Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Reduce fatigue failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

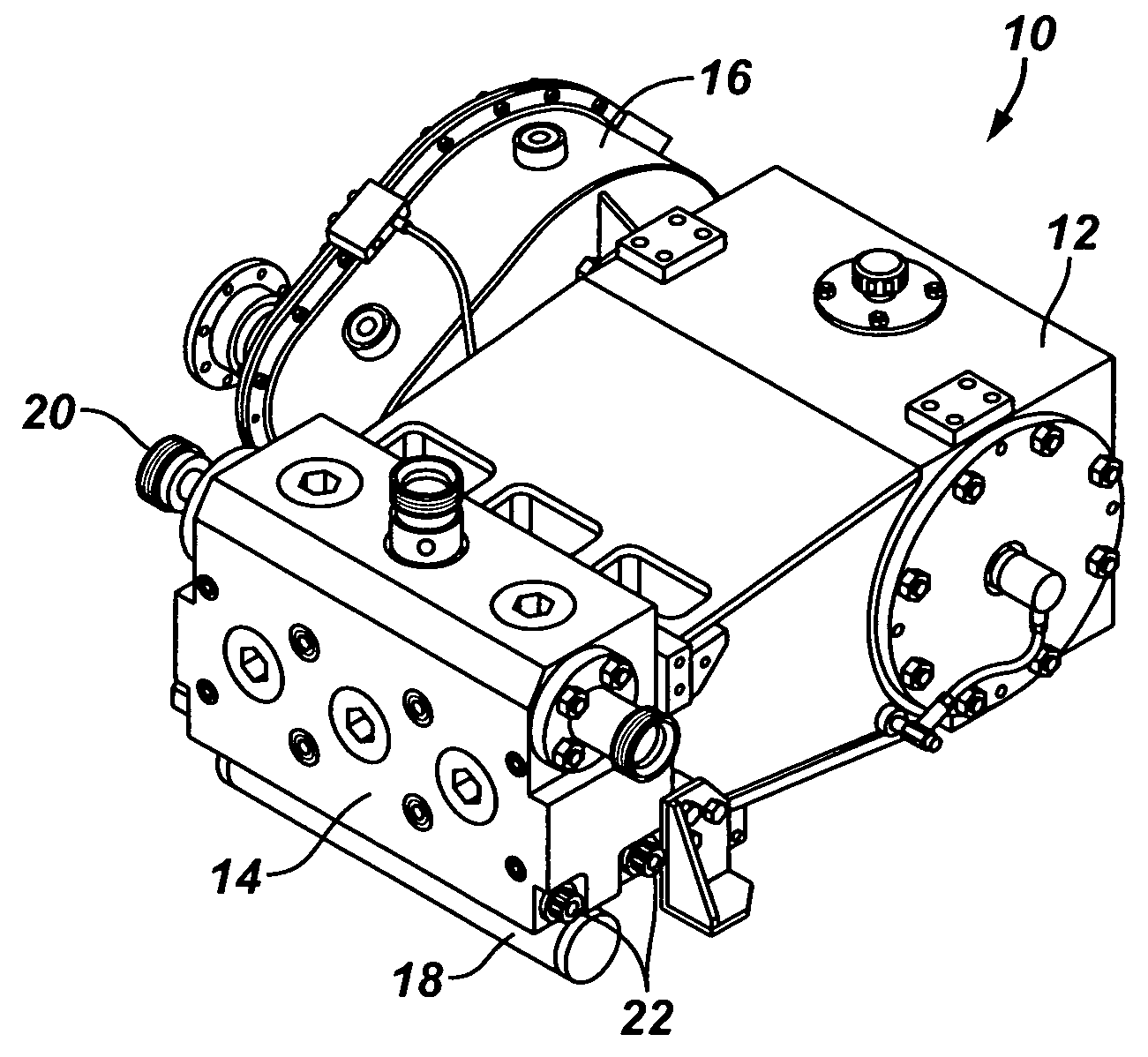

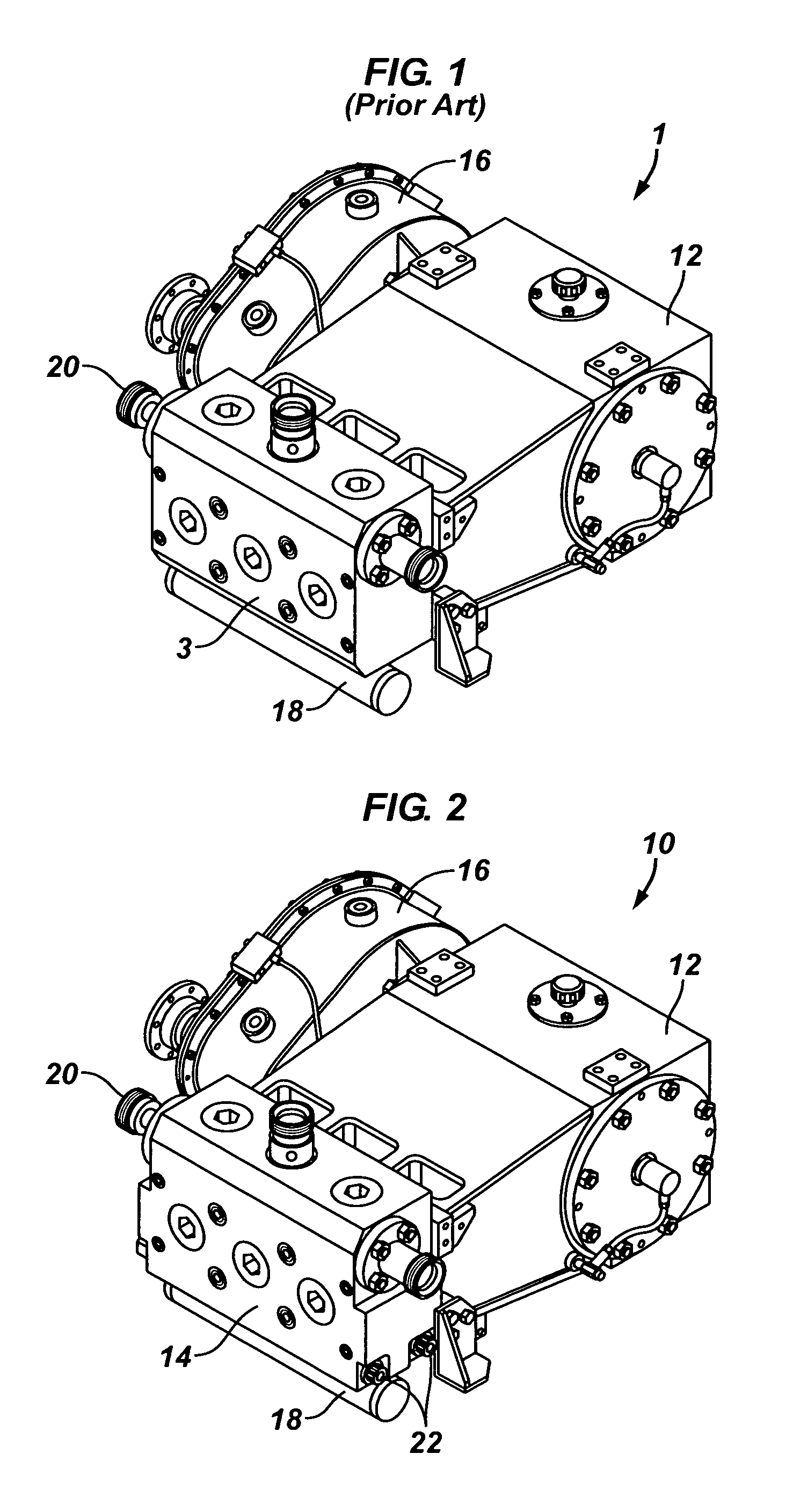

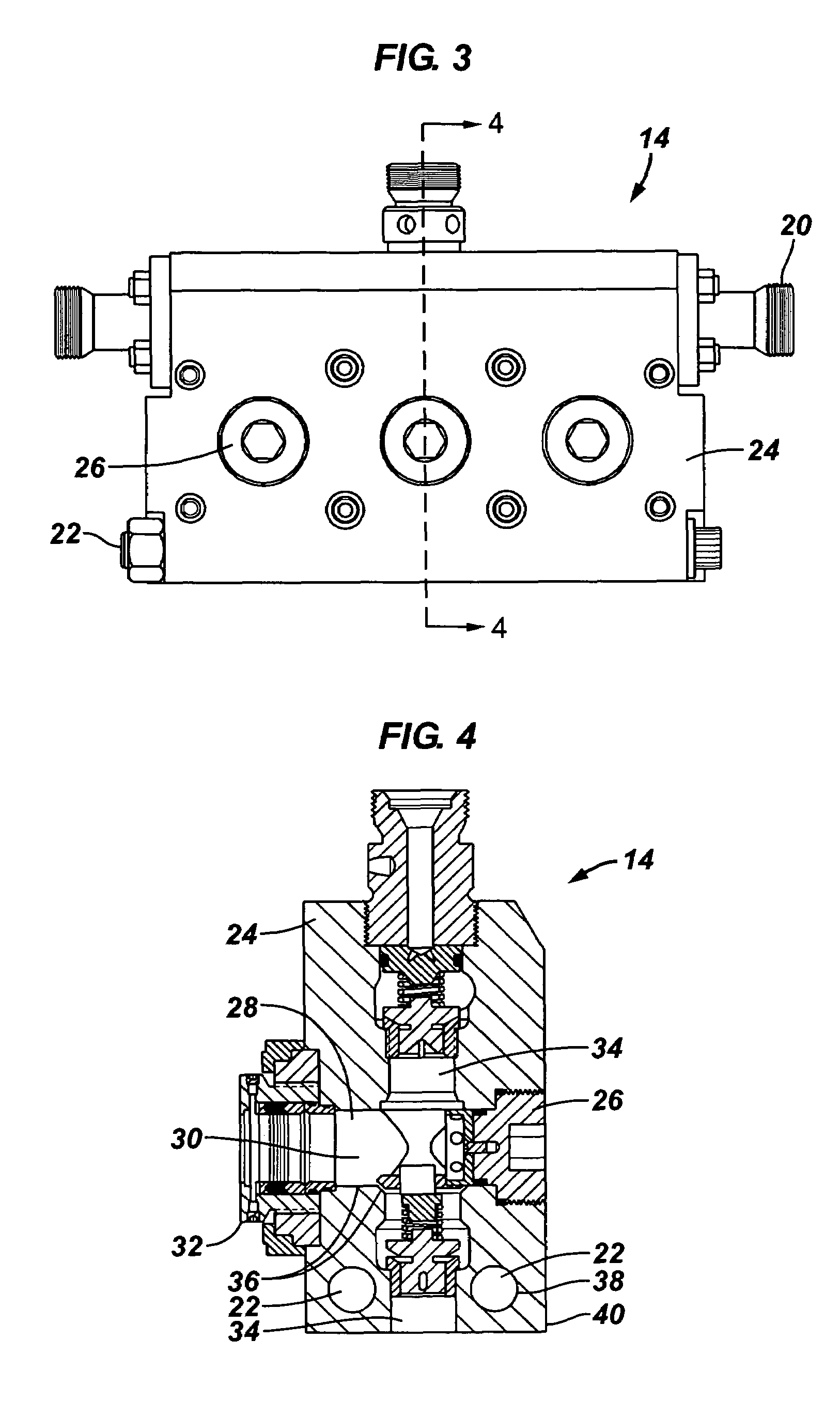

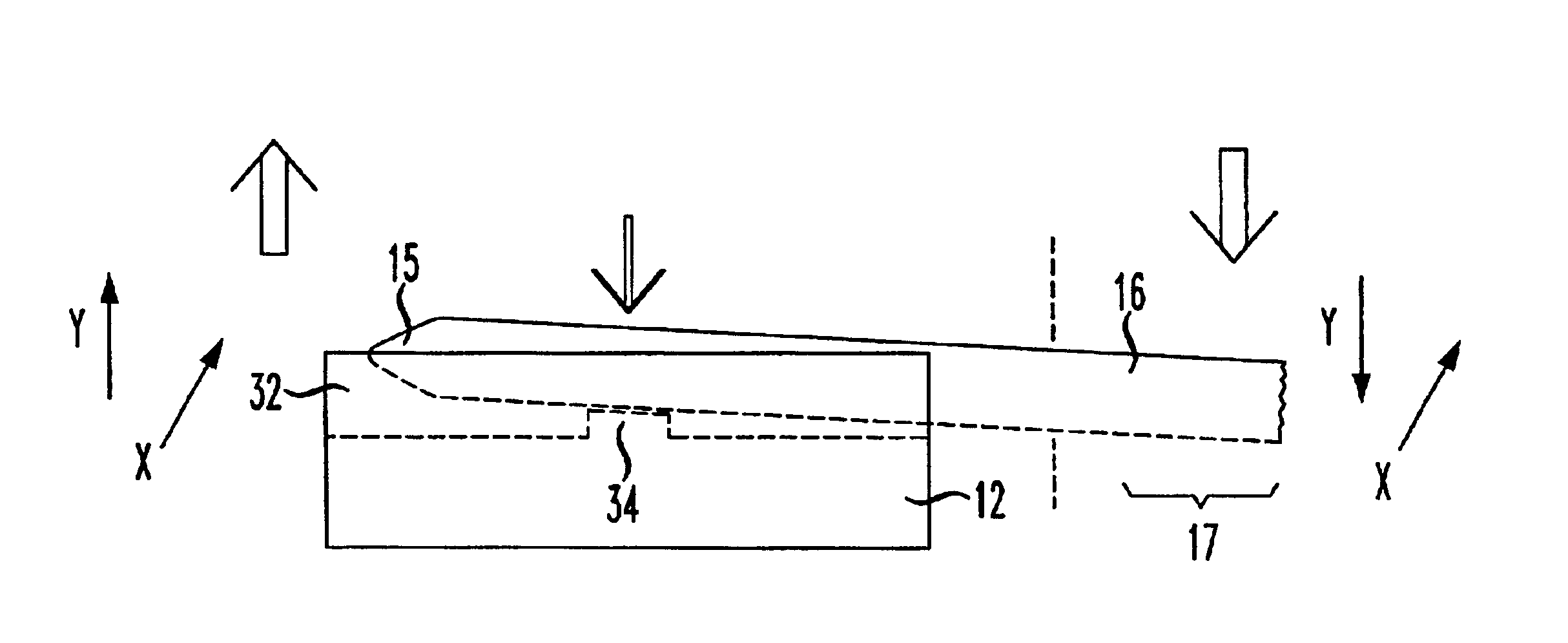

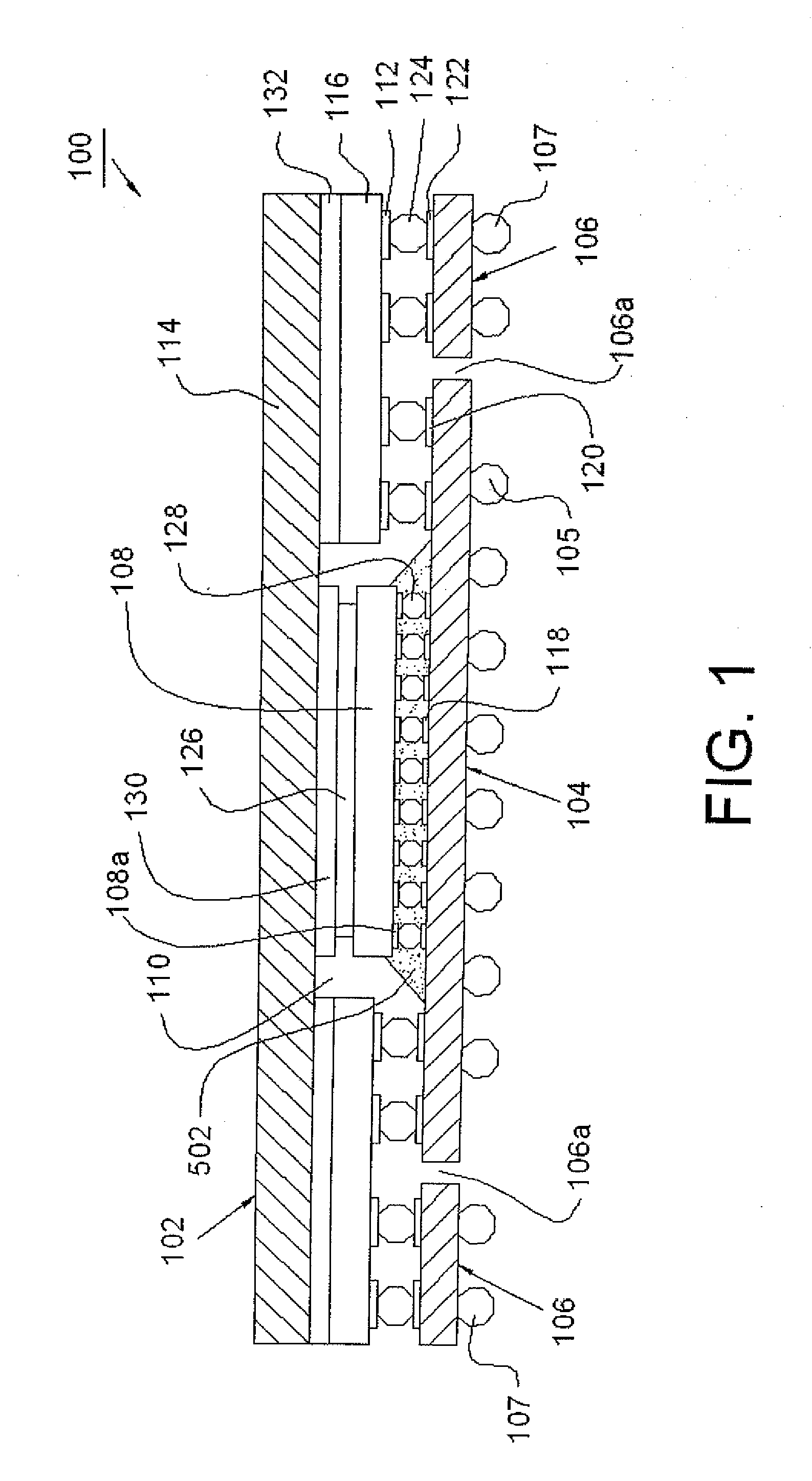

Fluid end for a plunger pump

ActiveUS7484452B2Relieve pressureReduces frequency costPositive displacement pump componentsCylindersEngineeringTension member

A fluid end for a reciprocating pump including a body having a base, a side and a longitudinal opposing side, a cylinder bore formed horizontally through the body and a vertical bore intersecting the cylinder bore defining a high stress region proximate the intersection, and a tension member extending through the body substantially parallel to the longitudinal axis of the body, wherein the tension member provides a compressive load on the body reducing the stresses encountered in the region during operation of the fluid end.

