Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Reduce the amount of steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

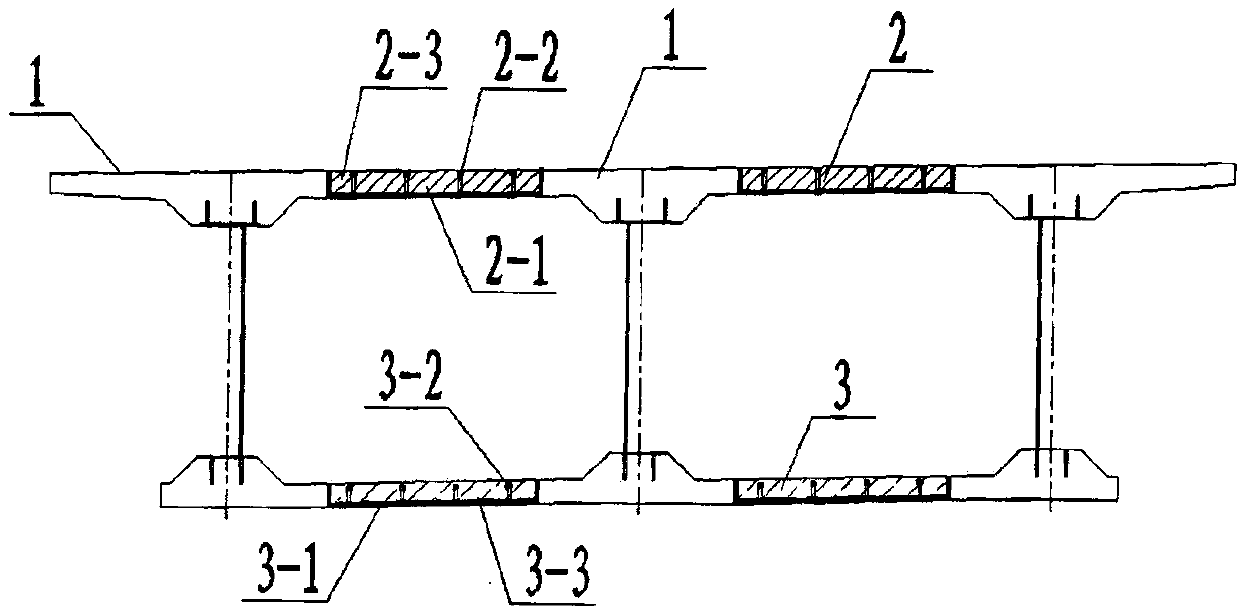

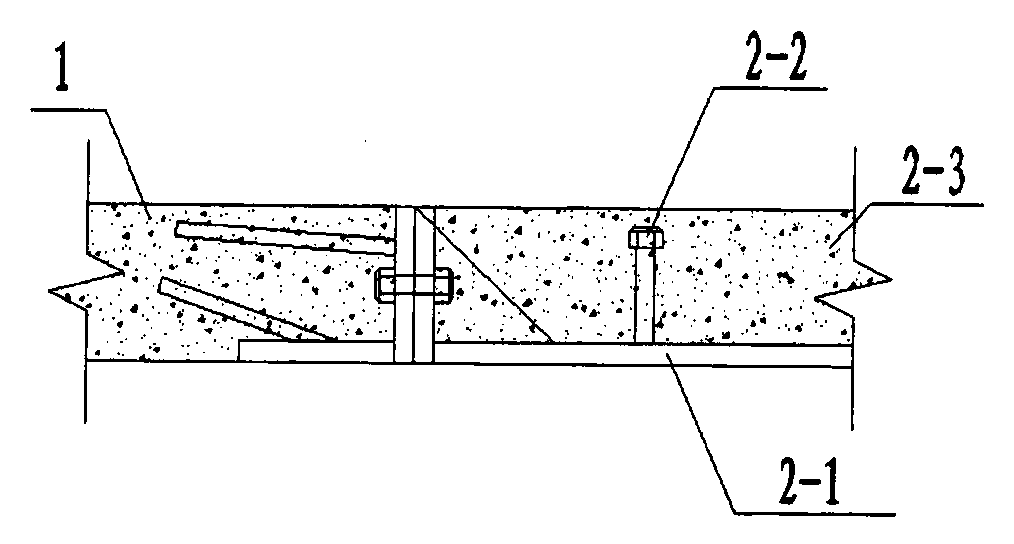

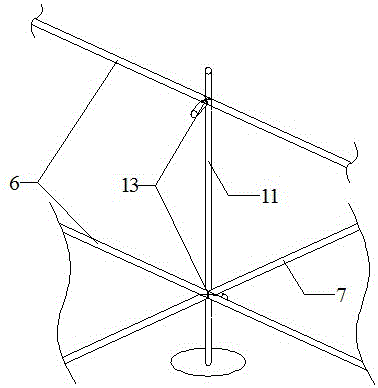

Horizontal splicing corrugated steel web plate combined box girder and construction method

InactiveCN103388303AReduce adverse effectsIncrease spacingBridge erection/assemblySheet steelAbutment

The invention discloses a horizontal splicing corrugated steel web plate combined box girder comprising a combined box girder formed by horizontally splicing multiple precast I-shaped girder units (1); and a top plate lower edge steel plate (2-1) and a bottom plate lower edge steel plate (3-1) are respectively connected to the lower end faces of a top plate wet jointing seam (2) and a bottom plate wet jointing seam (3) of two adjacent precast I-shaped girder units (1). The construction method comprises the steps of mounting the multiple precast I-shaped girder units onto a bridge pier abutment, fixing the top plate lower edge steel plates connected with shearing force nails to the top plate wet jointing seams of every two adjacent precast I-shaped girder units, and pouring top plate wet jointing seam concrete (2-3) by taking the top plate lower edge steel plates as support templates; and then fixing the bottom plate lower edge steel plates connected with the shearing force nails to the bottom plate wet jointing seams of every two adjacent precast I-shaped girder units, and pouring bottom plate wet jointing seam concrete (3-3) by taking the bottom plate lower edge steel plates as the support templates. The horizontal splicing corrugated steel web plate combined box girder and the construction method achieve the aims of simplifying the operation process, reducing work amount, shortening construction period, reducing weight and ensuring construction quality.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

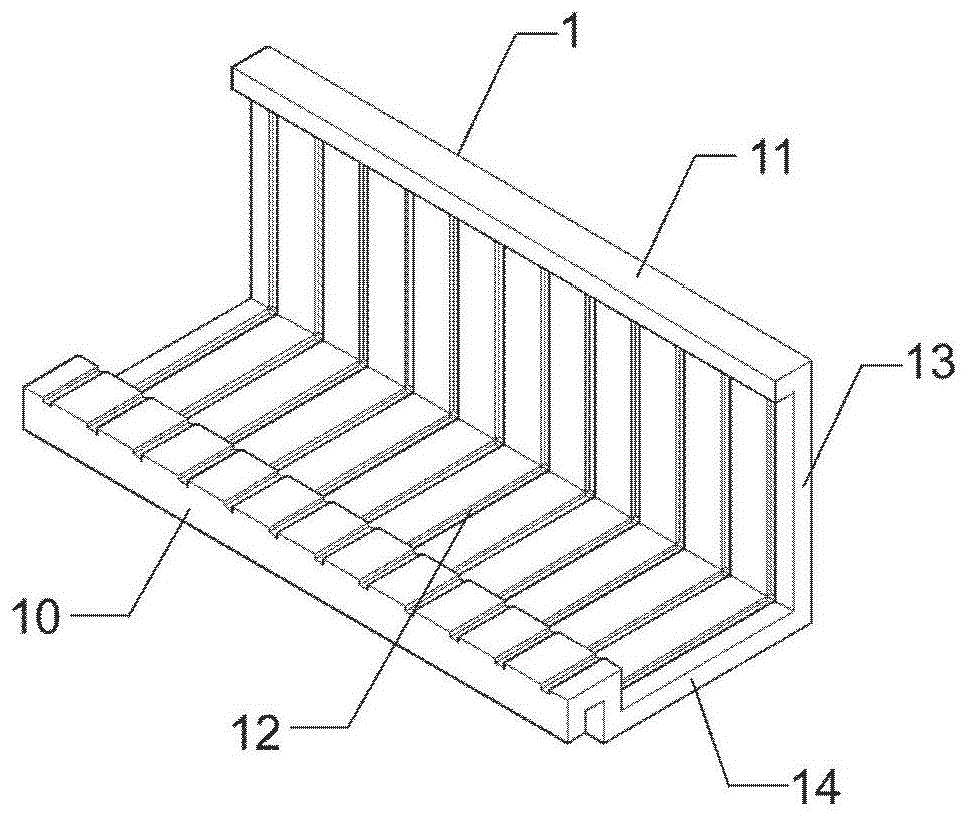

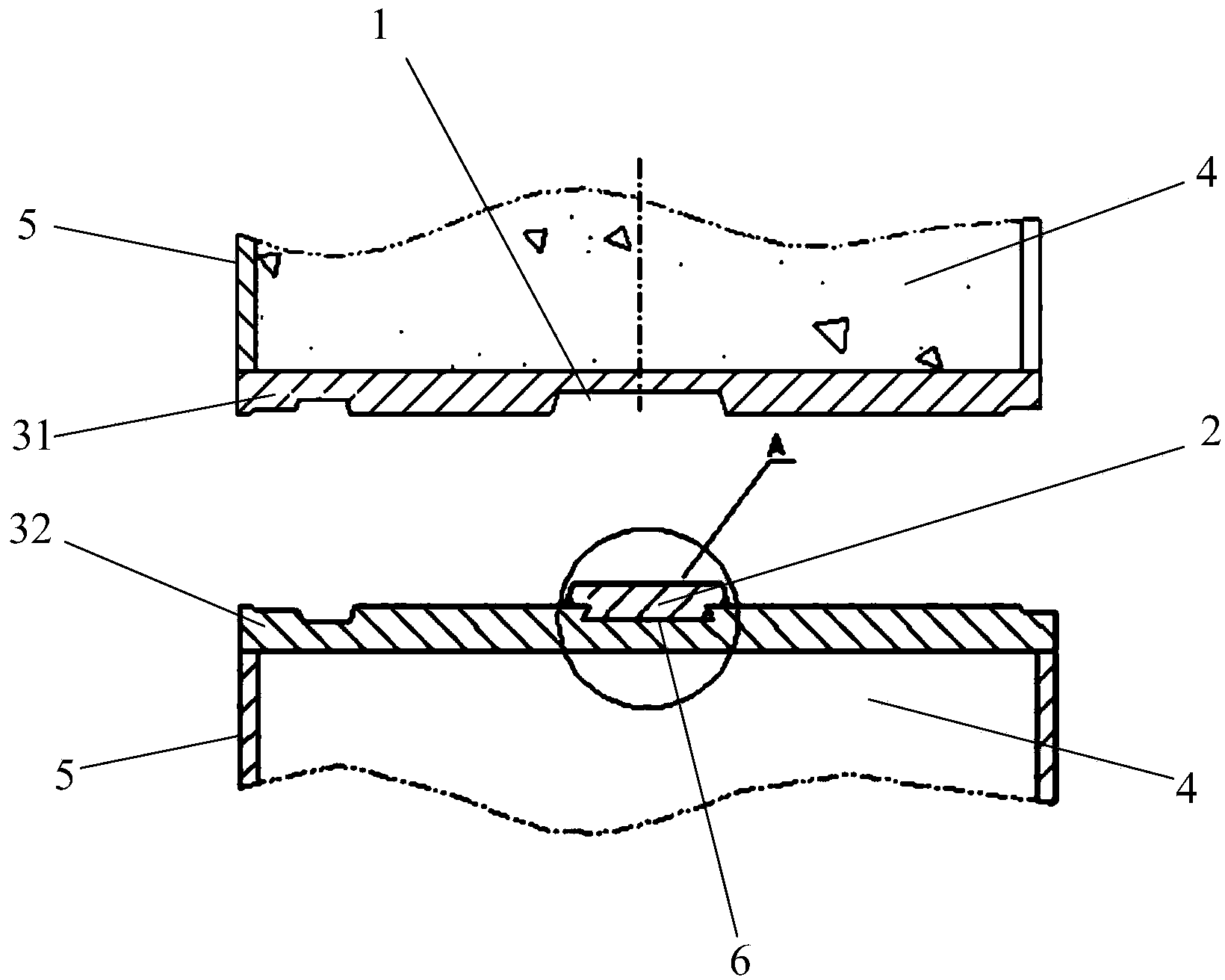

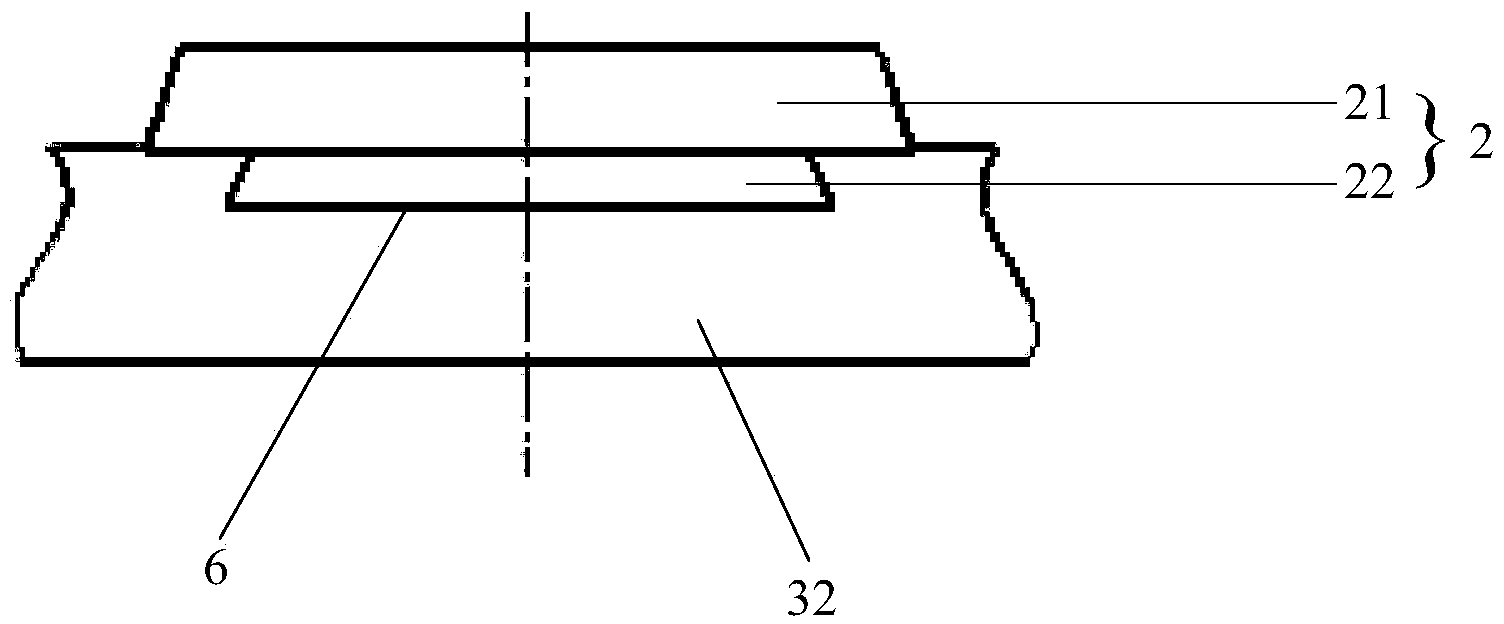

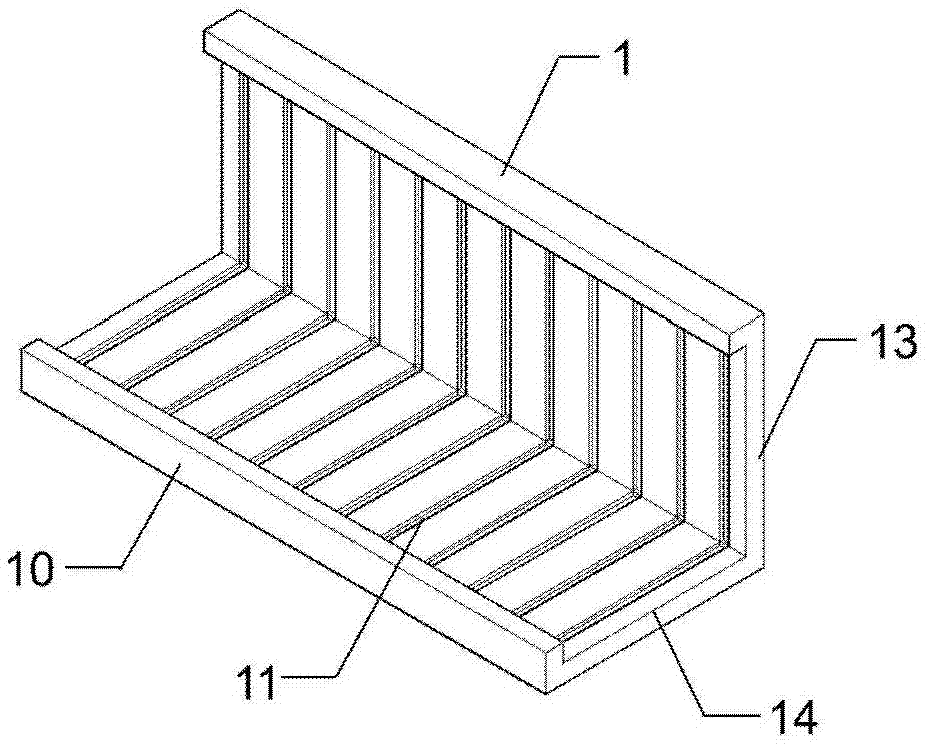

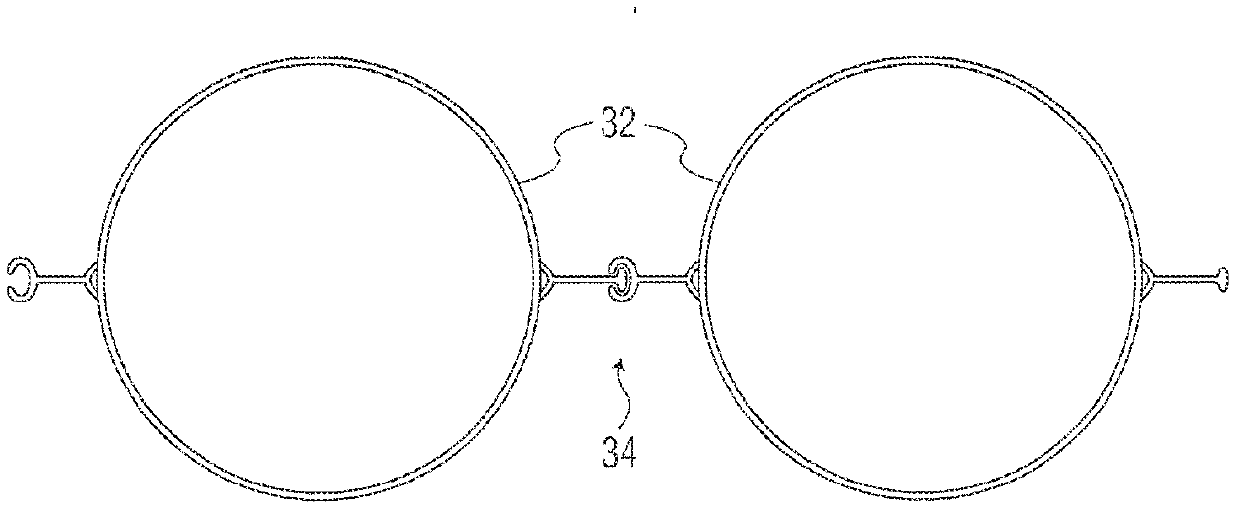

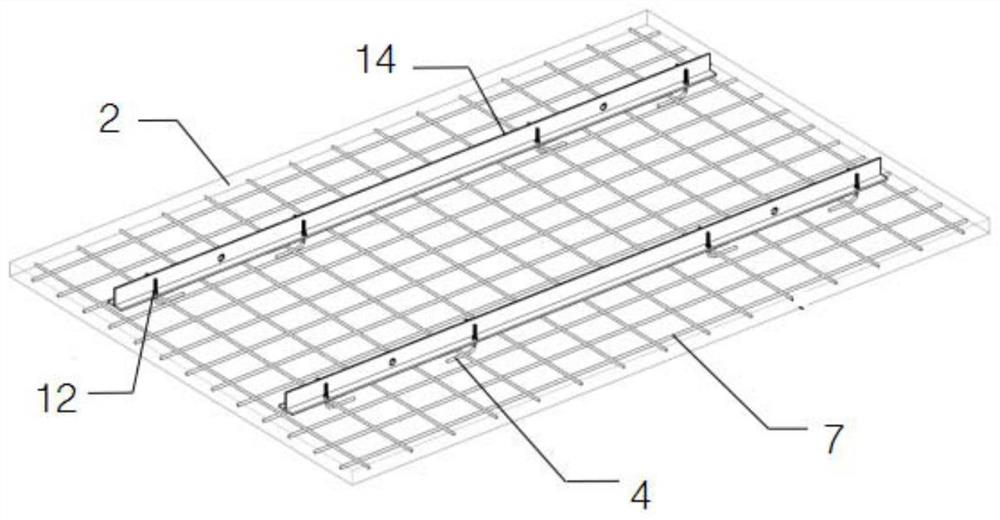

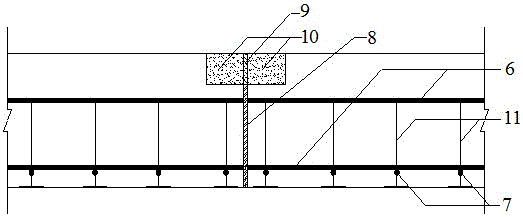

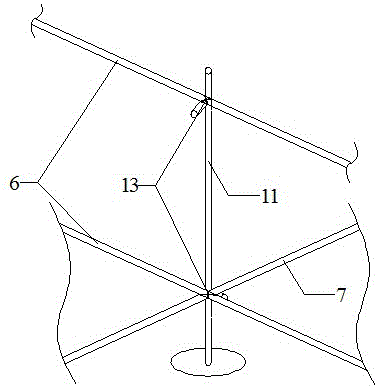

Concrete composite slab floorslab with shear key and prefabricated construction and construction method

InactiveCN102839773AReduce the amount of steelReduce plate thicknessFloorsBuilding material handlingRebarFloor slab

The invention relates to the field of fabricated type concrete buildings, in particular to a concrete composite slab floorslab with a shear key, a prefabricated construction and a construction method. The produced concrete composite slab floorslab can be used as a floorslab applied in the fabricated type concrete buildings. The concrete composite slab floorslab is composed of a prefabricated reinforced concrete base plate, a prefabricated concrete shear key and a cast-in-place reinforced concrete layer. The section of the prefabricated concrete shear key is designed to be in a lying-H shape, or a ring shape, or a hexagon shape or other shapes which can play a role in shearing resistance. One end of the prefabricated concrete shear key is embedded in the prefabricated reinforced concrete base plate, and the other end of the prefabricated concrete shear key is embedded in the cast-in-place reinforced concrete layer. When the cast-in-place reinforced concrete layer is made, concrete is poured to the top portion or above the top portion of the shear key. The shear key is used to connect the prefabricated reinforced concrete base plate and the cast-in-place reinforced concrete layer to form the whole floorslab, and the prefabricated concrete shear key is used to bear a shearing force and a tensile force between the prefabricated reinforced concrete base plate and the cast-in-place reinforced concrete layer. By means of the concrete composite slab floorslab with the shear key, using amount of steel bars used to connect the prefabricated reinforced concrete base plate and the cast-in-place reinforced concrete layer can be effectively reduced, and thickness of the concrete composite slab floorslab is reduced.

