Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Reduce the impact of subsequent processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

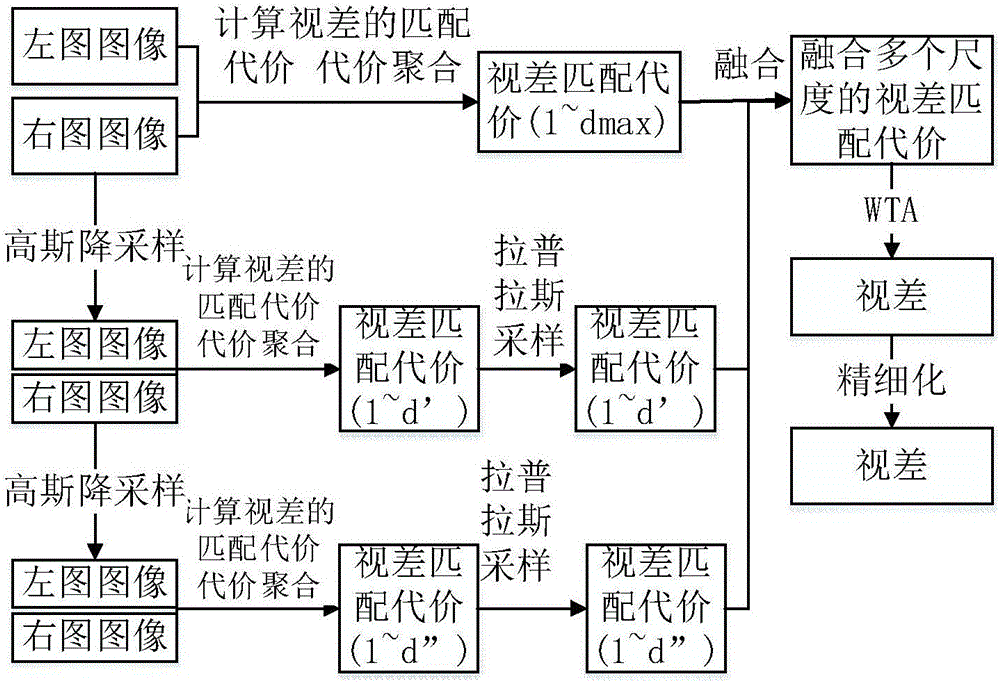

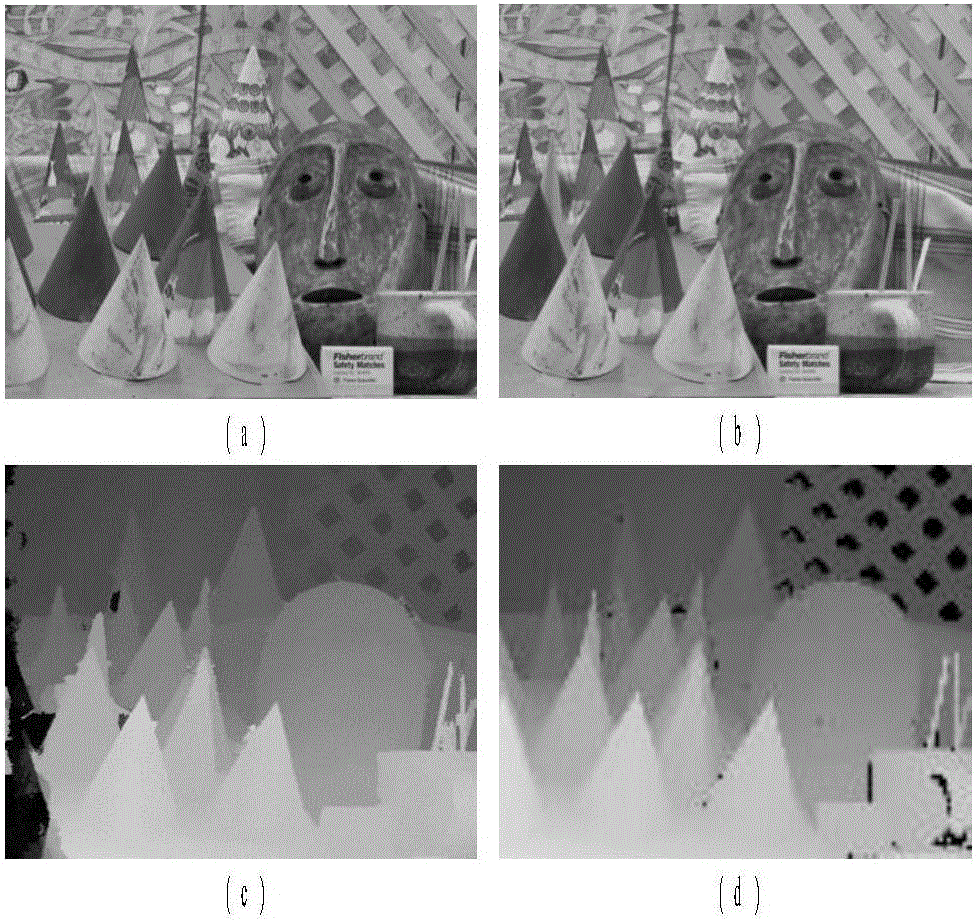

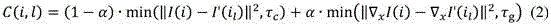

Binocular stereoscopic vision-based stereo matching method

InactiveCN106340036AHigh precisionAlleviate weak and repetitive texturesImage enhancementImage analysisGaussian pyramidA-weighting

The invention relates to a binocular stereoscopic vision-based stereo matching method. The method includes the following six stages: Gaussian pyramid construction; cost calculation matching and cost aggregation; cost fusion matching; disparity computation; disparity map repair and void filling; and disparity refinement. Laplacian pyramid transformation is additionally adopted in the cost aggregation stage. An edge-protection-based interpolation algorithm is used in the disparity map repair and hole filling stage. A weighting and bilateral filtering combination-based disparity refinement method is additionally adopted in the disparity refinement stage, so that a high-accuracy disparity map can be obtained. The calculation amount of the method of the invention is moderate; matching results at different scales are fused, improvement is made in the cost aggregation stage and the disparity refinement stage, and therefore, a better disparity map can be obtained; and the method has certain robustness to illumination, external noises and the like.

Owner:SOUTHEAST UNIV

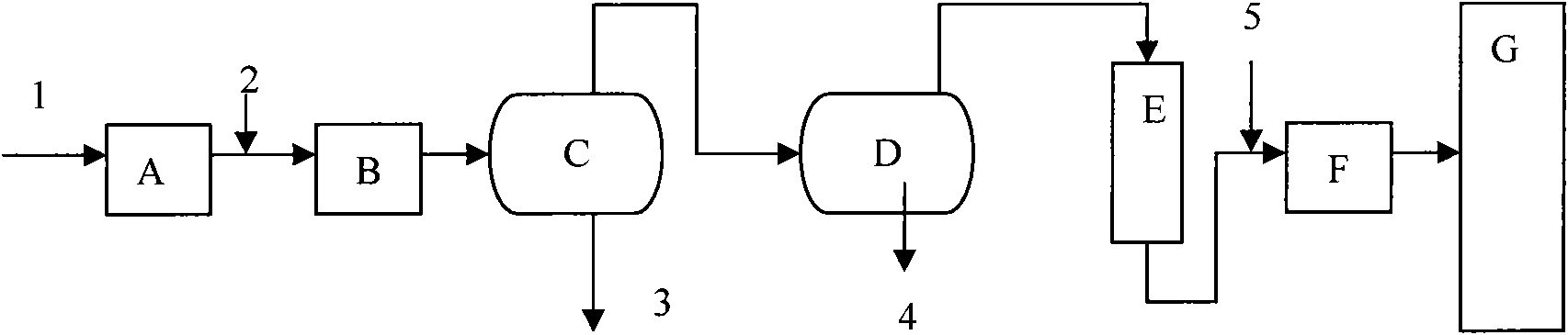

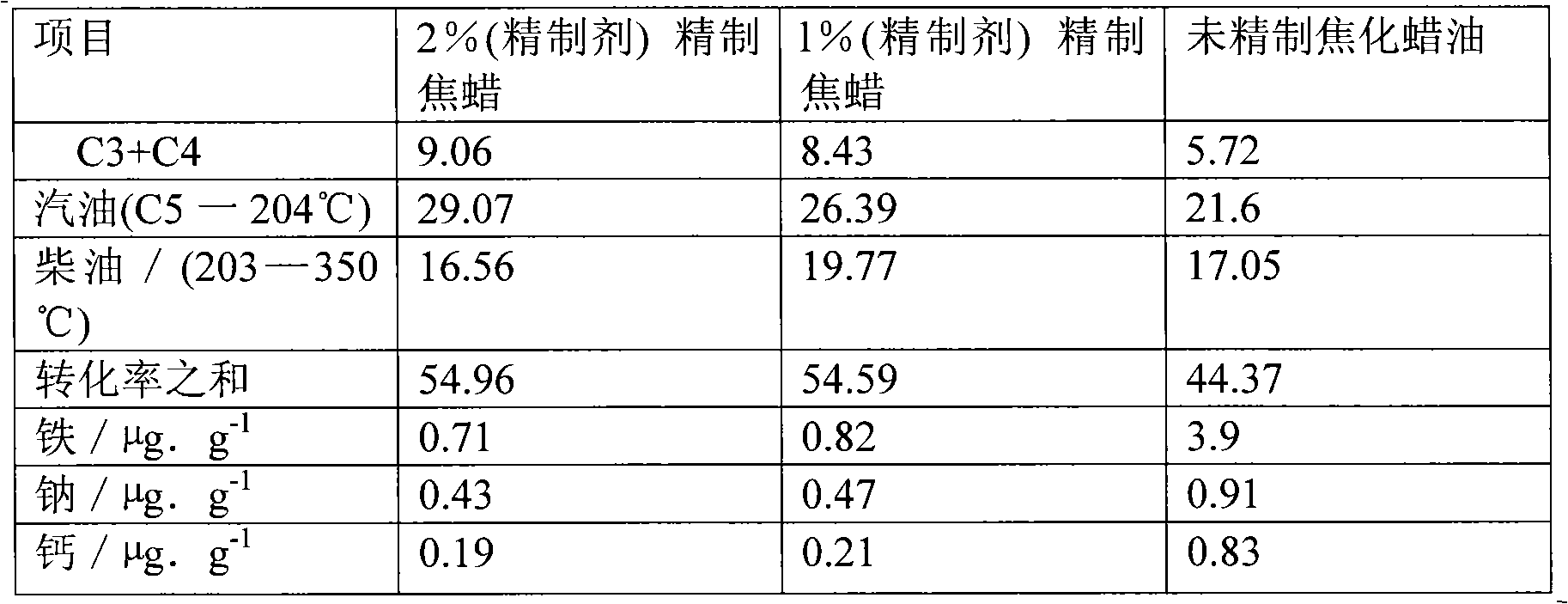

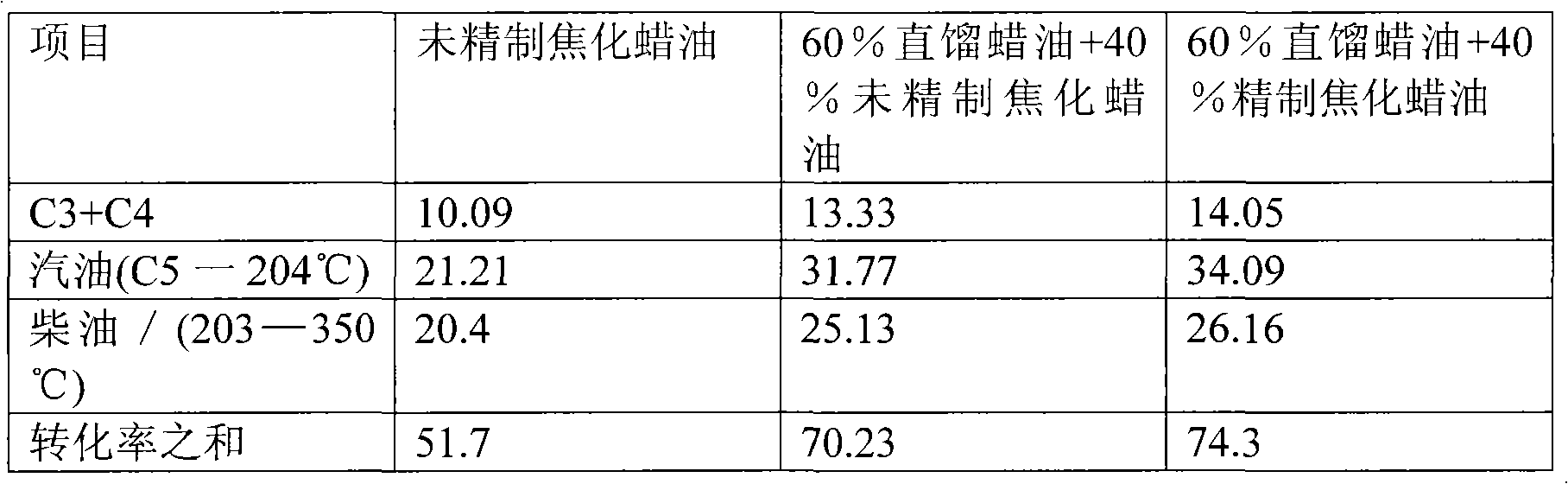

Method for processing fixed bed fishing coker gas oil

ActiveCN102485842AReduce the impact of subsequent processingTreatment with plural serial stages onlyTreatment with hydrotreatment processesSlagFixed bed

The invention relates to a method for processing fixed bed fishing coker gas oil, which comprises the following steps: carrying out heat exchange of a coker gas oil raw material in a heat exchanger A to the temperature of 25-150 DEG C, carrying out mixed reaction with a refining agent in a static mixer, depositing by a settler and separating slag, discharging the sediment from the bottom of the settler, passing the refining oil through an electric settler, discharging the sediment from the bottom of the settler, refining an upper level refining oil through an adsorption filter, carrying out heat exchange on the refined oil by a heat exchanger F to the temperature of 60-500 DEG C and then entering to a catalytic cracking apparatus for catalytic cracking treatment. The adding weight of the refining agent accounts for 0.2-5% of coker gas oil raw material, the adsorption filtering medium is one of active carbon, white clay and diatomite or a compound. The method of the invention solves the problem of washing emulsification and residual nitrogen removal ingredients, and can reduce the influence of subsequent treatment.

Owner:PETROCHINA CO LTD +2

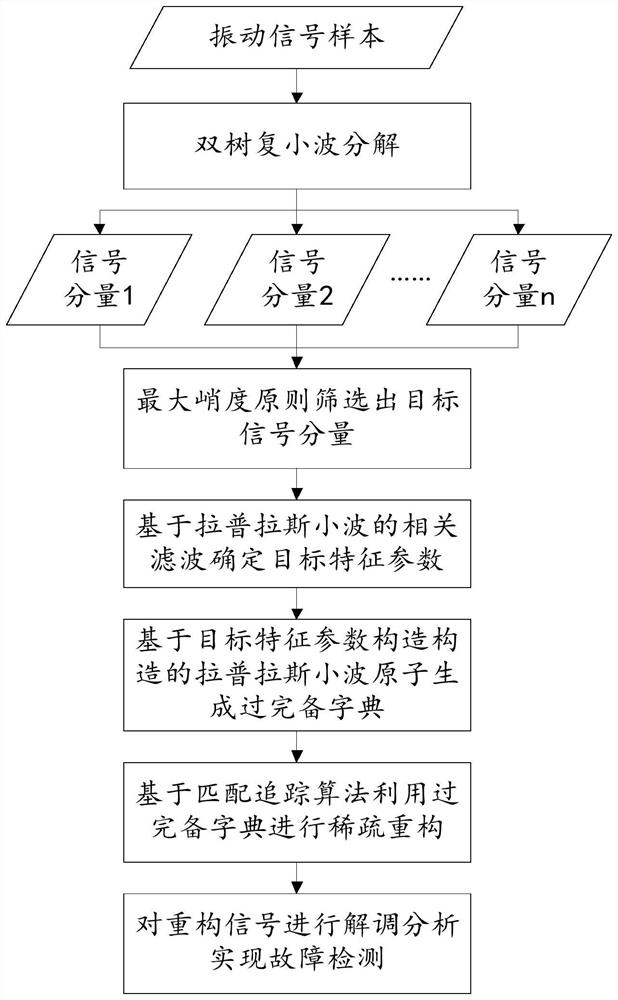

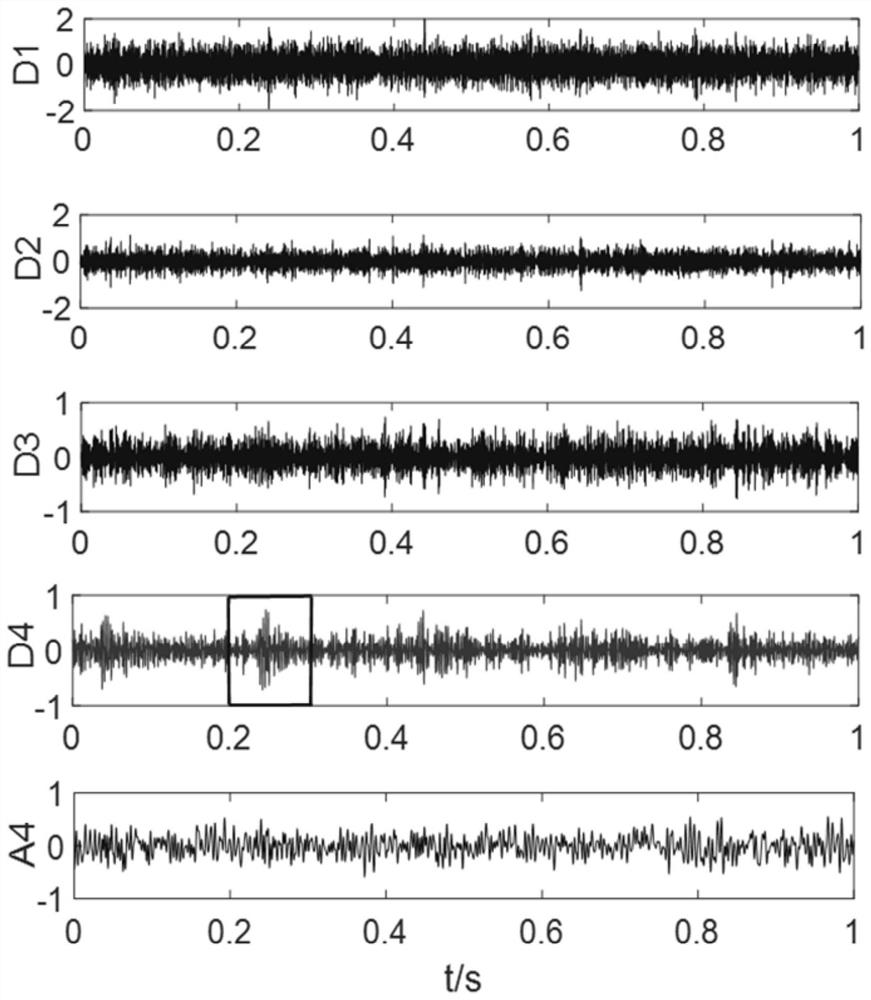

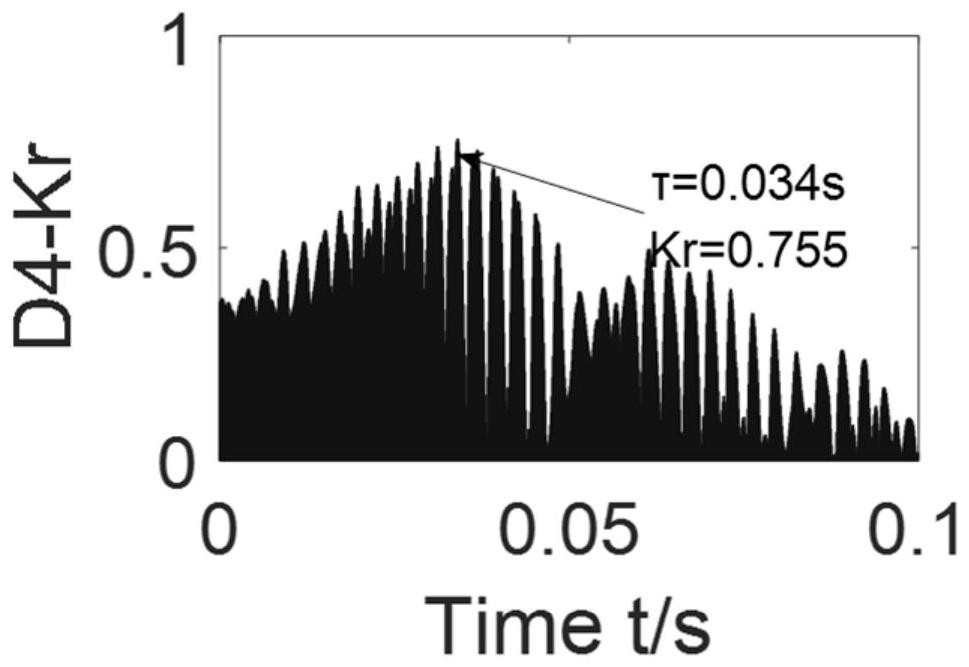

Gear fault detection method based on improved sparse decomposition algorithm

InactiveCN111678691AReduce redundancyEasy pretreatmentMachine part testingAlgorithmWavelet decomposition

The invention discloses a gear fault detection method based on an improved sparse decomposition algorithm, and relates to the technical field of fault detection. The method is based on traditional sparse reconstruction based on a parameter dictionary, and preprocessing of signals and optimization design of a parameter dictionary are added; signal preprocessing is realized by combining dual-tree complex wavelet decomposition with a maximum kurtosis principle; the influence of noise on subsequent processing is greatly reduced; target characteristic parameters are determined based on related filtering of Laplace wavelets so as to construct an over-complete dictionary; the dictionary redundancy can be effectively reduced, the designed dictionary is enabled to be more similar to the fault features, and finally, a matching pursuit algorithm is combined to realize extraction of the impact features in the vibration signals to realize fault detection; and the method can improve the calculationefficiency of sparse representation and realize effective fault diagnosis.