Owner:DIXIE IRON WORKS

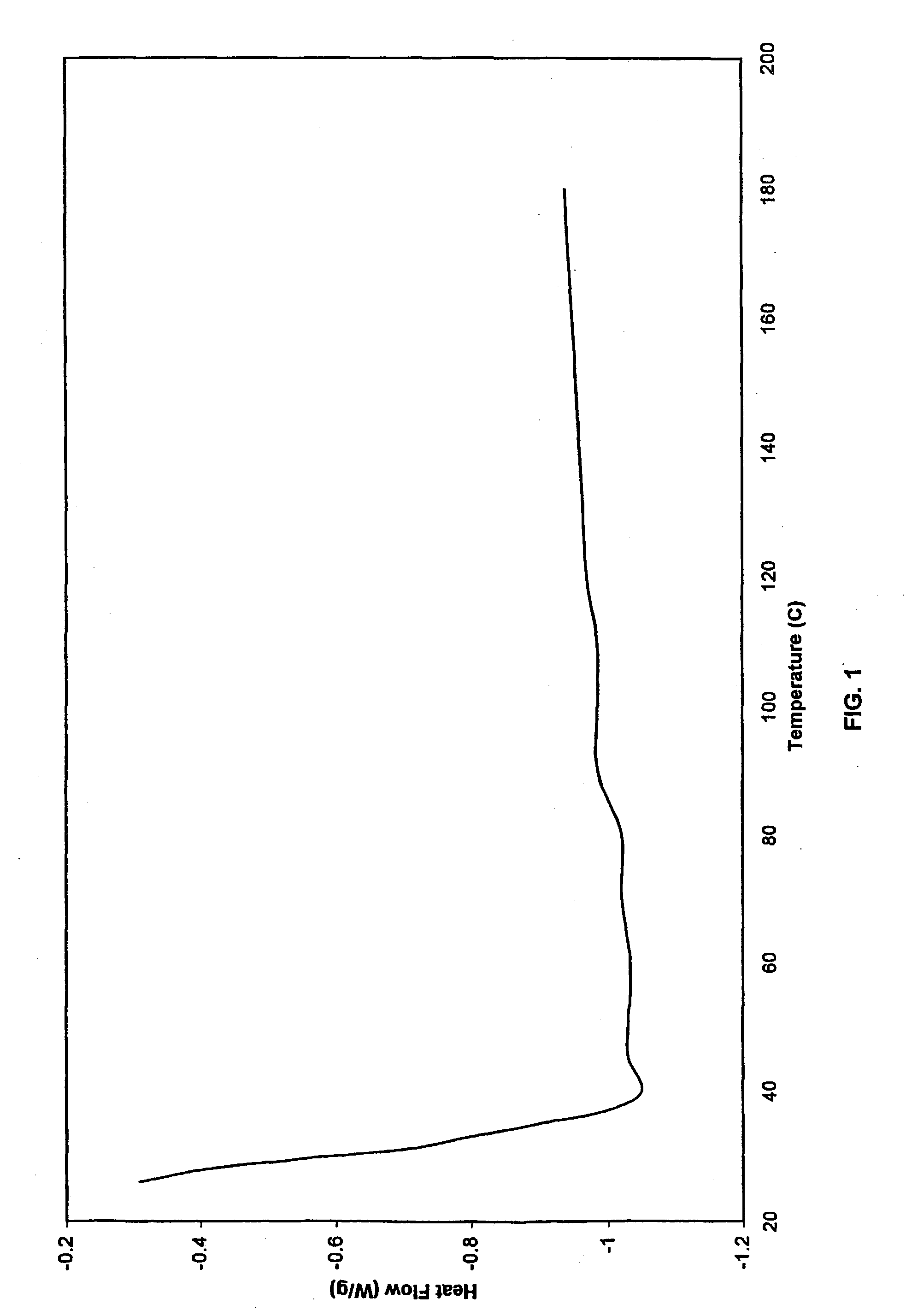

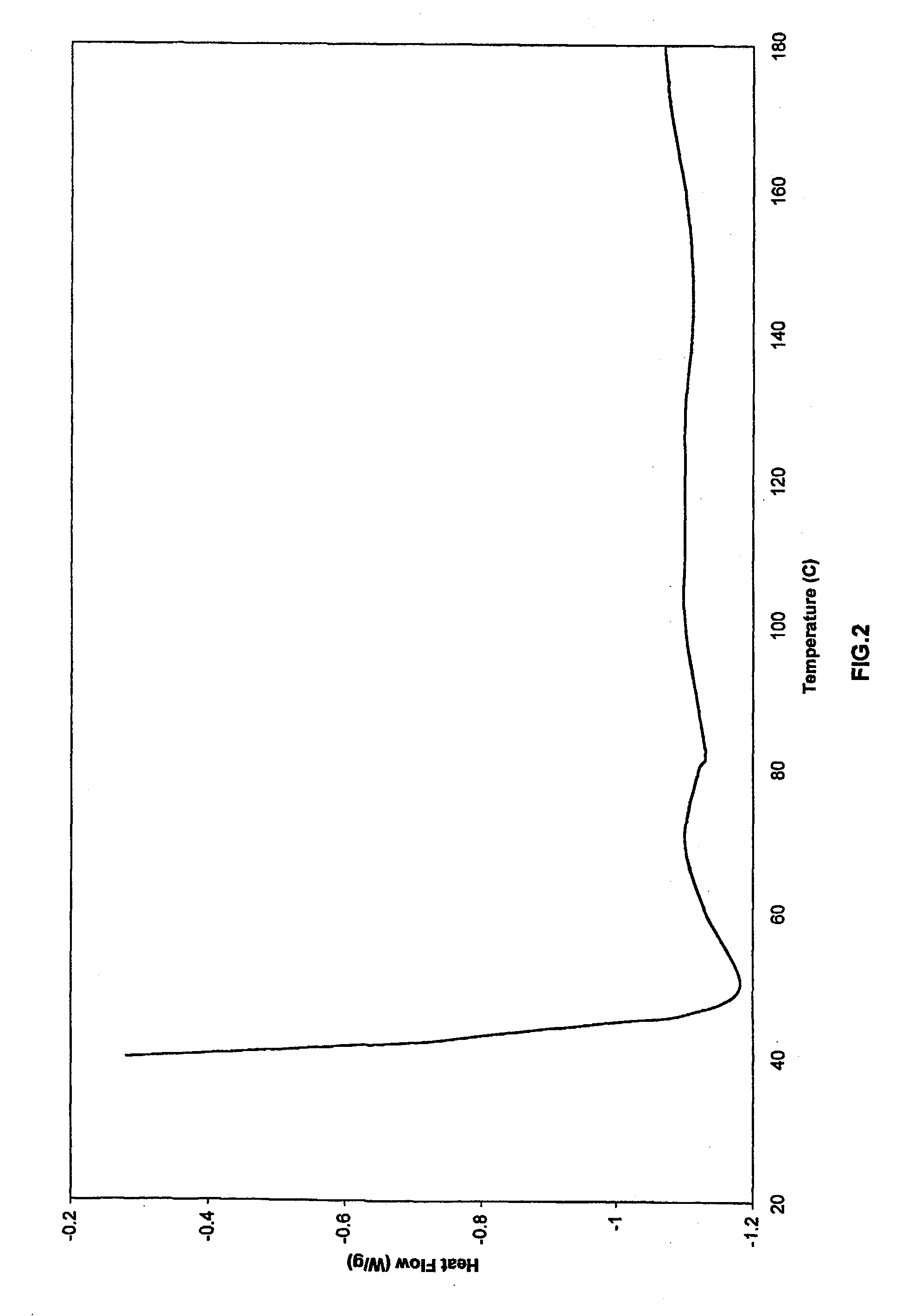

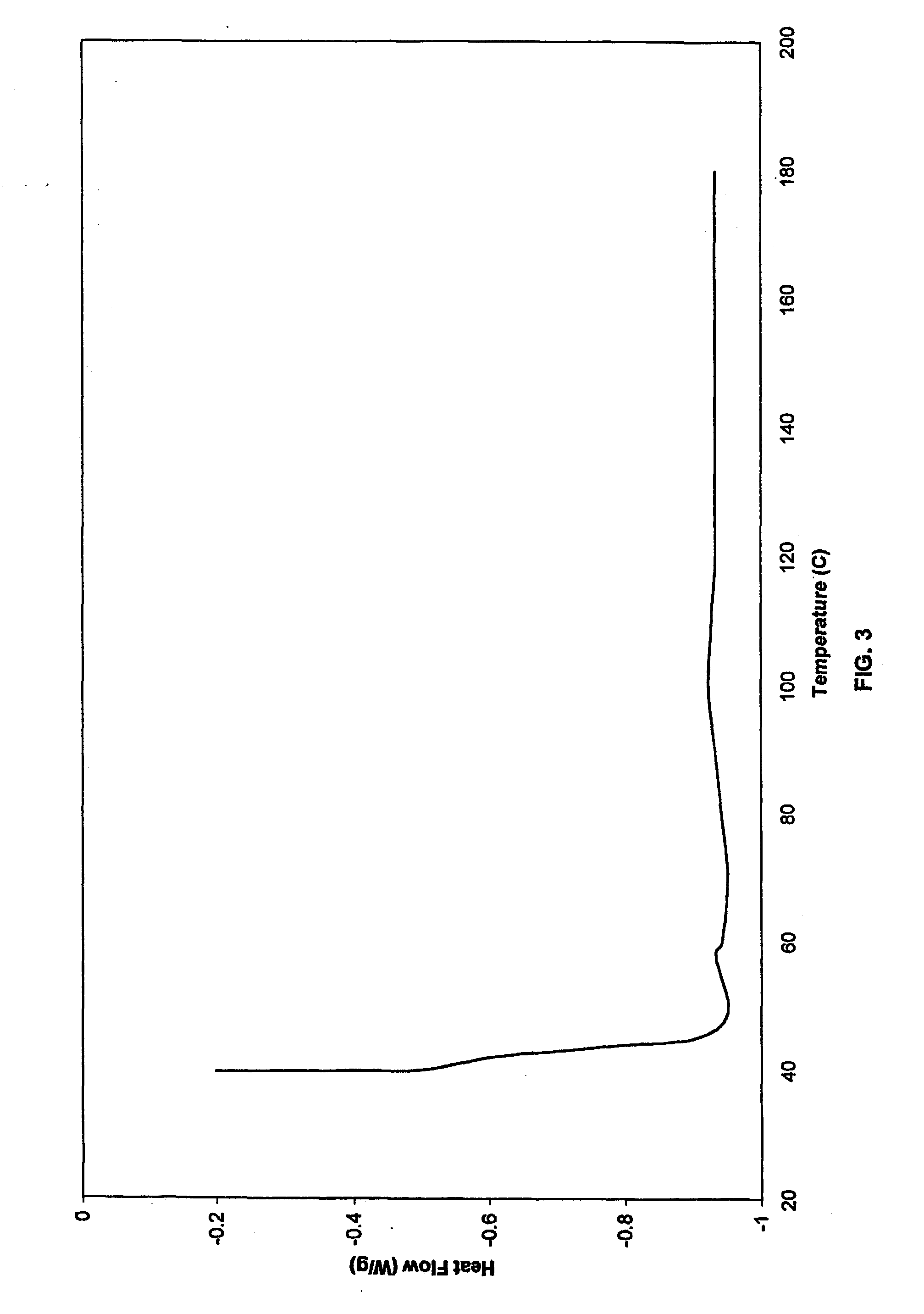

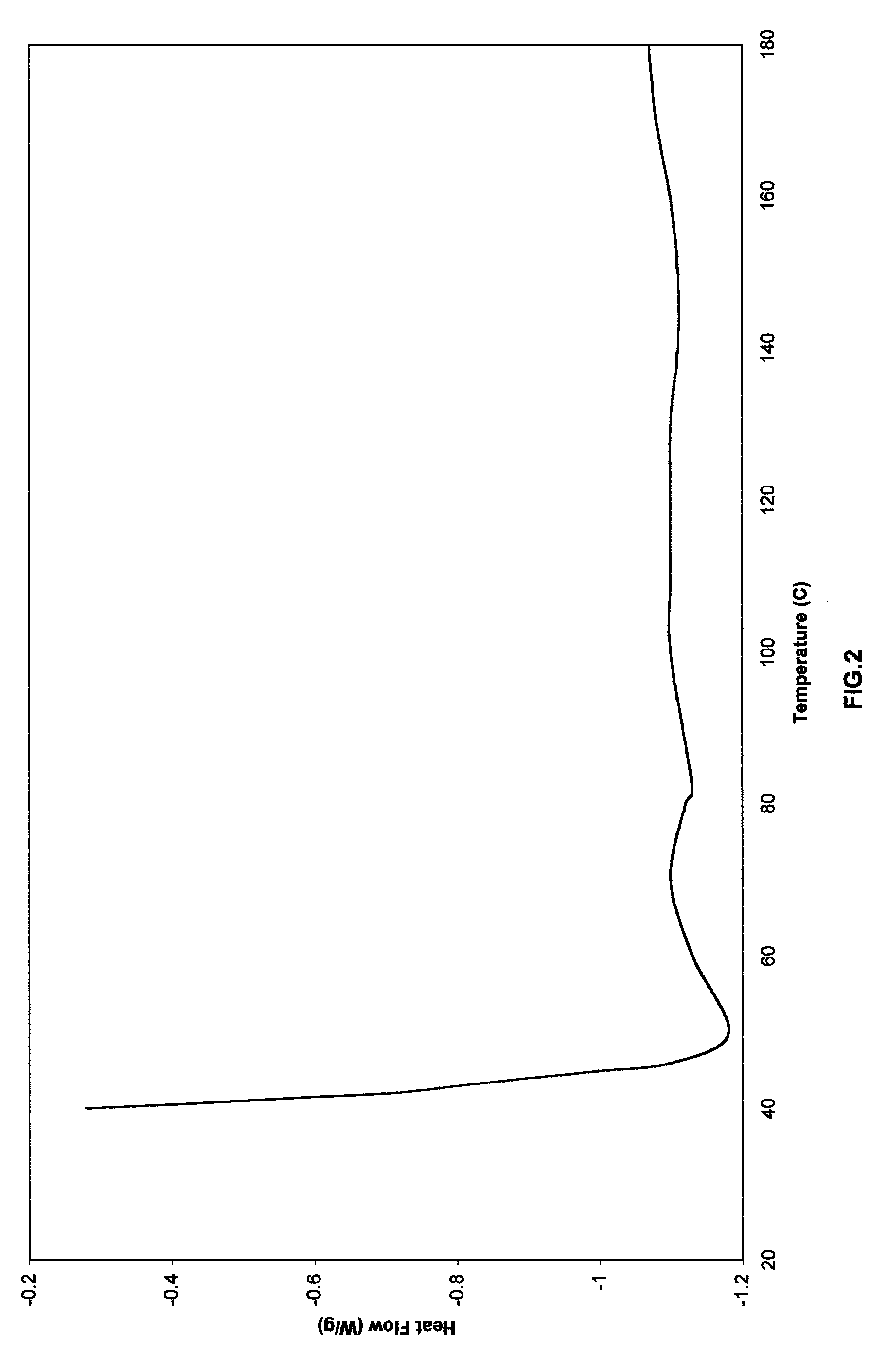

Petroleum asphalts modified by liquefied biomass additives

InactiveUS20030212168A1Increased durabilityReduce fatigue failureOrganic compound preparationCarboxylic acid esters preparationPhysical chemistryFatty acid

Liquefied biomass (16) obtained from direct liquefaction and / or fast-pyrolysis is reacted with mixtures of fatty acids (24) in the presence of an oxidizer (28) and with various reactive monomer and polymer additives (46, 48, 50) to create tailored compatibilizer-like bio-additives (34) that are compatible with petroleum