Integrated energy-saving blast furnace blast dehumidification system

A blast furnace blasting and dehumidification technology, applied in blast furnaces, blast furnace details, blast furnace parts and other directions, can solve the problems of large dehumidifiers and high equipment costs, achieve obvious system energy saving, improve the level of cold energy utilization, and reduce system costs. The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

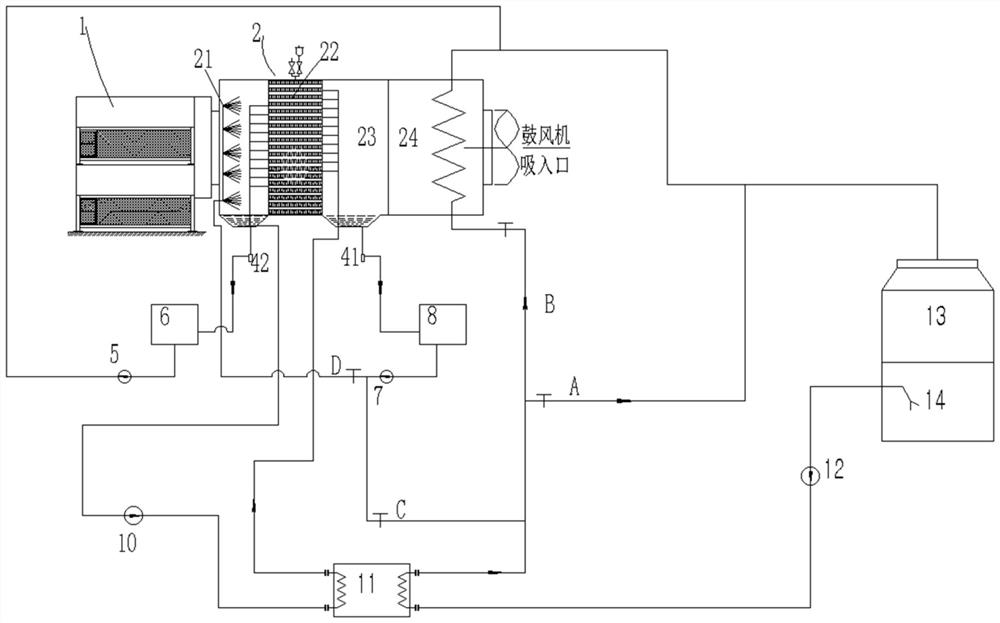

[0032] The conventional dehumidification process is as follows: the air enters the dehumidifier 2 through the filter 1 for dehumidification, and the dehumidified air is sent to the blast furnace blower after mechanical demisting; after the dehumidifier 2 imports chilled water to absorb the heat of the air, it passes through the chilled water pump 10 Send it to the evaporator of the refrigeration unit 11 for cooling, and then send the cooled chilled water to the dehumidifier 2 to form a cycle;

[0033] The refrigerant cooled by the cooling tower 13 enters the water pool 14, and the cooled refrigerant is sent to the condenser of the refrigeration unit 11 through the circulating water pump 12 to absorb the heat released by the cooling medium. to the cooling tower for cooling. The condensed water after the air passes through the dehumidifier 2 flows into the condensed water tank 8 through the first automatic drain device 41, is pressurized by the condensed water pump 7, and flows ...