Owner:JIANGNAN UNIV

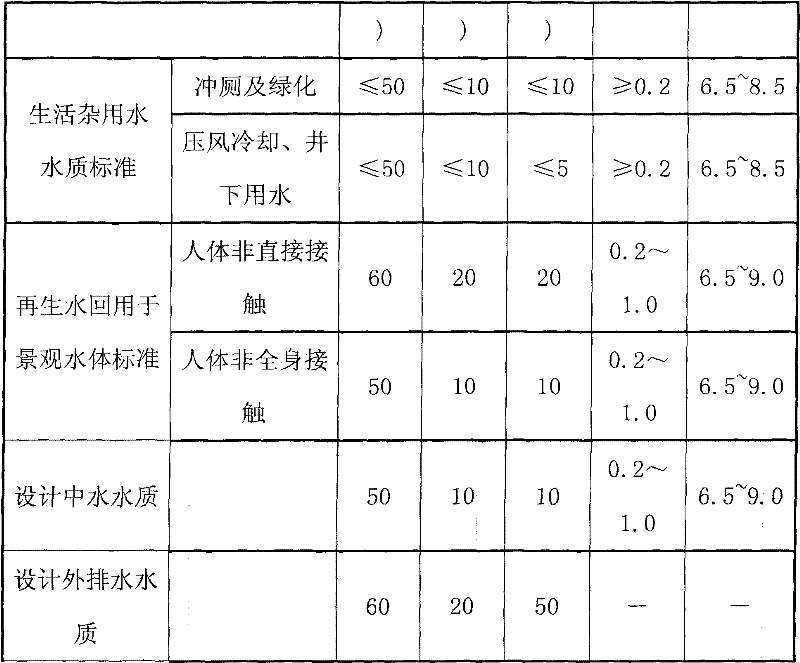

Method for processing emulsified crude oil containing iron sulfide solid particles

ActiveCN108264926AReduce oil content in drainageReduce the impact of subsequent processingDewatering/demulsification with chemical meansDewatering/demulsification regulation/controlPetrochemicalPetroleum

The invention relates to the field of petrochemical industry, and discloses a method for processing emulsified crude oil containing iron sulfide solid particles. The method includes (1), mixing the emulsified crude oil with water and an oil-soluble demulsifier and carrying out first-stage electro-desalting treatment to obtain a mixture; (2), subjecting the mixture obtained in the step (1) to second-stage electro-desalting treatment. By application of the method, oil and water intermediate layer can be thinned, oil content of water discharged can be reduced, and iron sulfide solid particles canbe washed into water phase, so that influence from iron sulfide solid particles to subsequent process can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

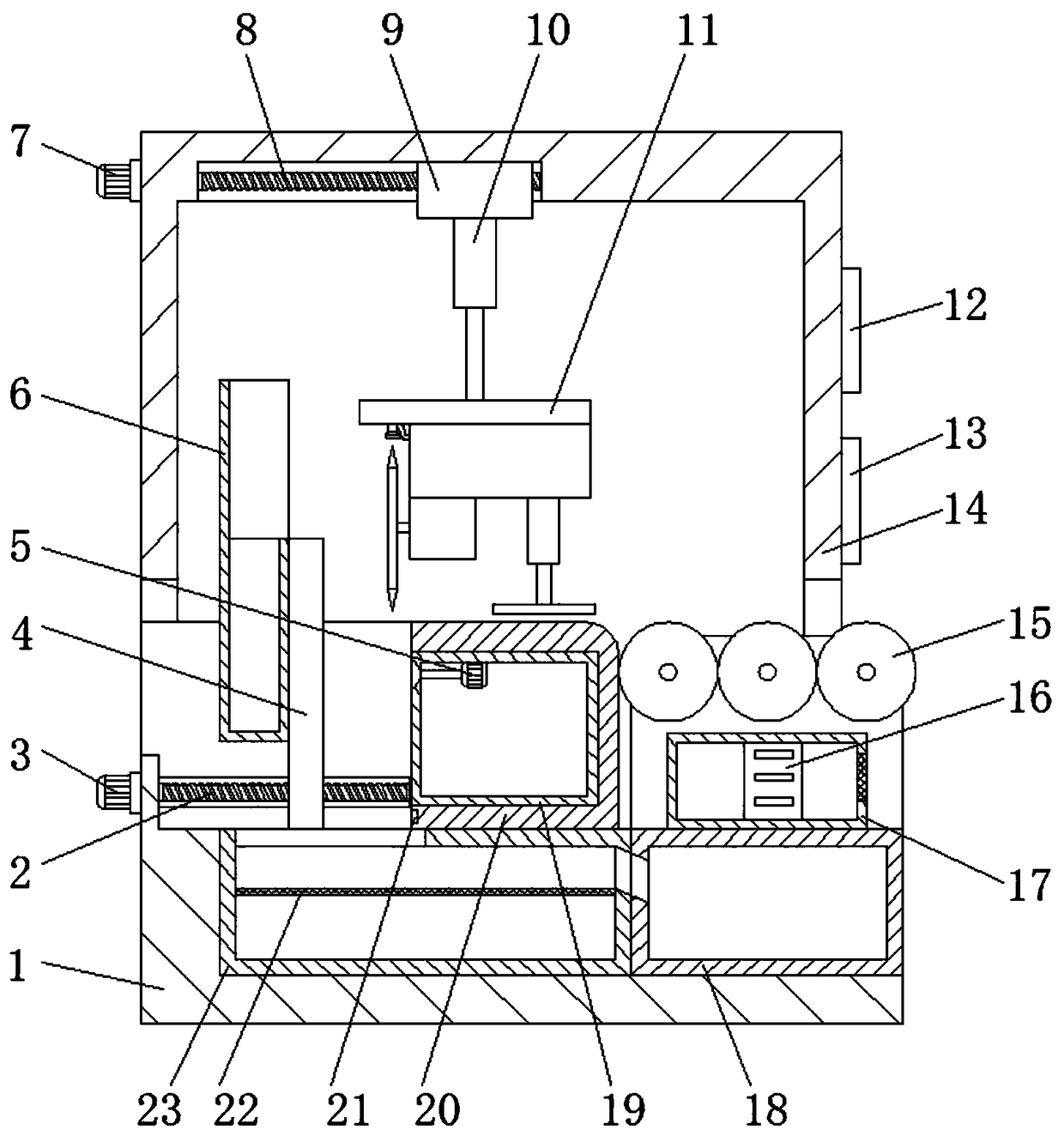

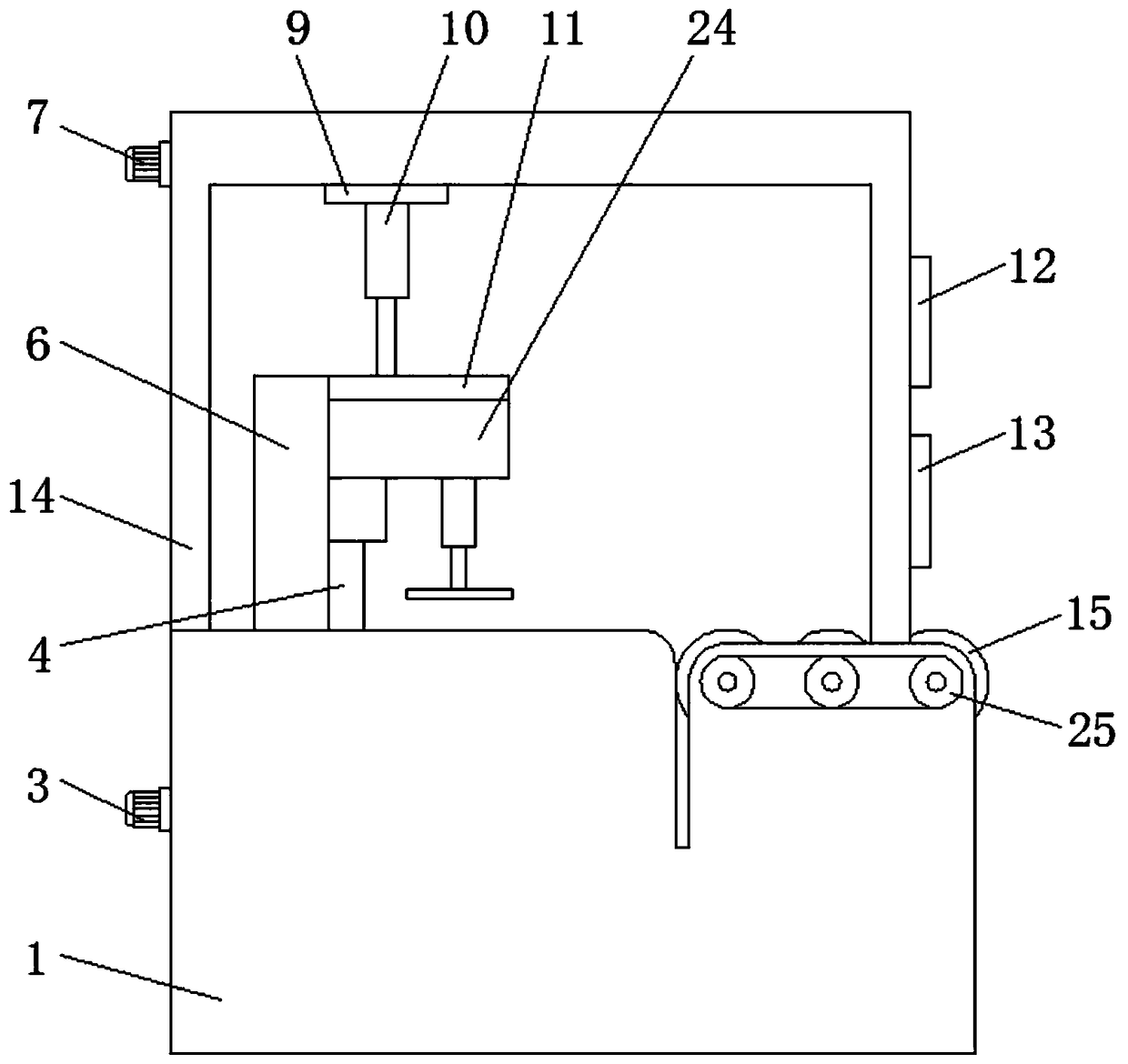

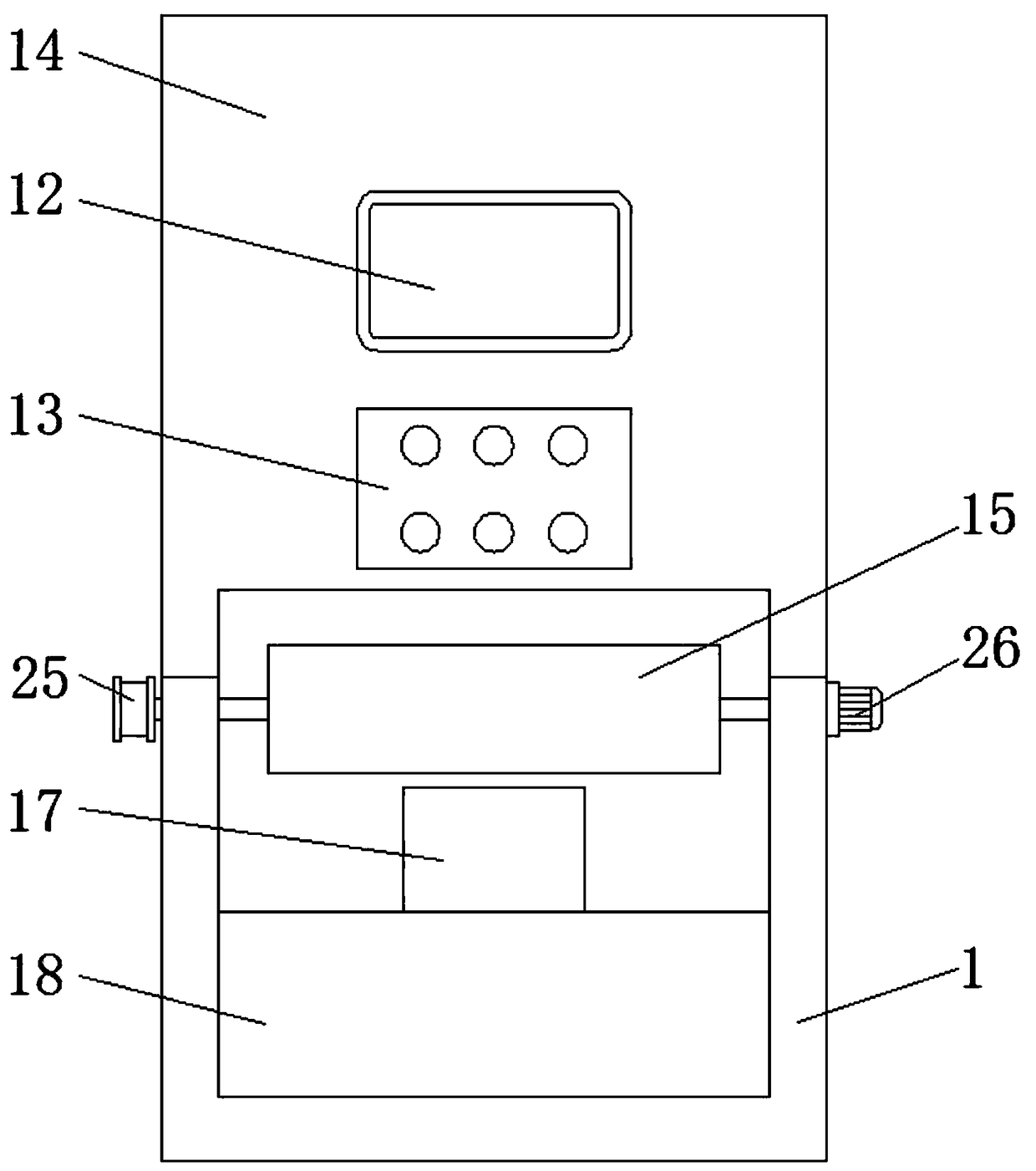

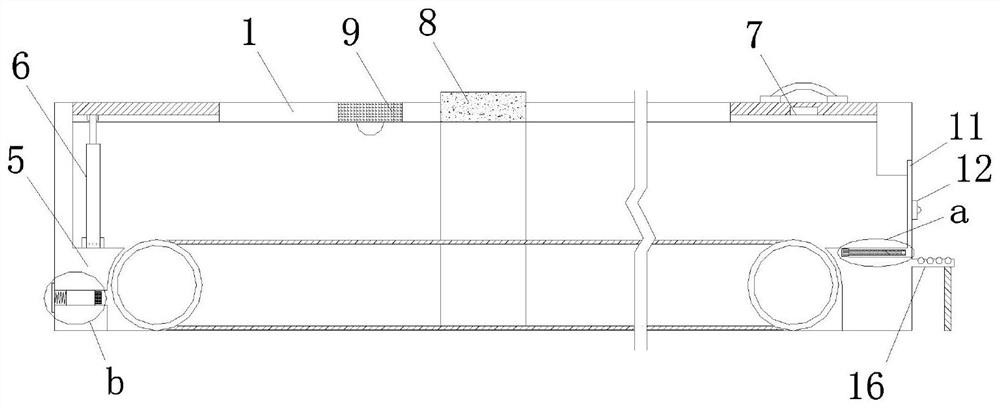

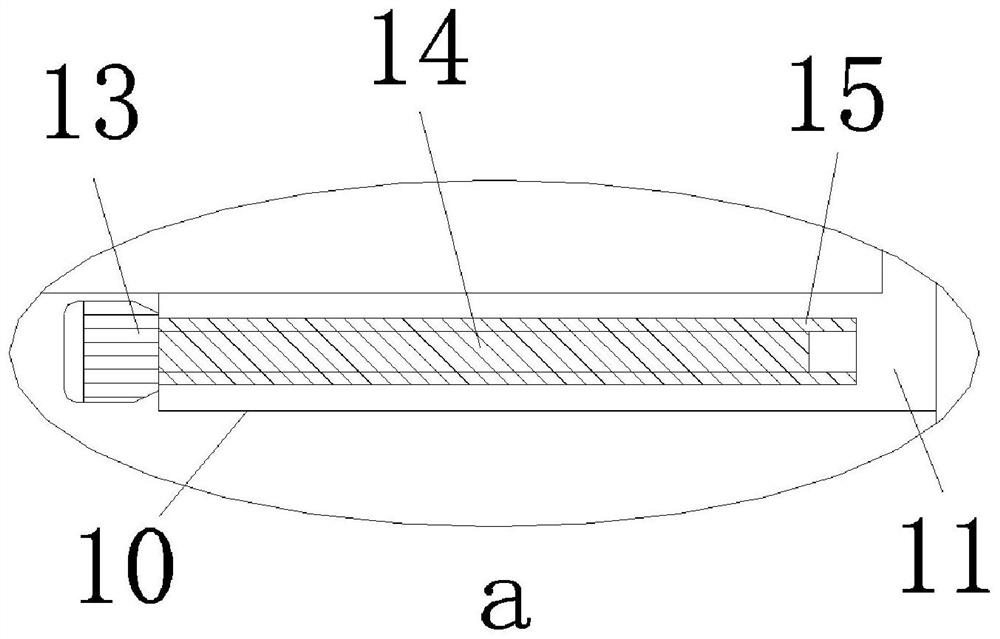

Slicing device with self-cleaning function based on computer technology

ActiveCN108972041AIncrease the fixation strengthPhenomena that improve processing qualityLarge fixed membersCleaning using liquidsTransmission beltDrive shaft

The invention belongs to the technical field of slicing devices, particularly relates to a slicing device with a self-cleaning function based on a computer technology and aims to solve the problems that an existing slicing device is inconveniently cleaned. The slicing device comprises a frame, a transmission shaft mounting hole is formed in the top of the outer wall of one side of the frame, the outer wall of the transmission shaft mounting hole is connected with a transmission shaft through a key, two sides of the outer wall of the transmission shaft are connected with a conveying roller anda belt pulley through keys, the outer wall of one side of the belt pulley is in sleeve connection with a transmission belt, the outer wall of one side of the frame is connected with a conveying motorthrough a key, and an output shaft of the conveying motor is fixed to the outer wall of one end of the transmission shaft through a coupler. The effect of displacement of a part to be machined on machining quality can be improved, cutting distances can be rapidly adjusted and measured, machining convenience and machining efficiency can be improved, a cutter can be kept clean, splashing of cleaningliquid can be avoided, pollution to a working environment can be avoided, and product quality can be improved.

