Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

164results about How to "Processing time is short" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

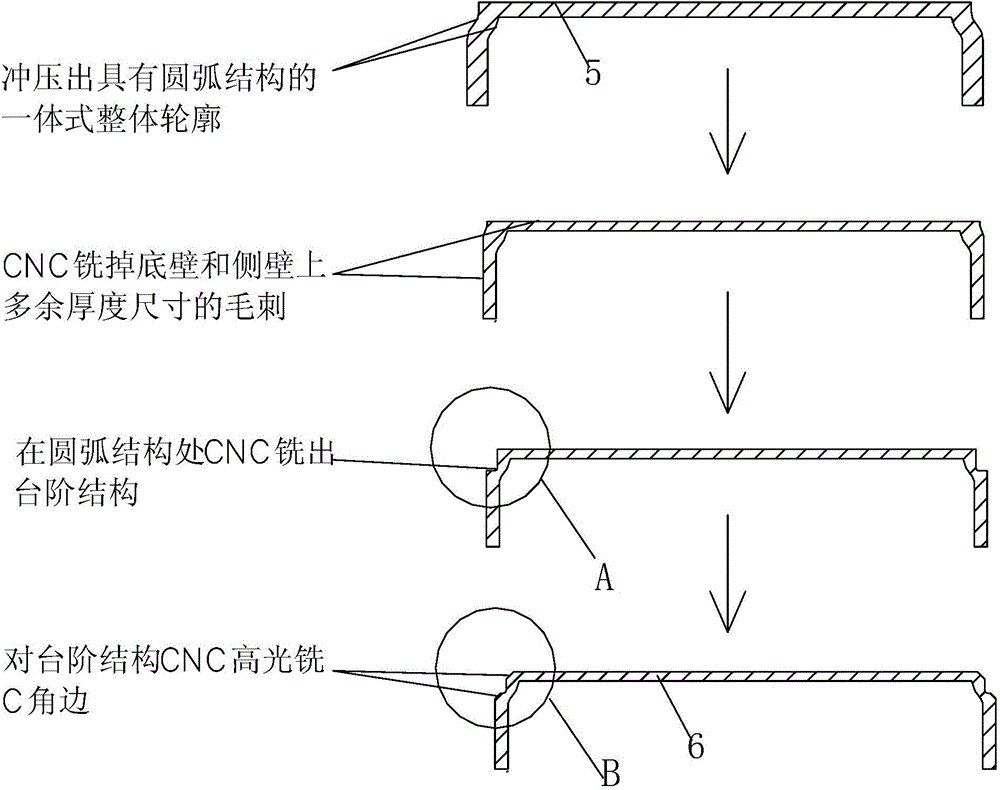

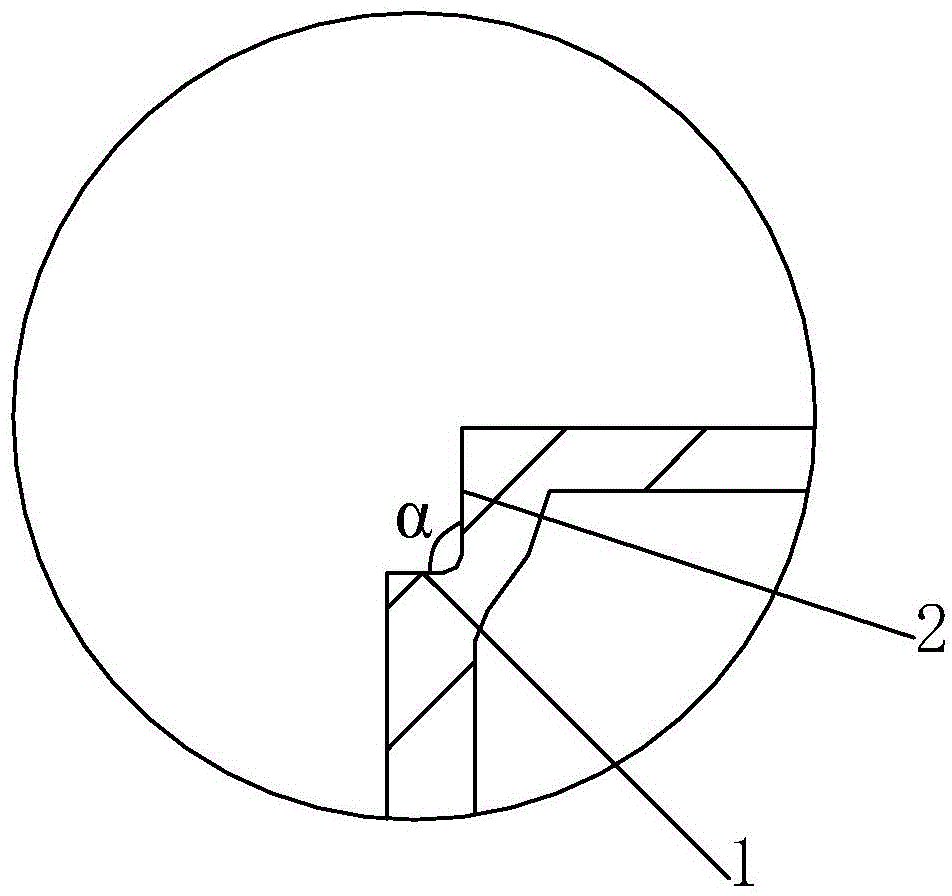

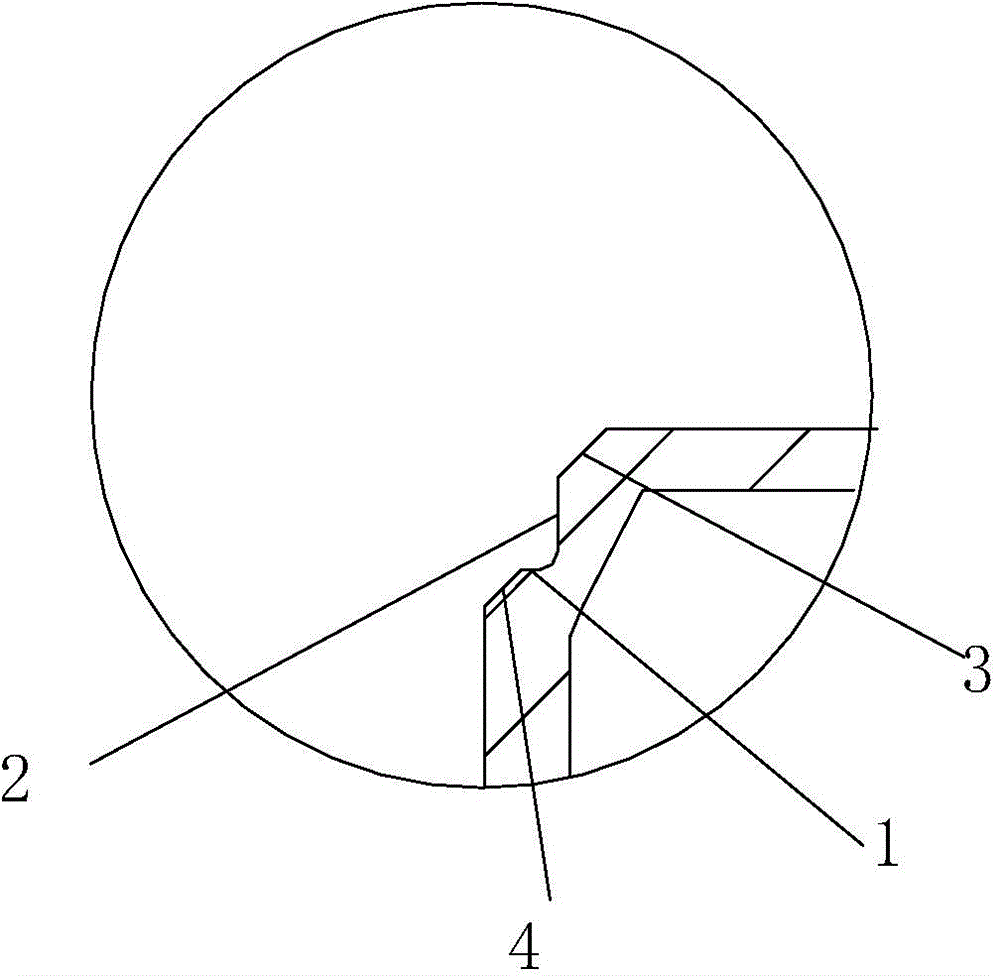

Method for forming metal mobile phone shells

ActiveCN104476136AProcessing time is shortSolve processabilitySubstation equipmentNumerical controlWork in process

The invention discloses a method for forming metal mobile phone shells, and relates to the technical field of mobile phones. The method for forming the metal mobile phone shells includes stamping and bending metal plates to obtain integral outlines of the integrated mobile phone shells so as to obtain initial blank products; carrying out CNC (computer numerical control) machining on the initial blank products to obtain semi-finished products of the metal mobile phone shells; carrying out post-processing on the semi-finished products of the metal mobile phone shells to obtain the metal mobile phone shells. Arc structures are arranged between the side walls and the bottom walls of the integral outlines of the integrated mobile phone shells. CNC machining procedures include (1), milling off burrs on redundant thickness-size sides of the bottom walls and the side walls of the initial blank products under the CNC; (2), inwardly milling the outer walls of arc corners between the side walls and the bottom walls of the initial blank products under the CNC to obtain step structures and respectively forming C-angle edges at the step structures; (3), finely milling the C-angle edges of the step structures under the CNC. The C-angle edges are close to the bottom walls and the side walls of the initial blank products. The method has the advantages that a stamping forming procedure and a CNC machining procedure are combined with each other, so that the metal mobile phone shells can be formed, and the method is stable in process, high in machining precision and production efficiency, short in machining elapsed time and low in production cost.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

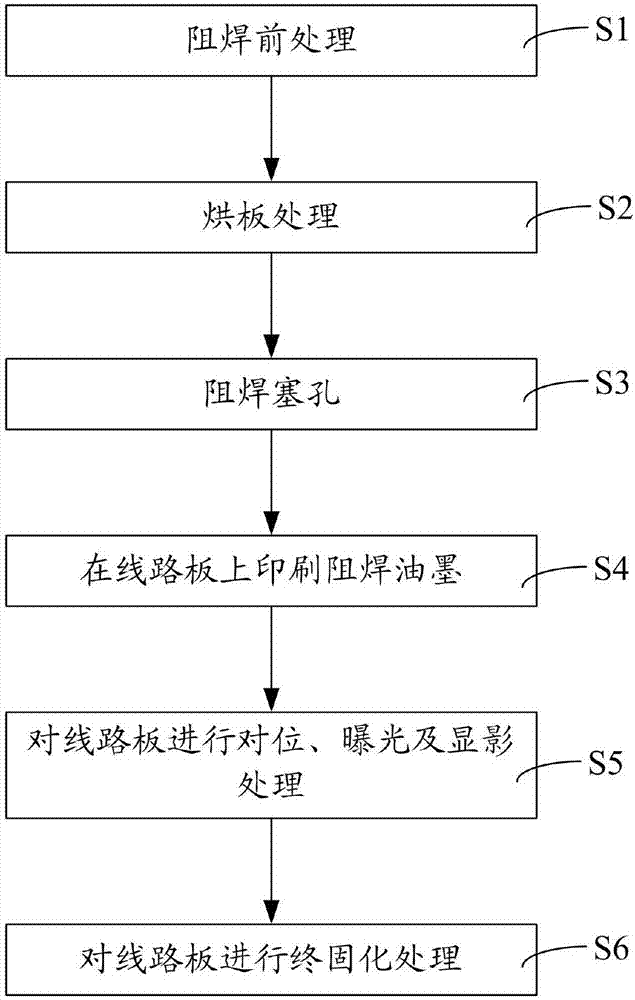

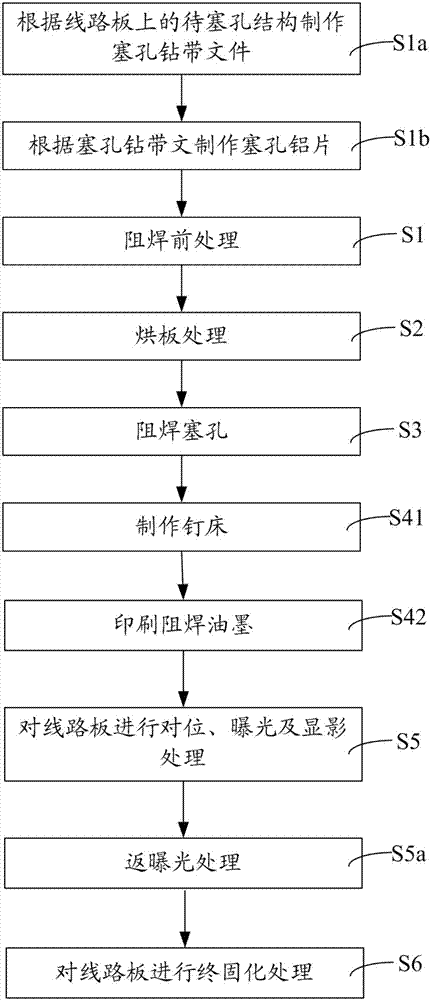

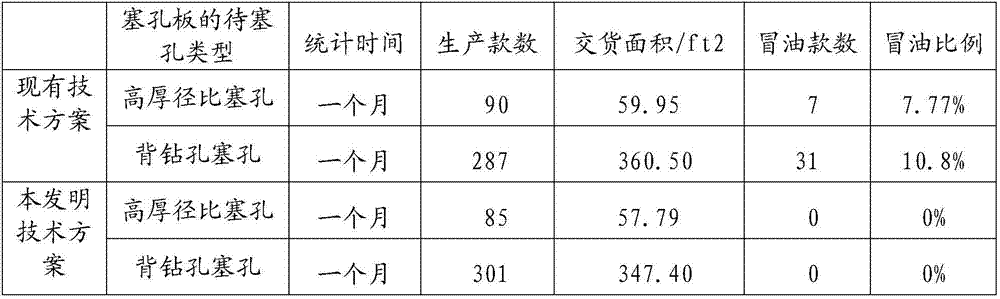

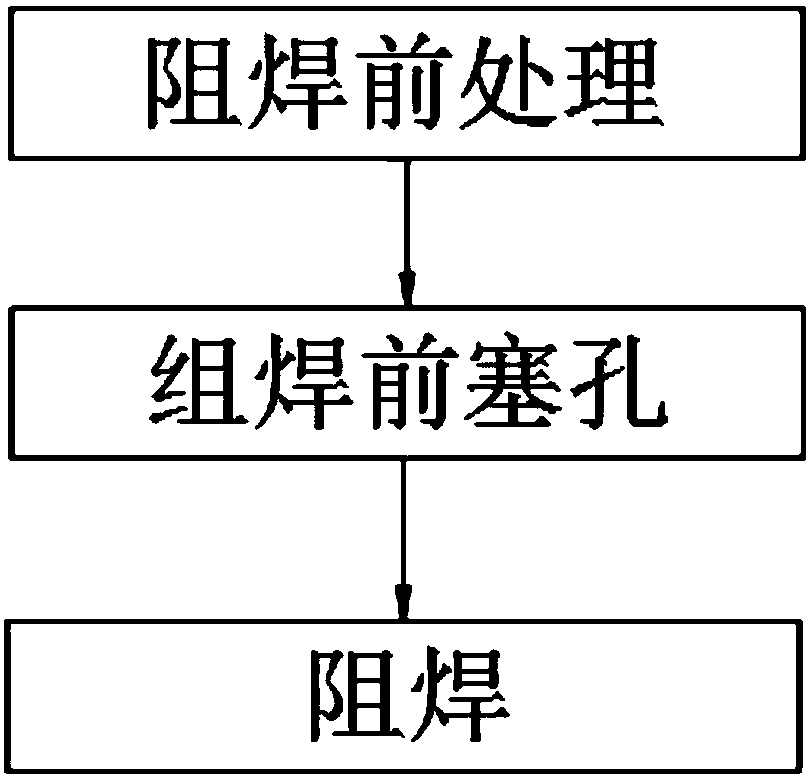

Method for improving resistance welding hole plugging oil seepage of circuit board

ActiveCN107124826AImprove the defect of oil leakageProcessing time is shortPrinted circuit manufactureCopperElectrical and Electronics engineering

The invention discloses a method for improving resistance welding hole plugging oil seepage of a circuit board. The method is used for performing resistance welding hole plugging treatment on a hole to be plugged in the circuit board. The method comprises the following steps: pretreatment of resistance welding: performing board grinding treatment, cleaning the surface of the circuit board, and generating coarseness on the copper surface of the circuit board; plate drying treatment: performing plate drying pretreatment before the pretreatment of the resistance welding, and / or performing plate drying posttreatment after the pretreatment of the resistance welding; resistance welding hole plugging: performing hole plugging treatment on the hole to be plugged in the circuit board; printing resistance welding ink on the circuit board; performing alignment, exposure and development of the circuit board; performing final curing treatment of the circuit board. According to the method for improving the resistance welding hole plugging oil seepage of the circuit board, water retained in the hole in the circuit board and a base material can be removed; the defect of oil seepage after resistance welding hole plugging and curing are performed on the circuit board is effectively improved, the quality of a product is improved, and the operation flow is simpler and more convenient.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

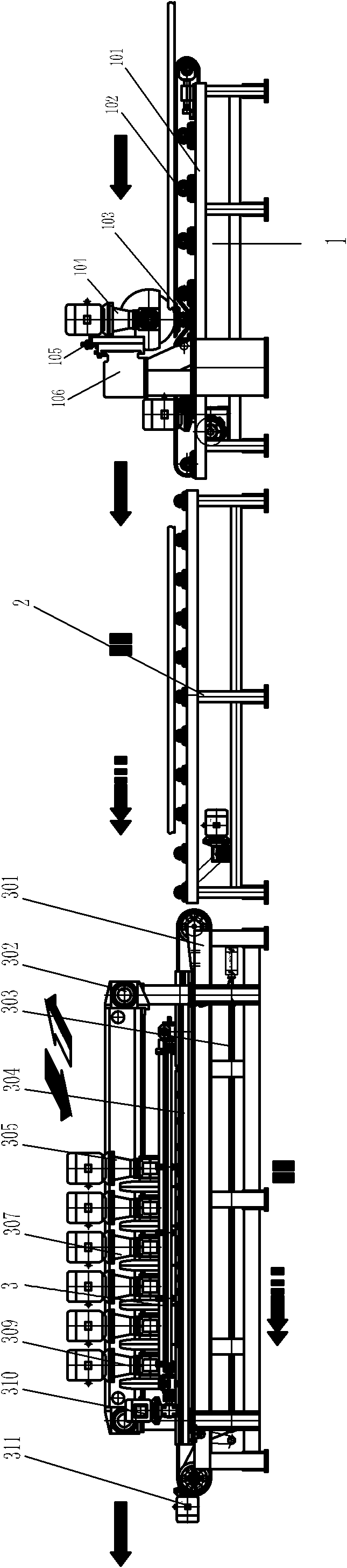

Full-automatic vertical-horizontal multi-cutter combined edge cutting machine

ActiveCN102528939AReduce labor intensityImprove working environmentWorking accessoriesStone-like material working toolsProduction lineEngineering

A full-automatic vertical-horizontal multi-cutter combined edge cutting machine comprises a longitudinal deckle machine, a transverse board cutting machine and an automatic controller, and is characterized in that the longitudinal deckle machine forms an automatic production line with the transverse board cutting machine through a two-speed intermediate conveyor of an embedded overrunning clutch. At least two independent longitudinal deckle machine power heads are transversely arranged abreast on a main frame crossbeam above a board conveying belt of the longitudinal deckle machine. A lifting conveying belt and a board transverse-cutting upright device are disposed on a frame of the transverse board cutting machine, at least two independent transverse board cutting machine power heads are longitudinally arranged abreast on a fixed operating table, and the independent longitudinal deckle machine power heads and the independent transverse board cutting machine power heads are structurally identical and all provided with structurally identical independent cutter power head transverse adjustment devices and identical independent cutter power head height adjusting devices. The multi-cutter longitudinal cutting and transverse cutting automatic production line is accurate, continuous and efficient, the full-automatic vertical-horizontal multi-cutter combined edge cutting machine is high in efficiency, low in cost, high in quality and yield, and labor intensity is relieved for operators.