asphalts. By judiciously selecting appropriate additives and additional constituent, such as non-reactive (18) and reactive diluents (30), these bio-additives can be tailored to modify low-temperature properties, high-temperature properties, compatibility with aggregate materials, application characteristics, and other properties of petroleum asphalts for paving, roofing and sealing uses.

Owner:WHITE DONALD H +1

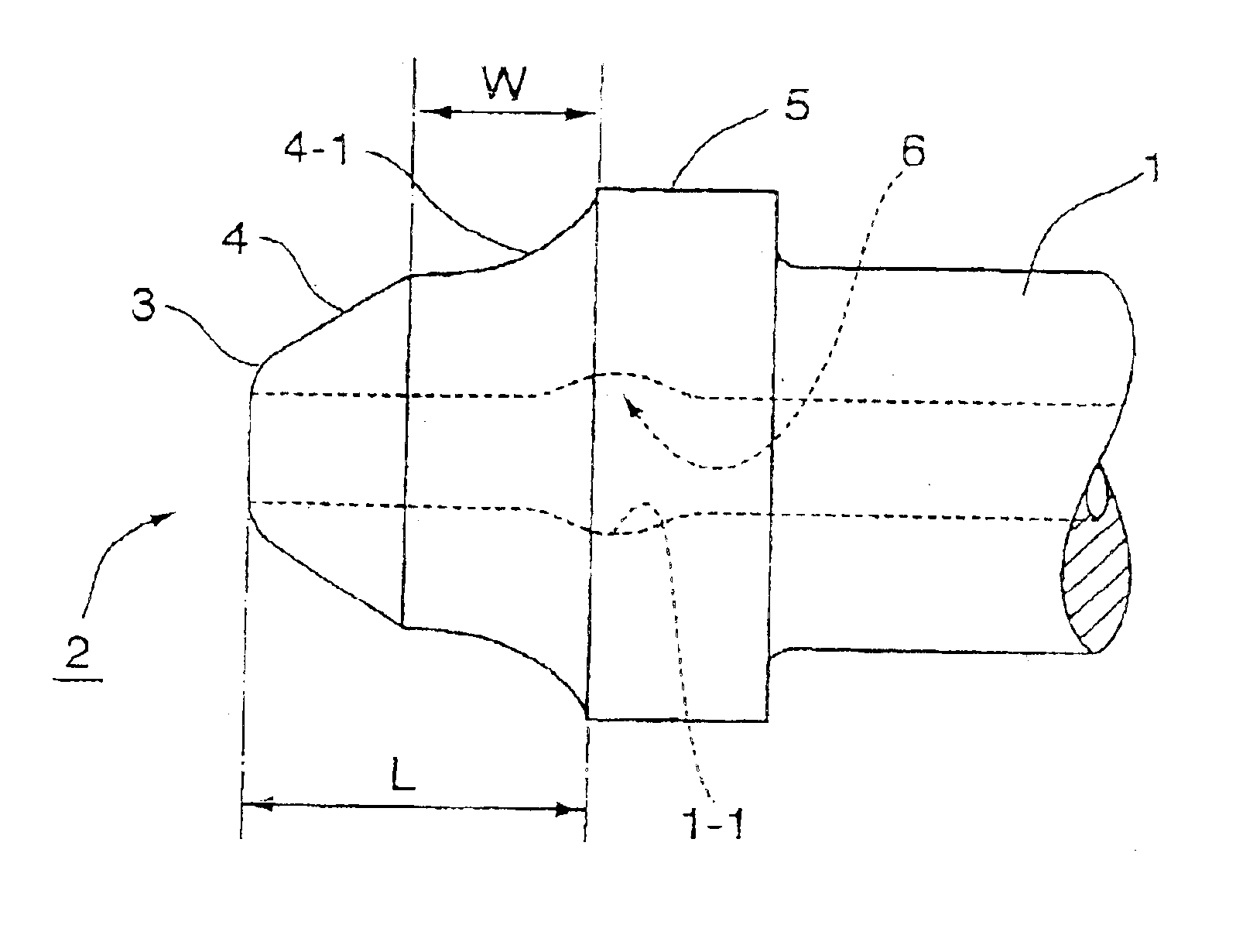

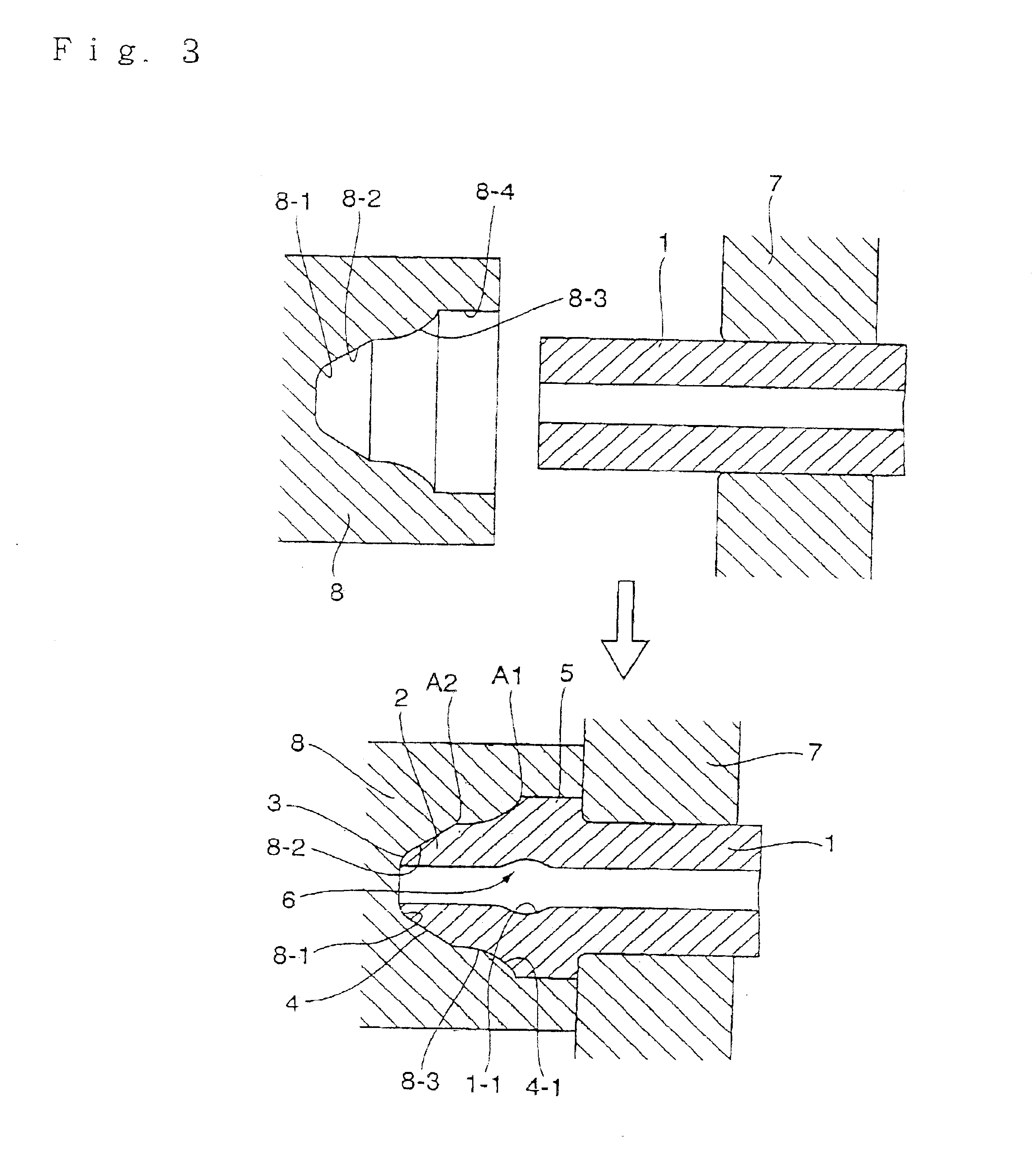

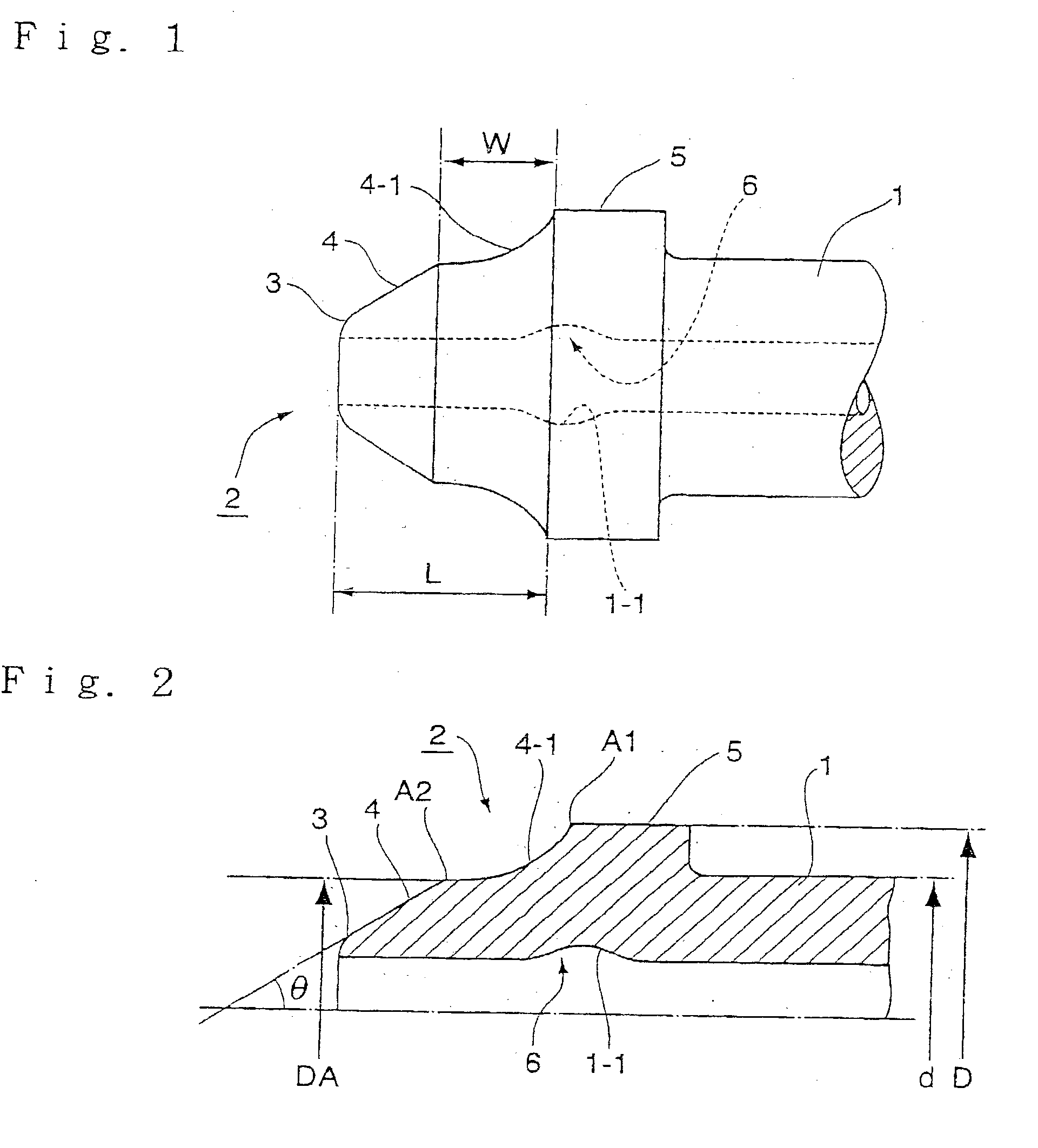

High-pressure fuel injection pipe having connecting head portion

InactiveUS6840283B2Eliminate fearReduce fatigue failureJoints with sealing surfacesMetal-working apparatusThick wallEngineering