Owner:徐州飞云泡沫制品有限责任公司

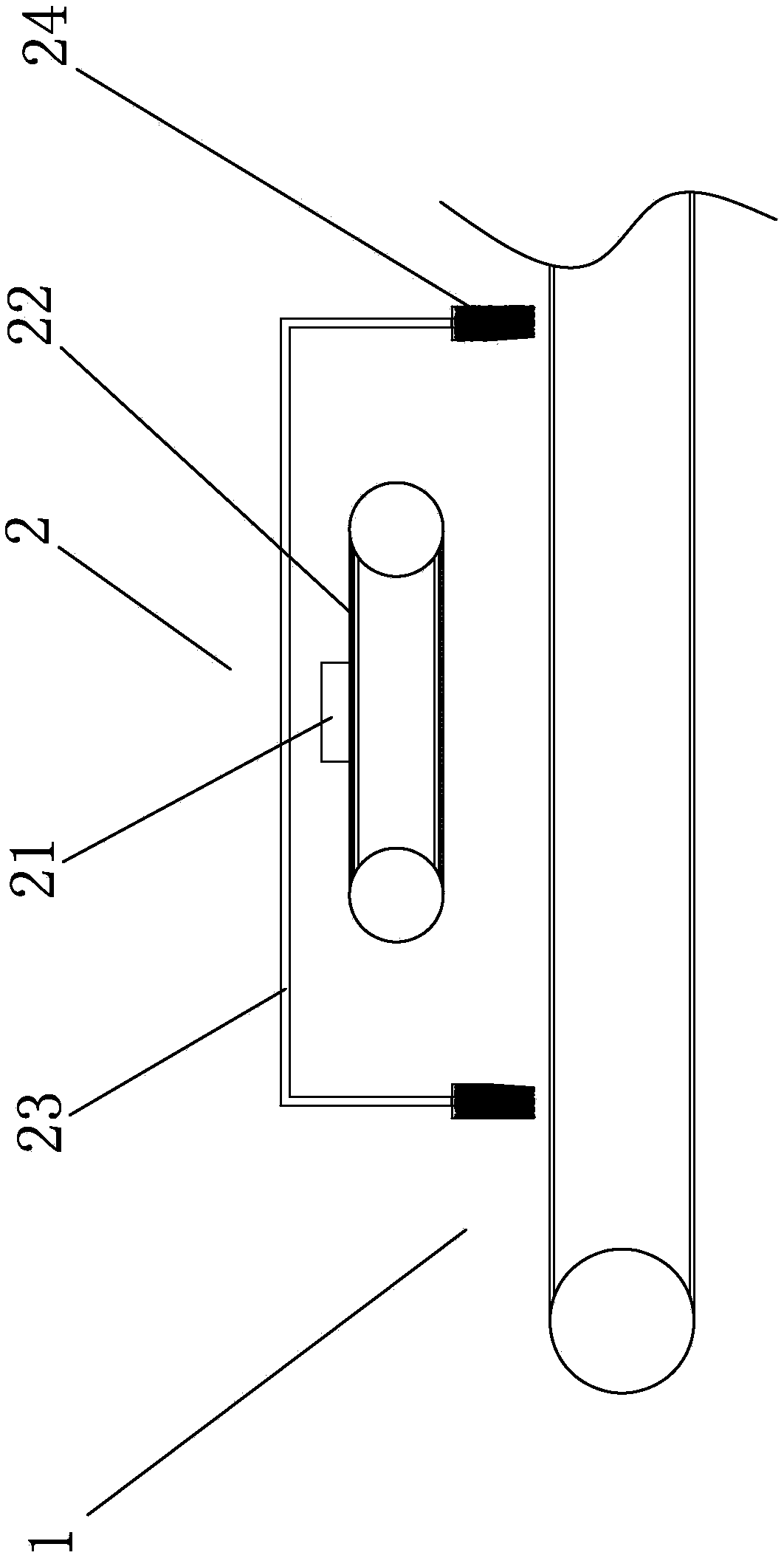

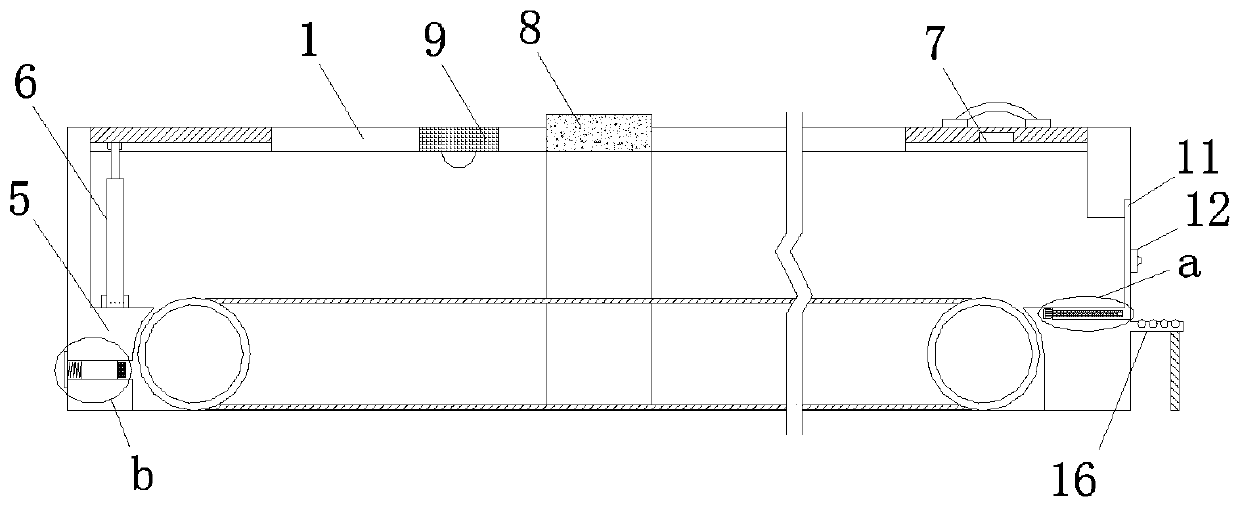

Electrostatic adsorption dust removal transport line

InactiveCN107891020AReduce the impactThe principle is simpleDirt cleaningCleaning using toolsElectrostatic adsorptionElectrostatic precipitator

The invention discloses an electrostatic adsorption dust removal conveying line. The dust removal conveying line comprises a rack, wherein the rack is provided with a conveying channel for conveying parts in a single direction and an electrostatic dust removal section used for adsorbing dust in the conveying channel through static electricity; the electrostatic dust removal section comprises a friction type electrostatic generator, and the friction type electrostatic generator comprises an electrostatic generation crawler belt, an insulating transmission wheel set and a friction block; and theinsulating transmission wheel set and the electrostatic generation crawler belt are of a belt-wheel transmission mechanism, the surface of the electrostatic generation crawler belt is a rubber layer,the inner side of the electrostatic generation crawler belt is an acrylic synchronous belt, and the friction block is in contact with the rubber layer of the electrostatic generation crawler belt. According to the electrostatic adsorption dust removal conveying line, the static electricity is generated by utilizing the electrostatic generation crawler belt and the friction block above the conveying channel, the dust generated in the part machining process is adsorbed, so that the influence of the dust on the subsequent machining of the part is effectively reduced; and the dust removal conveying line has the advantages that the principle is simple, the processing is convenient, time and labor are saved, production efficiency is high, and production cost can be saved.

Owner:吴肖颜

High-flowability high-performance concrete with low cementing material content, and preparation method thereof

The invention discloses high-flowability high-performance concrete with a low cementing material content, and a preparation method thereof. The high-flowability high-performance concrete with the lowcementing material content comprises the following raw materials in parts by weight: 520-570 parts of a cementing material, 626-702 parts of medium sand, 1061-1152 parts of broken stone, 130-140 partsof water and 4.88-8.67 parts of a water reducing agent. The preparation method comprises the following steps: adding the medium sand, the broken stone and the cementing material into a stirrer, carrying out stirring for 0.5-1.5 min at a rotating speed of 40-60 r / min to prepare a mixture, sequentially adding the water and the water reducing agent into the stirrer, and continuing stirring for 3-5 min at the rotating speed to prepare the high-flowability high-performance concrete with the low cementing material content. The concrete has high flowability, does not need to be vibrated, can pass through a steel bar dense area by means of dead weight, reduces concrete quality defects caused by incapability of vibrating or uncompacted vibration compared with common concrete, and realizes high flowability and high performance of the concrete under the condition of a low use amount of the cementing material.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

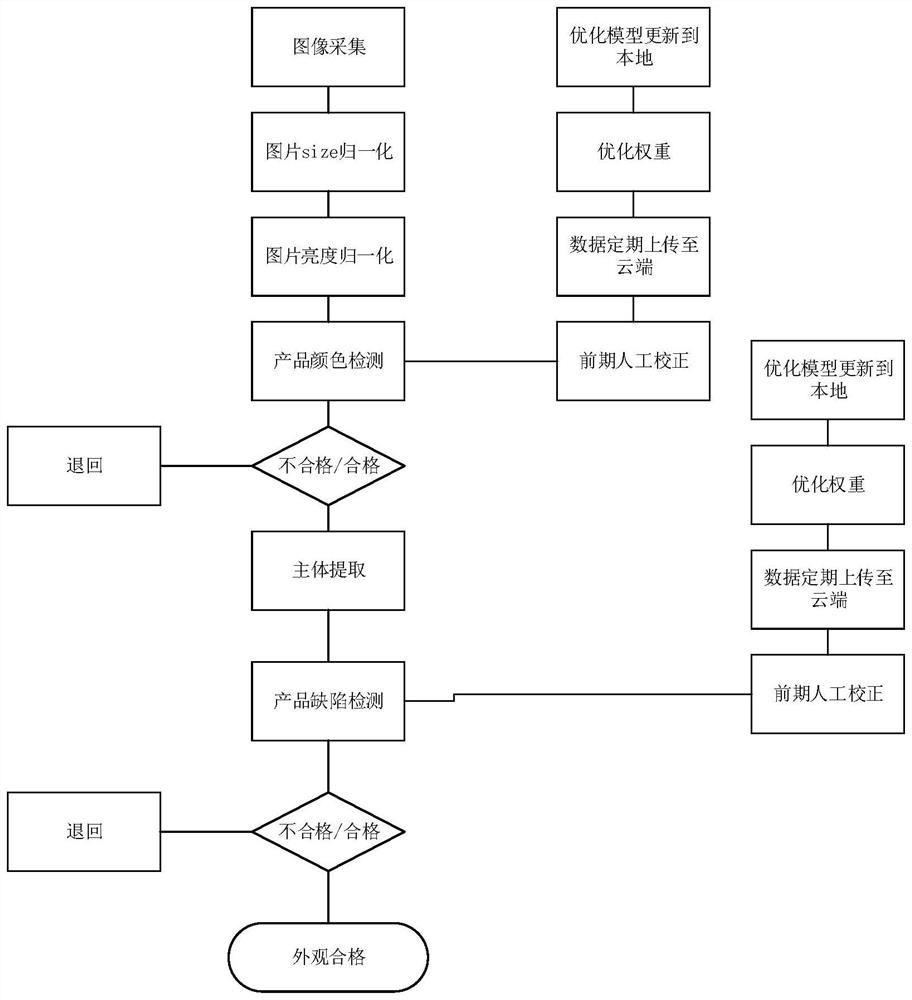

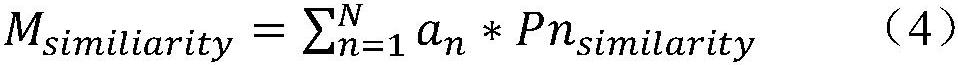

Machine vision algorithm for appearance inspection

ActiveCN111739003AImprove generalization abilityHigh precisionImage analysisCharacter and pattern recognitionMachine visionAlgorithm

The invention relates to a machine vision algorithm for appearance detection. The machine vision algorithm is used for appearance detection of the outer surface of a product which is smooth, opaque and consistent in main body color. The algorithm provided by the invention has the characteristics of high generalization, high accuracy and sustainable optimization, and can process two main requirements: 1) detecting the color of a product; 2) detecting the appearance of the product. According to the method, multiple algorithms are integrated, the accuracy is high, parameters can be optimized by using historical data, the SIFT image matching algorithm has excellent performance, the generalization is high, and the method is suitable for products with consistent main body colors.

Owner:SHANGHAI ELECTRICAL APPLIANCES RES INSTGROUP +2

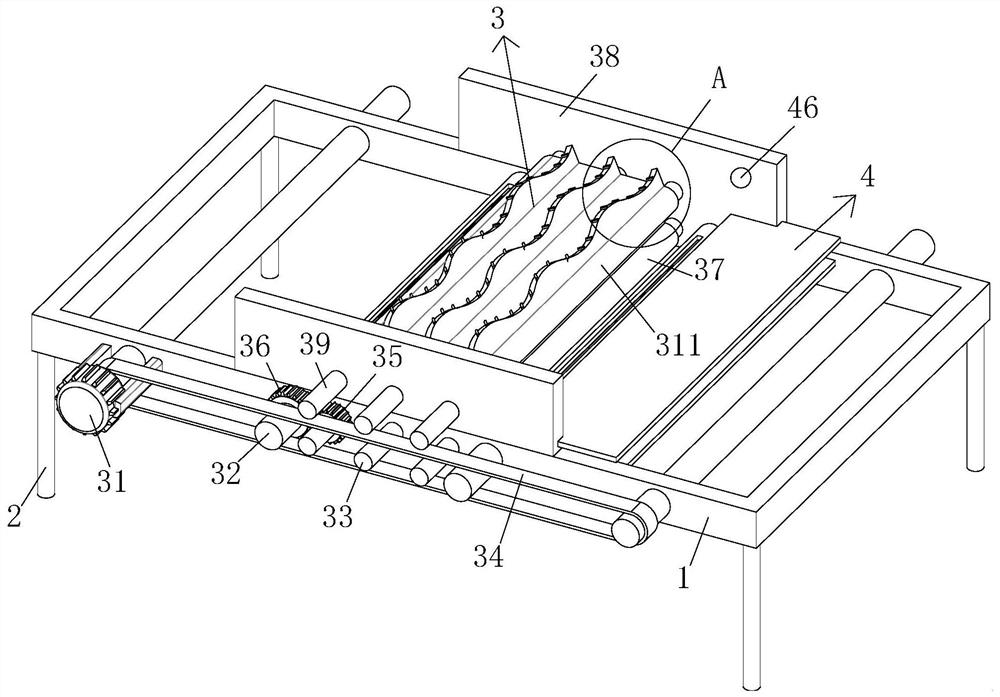

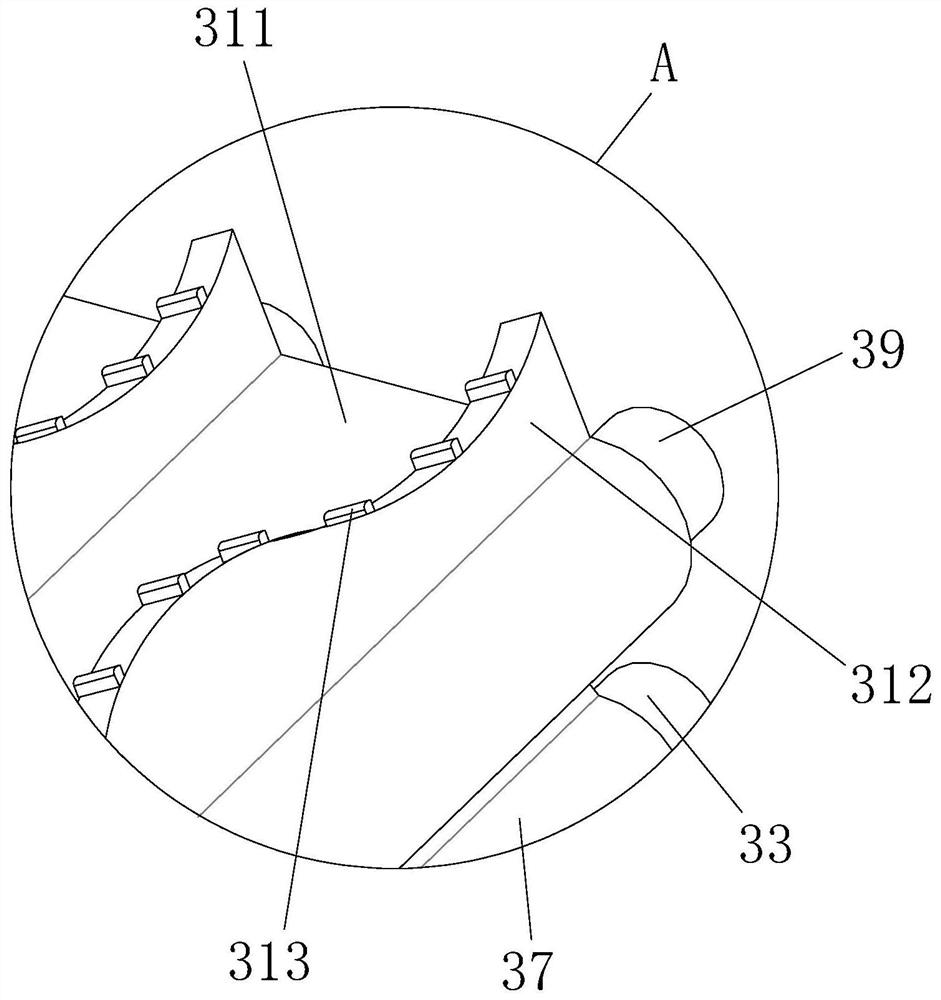

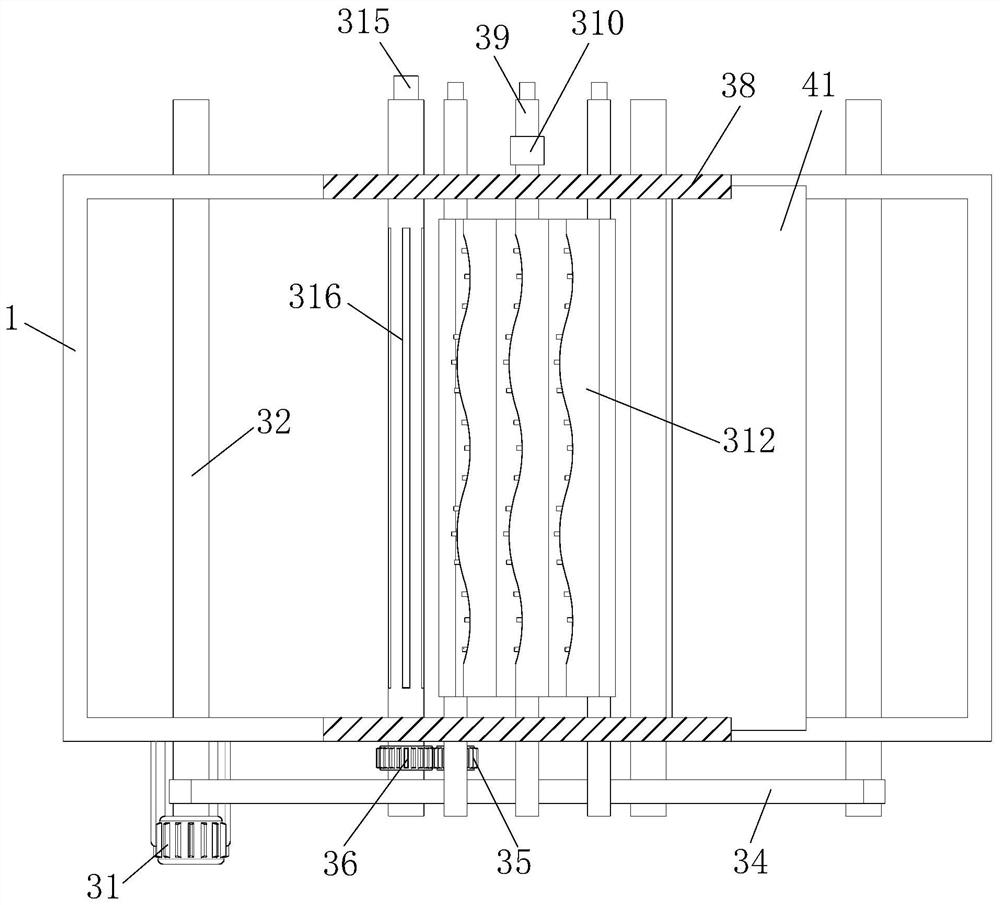

Singeing device for textile processing

InactiveCN113373636AEasy to stand independentlyPrevent collapseMechanical cleaningPressure cleaningMechanical engineeringMaterials science

The invention provides a singeing device for textile processing, and relates to the field of textile processing. The singeing device comprises a supporting frame for supporting equipment operation, supporting legs for supporting the supporting frame, an expanding carding mechanism for pretreating fluff on the surface of a textile fabric and a traction singeing mechanism for burning the fluff, the supporting legs are fixedly connected with the bottom of the supporting frame, and the expanding carding mechanism and the traction singeing mechanism are both arranged on the supporting frame. According to the singeing device for textile processing, a special structure capable of pretreating and carding the fluff is designed to solve the problems that the fluff on the surface of an existing textile fabric hides dirt and unified singeing is difficult, and the fluff can be dragged and burnt at a unified distance, so that the problems that a common singeing device is difficult to remove the fluff collapsing on the surface of the textile fabric, the fluff can be prone to containing dirt and block the dust in the textile fabric, and inconvenience is brought to subsequent processing procedures are effectively solved.