Owner:SHENYANG JIANZHU UNIVERSITY

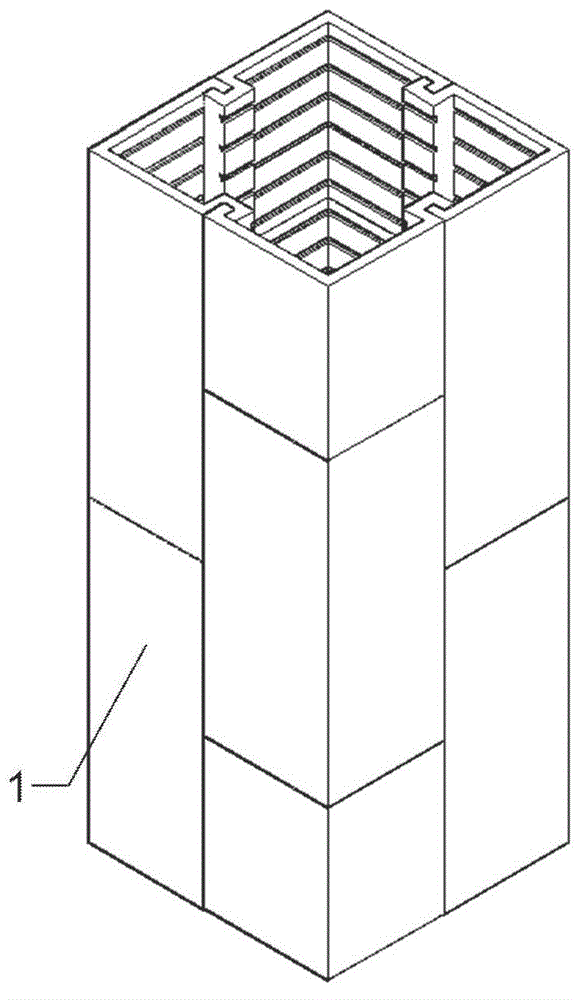

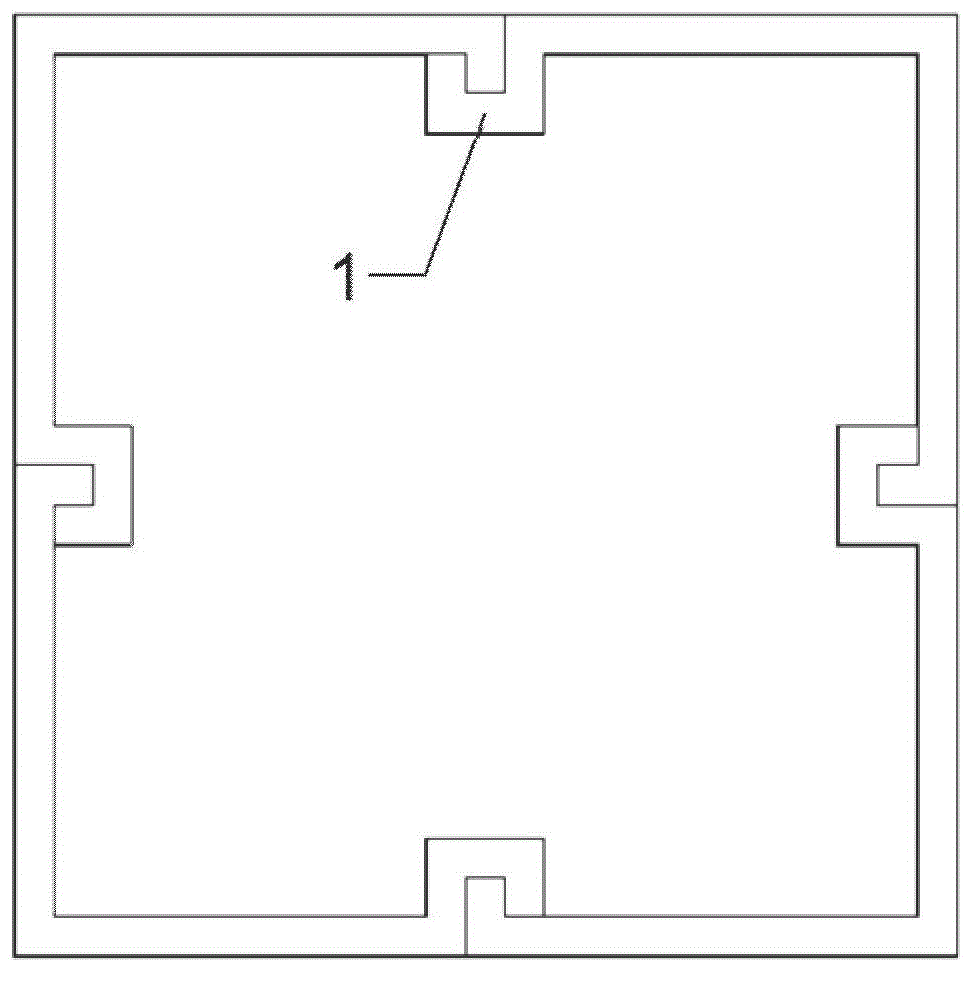

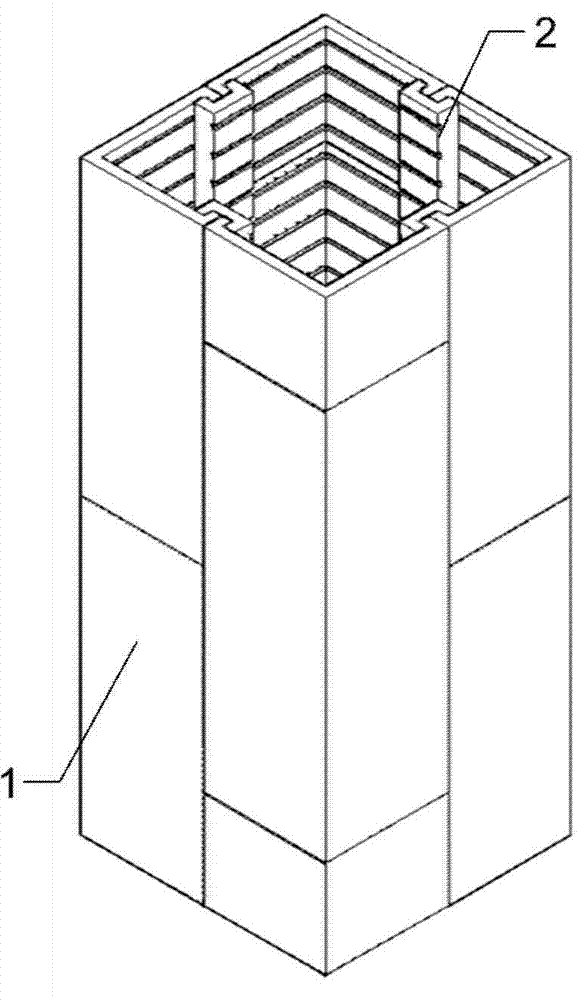

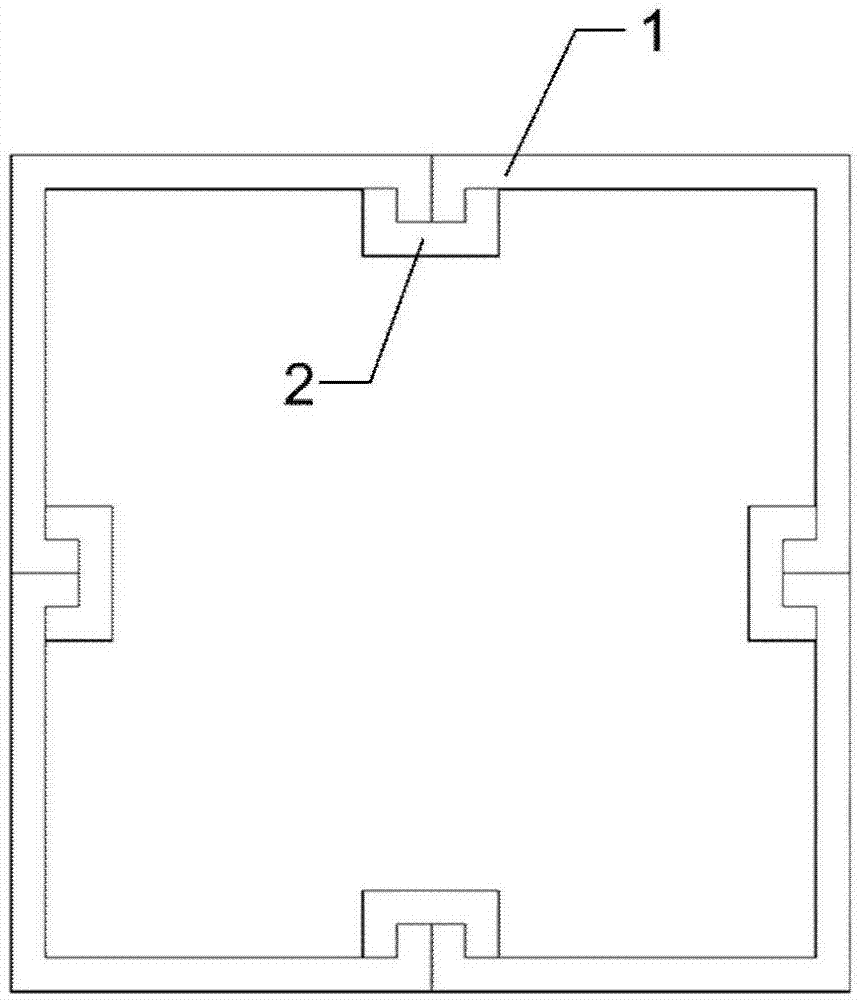

Mutually-buckled type assembled anti-cracking impermeable permanent column template

ActiveCN102912975AIncreased durabilityStrong service lifeStrutsForms/shuttering/falseworksAdhesiveHydraulic structure

The invention discloses a mutually-buckled type assembled anti-cracking impermeable permanent column template. Adjacent corner panels are buckled and are connected through an adhesive. The mutually-buckled type assembled anti-cracking impermeable permanent column template can be taken as a column template in a column pouring stage of structures, such as industrial and civil building structures, hydraulic structures, port structures and the like, and can be both taken as a protecting plate and an outer protecting layer of the structure after pouring molding, and can bear a part of load. According to the invention, the template can be made by the following different kinds of materials including a self-compaction ultra-high toughness cement based cementitious material (self-compaction UHTCC), a nonmetallic fiber woven net, a chopped fiber combined enhanced cement based composite material, a steel mesh chopped fiber combined enhanced cement based composite material and the like, and the mutually-buckled type assembled anti-cracking impermeable permanent column template has the characteristics of simple production, convenience for use, high durability, and capability of controlling crack developing.

Owner:CHANGZHOU GUBANG COMPOSITE MATERIAL TECH +1

Large-tonnage prestressed superposed crane beam and construction method

ActiveCN102852276ALow bending stiffnessSolve the problem of anti-cracking of oblique sectionGirdersJoistsPre stressInverted t

The invention discloses a large-tonnage prestressed superposed crane beam, which comprises an inverted T-shaped precast beam part and a T-shaped cast-in concrete part, wherein the two parts are combined to form an I-shaped crane beam; and the large-tonnage prestressed superposed crane beam is characterized in that the inverted T-shaped precast beam part comprises a web plate, wherein the web plate and the bottom flange are uniform sections along the longitudinal direction; a pre-tensioning method prestressed steel strand is longitudinally buried in the beam body; a stirrup is buried in the web plate of the beam body; the stirrup is exposed out of the upper surface of the web plate for a certain length and is buried in the cast-in concrete part; a shear-resistant piece is connected to the joint surface of a precast part and the cast-in-situ part. The inverted T-shaped uniform-section prestressed precast part is manufactured by a long line method in a factory, the die is a standard universal template, the template is low in distribution expense and convenient to manufacture, and because a bottom die is not required on the cast-in-situ part on a construction site, the die is particularly convenient to erect.

Owner:杨众 +1

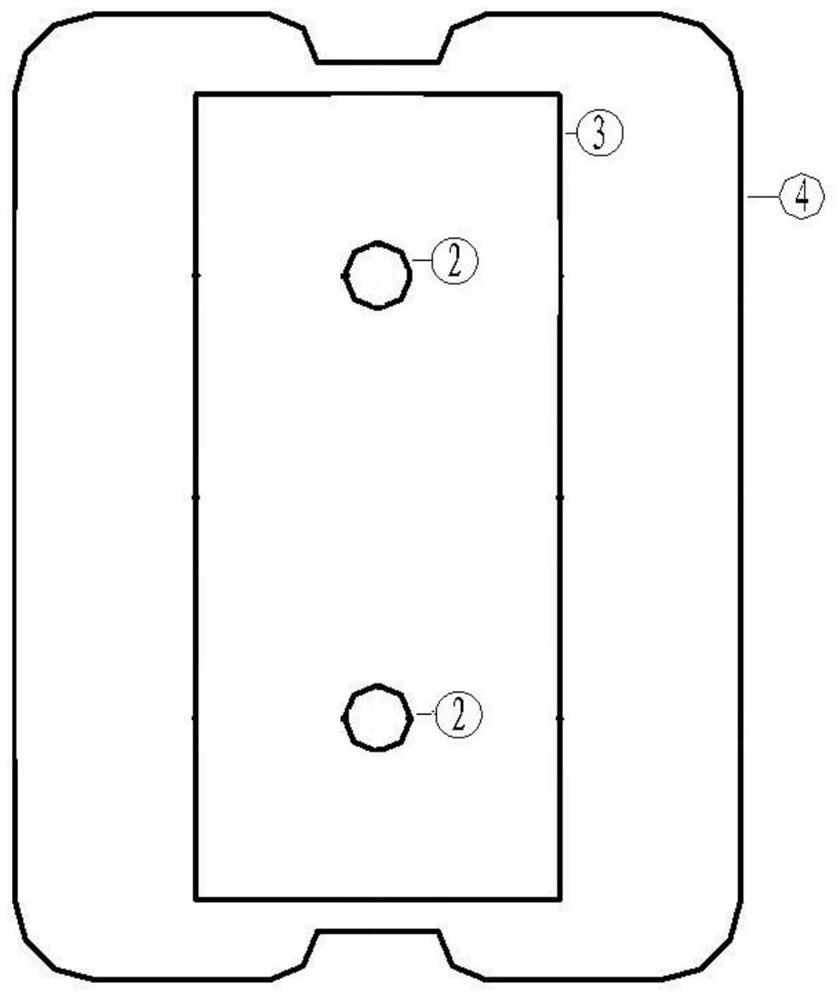

Splicing machining method of rectangular shield duct piece and anti-shear structure of rectangular shield duct piece

ActiveCN103821537AHigh strengthReduce the amount of steelUnderground chambersTunnel liningMaterials scienceMachining

The invention provides a splicing machining method of a rectangular shield duct piece and an anti-shear structure of the rectangular shield duct piece. Each circle of duct piece comprises an annular steel structure and annular concrete arranged on the steel structure; the steel structure comprises a plurality of steel sections and is spliced to be a ring by the steel sections; two adjacent steel sections are connected by two steel end plates respectively arranged on the two steel sections; the anti-shear structure comprises dovetail slot, anti-shear plates and anti-shear slots; the dovetail slots and the anti-shear slots are respectively arranged at the mutually spliced splicing end surfaces of every two adjacent steel end plates; the anti-shear plates are connected with the dovetail slots and the anti-shear slots respectively. The duct piece suitable for combining the concrete and a steel material is provided, and the splicing machining method of the rectangular shield duct piece and the anti-shear structure of the rectangular shield duct piece can enable the strength, splicing precision and sealing performance of the duct piece to be better.

Owner:SHANGHAI MECHANIZED CONSTR GRP

Keel embedded-buckled assembling anti-cracking anti-seepage permanent cylinder shuttering

ActiveCN102828579AFirmly connectedIncreased durabilityStrutsSolid waste managementKeelHydraulic structure

The invention discloses a keel embedded-buckled assembling anti-cracking anti-seepage permanent cylinder shuttering, which comprises shuttering corner panels and connecting pieces. The invention can be used as a cylinder shuttering in cylinder pouring phases of structures such as industrial and civil building structures, hydraulic structures, harbor structures, and the like, and can be used as a protection plate and an outer protective layer of the structures after pouring molding, and bear a part of loads. The shuttering provided by the invention can be made of the following different kinds of materials: ultrahigh-toughness cement-based composite materials UHTCC, cement-based composite materials reinforced by nonmetal fiber meshes combined with short fibers, cement-based composite materials reinforced by steel wire meshes combined with short fibers, and the like, and has the characteristics of simple manufacturing, convenient usage, high endurance, and crack extension controllability.

