A mine water treatment process

A treatment process and mine water technology, applied in water/sewage multi-stage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. Status and other issues to achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

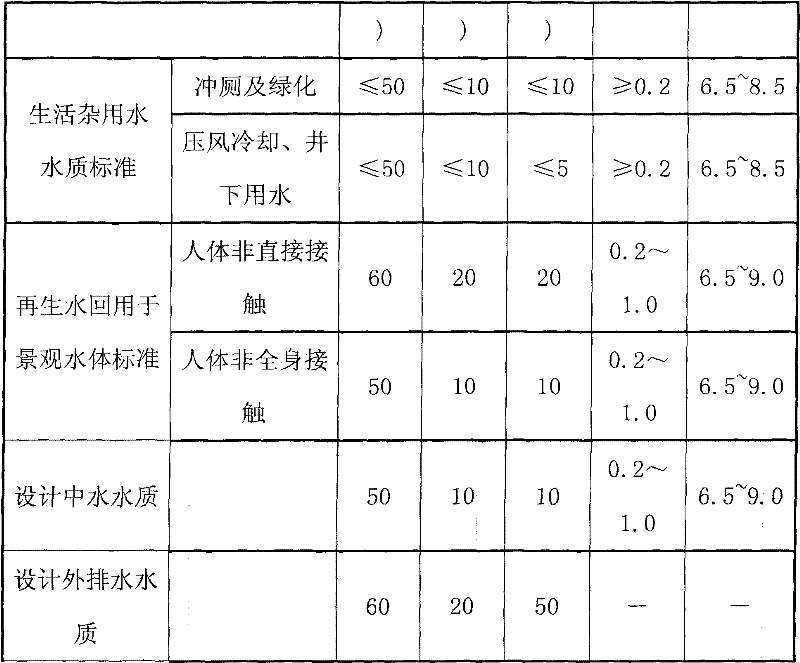

[0020] The process of the present invention is as follows: after the mine water is premixed and flocculated and precipitated, it is put into the adjustment tank for preliminary hydrolysis and acidification, after the macromolecules of the organic matter are changed into small molecules, and then the solid suspension is separated through the mechanical grid pool, and then Enter the hydrolytic acidification tank, after hydrolytic acidification, contact oxidation under the action of aerobic organisms, degrade the organic matter in the sewage, and then precipitate the degraded water source, separate the aging biofilm shed by the aerobic organisms, and the clear water flows naturally Enter the reclaimed water pool, in the reclaimed water pool, the water source is filtered by quartz sand or activated carbon according to the nature of use, and the entire mine water treatment process is completed. Each process of the above treatment is in a separate pool, and each pool is independent o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com