A high-pressure fuel injection pipe having connecting head portion is provided which is capable of eliminating a fear of the occurrence of cavitation erosion of the inner surface of the connecting head portion and a fatigue failure of the same head portion by having a contour of a cross section of an annular pocket occurring in an inner part of the connecting head portion during a head portion processing operation extend shallowly and gently. This fuel injection pipe has at a connecting end portion of a thick-walled steel pipe having a relatively small diameter, including a seat surface, an annular flange formed so that the flange is axially spaced from the seat surface, and a conical surface connected to the seat surface, extending therefrom to the annular flange and tapering off to a free end of the connecting head portion, wherein the conical surface is provided at a part thereof with an annular, shallow, cross-sectionally curved recess.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

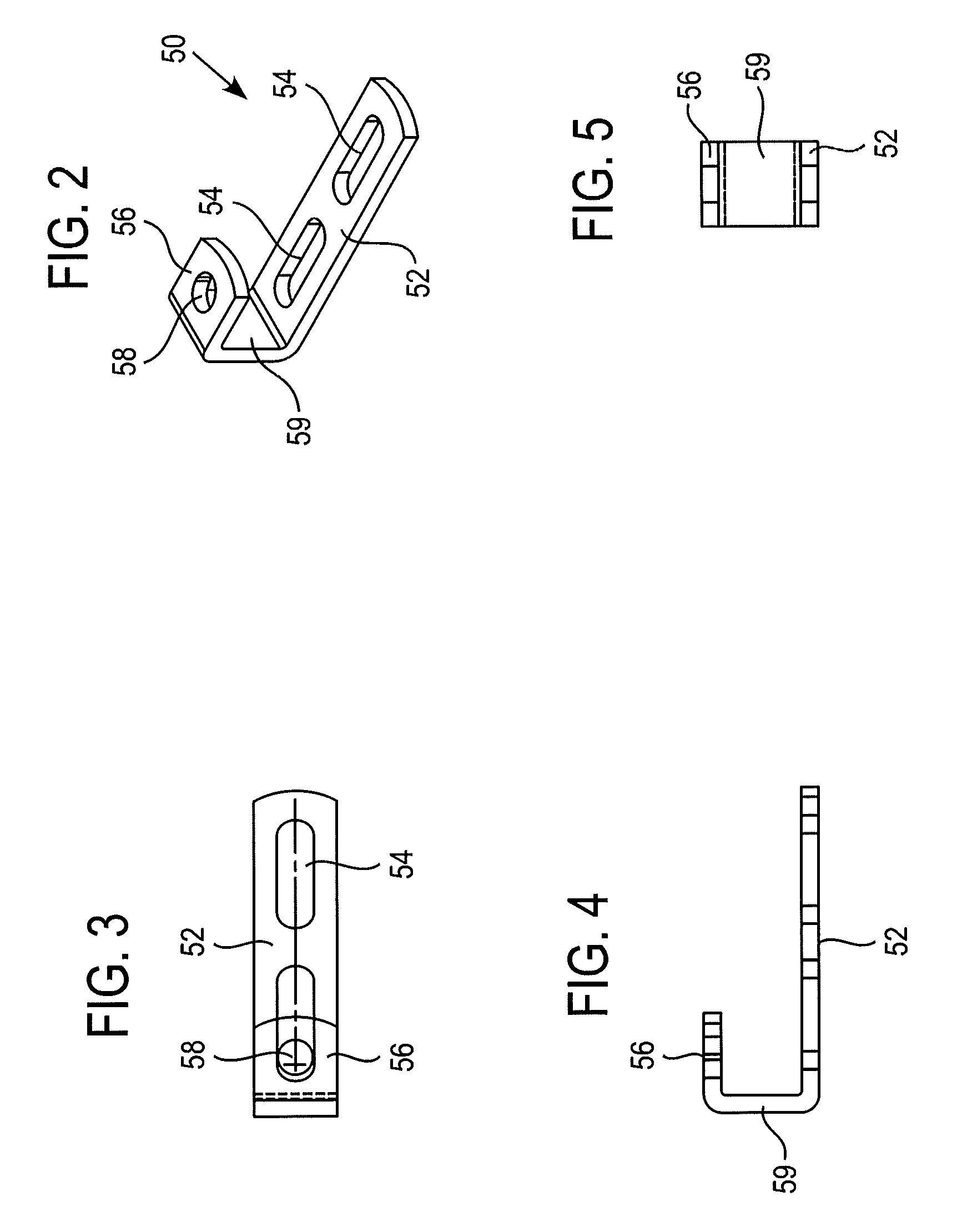

Conveyor belt with improved edge configuration

A flat wire conveyor belt having a plurality of spaced tractive rods, a plurality of rows of flat wire wickets transversely disposed with respect to a direction of travel and interconnecting the plurality of spaced tractive rods, a plurality of reinforcing bars, a plurality of belt drive clips, and a plurality of belt hold-down clips. The plurality of reinforcing bars, belt drive clips and belt hold-down clips are disposed on at least one outer edge of the flat wire conveyor belt to reduce fatigue failures on the driven edges of the conveyor belt and thereby improve the edge drive capability thereof.

Owner:CAMBRIDGE INT

Petroleum Asphalts Modified by Liquefied Biomass Additives

InactiveUS20080314294A1Increased durabilityReduce fatigue failureWorking-up pitch/asphalt/bitumen by chemical meansBuilding insulationsReactive diluentFatty acid

Liquefied biomass obtained from direct liquefaction and / or fast-pyrolysis is reacted with mixtures of fatty acids in the presence of an oxidizer and with various reactive monomer and polymer additives to create tailored compatibilizer-like bio-additives that are compatible with petroleum asphalts. By judicially selecting appropriate the additives and additional constituent, such as non-reactive and reactive diluents, these bio-additives can be tailored to modify low-temperature properties, high-temperature properties, compatibility with aggregate materials, application characteristics, and other properties of petroleum asphalts for paving, roofing and sealing uses.

Owner:WHITE DONALD H +1

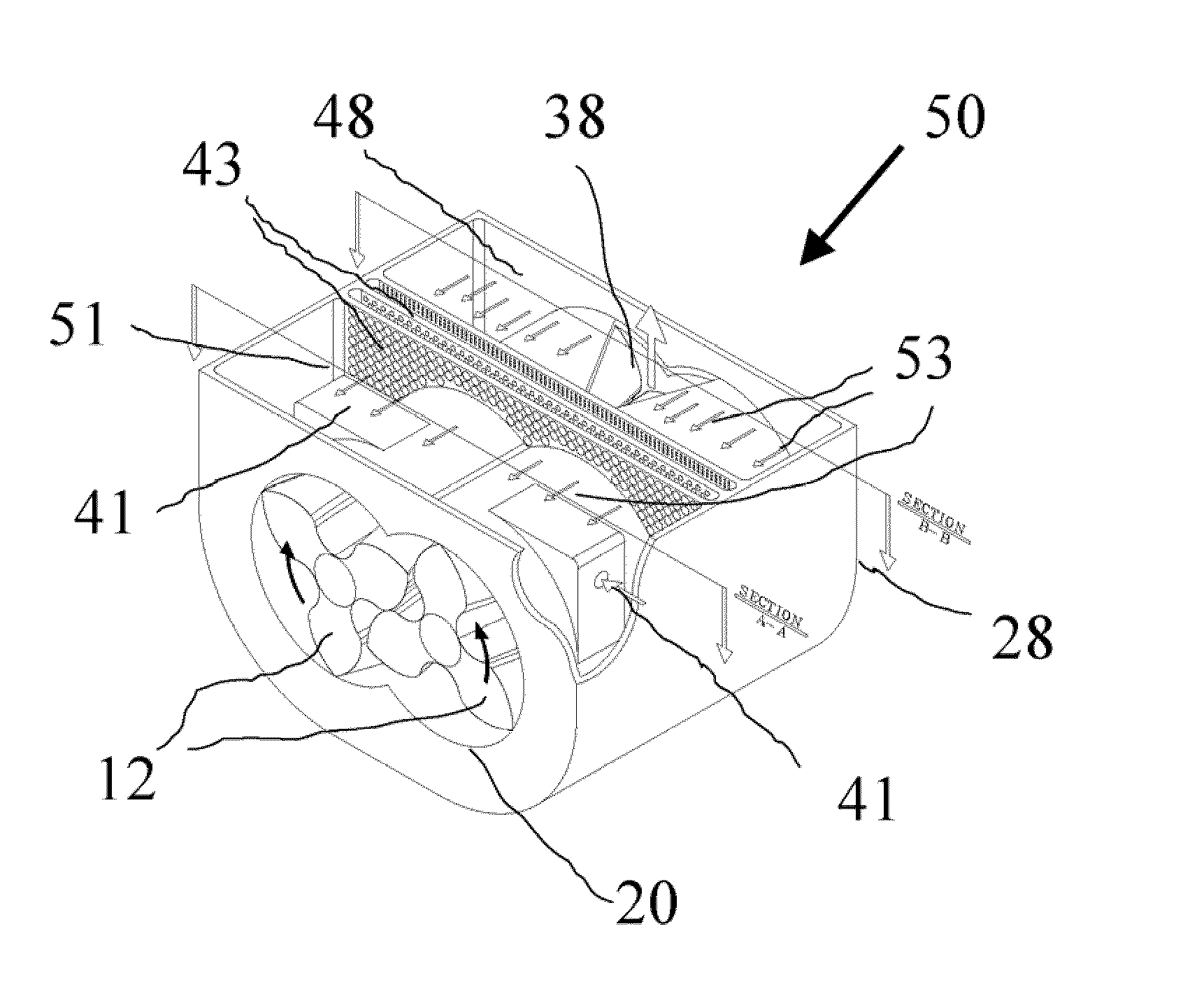

Roots supercharger with a shunt pulsation trap

InactiveUS20120020824A1Reduce weightSmall sizeOscillating piston enginesRotary piston pumpsInjection portHelical blade

A shunt pulsation trap for a Roots supercharger reduces pulsation, NVH and improves efficiency without significantly increasing overall size of the supercharger. Generally, a Roots supercharger with the shunt pulsation trap has a pair of interconnected and synchronized parallel multi-helical-lobe rotors housed in a transfer chamber with the same number of lobes for propelling flow from a suction port to a discharge port of the transfer chamber without internal compression. The shunt pulsation trap comprises an inner casing as an integral part of the transfer chamber, and an outer casing oversized surrounding the inner casing, therein housed various pulsation dampening means or pulsation energy recovery means or pulsation containment means, at least one injection port (trap inlet) branching off from the transfer chamber into the pulsation trap chamber and a feedback region (trap outlet) communicating with the supercharger outlet pressure.

