Small-diameter rod material cut-off device

A cutting device and small-diameter technology, applied in the mechanical field, can solve the problems that the length of the cut part cannot be adjusted in a large range, the semicircular upper and lower knife edges are difficult to ensure alignment, and the broken product is squeezed, etc., to achieve the quality of the cut surface and stable, Easy and fast adjustment, reliable output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

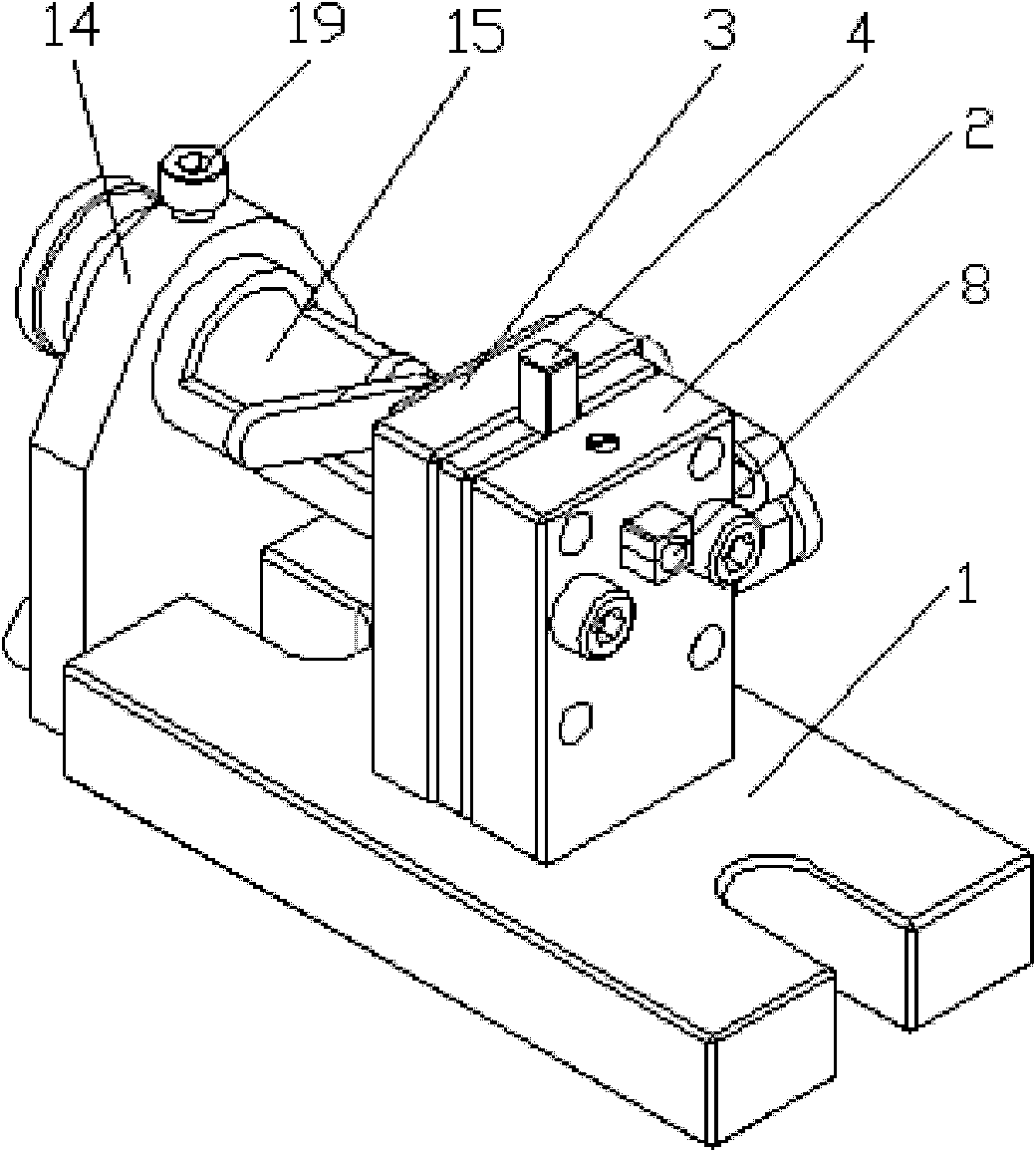

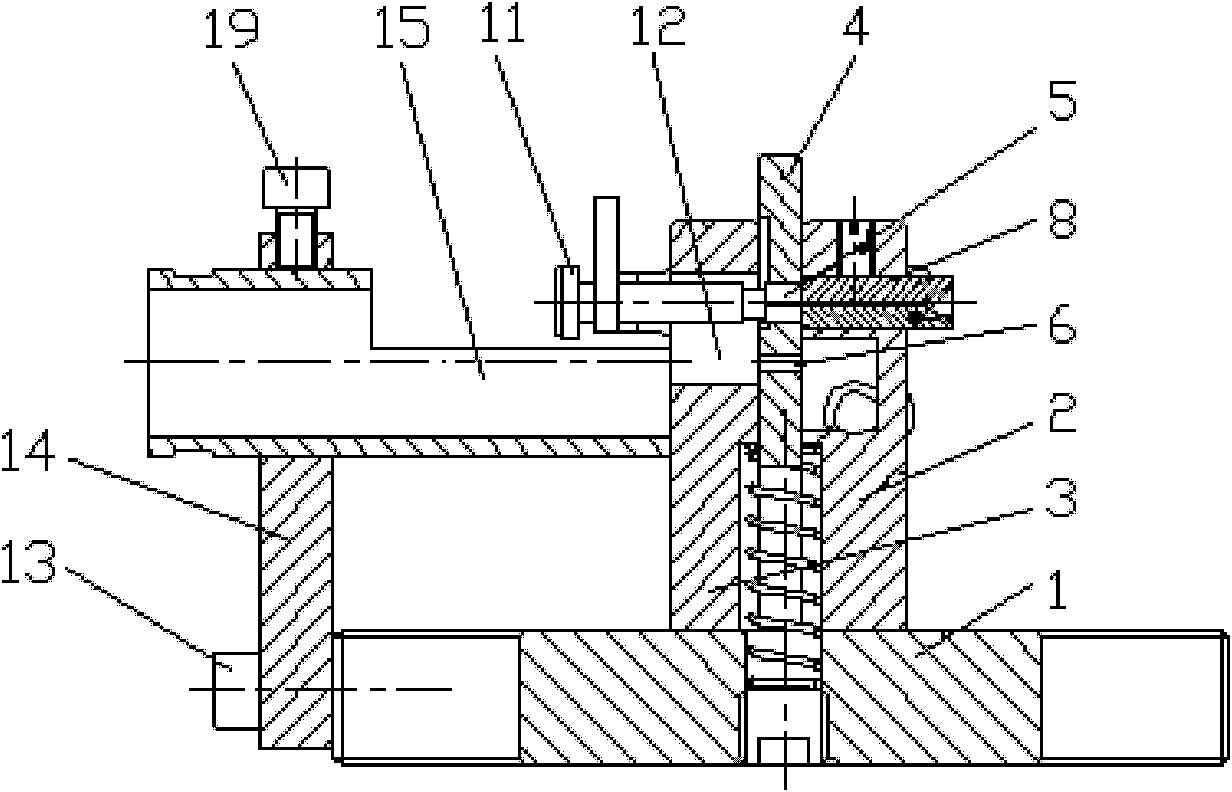