Owner:许凤仙

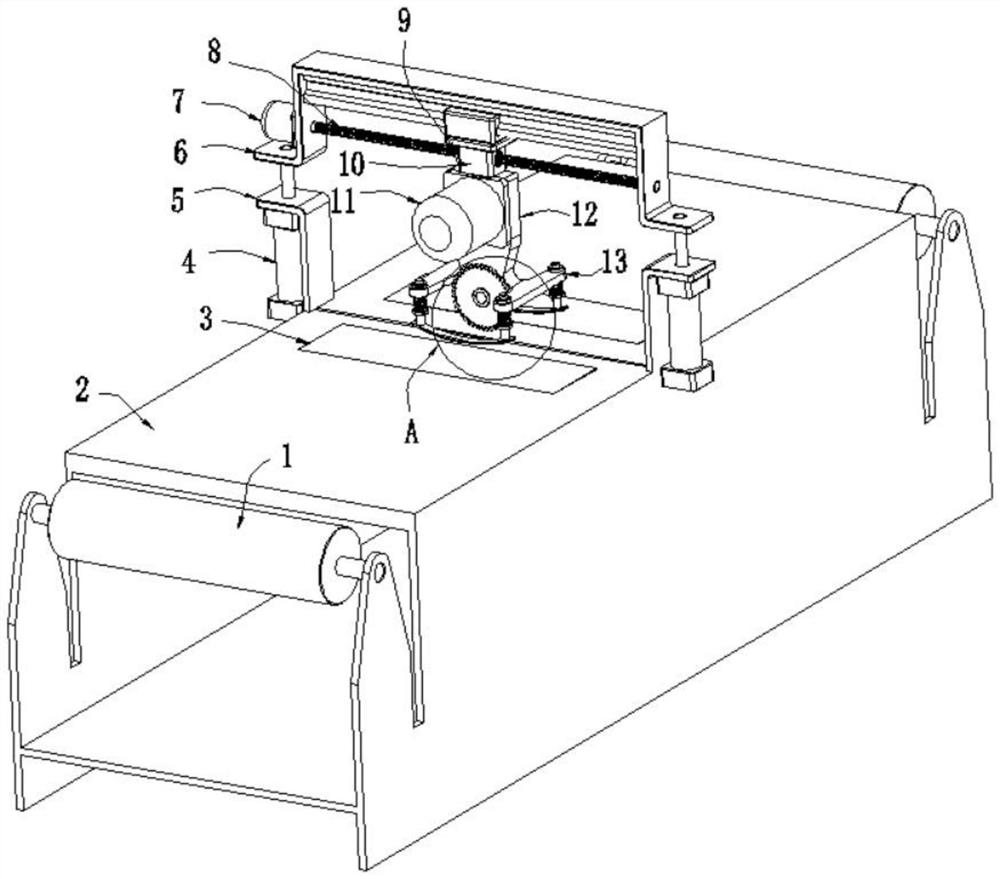

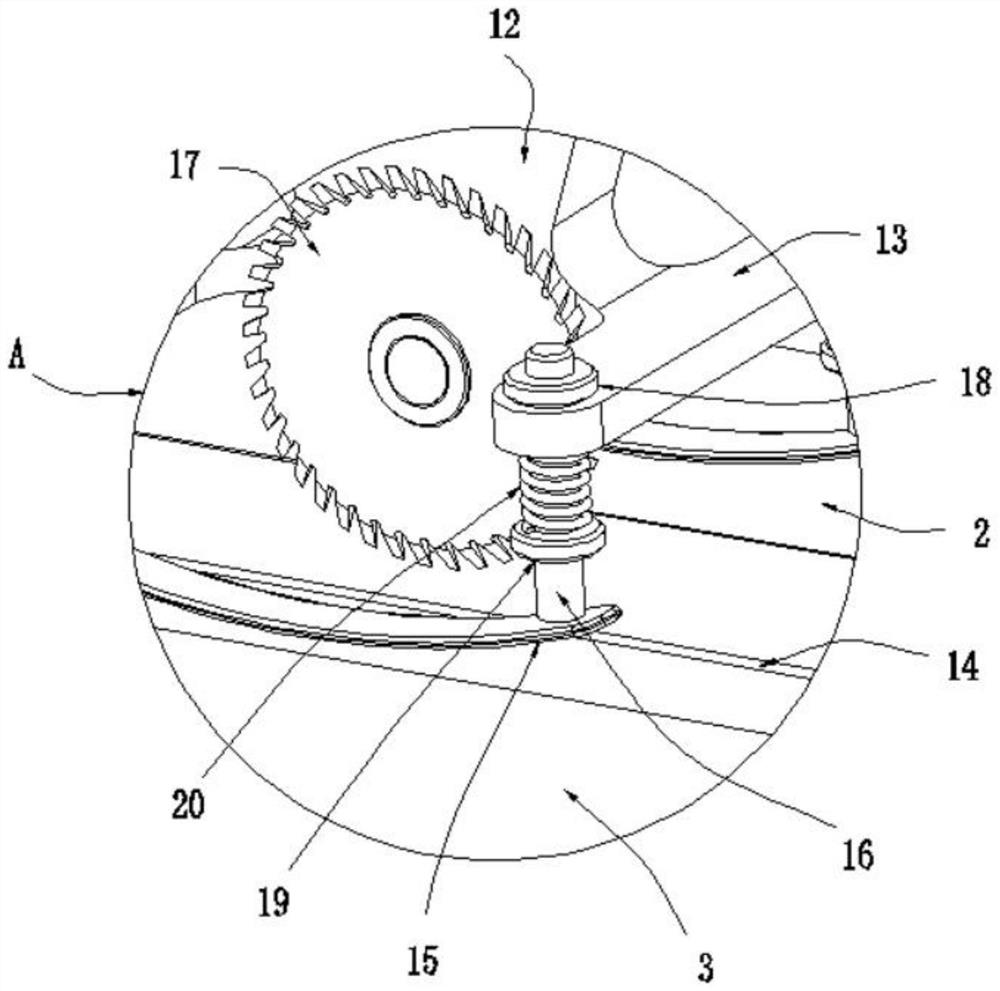

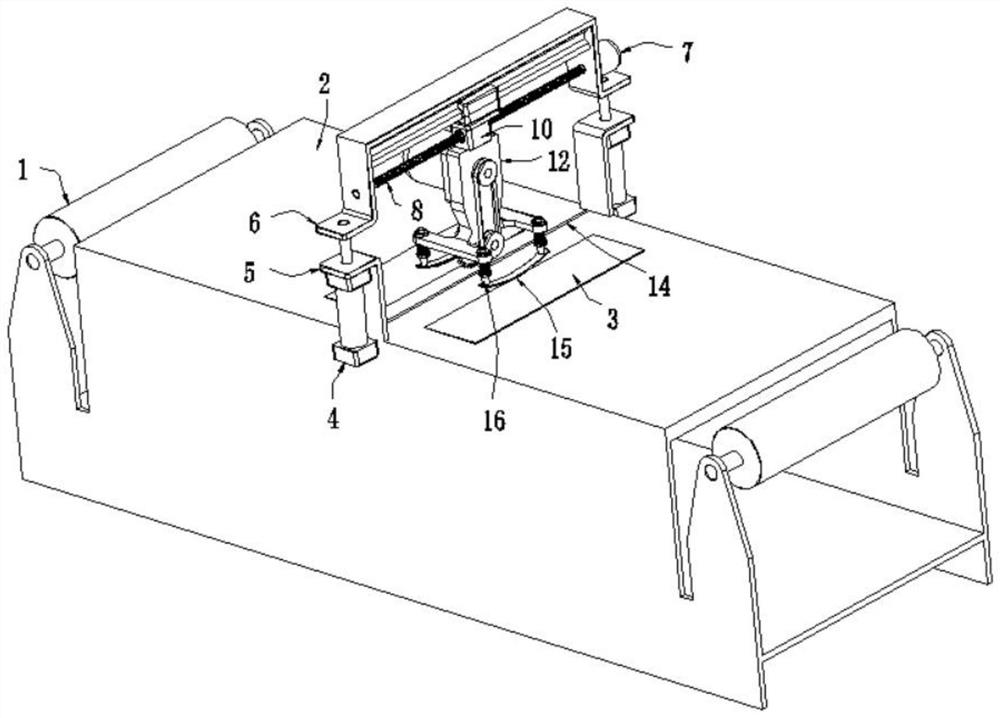

Automatic cutting and shearing machine for clothing processing

InactiveCN113584865AImprove end face qualityAvoid damageSevering textilesElectrostatic chargesEngineeringMechanical engineering

The invention discloses an automatic cutting and shearing machine for clothing processing in the technical field of clothing processing equipment. The automatic cutting and shearing machine comprises a winding roller, a floating mounting seat, a lifting mechanism, a sliding seat, a translation mechanism, a mounting seat and a cutting and shearing wheel rotating mechanism; and a pressing mechanism for pressing cloth on a cutting and shearing seat is arranged on the mounting seat. By arranging the pressing mechanism, the cloth can be synchronously pressed when being cut and sheared, so that the flatness of an area to be cut and sheared on the cloth is guaranteed and the end face quality of the cut and sheared cloth is improved; by arranging the translation mechanism, the cutting and shearing wheel can horizontally move to conduct cutting and shearing operation on the cloth; and a spring in the pressing mechanism elastically abuts against a fixing ring, so that an arc-shaped plate cannot cause relatively large pressing force on the cloth, on one hand, the damage to the surface of the cloth and the influence on the weight of the cloth are avoided, and on the other hand, the arc-shaped plate can conveniently slide on the surface of the cloth and then can horizontally move along with a cutting and shearing wheel to press the area to be cut and sheared on the cloth.

Owner:湖南新姿服饰有限公司

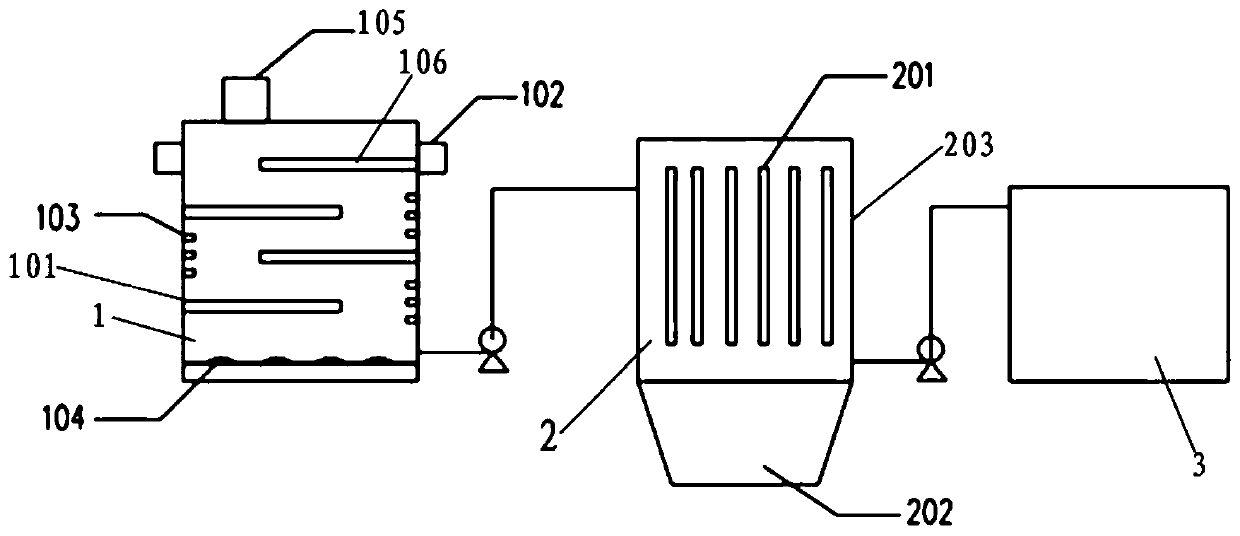

Printing and dyeing wastewater treatment system and printing and dyeing wastewater treatment method

InactiveCN111003880AImprove degradation efficiencyIncrease energy levelWater/sewage treatment by irradiationWater treatment compoundsTreatment systemTreatment unit

The invention provides a printing and dyeing wastewater treatment system, which comprises a microwave photoelectric Fenton treatment unit and a magnetic separation unit, wherein the microwave photoelectric Fenton treatment unit and the magnetic separation unit are sequentially communicated through a pipeline, the microwave photoelectric Fenton treatment unit comprises a reaction container, a microwave generation device and an ultraviolet light generation device, the reaction container is provided with a solid inlet, a positive electrode and a negative electrode, the positive electrode and thenegative electrode are electrically connected with a voltage output device, the magnetic separation unit comprises a separation container and an electromagnet, the water inlet of the magnetic separation unit is communicated with the water outlet pipeline of the microwave photoelectric Fenton treatment unit, and the electromagnet is arranged in the separation container. The printing and dyeing wastewater treatment system disclosed by the invention treats printing and dyeing wastewater by combining the microwave and the magnetic charcoal photoelectric Fenton device, is high in degradation efficiency of organic matters in printing and dyeing wastewater, and can disperse magnetic biochar as a photoelectric Fenton reaction catalyst in water so as to separate and recover again, so that the costof the magnetic biochar is saved, and the influence on subsequent treatment is reduced.

Owner:GUANGZHOU EP ENVIROMENTAL ENG

An international express mail image inspection device and system based on CT equipment

ActiveCN111598147BGuaranteed clarityImprove cleanlinessStill image data indexingCharacter and pattern recognitionImage InspectionElectromagnetic lock

The invention provides a CT equipment-based international express mail image inspection device and system. The CT-based international express mail image inspection device and system may include a main body of the inspection device, the main body of the inspection device is covered outside the conveyor belt for conveying international express mail, and the upper side wall of the main body of the inspection device is symmetrically provided with an object inlet and an object outlet The inlet of the object and the outlet of the object are symmetrically hinged with a protective upper cover, the inner cavity of the main body of the inspection device is integrally formed with a mounting platform, and the upper side wall of the mounting platform on one side is symmetrically hinged with a push rod motor, so The output end of the push rod motor is hinged to the protective upper cover of the object inlet, and the protective upper cover of the object outlet is provided with an electromagnetic lock; CT equipment, the CT equipment is arranged on the main body of the inspection device; Bar code scanner. By providing a relatively closed space, the cleanliness of the device is maintained, thereby ensuring the clarity of the shooting effect and the tidiness of the objects.

Owner:合肥格泉智能科技有限公司

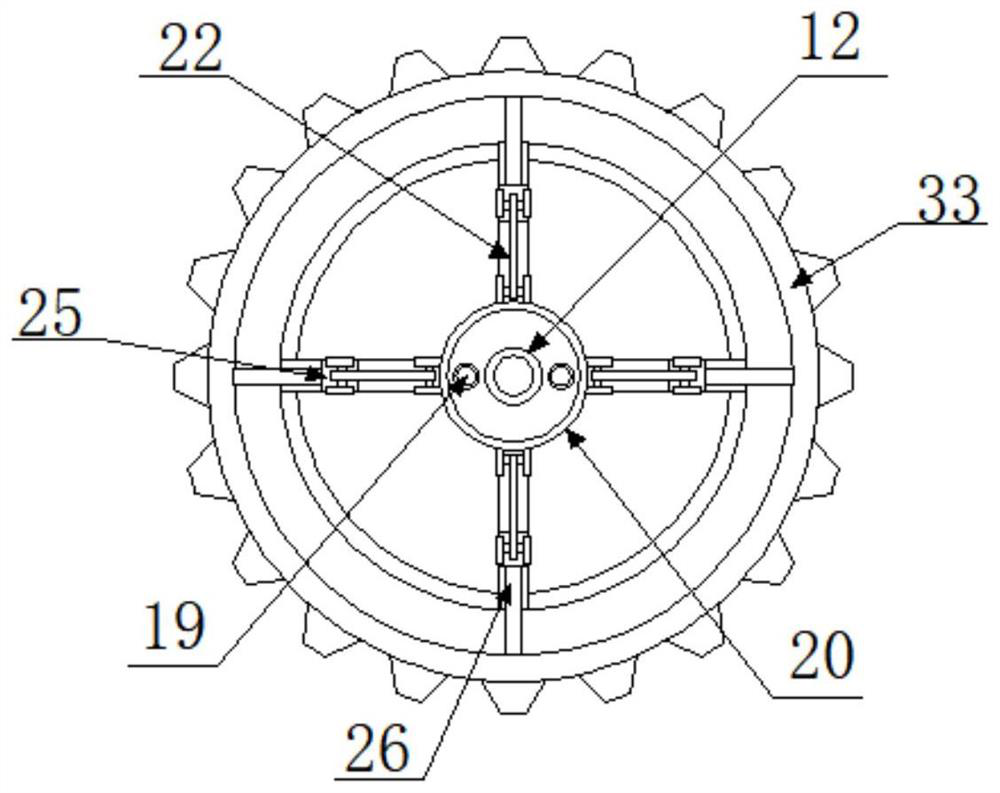

Burr cleaning mechanism for gear machining

ActiveCN113199091AGood cleaning efficiencyFast efficiencyGear-cutting machinesMaintainance and safety accessoriesPhysicsMachining

The invention relates to the technical field of gear machining, in particular to a burr cleaning mechanism for gear machining. The burr cleaning mechanism for gear machining comprises a machining table, a separation net, a servo motor, a long edge cleaning plate, an ejector rod and a short edge cleaning block, a separation groove is formed in the upper surface of the machining table, a water outlet is formed in the lower surface of the machining table, the servo motor is fixed to the upper surface of the machining table through bolts, and a connecting plate is welded and fixed to the upper surface of the machining table. A fixing plate and a placing plate are fixedly welded to the lower surface of the upper end of the machining table, and the connecting plate is fixedly welded to the upper surface of the machining table. The burr cleaning mechanism for gear machining has the beneficial effects that by means of a linkage structure on the burr cleaning mechanism, five faces of a gear block on a gear body can be cleaned at the same time while the gear body is fixed through the whole burr cleaning mechanism, so that the machining efficiency of the whole burr cleaning mechanism is higher, a screen is extruded through the ejector rod, the secondary use of the wastewater is not affected.