Owner:CHANGZHOU GUBANG COMPOSITE MATERIAL TECH +1

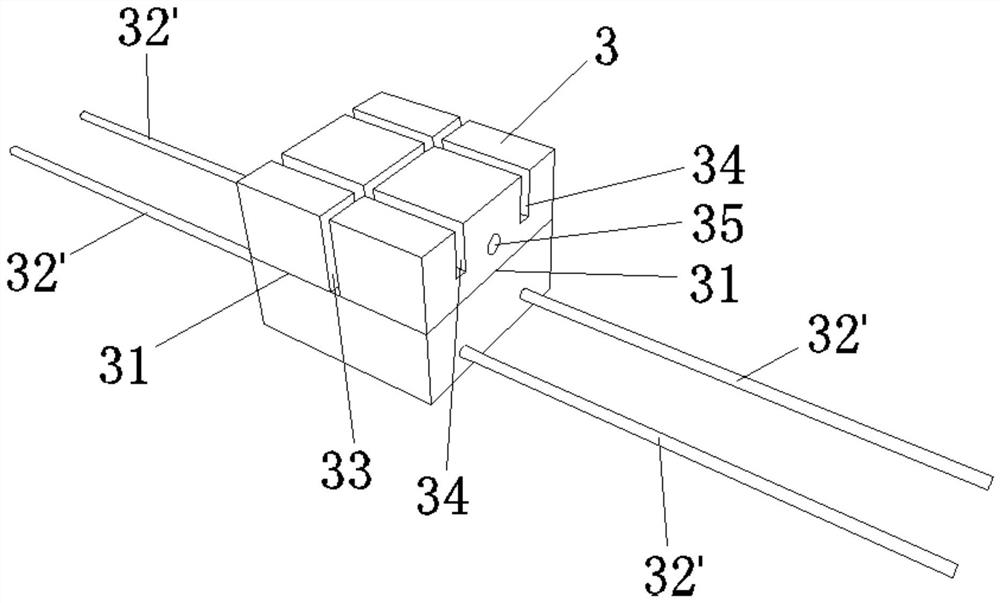

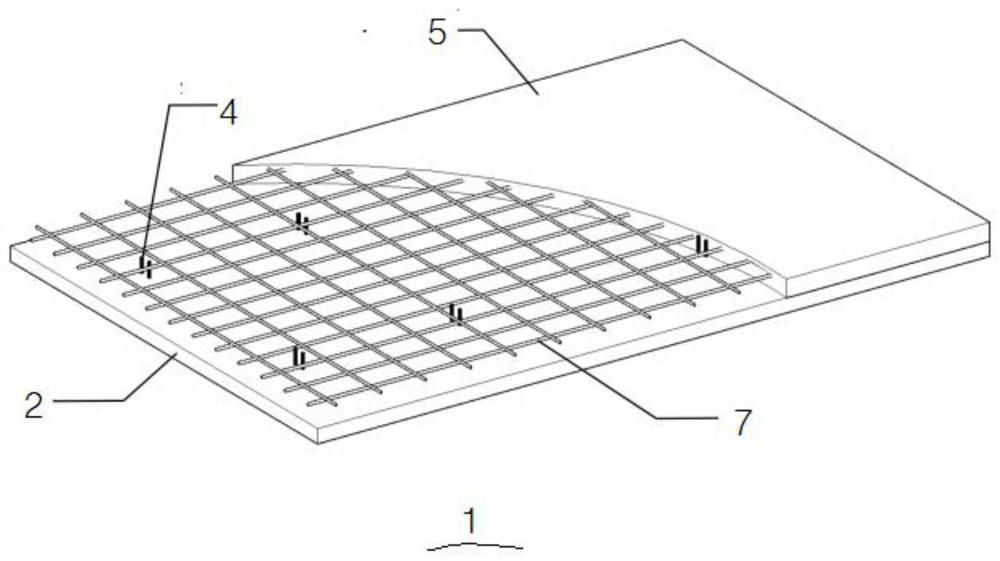

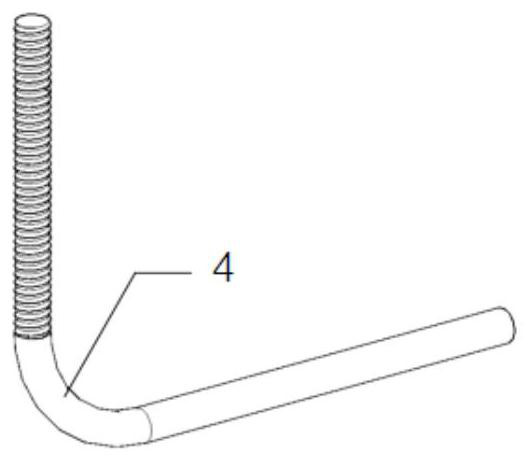

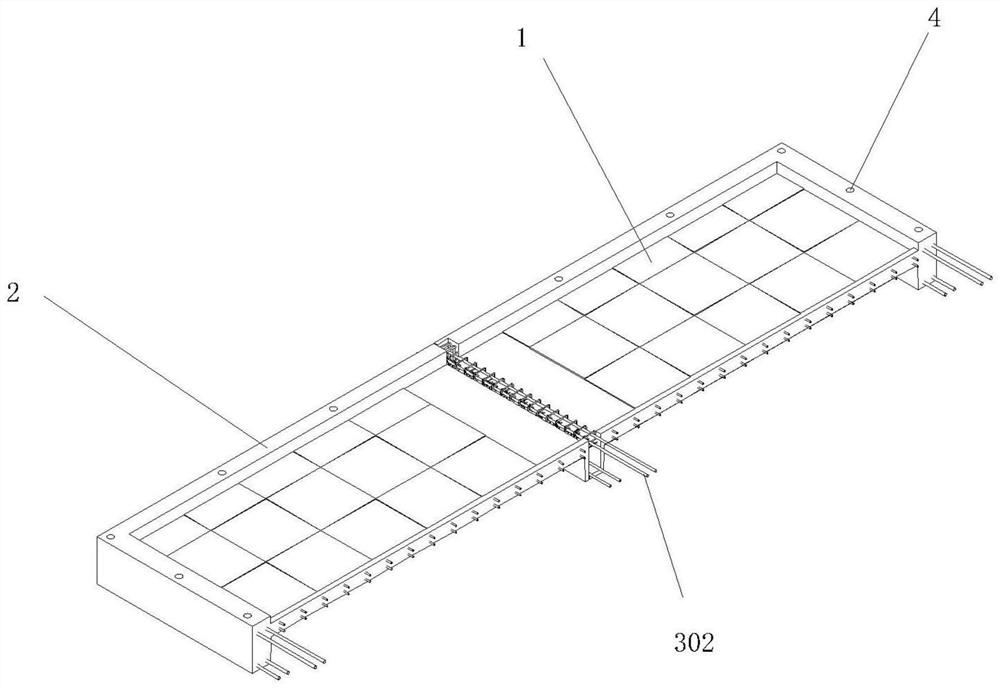

Prefabricated bottom plate of laminated slab, laminated slab, and preparation method of laminated slab

ActiveCN112012386AEasy to disassembleConvenient positioning and bindingFloorsCeramic shaping apparatusEngineeringRebar

The invention discloses a prefabricated bottom plate of a laminated slab, the laminated slab, and a preparation method of the laminated slab, and belongs to the field of prefabricated buildings. The prefabricated bottom plate of the laminated slab comprises connecting part groups, a first composite steel bar layer, and a concrete bottom plate. Each of connecting parts comprises a connecting blockand positioning steel bars horizontally penetrating through the lower part of the connecting block; the upper part of each of the connecting blocks is provided with a downwards concave connecting groove and penetrated plug pin holes vertical to the connecting groove; and the connecting grooves are used for inserting webs, with inserted holes, of profile steel parts. The first composite steel bar layer comprises an upper steel bar layer and a lower steel bar layer; the positioning steel bars of the connecting parts and the lower steel bar layer are located on the same plane; the connecting blocks penetrate through meshes of the first composite steel bar layer; and the plug pin holes are located above the concrete bottom plate. Due to the design of the connecting grooves and the plug pin holes in the upper side of the prefabricated bottom plate, the profile steel parts can be detached, hoisting and stacking are convenient, and the positioning steel bars of the prefabricated bottom platecan also prevent the risk that the multifunctional concrete block connecting parts are pulled out of the prefabricated bottom plate in the lifting and hoisting process.

Owner:上海凯汇建筑设计有限公司

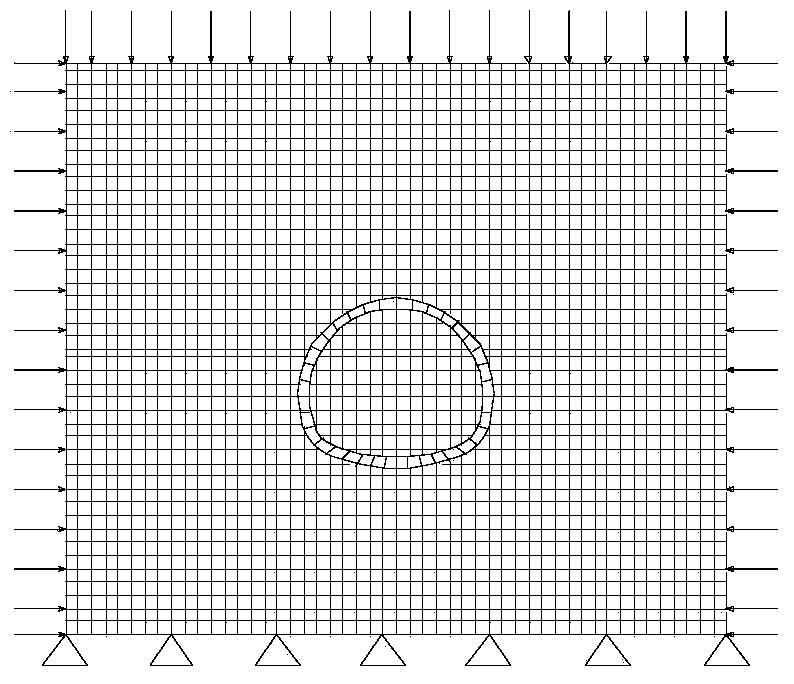

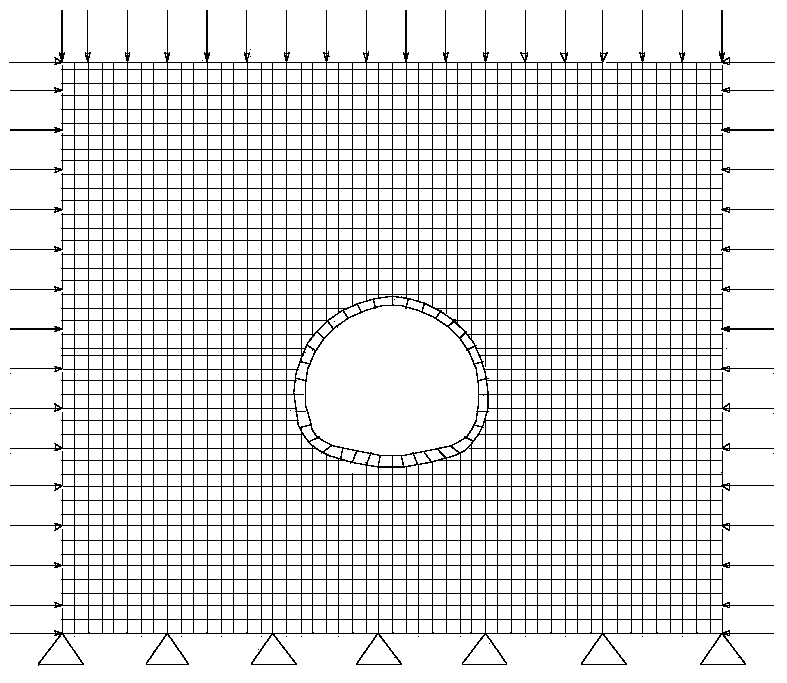

Method for designing tunnel composite lining structure with load acting on stratum boundaries

ActiveCN103924984ACalculation results are accurate and reliableReduce the amount of steelUnderground chambersTunnel liningRebarTunnel engineering

The invention discloses a method for designing a tunnel composite lining structure with the load acting on stratum boundaries. By the adoption of the method for designing the tunnel composite lining structure with the load acting on the stratum boundaries, a more reasonable and more economical tunnel lining structure can be designed, a large amount of lining concrete masonry can be saved, the use amount of steel bars can be reduced greatly, and the construction cost of a tunnel is effectively reduced. The method for designing the tunnel composite lining structure with the load acting on the stratum boundaries comprises the steps that basic parameters required by designing are determined; the load of the tunnel is calculated; a design method model is established, surrounding rock is simulated with a two-dimensional solid structure unit, a plane strain model is selected to serve as the design model, the composite lining is supported preliminarily and a beam unit used for secondary lining is simulated according to the elastoplasticity constitutive relation, a chain rod unit for a waterproof layer is simulated, and the chain rod unit is only under the action of pressure; meshing is conducted, wherein the preliminary support and the second lining are divided through mapped meshing; the lower boundary of the surrounding rock is constrained, so that it is guaranteed that rigid body displacement does not occur; the pressure of the surrounding rock acts on the upper boundary, the left boundary and the right boundary respectively; the soil body in the center of the tunnel is excavated for calculation, and the internal force and deformation during preliminary support and second lining are extracted respectively; the reasonable lining thickness and the reasonable reinforcement ratio are designed according to an internal force deformation result during preliminary support and second lining.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

T-type multifunctional small block and its production forming method

InactiveCN1341798AReduce dosageIncrease productivityConstruction materialCeramic shaping apparatusMultiple formsAdditional values

The present invention relates to a T-type multifunctional small block and its production forming method. Said invention adopts T-shaped block type series and composite forming process to solve the problem of combination of several layer materials in the production of concrete small blocks, and greatly raise technical content and additional value of product, implement high prefabrication extent ofsmall blocks, improved reinforcement scheme of block and block bonding body, and can more flexibly and reaonsably arranged steel bar, can conveniently make construction and can flexibly form various structures with different forms, and can obviously raise strength of block hollow bonding body so as to raise quality and efficiency of building construction.

Owner:虞新华

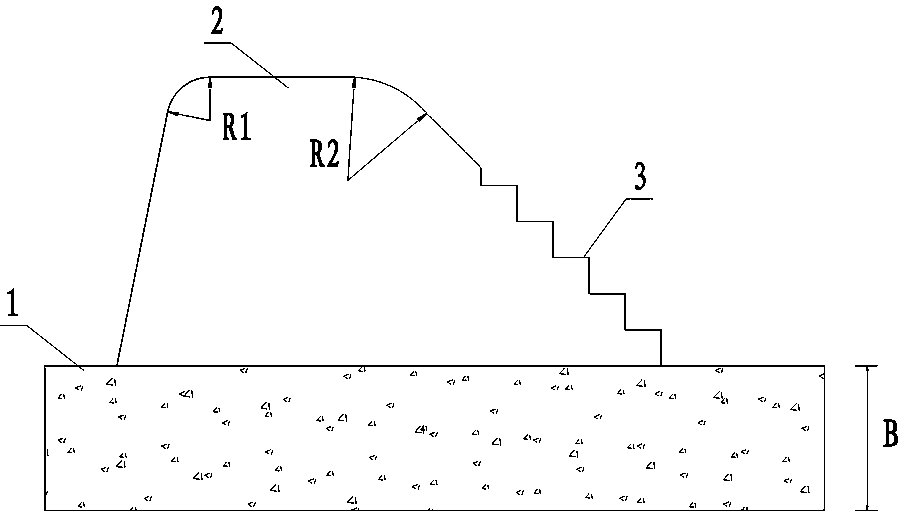

Overflow dam building structure suitable for ecological water landscape

InactiveCN103243685AImprove anti-scourabilityImprove stabilityBarrages/weirsGravity damsEngineeringErosion

The invention discloses an overflow dam building structure suitable for an ecological water landscape. The overflow dam overflow dam comprises a gravity type overflow dam built on a plain concrete foundation and built by concrete or masonry-mortar-stones, and the downstream side of a dam body of the gravity type overflow dam is of a slope type multistage energy dissipation step structure. The overflow dam building structure has the advantages that the retaining dam is set to be the gravity type overflow dam and the downstream side of the dam body is designed to be of the slope type multistage energy dissipation step structure so that erosion resistibility and stability of the gravity type overflow dam are improved and the whole building structure is led to be simple in form, small in steel bar consumption and fast in construction. In addition, perfect combination of landscape performance and ecological performance is achieved, and the project benefits of sufficiently utilizing hydroelectric resources, greatly saving project investment and improving the river way embankment water landscape are achieved.

Owner:YELLOW RIVER ENG CONSULTING

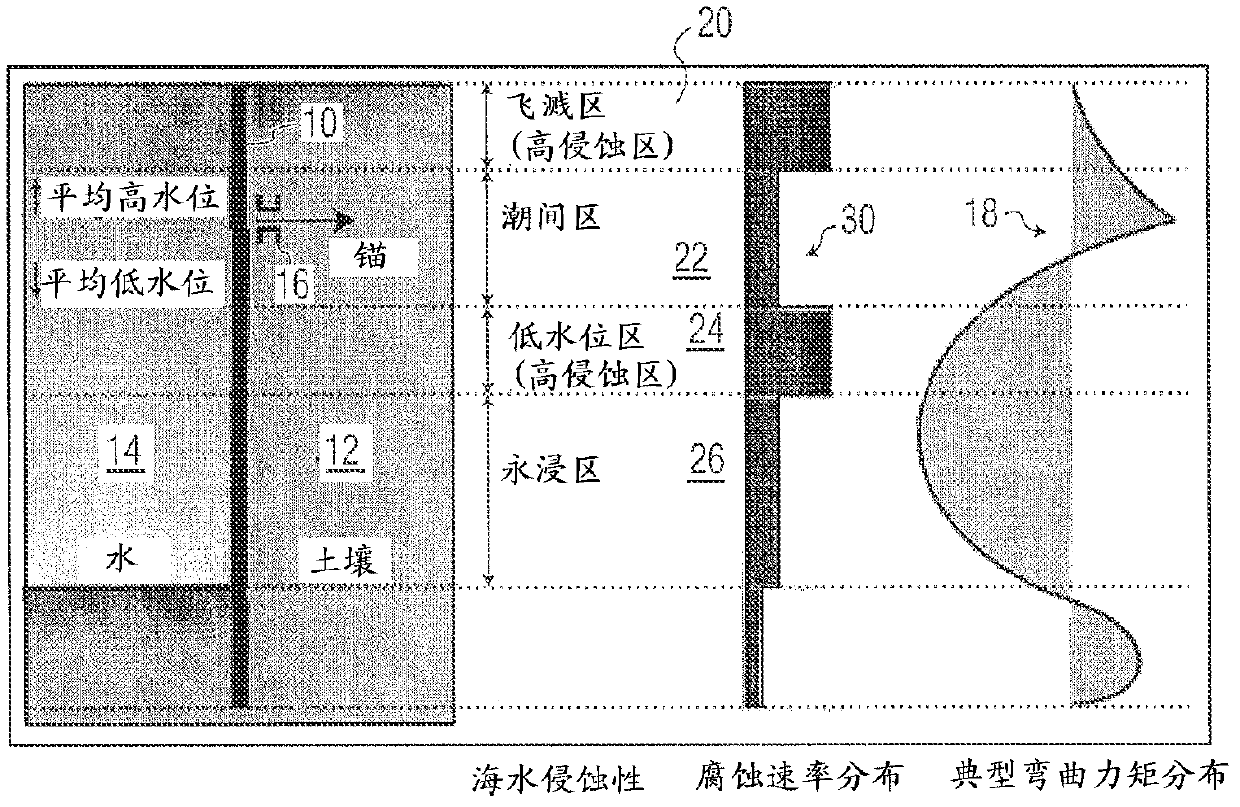

Improved steel pipe piles and pipe pile structures

InactiveCN103314163AExtended service lifeReduce the amount of steelProtective foundationBulkheads/pilesRetaining wall