Owner:南安市锋源机械有限责任公司

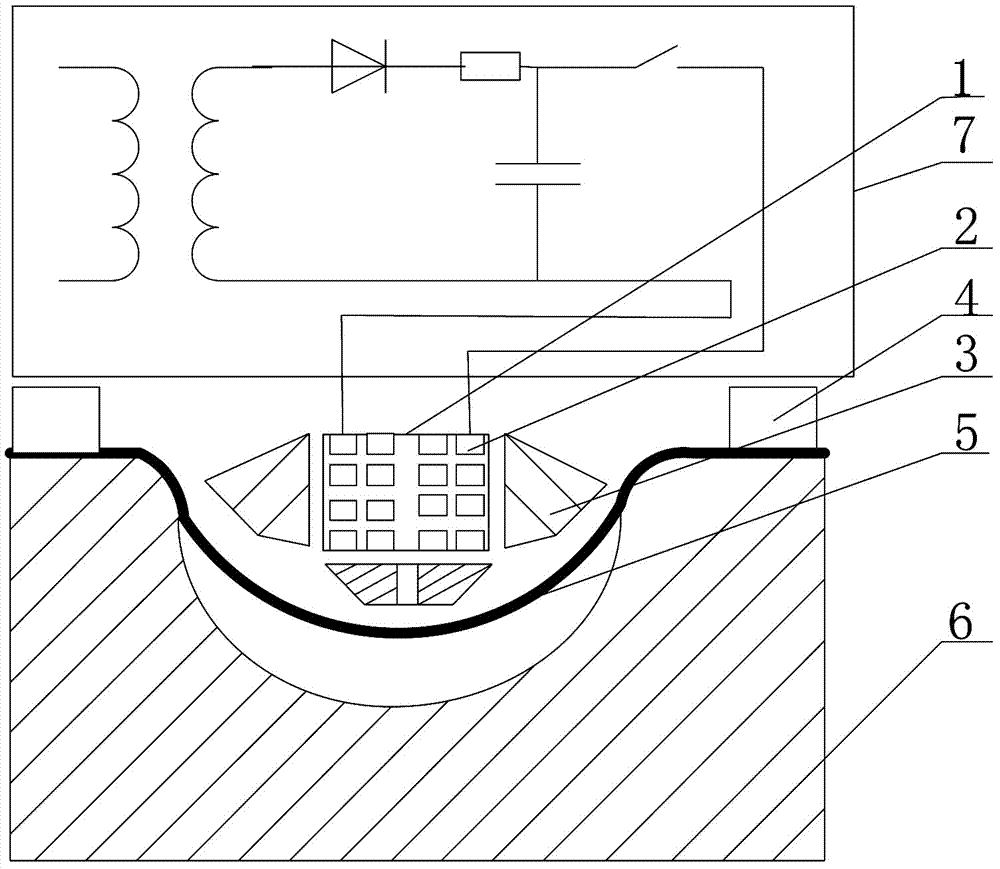

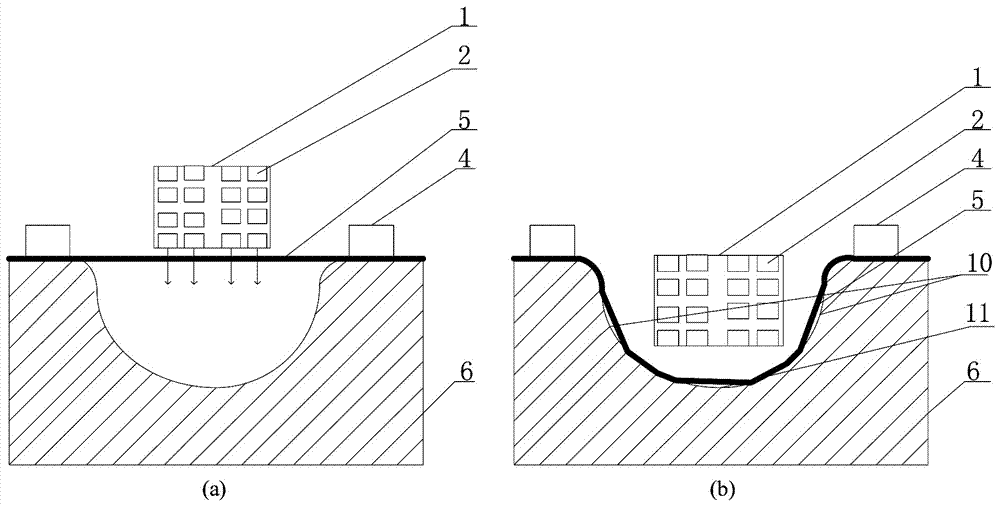

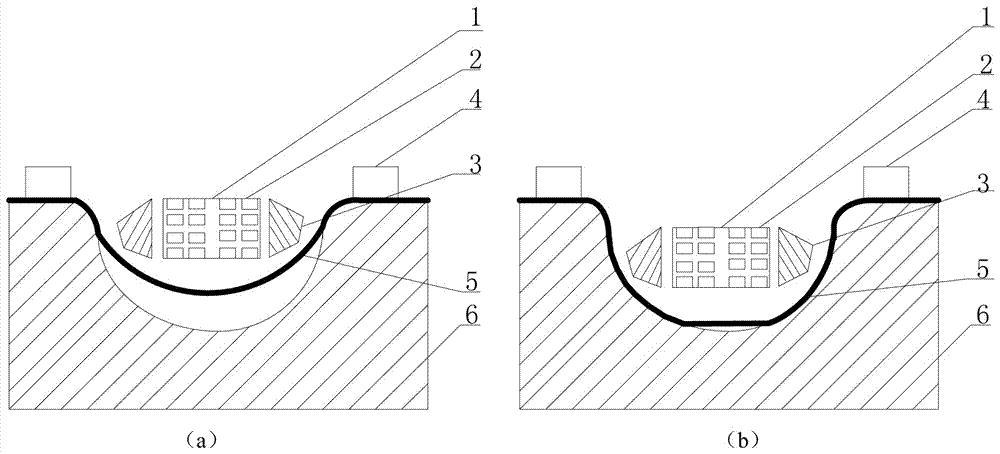

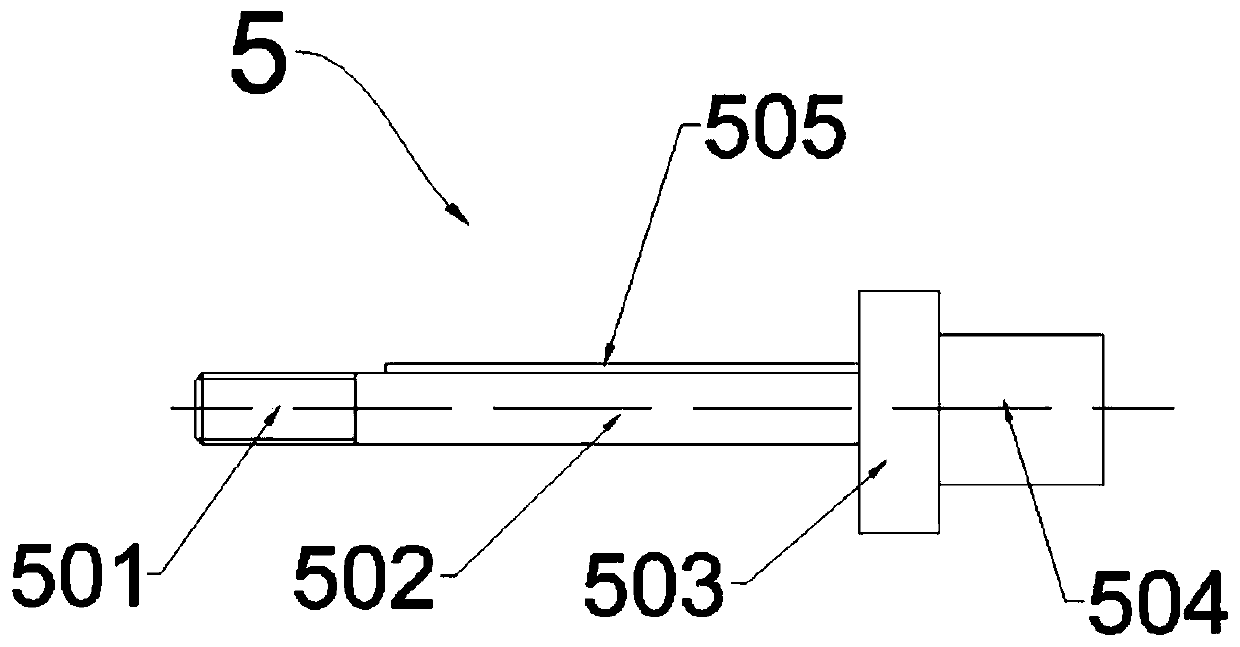

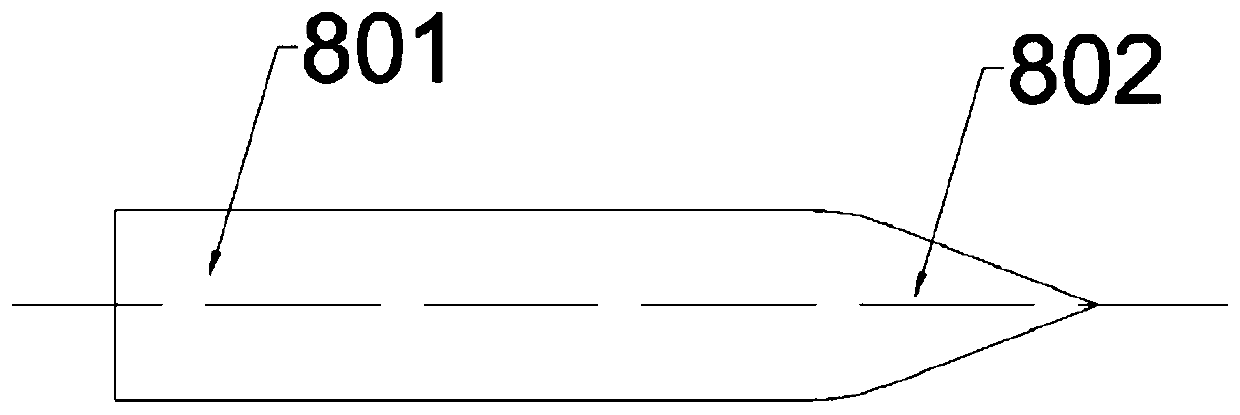

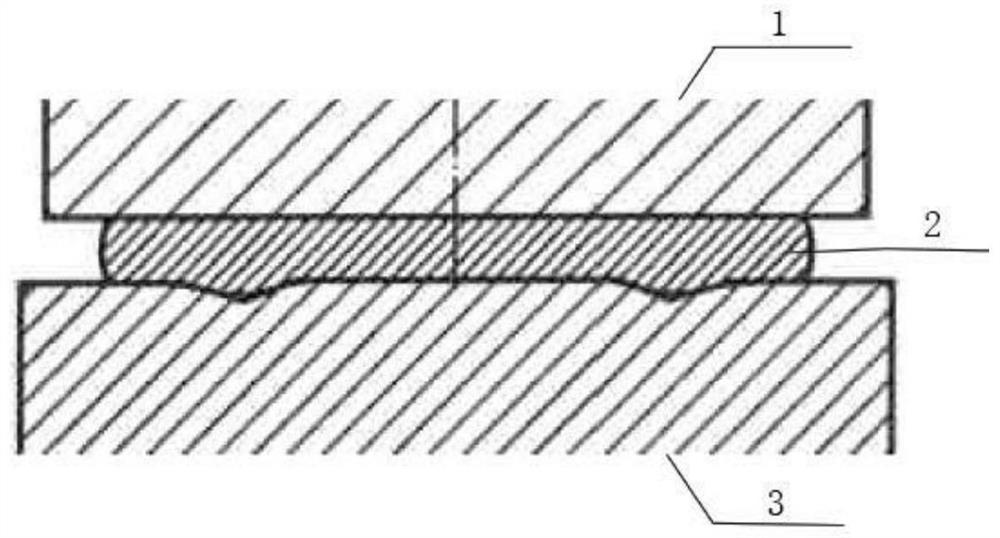

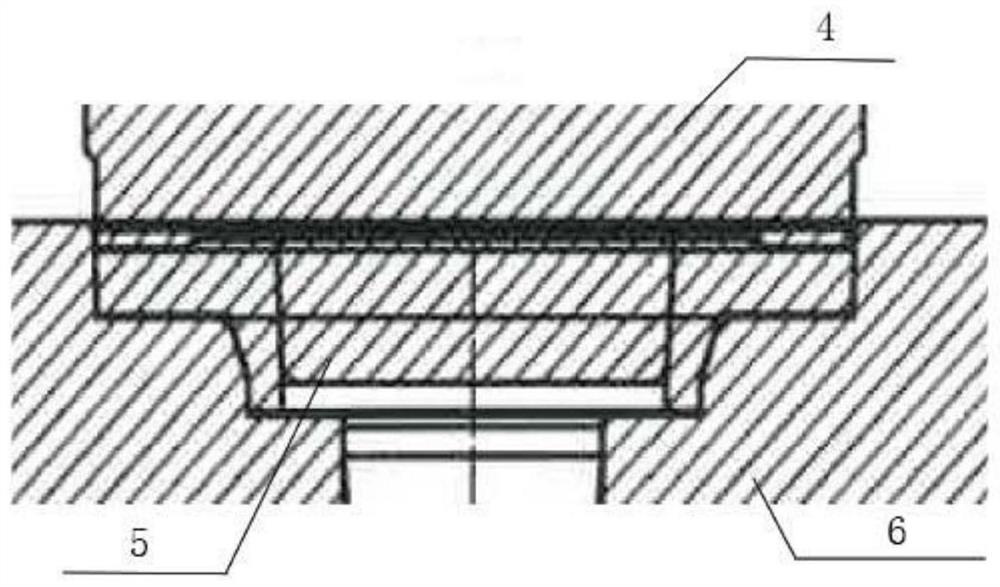

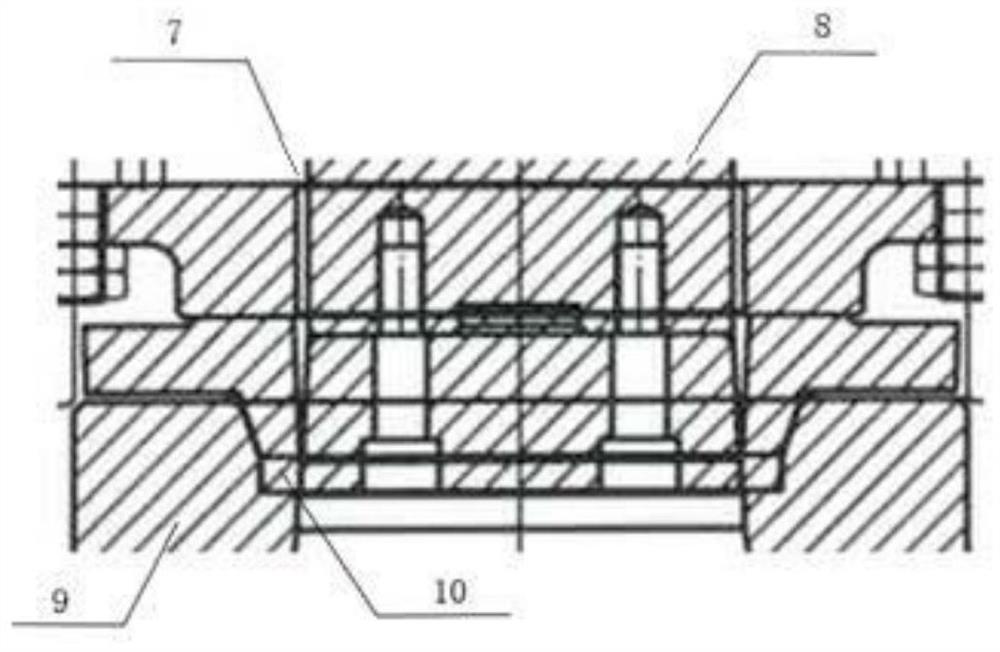

Device and method for improving die attaching performance of electromagnetic formed workpiece

The invention relates to a device and method for improving die attaching performance of an electromagnetic formed workpiece. One or more magnetism collector devices are additionally arranged at the outer portion of a drive coil; and under the situation that a coil structure is not changed, magnetism collectors are used for transmitting coil energy to an area where approaching workpiece die attaching is difficult, distribution of electromagnetic force is changed, electromagnetic force in the area where die attaching is difficult is increased, seamless die attaching can be achieved for the metal workpiece, and the forming precision is improved. On the other hand, under the situation that the coil is not replaced, forming of different workpieces is achieved by replacing the different magnetism collector devices, and the flexibility of the device can be greatly improved. Due to the fact that the magnetism collectors are simple in structure, the machining period is short, the material is generally the most common copper, and the price is relatively low; and compared with coil replacement, magnetism collector replacement is more flexible, and cost is lower.