Owner:JIANGSU AIRSHIP GEAR

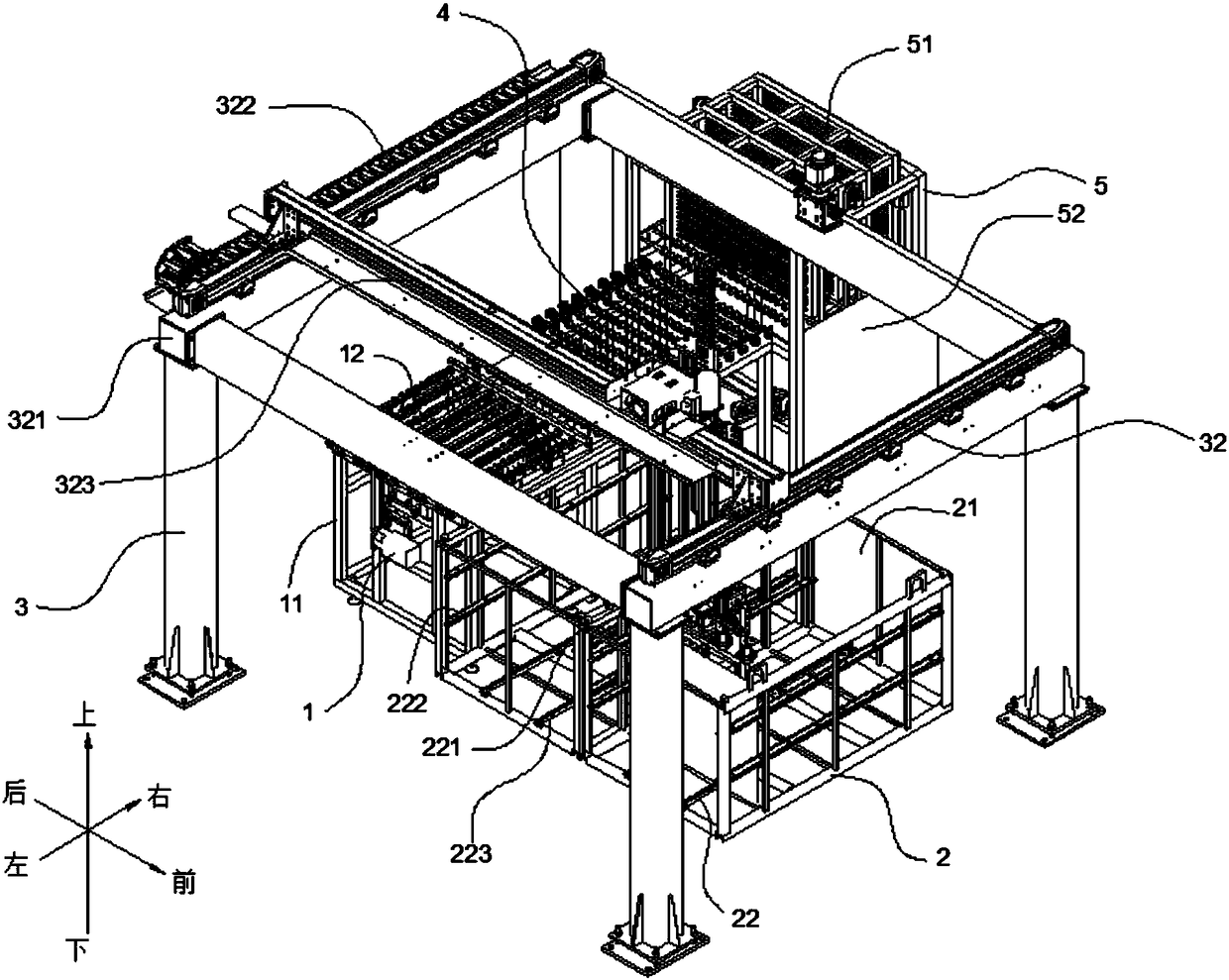

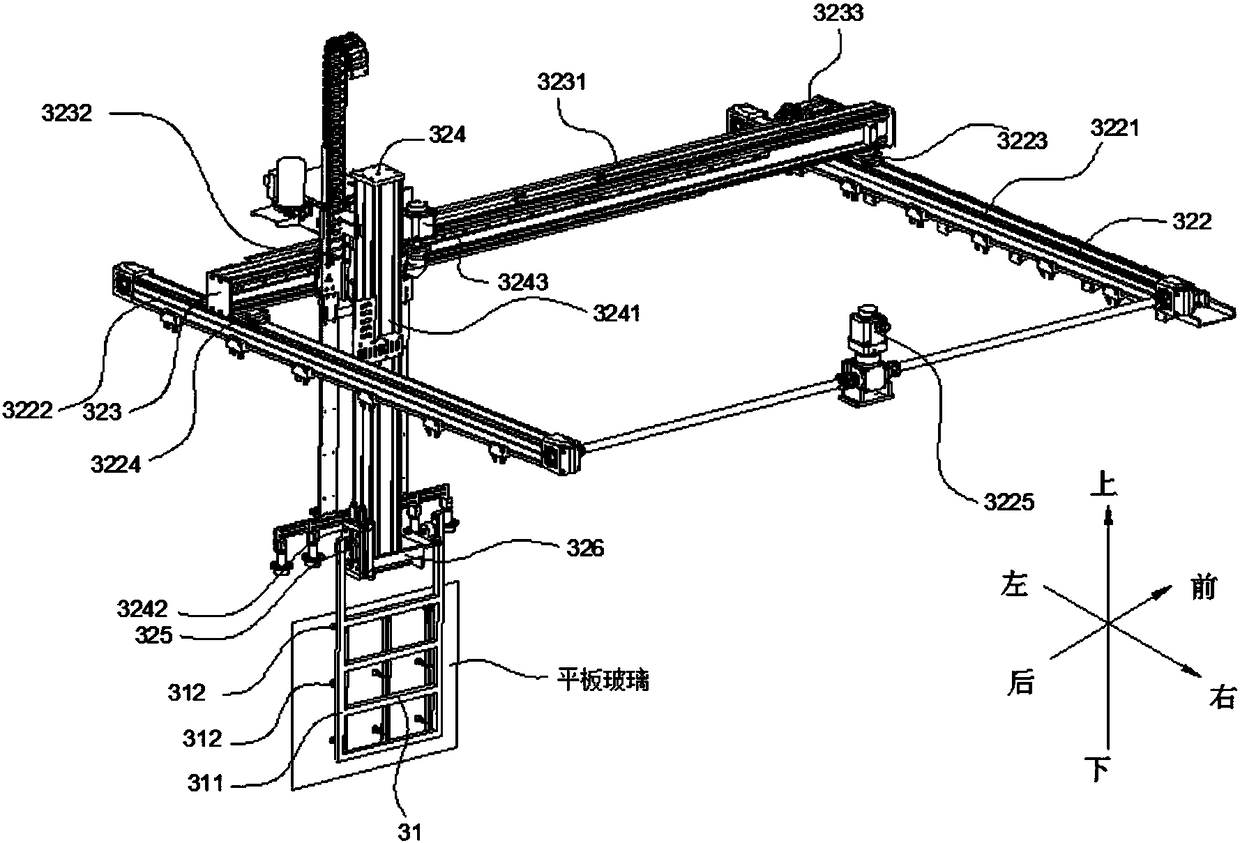

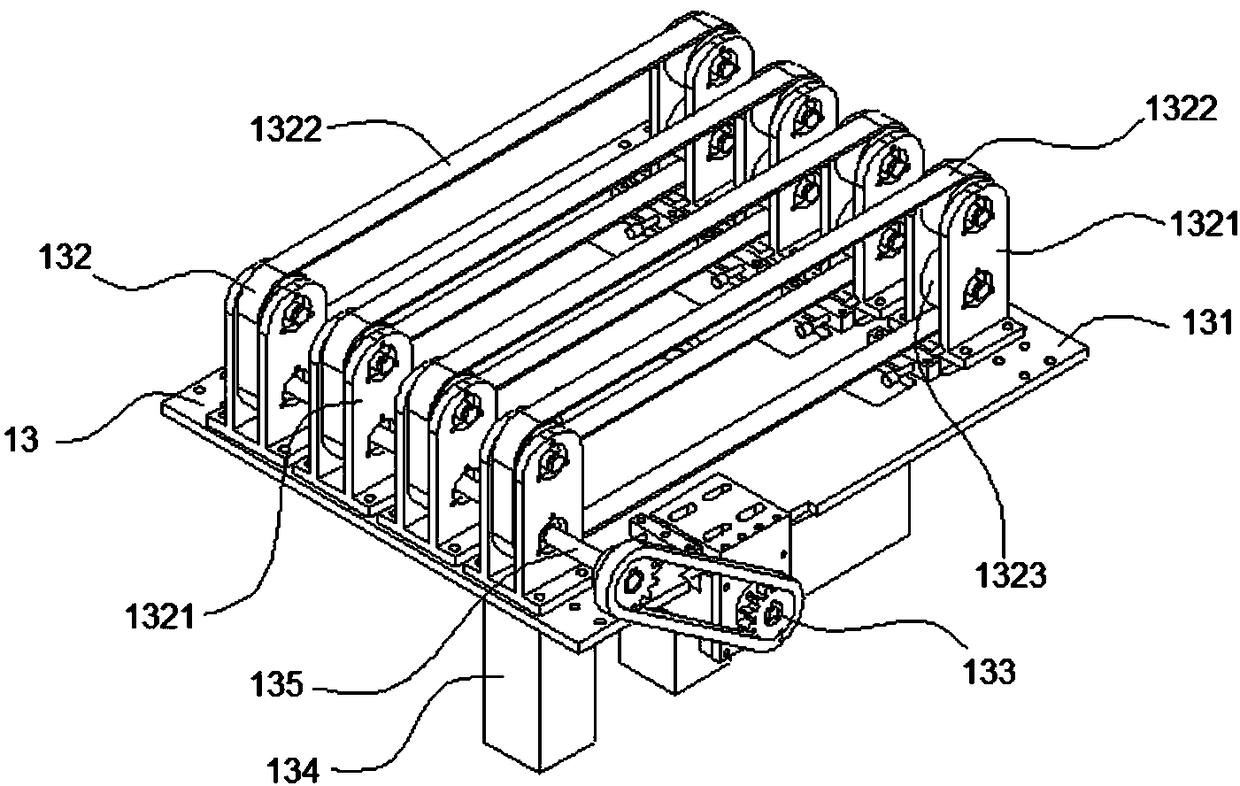

Automatic inserting-stacking-carrying device for glass

PendingCN108455282ASave human effortEliminate security concernsCharge manipulationConveyor partsComputer moduleTransfer mechanism

The invention discloses an automatic inserting-stacking-carrying device for glass. The carrying device comprises a first bearing platform, a lifting cage and a transfer mechanism, wherein the first bearing platform is used for horizontally supporting the glass; the lifting cage is arranged at one side of the first bearing platform, and provided with an upward inlet capable of allowing the glass tobe vertically inserted, and a fixing part used for vertically fixing a plurality of pieces of the glass; and the transfer mechanism comprises a suction part and a drive module connected with the suction part, the suction part is used for horizontally sucking one piece of the glass from the first bearing platform, and the drive module is used for driving the suction part sucking the glass to vertically stretch into the lifting cage from the inlet to vertically fix the glass to the fixing part. In this way, mechanically automatic transfer for the glass is realized, and the glass can be placed in the lifting cage without the need of manual operation, so that lots of labor is saved.

Owner:深圳市诸脉科技有限公司

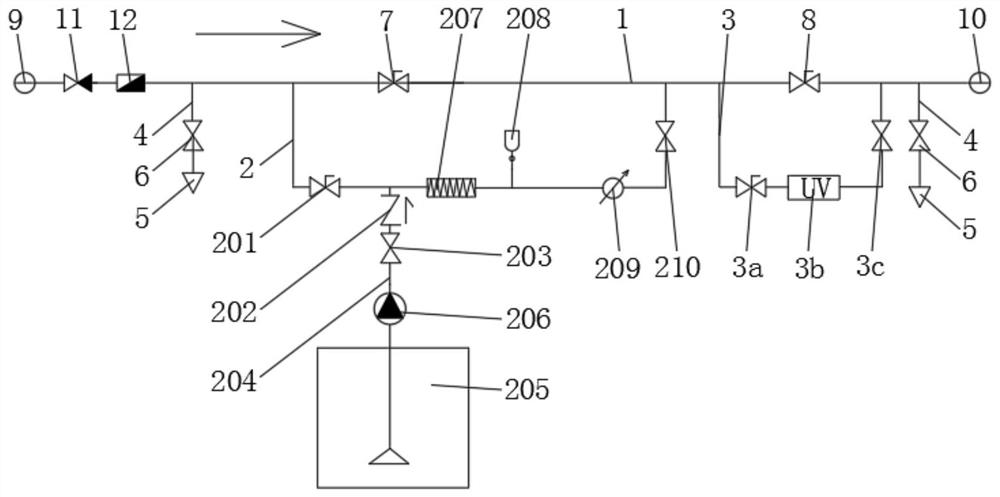

Building water supply pretreatment device based on ultraviolet chlorine advanced oxidation

InactiveCN112939302AEnsure water safetyEasy dischargeWater/sewage treatment by irradiationMultistage water/sewage treatmentWater useWater flow

The invention discloses a building water supply pretreatment device based on ultraviolet chlorine advanced oxidation. The device comprises a water supply pipe main body and a controller, the two ends of the water supply pipe main body are respectively provided with a water inlet and a water outlet, and the water supply pipe main body is respectively provided with a first electromagnetic valve and a second electromagnetic valve; the water supply pipe main body is connected with a first branch water pipe, a water inlet and a water outlet of the first branch water pipe are communicated with the water supply pipe main body positioned on two sides of the first electromagnetic valve, and the first branch water pipe is provided with a chlorine metering and dosing device for performing chlorination and disinfection on water flowing through the first branch water pipe; through cooperation of the chlorine metering and dosing device and the ultraviolet device, different disinfection treatment modes can be adopted for tail end water according to different results obtained after detection water sample analysis, the disinfection treatment is more reasonable and efficient, and the water use safety of a user is guaranteed.

Owner:TONGJI UNIV

Industrial wastewater purification device

PendingCN114314932APlay a protective effectWell mixedRotary stirring mixersTransportation and packagingIndustrial waste waterUltraviolet lights

The invention discloses an industrial wastewater purification device which comprises a first shell, a first filter screen plate and two material agent boxes, a hydraulic telescopic rod is arranged on the side face of the first shell, the upper end of the hydraulic telescopic rod is connected with a filter frame, the filter frame is arranged in the first shell in a penetrating mode, and the two material agent boxes are arranged in the first shell. The two material boxes are arranged on the side face of the first shell and the side face of the second shell correspondingly, the upper end of the second shell is connected with the first shell through a connecting pipe, a control panel is arranged on the front side of the second shell, a liquid conveying pump is arranged on the right side of the second shell, and the liquid conveying pump is connected with a third shell through an external pipe. And the third shell is arranged on the right side of the second shell. According to the industrial wastewater purification device, treated wastewater is pumped into the third shell, and the industrial wastewater is sterilized under the action of ultraviolet lamps, so that the purification effect on the industrial wastewater is improved, peculiar smell discharge is reduced, bolts are disassembled, and the ultraviolet lamps can be maintained or replaced by pulling out the corresponding ultraviolet lamps through pulling plates.

Owner:徐州惜能环境工程设备有限公司

Method for demoulding chip

ActiveCN102157346AImprove stripping efficiencyLow costSemiconductor/solid-state device manufacturingElectrical componentsGlass sheetFilm-coated tablet

The invention relates to a method for demoulding a glass passivation chip, belonging to the field of chip production methods. The method for demoulding the glass passivation chip is characterized by comprising the following steps of: a, taking a film adhering chip, and soaking one surface of the film coating chip, which is not adhered with a film, by using water; b, adhering the soaked chip to a clean glass sheet; c, placing the glass sheet adhered with the chip into a freezer for freezing; d, freezing for certain time, and then taking out the glass sheet from the freezer, and tearing the film by using a hand; e, placing the glass sheet with the chip into high-purity water, unfreezing and separating the chip and the glass sheet; and f, taking out the chip from a water tank, cleaning, and drying. The invention has the advantages of solving the problems of much demanded labor power and low efficiency of manual demoulding, also solving the problem of high cost of mechanical demoulding by adopting lower-cost equipment, additionally preventing the scratch of the surface of the chip during preorder processing, reducing the waste of the chip during the preorder processing and saving the cost.