example 2

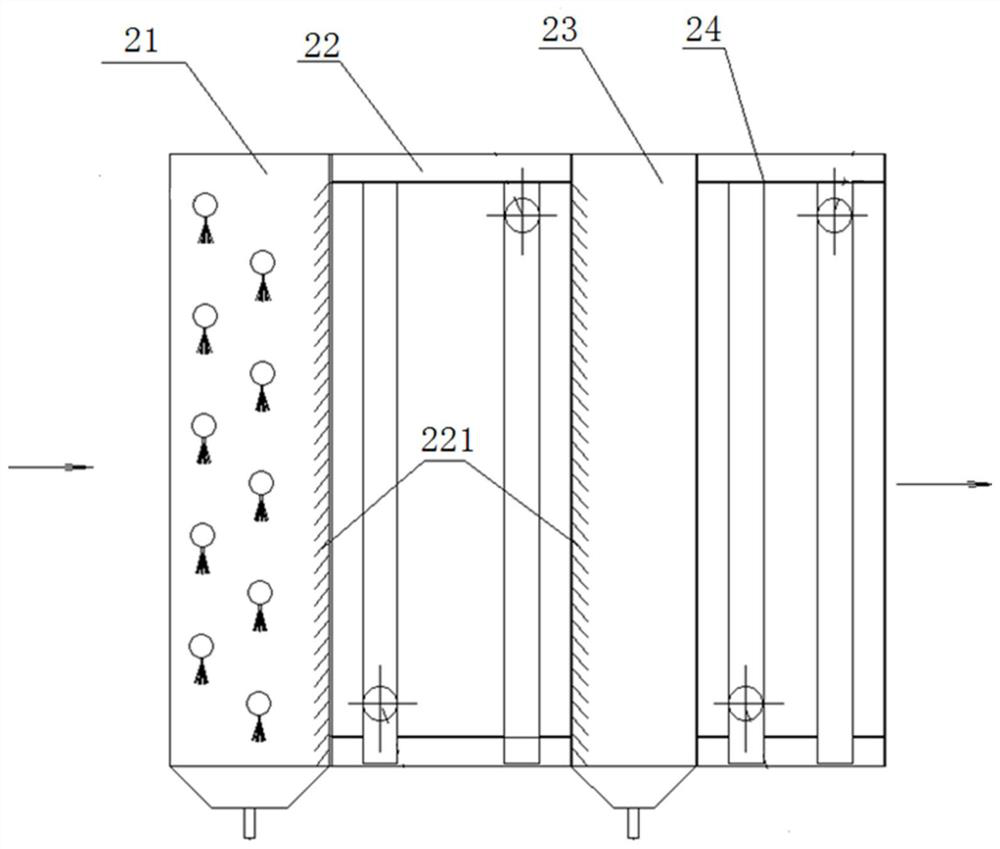

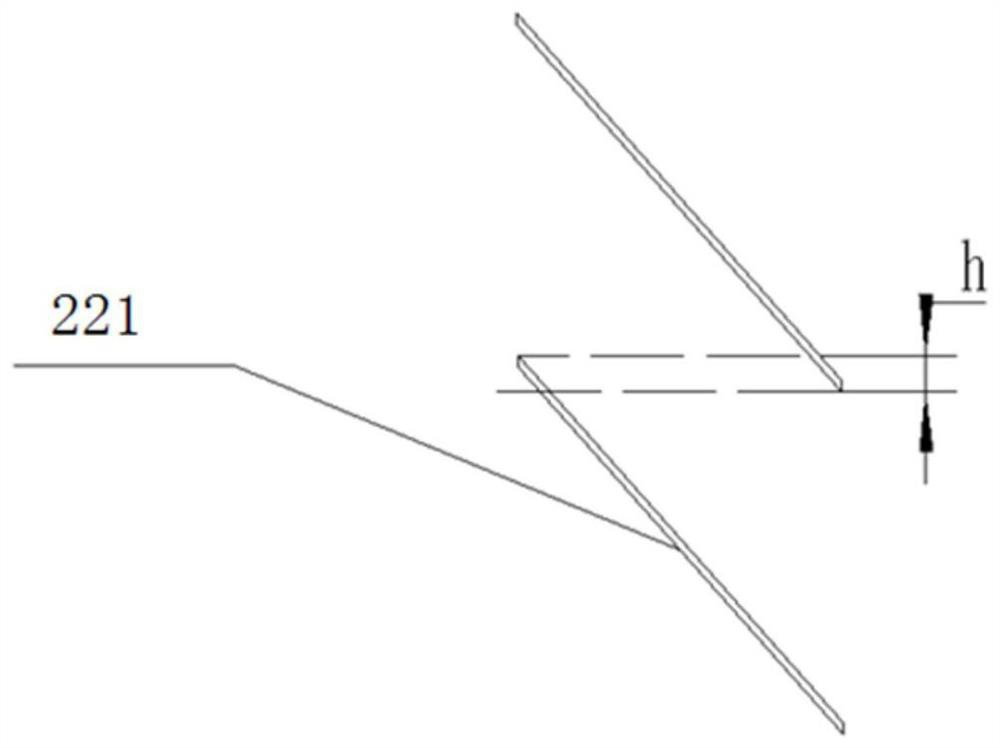

[0035] Aiming at the loss of cold energy caused by the failure of the condensed water in Example 1 to directly recycle its cooling capacity, in Example 2, the condensed water in the condensed water tank 8 is sent into the spray chamber 21 through the condensed water pump 7, and the spray chamber 21 passes through The nozzle atomizes the condensed water into small droplets, and the SMD of the droplets is usually controlled below 100μm. The atomized water mist first contacts the air at the outlet of filter 1, which can pre-cool the air by 3-5°C, which is equivalent to 3% energy saving of the system ~5%. A part of the spray water falls directly to the lower sump, is collected by the second automatic drainage device 42, and then sent to the drainage tank 6. After passing through the drainage pump 5 and the outlet water of the air-water heat exchanger, it flows into the refrigerant return pipe together as a cooling tower replenishment.

example 3

[0037] The temperature of the refrigerant passing through the refrigerating unit 11 rises by 5°C, and the refrigerant enters the air-water heat exchanger 24 through the second pipeline B, which can heat the cooled saturated humid air by 3-10°C, and the refrigerant itself drops by 1-2°C. After the saturated humid air is heated by the air-water heat exchanger 24, not only can the mechanical water be removed, but also the temperature and dryness of the air entering the blower can be improved by heating up, so as to ensure the safety of the blower blades.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com