Keel embedded-buckled assembling anti-cracking anti-seepage permanent cylinder shuttering

An embedded, permanent technology, applied in the direction of climate sustainability, columns, piers, etc., can solve the problems of affecting durability and service life, common concrete is easy to crack, affecting the safe operation of structures, etc., to improve durability. and service life, high tensile ductility and crack control, and the effect of shortened construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

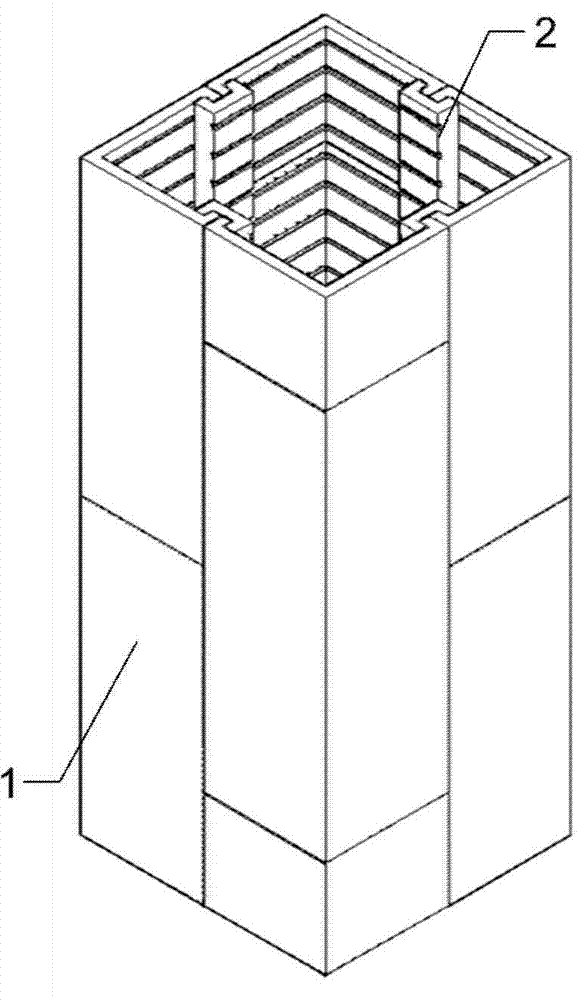

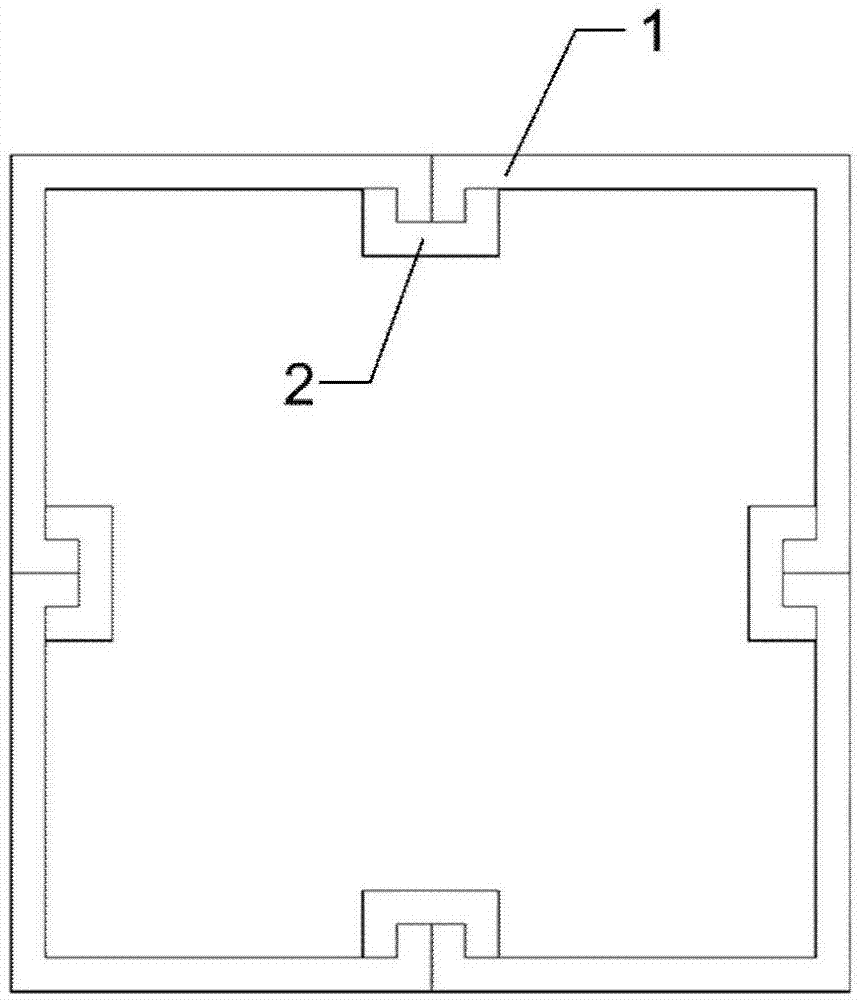

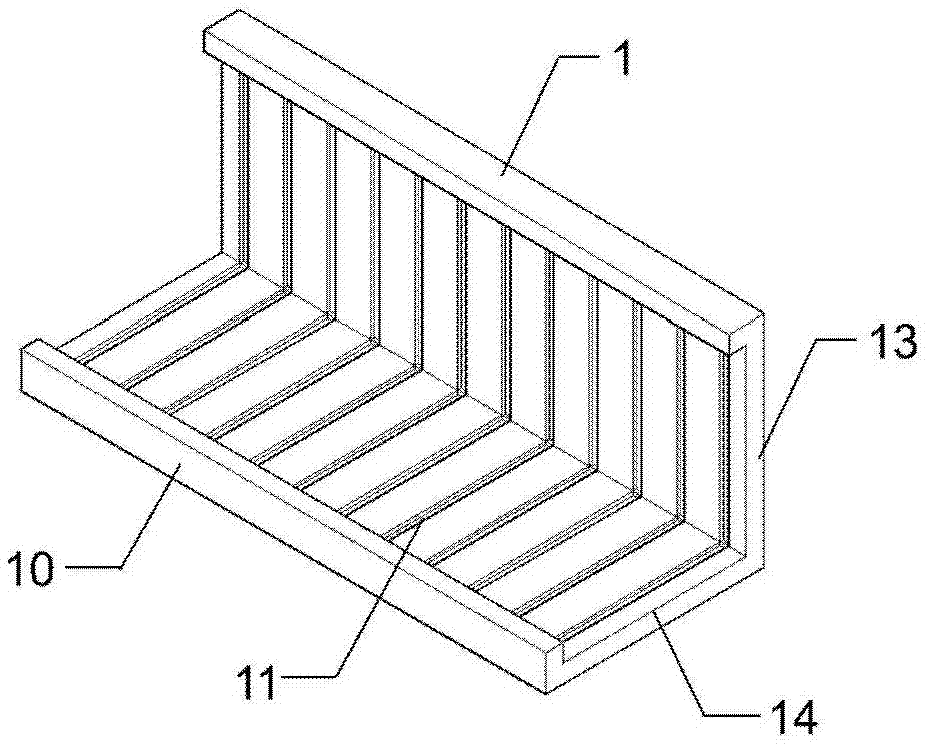

[0046] The specific implementation of the keel-embedded, crack-proof and anti-seepage permanent column formwork provided by the present invention will be further described below in conjunction with the accompanying drawings. This implementation example is an illustration of the present invention, rather than limiting the present invention.

[0047] A kind of keel-embedded buckle-type permanent column formwork that can be assembled to prevent cracking and seepage in this embodiment is connected by ten corner panels 1 and twelve connecting strips 2, and the transverse seams between the corner panels are staggered from each other, and the connecting strips are connected to each other. The joints between the corner panels and the horizontal joints between the corner panels are staggered and connected. The corner panel 1 is composed of a vertical first panel 13 and a second panel 14, and the two sides of the corner panel 1 have connecting parts 10 protruding to the inside or outside...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com