Owner:CHANGZHOUSR SEA ELECTRONICS

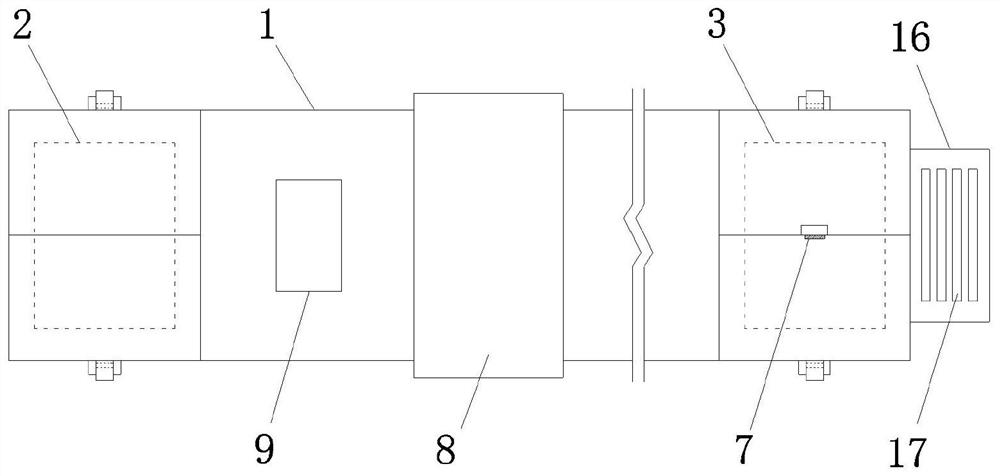

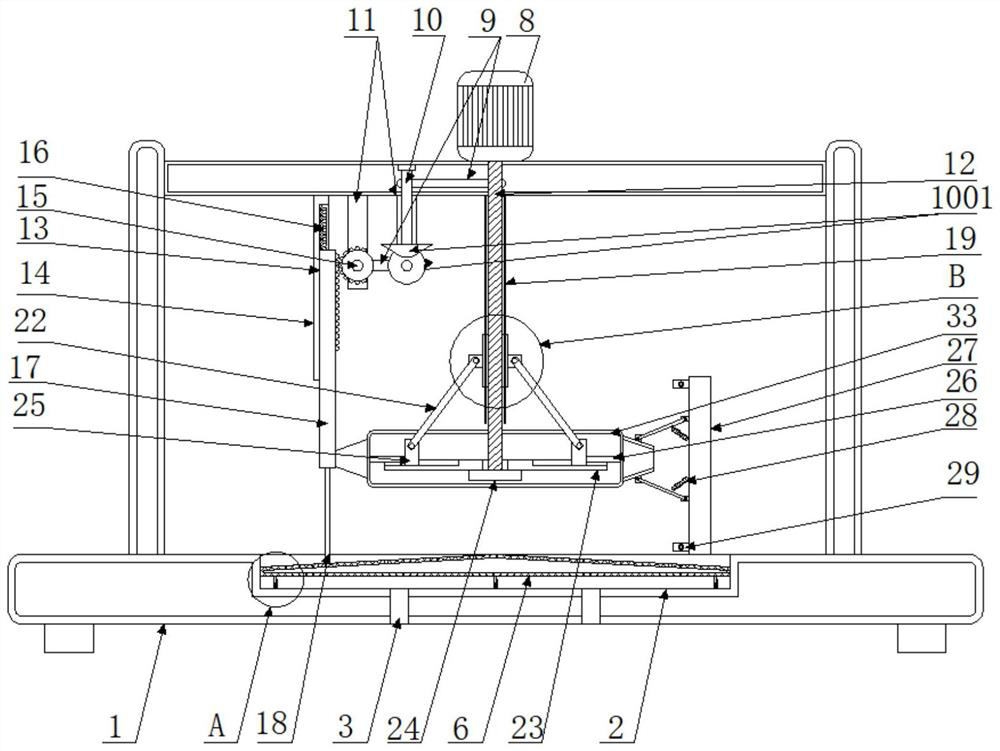

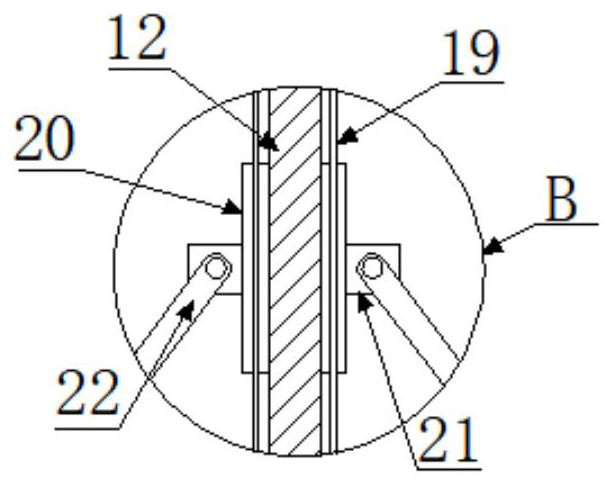

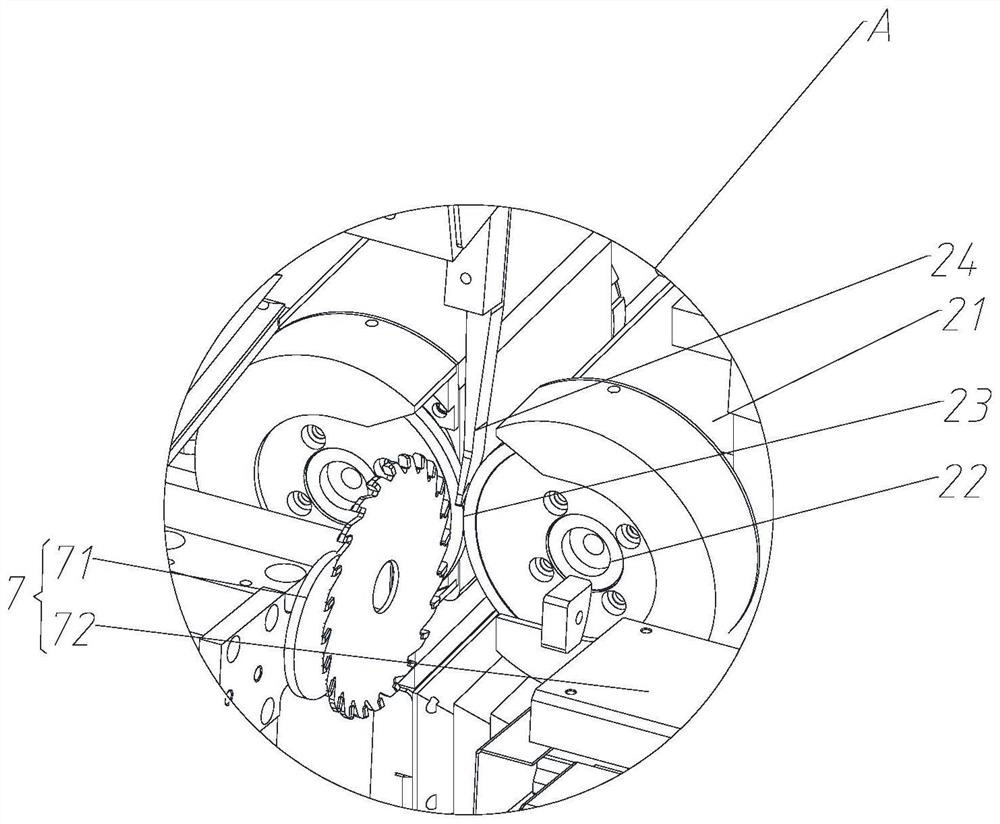

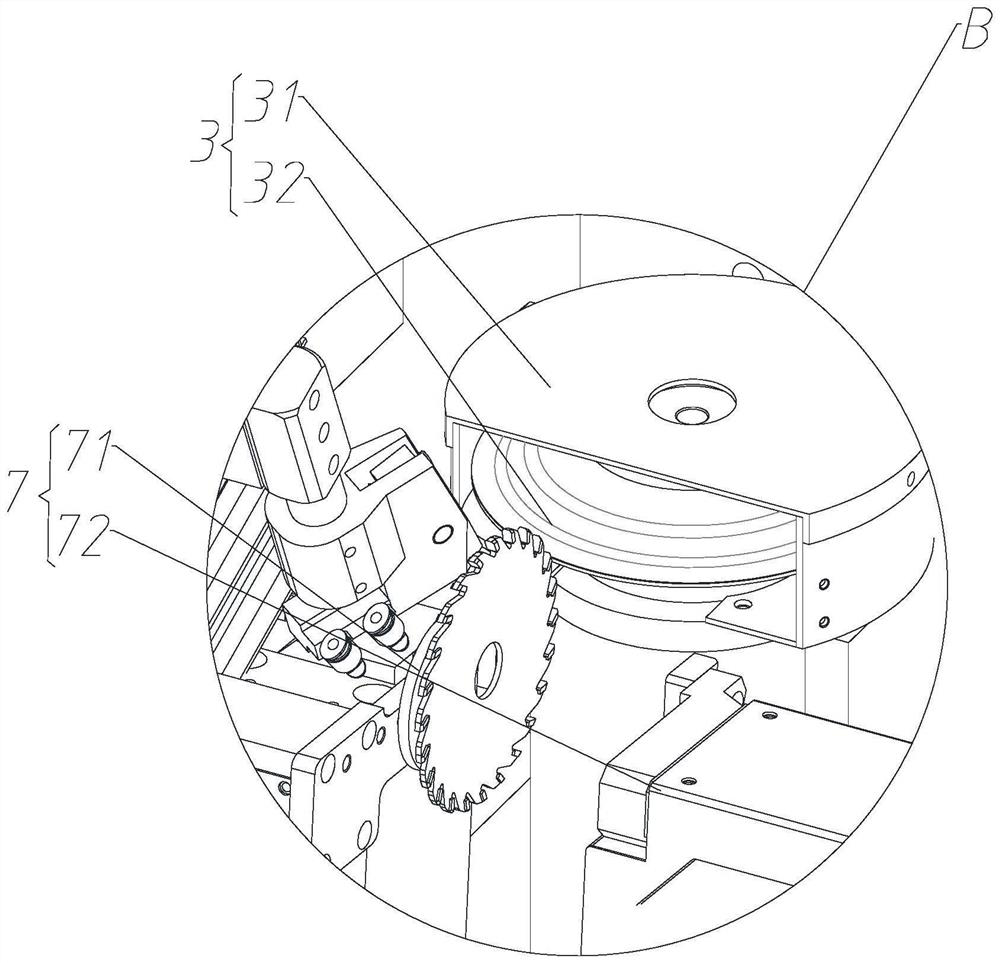

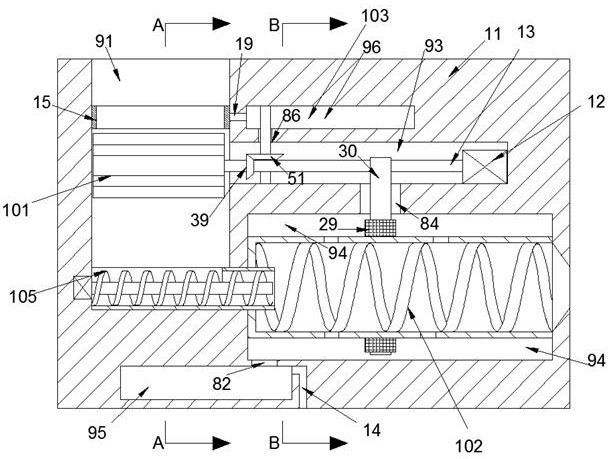

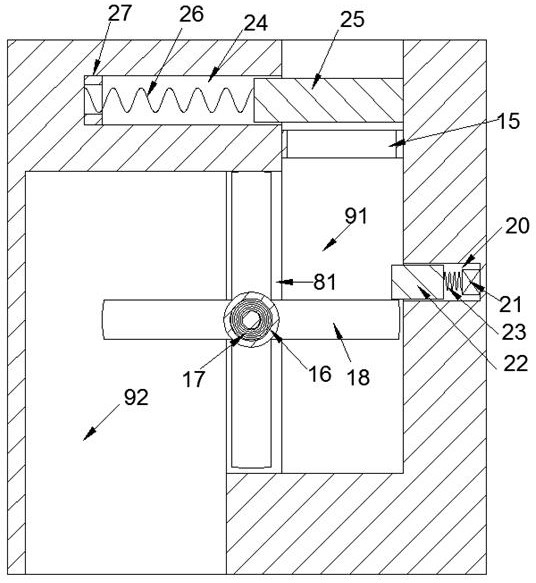

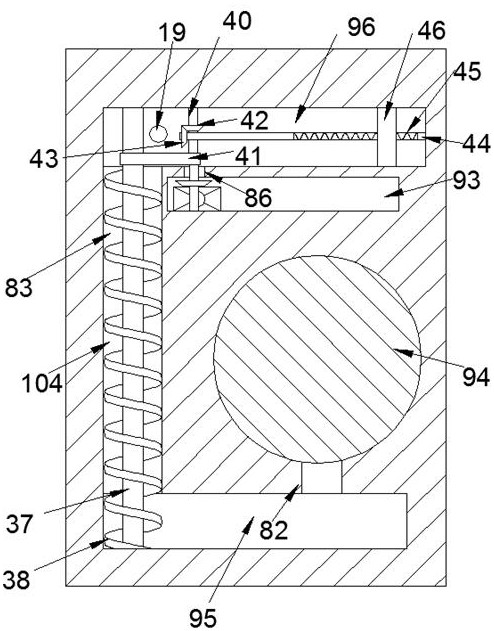

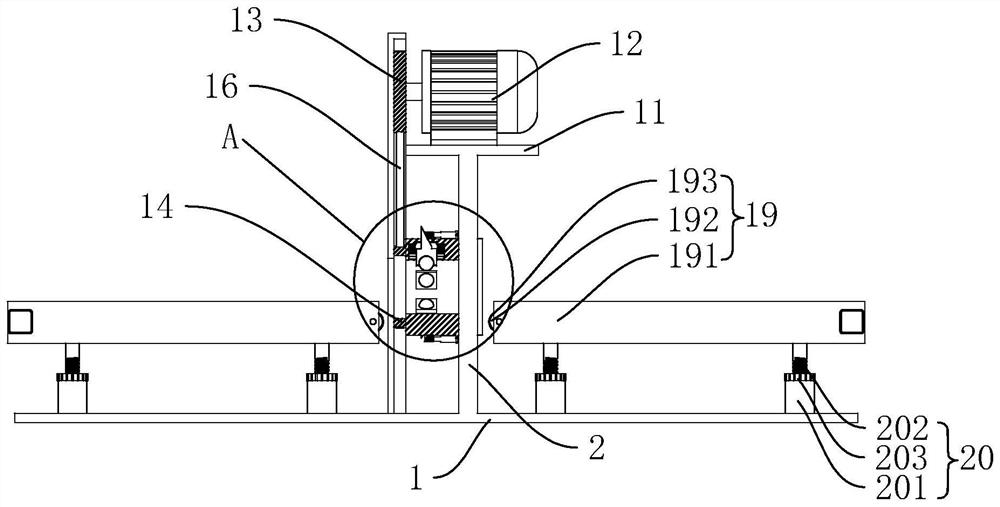

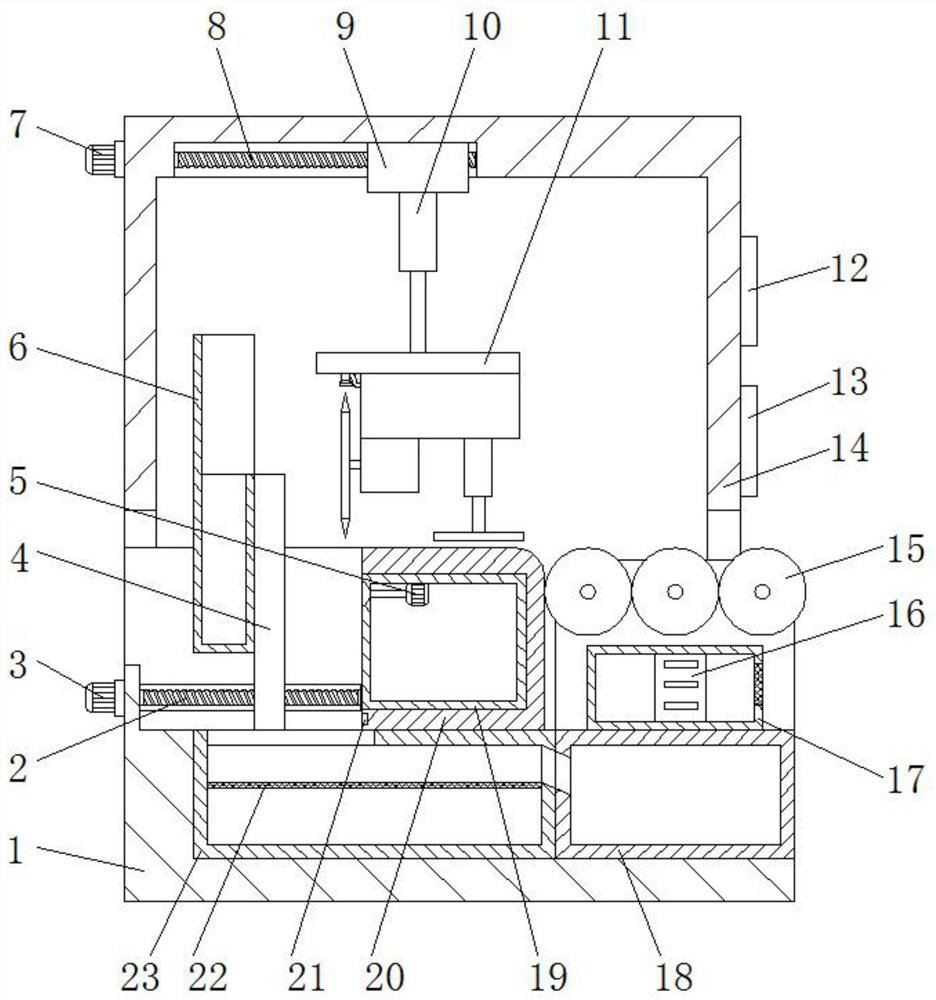

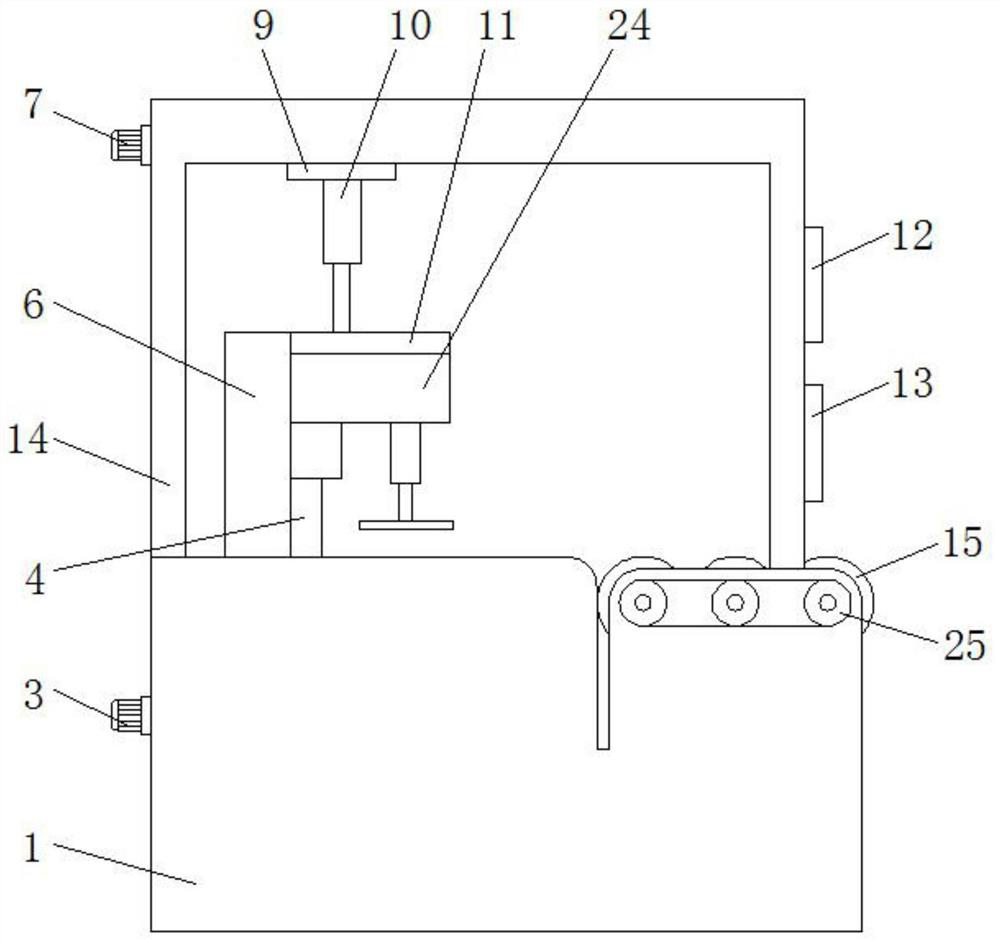

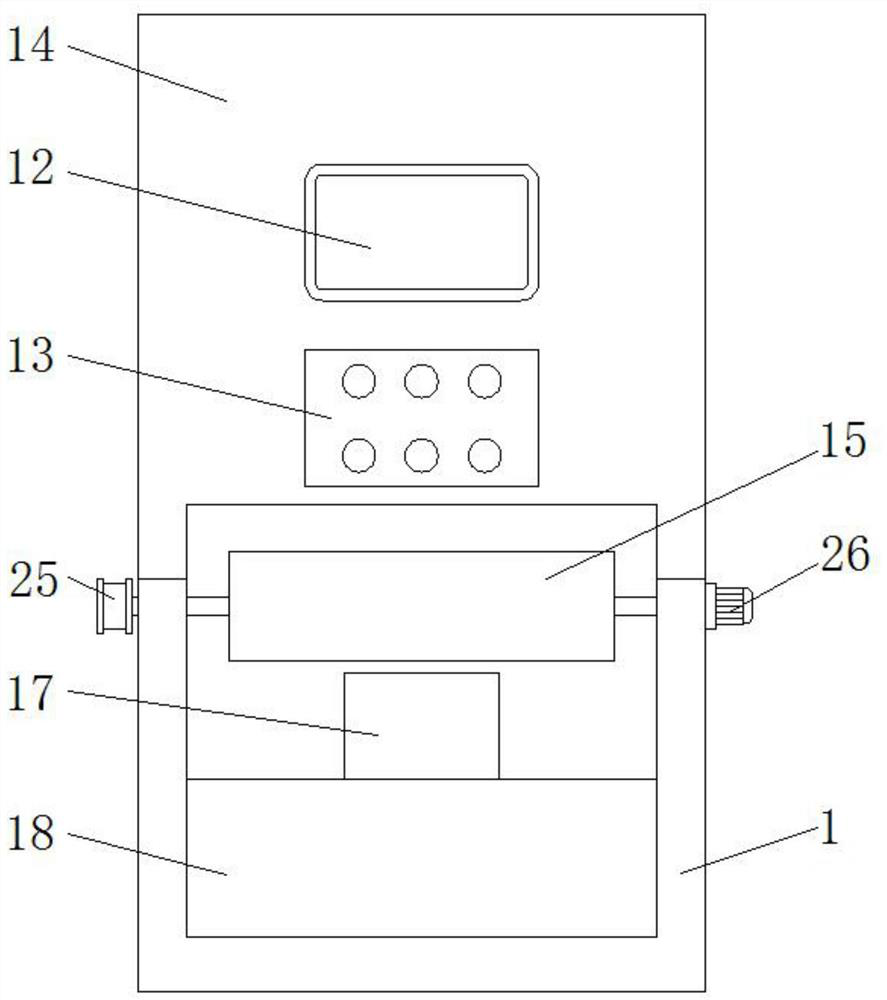

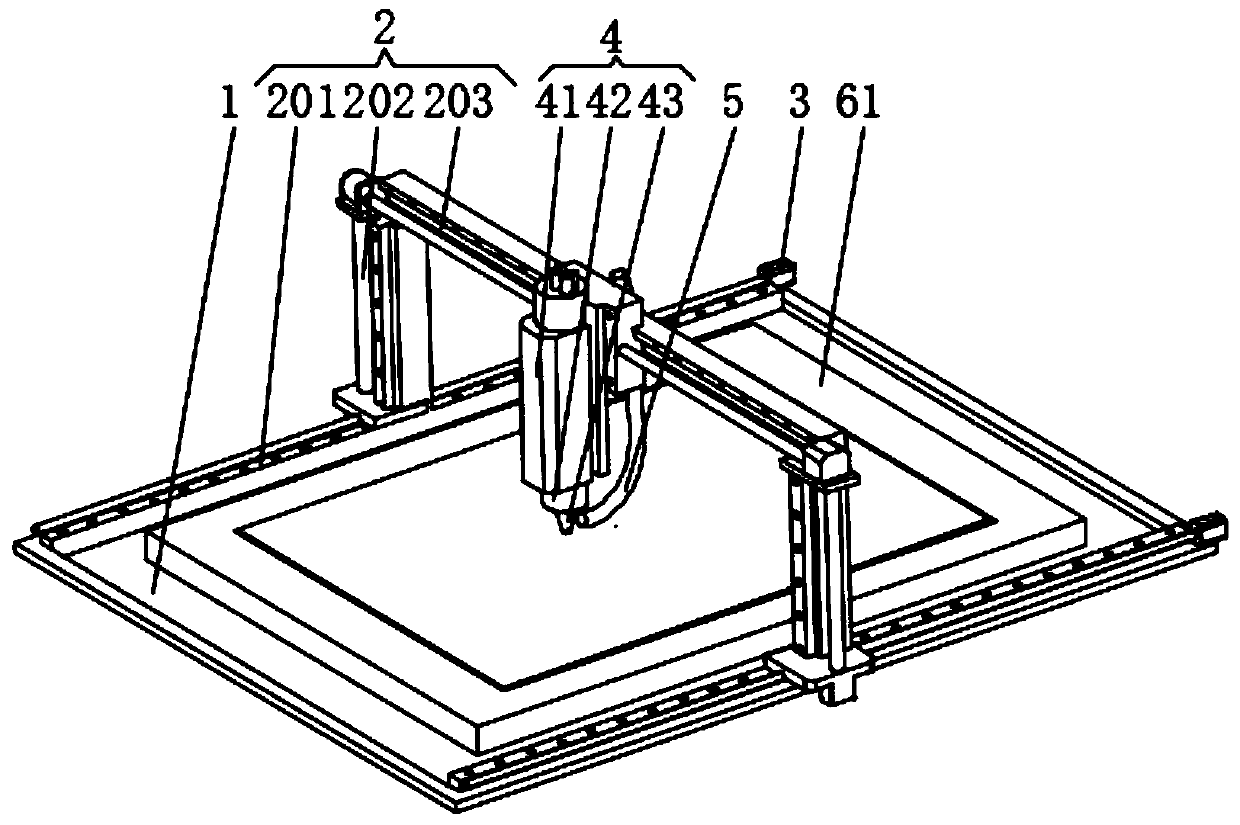

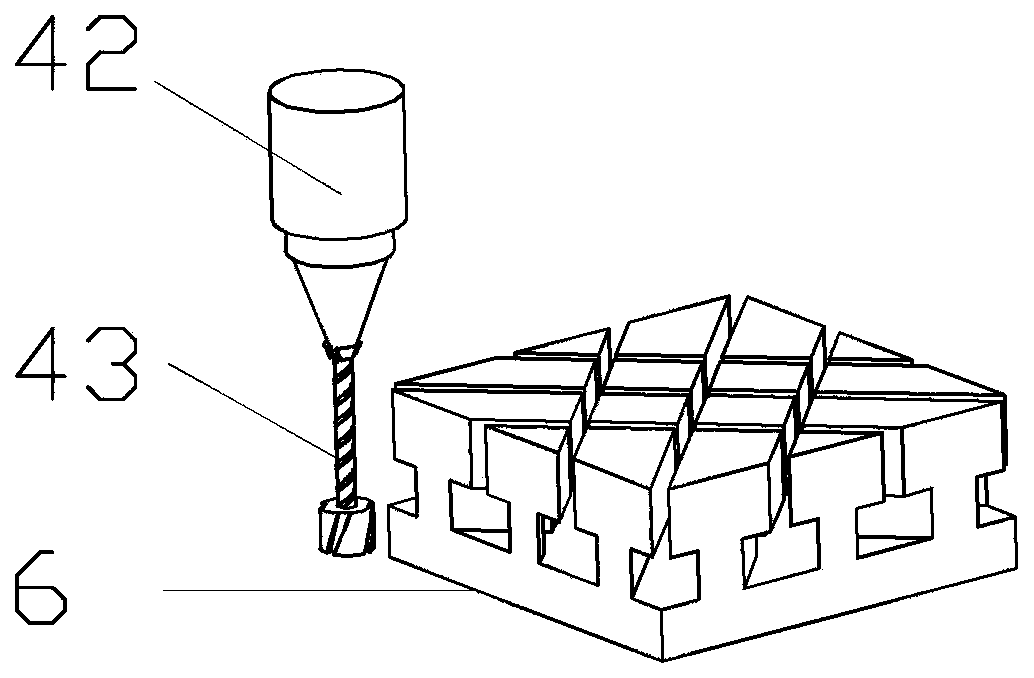

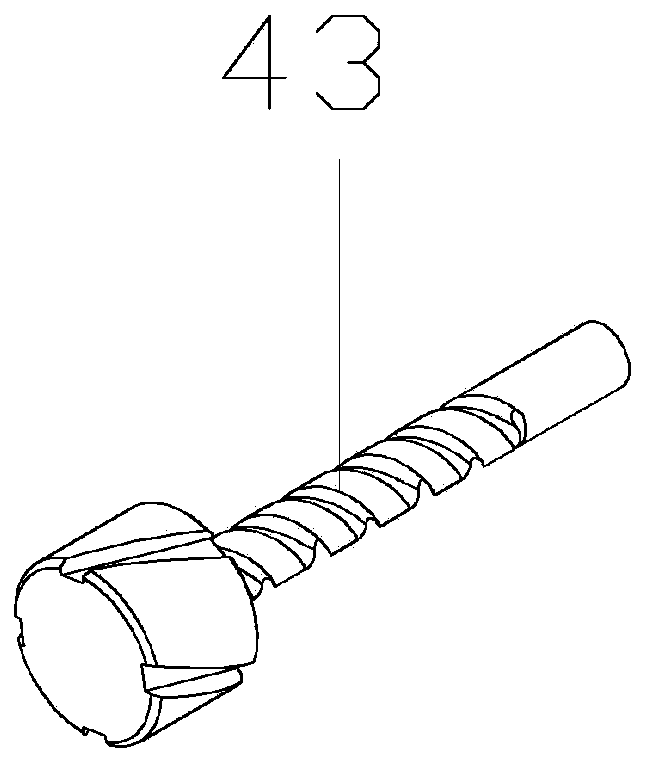

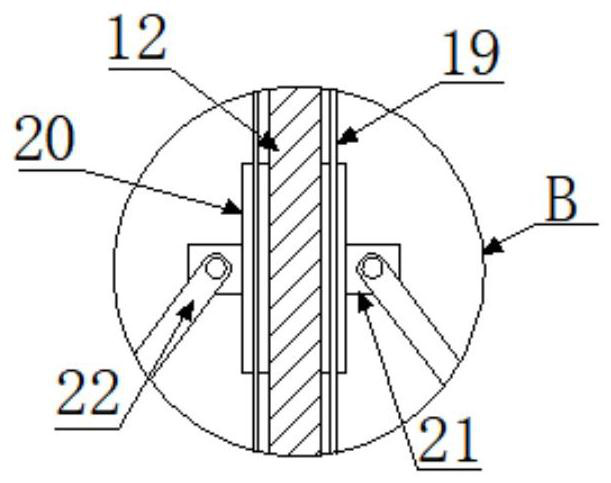

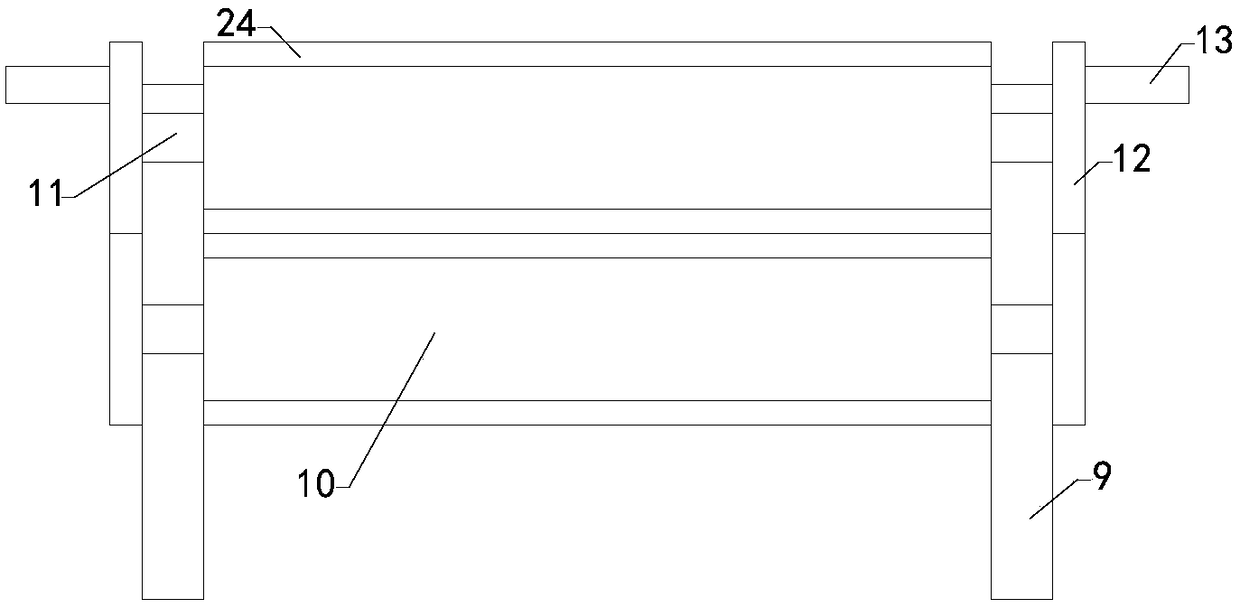

Integrated gear grinding machine

PendingCN114160884AReduce the impactReduce the impact of subsequent processingSawing tools dressing arrangementsGear grindingRooted tooth

The invention relates to the technical field of grinding machines, and provides an integrated gear grinding machine which comprises a machine body and a side face grinding device, a tooth root grinding device and an inner tooth face grinding device which are sequentially arranged on the machine body in the working direction and further comprises a conveying device, the conveying device is arranged on the machine body and comprises a grabbing part, and the grabbing part is arranged on the machine body in a sliding mode. The grabbing piece slides to be used for sequentially feeding the tooth pieces into the working ends of the side face grinding device, the tooth root grinding device and the inner tooth face grinding device. According to the technical scheme, the problems that the machining efficiency is low and the machining effect is poor due to the fact that the whole sawteeth cannot be integrally machined in the prior art are solved.

Owner:河北拓思机械设备有限公司

Method for demoulding chip

ActiveCN102157346BEasy to useAvoid stayingSemiconductor/solid-state device manufacturingElectrical componentsEngineeringGlass sheet

The invention relates to a method for demoulding a glass passivation chip, belonging to the field of chip production methods. The method for demoulding the glass passivation chip is characterized by comprising the following steps of: a, taking a film adhering chip, and soaking one surface of the film coating chip, which is not adhered with a film, by using water; b, adhering the soaked chip to a clean glass sheet; c, placing the glass sheet adhered with the chip into a freezer for freezing; d, freezing for certain time, and then taking out the glass sheet from the freezer, and tearing the film by using a hand; e, placing the glass sheet with the chip into high-purity water, unfreezing and separating the chip and the glass sheet; and f, taking out the chip from a water tank, cleaning, and drying. The invention has the advantages of solving the problems of much demanded labor power and low efficiency of manual demoulding, also solving the problem of high cost of mechanical demoulding by adopting lower-cost equipment, additionally preventing the scratch of the surface of the chip during preorder processing, reducing the waste of the chip during the preorder processing and saving the cost.