Owner:PILEPRO LLC

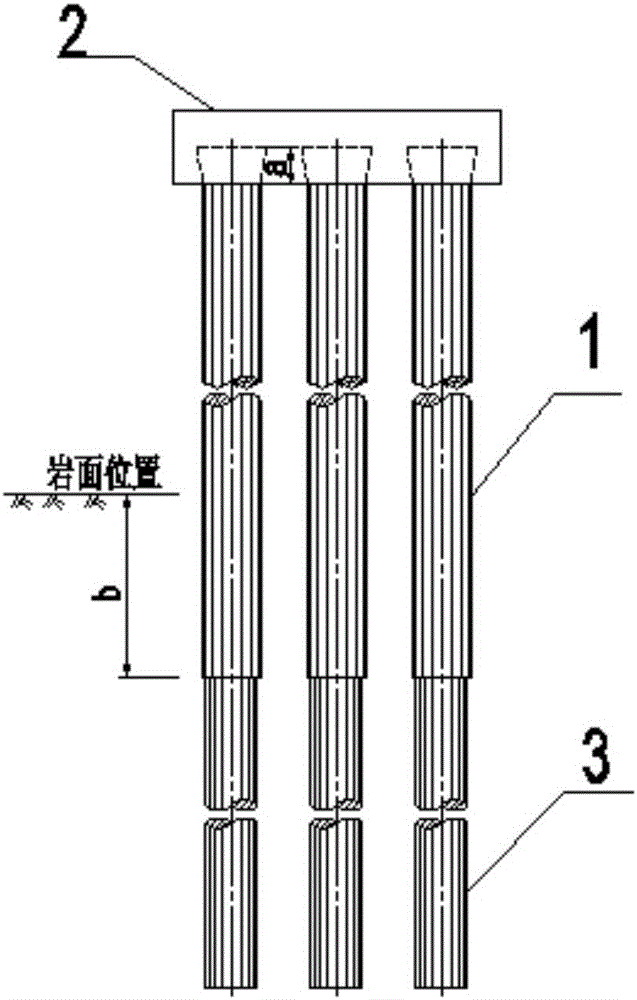

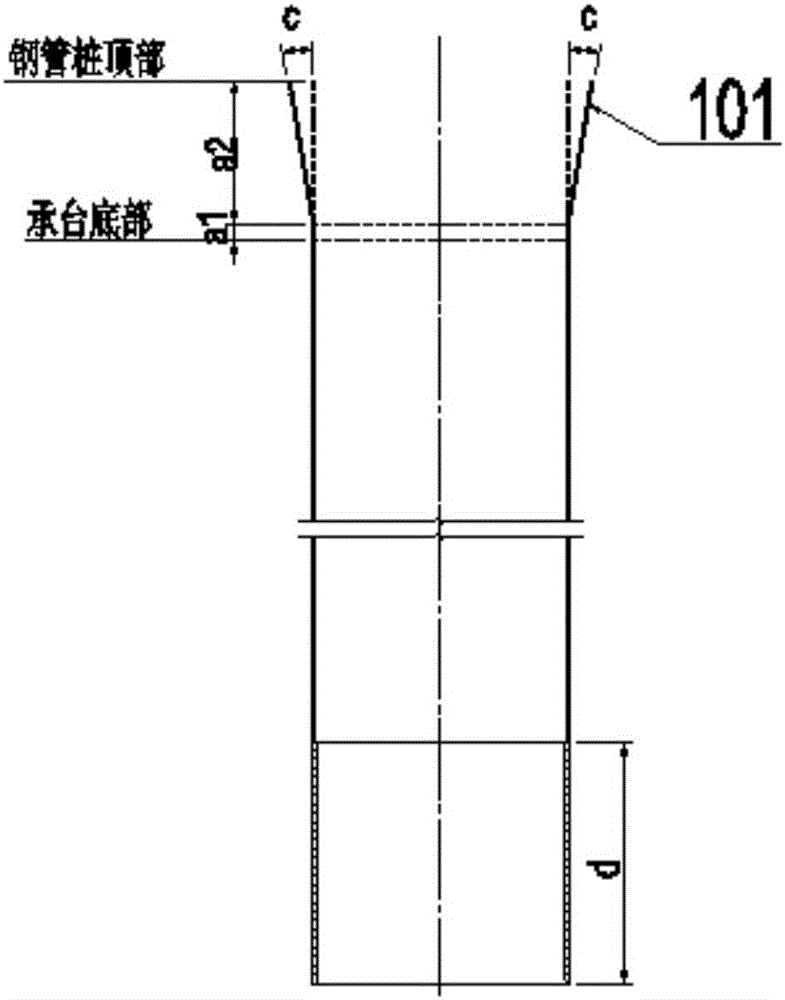

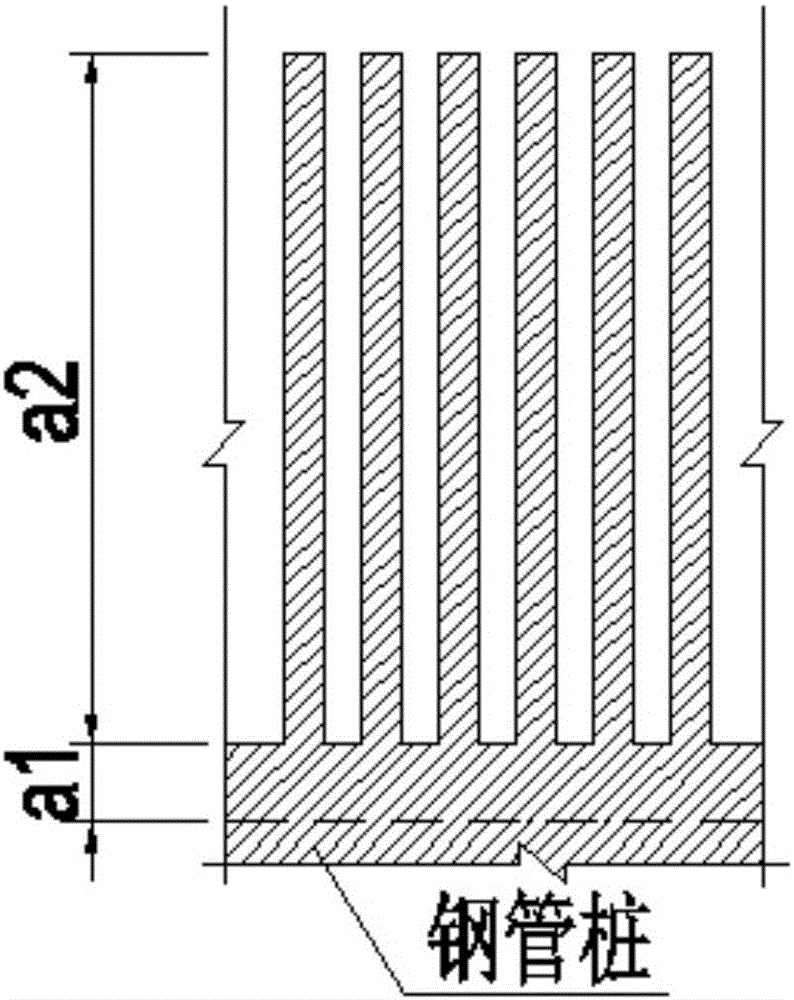

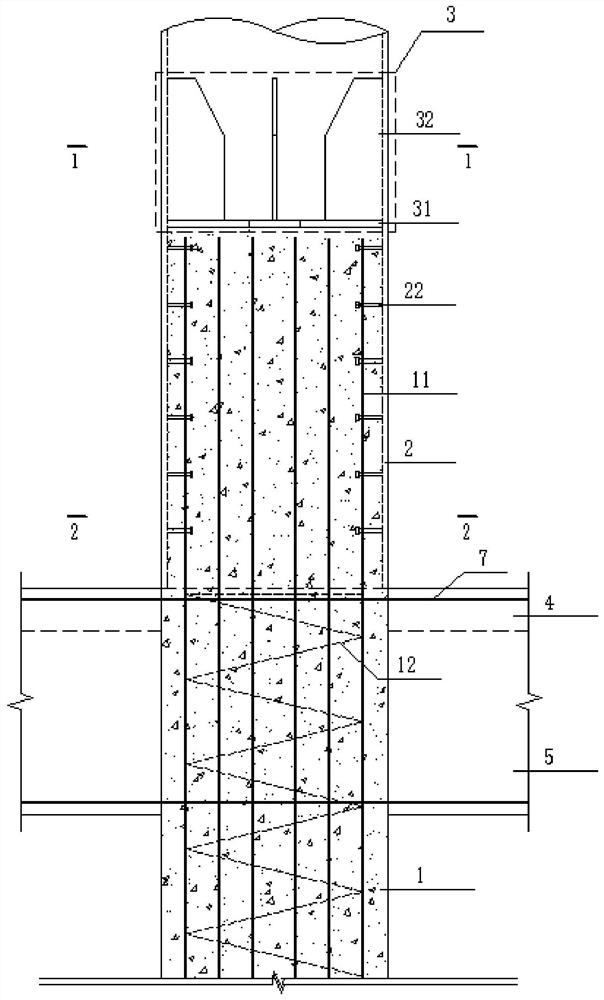

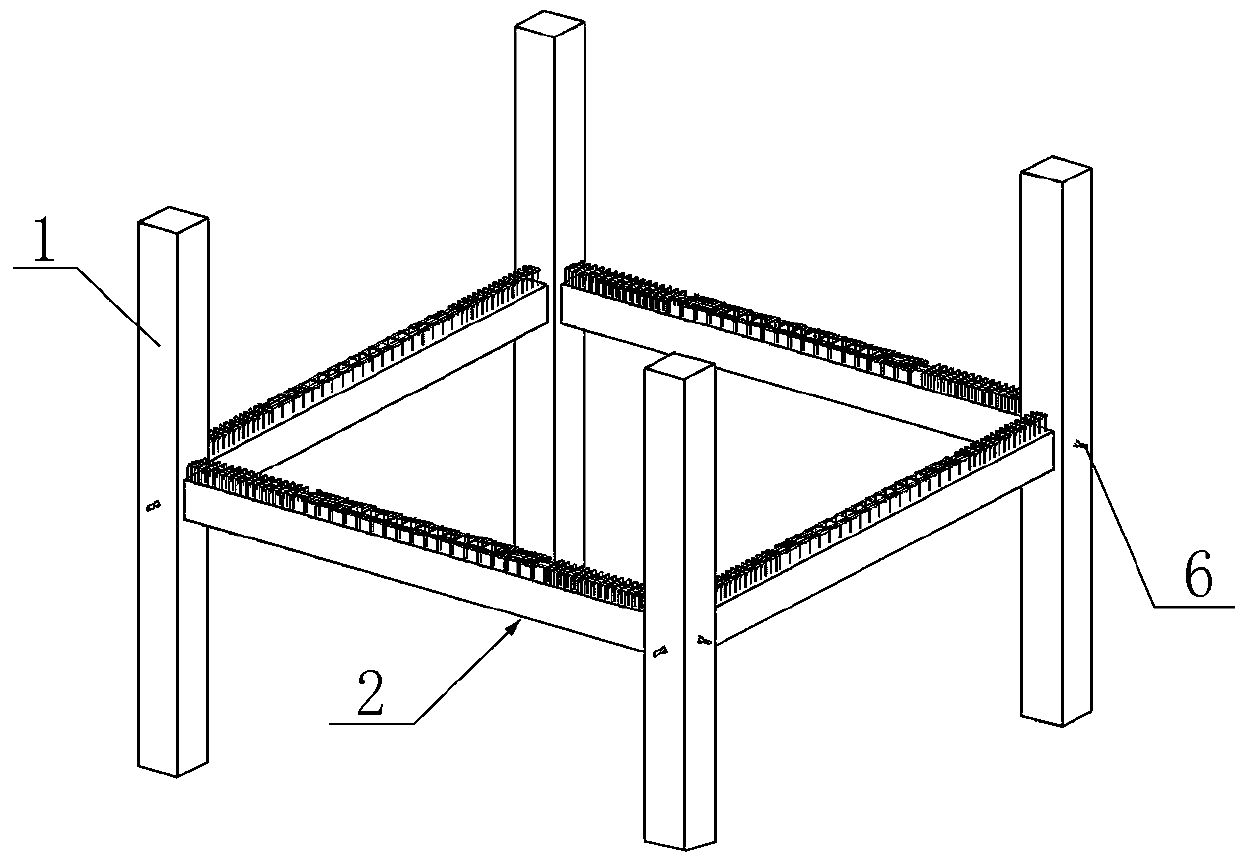

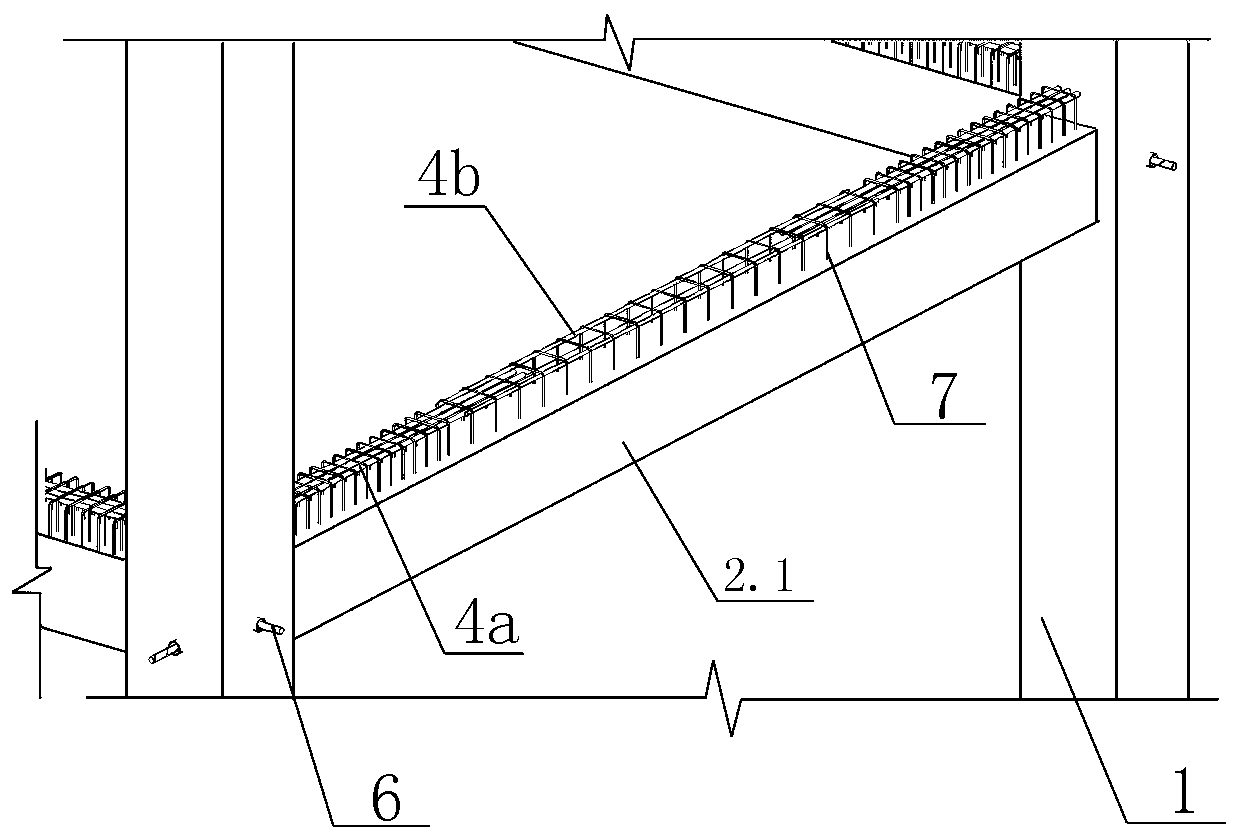

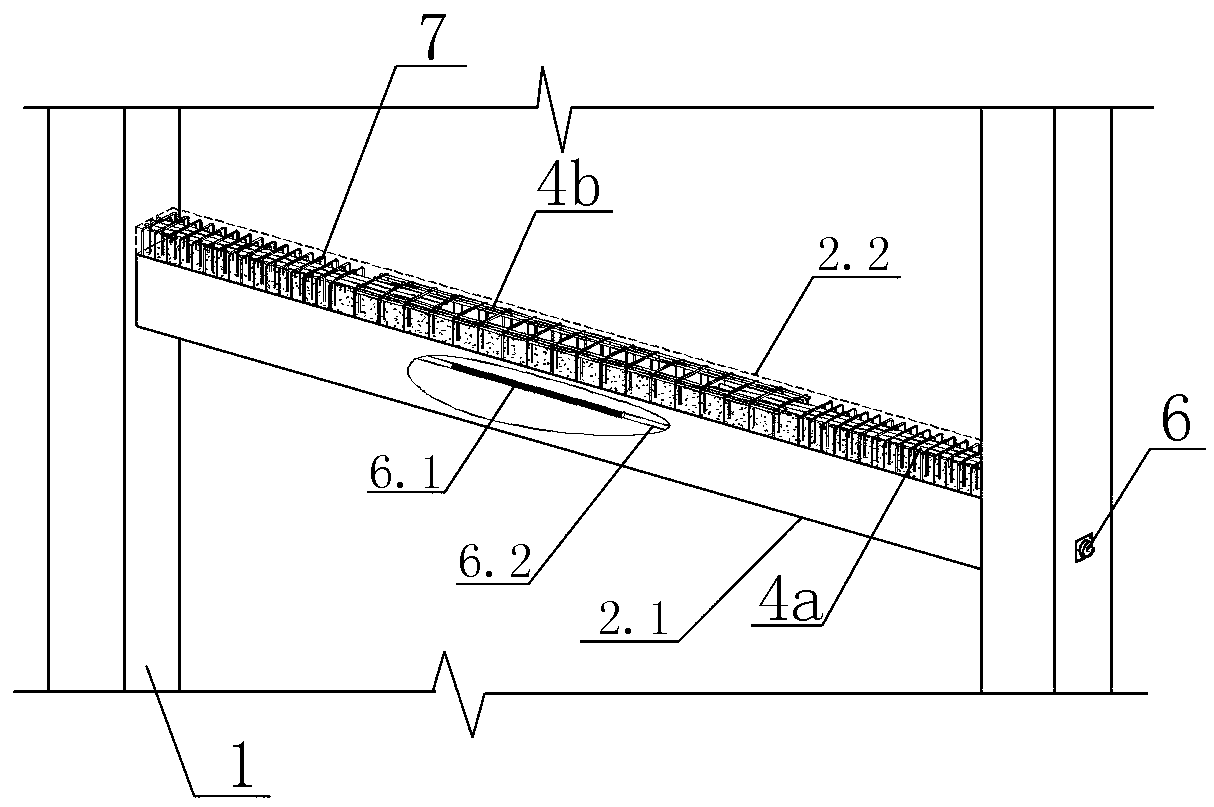

Steel pipe composite pile foundation applicable to deep water and coral reef geology

InactiveCN106400828AImprove carrying capacityReduce the amount of steelBulkheads/pilesReinforced concreteRebar

The invention discloses a steel pipe composite pile foundation applicable to deep water and coral reef geology. The steel pipe composite pile foundation comprises a bearing platform and pile foundations for supporting the bearing platform. Each pile foundation comprises a reinforced concrete pile body and a steel pile casing enclosing the outside of the reinforced concrete pile body, wherein the steel pile casing and the upper end of the reinforced concrete pile body are embedded into the bearing platform. The part, embedded into the bearing platform, of each steel pile casing comprises a ring-shaped steel ring and steel planks which are uniformly arranged on the ring-shaped steel ring in a surrounding manner. An included angle between each steel plank and the cross section of the corresponding reinforced concrete pile body ranges from 90 degrees to 110 degrees, and the gap between every two adjacent steel planks is 0.8-1.2 times the width of the steel planks. According to the steel pipe composite pile foundation, the bearing ability of the pile foundations is improved, particularly, the horizontal bearing capacity of the pile foundations can be increased, the number of adopted reinforcing steel bars for pile foundation reinforcement cages can be reduced, and the foundation construction risk and the manufacturing cost are reduced greatly.

Owner:CCCC SECOND HARBOR ENG

Perlite polyphenylene compound filling block, method for preparing same and filled floor plate construction method

InactiveCN101684676ALight weightAvoid deformationConstruction materialCeramic shaping apparatusCombustionRebar

The invention provides a perlite polyphenylene compound filling block, a method for preparing the same and a filled floor plate construction method, wherein the perlite polyphenylene compound fillingblock is a cuboid with the rectangular top surface; and a block body is formed by up-and-down lamination of a rectangular expanded perlite agglomerate and a polyphenylene plate, and the outer surfaceof the block body is wrapped by a plastic adhesive tape, a positioning metallic wire is embedded in the expanded perlite agglomerate in advance, the bottom part of the positioning metallic wire is U-shaped, both ends of the positioning metallic wire upward pass the expanded perlite agglomerate and are extended to the outer side of the plastic adhesive tape. The perlite polyphenylene compound filling block has low cost, relatively light deadweight and insusceptibility to breakage, combustion and deformation, and can effectively solve the problem that the block body is susceptible to water absorption; when the perlite polyphenylene compound filling block is arranged in the floor plate in advance, the cement consumption of the floor plate is reduced, the weight of the floor plate is reduced,the whole deadweight of the structure of the building is reduced, but the bearing capacity of the floor plate is not lowered; moreover, the total consumption of reinforcing steel bars in the floor plate and the building is also lowered.

Owner:杨晓宏

Production process of lining-type anti-corrosion reinforced concrete pipe

InactiveCN102059739AImprove the ability to resist external compressive loadsReduce the amount of steelCeramic shaping apparatusRebarReinforced concrete

The invention discloses a production process of a lining-type anti-corrosion reinforced concrete pipe, comprising: evenly spreading concrete filled into an inner mould by utilizing centrifugal force generated by high-speed rotation; after extruding and shaping the concrete into a common drain pipe, laying a PVC (poly vinyl chloride) lining with an anchoring key on the inner wall of the shaped concrete pipe; and vibrating and extruding while laying, thus firmly embedding the PVC lining on the surface of the concrete. The production process provided by the invention has the following advantages and beneficial effects: 1, the external pressure load resisting capability of the pipe can be improved, and the use amount of rebars can be lowered in the production process; 2, the PVC lining is tightly combined with the inner wall of the pipe; and 3, the minimum diameter of the pipe shaped by the method can reach 300mm, and the thickness of the wall of the pipe can reach 40mm.

