Improved steel pipe piles and pipe pile structures

A technology for pipe piles and support structures, which is applied in infrastructure engineering, sheet pile walls, buildings, etc., and can solve the problems of coating damage, high initial cost, and expensive coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] will now refer to the attached Figure 1 to Figure 11 Preferred embodiments of the present invention will be described.

[0037] The same elements in the various figures are indicated with the same reference numerals.

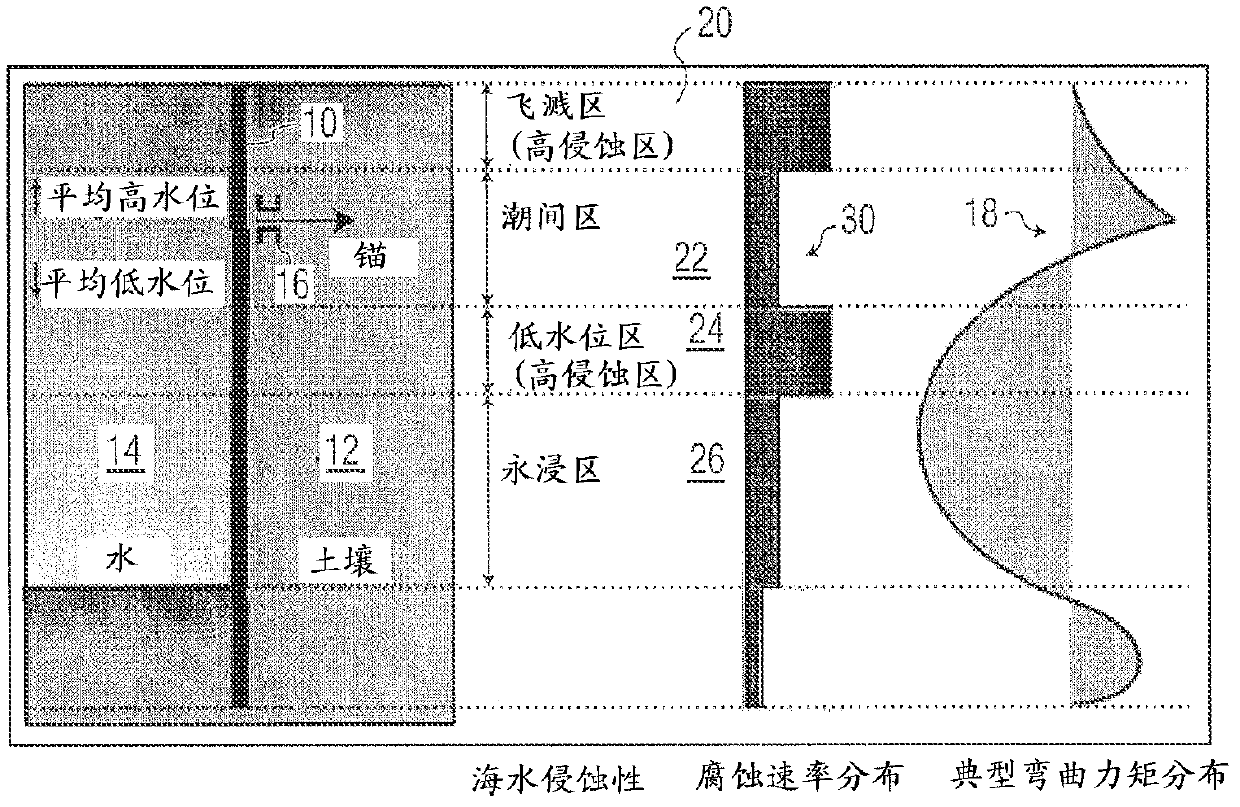

[0038] figure 1 A retaining wall 10 of steel pipe piles is shown, which retains soil 12 on one side and separates it from seawater 14 on the other side. As explained above in the Background of the Invention section, the pipe piles in the retaining wall are subjected to continuous stress due to the action of air and water, as well as continuous corrosion.