Owner:HUANG PAUL XIUBAO +1

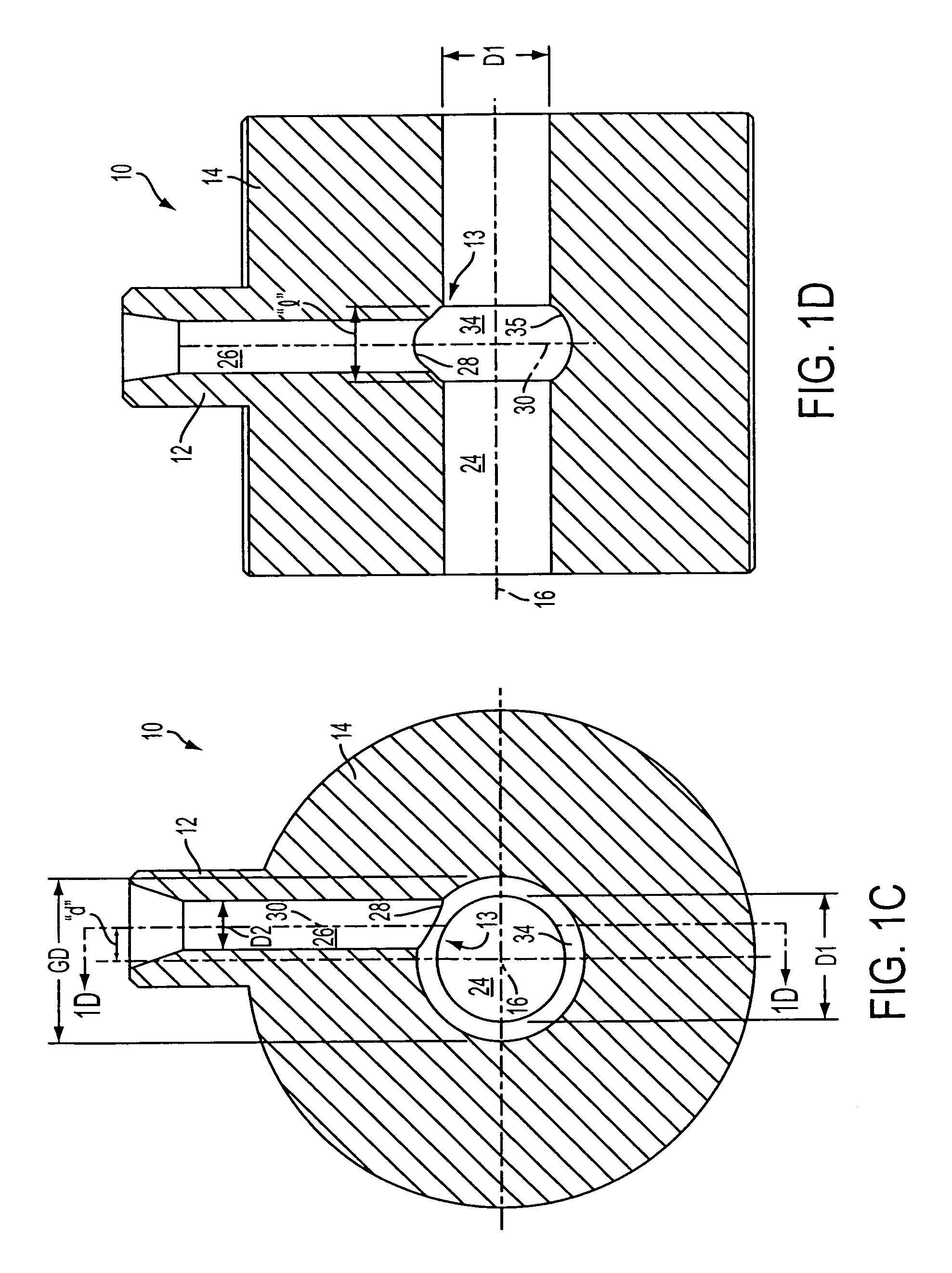

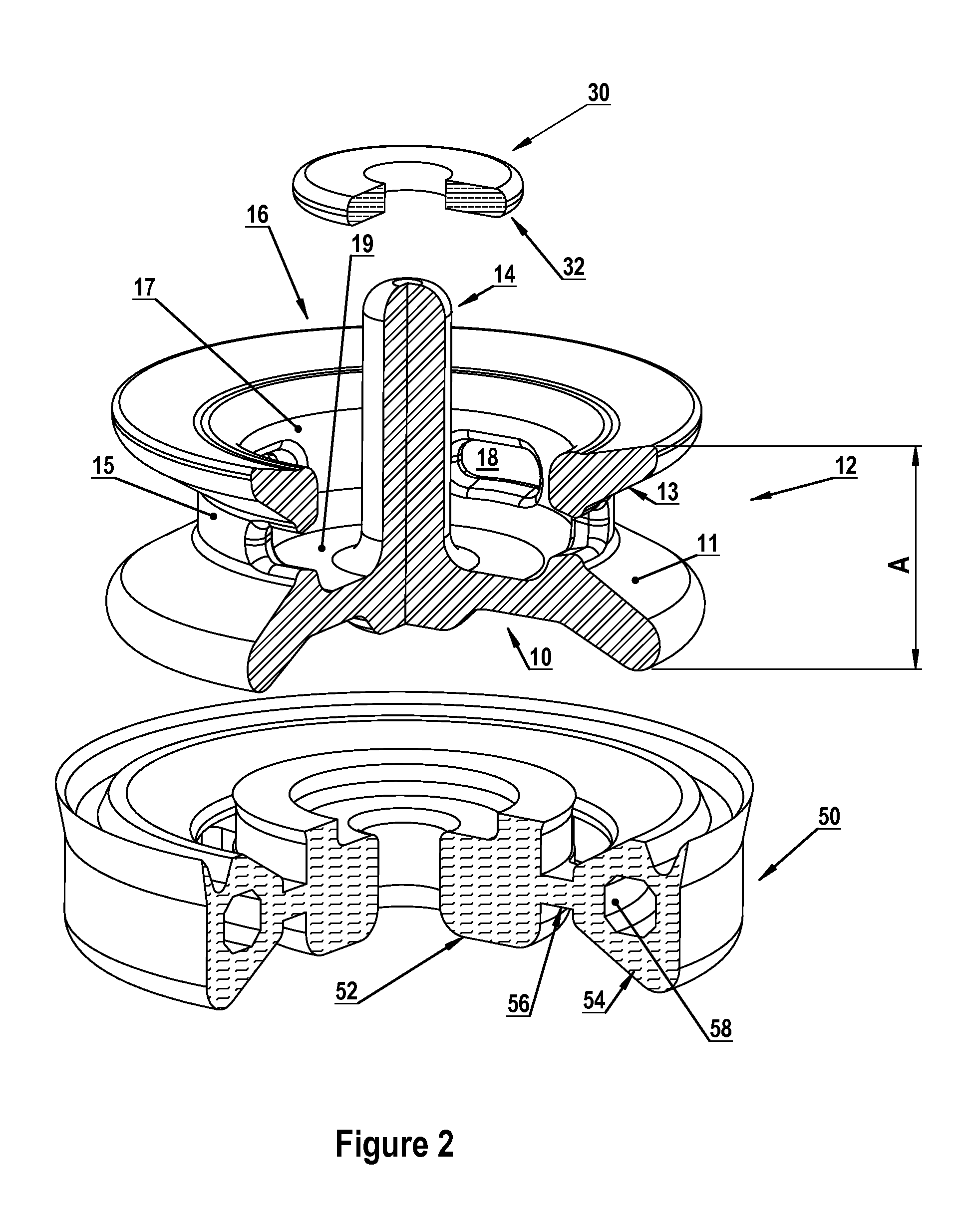

Juncture for a high pressure fuel system

ActiveUS20050144558A1Reducing likelihood of fatigue failureReduce fatigue failureLow pressure fuel injectionMachines/enginesEngineeringFuel pump

A juncture and method for changing direction of fuel flow in a high pressure fuel injection system such as a common rail and / or a fuel pump, the juncture comprising a body, a first passage formed in the body having a first diameter and a longitudinal axis extending therethrough, the first passage including a groove positioned along a portion of the longitudinal axis, and a second passage formed in the body having a second diameter, a central axis extending therethrough, and an opening, the opening of the second passage being provided in the groove of the first passage to allow fluidic communication between the second passage and the first passage so that stresses at the juncture caused by high pressure fuel changing direction of flow is reduced.

Owner:CUMMINS INC

High-pressure fuel injection pipe having connecting head portion

InactiveUS20030230349A1Eliminate fearReduce fatigue failureJoints with sealing surfacesMetal-working apparatusThick wallHigh pressure

A high-pressure fuel injection pipe having connecting head portion is provided which is capable of eliminating a fear of the occurrence of cavitation erosion of the inner surface of the connecting head portion and a fatigue failure of the same head portion by having a contour of a cross section of an annular pocket occurring in an inner part of the connecting head portion during a head portion processing operation extend shallowly and gently. This fuel injection pipe has at a connecting end portion of a thick-walled steel pipe having a relatively small diameter, including a seat surface, an annular flange formed so that the flange is axially spaced from the seat surface, and a conical surface connected to the seat surface, extending therefrom to the annular flange and tapering off to a free end of the connecting head portion, wherein the conical surface is provided at a part thereof with an annular, shallow, cross-sectionally curved recess.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

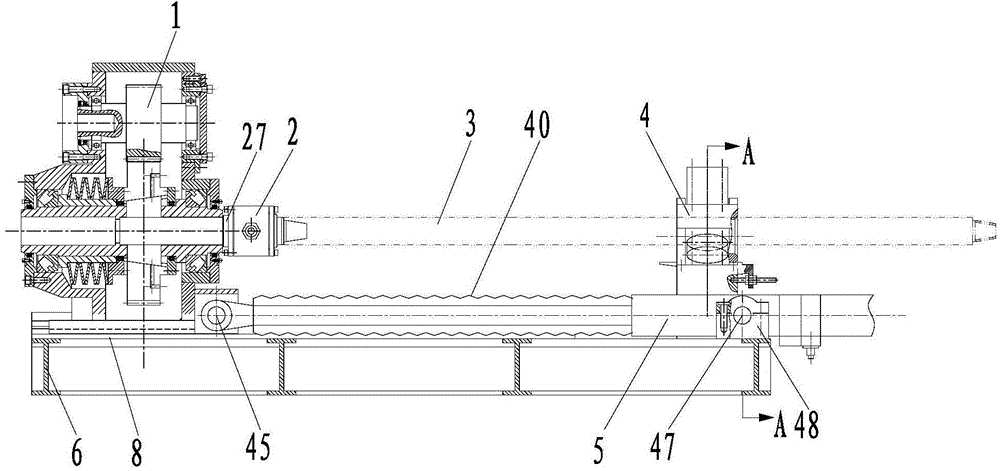

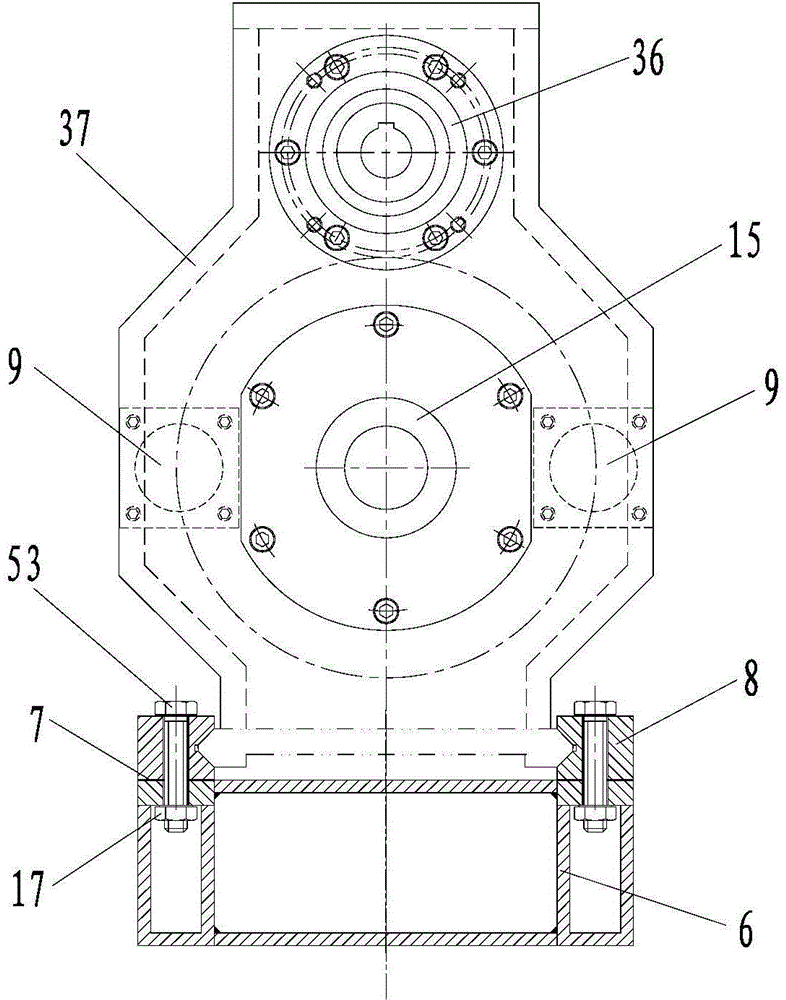

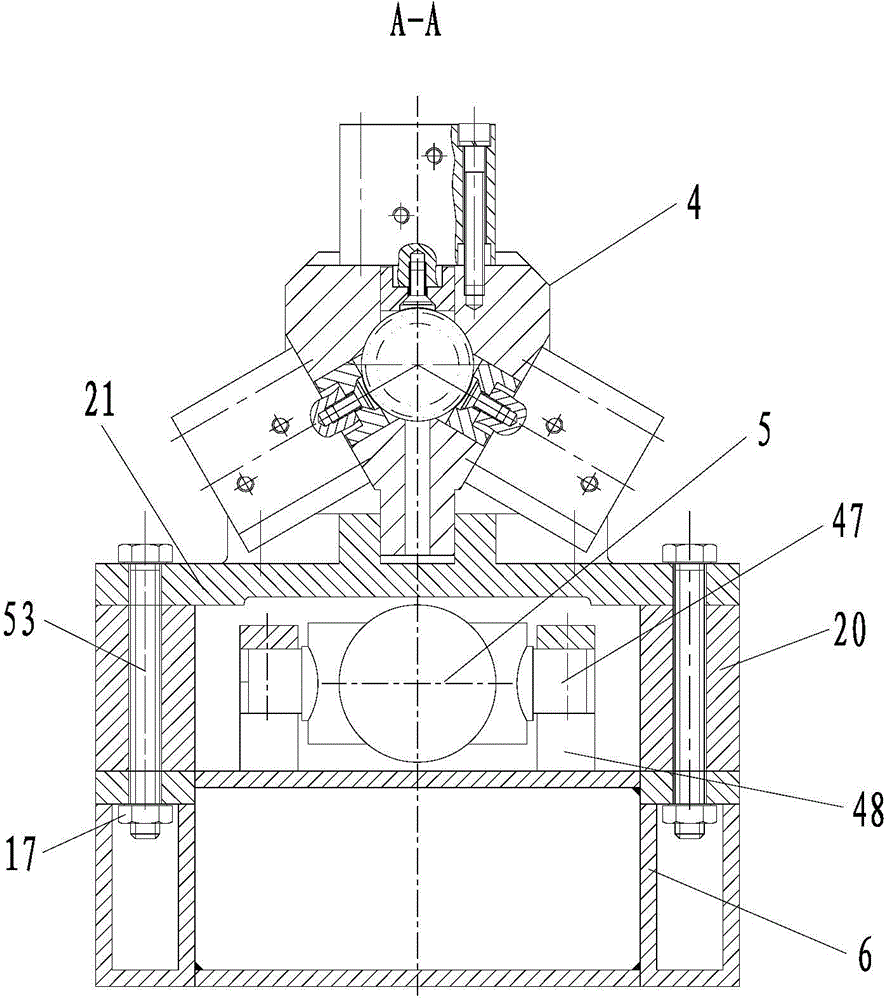

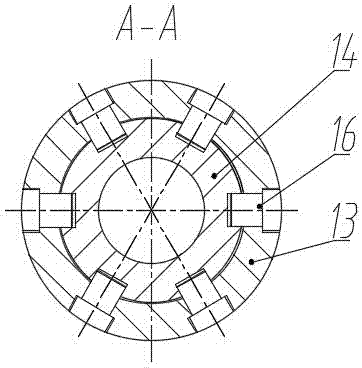

Light-type full-hydraulic drilling machine for underground drilling of coal mine

The invention discloses a light-type full-hydraulic drilling machine for underground drilling of a coal mine. The light-type full-hydraulic drilling machine comprises a stander, a drilling rod, a water braid, a guide rail, a propelling hydraulic cylinder, a hydraulic clamp and a drill power head, wherein the hydraulic clamp comprises a clamp base, a supporting seat, a clamping hydraulic cylinder and a clamp clamping tile; the water braid comprises a water braid shell, a water braid shaft, a water braid hollow shaft, two anti-abrasion ring, an isolating ring, a front end cover, a rear end cover and an anti-abrasion sealing ring; the drill power head comprises a speed reduction box body, a connection frame, a gear shaft, a hollow stepped shaft, a hydraulic motor, a spring mounting seat, a spring limiting seat, an end face check ring, a gear, a disk-type spring group, a power head clamping tile and a clamping hydraulic cylinder. The light-type full-hydraulic drilling machine is compact in structure, convenient and low in cost; the energy consumption is reduced, the power transmission efficiency is improved, and the clamping force on the drilling rod is stable and reliable; the service lives of the anti-abrasion sealing ring and the water braid shaft can be prolonged, the replacement trouble is reduced, the construction progress and safe production are guaranteed, vibration of the drilling machine is reduced, and the drilling rod is prevented from being broken.

Owner:XIAN UNIV OF SCI & TECH

Mechanical multidirectional absorber

InactiveCN101608535AEliminate or reduce shock loadsChange natural frequencyDrilling rodsDrilling casingsElastomerVibration attenuation

A mechanical multidirectional absorber relates to the field of oil and gas well projects and geological exploration drilling and comprises an upper joint. The lower end of the upper joint is connected with a mandrel which comprises a large-outer-diameter mandrel, a medium-outer-diameter mandrel and a small-outer-diameter mandrel. A mud scraping ring seat, a stabilizing cylinder, a spline cylinder and a guide cylinder are arranged outside the mandrels. The stabilizing cylinder comprises a large-inner-diameter stabilizing cylinder and a small-inner-diameter stabilizing cylinder. An upper hydraulic chamber is arranged between the medium-outer-diameter mandrel and the large-inner-diameter stabilizing cylinder. A damping ring gap is arranged between the medium-outer-diameter mandrel and the small-inner-diameter stabilizing cylinder. A piston, a thrust bearing and an upper elastomer are arranged between the mandrel and the spline cylinder as well as the guide cylinder. The piston comprises a piston body and a piston joint. The piston body comprises a large-inner-diameter piston body and a small-inner-diameter piston body and is provided with a torque transforming mechanism. A lower hydraulic chamber is arranged between the small-outer-diameter mandrel and the large-inner-diameter piston body. A guide rod is connected with the lower end of the mandrel. A lower elastomer and a lower joint are arranged between the guide rod and the guide cylinder. The lower joint is connected with the lower end of the guide cylinder. The mechanical multidirectional absorber integrates the functions of damping, vibration attenuation and vibration isolation and has good safety.