Owner:TIANJIN ZEBAO CEMENT PROD

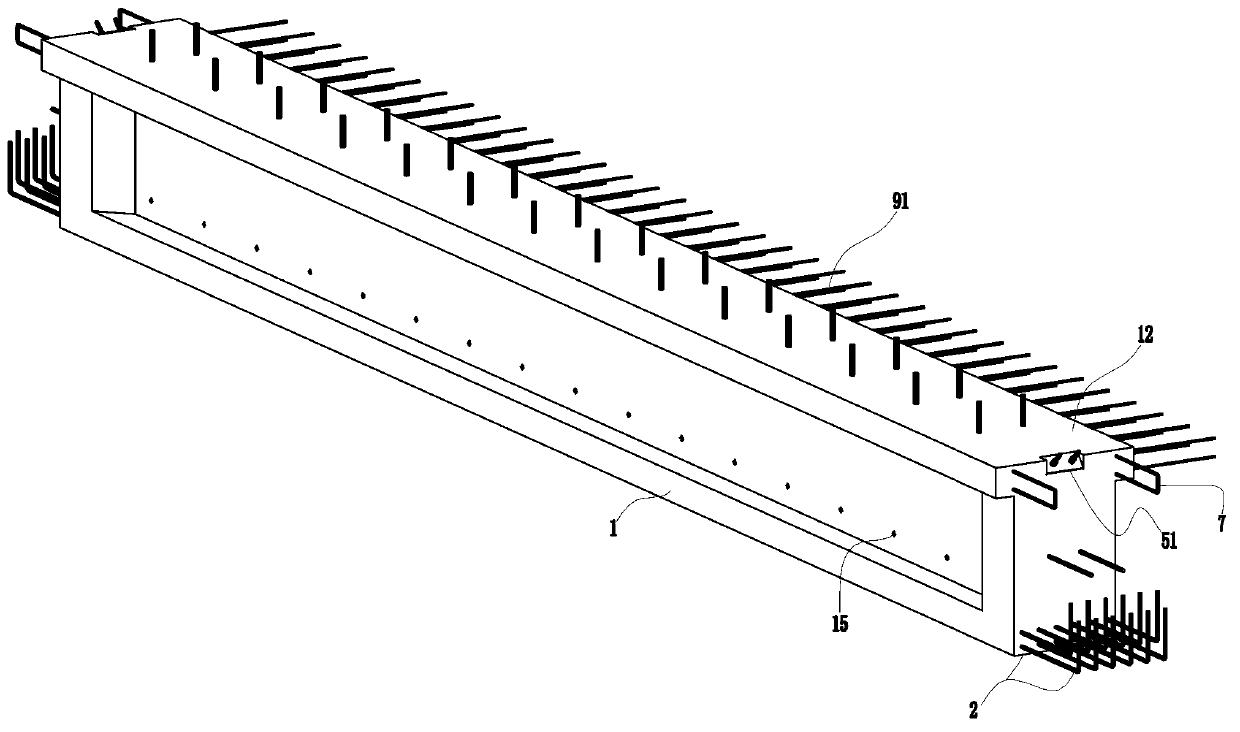

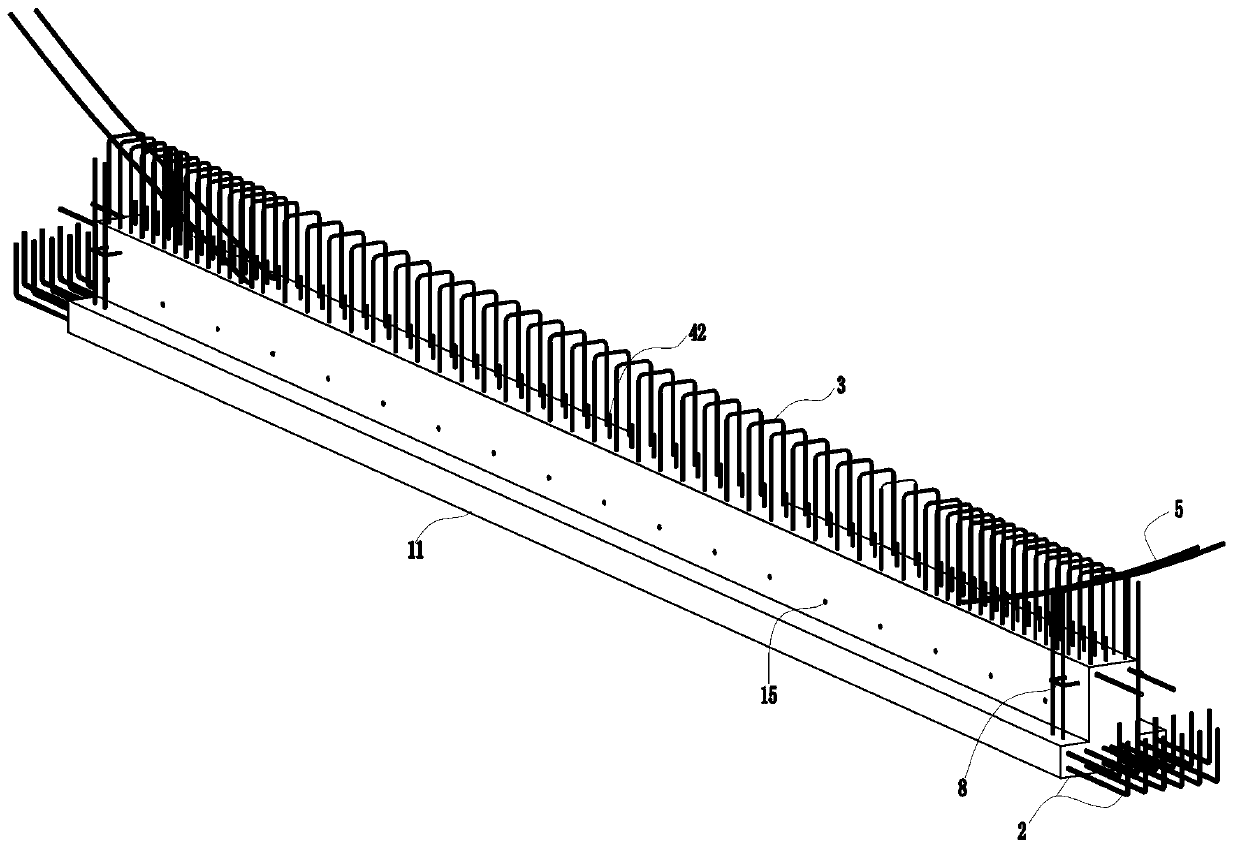

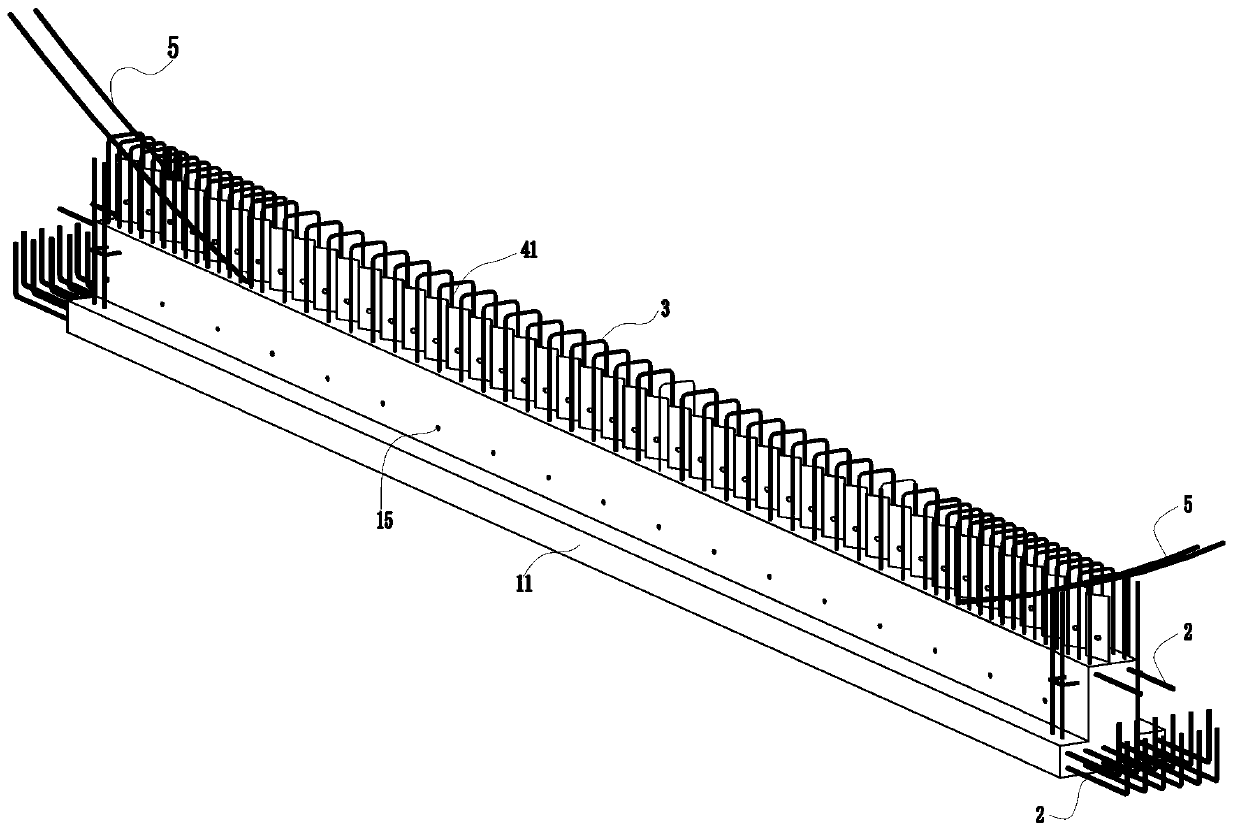

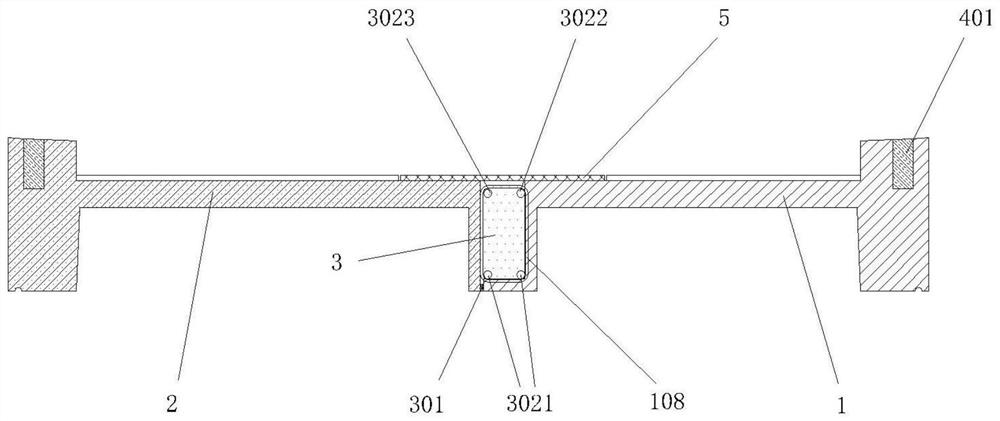

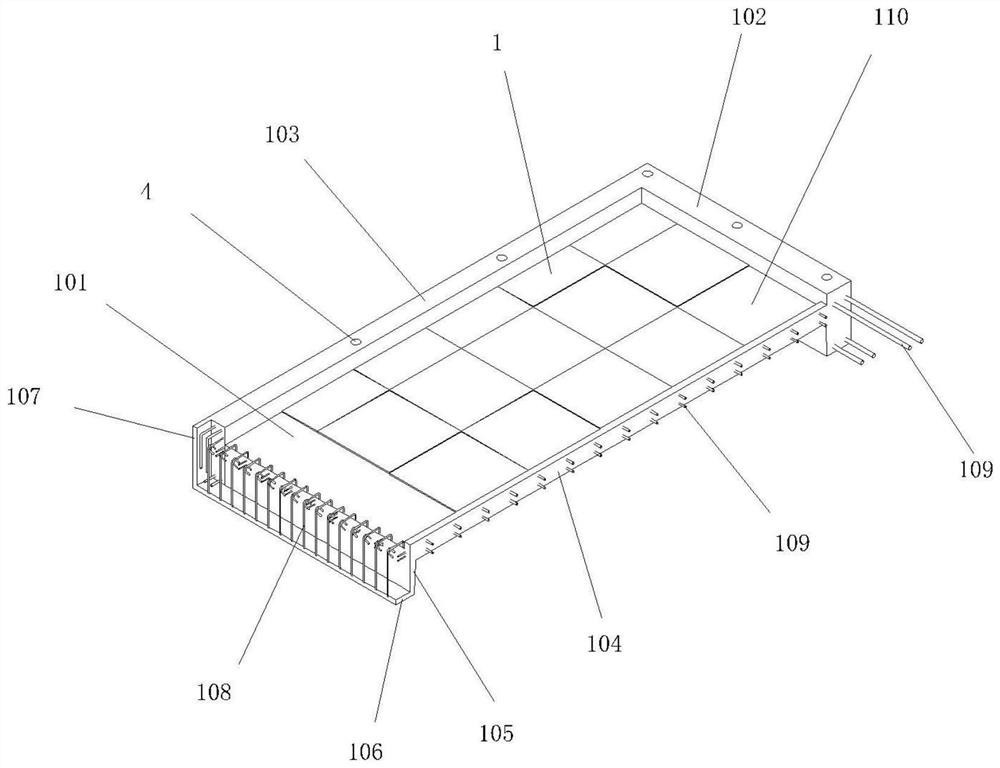

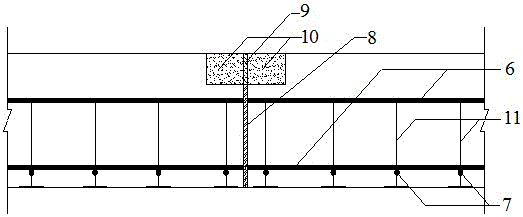

Laminated slab, connecting structure of laminated slab and composite beam and construction method

The invention discloses a laminated slab, a connecting structure of the laminated slab and a composite beam and a construction method. The laminated slab comprises a prefabricated layer and a post-pouring layer, the prefabricated layer comprises a prefabricated bottom plate and a plurality of shear reinforcements, the post-pouring layer comprises post-pouring concrete and surface layer reinforcements, the post-pouring concrete is poured on the prefabricated bottom plate, and the top ends of the shear reinforcements and the surface layer reinforcements are anchored in the post-pouring concrete. The connecting structure of the laminated slab and the composite beam comprises the laminated slab and the composite beam, the composite beam comprises a steel beam and studs, the prefabricated layer is placed on the steel beam, and a splicing seam between the steel beam and the prefabricated layer is filled with the post-pouring concrete. The construction method of the connecting structure of the laminated slab and the composite beam comprises the steps that S1, the prefabricated layer is produced; S2, the composite beam is hoisted and positioned, the prefabricated layer is hoisted and placed on the steel beam; and S3, the surface layer reinforcements are paved, and the post-pouring concrete is poured. The laminated slab is high in shear resistance and good in integrity; and the connecting structure of the laminated slab and the composite beam and the construction method are high in efficiency, the laminated slab is high in rigidity, and the using amount of the reinforcements is low.

Owner:筑友智造建设科技集团有限公司

Cabin type refrigerating machine room and construction method thereof

ActiveCN110107972AReduce the difficulty of assemblyImprove securityLighting and heating apparatusSpace heating and ventilation detailsSurface coolingEngineering

The invention relates to a cabin type refrigerating machine room and a construction method thereof. The refrigerating machine room comprises a room body, wherein a plurality of refrigerators, a plurality of frozen water pumps, a plurality of cooling water pumps, surface frozen water pipelines and a surface cooling water pipelines are arranged on a floor of the room body; frozen water pipe systemsof the refrigerators and the frozen water pipe systems of the frozen water pumps correspondingly communicate with the surface frozen water pipelines through adapting pipes; cooling water pipe systemsof the refrigerators and the cooling water pipe systems of the cooling water pumps correspondingly communicate with the surface cooling water pipelines through adapting pipes; an overhauling platformis erected in the room body; and each refrigerator, each water pump, each surface frozen water pipeline and each surface cooling water pipeline are positioned at the lower part of the overhauling platform. According to the cabin type refrigerating machine room, the splicing process of the whole machine room is performed on the floor, so that the splicing difficulty is low; both work and materialsare saved; the construction period is reduced; the machine room construction safety is high; the overhauling platform is arranged, so that the space in the room body is fully utilized to form the cabin type refrigerating machine room, and the repairing and maintaining work of the machine room are conveniently carried out.

