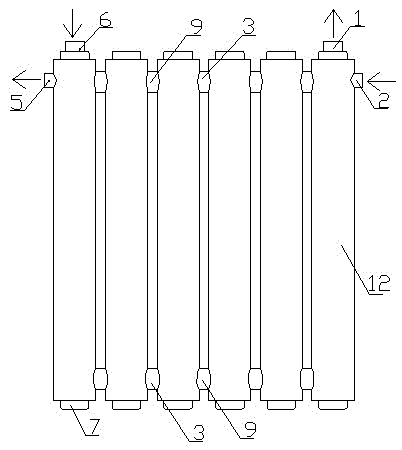

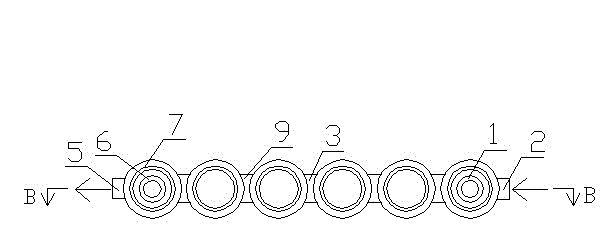

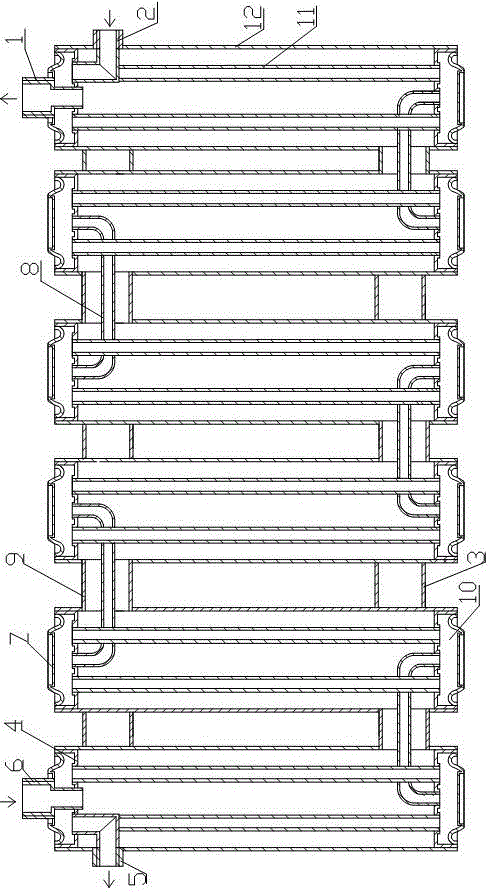

[0041] A kind of cold water pipe open to communicate with heat absorption heat exchanger, including six heat supply pipes 12, heating inlet 6 and heating outlet 1, cold water inlet 2 and cold water outlet 5, such as image 3 As shown, the two ends of the heat supply pipe 12 are respectively welded with heads 7, the heating inlet 6 and the heating outlet 1 pass through the water storage Unicom shunt chamber 10 and the partition (4) in turn to communicate with the inner cavity of the heat supply pipe 12, and the cold water inlet 2 and the cold water outlet 5 pass through the inner cavity of the heat supply pipe 12 and the partition plate 4 to communicate with the water storage communication distribution chamber 10, and the two ends of each heat supply pipe 12 are respectively provided with a water storage communication distribution chamber 10 for supplying The inner cavity of the heat pipe 12 is separated from the water storage Unicom shunt chamber 10 by welding the partition 4; ...

Embodiment 2

[0050] A kind of cold water pipe open to communicate with the heat absorption heat exchanger, including two heat supply pipes 12, heating inlet 6 and heating outlet 1, cold water inlet 2 and cold water outlet 5, such as Figure 6As shown, the two ends of the heat supply pipe 12 are respectively welded with a head 7, the cold water outlet 5 and the cold water inlet 2 are arranged on the head 7 to communicate with the water storage Unicom diversion chamber 10, and the heating inlet 6 and the heating outlet 1 are arranged on the heating pipe 12 communicates with the inner cavity of the heat supply pipe 12, and the two ends of each heat supply pipe 12 are respectively provided with a water storage Unicom shunt chamber 10, and the inner cavity of the heat supply pipe 12 communicates with the water storage Unicom shunt chamber 10 through welding The plate 4 is isolated; the heating pipe 12 is pierced with two cold water pipes 11; The inner cavity of 12 is welded and communicated thr...

Embodiment 3

[0058] A kind of cold water pipe open to communicate with the heat absorption heat exchanger, including four heat supply pipes 12, heating inlet 6 and heating outlet 1, cold water inlet 2 and cold water outlet 5, such as Figure 9 As shown, the two ends of the heat supply pipe 12 are respectively welded with a head 7, the cold water outlet 5 and the cold water inlet 2 are arranged on the head 7 to communicate with the water storage Unicom distribution chamber 10, and the heating inlet 6 and the heating outlet 1 pass through the water storage in turn The Unicom splitter chamber 10 and the partition (4) communicate with the inner cavity of the heat supply pipe 12, and the ports of the heating inlet (6) and the heating outlet (1) are arranged on the partition (4) and inside the heat supply pipe (12) Cavity interlinked;

[0059] The two ends of each heating pipe 12 are provided with a water storage Unicom shunt chamber 10 respectively, and the inner cavity of the heat supply pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com