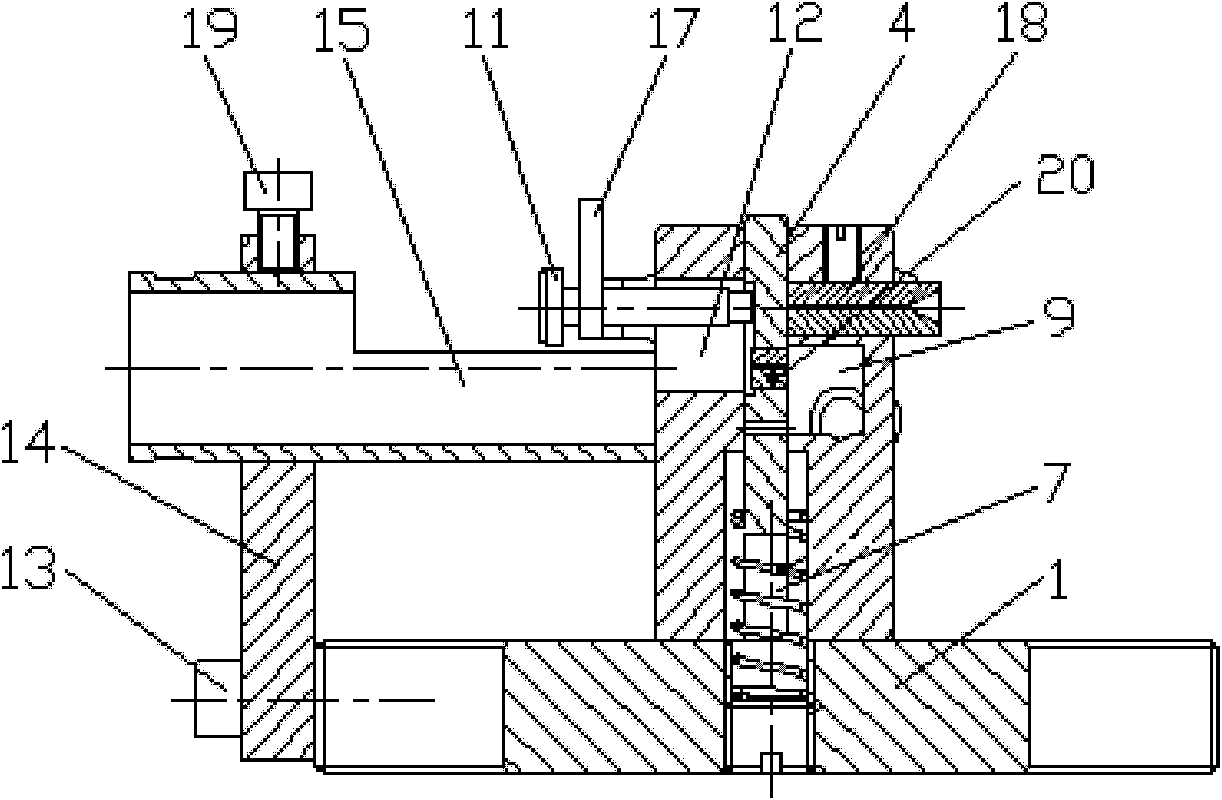

[0018] Example 1. Such as figure 1 , 4 As shown, including base 1, front support 2 and rear support 3, front support 2 and rear support 3 are fixed on the base 1, between front support 2 and rear support 3, cutting knife 4, cutting hole are housed from top to bottom 5. The exhaust hole 6 and the return spring 7, the return spring 7 plays the role of resetting the cutting knife 4; the front bracket 2 is provided with a feeding hole 8, before work, the feeding hole 8 communicates with the cutting hole 5, and the bar material 18 can enter the cutting hole 5 through the feeding hole 8; there is a space 9 below the feeding hole 8, and the front bracket 2 is equipped with an air nozzle 10, which communicates with the space 9, and the air nozzle 10 can cut off the bar. 20 Blow out the cut-off hole 5; the rear support 3 is equipped with an adjustment stop nail 11 and an adjustment piece 21, the adjustment stop nail 11 is equipped with a lock nut 17, and the adjustment piece 21 is eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com