Owner:YANGZHOU TIANYE GASOLINEEUM MACHINERY

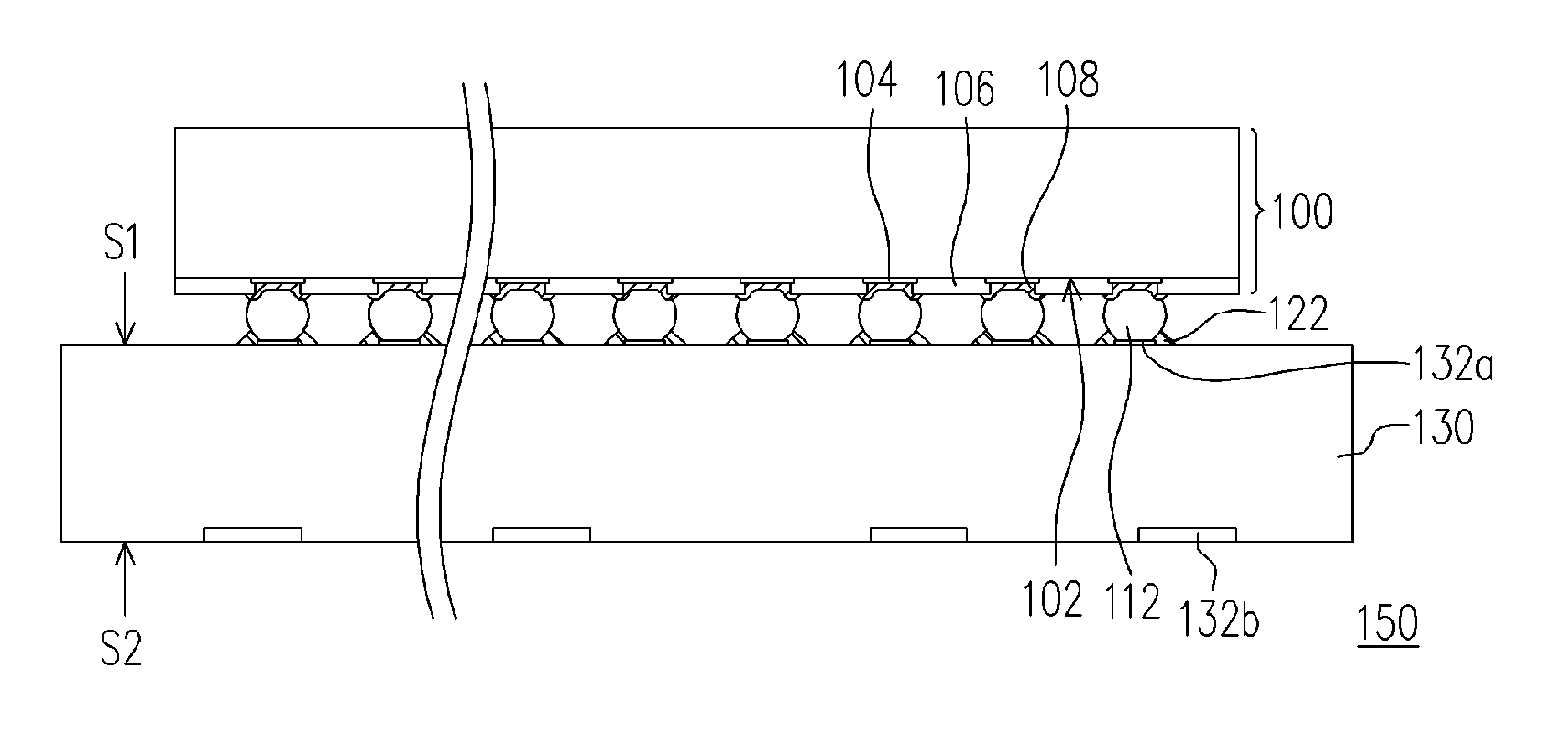

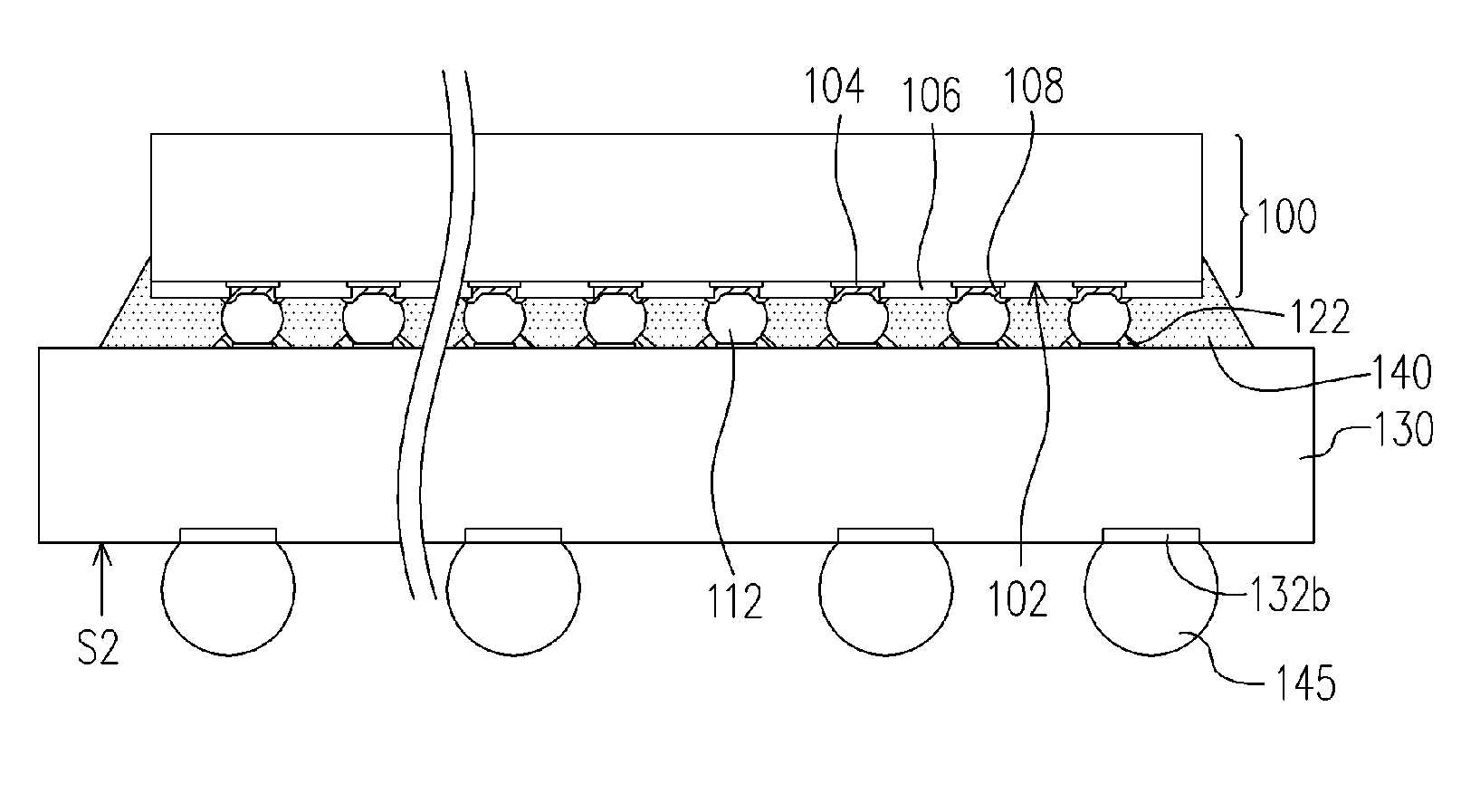

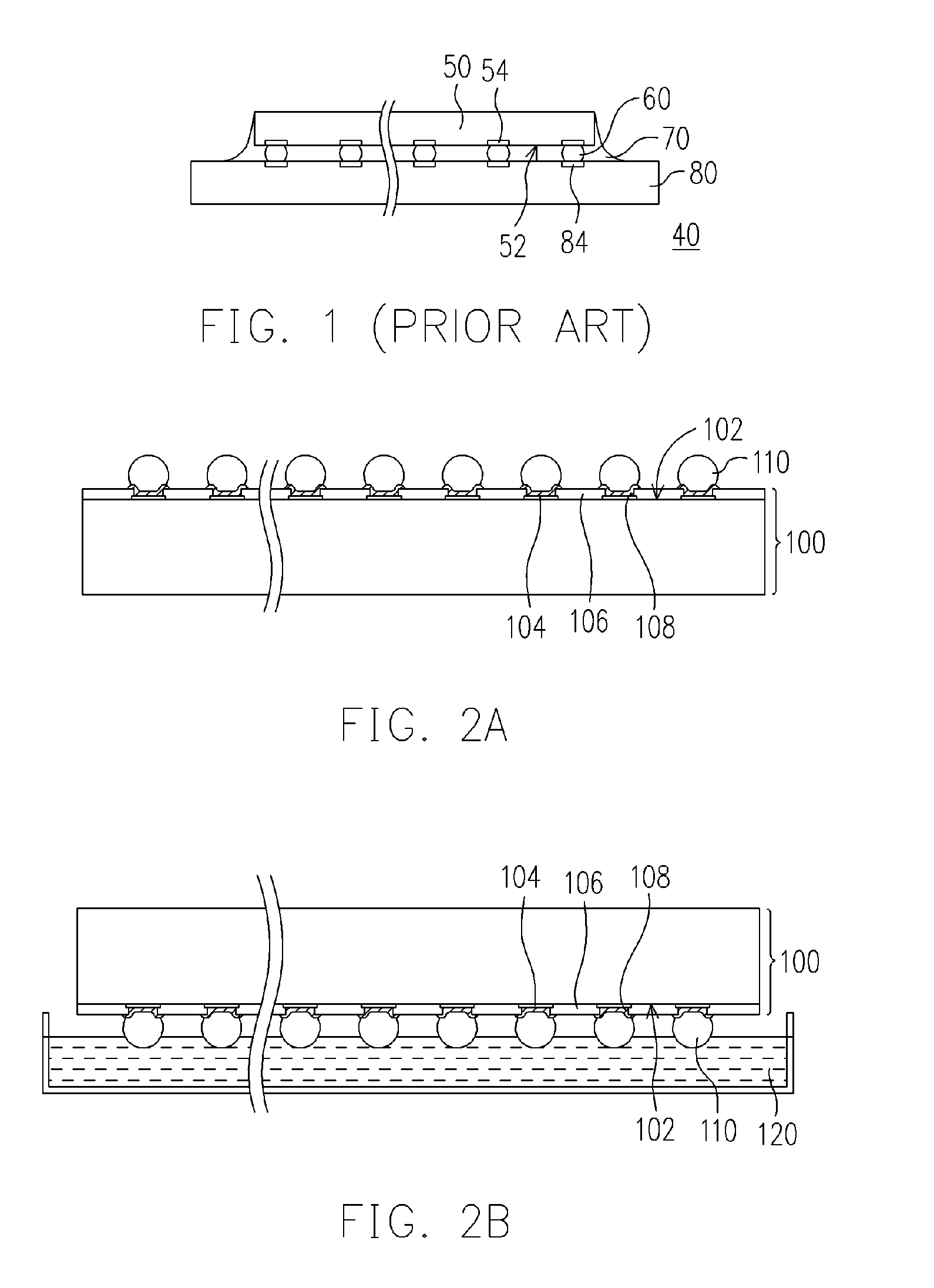

Chip package structure and process for fabricating the same

ActiveUS20060024863A1Reduce fatigue failureImprove tolerancePrinted circuit assemblingFinal product manufactureManufacturing technologyEngineering

A process for fabricating a chip package structure with the following steps is provided. First, a chip having an active surface is provided. A plurality of solder bumps is disposed on the active surface. Then, a polymer material including flux is placed on the surface of the solder bumps by a dipping process. The chip is disposed on a carrier such that the carrier is in contact with the solder bumps. A reflow process is carried out so that the chip and the carrier are electrically connected through the solder bumps and a plurality of supporting structures made from the polymer material are formed around the junctions between the solder bumps and the carrier. The supporting structures enhance the endurance of the solder bumps to thermal stress and reduce damage due to fatigue.

Owner:ADVANCED SEMICON ENG INC

Process for fabricating chip package structure

ActiveUS20070259481A1Reduce fatigue failureImprove tolerancePrinted circuit assemblingFinal product manufactureActive surfacePolymer

A process for fabricating a chip package structure with the following steps is provided. First, a chip having an active surface is provided. A plurality of solder bumps is disposed on the active surface. Then, a polymer material including flux is placed on the surface of the solder bumps by a dipping process. The chip is disposed on a carrier such that the carrier is in contact with the solder bumps. A reflow process is carried out so that the chip and the carrier are electrically connected through the solder bumps and a plurality of supporting structures made from the polymer material are formed around the junctions between the solder bumps and the carrier. The supporting structures enhance the endurance of the solder bumps to thermal stress and reduce damage due to fatigue.

Owner:ADVANCED SEMICON ENG INC

Chip package structure

ActiveUS7262510B2Reduce fatigue failureImprove tolerancePrinted circuit assemblingFinal product manufactureActive surfacePolymer

A process for fabricating a chip package structure with the following steps is provided. First, a chip having an active surface is provided. A plurality of solder bumps is disposed on the active surface. Then, a polymer material including flux is placed on the surface of the solder bumps by a dipping process. The chip is disposed on a carrier such that the carrier is in contact with the solder bumps. A reflow process is carried out so that the chip and the carrier are electrically connected through the solder bumps and a plurality of supporting structures made from the polymer material are formed around the junctions between the solder bumps and the carrier. The supporting structures enhance the endurance of the solder bumps to thermal stress and reduce damage due to fatigue.

Owner:ADVANCED SEMICON ENG INC

Shunt pulsation trap for positive displacement (PD) internal combustion engines (ICE)

ActiveUS9243557B2Reduce exhaust back pressureImprove fuel efficiencyValve arrangementsInternal combustion piston enginesCombustionExternal combustion engine

A shunt pulsation trap for a positive displacement (PD) internal combustion engine (ICE) reduces pulsation, as well as noise, vibration and harshness (NVH), and the overall size of the exhaust system, and also improves cycle (fuel) efficiency. A shunt pulsation trap for a PD-ICE is configured to trap and attenuate gas pulsations before discharge to engine outlet and includes a chamber (trap volume) adjacent to the PD-ICE cavity. The chamber houses at least one pulsation dampening device, at least one relief port (trap inlet) branching off from the PD-ICE cavity into the pulsation trap chamber and a feedback region (trap outlet) communicating with the PD-ICE outlet. The associated methods of reducing pulsations are included as another aspect of the invention.

Owner:HUANG PAUL XIUBAO +1

Juncture for a high pressure fuel system

ActiveUS7021291B2Reducing likelihood of fatigue failureReduce fatigue failureLow-pressure fuel injectionMachines/enginesCommon railEngineering

A juncture and method for changing direction of fuel flow in a high pressure fuel injection system such as a common rail and / or a fuel pump, the juncture comprising a body, a first passage formed in the body having a first diameter and a longitudinal axis extending therethrough, the first passage including a groove positioned along a portion of the longitudinal axis, and a second passage formed in the body having a second diameter, a central axis extending therethrough, and an opening, the opening of the second passage being provided in the groove of the first passage to allow fluidic communication between the second passage and the first passage so that stresses at the juncture caused by high pressure fuel changing direction of flow is reduced.