Owner:CHINA CONSTR THIRD ENG BUREAU INSTALLATION ENG CO LTD

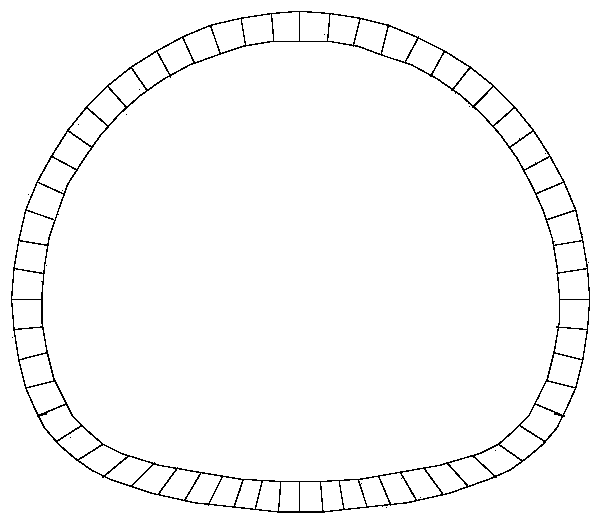

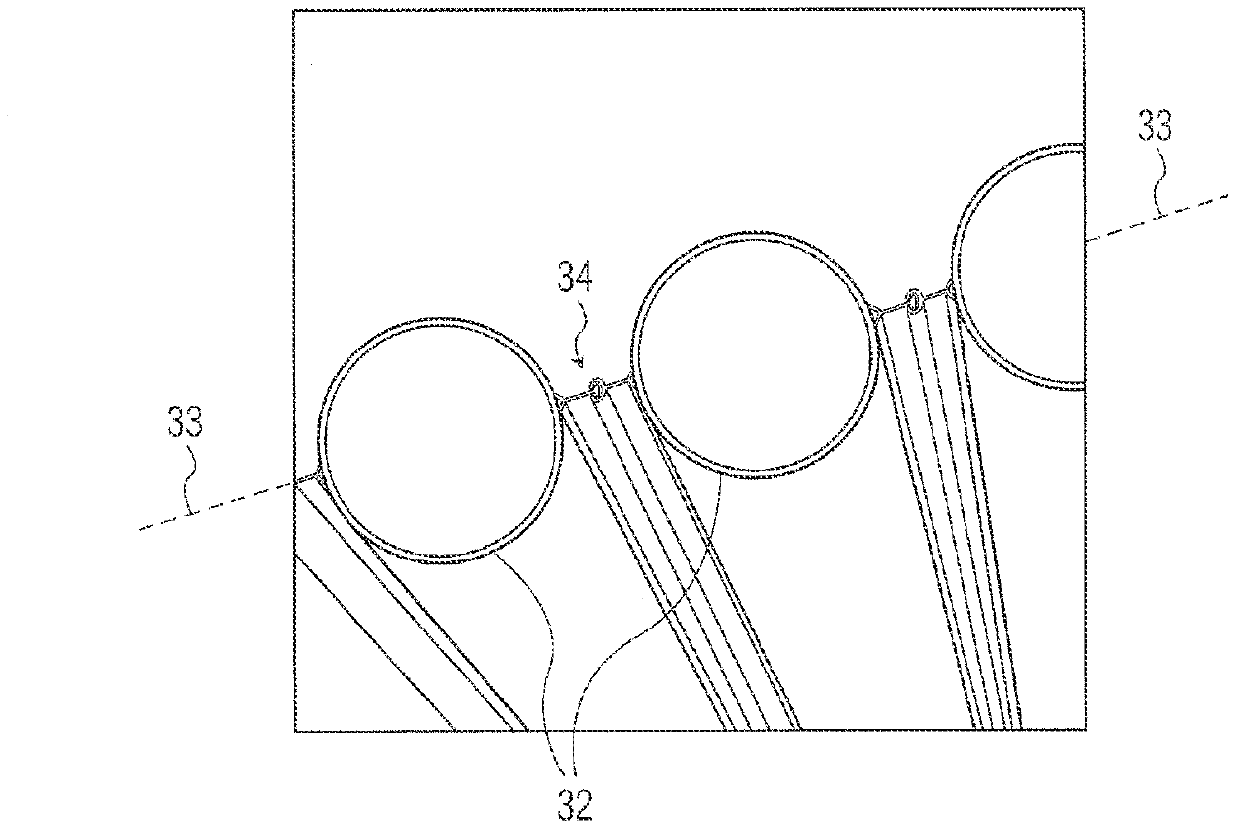

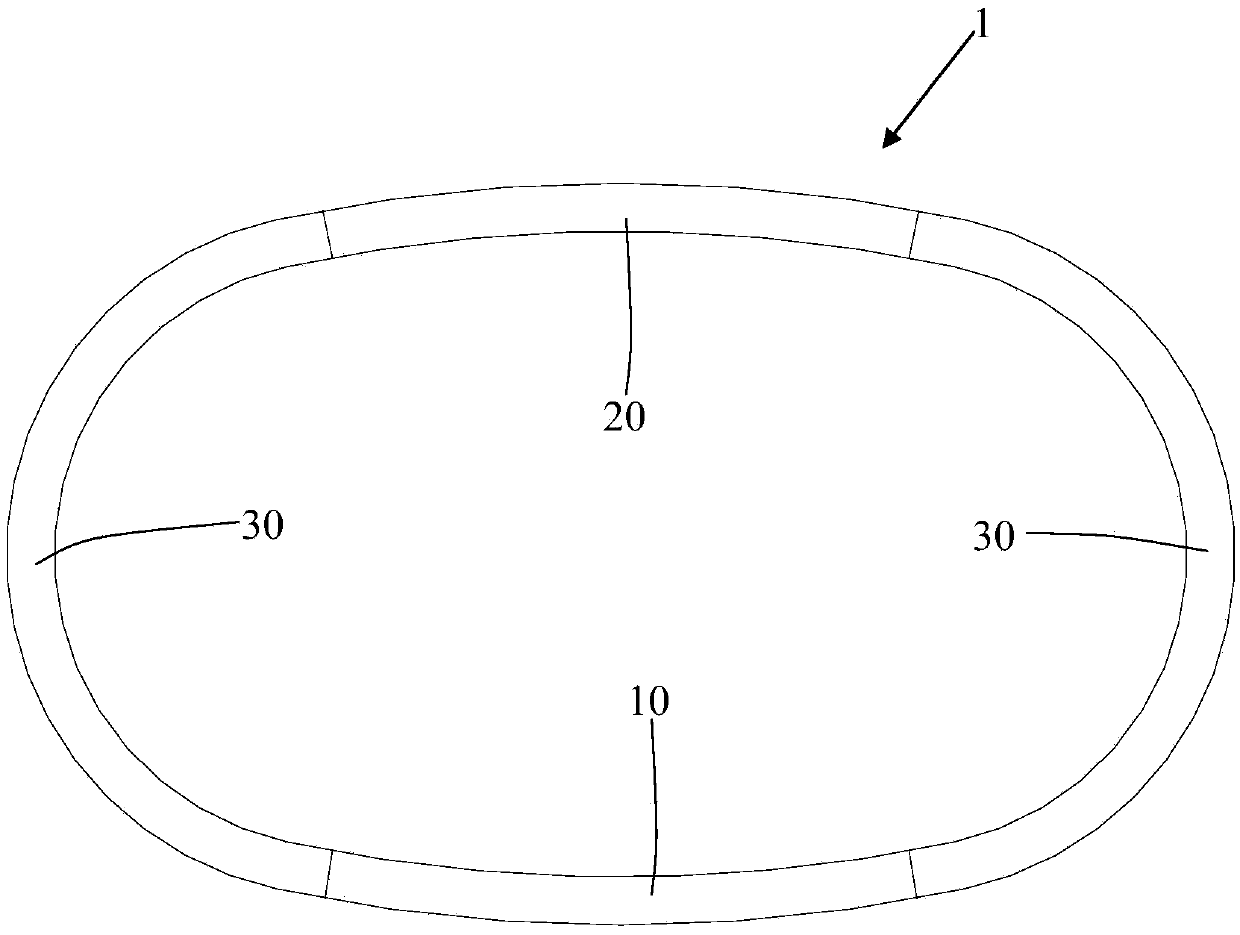

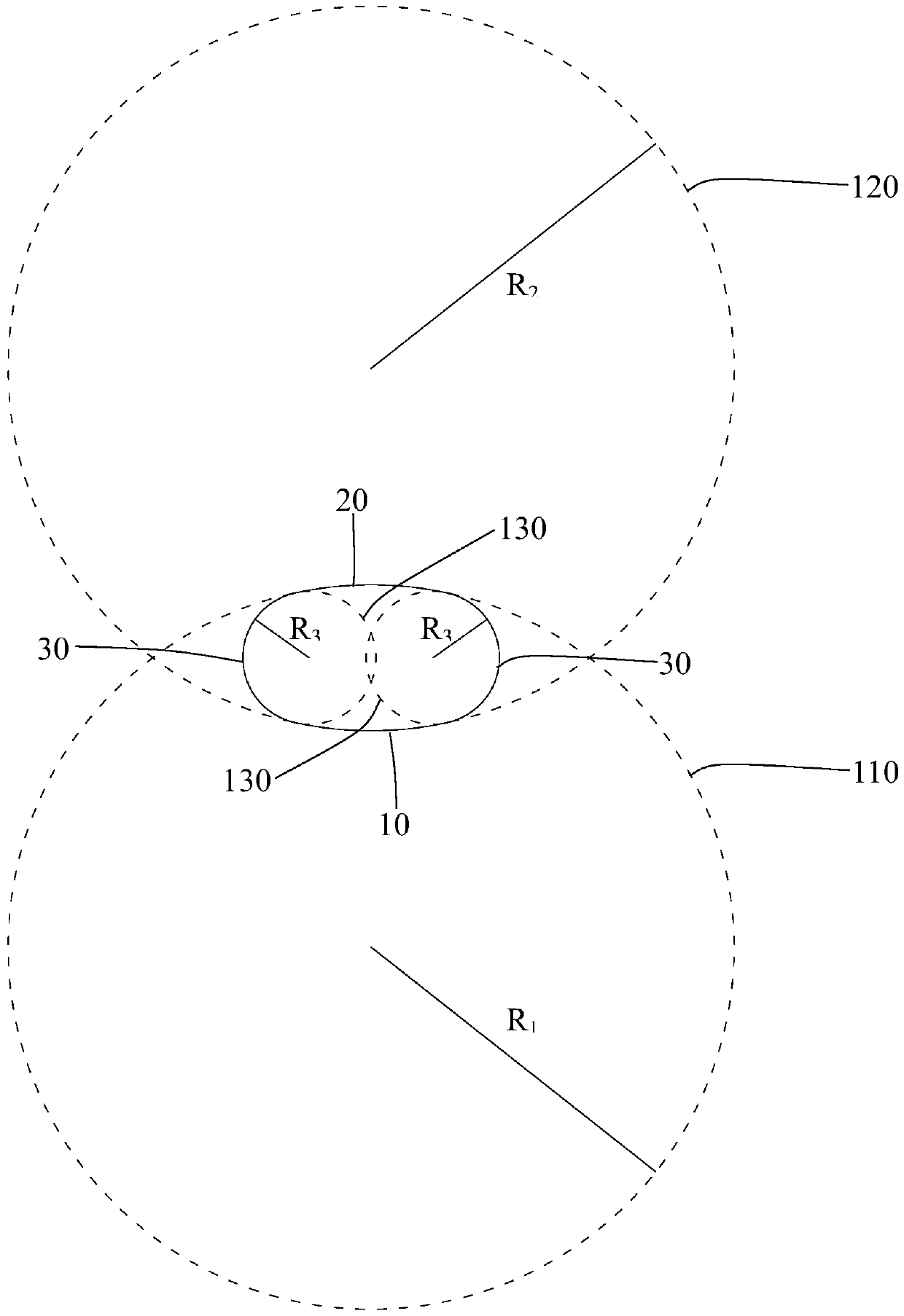

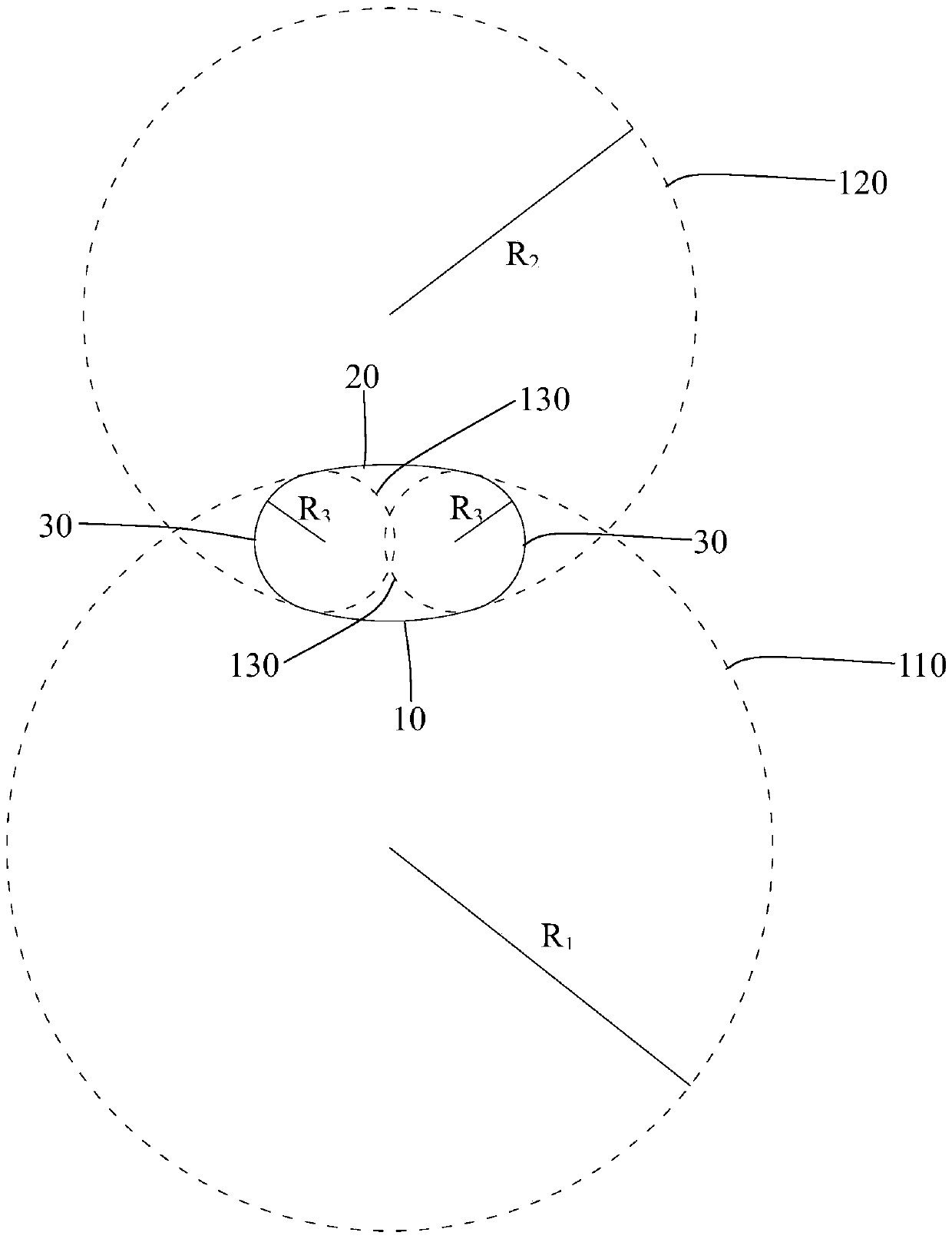

Segment structure applicable to quasi-rectangular shield tunnels

ActiveCN105507925AReduce bending momentReduce eccentricityUnderground chambersTunnel liningEngineeringRebar

The invention relates to a segment structure applicable to quasi-rectangular shield tunnels. The segment structure with the cross section being quasi-rectangular comprises an arch bottom arc section located at the arch bottom of the cross section, an arch crown arc section located at the arch crown of the cross section and two arch haunch arc sections located at the arch haunch positions on two sides of the cross section; the arch haunch arc sections are equal in radius which is smaller than the radius of the arch bottom arc section and the radius of the arch crown arc section; the arch bottom arc section is connected with both the arch haunch arc sections in smooth tangency, and the arch crown arc section is connected with both the arch haunch arc sections in smooth tangency. The segment structure has good arching effect, bending moment and eccentricity upon lining segments are reduced favorably, reinforcement consumption and lining thickness needed are reduced, and corresponding soil excavation volume and concrete consumption are less. In addition, shield equipment can cut soil mass on the whole section beneficially, and impact on surroundings is smaller.

Owner:SHANGHAI TUNNEL ENG CO LTD +2

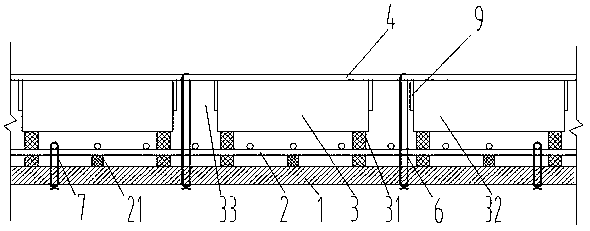

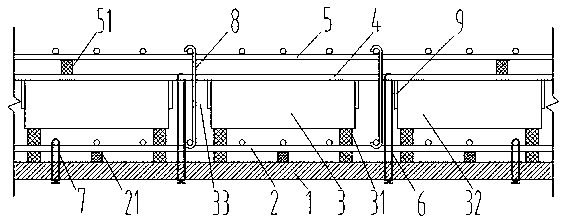

Construction method facilitating guarantee of hollow floor structural size

The invention relates to a construction method facilitating guarantee of hollow floor structural size. The construction method comprises the following steps that S1, a horizontal bottom formwork is laid; S2, a plurality of bottom layer steel bar cushion blocks are arranged on the bottom formwork, and a bottom steel bar layer is laid; S3, a plurality of second connecting pieces are used for connecting the bottom steel bar layer with the bottom formwork; S4, a plurality of placeholder box body cushion blocks are arranged on the bottom formwork, and a placeholder box body layer is laid; S5, an anti-floating steel bar layer is laid on the placeholder box body layer, and the anti-floating steel bar layer is supported by the placeholder box body layer; S6, a plurality of first connecting piecesare used for connecting anti-floating layer and the bottom formwork; S7, a plurality of top layer steel rib cushion blocks are arranged on the placeholder box body layer, and a top steel bar layer islaid; and S8, a plurality of third connecting pieces are used for connecting the top steel bar layer and the bottom steel bar layer. The anti-floating steel bar layer and the first connecting pieces are used for preventing placeholder box body tilting float after concrete slurry pouring, components in the floor are effectively fixed to guarantee the structure size of the floor to meet design sizerequirements and improve floor quality.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Connecting structure of prefabricated combined type duplex balcony and construction method

ActiveCN113737936AReduce weightReduce use costBalconiesForms/shuttering/falseworksArchitectural engineeringPrefabrication

The invention discloses a connecting structure of a prefabricated combined type duplex balcony and a construction method. The connecting structure structurally comprises a first prefabricated balcony component, a second prefabricated balcony component and a middle cantilever beam, wherein the first prefabricated balcony component and the second prefabricated balcony component are horizontally and oppositely arranged side by side, a side die, a bottom die and a rear end sealing plate of the middle cantilever beam are respectively arranged on the opposite ends of the first prefabricated balcony component and the second prefabricated balcony component, the end of the first prefabricated balcony component extends out of a stirrup of the middle cantilever beam, four longitudinal bars are bound to the four corners of the stirrup, the middle cantilever beam is formed between the first prefabricated balcony component and the second prefabricated balcony component through pouring, and the first prefabricated balcony component and the second prefabricated balcony component are integrated with the middle cantilever beam. According to the connecting structure, the single component is light in weight, the hoisting requirement of common hoisting equipment is met, the construction cost input is reduced, the degree of factory prefabrication is high, high-altitude construction operation is little, and the construction efficiency is improved.

Owner:ELITE ARCHITECTURAL CO LTD

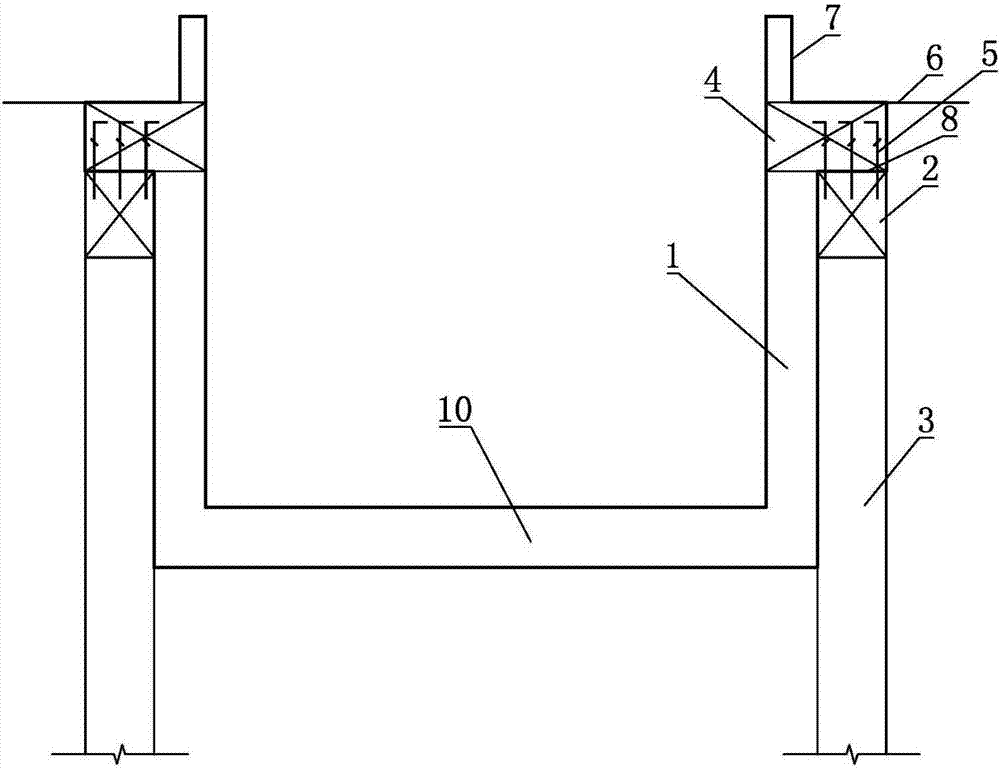

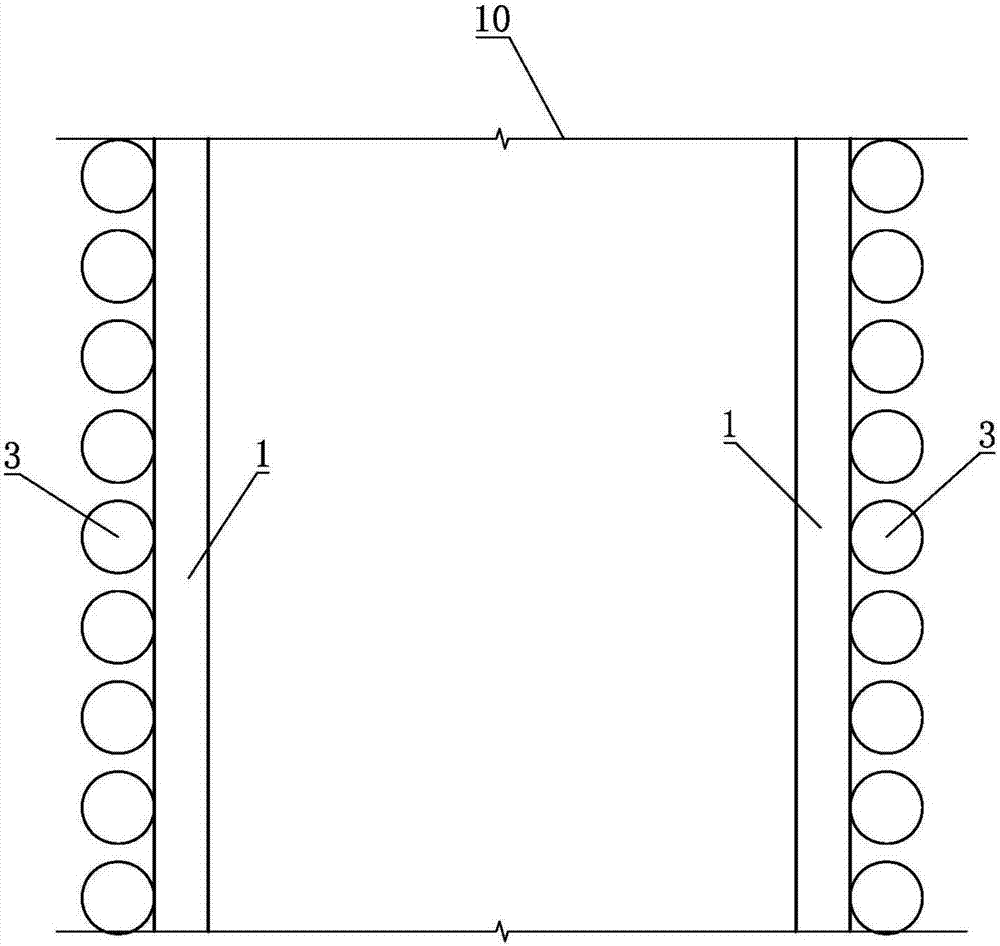

Lateral rigidity enhancing structure of open section of subway entrance

PendingCN107090850AIncrease constraintsImprove the forceArtificial islandsProtective foundationArchitectural engineeringRebar

The invention belongs to the field of deep foundation pit engineering, and discloses a lateral rigidity enhancing structure of an open section of a subway entrance. The lateral rigidity enhancing structure comprises a bottom slab, two main body side walls, top beams, two rows of fender posts, ring beams and joint bars. The two main body side walls are arranged on the bottom slab, and a U-shaped structure is formed by the two main body side walls and the bottom slab jointly. The tops of each row of fender posts bear the corresponding top beam, and the top of each top beam is flush with the top end face of the corresponding main body side wall of the U-shaped structure. Each main body side wall and the adjacent top beam jointly form a ring beam bearing structure. Each ring beam bearing structure bears the corresponding ring beam. The top beams and the ring beams are connected through the multiple joint bars. The lower ends of the joints bars are anchored into the top beams, and the upper ends of the joint bars stretch into the ring beams. The lateral rigidity enhancing structure has the advantages that construction is convenient and fast, the amount of steel bars is small, investment is reduced, and structure safety and the waterproof effect are guaranteed, and has great application prospects in the field of deep foundation pit engineering including subways.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

