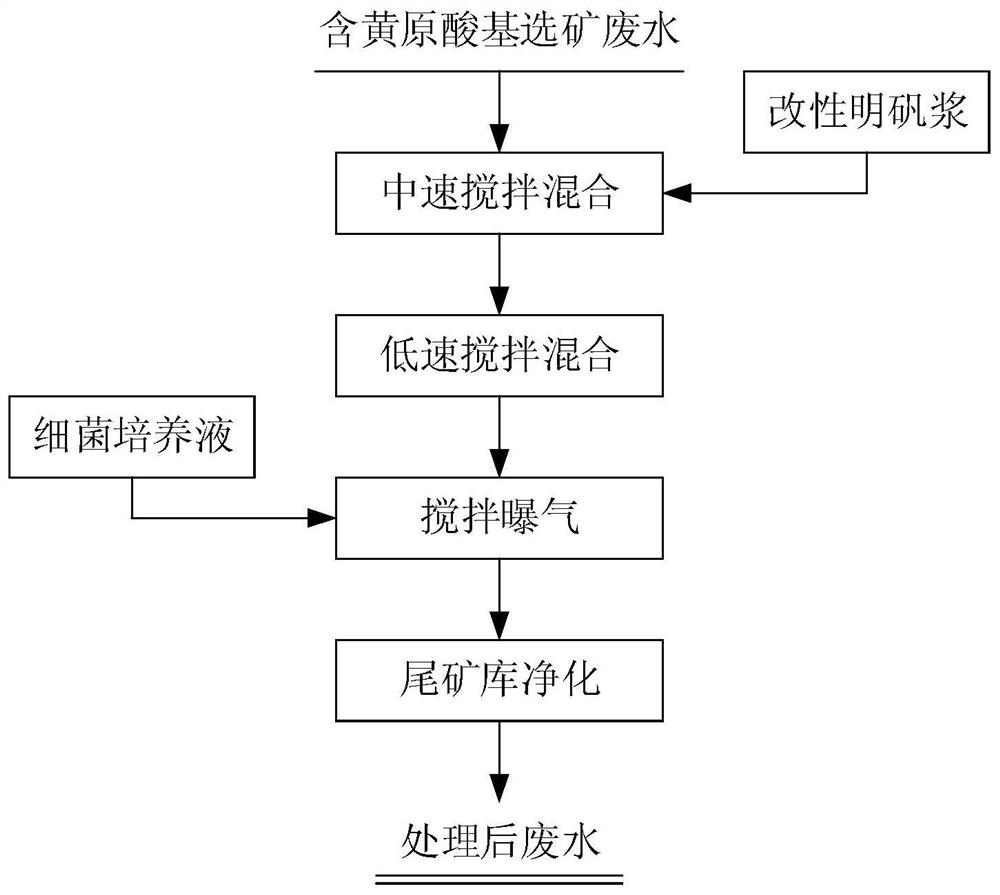

A combined treatment method for beneficiation wastewater containing xanthate residues

A technology of mineral processing wastewater and combined treatment, which is applied in the direction of mining wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of incomplete treatment, complicated treatment process, and return of no liquid to tailings obtained from mineral processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

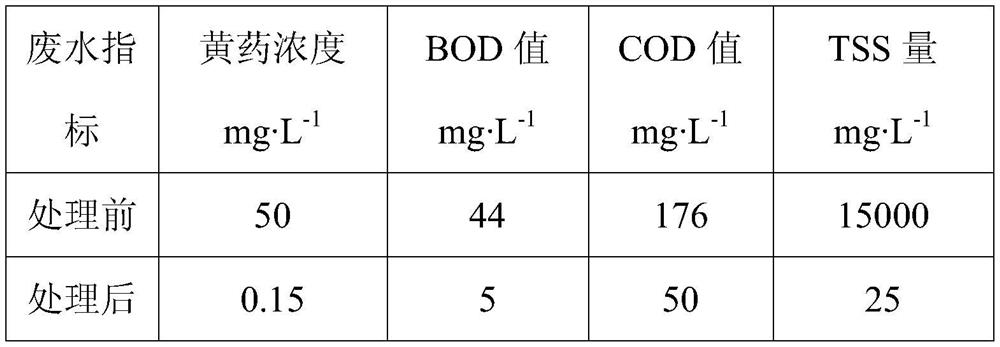

Embodiment 1

[0044] The mineral processing wastewater containing xanthate residues from a copper ore dressing plant in Kunming City, Yunnan Province was taken, and the concentration of residual xanthate in the wastewater was 50 mg L -1 , wastewater pH=9.3, mineral fine mud content, particle size and particle size distribution in wastewater: 1.5%, -400 mesh 97%.