Owner:CUMMINS INC

Shunt pulsation trap for positive displacement (PD) internal combustion engines (ICE)

ActiveUS20130247849A1Reduce exhaust back pressureImprove fuel efficiencyValve arrangementsInternal combustion piston enginesCombustionExternal combustion engine

A shunt pulsation trap for a positive displacement (PD) internal combustion engine (ICE) reduces pulsation, noise, vibration and harshness (NVH), and overall size of the exhaust system and improves cycle (fuel) efficiency. Generally, a shunt pulsation trap for a PD-ICE is configured to trap and attenuate gas pulsations before discharge to engine outlet and comprises a chamber (trap volume) adjacent to the PD-ICE cavity, therein housed various pulsation dampening means or pulsation containment means, at least one relief port (trap inlet) branching off from the PD-ICE cavity into the pulsation trap chamber and a feedback region (trap outlet) communicating with the PD-ICE outlet. The associated principles, methods and embodiments are disclosed.

Owner:HUANG PAUL XIUBAO +1

Split mainframe including tramp release cylinders

InactiveUS20150174581A1Reduce tensionReduce fatigue failureGrain treatmentsCyclic tensionEngineering

A split mainframe for use in a cone crusher that includes an upper mainframe and a lower mainframe joined to each other. The upper mainframe is positioned between the lower mainframe and adjustment ring. A series of tramp release cylinders extend between an upper flange formed on the lower mainframe and an attachment flange formed on the adjustment ring. The series of tramp release cylinders compress the upper mainframe between the adjustment ring and the lower mainframe. The series of hydraulic tramp release cylinders create a compression force that prevents cyclic tension during crushing for the fasteners used to secure the lower mainframe to the upper mainframe.

Owner:METSO MINERALS IND INC

Semiconductor chip package

ActiveUS7151308B2Reduce stressRelieve pressureSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipInterconnection

A semiconductor chip package includes an interconnection substrate, a central substrate, a peripheral substrate and a semiconductor chip sandwiched between the interconnection substrate and the central substrate. The interconnection substrate has a recessed cavity for receiving the semiconductor chip. The peripheral substrate is separated from the central substrate thereby decreasing the stresses caused by CTE mismatch of the semiconductor chip package. Furthermore, both the central substrate and the peripheral substrate are mechanically and electrically connected to the interconnection substrate such that the semiconductor chip is electrically connected to the peripheral substrate through the central substrate and the interconnection substrate.

Owner:ADVANCED SEMICON ENG INC

Wind farm turbulence optimization method and system

ActiveCN107315855AIncrease airflowAvoid damageDesign optimisation/simulationSpecial data processing applicationsElectricityTurbine

The invention belongs to the field of wind power technology, and particularly relates to a wind farm turbulence optimization method and system. The method includes: acquiring turbulence intensity data in a main flow direction within a predetermined distance in front of an installation location of a wind turbine on the basis of CFD (Computational Fluid Dynamics) flow field analysis; and analyzing and determining, on the basis of the acquired turbulence intensity data and wind farm measurement data, a location and a flow-guiding height of a flow-guiding wind grid mesh of utilizing mesh flow-guiding to optimize turbulence, According to the method and system, a mesh flow-guiding scheme is utilized, airflow of a wind farm is optimized, the turbulence intensity is reduced, component damage and gear box and blade fatigue invalidation caused by violent vibration, due to the turbulence, of the wind turbine are reduced, and the safety of wind turbine running is improved.

Owner:中国大唐集团科学技术研究总院有限公司

Reduced stress superback wheel

ActiveUS9624776B2Improve balanceLess susceptible to stressInternal combustion piston enginesBlade accessoriesTurbine wheelLow-cycle fatigue

Turbocharger turbine wheels are designed to accelerate rapidly and to rotate at very high RPM. A turbine wheel is provided with improved low cycle fatigue resistance. The wheel can be balanced by conventional methods.

Owner:BORGWARNER INC

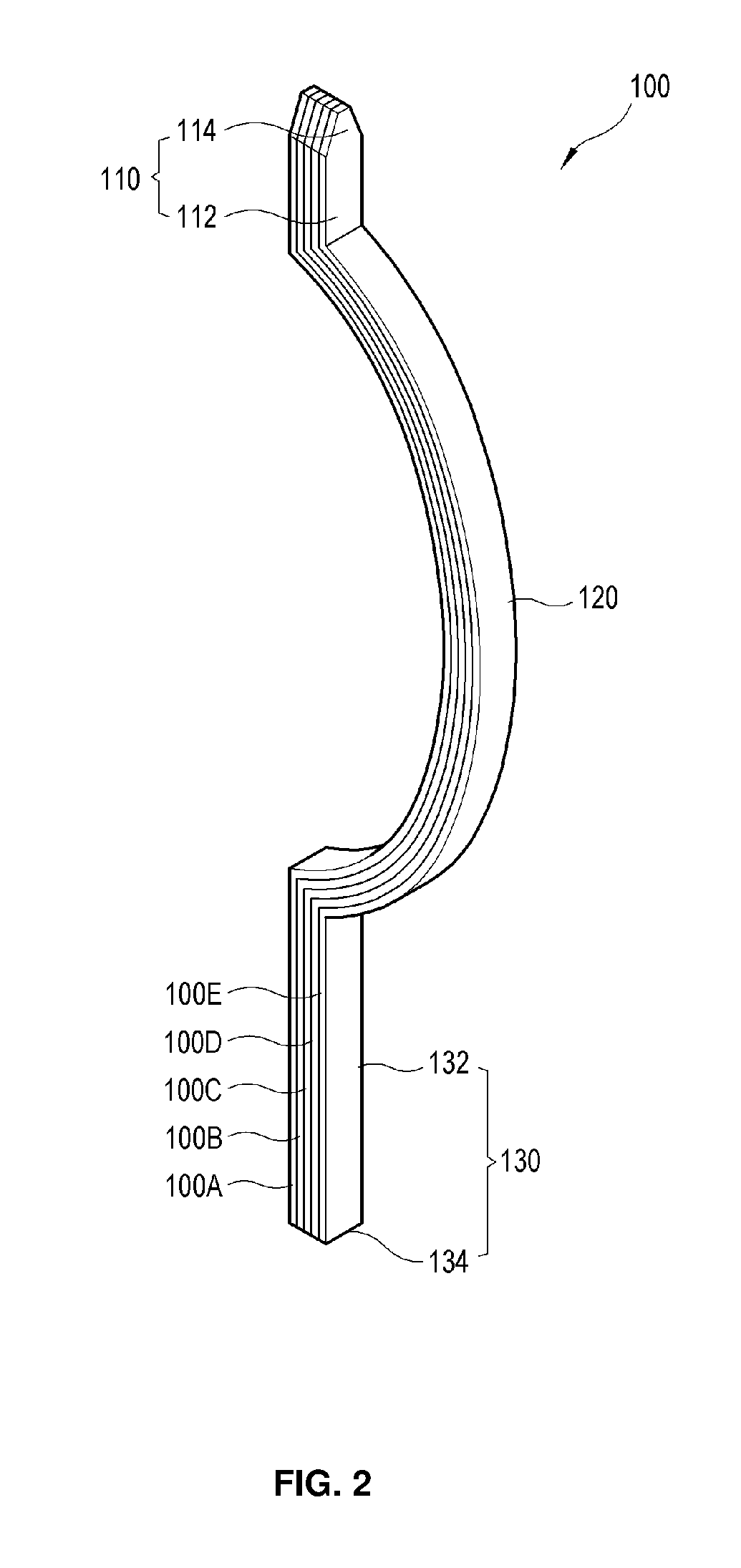

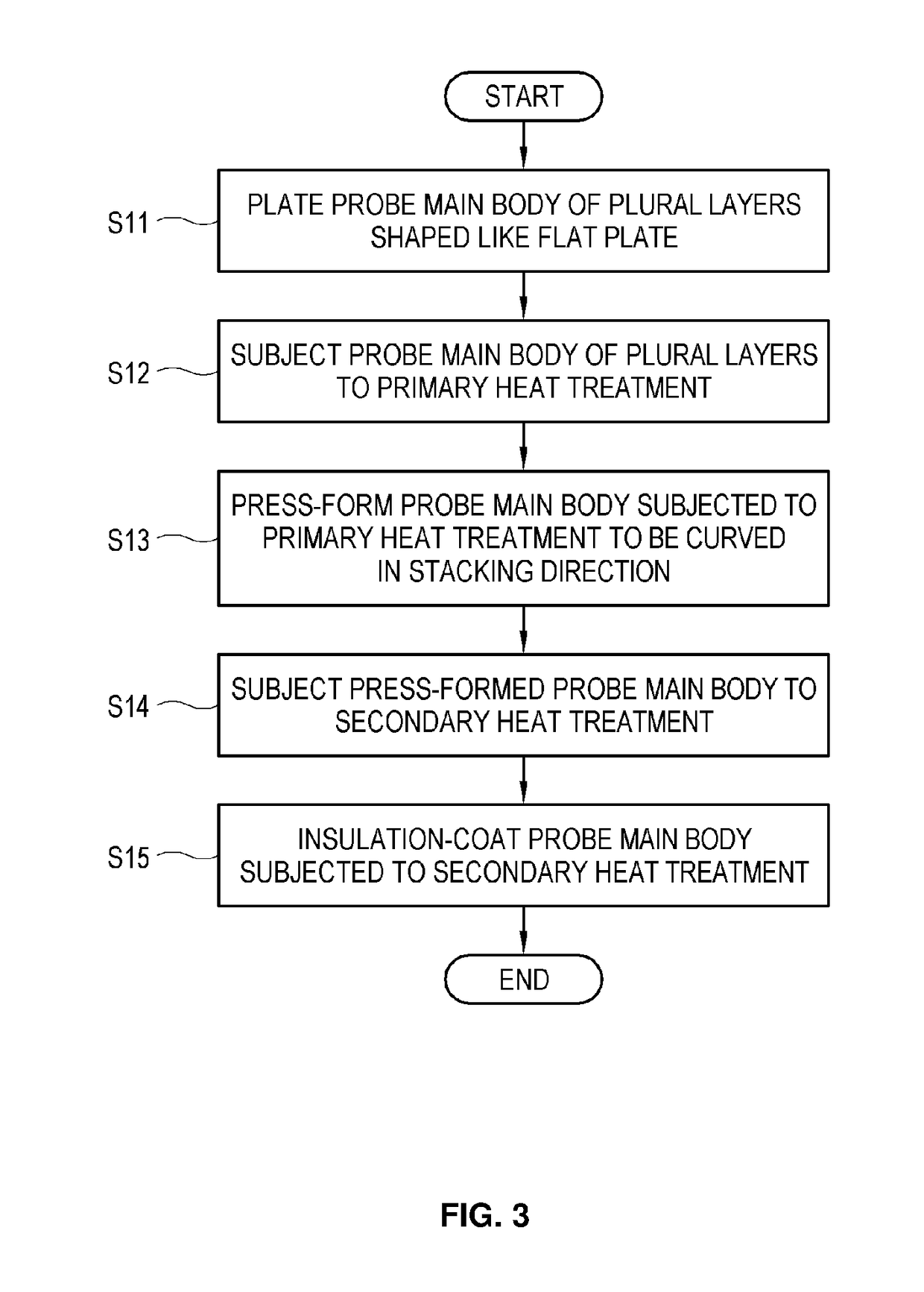

MEMS probe and test device using the same

ActiveUS20190064215A1Increased durabilityReduce fatigue failureContact member manufacturingElectronic circuit testingElectricityMicroelectromechanical systems

A microelectromechanical system (MEMS) probe for electric connection between a tested contact point of an object to be tested and a testing contact point of a test circuit. The MEMS probe includes: a first terminal contact portion; a second terminal contact portion movable close to and away from the first terminal contact portion; and an elastic connecting portion connecting the first terminal contact portion and the second terminal contact portion, elastically deformed by an approach of the second terminal contact portion and comprising a plurality of plating layers stacked in the elastic deformation direction. According to the present disclosure, the MEMS probe includes a plurality of plating layers stacked in the elastic deformation direction, thereby decreasing fatigue failure and improving durability.

Owner:LEENO INDAL

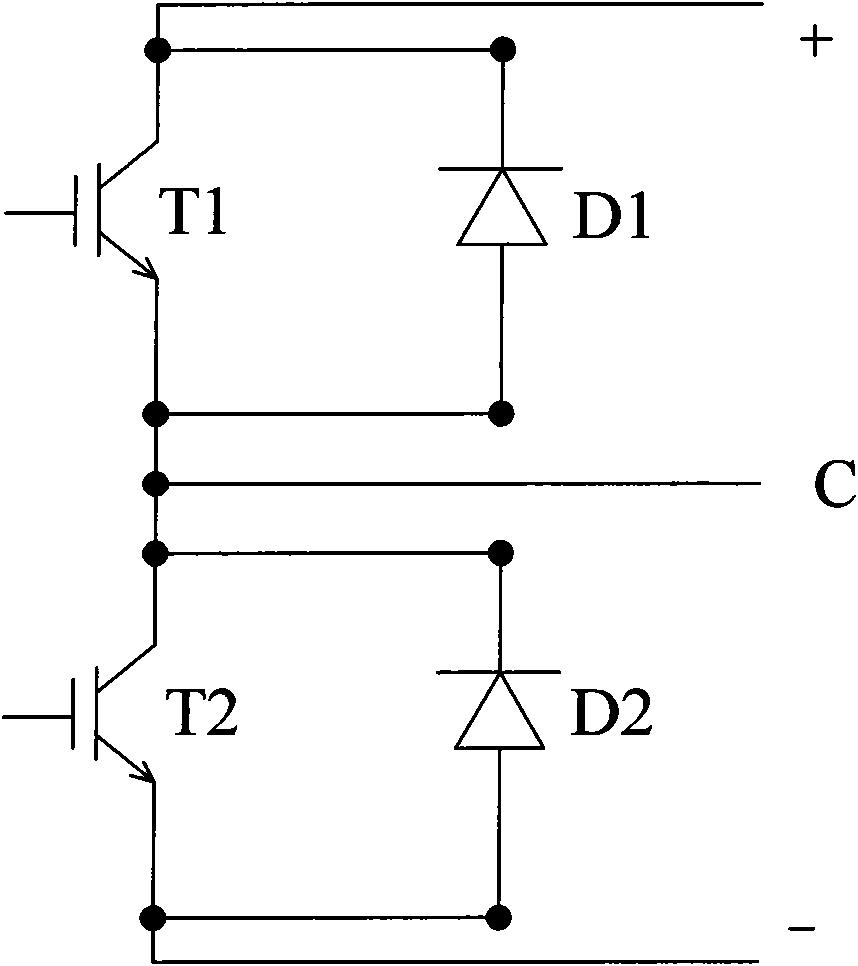

Double side cooling and plane high temperature inverter for hybrid electric automobile

ActiveCN101594067AReduce manufacturing costReduce maintenance costsCooling/ventilation/heating modificationsDc-ac conversion without reversalJunction temperatureActive switch

The invention discloses a double side cooling and plane high temperature inverter for a hybrid electric automobile, which comprises an active switch chip and a diode chip. The active switch chip and the diode chip are arranged between an upper layer copper clad ceramic substrate and a lower layer copper clad ceramic substrate side by side; interfaces between the active switch chip and the diode chip and the upper layer copper clad ceramic substrate and the lower copper clad ceramic substrate are connected by sintering silver joints; a sealing material is filled in gaps among the active switch chip, the diode chip, the upper layer copper clad ceramic substrate and the lower copper clad ceramic substrate; and a metallic gasket is arranged below the relatively thin chip in the active switch chip and the diode chip to ensure that the heights of the active switch chip and the diode chip are equal. The inverter has good heat dissipation capability, can work under the condition of higher junction temperature, has high reliability of modules, can reduce the manufacturing and maintenance cost of the hybrid electric automobile, has the characteristics of lead-free, energy conservation, consumption reduction and environmental protection, reduces the consumption of energy such as gasoline and the like, and reduces the discharge of carbon dioxide.