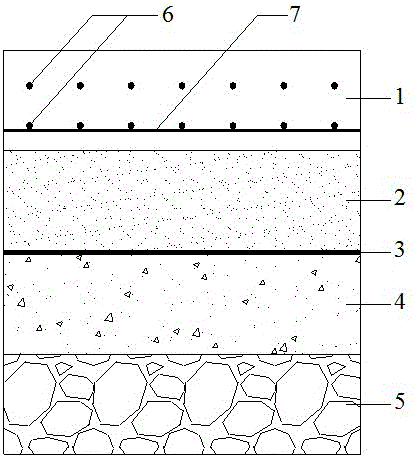

Double-layer reinforced concrete pavement structure suitable for pluvial region urban road

ActiveCN105780625ALow flexural strengthImprove flexural strengthPaving reinforcementsIn situ pavingsReinforced concreteStructure of the Earth

The invention discloses a double-layer reinforced concrete pavement structure suitable for a pluvial region urban road. The pavement structure comprises base layers. The base layers are divided into the upper base layer and the lower base layer. The upper base layer is made of lean concrete, the lower base layer is made of asphalt macadam, a cement concrete face layer is laid on the base layers, and a graded broken stone cushion layer is laid below the base layers. The cement concrete face layer is provided with double-layer continuous reinforcing steel bars and supports. The double-layer continuous reinforcing steel bars are the longitudinal reinforcing steel bars continuous on the upper layer and the transverse reinforcing steel bars and the longitudinal reinforcing steel bars continuous on the lower layer. A transverse joint is formed in the face layer every 150 m, and a pre-cutting joint transversely penetrating a well lid is formed in the position of the well lid on the face layer. A fine dense graded asphaltic concrete interlayer is arranged between the base layers and the face layer. 2% to 3% of road camber cross slopes are arranged on the base layers and the face layer. By the adoption of the pavement structure, the problem that a pavement structure of the urban road is seriously damaged at the early stage due to the fact that water systems are rich or drainage is not smooth can be effectively solved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

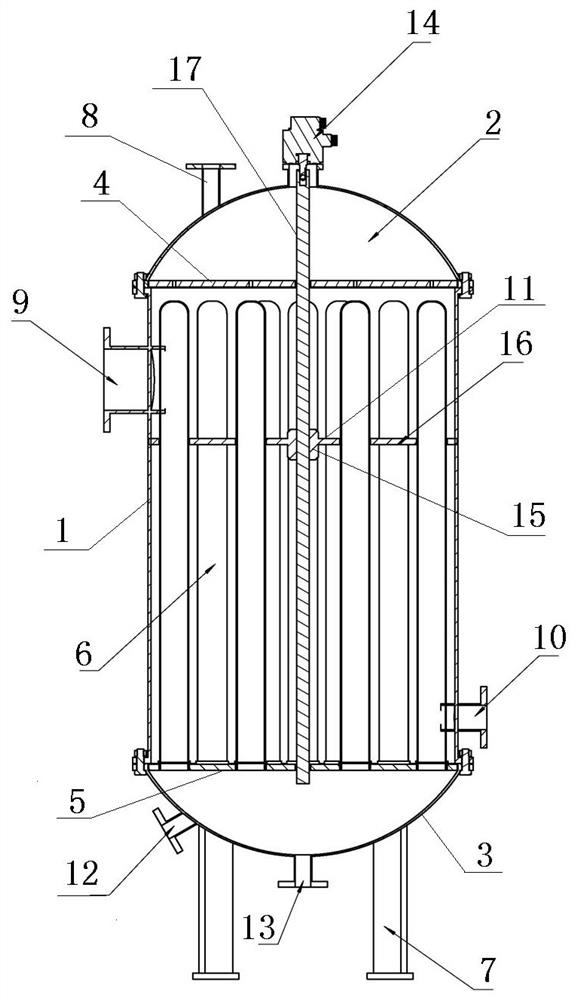

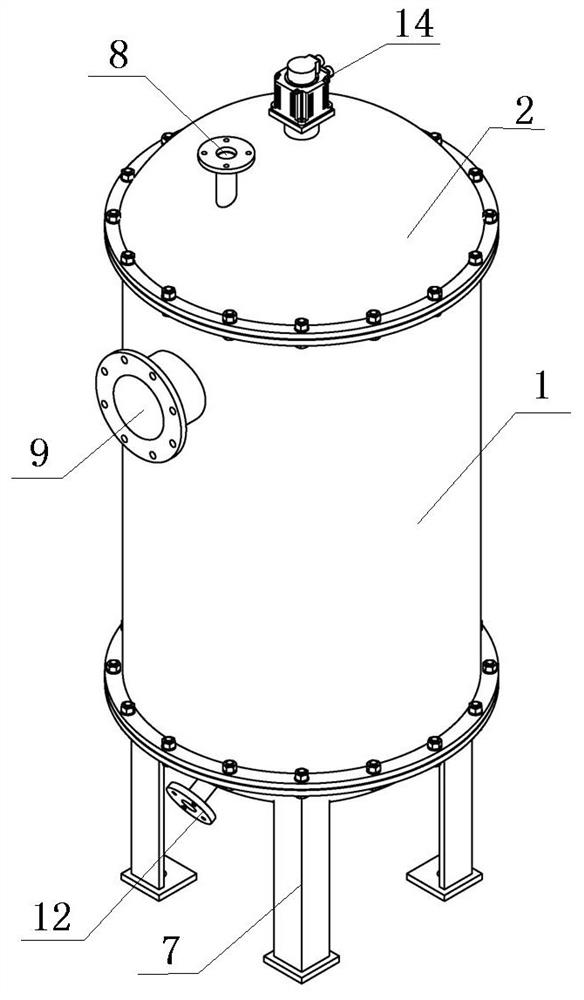

Single-end-face heat pipe anti-scaling evaporator

PendingCN111960493AIncrease capacitySimple structureSpecific water treatment objectivesWater/sewage treatment by heatingReciprocating motionEngineering

The invention discloses a single-end-face heat pipe anti-scaling evaporator. The evaporator comprises a shell, a heat conduction pipe, a first end face, a second end face, a descaling unit and a support. The shell comprises a cylindrical shell body, a first cover body and a second cover body, the first cover body and the second cover body are fixedly installed on the upper end face and the lower end face of the cylindrical shell body through flanges respectively, the first end face is located between the first cover body and the upper end face of the cylindrical shell body, and the second endface is located between the second cover body and the lower end face of the cylindrical shell body. One end of the heat conduction pipe is closed and the other end is open. The open end of the heat conduction pipe is welded to the hole of the second end face. The evaporator has the beneficial effects that scaling accumulation is effectively avoided, shutdown maintenance caused by descaling is avoided, equipment maintenance is reduced, and the productivity is improved, due to the design of the scale scraping device, on one hand, scales on the heat conduction pipe are effectively scraped, the steam crystallization process is accelerated in the up-down reciprocating motion process, the productivity is effectively improved, energy is saved, and the evaporator is simple in structure, free of manufacturing dead angles and easy and convenient to maintain.

Owner:北京璟航环境技术有限公司

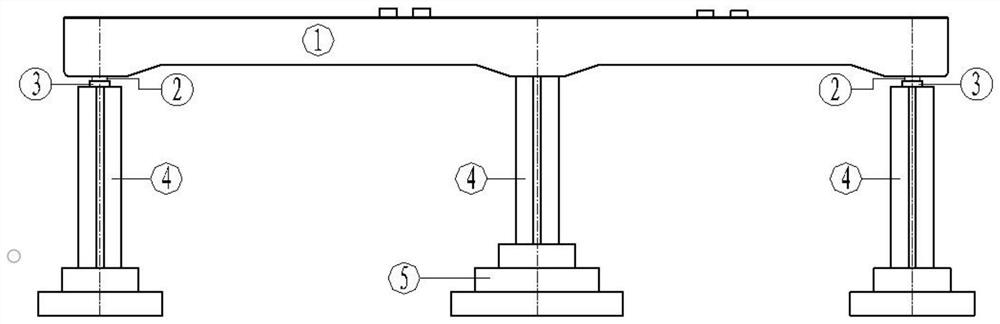

Rail transit three-column type prestressed concrete portal pier and construction method thereof

PendingCN112359712AMeet driving requirementsSatisfy crossing requirementsBridge structural detailsBridge erection/assemblyPre stressArchitectural engineering

The invention provides a rail transit three-column type prestressed concrete portal pier and a construction method thereof. The rail transit three-column type prestressed concrete portal pier comprisea prestressed bent cap and three pier columns sequentially arranged at intervals in the length direction of the prestressed bent cap, the pier columns are constructed on a pier column foundation, thepier column located in the middle serves as a middle pier column, and the other two pier columns serve as side columns. The middle of the prestressed bent cap is fixedly connected with the top of themiddle pier column, a padstone is constructed at the top of each side column, a support is installed on each padstone, and each end of the prestressed bent cap is supported on the support of the sidecolumn on the corresponding end and is movably connected with the top of the side column on the corresponding end. According to the invention, the supports are reasonably adopted for dynamic connection of the prestressed bent cap and the pier columns, so that the secondary internal force of the structure can be greatly reduced, the structure size and the number of steel bars are optimized, and the purpose of optimal design is achieved. The method is particularly suitable for the three-column type prestressed concrete portal pier structure which is good in foundation condition and short in pier height, and can be popularized to a beam-column type prestressed concrete portal pier structure.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Continuous reinforced concrete pavement structure suitable for urban road

ActiveCN105735077ALow flexural strengthImprove flexural strengthIn situ pavingsPaving gutters/kerbsReinforced concreteCrushed stone

The invention discloses a continuous reinforced concrete pavement structure suitable for an urban road. The pavement structure comprises a base layer which is divided into an upper base layer body and a lower base layer body. The upper base layer body is made of lean concrete. The lower base layer body is made of cement stabilized macadam. The base layer is paved with a cement concrete pavement layer, and the position under the base layer is paved with a graded broken stone hardcore. The cement concrete pavement layer is provided with double-layer continuous rebars and supporting bases. The double-layer continuous rebars comprise the upper-layer continuous longitudinal rebars, the lower-layer continuous transverse rabars and the lower-layer continuous longitudinal rebars. Transverse joints are arranged on the pavement layer at intervals of 150 m. A pre-cutting joint transversely penetrating through a well cover is arranged at the well cover on the pavement layer. A emulsified asphalt slurry seal modified through styrene butadiene rubber latex is arranged between the upper base layer body and the lower base layer body. The base layer and the pavement layer are provided with 2%-3% crown slopes. According to the continuous reinforced concrete pavement structure suitable for the urban road, the problem that in the urban road, the pavement structure is severely damaged early due to abundant water systems or impeded drainage can be effectively solved.

Owner:CCFEB CIVIL ENG +1

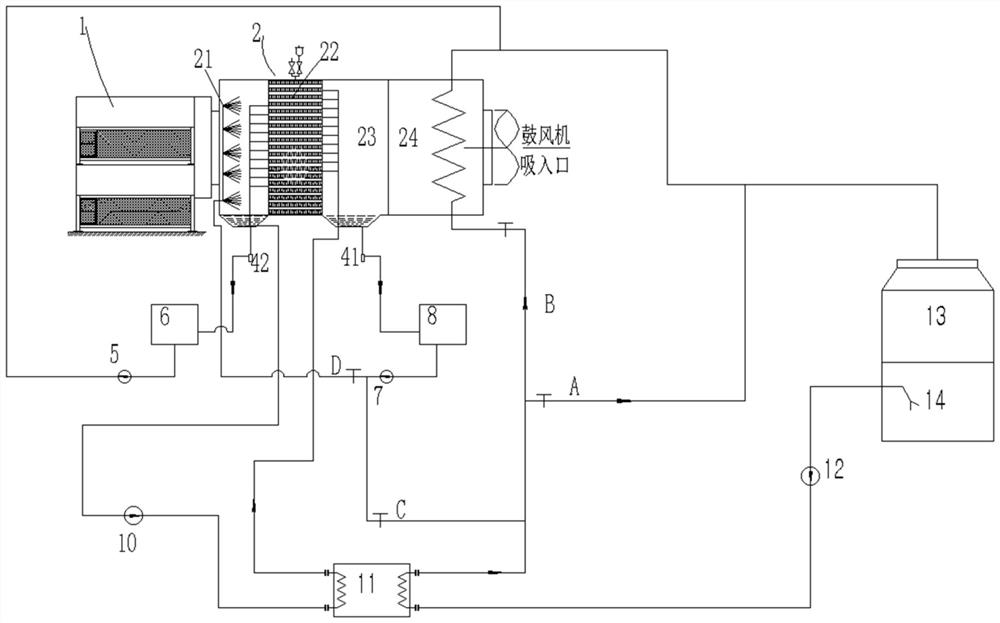

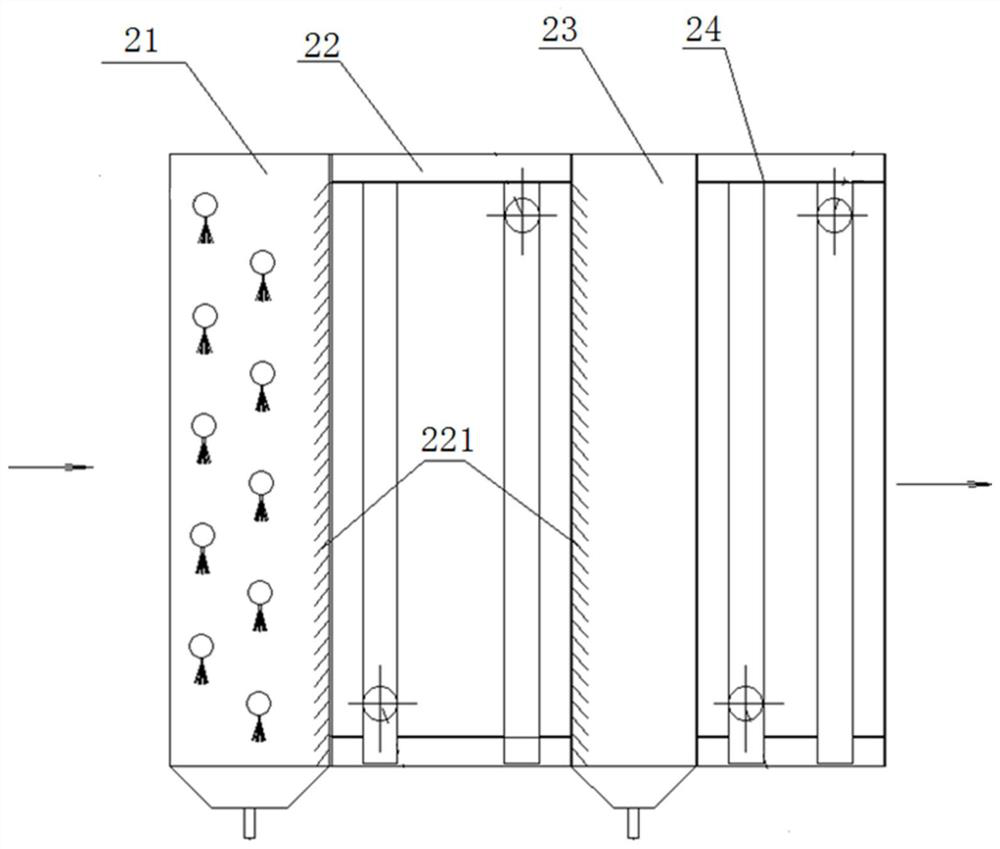

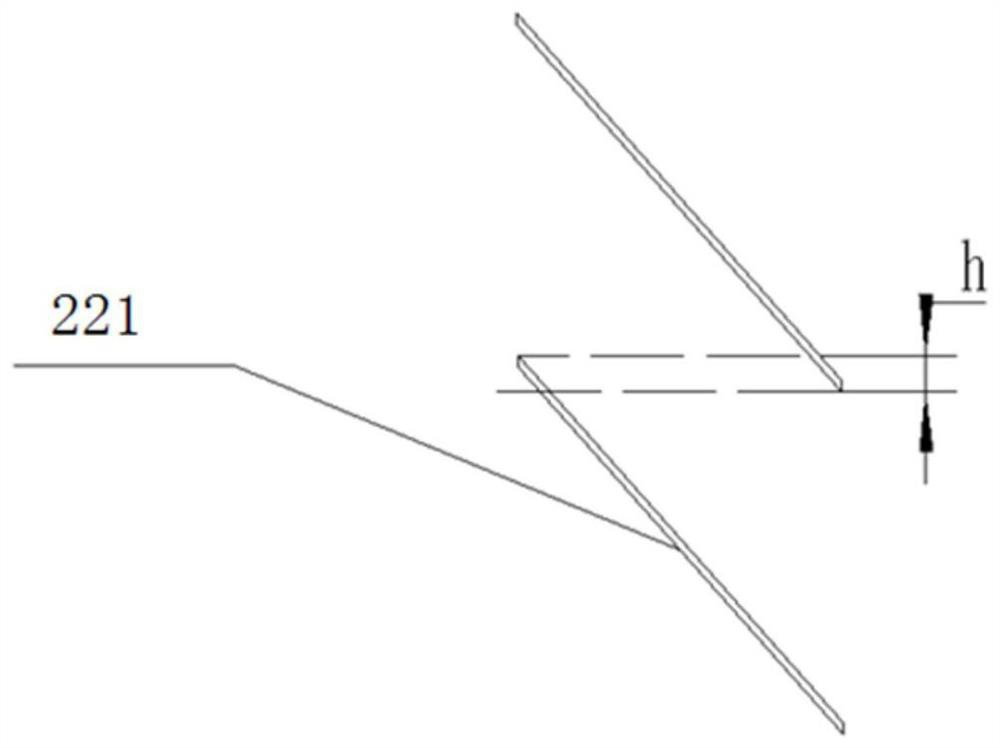

Integrated energy-saving blast furnace blast dehumidification system

The invention discloses an integrated energy-saving blast furnace blast dehumidification system comprising a filter and a dehumidifier which are connected in sequence. The dehumidifier comprises a spraying room, a surface air cooler and a buffer room which are connected in sequence, and header tanks are arranged at the lower parts of the spraying room and the buffer room; the spraying room is provided with nozzles, and a water inlet of the surface air cooler communicates with a water outlet of a refrigeration unit; a water outlet of the surface air cooler communicates with a water inlet of therefrigeration unit, and a water tank is located below a cooling tower; a refrigerant inlet of the refrigeration unit communicates with a water outlet of the water tank, and a refrigerant outlet of the refrigeration unit communicates with the interior of the cooling tower through a first pipeline; the blast dehumidification system further comprises a first automatic drainage device, a condensate pump and a condensate water tank, and the first automatic drainage device communicates with the header tanks in the buffer room; and a water outlet of the condensate pump communicates with the nozzlesof the spraying room through fourth pipelines. According to the blast dehumidification system, through additional arrangement of a condensate water recycling system and a cooling air heating system, the cold energy utilization of the system is improved effectively, and the air dryness is improved; and the energy saving of the system is ensured, and the system safety is improved.