Owner:CHANGZHOUSR SEA ELECTRONICS

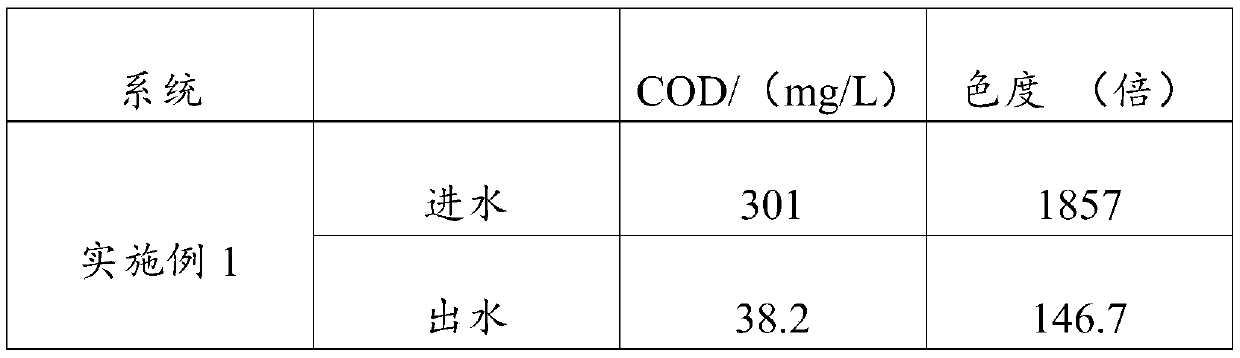

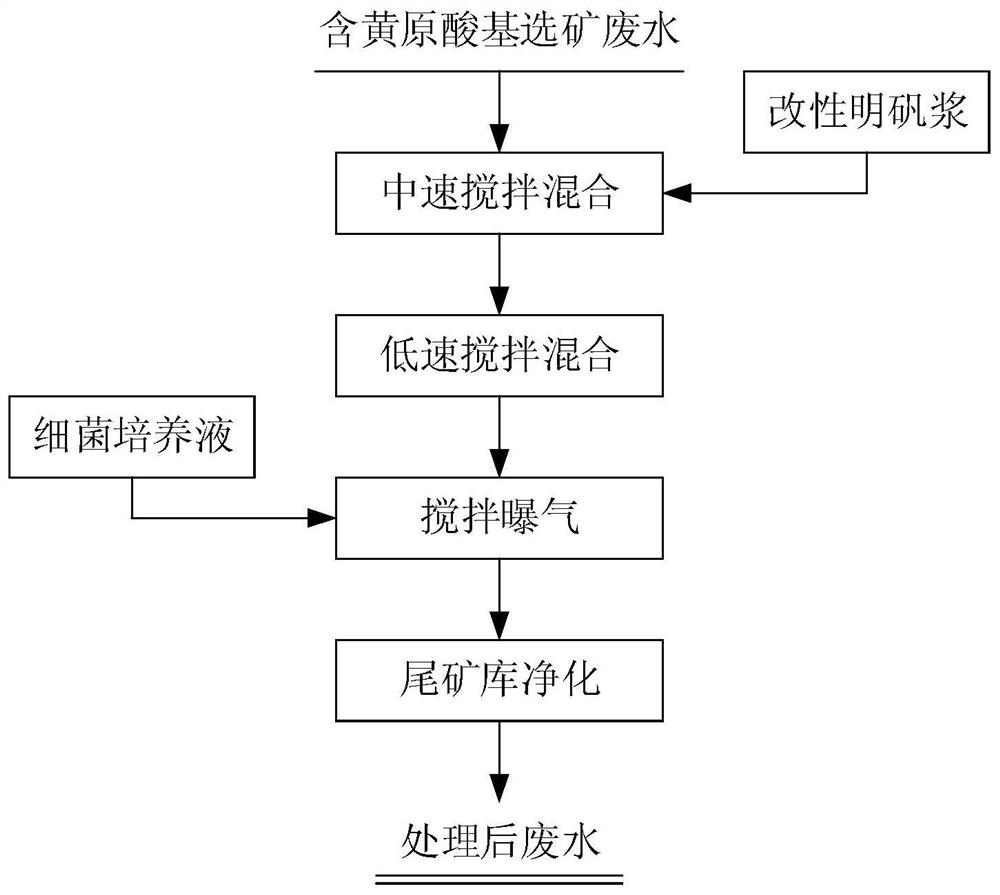

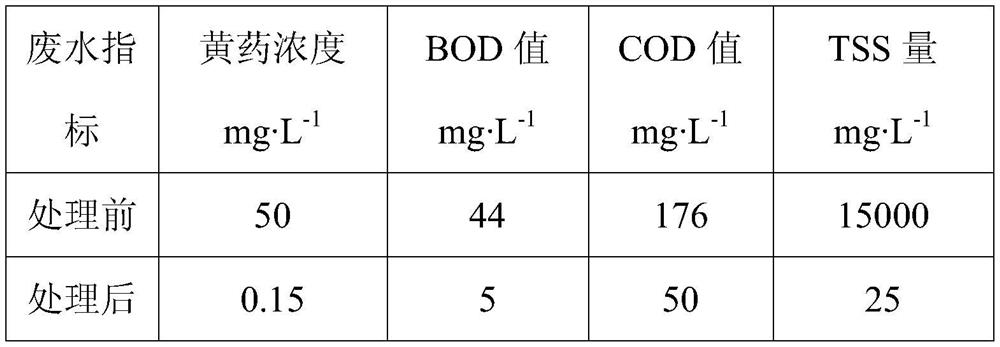

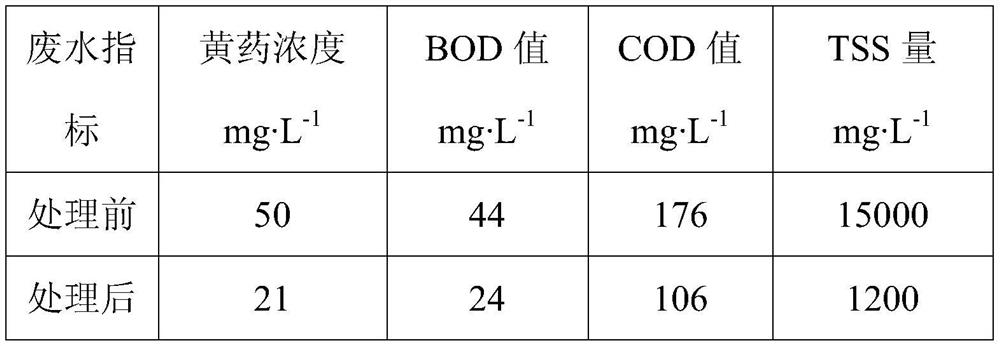

A combined treatment method for beneficiation wastewater containing xanthate residues

ActiveCN107487952BHarm reductionReduce the impact of subsequent processingWaste water treatment from quariesWater/sewage treatmentPseudomona aeruginosaSewage treatment

The invention relates to the field of sewage treatment and particularly relates to a combined processing method for xanthate residue-containing beneficiation wastewater. The method comprises: firstly, adding modified alum plasma into the wastewater, and after stirring, obtaining a primary processed solution; then according to 3% to 10% of a volume of the primary processed solution, preparing a bacterial culture solution containing pseudomonas aeruginosa; adding the prepared bacterial culture solution containing the pseudomonas aeruginosa into the primary processed solution, and under the stirring aeration condition, processing for at least 10 hours to obtain beneficiation wastewater subjected to bacterial processing; next, introducing the obtained beneficiation wastewater subjected to bacterial processing into a tailings reservoir to carry out natural purification for at least 3d, so that the xanthate residue-containing beneficiation wastewater can reach the discharge standard or the recycling standard. The combined processing method is short in flow, high in efficiency and low in cost, cannot generate secondary pollution, has excellent economic benefits and is convenient for large-scale application.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Anti-loose buckle for roll core of steel roll

The invention provides an anti-loose buckle for a roll core of a steel roll, and relates to the technical field of inner coil clamping tools. The anti-loose buckle comprises a clamping body which is a long-strip-shaped steel plate, wherein the clamping body is bent in a U shape in the direction perpendicular to the length direction of the clamping body to form a bent part, and a deformation joint facilitating deformation of the clamping body is formed in the middle of the clamping body. The anti-loose buckle has the advantage of conveniently clamping the steel coil with the loose coil core so as to reduce the influence of the reduction of the inner diameter of the coil core on the subsequent processing of the steel coil.