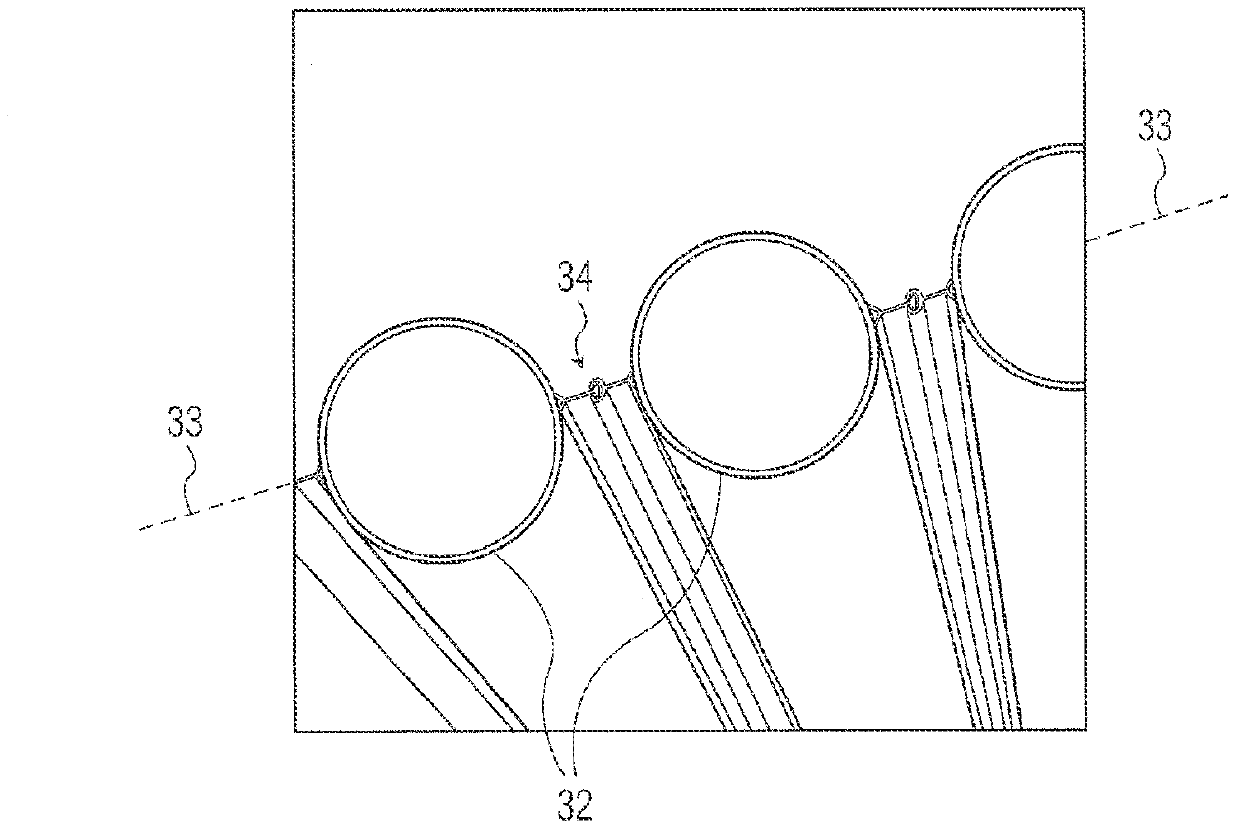

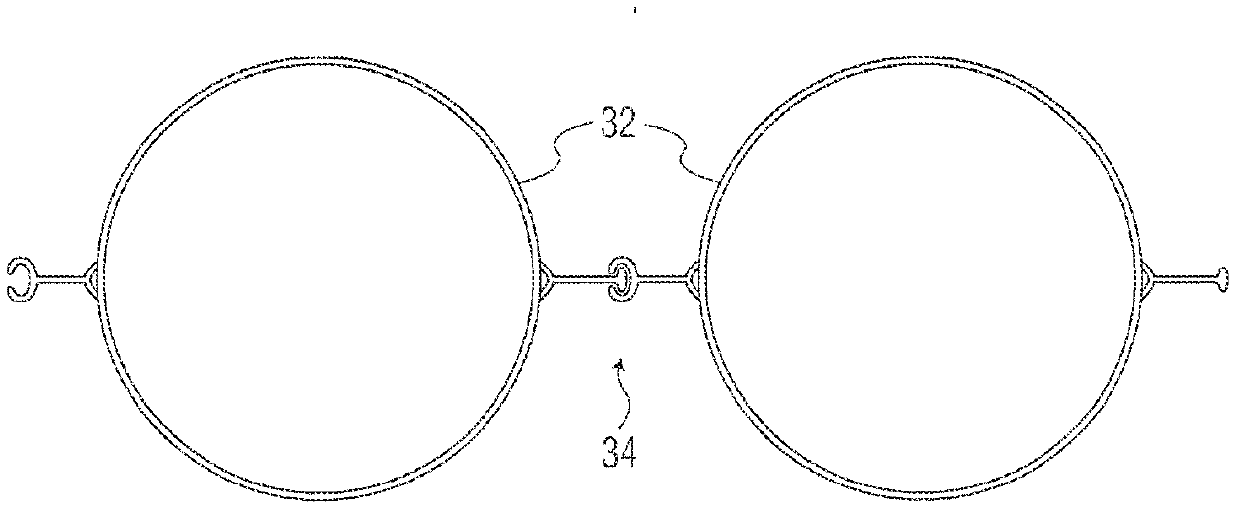

[0039] The tubular piles of the retaining wall are driven into the soil below the seabed with the longitudinal axes of the tubular piles arranged generally parallel and along a common generally horizontal line. figure 2 Shown is a series of pipe piles 32 arranged along a horizontal line 33 and connected together by intermediate connecting elements 34 secured by welding to the curved outer surfaces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com