Owner:CHINA THREE GORGES UNIV

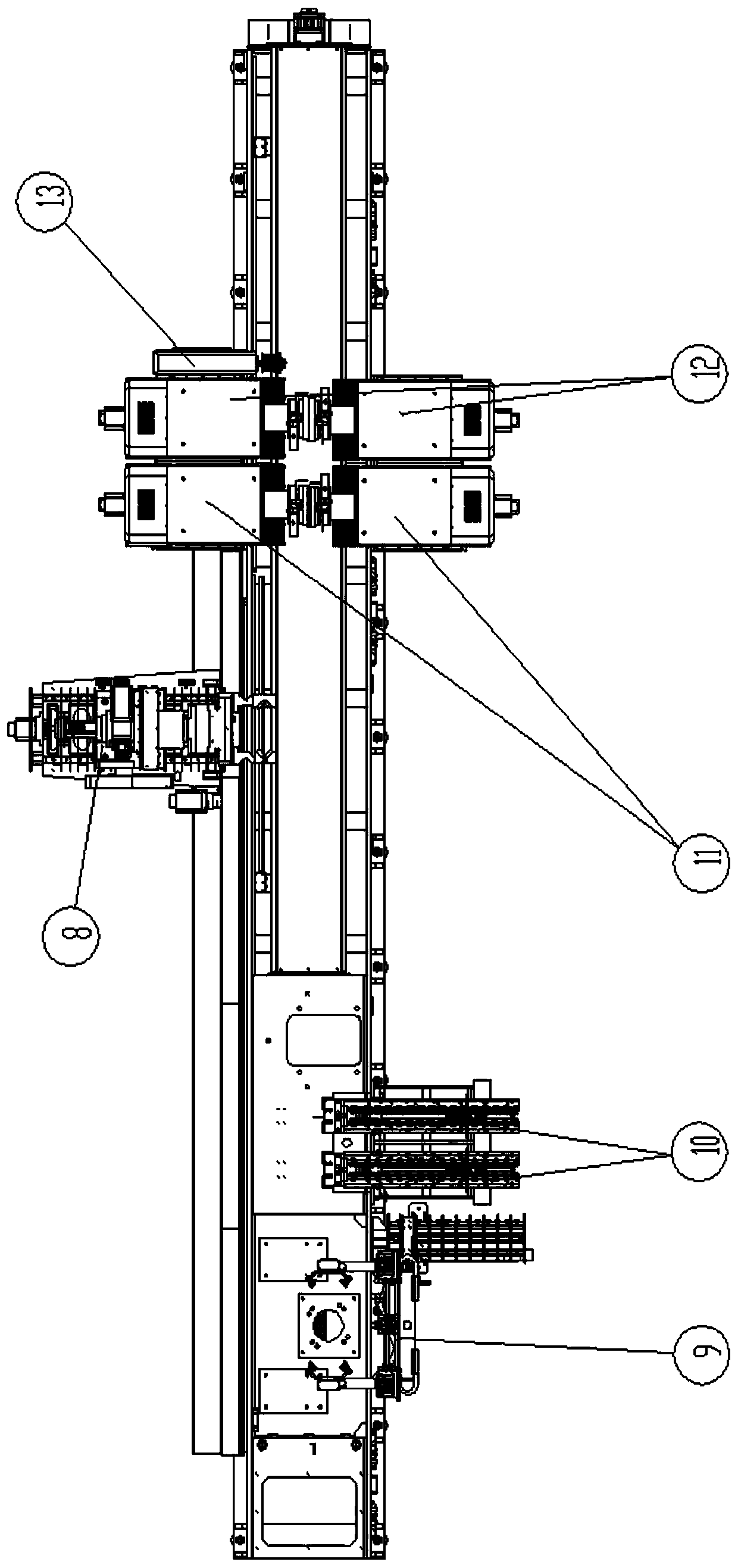

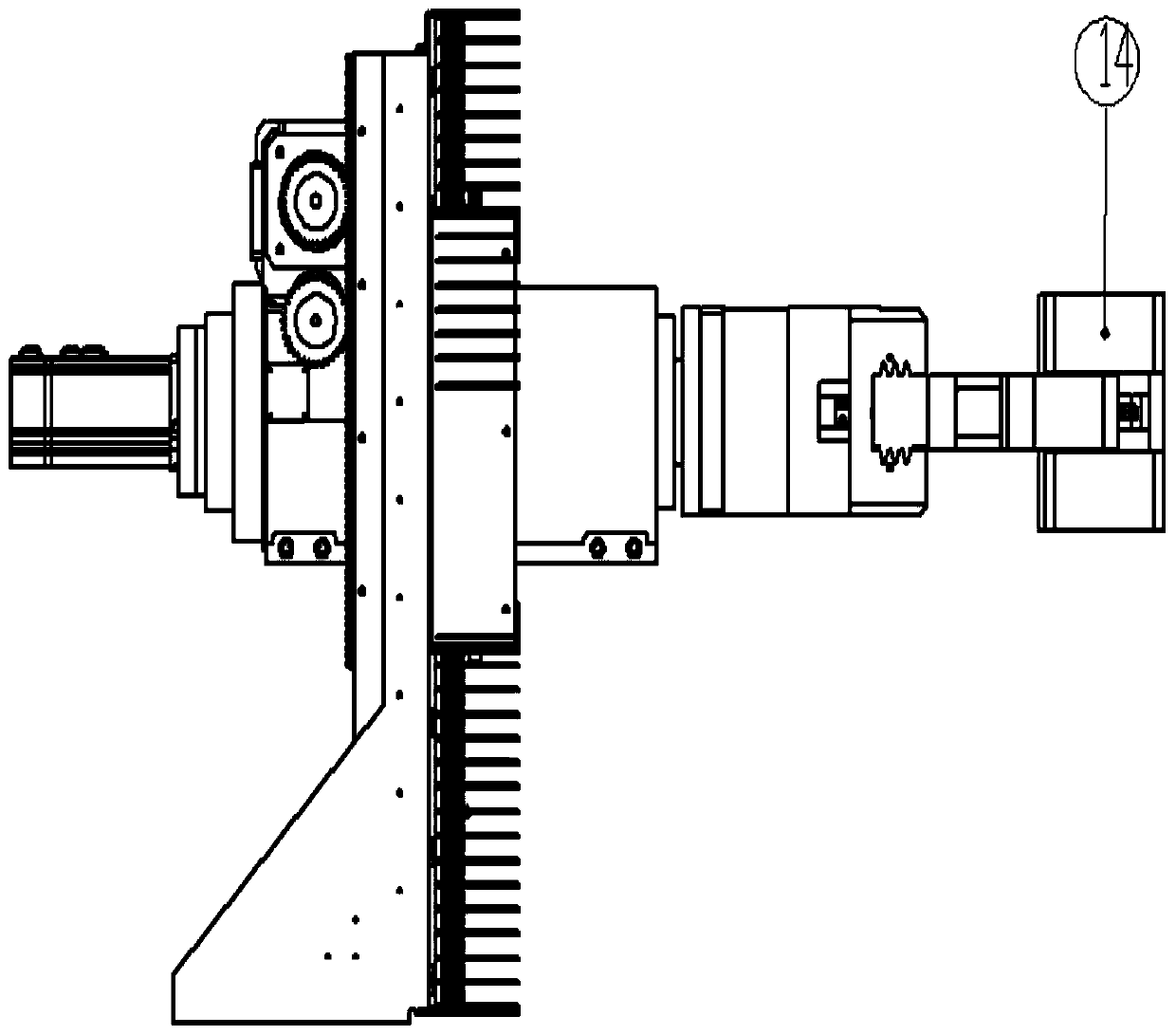

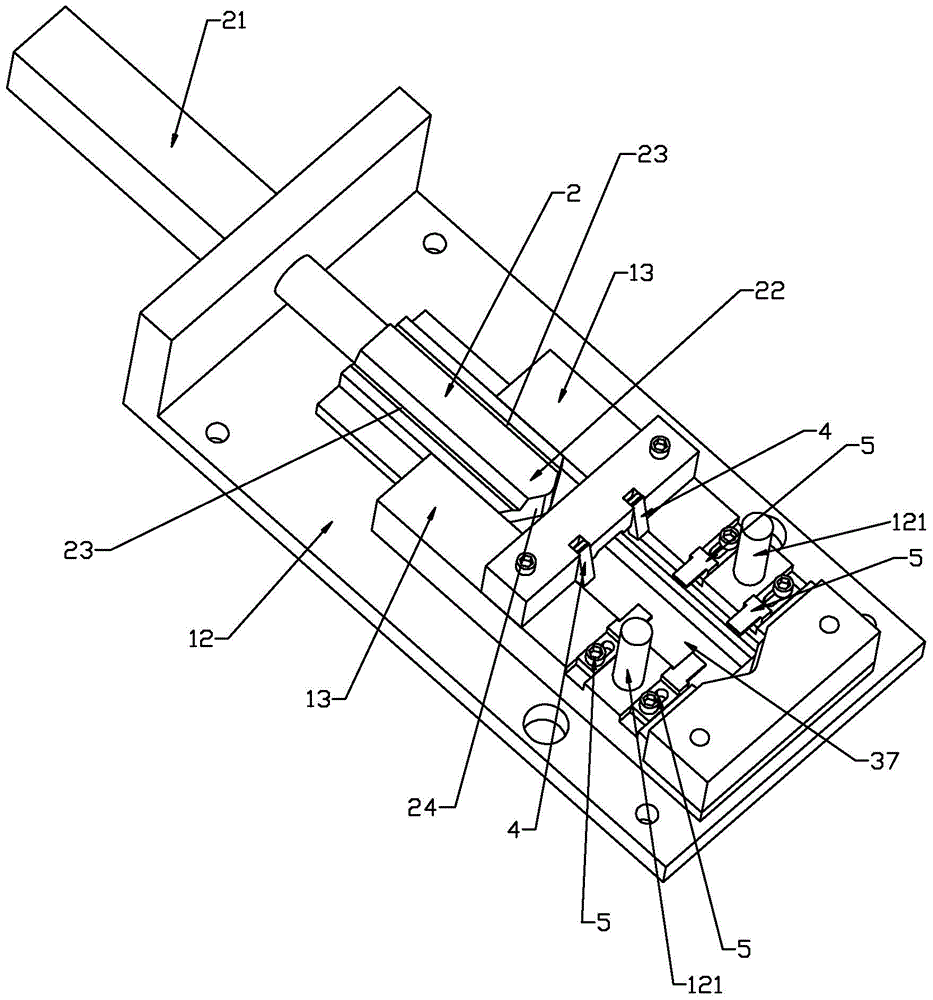

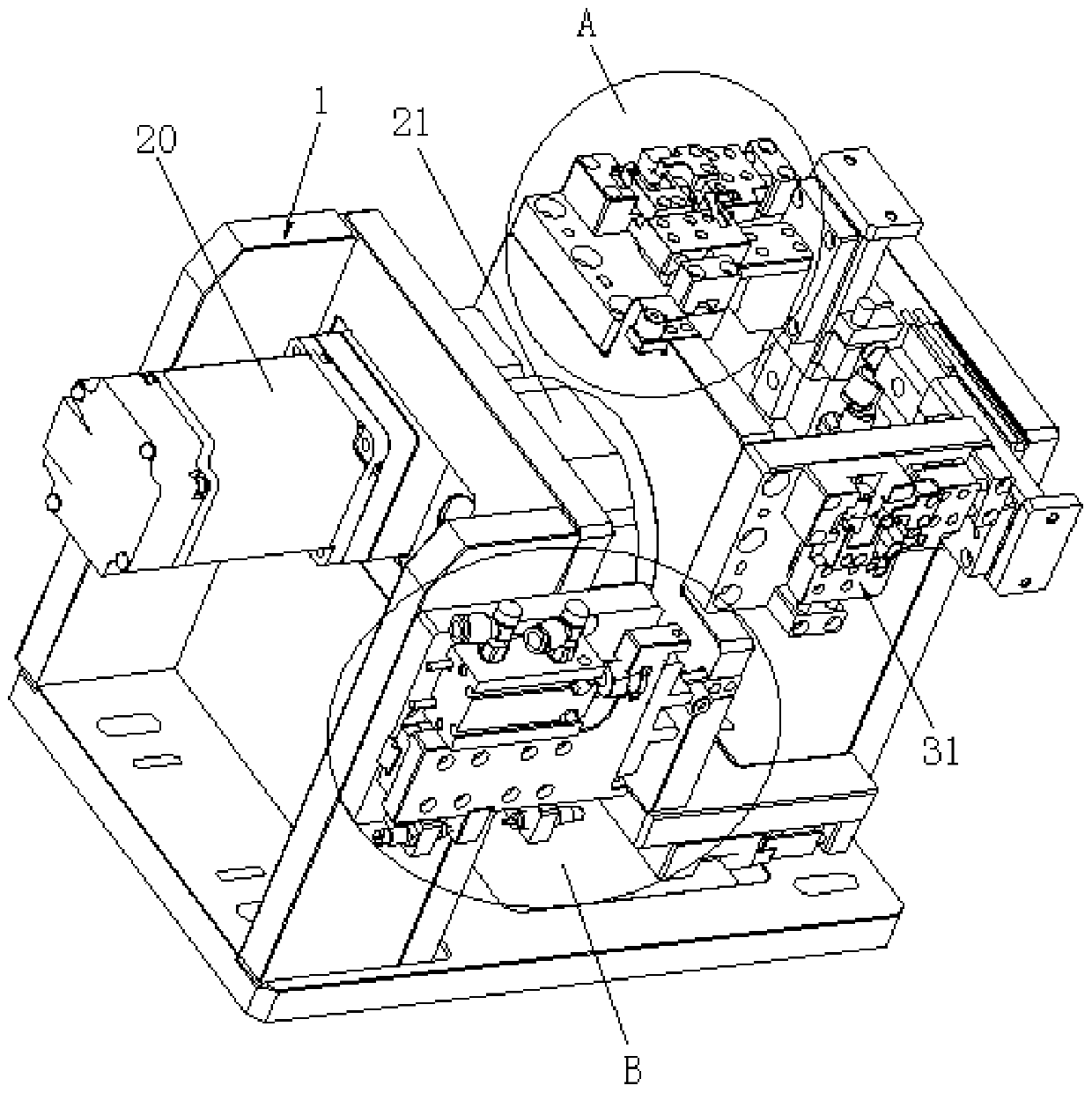

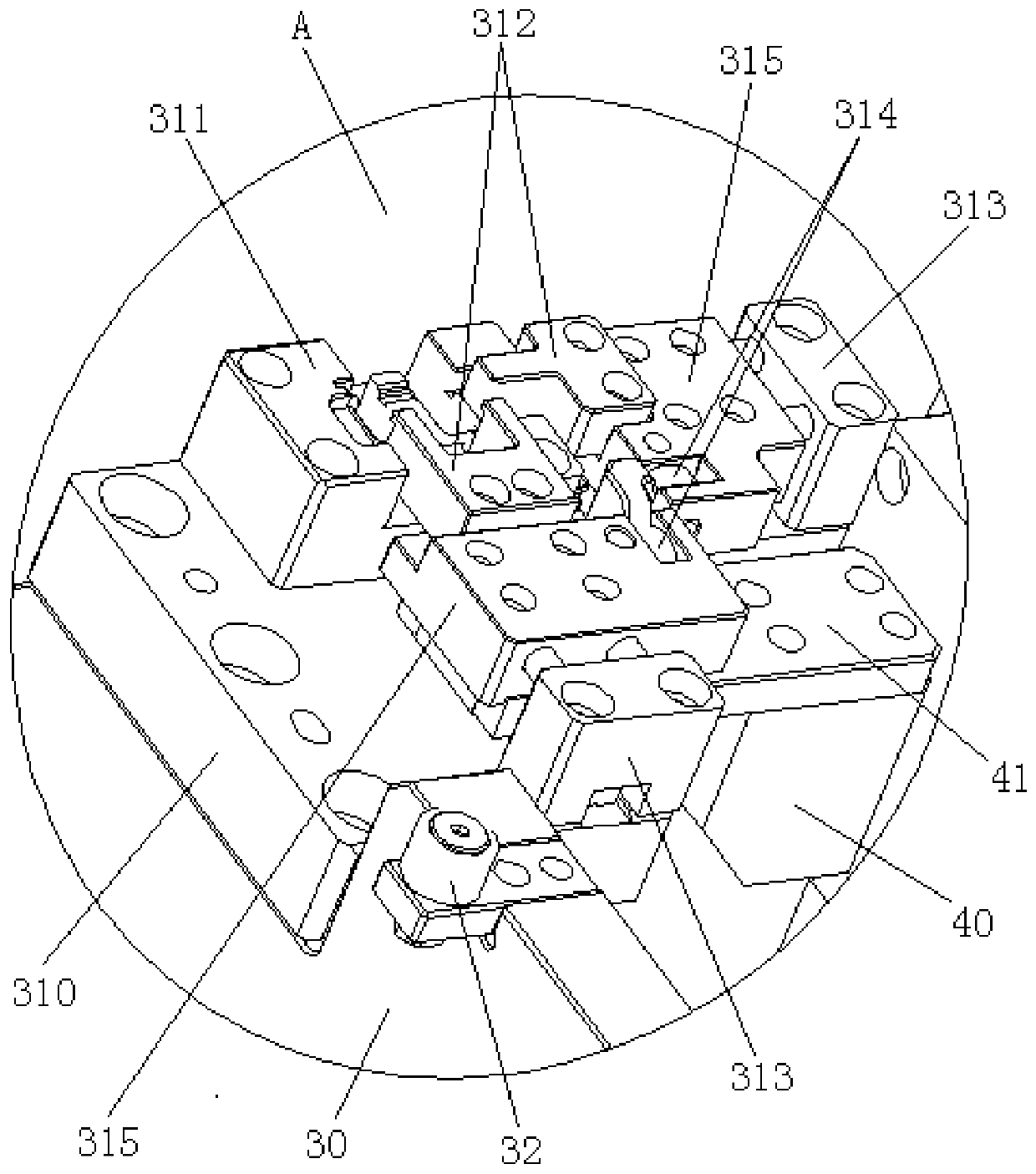

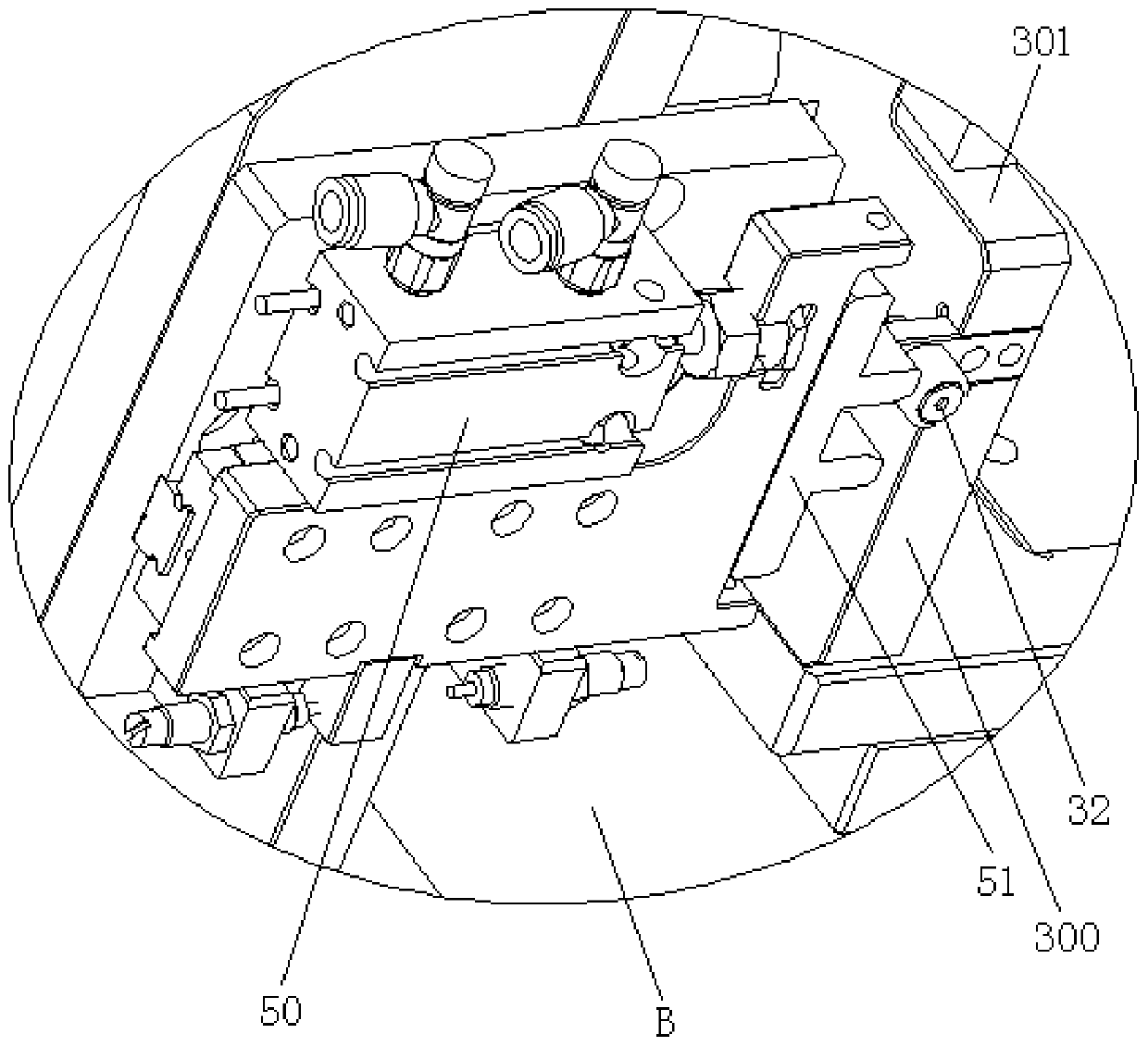

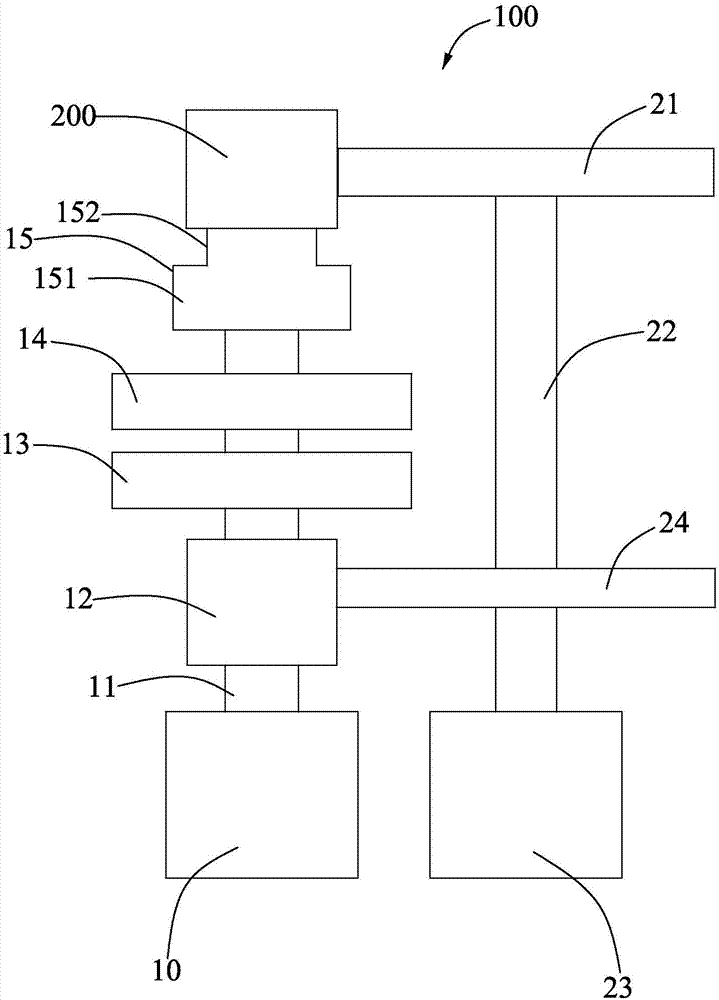

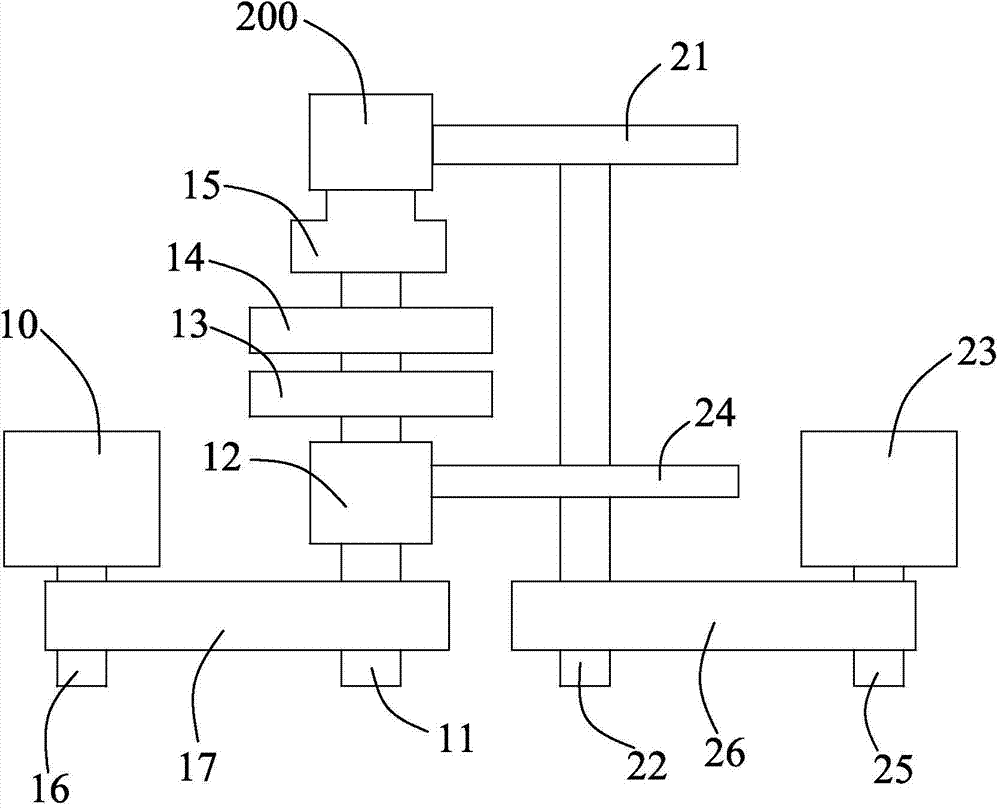

Full-automatic single crystal silicon rod cutting and grinding combined processing integrated equipment and using method thereof

PendingCN110026826AShorten the circulation processProcessing time is shortGrinding carriagesGrinding machinesEngineeringRound bar

The invention relates to full-automatic single crystal silicon rod cutting and grinding combined processing integrated equipment and an using method thereof, and the invention provides the full-automatic single crystal silicon rod cutting and grinding combined processing integrated equipment, which can process a round rod into a square rod by integrated processing of square cutting, corner grinding and surface grinding, so that the problems in the prior art can be solved effectively; the type and quantity of the equipment can be reduced, the area of a plant, the labor and logistics cost can besaved when the processing efficiency of the silicon rod is improved, the processing cost of the silicon rod is reduced and the size precision of the crystal rod is improved. The invention can make asquare cutting assembly and a grinding assembly work independently without interference, and the processing efficiency is improved; in addition, a square cutting grinding power head adopts a symmetrical layout, meanwhile double-sided machining is carried out, so the processing efficiency is doubled.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL

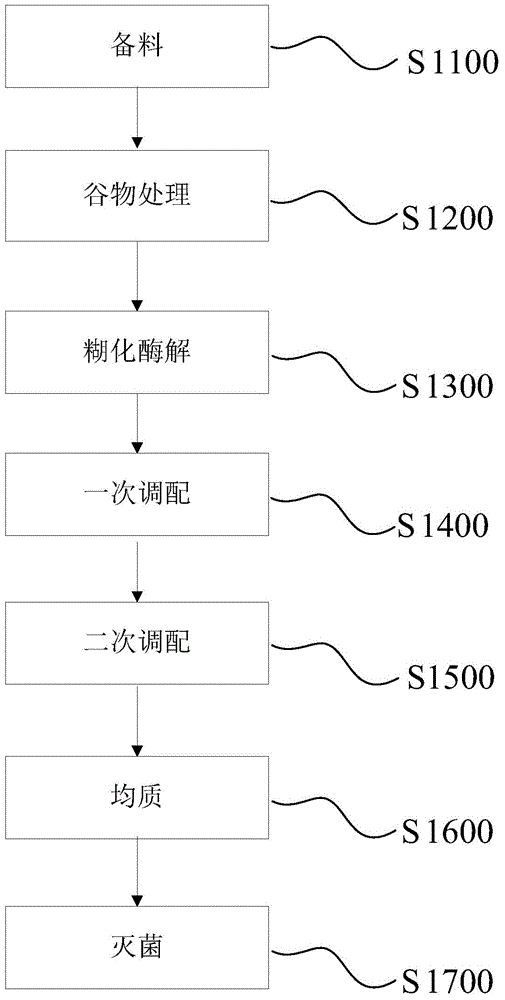

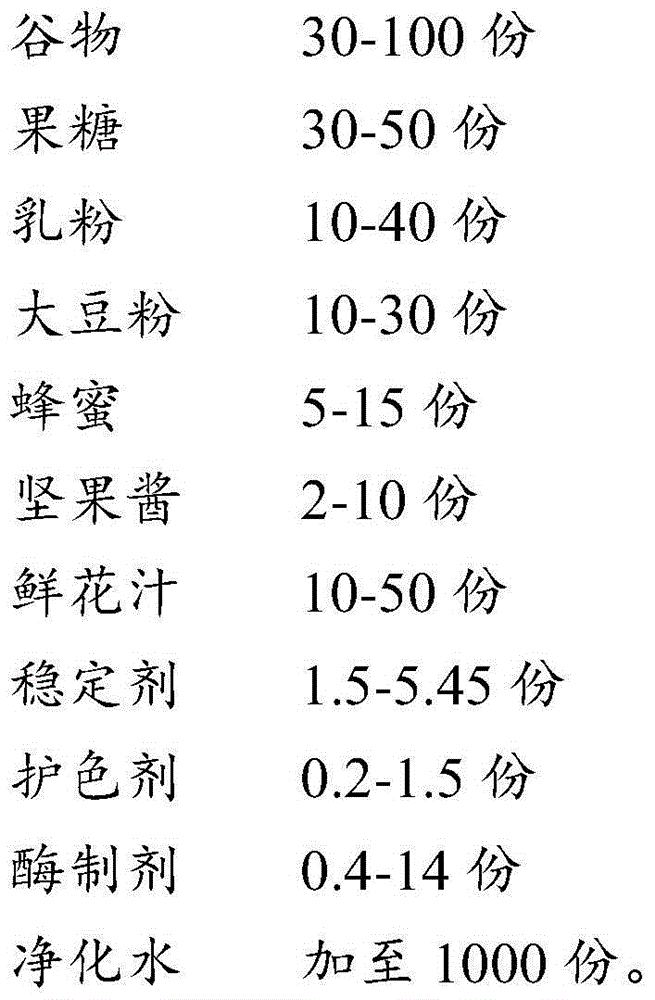

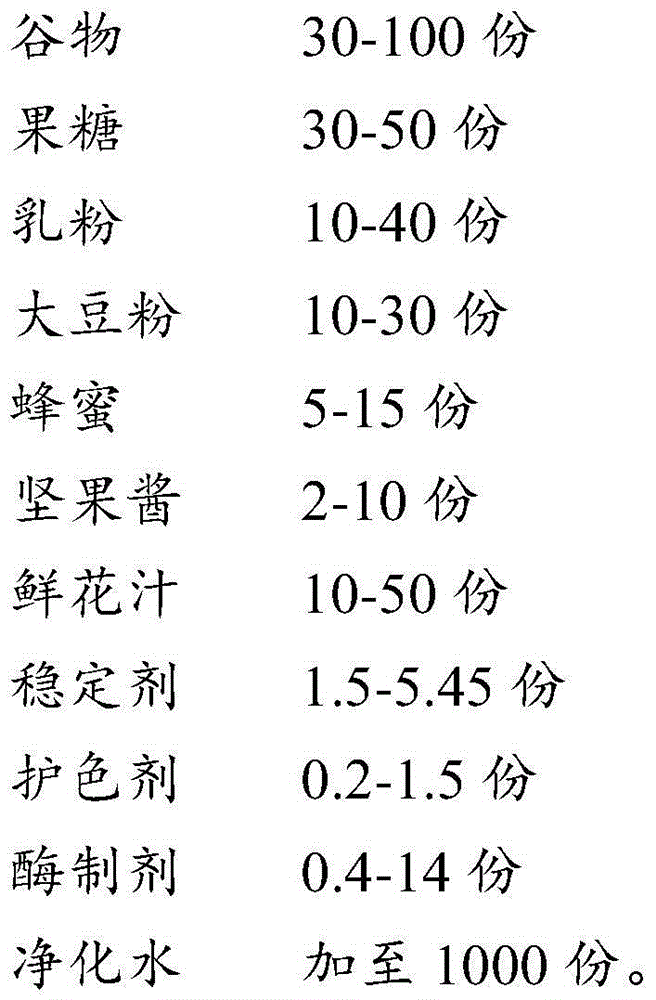

Flower and cereal beverage and preparation method thereof

InactiveCN104473281ASimple production processProcessing time is shortFood scienceMilk productsRaw material

The invention discloses a flower and cereal beverage prepared from the following raw materials in parts by weight: 30-100 parts of cereals, 30-50 parts of fructose, 10-40 parts of milk powder, 10-30 parts of soybean flour, 5-15 parts of honey, 2-10 parts of nut jam, 10-50 parts of fresh flower juice, 1.5-5.45 parts of a stabilizer, 0.2-1.5 parts of a color fixative, 0.4-14 parts of an enzyme preparation and the balance of purified water which is added until the total weight is 1000 parts. The invention also discloses a preparation method of the flower and cereal beverage. The flower and cereal beverage disclosed by the invention is a cool and health beverage prepared from the cereals, the fructose, the milk powder, the soybean flour, the honey, the nut jam, the fresh flower juice and the like and contains dietary elements such as the cereals, nuts, a milk product, beans, the honey and herbage flowers, so that the aims of reasonably replenishing nutrition, balancing the diet and keeping comprehensive nutrition are achieved, and the advantages of edible flower resources in the local of Yunnan are exerted.

Owner:KUNMING XUELAN MILK

Manufacture method for improving solder resist hole plugging ink seepage

InactiveCN108055776ASo as not to damageImprove the defect of oil leakageNon-metallic protective coating applicationResistLight sensing

The invention discloses a manufacture method for improving solder resist hole plugging oil seepage. The method comprises the following steps of: pre-solder resist procedure treatment; pre-solder resist procedure hole plugging; and solder resist treatment. According to the manufacture method of the invention, board baking treatment is additionally adopted, and therefore, residual moisture left in the holes and base materials of a circuit board can be removed, the defect of ink seepage which appears after the solder resist hole plugging and solidification of the circuit board are performed can be effectively eliminated, the quality of a product can be improved, time consumed by solder resist hole plugging and solder resist treatment is shortened, production efficiency can be improved; an abrasive belt is adopted to perform board grinding treatment, so that solder resist can be prevented from sputtering to hole plugging ink on the circuit board during the pre-solder resist procedure holeplugging, and therefore, it can be ensured that a circuit formed during the formation process of an outer-layer pattern will not be damaged; a negative film for solder resist exposure is improved, evenly distributed light sensing points are added on blocking points on the double-side-windowed negative film which are used for solder resist hole plugging, and therefore, the solder resist in throughholes can be exposed to a certain extent; and under the same development condition, the technical procedures of the solder resist in the through holes are decreased compared with those of the ink on the surface of the circuit board, and production efficiency is improved.

Owner:KIN YIP TECHNOLDGY ELECTRONICS HUI ZHOUCO LTD

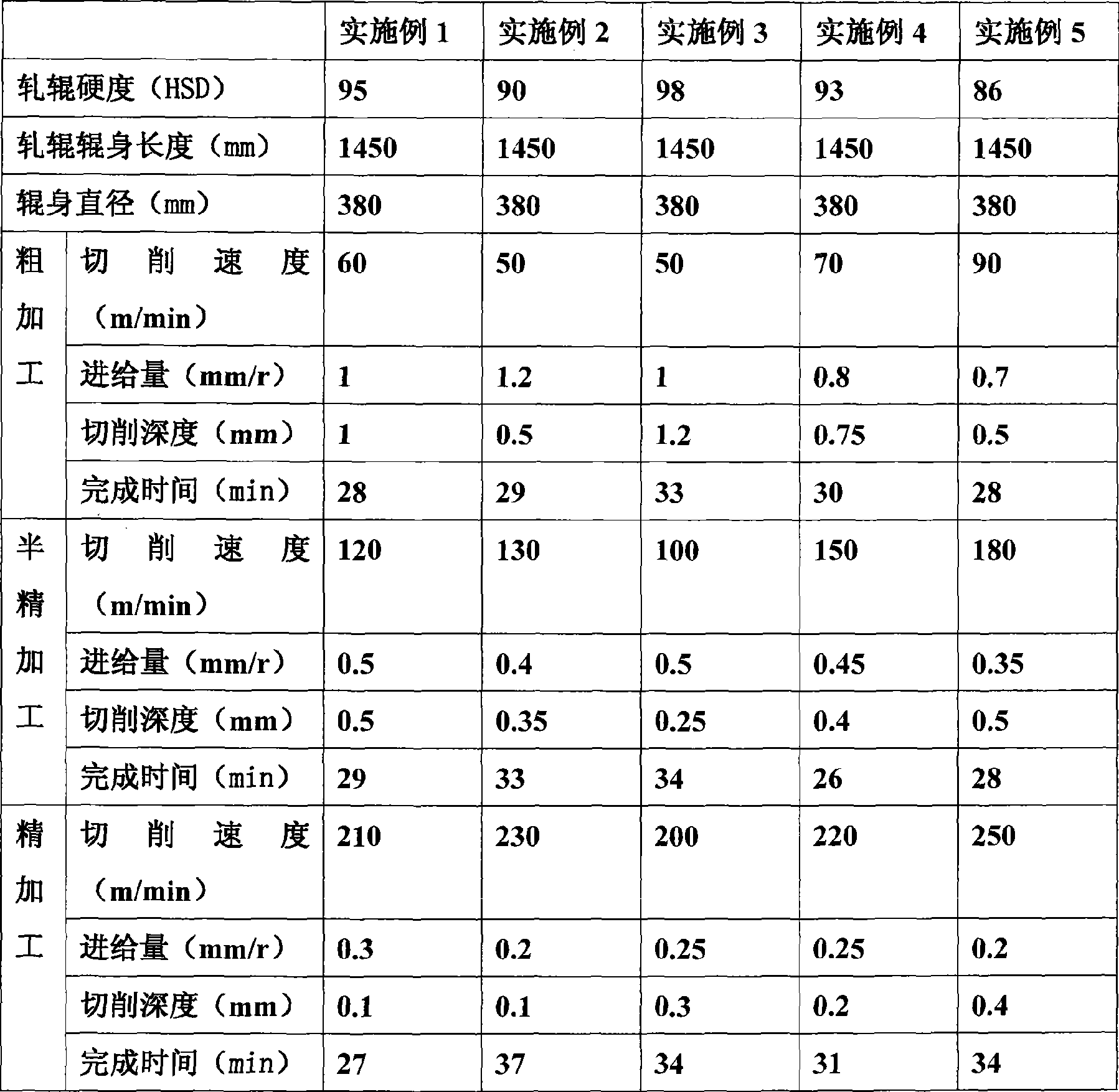

High-hardness roller processing method

ActiveCN101417342AImprove toughnessReduce heat transferAutomatic control devicesFeeding apparatusEngineeringHardness

The invention discloses a processing method of high-hardness rolls, comprising the following steps: (1) the roll with the hardness of 86HSD to 99HSD is placed on a lathe, a CBN polycrystalline blade is used as a lathe tool for carrying out rough machining to the roll at the cutting speed of 50 to 90m / min, the feed amount is 0.7 to 1.2mm / r, and the cutting depth is 0.5 to 1.5mm; (2) the CBN polycrystalline blade is used as the lathe tool for carrying out semifinishing machining to the roll at the cutting speed of 100 to 180m / min, the feed amount is 0.35 to 0.5mm / r, and the cutting depth is 0.2 to 0.5mm; and (3) the CBN polycrystalline blade is used as the lathe tool for carrying out finishing machining to the roll at the cutting speed of 200 to 250m / min, the feed amount is 0.15 to 0.3mm / r, and the cutting depth is 0.1 to 0.5mm. The method has short processing time, high efficiency and low cost.

Owner:BAOSTEEL ROLL SCI & TECH

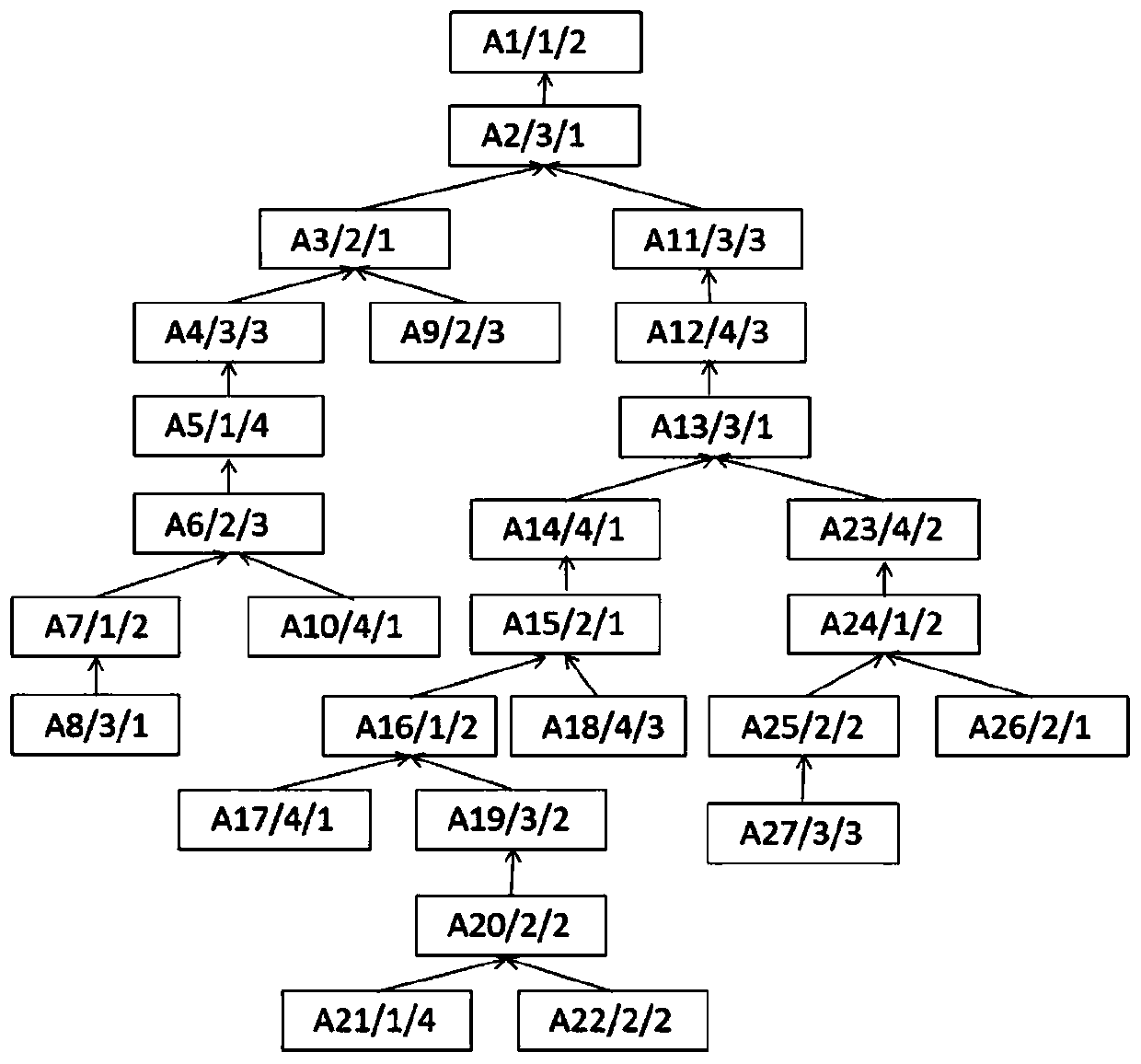

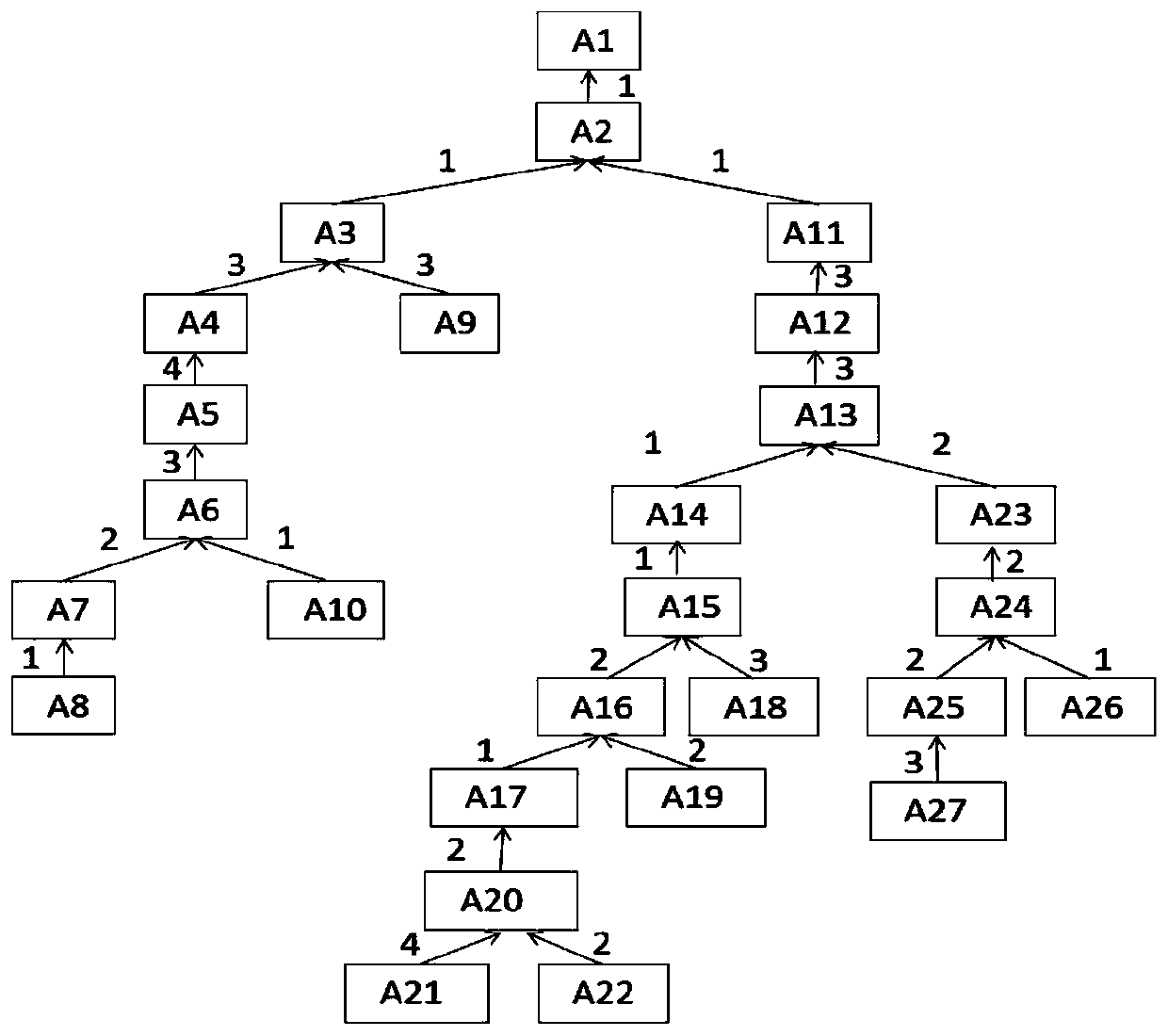

Comprehensive scheduling method based on Dijkstra algorithm

The invention provides a comprehensive scheduling method based on a Dijkstra algorithm, and the method comprises the steps: extracting the processing time of each process according to the natural attribute of a complex product process, and carrying out the path assignment of all processes; calculating a layer priority, an equipment priority and a process constraint degree of each process; according to a Dijkstra algorithm, respectively calculating path values from the root node process to all other processes; and according to the path value judgment strategy, the layer priority judgment strategy and the leaf node process judgment strategy, reversely scheduling each process according to the shortest path principle. The method provided by the invention provides a new method for solving comprehensive scheduling of general complex products, expands thinking for further deep research on comprehensive scheduling, and has certain theoretical and practical significance.