Owner:鞍钢蒂森克虏伯(重庆)汽车钢有限公司

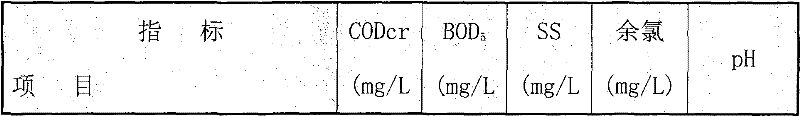

A mine water treatment process

InactiveCN101786760BReduce the impact of subsequent processingTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentChemical treatmentWater source

Owner:NANTONG BEICHEN MACHINERY EQUIP MFGCO

A method for treating emulsified crude oil containing iron-containing sulfide solid particles

ActiveCN108264926BReduce oil content in drainageReduce the impact of subsequent processingDewatering/demulsification with chemical meansDewatering/demulsification regulation/controlDemulsifierDesalination

The invention relates to the field of petrochemical industry, and discloses a method for processing emulsified crude oil containing iron sulfide solid particles. The method includes (1), mixing the emulsified crude oil with water and an oil-soluble demulsifier and carrying out first-stage electro-desalting treatment to obtain a mixture; (2), subjecting the mixture obtained in the step (1) to second-stage electro-desalting treatment. By application of the method, oil and water intermediate layer can be thinned, oil content of water discharged can be reduced, and iron sulfide solid particles canbe washed into water phase, so that influence from iron sulfide solid particles to subsequent process can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

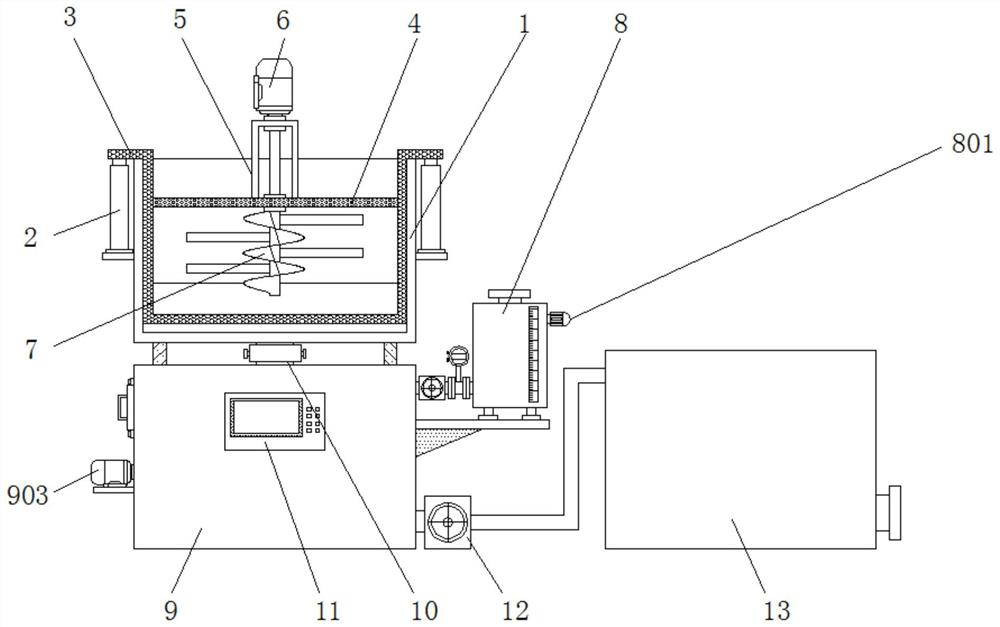

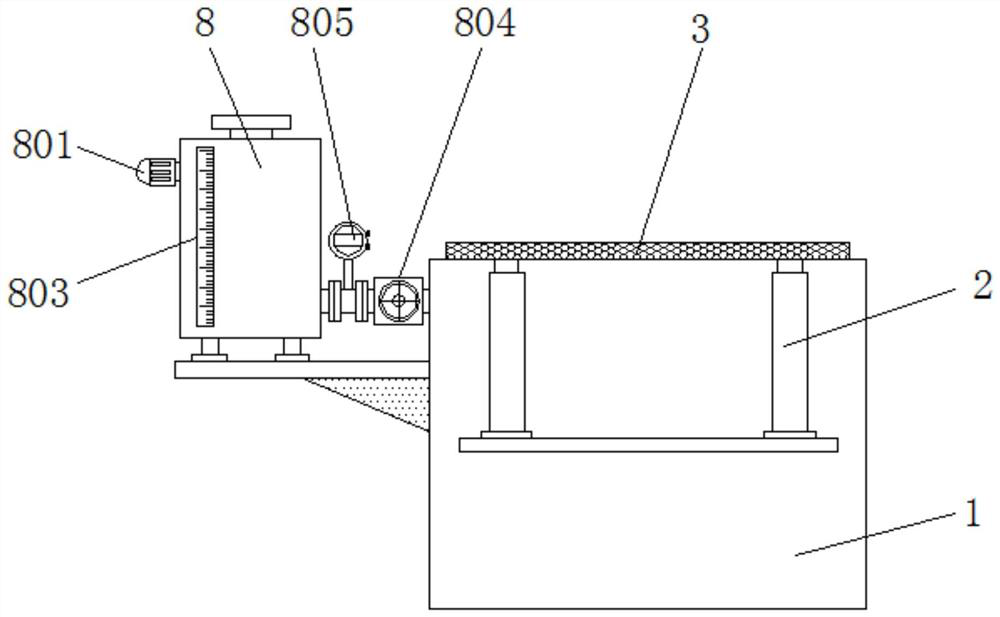

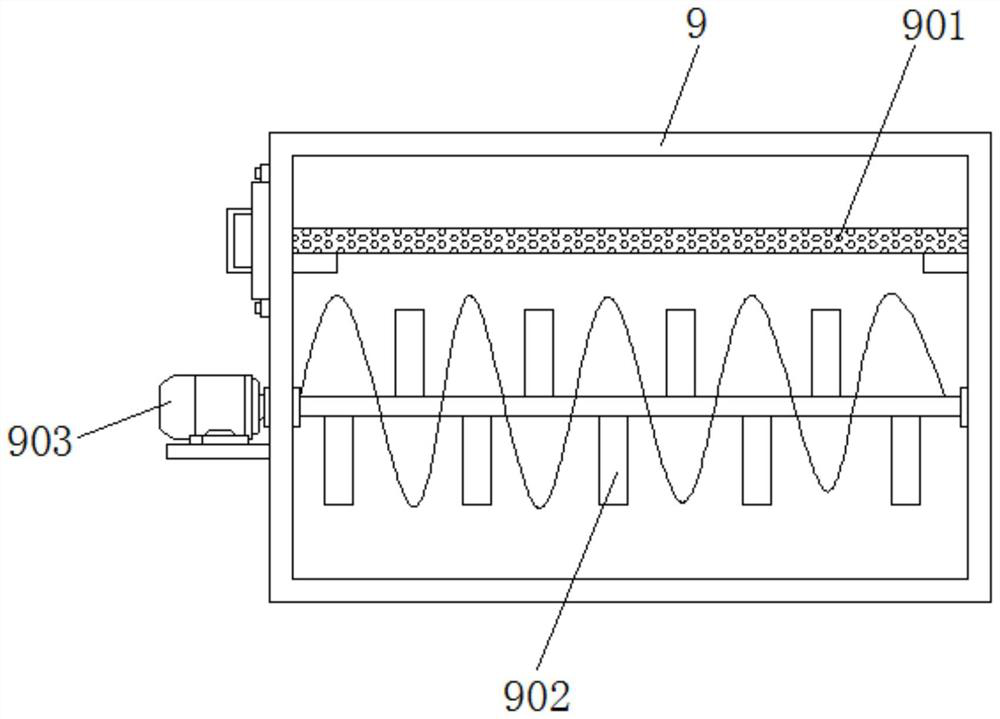

Energy-saving sludge impurity removal dehydrator and using method thereof

InactiveCN112607985AReduce the impact of subsequent processingReduce moisture contentSludge treatmentProcess engineeringSewage

The present invention discloses an energy-saving sludge impurity removal dehydrator and a using method thereof. The energy-saving sludge impurity removal dehydrator comprises a shell, a first cavity with an upward opening is formed in the shell, a second cavity with a downward opening is formed in the rear side of the first cavity, and the first cavity is connected with the second cavity through a first through hole; and a third cavity communicating with the first through hole is formed in the right side of the first through hole. By arranging the screening device capable of screening the sludge, solid impurities in the sludge can be discharged out of the sludge treatment device, and the influence of the solid impurities on subsequent treatment of the sludge is reduced; the sludge dewatering device is provided with the centrifugal dewatering device, so that the water content of sludge can be reduced, and the transportation cost is reduced; and the sludge screening device is provided with the flushing device, the flushing device can work when the viscosity of sludge is high so as to guarantee normal work of the screening device, the flushing device is driven by a power source of the centrifugal dewatering device, sewage is recycled, and electric power and resource losses are reduced.

Owner:王承友

Machining process for shaft parts and polishing equipment applied to machining process

PendingCN113618503AImprove corrosion resistanceImprove flatnessLiquid/solution decomposition chemical coatingCorrosionMachining process

The invention relates to a machining process for shaft parts. The machining process comprises the following steps that 1, CNC machining is conducted, specifically, raw materials are machined into blank pieces through a numerical control machine tool; 2, deburring is conducted, specifically, the blank pieces are polished and deburred through a grinding machine; 3, rough grinding is conducted, specifically, rough grinding is conducted on the blanks through a grinder; 4, fine grinding is conducted, specifically, fine grinding is carried out on the blank pieces through the grinder; 5, electroplating is conducted, specifically, nickel plating is conducted on the blank pieces obtained after fine grinding through a nickel plating pool; 6, polishing is conducted, specifically, the electroplated blank pieces are ground and polished through polishing equipment to be machined into workpieces; 7, degreasing is conducted, specifically, after polishing is completed, the workpieces are cleaned and degreased, and drying is conducted after degreasing; 8, inspection is conducted, specifically, the roughness and the circle run-out degree of the degreased and dried workpieces are inspected; 9, correction is conducted, specifically, pressing correction is conducted on the workpieces with the circle run-out degree not reaching the standard; and 10, packaging is conducted, specifically, the qualified workpieces are packaged and conveyed. The machining process has the effect of improving the corrosion resistance of the workpiece surfaces.

Owner:JIASHAN PINHUI PRECISION

International express item image checking device and system based on CT equipment

ActiveCN111598147AGuaranteed clarityImprove cleanlinessCharacter and pattern recognitionStill image data indexingElectromagnetic lockElectric machinery

The invention provides an international express item image checking device and system based on CT equipment. The international express item image checking device and system based on the CT equipment can comprise a checking device main body, wherein the inspection device main body is arranged outside a conveying belt for conveying international express items in a covering manner; an object inlet and an object outlet are symmetrically formed in the upper side wall of the inspection device main body; protective upper covers are symmetrically hinged to the object inlet and the object outlet; a mounting table is integrally formed in an inner cavity of the inspection device body, push rod motors are symmetrically hinged to the upper side wall of the mounting table on one side, the output ends ofthe push rod motors are hinged to the upper protection cover of the object inlet, and an electromagnetic lock is arranged on the upper protection cover of the object outlet. The device and the systemcomprise CT equipment which is arranged on the inspection device main body, and a bar code scanner. By providing a relatively closed space, the cleanliness in the device is maintained, so that the clearness of the shooting effect and the tidiness of an object are ensured.

Owner:合肥格泉智能科技有限公司

A slicer with self-cleaning function based on computer technology

ActiveCN108972041BIncrease the fixation strengthPhenomena that improve processing qualityLarge fixed membersCleaning using liquidsTransmission beltDrive shaft

The invention belongs to the technical field of slicing devices, particularly relates to a slicing device with a self-cleaning function based on a computer technology and aims to solve the problems that an existing slicing device is inconveniently cleaned. The slicing device comprises a frame, a transmission shaft mounting hole is formed in the top of the outer wall of one side of the frame, the outer wall of the transmission shaft mounting hole is connected with a transmission shaft through a key, two sides of the outer wall of the transmission shaft are connected with a conveying roller anda belt pulley through keys, the outer wall of one side of the belt pulley is in sleeve connection with a transmission belt, the outer wall of one side of the frame is connected with a conveying motorthrough a key, and an output shaft of the conveying motor is fixed to the outer wall of one end of the transmission shaft through a coupler. The effect of displacement of a part to be machined on machining quality can be improved, cutting distances can be rapidly adjusted and measured, machining convenience and machining efficiency can be improved, a cutter can be kept clean, splashing of cleaningliquid can be avoided, pollution to a working environment can be avoided, and product quality can be improved.

Owner:徐州飞云泡沫制品有限责任公司

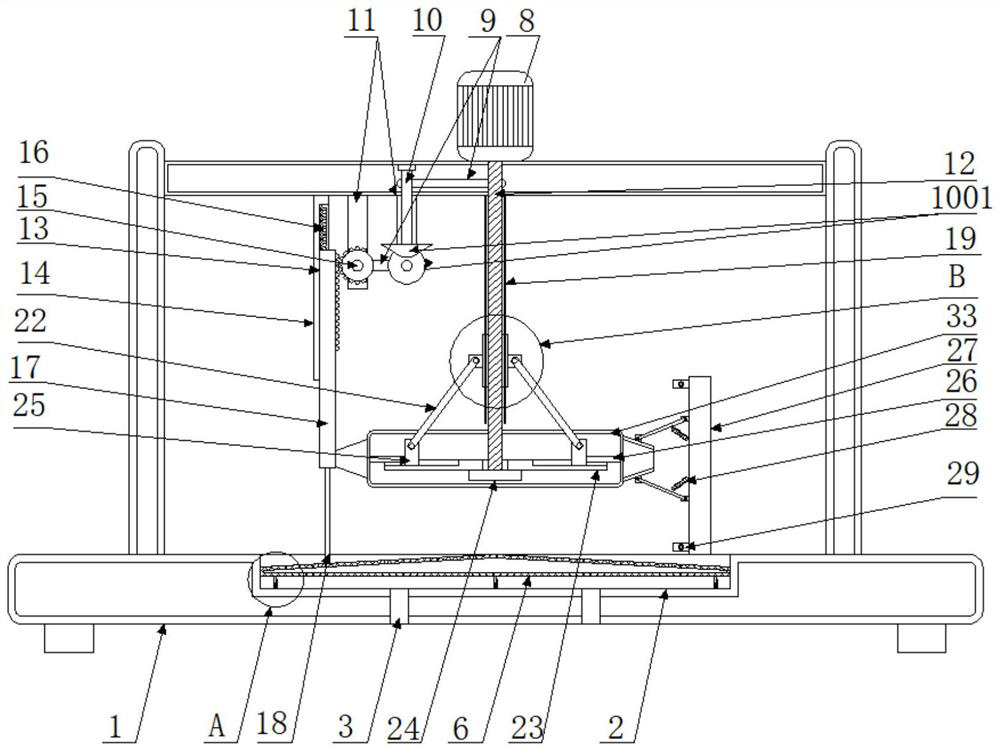

Air flow temperature-regulating mattress and processing technology

InactiveCN110664165AReduce processing timeReduce the difficulty of operationStuffed mattressesSpring mattressesThermal insulationProcess engineering

The invention discloses an air flow temperature-regulating mattress and a processing technology, and relates to the technical field of air flow mattress processing. The structure comprises a machine tool, a portal frame is arranged above the machine tool, the portal frame is arranged on the machine tool in a sliding manner, a processing device is arranged on the portal frame, the processing deviceslides on the portal frame, and an air sucking pipe is arranged on the portal frame. For the air flow temperature-regulating mattress and the processing technology, the integrated processing mode isadopted, compared with the traditional manner that two layers or three layers are separately processed and then stacked, the processing technology provided by the invention has the advantages that theprocessing time is saved, the operation difficulty is reduced, meanwhile, the problems of dislocation and unevenness easily caused by multi-layer laminating can be eliminated, in addition, the single-side processing also adapts to the use during the different climates of winter and summer, the side with cutting can adapt to the air ventilation and moisture exhaust demand in summer, the other sidewithout cutting is closed, thus the thermal insulation demand in winter is adapted, the air exchange is realized, and the purposes of being warm but not dry, realizing moisture removal through hot air, as well as being dry and comfortable and inhibiting mites are achieved.

Owner:王九陵

A deburring mechanism for gear processing

ActiveCN113199091BImprove cleaning efficiencyHigh efficiency during deburringGear-cutting machinesMaintainance and safety accessoriesGear wheelWastewater

The invention relates to the technical field of gear processing, in particular to a burr cleaning mechanism for gear processing. A deburring mechanism for gear processing, comprising a processing table, a separation net, a servo motor, a long side cleaning plate, a push rod and a short side cleaning block, the upper surface of the processing table is provided with a separation groove, and the lower surface of the processing table is provided with a There is a water outlet, the upper surface of the processing table is bolted with a servo motor, the upper surface of the processing table is welded and fixed with a connecting plate, the upper and lower surfaces of the processing table are welded and fixed with a fixing plate and a placement plate, and the upper surface of the processing table is welded and fixed There are connecting plates. The beneficial effects of the present invention are: the deburring mechanism for gear processing utilizes the linkage structure on the device, so that while the whole device is fixed to the gear body, it can simultaneously clean the five surfaces of the tooth block on the gear body, so that the entire The processing efficiency of the device is higher, and the extrusion of the sieve by the ejector rod will not affect the secondary use of waste water.

Owner:JIANGSU AIRSHIP GEAR

Fabric sand washing device for garment production

InactiveCN109402906AImprove treatment uniformityImprove use reliabilityLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsEngineeringNozzle

The invention relates to the technical field of fabric processing auxiliary devices, in particular to a fabric sand washing device for garment production. A fabric can be conveyed conveniently, the fabric processing uniformity is improved, and the using reliability is improved; alkali water brought by the fabric obtained after processing is preliminarily cleaned, the influence on follow-up processing is reduced, and practicability is improved; the device comprises a working box and a set of supporting columns, further comprises a set of fixing plates, a set of transmission rollers, a set of fixing shafts, a set of limiting plates, a set of left limiting rollers, a set of right limiting rollers, a set of limiting shafts, a set of supporting plates, a set of driving rollers, a set of upper connecting shafts, a set of lower connecting shafts, a set of driving gears, a set of driven gears and a set of rotating handles, and further comprises a cleaning box, a fixing plate, a set of supporting shafts, an upper flow division box, a lower flow division box, a set of supporting pipes, a set of nozzles, a set of liquid inlet pipes, a set of conveying pumps, a liquid outlet pipe and a set ofbristles.

Owner:YANCHENG DIJIANI CLOTHING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com