Automatic cutting and shearing machine for clothing processing

A cutting and automatic technology, which is applied in the cutting of textile materials, textiles and papermaking, static electricity, etc., can solve the problems of fabric wrinkles, low work efficiency, and inability to compress fabrics, so as to avoid damage, reduce impact, and improve end surface quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

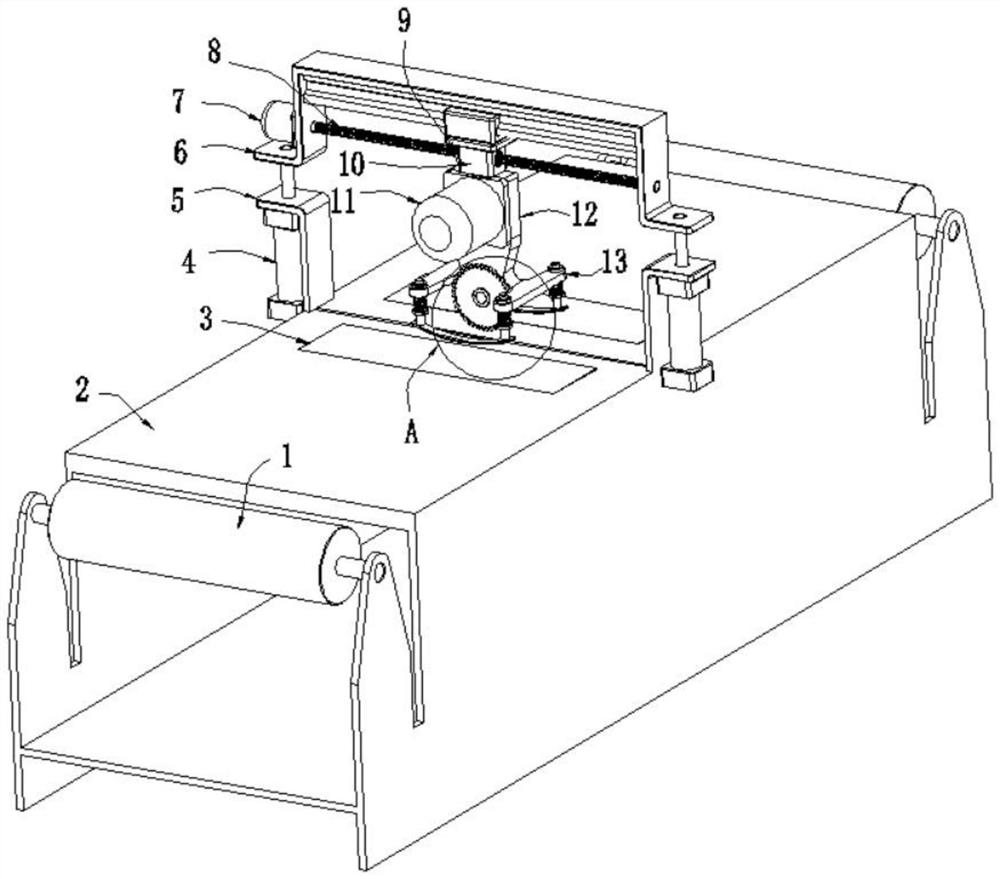

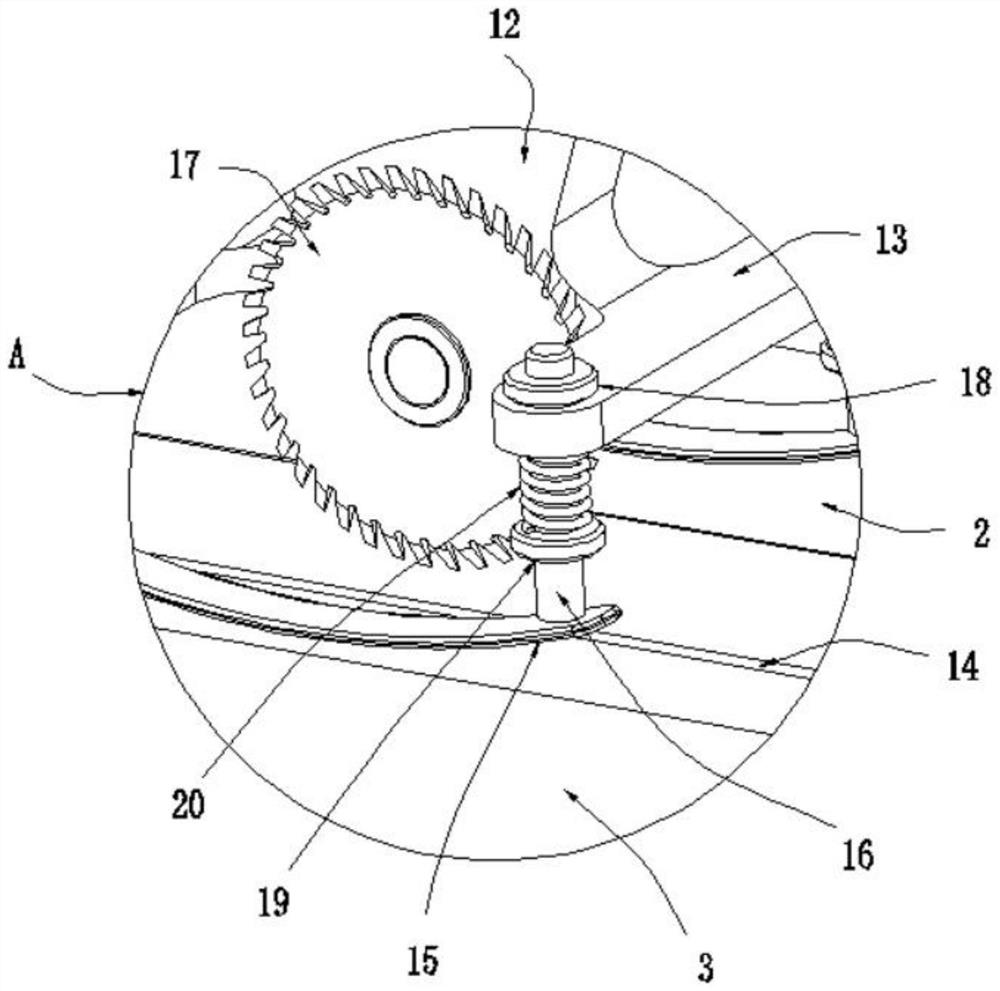

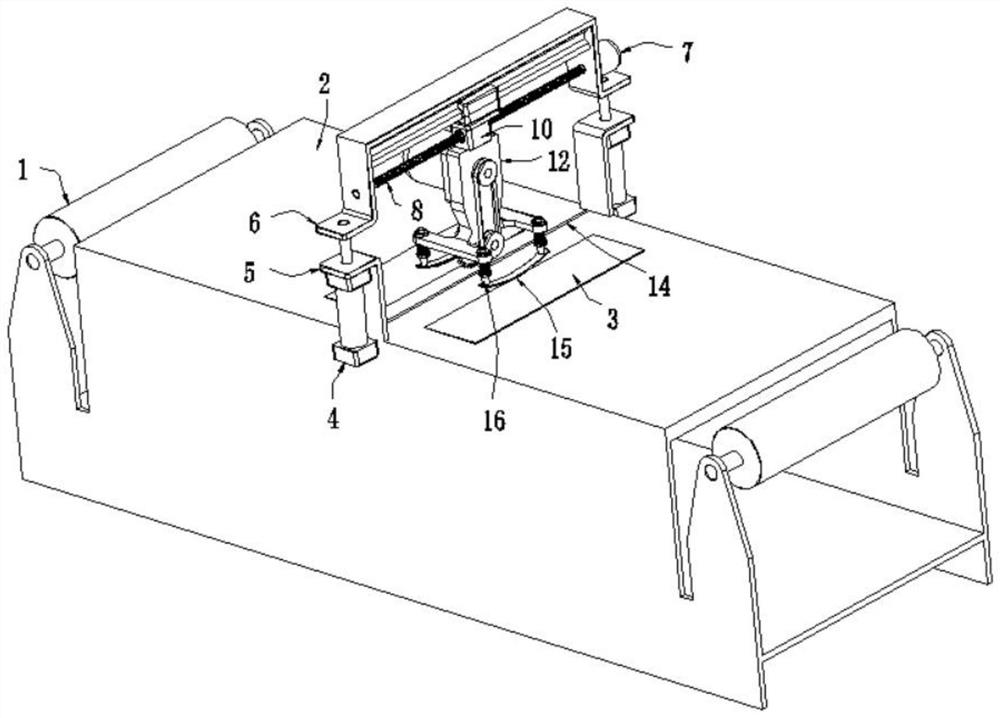

[0021] Such as Figure 1-3 As shown, an automatic cutting and shearing machine for clothing processing includes winding rollers 1 that are installed on both ends of the cutting seat 2 in the length direction and can rotate freely. The two winding rollers 1 can wind the cloth, That is, the cloth is unrolled by one of the winding rollers 1, and then the cloth is rewound by another winding roller 1, so that the cloth moves on the cutting seat 2, or in other words, the cloth is moved from the cutting seat 2 in the longitudinal direction. One end is conveyed to the other end, so that the cloth is spread on the cutting seat 2, and the top surface of the cutting seat 2 is on the same level as the highest point of the circumference of the winding roller 1, so that the cloth will not be wrinkled on the cutting seat 2, And then it is convenient for the cloth to be transported on the cutting seat 2, a floating mounting seat 6 is arranged above the cutting seat 2, and the floating mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com