Owner:HUATIAN ENG & TECH CORP MCC +1

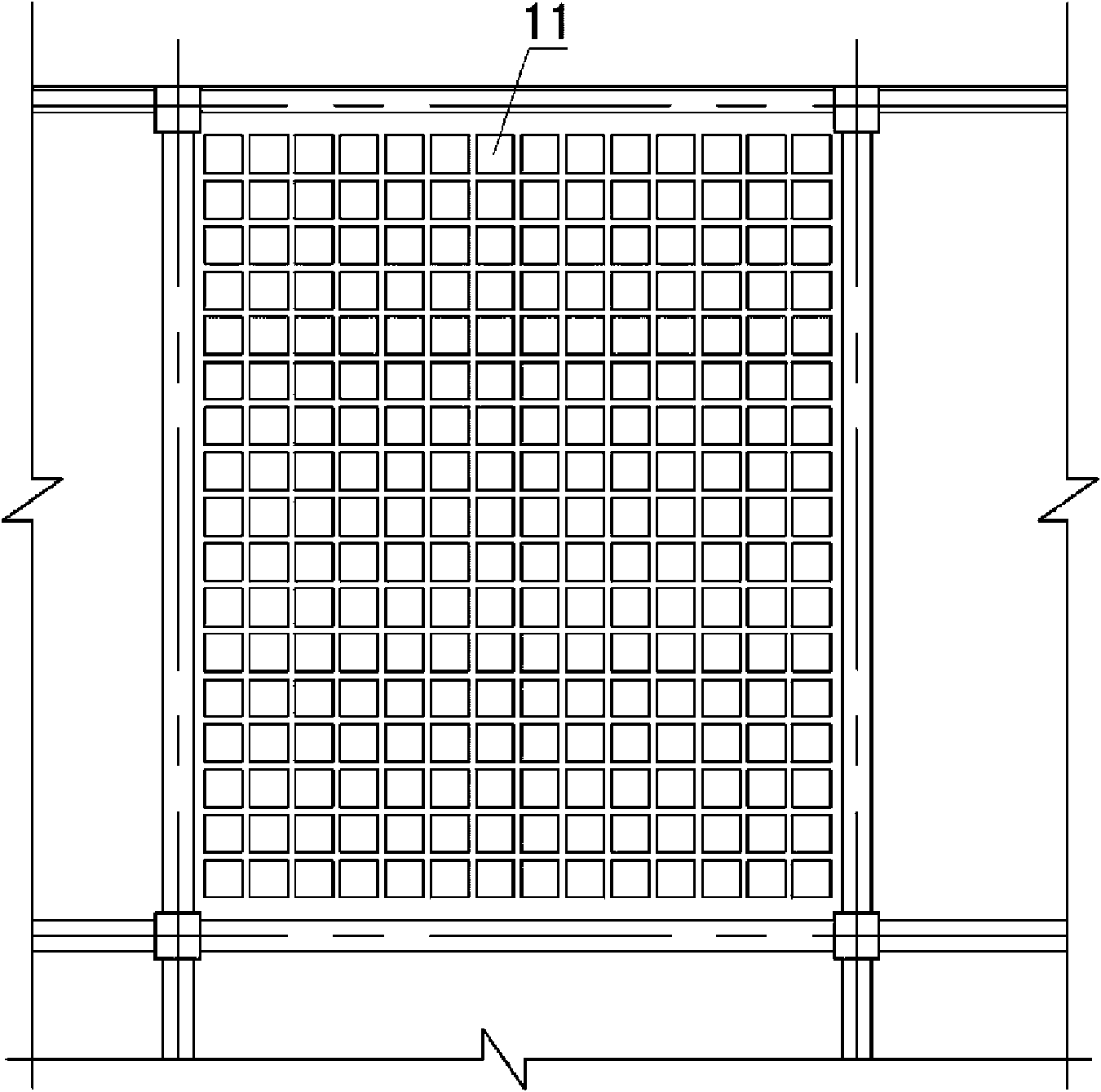

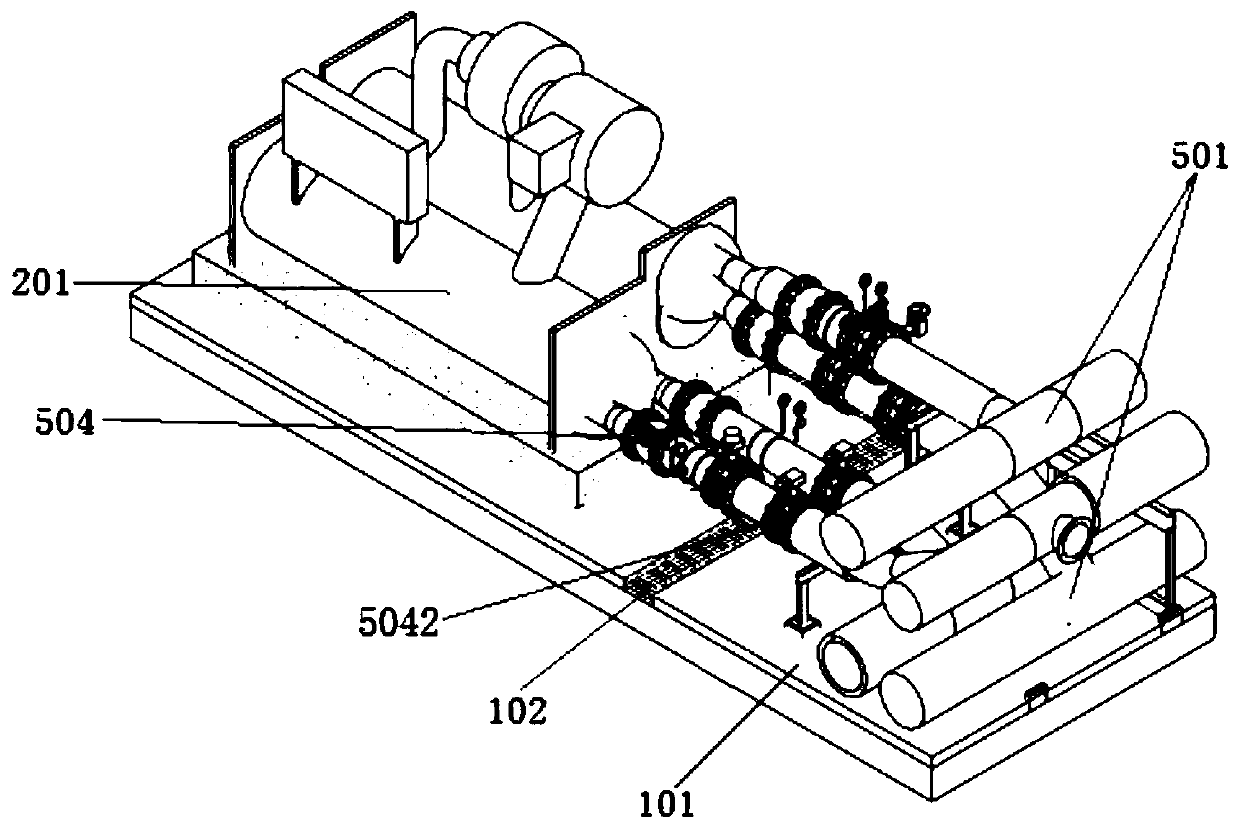

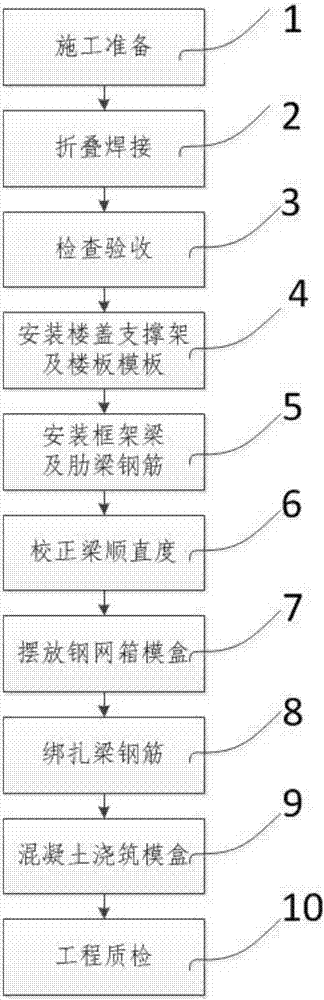

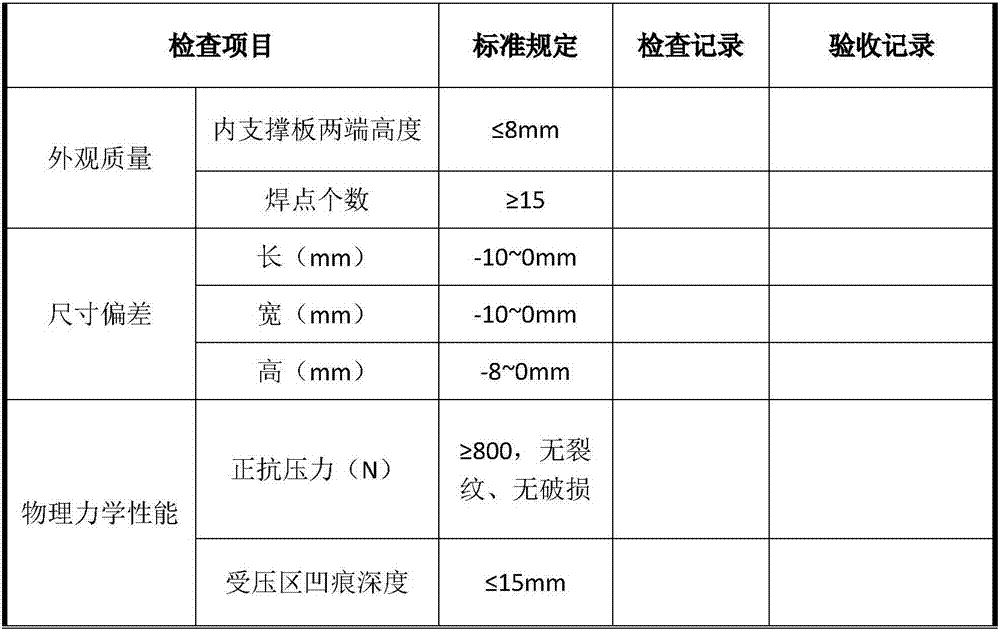

Open-web floor system steel net cage mould box construction method

InactiveCN106907007AReduce the amount of steelEasy to plankBuilding material handlingRebarReinforced concrete

The invention provides an open-web floor system steel net cage mould box construction method which comprises the following steps of construction preparation, folding welding, inspection and acceptance, mounting of a floor system support frame and floor templates, mounting of framed girders and ribbed beam steel bars, correction of beam straight degree, arrangement of a steel net cage mould box, tying of beam steel bars, pouring of concrete to the mould box and engineering quality testing. According to the construction method, the use level of the steel bars is decreased, and the steel bar use level is saved by approximately one third compared with an ordinary reinforced concrete solid floor; and the structural framed girders, the ribbed beam steel bars and the plate bottoms are all in the same horizontal plane, the plates are conveniently laid, formwork supporting construction difficulty is lowered, formwork supporting is accelerated, template consumption is extremely low, the number of turnover times of the templates is decreased, and the construction cost is lowered.

Owner:NO 1 CONSTR ENG CO LTD OF GUIZHOU CONSTR & ENG GRP

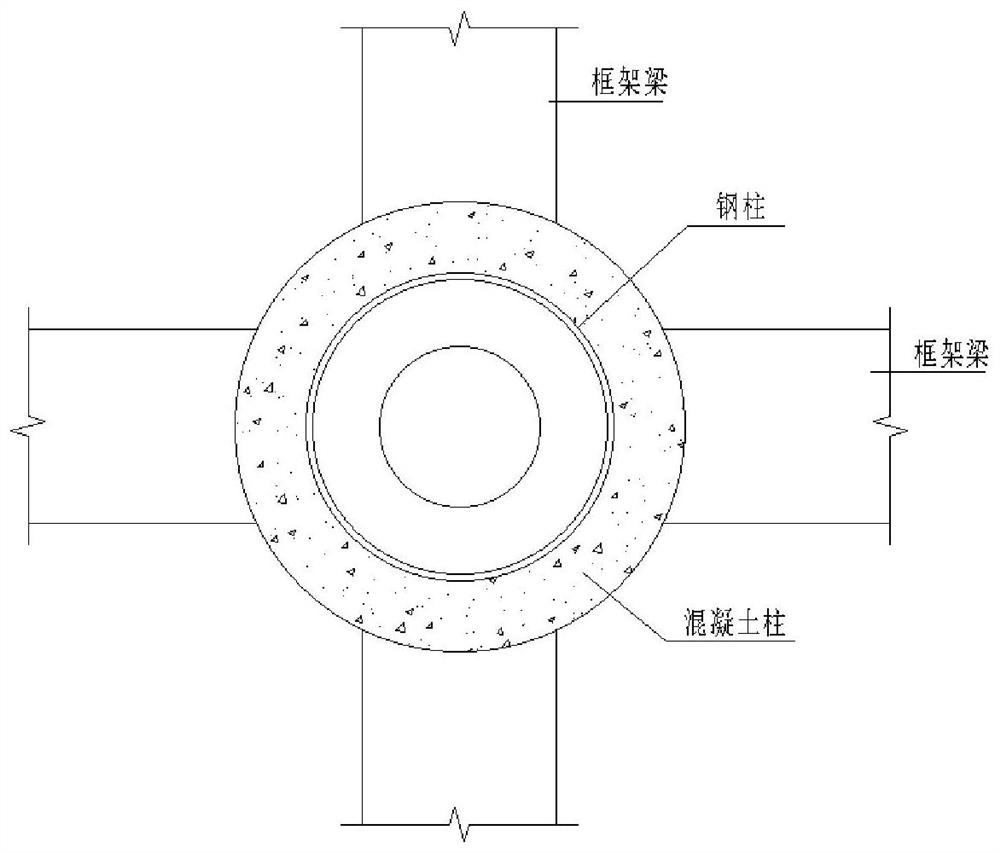

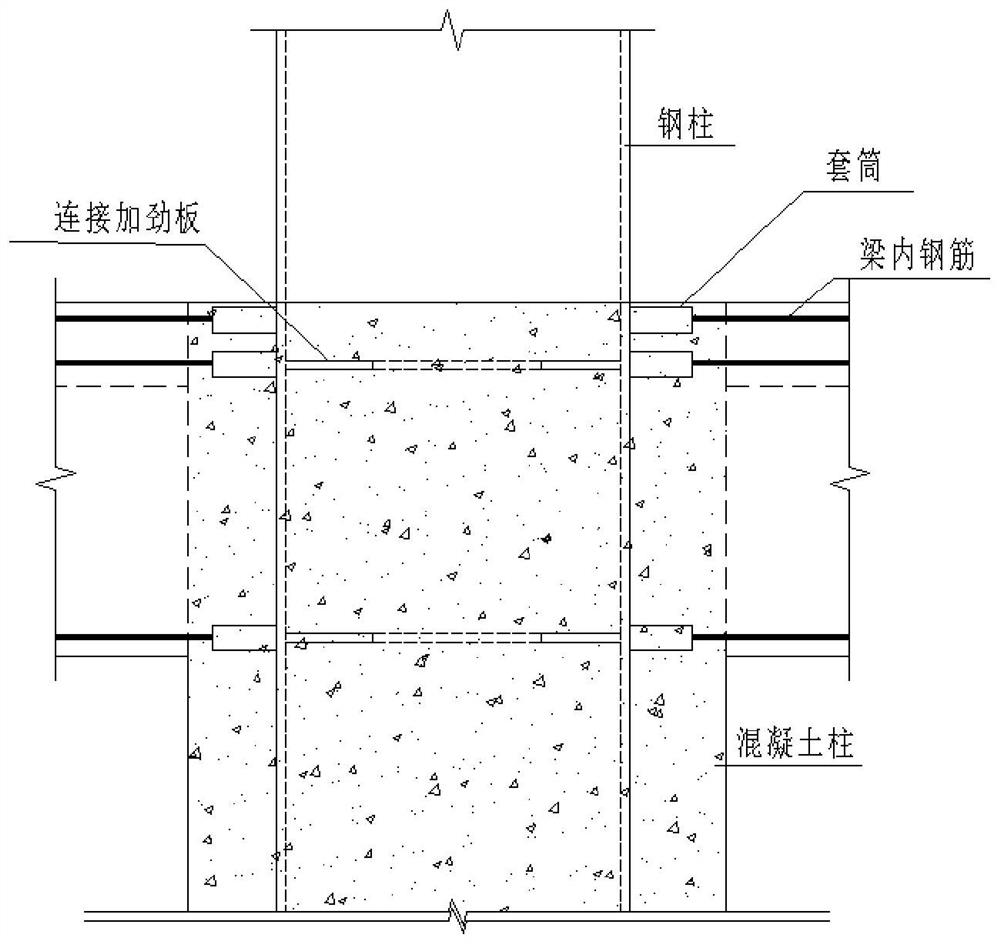

Nested steel column-concrete column connecting structure

The invention discloses a nested steel column-concrete column connecting structure. The nested steel column-concrete column connecting structure comprises a steel column and a concrete column which are connected up and down, the steel column comprises an external steel pipe, concrete and longitudinal bars, and the concrete and the longitudinal bars are poured in the steel pipe; studs are fixed to the periphery of the interior of the steel pipe, and the longitudinal bars penetrate through the concrete column on the lower part and the steel column in the middle; the concrete column further comprises stirrups surrounding the longitudinal bars, and the concrete in the steel column and the concrete column are poured at the same time; and the outer diameter of the steel column is defined as D1, the diameter of the concrete column is defined as D2, and D2 is larger than or equal to D1 and smaller than (D1+200 mm). The nested steel column-concrete column connecting structure ingeniously utilizes extrusion of the concrete core column and the steel column to transmit bending moment. Meanwhile, a bearing device is arranged in the steel pipe, and the axial force is transmitted through inverted stiffening ribs and column foot plates. The nested steel column-concrete column connecting structure is novel and unique in form, simple in structure and clear in stress.

Owner:ZHEJIANG PROVINCE INST OF ARCHITECTURAL DESIGN & RES

Production process for solving pitted surfaces of low-carbon steel wires

ActiveCN112077151AReduce the amount of steelIncrease the function of blowback waterTemperature control deviceProcess efficiency improvementWire rodCarbon steel

The invention belongs to the field of metallurgy, and particularly relates to a production process for solving pitted surfaces of low-carbon steel wires. According to the production process, by takingthe actual quality of the surfaces of rolling grooves of all sorts of rough and medium rolling as the purpose, the rolling temperature is improved, in other words, heating secondary section temperature, soaking zone temperature and initial rolling temperature are increased by 30 DEG C, and spinning temperature is increased by 30-40 DEG C ; the back flushing function of a water tank is added; andthe steel capacity of intermediate rolling is reduced, and the pitted surface depth of the large-specification low-carbon steel wires is reduced to 0.04 mm or below. The use requirements of customersfor drawing from phi 26mm to phi 25.5 mm for forming of a socket spanner are met.

Owner:JIANGSU YONGGANG GROUP CO LTD

Production process of autoclaved aerated concrete containing high-calcium dry red fly ash

InactiveCN110395962ALight weightWith sound insulationCeramic shaping apparatusCeramicwareCalcium silicateSlurry

The invention discloses a production process of autoclaved aerated concrete containing high-calcium dry red fly ash. The production process comprises the steps: pulping, powder grinding, casting, cutting and steam curing, wherein during pulping, the high-calcium dry red fly ash, quartz sand, gypsum and water are mixed uniformly at a ratio so as to prepare stand-by slurry, and after quicklime is ground into fine powder, pouring is performed; during pouring, the stand-by slurry, the powdery quicklime and cement are weighed at a ratio, then feeding is performed uniformly by a feeder, even stirring is performed so as obtain mixed slurry, and an aluminum powder solution is added at a ratio so as to form a liquid-phase mixture; and aluminum powder reacts with a medium water in an alkaline environment so as to generate hydrogen gas, the quicklime reacts with water, and silica in the quartz sand reacts with Ca(OH)2 and AL2O3 in the cement and quicklime under a hydrothermal synthesis conditionso as to produce hydrated calcium silicate and hydrated calcium aluminate and form a green body, and steam curing is performed after cutting is performed on the green body. The strength of the productis enhanced by the produced hydrated calcium silicate and hydrated calcium aluminate together, and the problem of difficult improvement of compression resistance, seismic resistance, tensile resistance and shear strength of walls in the prior art is solved.

Owner:河南环泰建材有限公司

Post-tensioned prestressed prefabricated type concrete composite beam reinforcing steel bar structure and design method thereof

PendingCN110644618AReduce the amount of steelReduce dosageGirdersJoistsPre stressArchitectural engineering

The invention provides a post-tensioned prestressed prefabricated type concrete composite beam reinforcing steel bar structure and a design method of the post-tensioned prestressed prefabricated typeconcrete composite beam reinforcing steel bar structure. The post-tensioned prestressed prefabricated type concrete composite beam steel reinforcing bar structure comprises beam lower part reinforcingsteel bars, waist ribs, beam upper part reinforcing steel bars, stirrups and prestressed tendon strands. The beam lower part reinforcing steel bars comprise beam lower part constructional reinforcingsteel bars distributed on the two sides of a cross section of a prefabricated layer, and the beam lower part constructional reinforcing steel bars are arranged in the longitudinal direction of the prefabricated layer in a full length manner. The beam upper part reinforcing steel bars comprise beam upper part energy dissipation reinforcing steel bars and beam upper part constructional reinforcingsteel bars, wherein the beam upper part constructional reinforcing steel bars are arranged in the span middle part of a post-poured superposed layer in parallel at intervals, the beam upper part energy dissipating reinforcing steel bars are arranged at the two ends of the post-poured superposed layer, the outer end of each beam upper part energy dissipating reinforcing steel bar exceeds the end ofthe post-poured superposed layer and is connected with a reinforcing steel bar connection device, and the inner end of each beam upper part energy dissipating reinforcing steel bar is in lap joint with the corresponding beam upper part constructional reinforcing steel bar. The prestressed tendon strands are arranged below the middle axis of the prefabricated layer and are distributed in a straight line shape. The ends of the prestressed tendon strands are anchored into prefabricated columns on the two sides of the composite beam. The post-tensioned prestressed prefabricated type concrete composite beam reinforcing steel bar structure solves the problems that a traditional post-tensioned prestressed prefabricated type concrete frame structure system is complicated in component and low in construction efficiency, the construction cost of the traditional post-tensioned prestressed prefabricated type concrete frame structure system is higher than a traditional assembly type system, and the anti-seismic performance of the traditional post-tensioned prestressed prefabricated type concrete frame structure system is poor.

Owner:CHINA CONSTR SCI & TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com