Owner:JILIN NORMAL UNIV

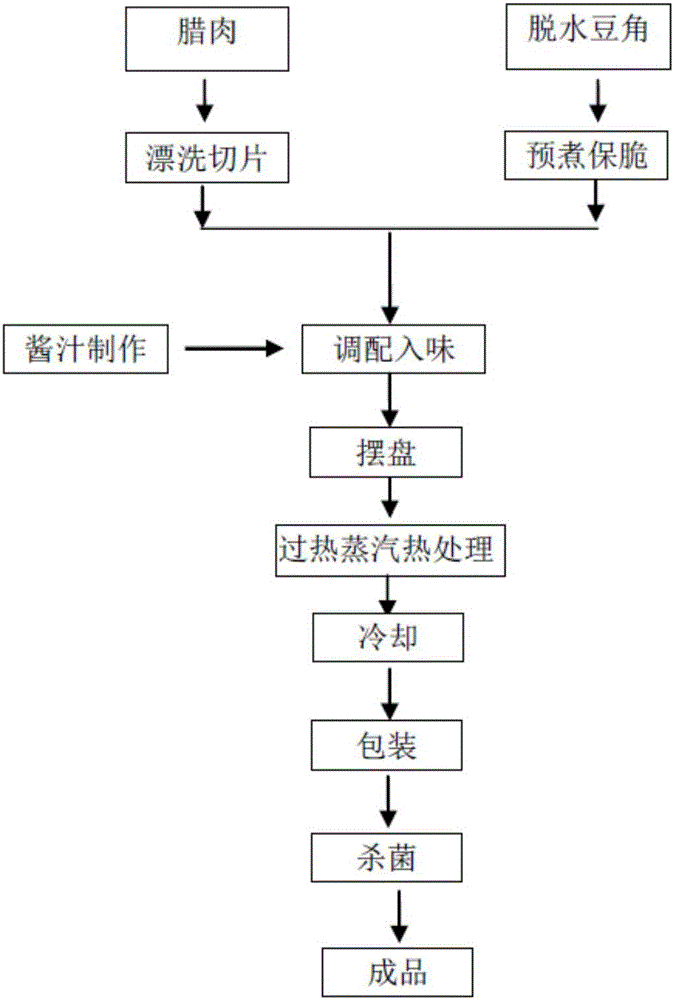

Convenient preserved meat dish and superheated steam processing method thereof

The invention discloses a superheated steam processing method of a convenient preserved meat dish. The method comprises the following steps of: placing raw materials in a superheated steam device; heating the raw materials for 3-10 min under the conditions that the upper fire temperature is 120-150 degrees, the lower fire temperature is 130-160 degrees and the superheated steam temperature is 120-180 degrees to obtain the convenient preserved meat dish, wherein the raw materials include preserved meat slices and blanched dehydrated green beans. The invention also discloses the convenient preserved meat dish. The convenient preserved meat dish is cooked by using the superheated steam, the time consumption for processing is short, the method is simple and convenient; a finished product of the convenient preserved meat dish has the characteristics of bright color, rich meat fragrance, lubrication and refreshing, rich nutrition, convenience for eating and the like, and is especially suitable for being eaten together with rice. A processing technique of the method is normative and scientific and convenient for mechanical operation; according to the method of the product, the raw materials are precooked, the precooked raw materials are pickled by sauce and the pickled raw materials are cooked by the superheated steam, the qualitative and quantitative standardized production can be realized, the quality consistency of preserved meat dishes is kept, and the method can be applied to central kitchen type industrial production.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Modern big-pot brewing method of duck-blood glutinous rice and gingko low-alcohol yellow rice wine

ActiveCN105087280AFunction increaseIncrease biological functionAlcoholic beverage preparationGinkgolideAlpha-amylase

The invention discloses a modern big-pot brewing method of duck-blood glutinous rice and gingko low-alcohol yellow rice wine, and belongs to the technical field of food processing. The modern big-pot brewing method comprises the following steps: polished round-grained rice is taken as the base stock, and mixed with duck-blood glutinous rice and gingko, so that the contents of such active substances as biochrome and ginkgolides in the final yellow rice wine product can be improved; high-temperature alpha-amylase and saccharifying enzyme are respectively adopted for two-step enzymolysis; the raw materials subjected to enzymatic saccharification are mixed with a saccharomyces cerevisiae Chinese yeast for fermentation; after main fermentation, Galactomyces geotrichum KG-1 is added for further fermentation and low-temperature maturation; squeezing, filtering clarification, sterilization and filling are performed to obtain the duck-blood glutinous rice and gingko low-alcohol yellow rice wine. The modern big-pot brewing method for the duck-blood glutinous rice and gingko low-alcohol yellow rice wine has the benefits that as the raw-material high-temperature enzymolysis soaking process is adopted, the processing time is remarkably shortened; as Galactomyces geotrichum KG-1 participates in fermentation of the yellow rice wine, the product alcoholic strength is low, the taste is mellow and refreshing, and the health-care function is enhanced.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

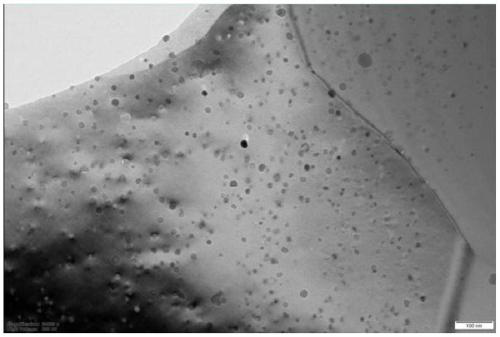

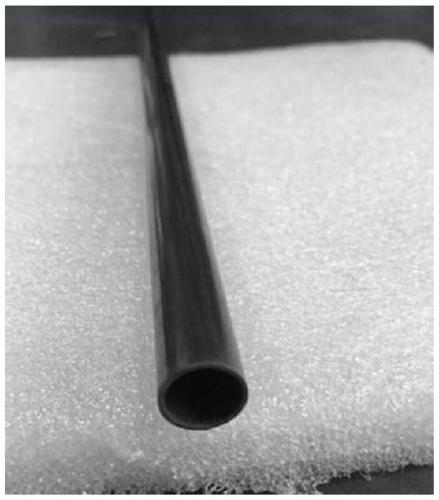

Preparation method for oxide dispersion strengthened FeCrAl alloy pipe

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +3

Gardenia tea and processing method thereof

The invention discloses a method for processing gardenia tea. The method comprises the following steps: performing sealing and standing treatment on fresh gardenia flower buds and tea leaves under certain temperature and humidity conditions, and separating the flowers from the tea leaves after the flowers wither; performing stepped drying treatment on the tea leaves by adopting stepped temperatures, and enabling the water content of the tea leaves to be 4% or less; packaging according to requirements, and storing in a low-temperature environment. The method disclosed by the invention is simple in process, low in energy consumption and low in processing cost, the processed finished product is excellent in condition, fragrant in flavor and lasting in aroma, and the gardenia tea is durable to make, good in taste, bitterness-free and high in yield.

Owner:安徽栀子花岛旅游开发有限公司

Heat-clearing pear powder and preparation method thereof

InactiveCN104286757AFragrant tasteQuenches heat and quenches thirstFood preservationFood preparationPEARFlavor

The invention discloses heat-clearing pear powder and a preparation method thereof. The heat-clearing pear powder is prepared from the raw materials in parts by mass as follows: 40-45 parts of pear powder, 5-10 parts of sugarcane powder, 10-20 parts of lotus root starch, 5-10 parts of mint powder, 10-20 parts of wolfberry powder, 10-15 parts of jasmine tea powder and 3-8 parts of white sugar. The heat-clearing pear powder is formed by composition of multiple raw materials and does not contain any additive, the prepared heat-clearing pear powder is fragrant in taste, sweet and tasty and has effects of clearing heat, quenching thirst, moistening the lung, cooling the heart, removing heat for treating the head and the like. According to the heat-clearing pear powder, nutrition ingredients and flavors of the raw materials are preserved as much as possible during processing, the vacuum low-temperature drying is adopted, the temperature is low, the time is short, the loss of heat-sensitive ingredients in the raw materials is small, and particularly, the preserving rate of Vc in the compound pear powder is high.

Owner:刘艳霞

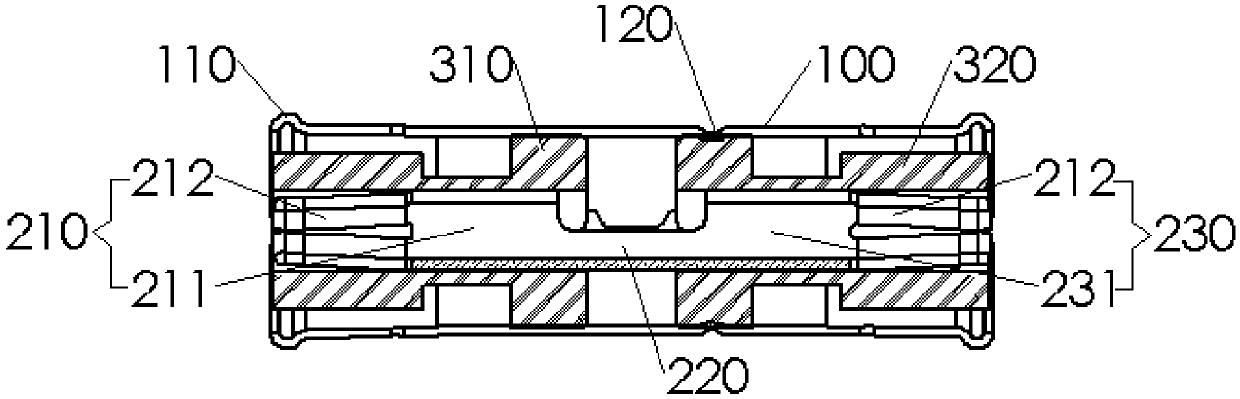

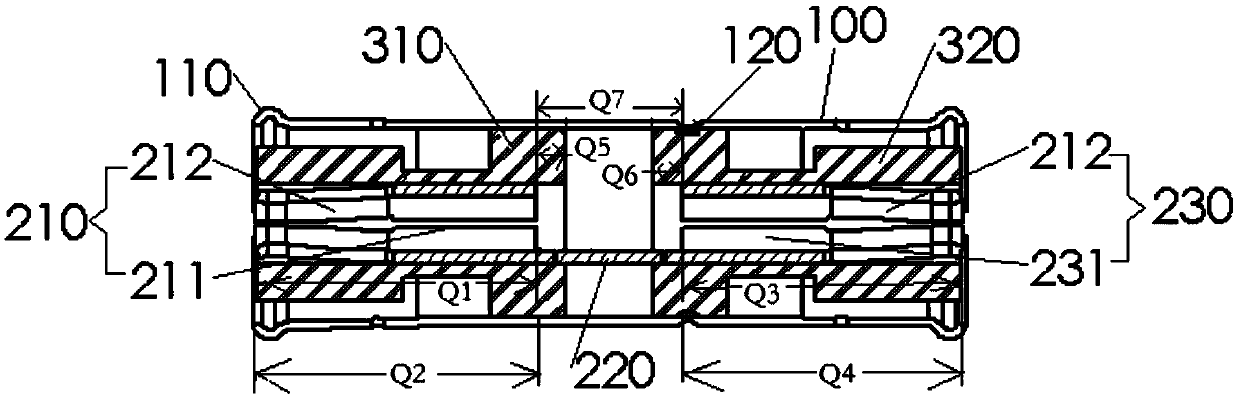

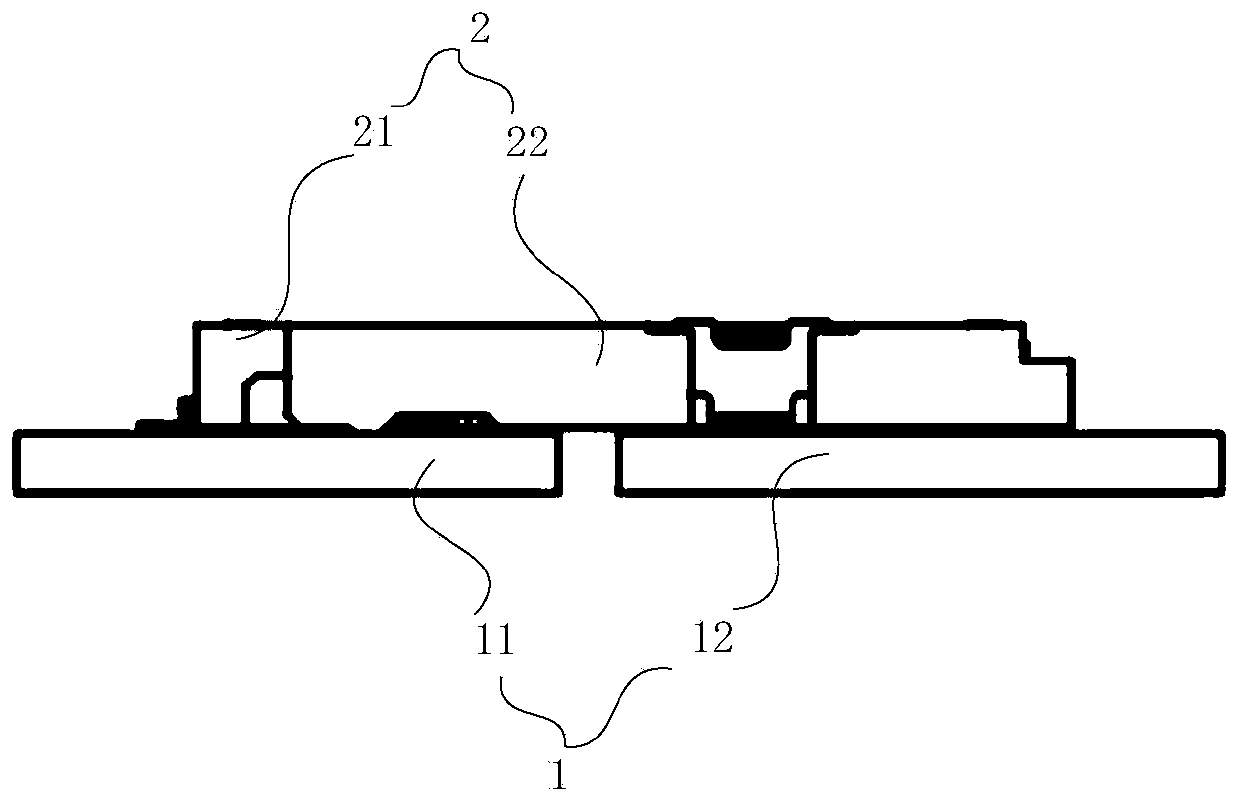

Hybrid RF connector

ActiveCN109728458AOvercome the problem of consuming more raw materialsReduce consumptionContact member manufacturingSecuring/insulating coupling contact membersElectrical conductorEngineering

The invention provides a hybrid RF connector. The hybrid RF connector comprises an outer conductor, a center pin, a first insulator and a second insulator. The outer conductor is made by a metal deepdrawing process; the center pin comprises a first pin portion, a middle portion and a second pin portion connected in order; the central axis of the first pin portion is collinear with the central axis of the second pin portion, the central axis of the first pin portion is taken as the central axis of the center pin; the center pin is made of stamping by employing plates having uniform wall thicknesses and then bending, the first pin portion and the second pin portion are rounded structures, and the middle portion is a bending structure; the center pin is coaxially disposed at the internal portion of the outer conductor; the two ends of the axial direction of the center pin are both provided with plug holes; the two ends of the center pin are respectively clamped into the first insulator and the second insulator, and the first insulator and the second insulator are clamped into the outer conductor. The hybrid RF connector is little in raw material consumption and short in processing time consuming, has two ends with a female pin mode, and can be used for connection between two PCBs.

Owner:SHANGHAI RADIALL ELECTRONICS

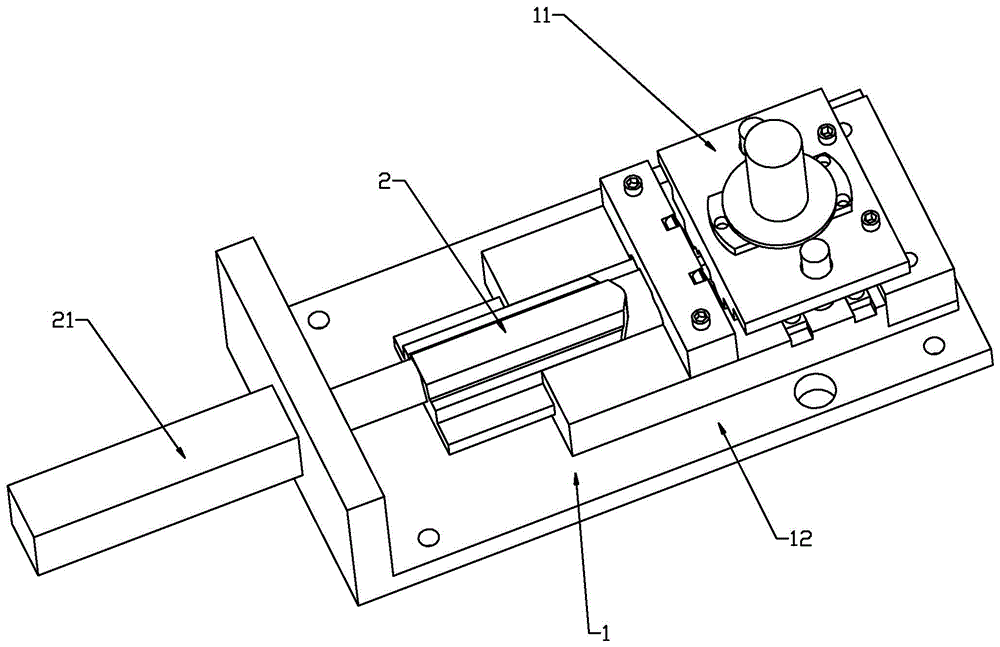

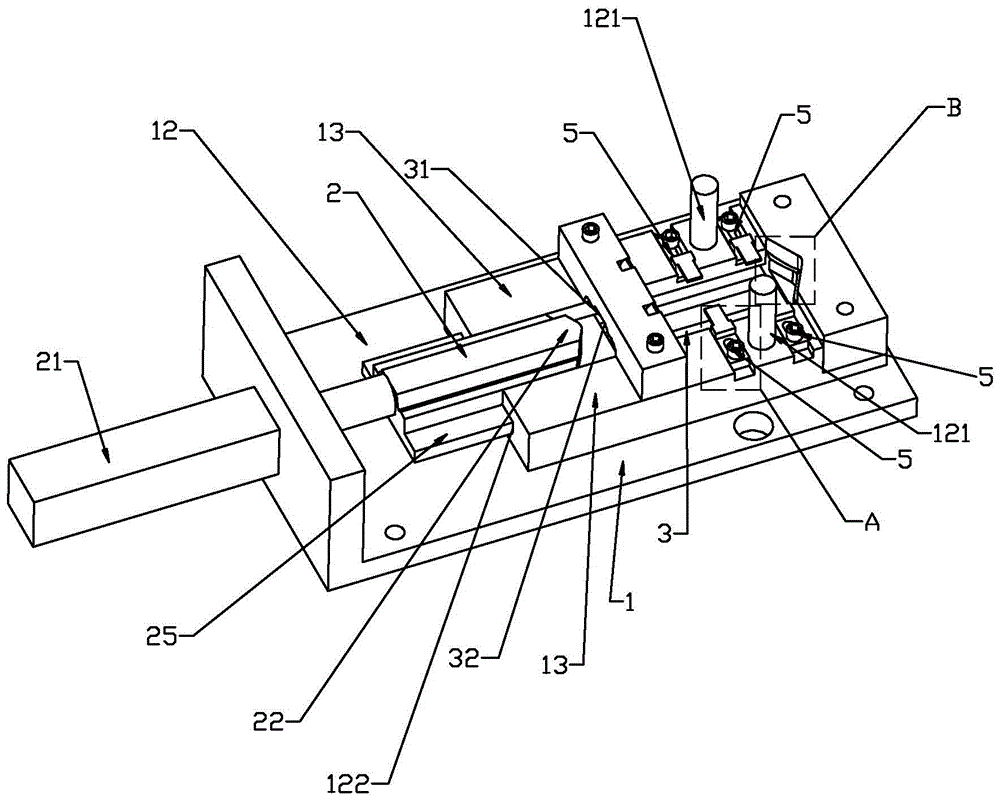

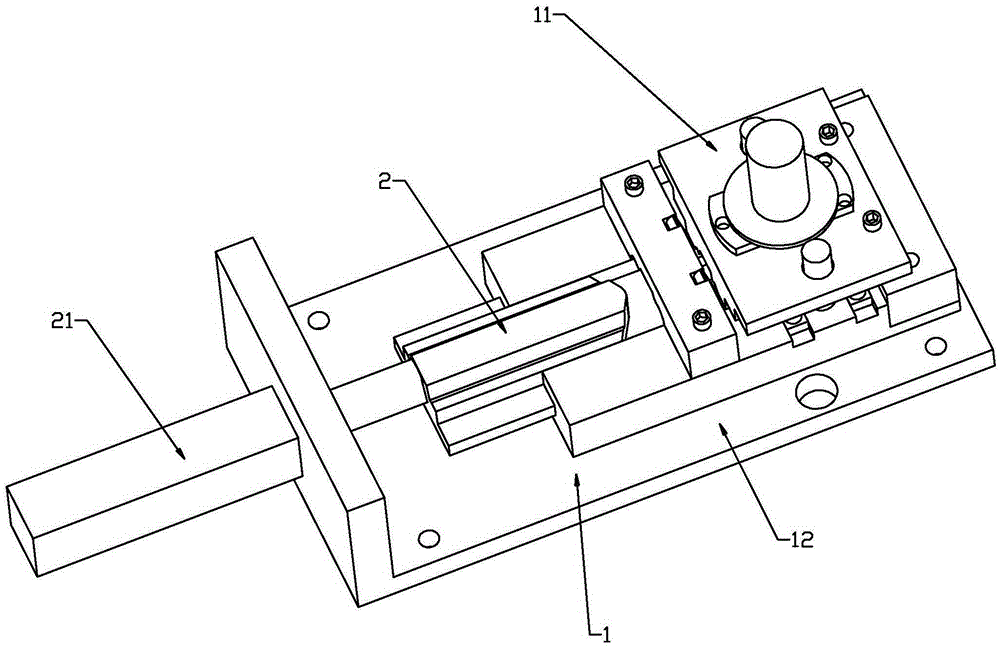

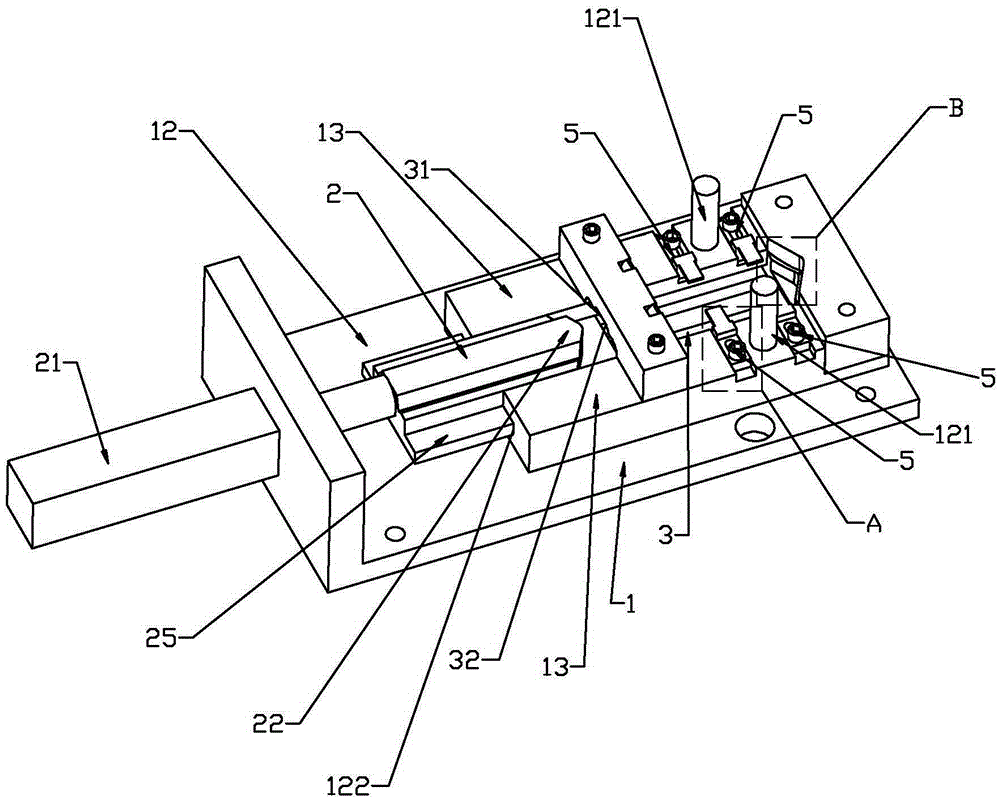

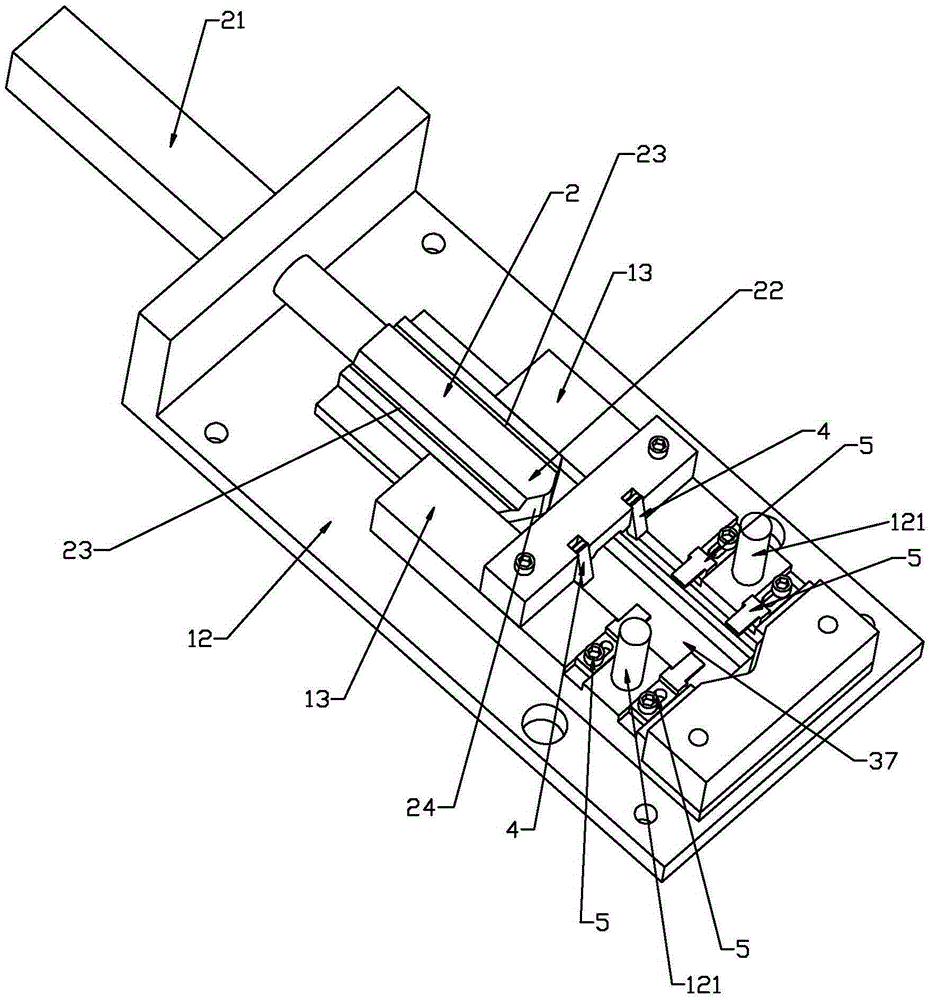

U-shaped metal parts processing equipment

The invention relates to a machining device for a U-shaped metal part. The machining device comprises a machining seat and a push block. A machining cavity is formed in the machining seat, and an inlet and outlet opening is formed in the position, opposite to the push block, of the machining cavity. The push block is provided with a drive mechanism for linearly pushing the push block into the machining cavity. The end, facing the inlet, of the push block serves as a push end for pushing a linear metal part into the machining cavity, and an initial machining part, a side edge shaping part and a bending shaping part are sequentially arranged in the machining cavity along the moving track of the push block. According to the machining device for the U-shaped metal part with the scheme, one-time molding is achieved, and production efficiency is high.

