Connecting structure of prefabricated combined type duplex balcony and construction method

A connection structure and combined technology, which is applied to balconies, building components, building structures, etc., can solve problems such as inconvenience, and achieve the effects of reducing procedures, reducing weight, and high production levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

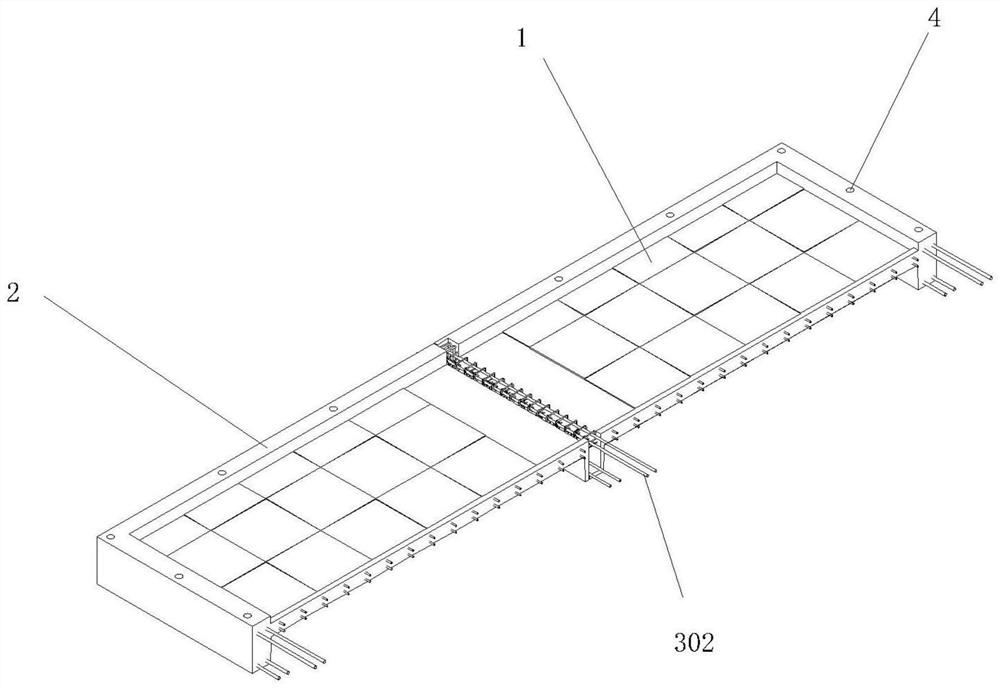

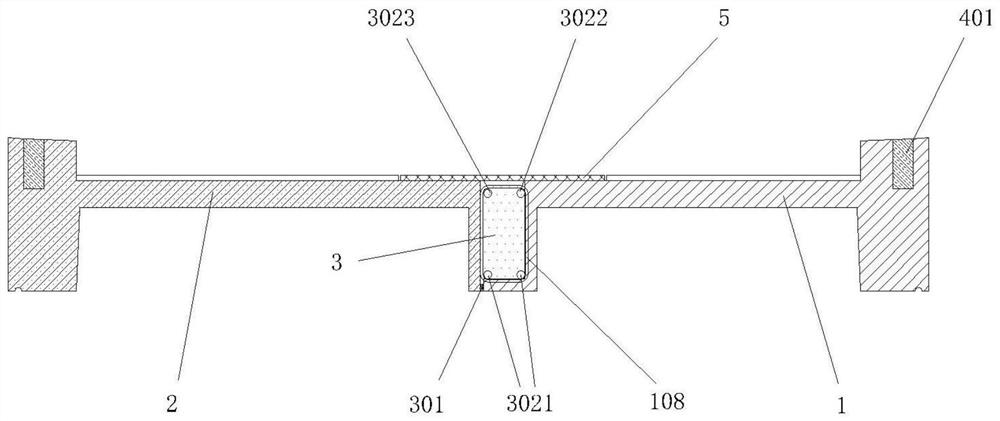

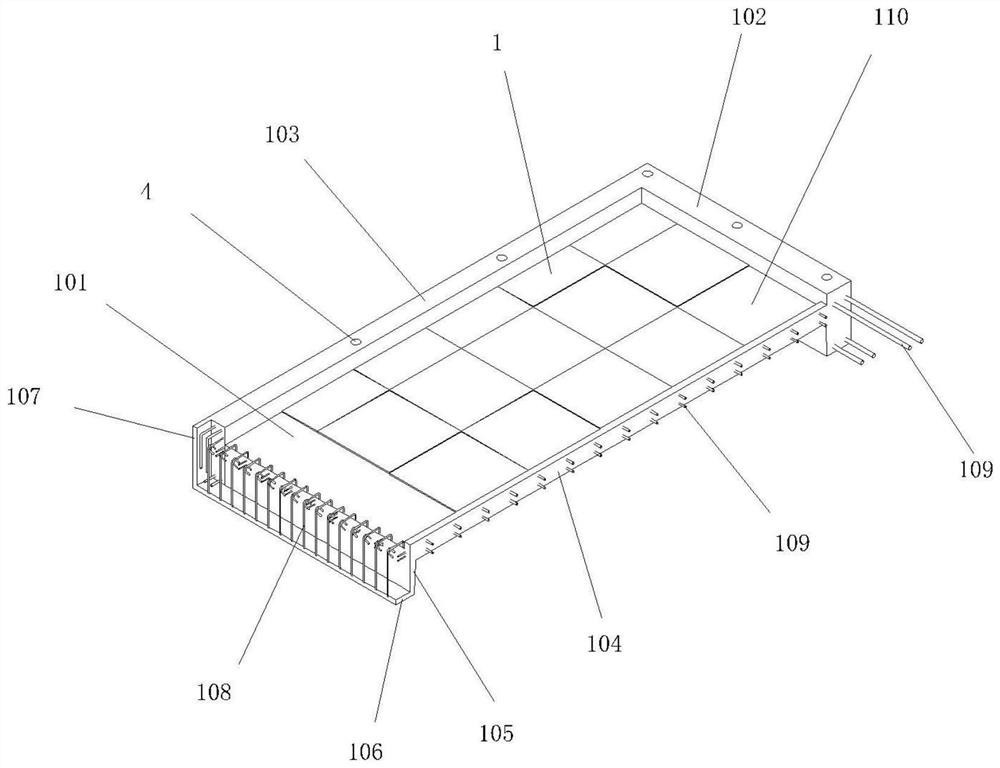

[0037] see figure 1 and figure 2 , the present invention provides a connection structure of a prefabricated combined double balcony, comprising a first prefabricated balcony component 1, a second prefabricated balcony component 2 and an intermediate cantilever beam 3, the first prefabricated balcony component 1 and the second prefabricated balcony The components 2 are horizontally side by side, and are connected as an integral structure through the cast-in-place intermediate cantilever beam 3 . The railing installation opening 4 is reserved on the first prefabricated balcony component 1 and the second prefabricated balcony component 2, and the railing installation filling 401 is poured in the railing installation opening when installing the railing to fix the railing. After the middle cantilever beam 3 is poured and formed, the top is pasted and then paved with floor tiles 5 .

[0038] see image 3 , the main body of the first prefabricated balcony component 1 is a balcony...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com