Owner:TIANJIN UNIV

Multi-stage hydraulic pressurizer based on mechanical devices

ActiveCN107091060ASimple structureExtended service lifeDrilling rodsDrilling casingsUpper jointAxial thrust

The invention relates to a three-stage one-stroke hydraulic pressurizer applied to drilling of conventional wells, slim holes and micro-holes. The technical scheme of the three-stage one-stroke hydraulic pressurizer is that an upper joint, different stages of piston cylinders and a lower joint are connected sequentially through threads; the lower end of the upper joint of the hydraulic pressurizer is connected with a third-stage piston cylinder through threads; the third-stage piston cylinder and a second-stage piston cylinder are connected with a main piston cylinder; a third-stage piston, a second-stage piston and a main piston are mounted in the corresponding cylinder bodies respectively; the main piston cylinder and a main piston rod are flexibly connected through a roller mounted on the cylinder body and a keyway formed in the piston rod; the upper end of the main piston rod is connected with the main piston through threads, and the lower end of the main piston rod is fixed on the lower joint through threads. With adoption of the hydraulic pressurizer, mud power is converted into axial thrust, so that constant bit pressure is applied to a drill bit, the bit pressure transfer efficiency can be increased, the problems of bit jumping, backing pressure and the like are solved effectively, the service life of the drill bit is prolonged, fatigue failures of a drilling tool are reduced, and drilling efficiency is increased.

Owner:山东王晁煤电集团新能发电有限公司

High-pressure metal hose and preparation method thereof

ActiveCN106523812AStrong high pressure resistanceImprove corrosion resistanceFlexible pipesTitaniumTin bronze

The invention discloses a high-pressure metal hose and a preparation method thereof. The metal hose comprises a net-body part and connectors arranged at two ends of the net-body part, wherein the net-body parts comprises a metal corrugated pipe, a connecting pipe, a ring and a steel wire net sleeve; and the metal corrugated pipe is prepared from the following components in parts by weight: 21-39 parts of iron, 12-25 parts of nickel, 11-22 parts of chromium, 4-11 parts of tin bronze, 5-11 parts of titanium, 3-8 parts of silicon nitride, 1-5 parts of aluminum oxide and 1-4 parts of tin oxide. The metal hose disclosed by the invention has the following advantages: (1) the high-pressure-resistance performance is excellent, and the water attack and the pressure of a conveying medium can be effectively resisted; and (2) through addition of a reasonable amount of carbon, the own anti-corrosion performance of the metal hose is improved, and the possibility of fatigue failure of the metal hose is lowered.

Owner:江苏亚星波纹管有限公司

Tunable Fluid End

ActiveUS20140034863A1Extend fluid end service lifeReduce fluid end fatigue failurePositive displacement pump componentsCheck valvesVibration attenuationUltrasound attenuation

Tunable fluid end embodiments comprise a family, each family member comprising a pump housing with at least one installed tunable component chosen from: tunable valve assemblies, tunable valve seats, tunable radial arrays and / or tunable plunger seals. For example, a tunable valve assembly or tunable radial array selectively attenuates valve-generated vibration at its source, thus reducing the likelihood of fluid end failures associated with fatigue cracking and / or corrosion fatigue. Adding tunable valve seats and / or tunable plunger seals to a fluid end facilitates optimal damping and / or selective attenuation of vibration at one or more predetermined (and frequently localized) fluid end resonant frequencies. Thus, the likelihood of exciting destructive resonances in a pump's fluid end housing is further reduced. Optimized vibration attenuation and optimized fluid end damping are provided by altering resonant frequencies in each tunable component in relation to one or more fluid end resonant frequencies and / or tunable component resonant frequencies.

Owner:GILSTAD DENNIS W +1

Fiber alignment using a channel incorporating a fulcrum structure

InactiveUS6862389B2Reduce fatigue failureCoupling light guidesOptical waveguide light guideFiberEngineering

Optical alignment between a communication optical fiber and an optical device is achieved by using a substrate including a fiber-holding channel formed in the top surface of the substrate. The channel is particularly formed to include a central fulcrum region, against which the fiber is pressed into as the fiber-to-device alignment is performed. In particular, the fulcrum functions as a pivot point to allow for the free endface of the fiber nearest the optical device to be adjusted (performing a “fine” adjustment) by manipulating the opposing end of the fiber (using a “gross” movement) until alignment with the optical device is achieved. A reduction of, for example, 14:1 between the gross movement and the fine adjustment can be achieved by using the inventive fulcrum structure.

Owner:QORVO US INC

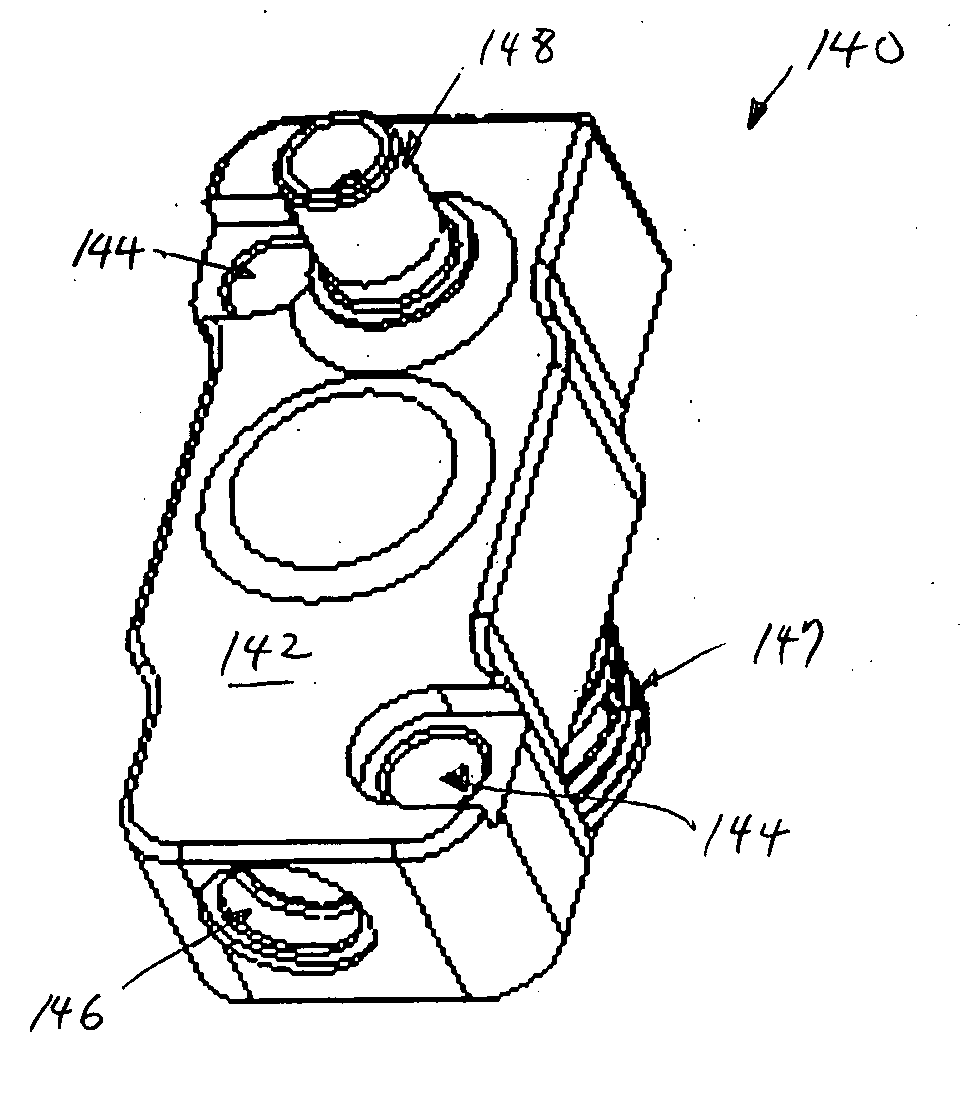

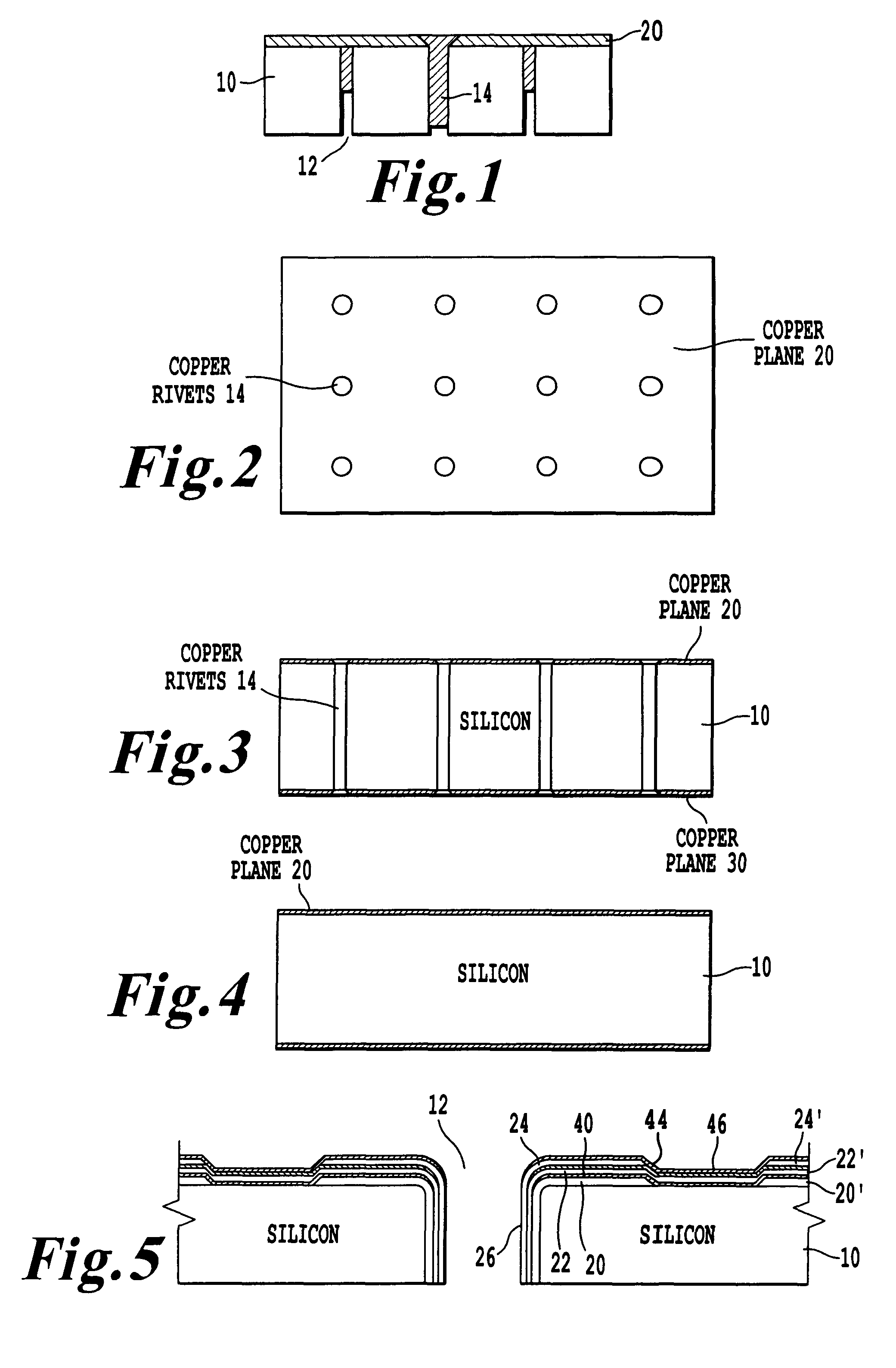

Large substrate structural vias

ActiveUS7709966B2Reduce fatigue failureSemiconductor/solid-state device detailsSolid-state devicesThermal fatigueElectrical conductor

An electronic package and methods by which the package reduces thermal fatigue failure of conductors in the electronic package. The electronic package includes a carrier substrate having first and second surfaces and a plurality of anchor vias having a via material extending from the first surface toward the second surface. The electronic package includes a first conducting layer having a length and a width extending laterally in two dimensions across a major part of the first surface of the carrier substrate. The anchor vias have plural attachments along the length and the width of the first conducting layer to secure the first conducting layer to the carrier substrate.

Owner:MICROSS ADVANCED INTERCONNECT TECH LLC

Semiconductor chip package and method for manufacturing the same

ActiveUS20070087478A1Relieve pressureSolve the low heat dissipation efficiencySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A semiconductor chip package mainly comprises an interconnection substrate, a central substrate, a peripheral substrate and a semiconductor chip sandwiched between the interconnection substrate and the central substrate. The interconnection substrate has a recessed cavity for receiving the semiconductor chip. The present invention is characterized in that the peripheral substrate is separated from the central substrate thereby decreasing the stresses caused by CTE mismatch of the semiconductor chip package. Furthermore, both the central substrate and the peripheral substrate are mechanically and electrically connected to the interconnection substrate such that the semiconductor chip is electrically connected to the peripheral substrate through the central substrate and the interconnection substrate. The present invention further provides a method for manufacturing the semiconductor chip package.

Owner:ADVANCED SEMICON ENG INC

Tunable Fluid End

ActiveUS20140034862A1Reduce fatigue failureReduce likelihoodPositive displacement pump componentsCheck valvesUltrasound attenuationEngineering

Tunable fluid end embodiments comprise a family, each family member comprising a pump housing with at least one installed tunable component chosen from: tunable valve assemblies, tunable valve seats, tunable radial arrays and / or tunable plunger seals. For example, a tunable valve assembly or tunable radial array selectively attenuates valve-generated vibration at its source, thus reducing the likelihood of fluid end failures associated with fatigue cracking and / or corrosion fatigue. Adding tunable valve seats and / or tunable plunger seals to a fluid end facilitates optimal damping and / or selective attenuation of vibration at one or more predetermined (and frequently localized) fluid end resonant frequencies. Thus, the likelihood of exciting destructive resonances in a pump's fluid end housing is further reduced. Optimized vibration attenuation and optimized fluid end damping are provided by altering resonant frequencies in each tunable component in relation to one or more fluid end resonant frequencies and / or tunable component resonant frequencies.

Owner:GILSTAD DENNIS W +1

Anodic oxidation protection method for bearing surface

The invention discloses an anodic oxidation protection method for a bearing surface and belongs to the technical field of machine manufacturing. The method comprises the processing steps: (1) preparing an electrolyte; (2) preparing a bearing material; (3) carrying out oxidation treatment; (4) carrying out after-treatment. According to the method, the problem of fatigue failure caused by long-time rolling friction between internal surfaces of the existing bearings and rolling balls is solved; the method has the advantages of simplicity, low cost and easiness in processing.

Owner:WUHU JINLONG MOLD FORGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com