[0045] The processing method is as follows:

[0046] (1) Preparation of modified alum slurry: crush the alum slurry and pass it through a 200-mesh sieve, take the sieved material and 0.5mol / L sulfuric acid solution and mix evenly at a solid-liquid mass ratio of 1:2, heat to 75°C, Insulated for 2 hours to obtain the sulfuric acid treatment mixture of the alum slurry. Then add an appropriate amount of lime to the sulfuric acid treatment mixture of the alum slurry to adjust the pH to 4.5, and cool to 25°C, age for 1.0h and then filter to obtain a semi-solid to solid modified alum slurry;

[0047] The median particle size of the mod...

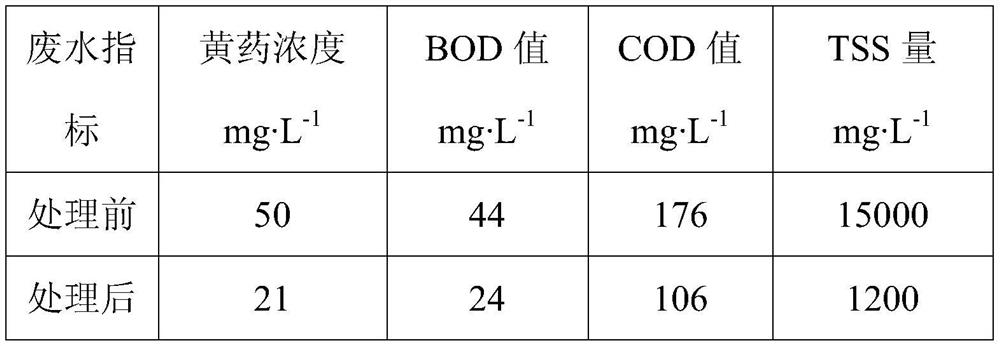

Embodiment 2

[0063] Take the mineral processing wastewater containing xanthate residues from a lead-zinc ore dressing plant in Luoyang City, Henan Province. The concentration of residual xanthate in the wastewater is 165 mg L -1 , wastewater pH=8.0, mineral fine mud content, particle size and particle size distribution in wastewater: 0.1%, -400 mesh 95%.

[0064] The processing method is as follows:

[0065] (1) Preparation of modified alum slurry: crush the alum slurry and pass it through a 200-mesh sieve, take the sieved material and 1mol / L sulfuric acid solution and mix evenly at a solid-liquid mass ratio of 1:3, heat to 85°C, and keep warm 3h, the sulfuric acid treatment mixed solution of the alum slurry was obtained. Next, add an appropriate amount of limestone to the sulfuric acid-treated mixed solution of the alum slurry to adjust the pH to 5.0, cool to 30° C., and centrifuge after aging for 1.5 hours to obtain a semi-solid to solid modified alum slurry;

[0066] The median partic...

Embodiment 3

[0082] The mineral processing wastewater containing xanthate residues from a copper ore dressing plant in Baoding City, Hebei Province, the concentration of residual xanthate in the wastewater was 233mg L -1 , Wastewater pH=11.0. The mineral fine mud content, particle size and particle size distribution in the mineral processing wastewater containing xanthate residues are: 3.7%, -400 mesh 98%.

[0083] The processing method is as follows:

[0084] (1) Preparation of alum slurry additives: crush the alum slurry and pass it through a 200-mesh sieve, take the sieved material and 1.5mol / L sulfuric acid solution and mix evenly at a solid-liquid mass ratio of 1:4, heat to 85°C, Insulated for 3 hours to obtain the sulfuric acid treatment mixture of the alum slurry. Then add an appropriate amount of dolomite and calcium carbide slag to the sulfuric acid treatment mixture of the alum slurry to adjust the pH to 5.5, and cool it to 35°C, and centrifuge after aging for 2 hours to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com