Owner:ZHEJIANG RUISHEN AUTO PARTS

Vertical overturning carrier device

PendingCN110203660AHigh degree of automationProcessing time is shortConveyor partsMotor driveElectric machinery

The invention discloses a vertical overturning carrier device. The vertical overturning carrier device comprises a machine base, a power mechanism and a carrier mechanism. The power mechanism is provided with a motor positioned and mounted on the machine base. The carrier mechanism is provided with a mounting plate and multiple carriers. The mounting plate is positioned and connected to a power output shaft of the motor. Each carrier is provided with a carrying plate positioned and mounted on the mounting plate, a carrying base positioned and mounted on the carrying plate and used for containing products, and at least two clamping blocks movably mounted on the carrying plate, wherein the at least two clamping blocks can synchronously draw close to each other and keep away from each other relative to the carrying base in order to clamp and loosen the products. In addition, when the motor drives the mounting plate to rotate, the multiple carrying plates can have horizontal states and vertical states through rotation of the mounting plate, and when one carrying plate is in the horizontal state, at least one of the remaining carrying plates is in the vertical state. By means of the vertical overturning carrier device, the products can be vertically overturned at high speed, high precision and high stability.

Owner:苏州峰之建精密设备有限公司

Machining device for U-shaped metal part

The invention relates to a machining device for a U-shaped metal part. The machining device comprises a machining seat and a push block. A machining cavity is formed in the machining seat, and an inlet and outlet opening is formed in the position, opposite to the push block, of the machining cavity. The push block is provided with a drive mechanism for linearly pushing the push block into the machining cavity. The end, facing the inlet, of the push block serves as a push end for pushing a linear metal part into the machining cavity, and an initial machining part, a side edge shaping part and a bending shaping part are sequentially arranged in the machining cavity along the moving track of the push block. According to the machining device for the U-shaped metal part with the scheme, one-time molding is achieved, and production efficiency is high.

Owner:ZHEJIANG RUISHEN AUTO PARTS

High-precision plane surface processing method for large planar part

InactiveCN101209532BMeet the precision requirementsExpand the scope of processingPlane surface grinding machinesEngineeringRoughcast

Owner:WUHAN MARINE MACHINERY PLANT

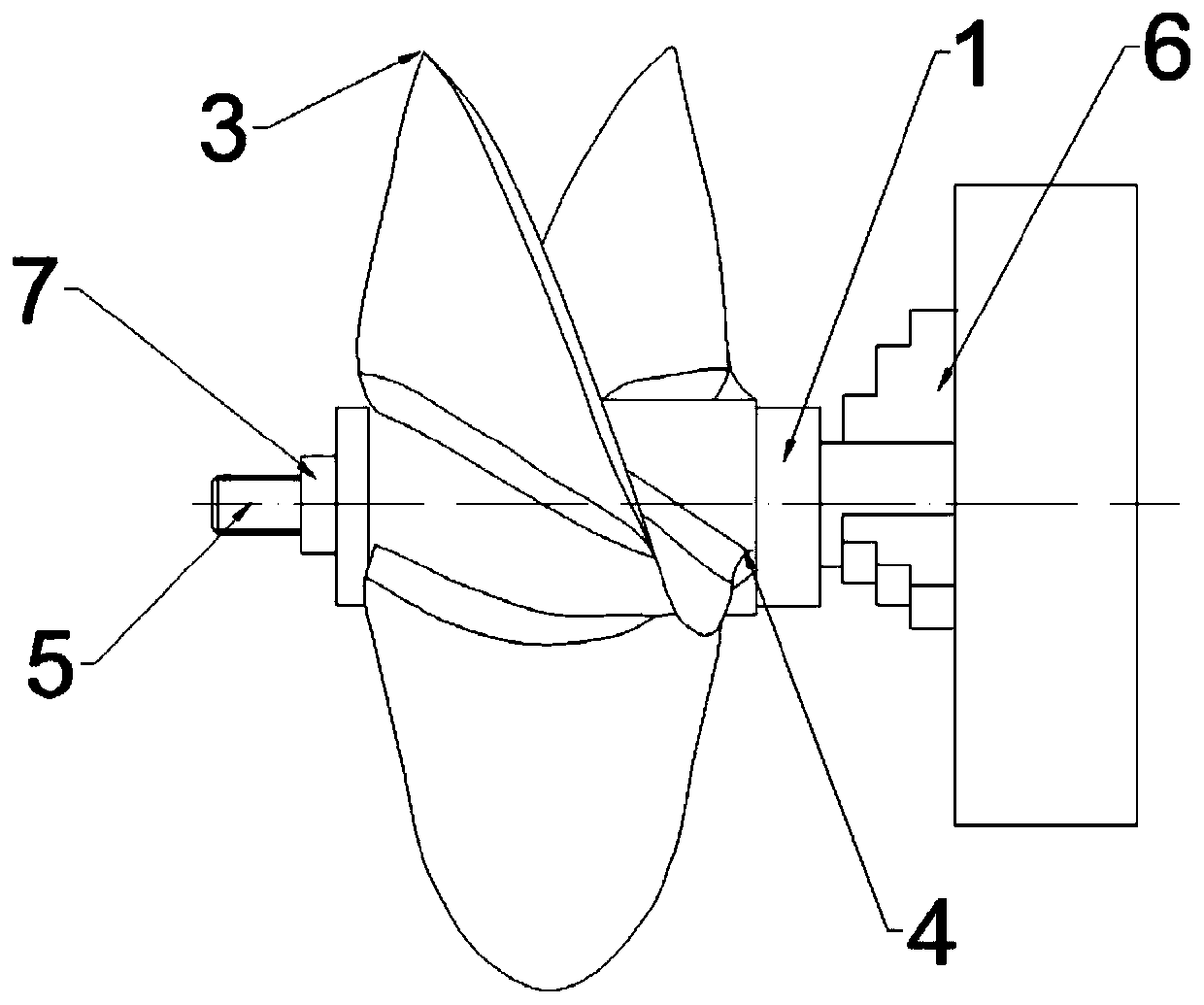

Propeller machining technology

ActiveCN110315295AProcessing time is shortReduce manufacturing costPropellersRotary propellersPropellerEngineering

The invention discloses a propeller machining technology. According to the propeller machining technology, a four-axis machining center presets a movement path of a marking knife, and according to comparison of the thicknesses of the outer contours of a blank blade on the two sides of the movement path of the marking knife, whether the position of the marking knife is right or not is judged; afterthe position of the marking knife is centered, the null position of the four-axis machining center is determined, with the intersection point between the axis of a center through hole of a propellerhub and the front end face of the propeller hub at the moment as the null point, blade backs and blade faces of all the propeller blades are sequentially machined; during machining, marking on each blade of the blank is not needed, so that the machining time is greatly shortened, and production cost is lowered.

Owner:重庆市万州区腾伟机械有限公司

Process for forging and forming welding neck flanges for connecting pipelines

InactiveCN112475203AUniform heating rateUniform temperatureMetal-working apparatusWheelsPunchingIntermediate frequency

The invention belongs to the technical field of forging of flanges and particularly relates to a process for forging and forming welding neck flanges for connecting pipelines. The process comprises the following steps: blanking, heating, preforming, forming and punching. An intermediate frequency furnace is used for heating blanks; the blanks are firstly preformed and upset into cake shapes afterbeing heated, and then the upset blanks are inversely placed into a forming die and are closed and formed; in the preforming process, a 1000T electric screw press is used for preforming and upsettingcylindrical blanks; then a neck part of a 2500T electric screw press forming die is filled by a punch; and 315T closed single-point punching is used for cutting off the connected skin and blanking. The process has the beneficial effects that accurate discharging is achieved after allowance is added to the finished product; the sizes of the forged products are uniform and controllable; stable batchproduction is realized; the production efficiency is improved; in addition, the effects of saving the cost and reducing the time consumption are achieved; and the the economic benefit is increased.

Owner:SHANDONG IRAETA HEAVY IND

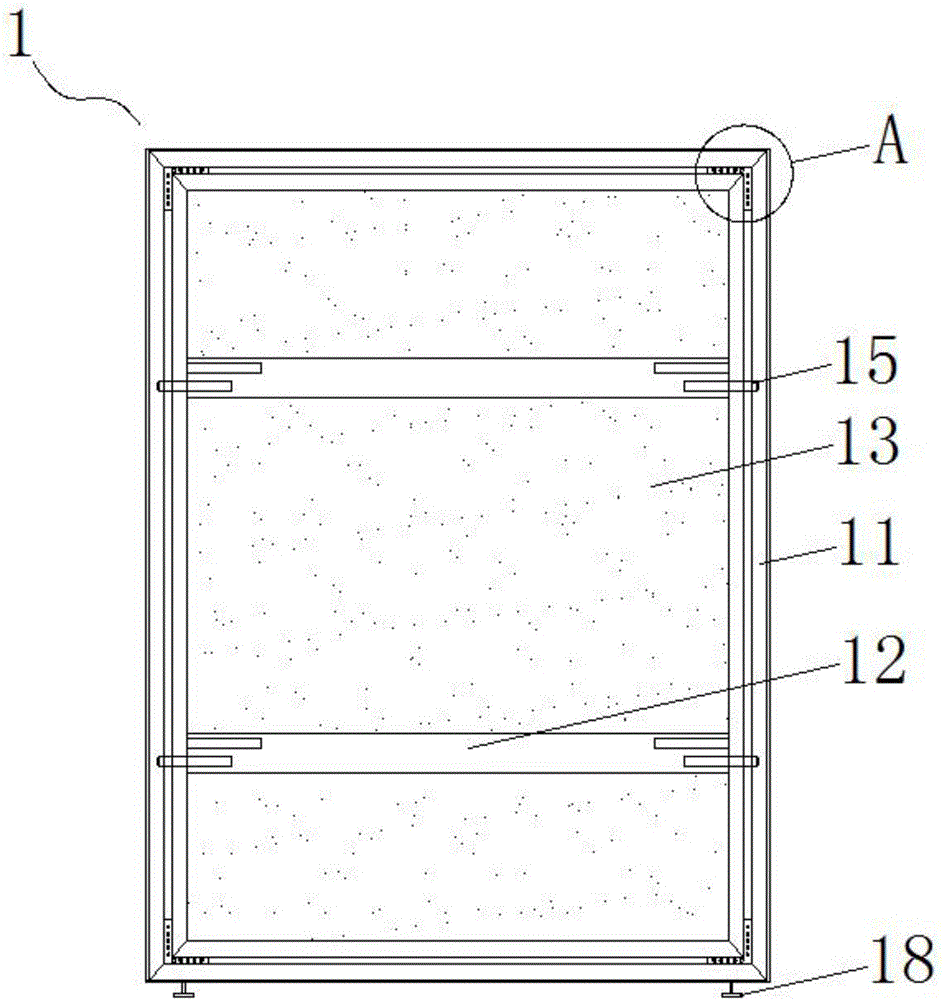

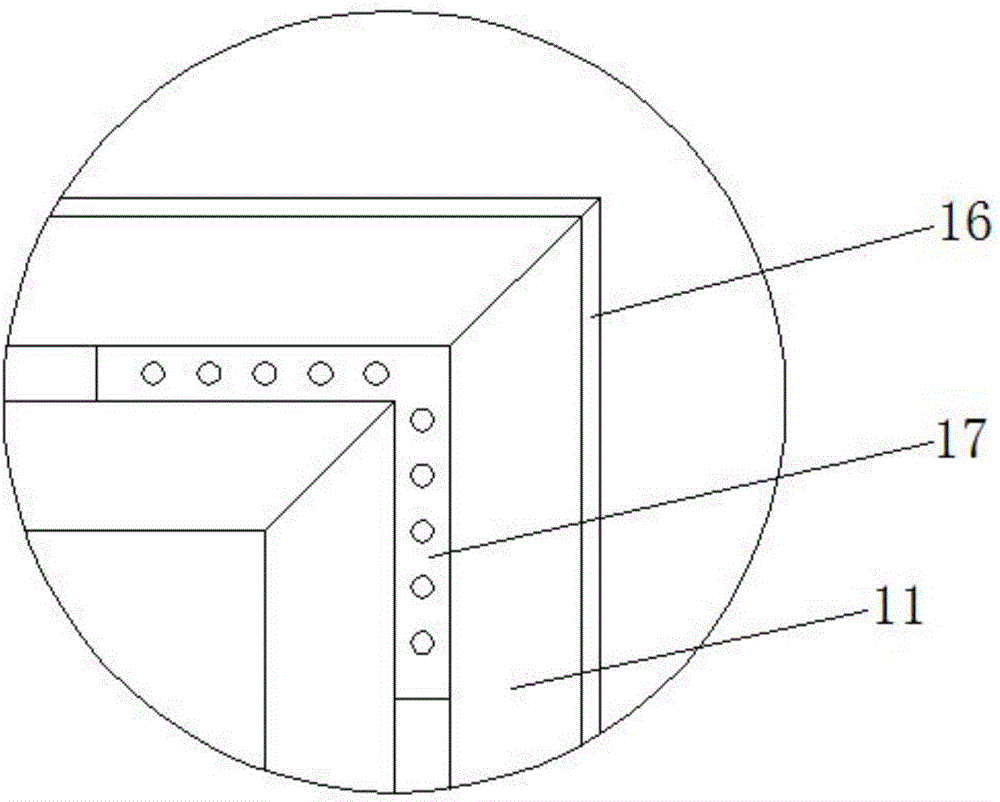

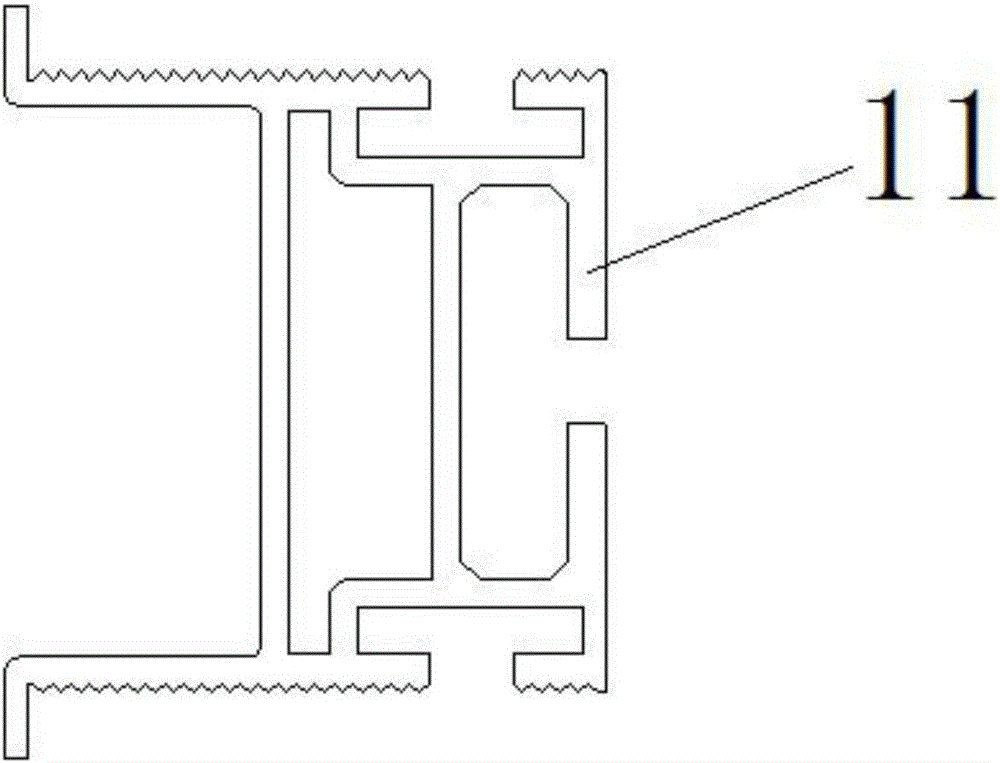

Partition assembly of exhibition room

The invention discloses a partition assembly of an exhibition room. The assembly comprises a plurality of integral wall boards and connecting columns for connecting the integral wall boards. The connecting columns comprise an L-shaped connecting column, a cross-shaped connecting column, a T-shaped connecting column, a 135-degree connecting column and a straight line connecting column; connecting grooves are formed in two sides of each of the integral wall boards; bosses which are consistent with the connecting grooves of the integral wall boards in width and thickness are formed in the previous four connecting columns, and the width of the side face, provided with the bosses, of the previous four connecting columns is consistent with the thickness of the integral wall boards; the width of the straight line connecting column is consistent with that of the connecting groove of the integral wall board, and the thickness of the straight line connecting column is twice as much as the depth of the connecting groove of the integral wall board. The combined partition disclosed by the invention is small in gap, more attractive in appearance, easy to process, short in processing period, good in consistency, relatively light in weight and stable and reliable in structure.

