Leakage detection ditch for building protection in large-thickness collapsible loess area

A technology for collapsible loess and buildings, which is used in construction, underwater structures, water conservancy projects, etc., can solve the problem of not making clear regulations for the subsection leak detection, and achieves narrow leak detection range, small footprint, Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

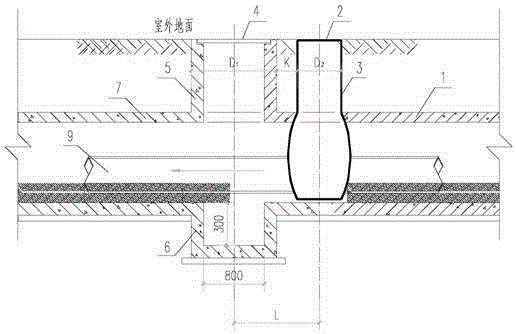

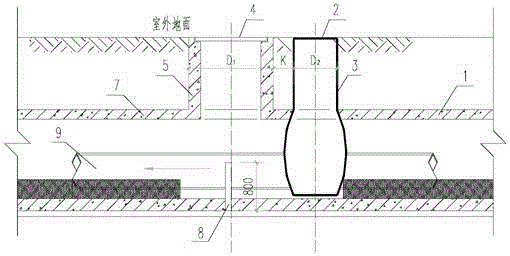

[0033] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

[0034] See attached Figure 3-5 As shown, this kind of leak detection ditch used for building protection in collapsible loess areas, the non-self-weight collapsibility level of the collapsible loess areas is Ⅰ~Ⅳ level, and the leak detection ditch used for building protection ( 1) It is built in accordance with the national standard GB50025-2004 and the national standard atlas S531-1~5, the drainage system and other pipelines are laid in the leak detection ditch, and the inspection well (2) built in the leak detection ditch (1) is made of hard polyvinyl chloride or double-wall bellows, the well base (3) at the lower part of the inspection well (2) is socket-connected with the pipeline (9) laid in the leak detection ditch (1), and the upper part of the inspection well (2) communicates with the atmosphere. The leak detection w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com