Owner:常州创高展览用品有限公司

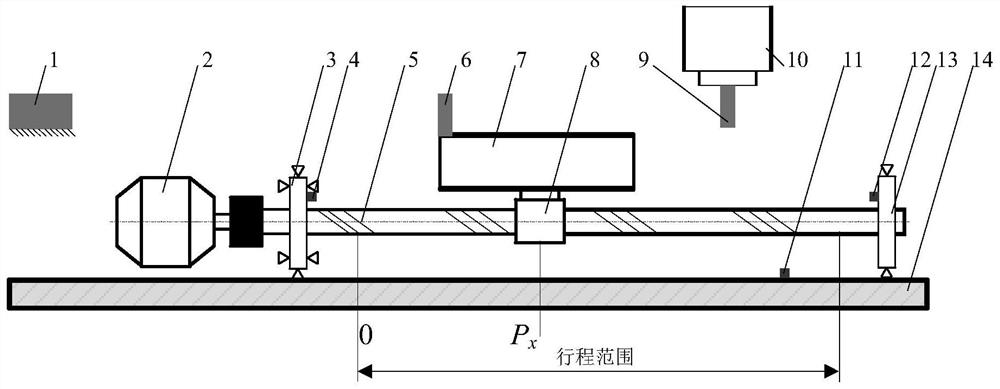

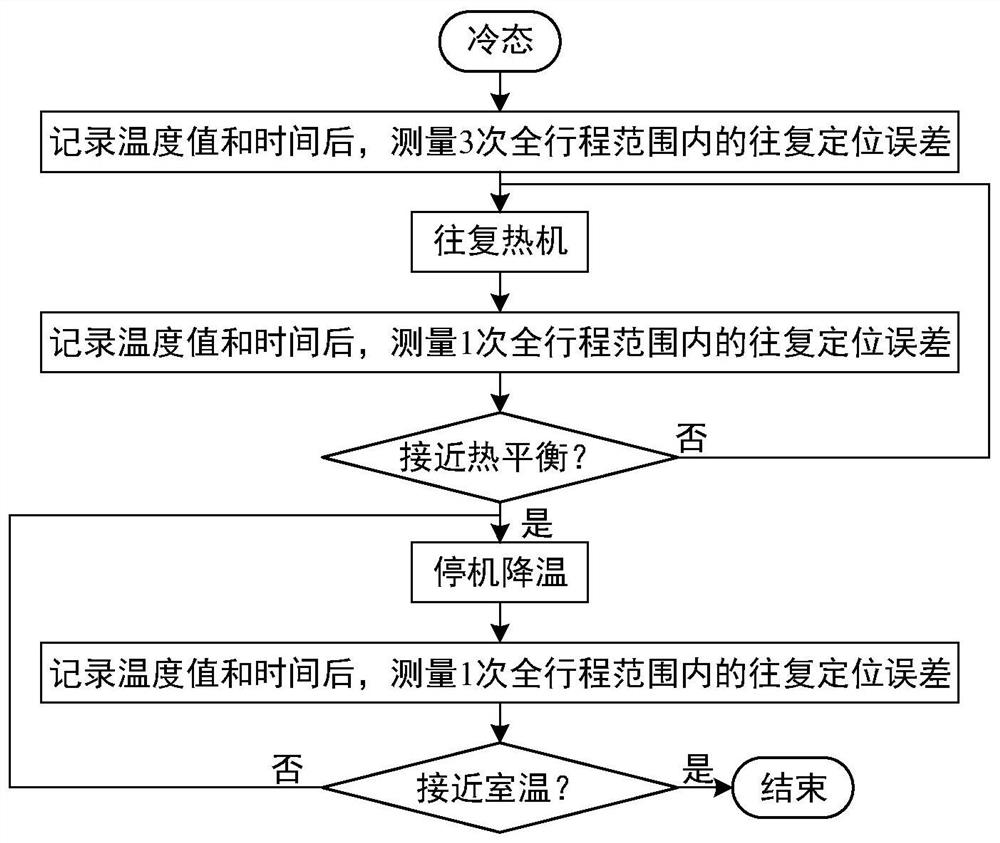

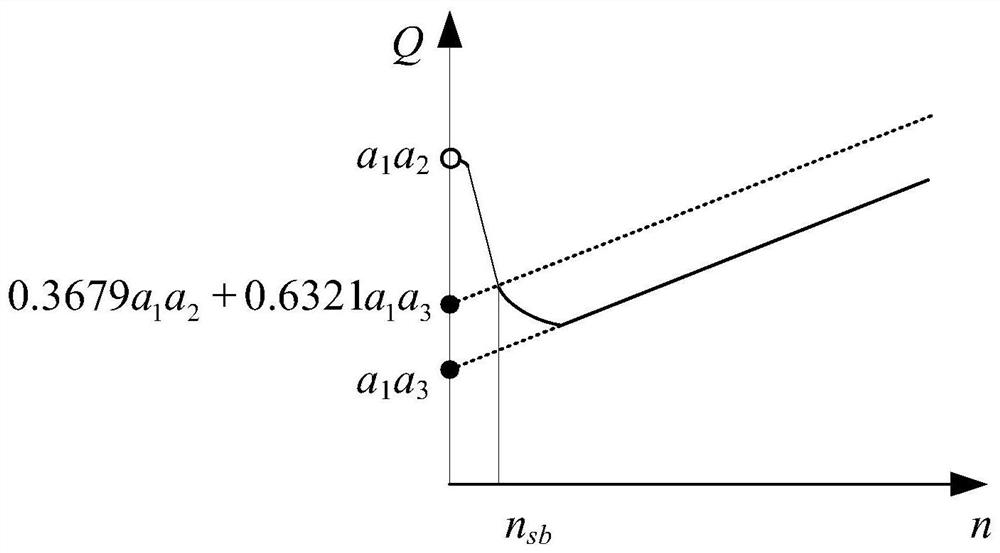

Numerical control machine tool thermal error self-adaptive compensation method

InactiveCN113009882AImprove machining accuracyExpand the scope of processingProgramme controlComputer controlNumerical controlThermodynamics

The invention belongs to the field of numerical control machine tool error compensation, and discloses a numerical control machine tool thermal error self-adaptive compensation method, which comprises the following steps of: obtaining a thermal error of a feed shaft and a corresponding key point temperature by adopting a laser interferometer and a temperature sensor according to a specific measurement mode; establishing a thermal error prediction model of the lead screw under the excitation of the multi-time-varying dynamic heat source; automatically identifying thermal characteristic parameters in the temperature field prediction model by adopting an interior point method; establishing an adaptive adjustment model for a friction heat generation coefficient Q in the thermal error prediction model under the excitation of the multi-time-varying dynamic heat source; providing a thermal error self-adaptive compensation method capable of correcting the friction heat generation coefficient Q in real time by considering the short-term friction characteristic change of the lead screw nut pair; and finally, compensating the thermal error of the machine tool through a thermal error compensation system. The numerical control machine tool thermal error self-adaptive compensation method is high in prediction precision, the problem that thermal error compensation precision fluctuates due to short-term friction characteristic changes is solved, and the robustness of the thermal error compensation method is improved.

Owner:DALIAN UNIV OF TECH

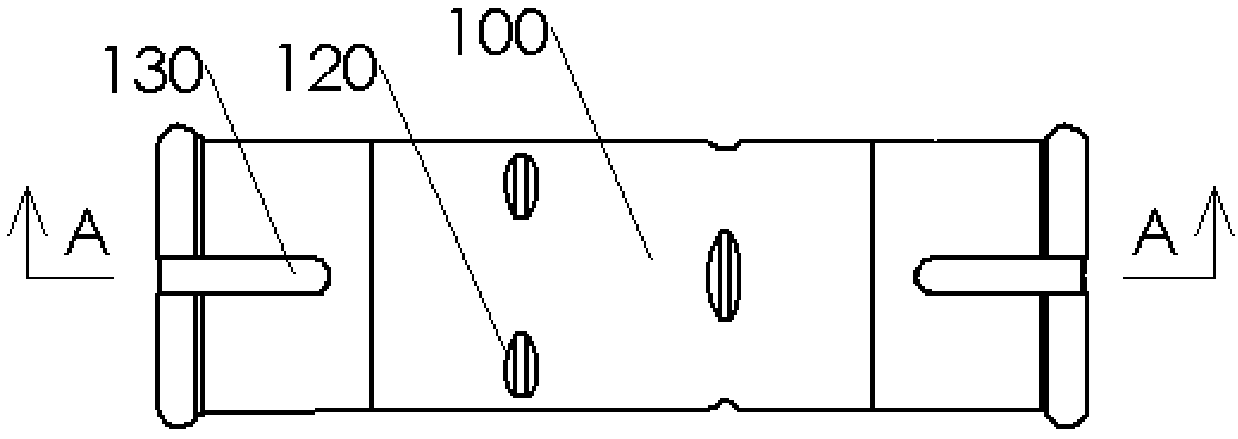

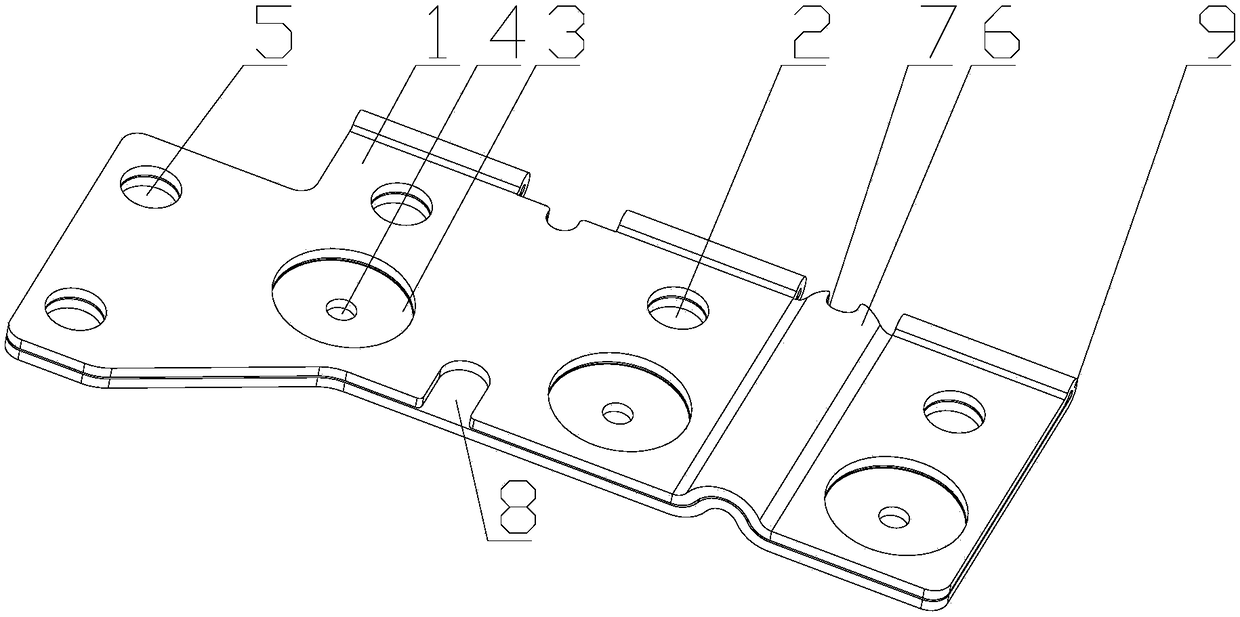

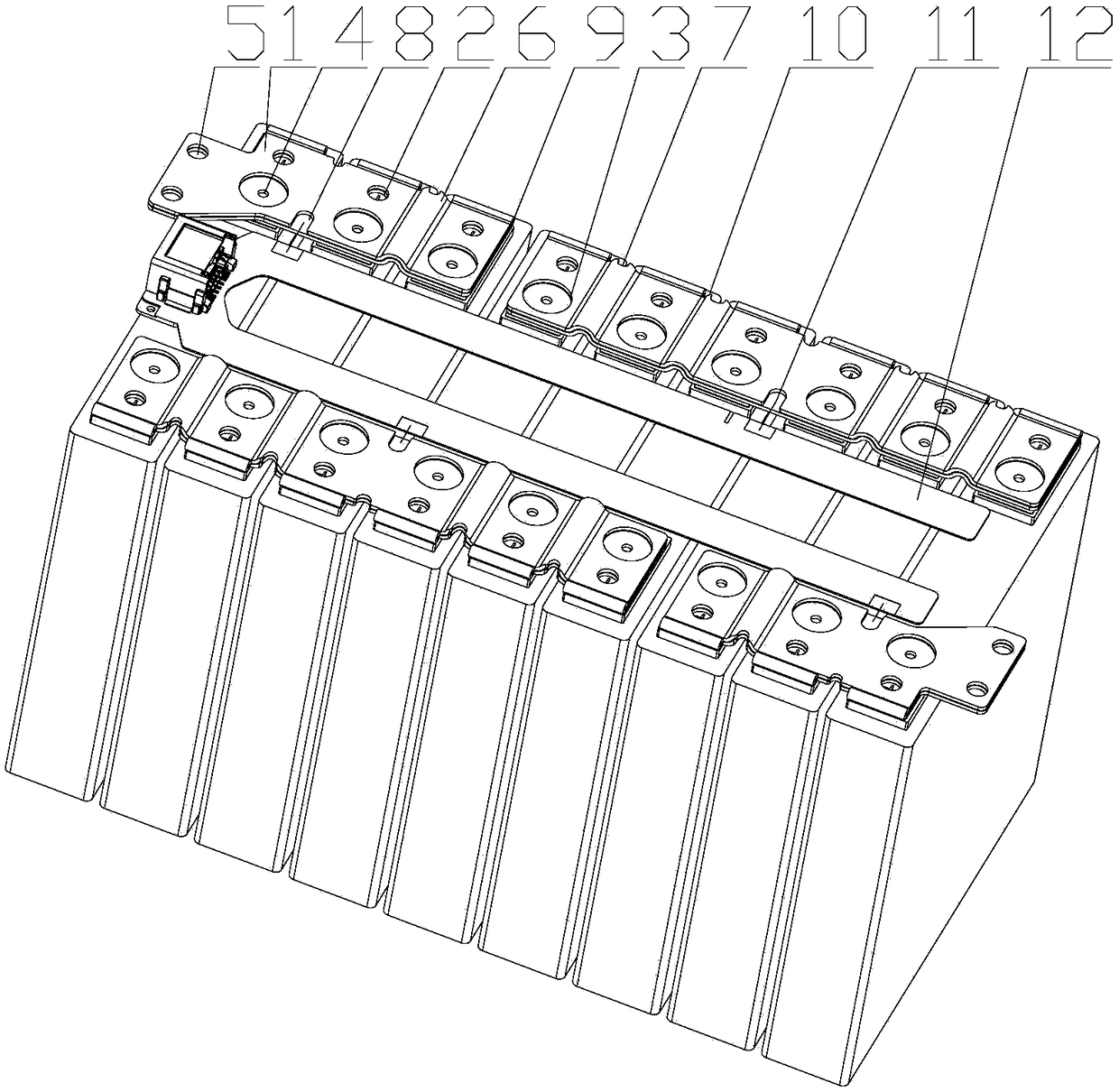

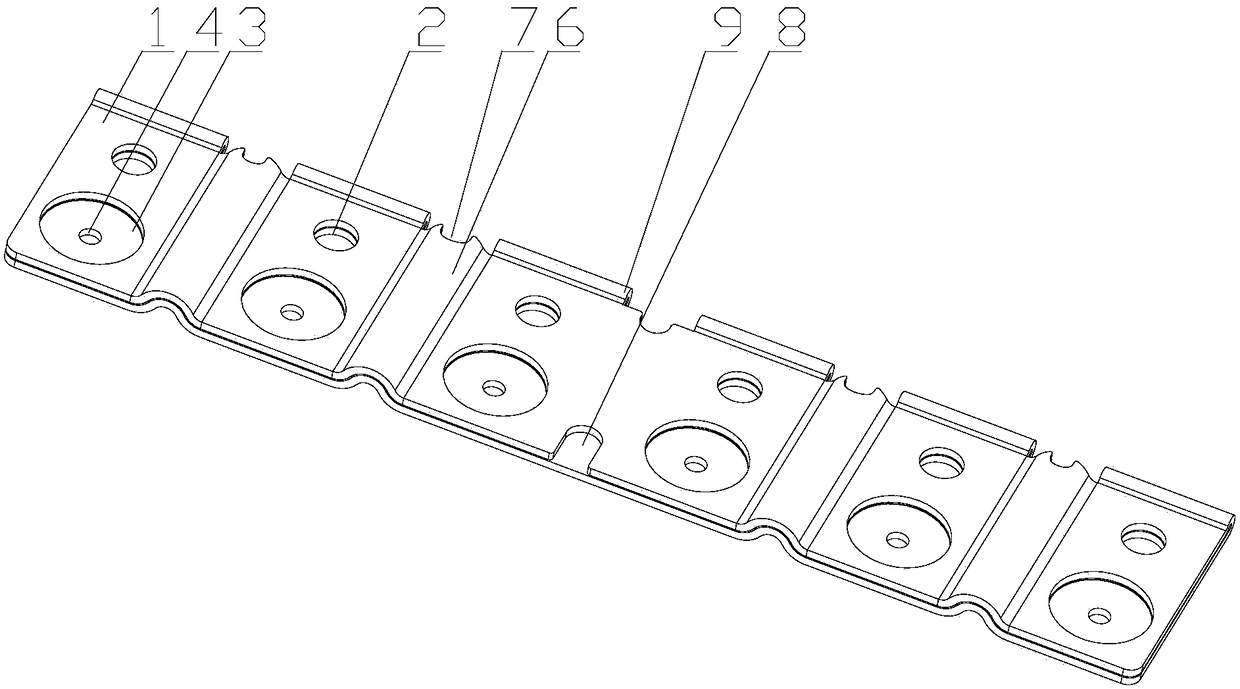

Busbar of high-rate discharging module

PendingCN108429101AAvoid damageIngenious structureCoupling device connectionsCell component detailsHigh rateBusbar

The invention discloses a busbar of a high-rate discharging module. The busbar comprise a busbar body, the busbar body is composed of two layers of base materials, battery-cell-polarity observing holes are formed in the two layers of base materials of the busbar body through penetrating, and positions of the battery-cell-polarity observing holes correspond to pole-column identification positions of battery cells; welding area holes are formed in the first layer of base material of the busbar body, positions of the battery-cell-polarity observing holes correspond to pole-column positions of thebattery cells, and welding observing holes are formed in the portions, located in the welding area holes, of the second layer of base material of the busbar body. The busbar has the advantages that the structure is ingenious, the busbar completely fits pole columns of the battery cells, laser welding welding is achieved, and the performance is safe and stable; the busbar is formed through stamping and bending of the single layer of base material, the cost is low, the requirement of the high-rate discharging module can be met, the processing labor hour is short, manpower and material resourcesare saved, dissipation is reduced, and batch and automatic production can be achieved.

Owner:镇江科信动力系统设计研究有限公司

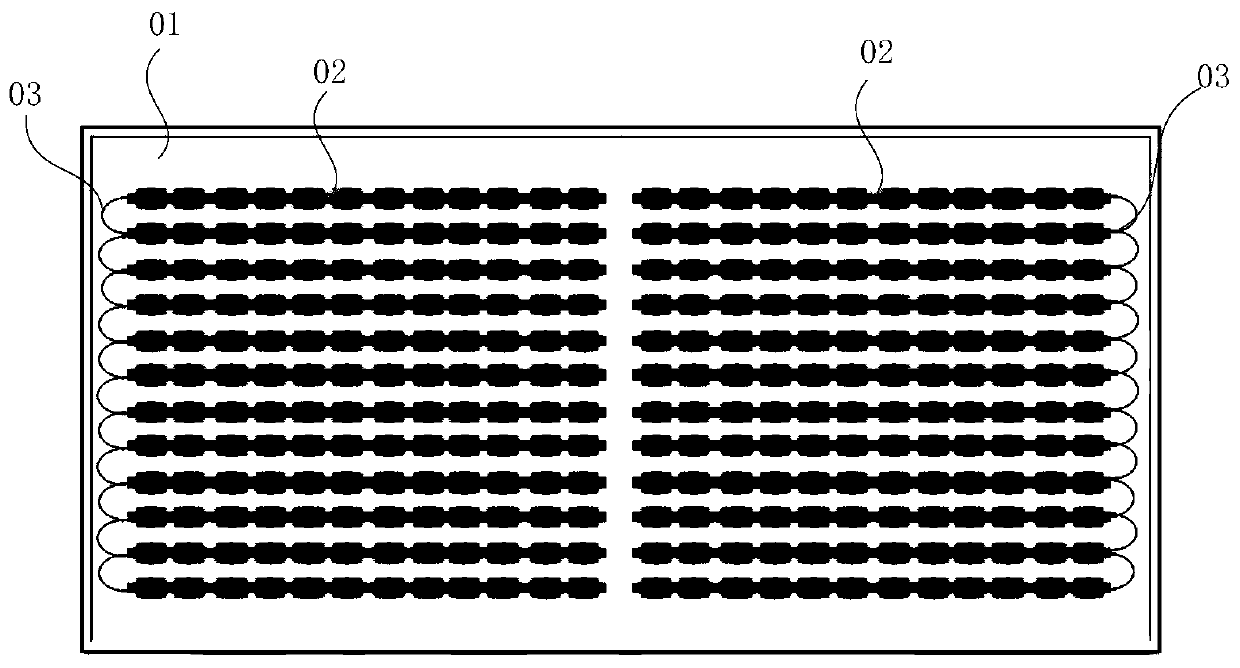

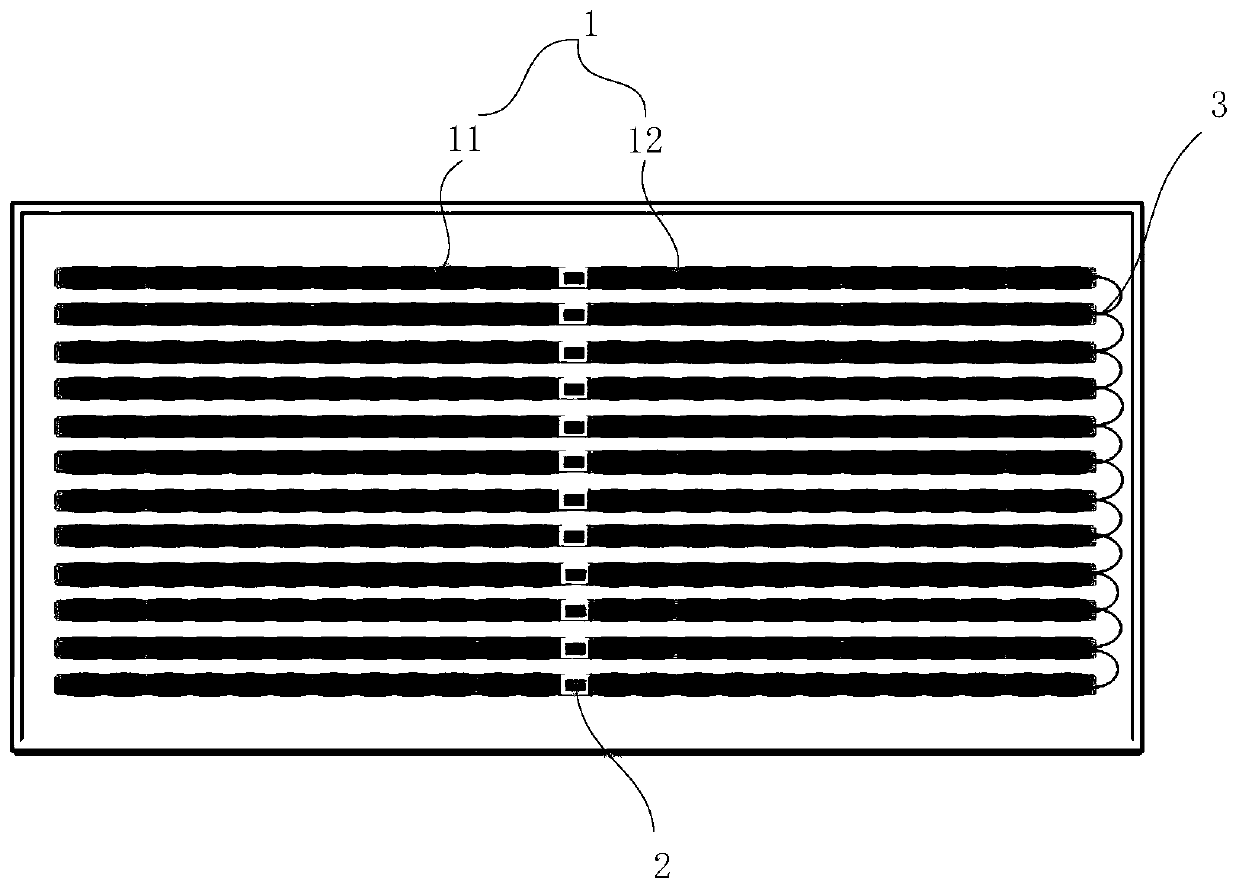

Display device

PendingCN110148355AProcessing time is shortIncrease productivityNon-linear opticsIdentification meansDisplay deviceOptoelectronics

The invention discloses a display device, and relates to the technical field of backlight. The time needed for processing the display device is shortened, and the production efficiency of the displaydevice is improved. The display device comprises a direct type backlight module, the direct type backlight module includes a light bar for providing the backlight, the light bar is characterized in that the light bar comprises a first light bar and a second light bar which are connected by the ends to make circuits communicate, the first light bar and the second light bar are connected through anadapter, the adapter includes an adapter socket on the first light bar and an adapter plug on the second light bar, and the adapter plug is matched with the adapter socket to allow the circuit of thefirst light bar to communicate with the second light bar.

Owner:HISENSE VISUAL TECH CO LTD

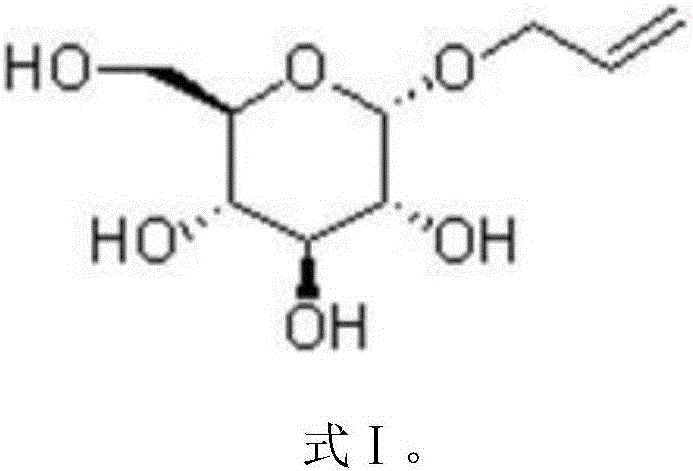

Amphiphilic acetochlor magnetic molecularly imprinted polymer and preparation method and application thereof

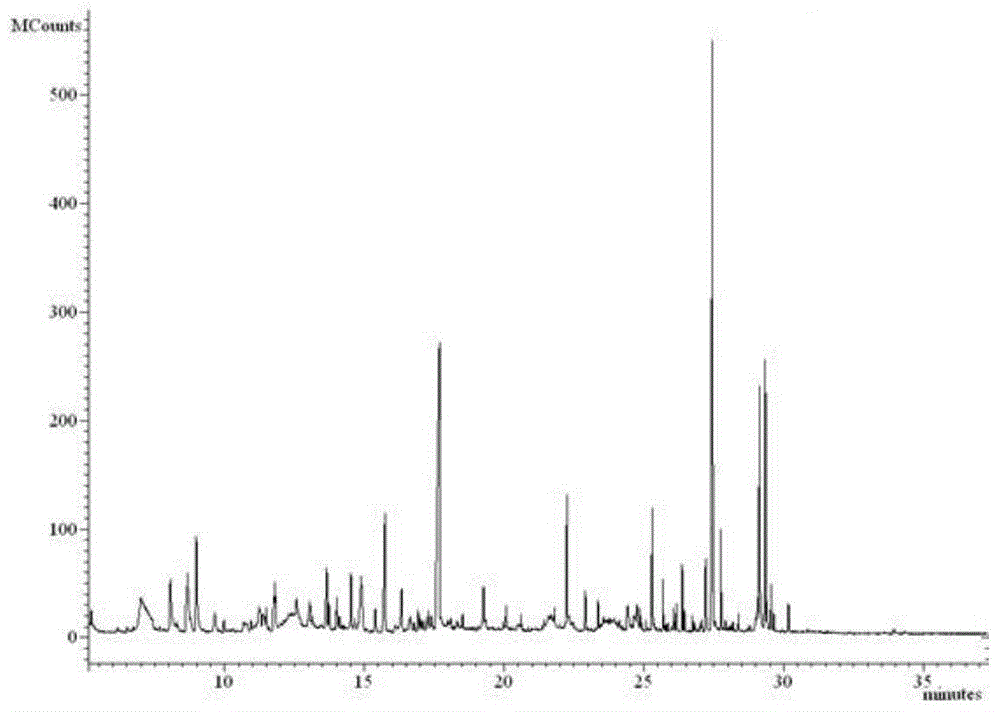

ActiveCN106749903AImprove separation efficiencyHigh specific selectivityComponent separationOther chemical processesFunctional monomerChemistry

The invention provides an amphiphilic acetochlor magnetic molecularly imprinted polymer and a preparation method and application thereof. Glucose is used as a structural unit, thereby synthesizing hydrophilic alkenyl glycoside type functional monomer modified with imprinting acting site. By use of a hydrophilic-lyophobic dual-functional monomer molecular imprinting technology, the amphiphilic magnetic molecularly imprinted polymer is prepared. The prepared amphiphilic magnetic molecularly imprinted polymer has high specific selectivity, has amphipathicity and good adsorptive property in a water medium, and can be used for acetochlor content determination sample pretreatment in the agricultural products, and then an extraction system for complex sample pretreatment is established through the analytic detection and quantitative analysis of a liquid chromatogram system. The method provided by the invention is simple in step, convenient for operation, and strong in practicability.

Owner:SHANDONG ANALYSIS & TEST CENT

Polishing device

InactiveCN104708516ASimple structureProcessing time is shortPolishing machinesBelt grinding machinesMotor driveEngineering

The invention discloses a polishing device which comprises a first motor, a first rotating shaft, a master form, a first bearing, a second bearing, a vehicle, an abrasive belt wheel, a second rotating shaft and a second motor, the first rotating shaft and the second rotating shaft are arranged in parallel, the first motor drives the first rotating shaft to rotate, the second motor drives the second rotating shaft to rotate, the master form, the first bearing, the second bearing and the vehicle are all arranged on the first rotating shaft and can rotate along with the first rotating shaft, the first bearing is located in front of the master form, the second bearing is located in front of the first bearing, and the vehicle is located in front of the second bearing; the polishing device is further provided with a workpiece which is arranged on the first rotating shaft and located at the front end of the vehicle, the abrasive belt wheel is arrange at the front end of the second rotating shaft, and the abrasive belt wheel is used for polishing the workpiece arranged at the front end of the second rotating shaft. The structure of an abrasive belt wheel polishing workpiece is simple, due to the fact that the master form is arranged, the shape of the polishing workpiece conforms to the shape of the master form, and the machining time is short.

Owner:SUZHOU RS TECH

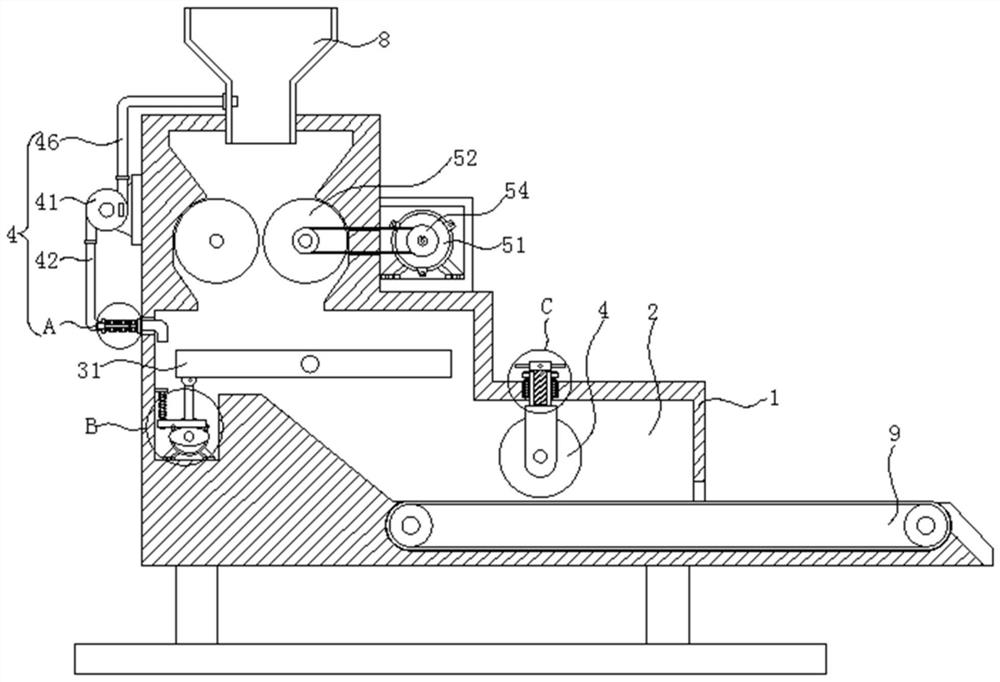

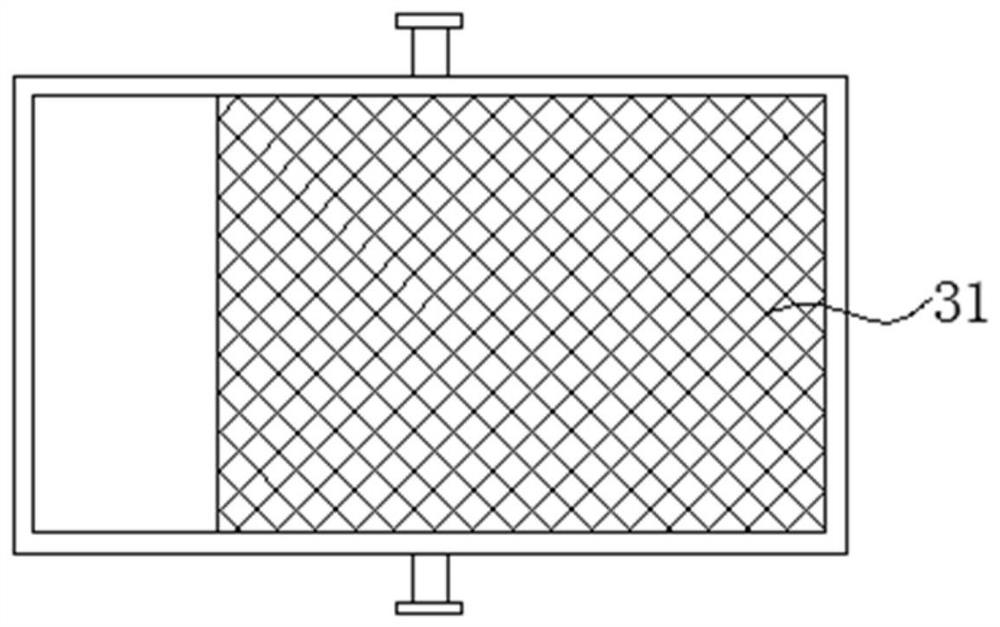

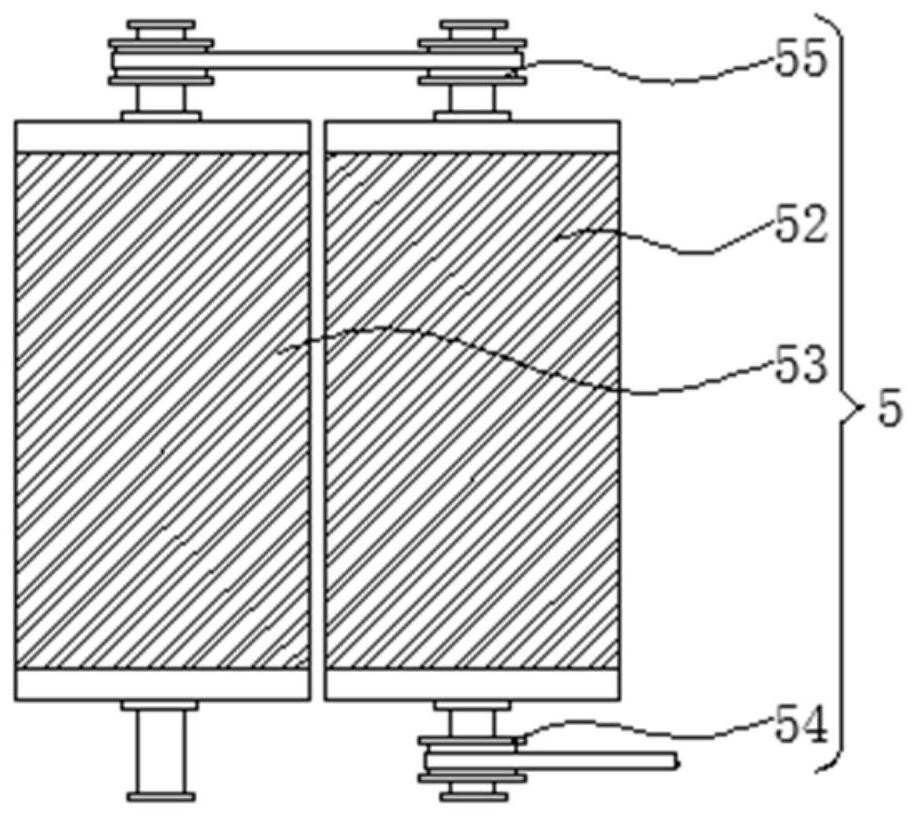

Food material crushing machine integrating crushing, screening and extruding and using method

InactiveCN112058388ARealize secondary crushingMeet production standardsSievingScreeningElectric machineryEngineering

The invention provides a food material crusher integrating crushing, screening and extruding and a using method. The food material crushing machine integrating crushing, screening and extruding comprises a machine body and a treatment groove. The treatment groove is formed in the machine body; and a screening structure is arranged in the treatment groove and comprises a screening hopper, a rotating motor and a sliding rod piece. According to the food material crushing machine integrating crushing, screening and extruding and the using method, by arranging the screening structure, a crushing structure and an extruding structure, crushing, screening and extruding integrated processing is achieved, three different types of processing treatment can be conducted on food materials simultaneously, and single machining equipment is not used for machining any more, so that the machining operation is simpler, the operation is very convenient, the machining time consumption is further reduced, the working efficiency is effectively improved, the using demands of people can be well met, and the practicability of the food material crushing machine is higher.

Owner:安徽悠之优味食品有限公司

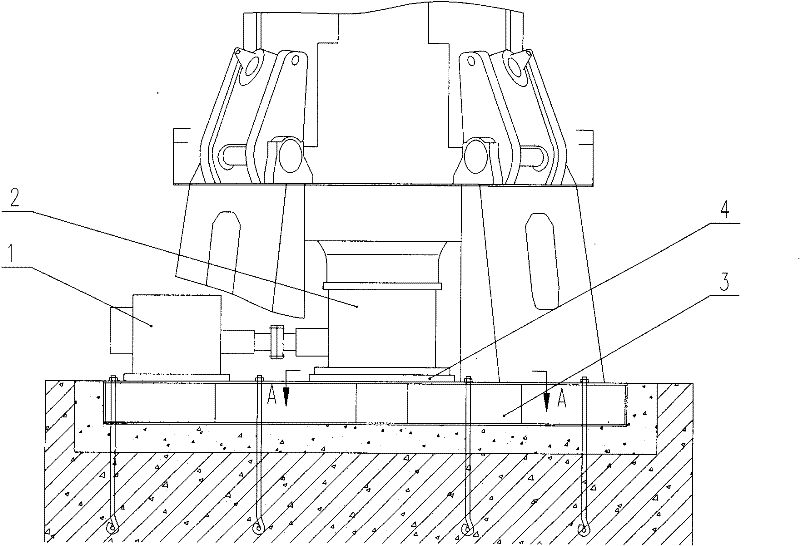

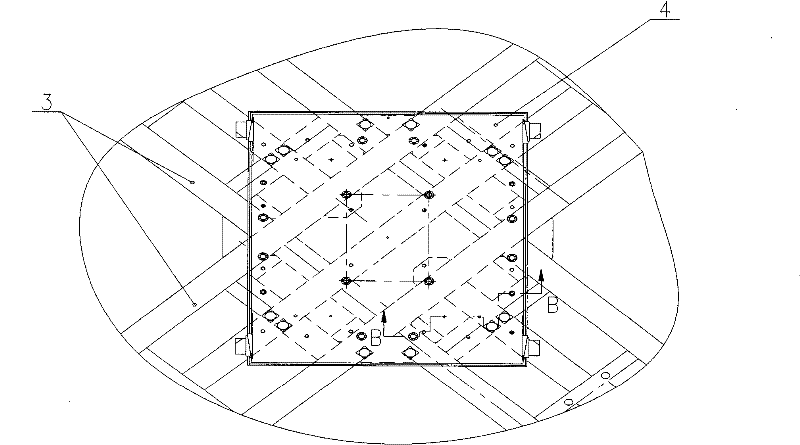

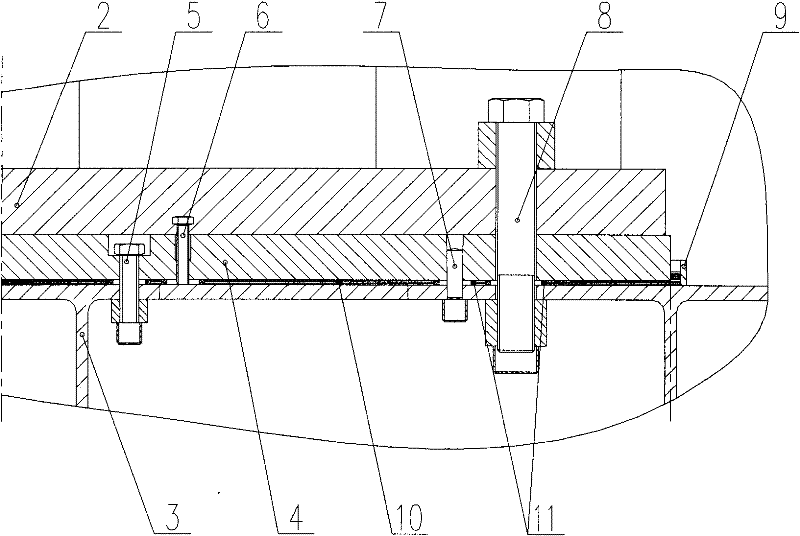

Installation structure body for main reducer of roller mill and application method thereof

The invention relates to an installation structure body for a main reducer of a roller mill and an application method thereof. The structure body comprises a mill reducer, a reducer foundation slab and a mill foundation frame which are sequentially connected, wherein a packer is arranged between the reducer foundation slab and the mill foundation frame. The application method comprises the following steps: 1) putting the reducer foundation slab on the mill foundation frame, adjusting a leveling bolt to generate a certain distance between the reducer foundation slab and the mill foundation frame; 2) putting a protecting sleeve and a locating taper pin; 3) sealing the periphery of the reducer foundation slab by a baffle plate on the periphery of the reducer foundation slab; 4) pouring the packer, and 5) fixedly connecting the mill reducer, the reducer foundation slab and the mill foundation frame together through the connection of the reducer a bolt. The installation structure body disclosed by the invention has the advantages of conveniently dismantling, easily leveling the reducer foundation slab and the like compared with the prior art because the reducer foundation slab is movably connected with the mill foundation frame.

Owner:LOESCHE (SHANGHAI) CO LTD

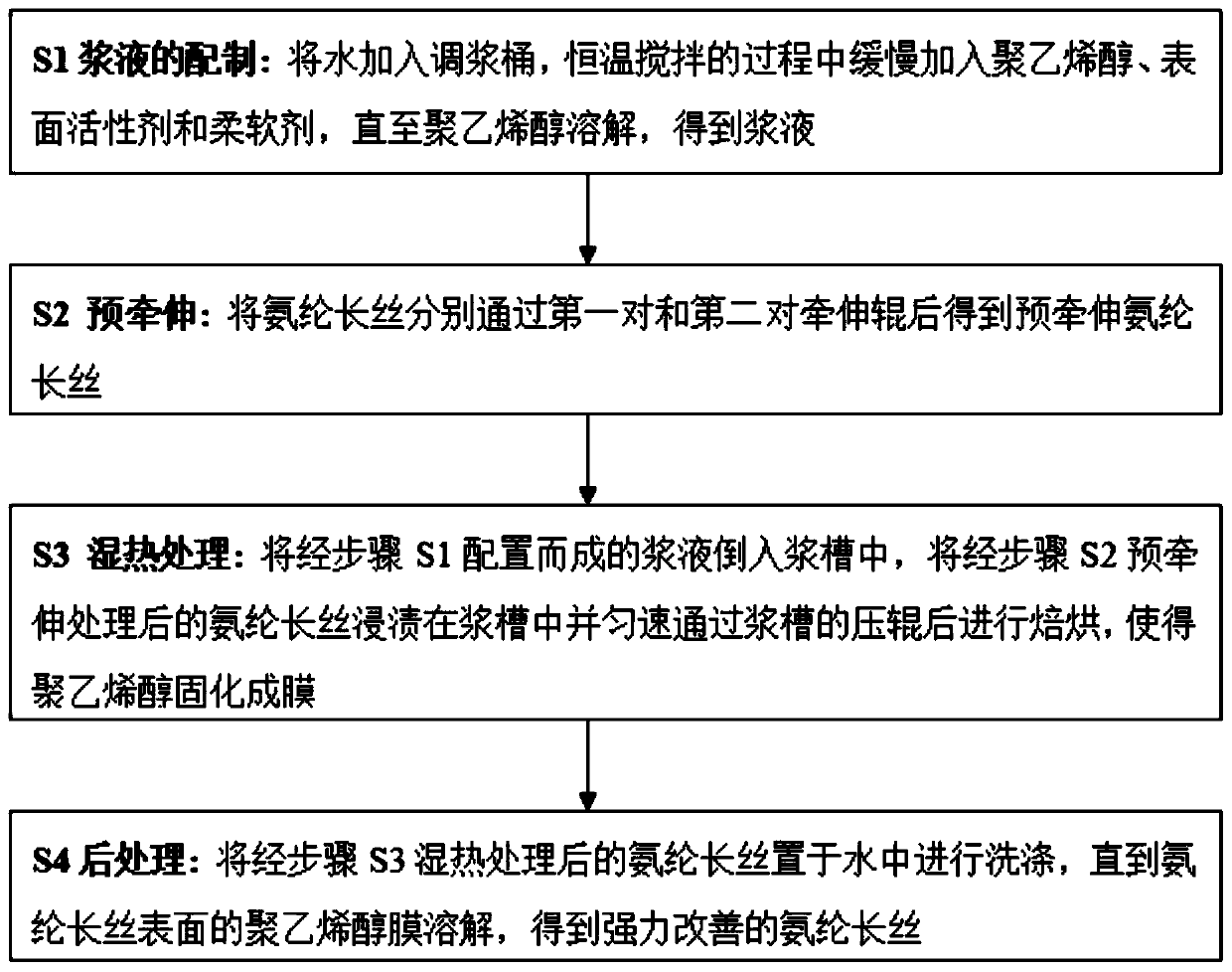

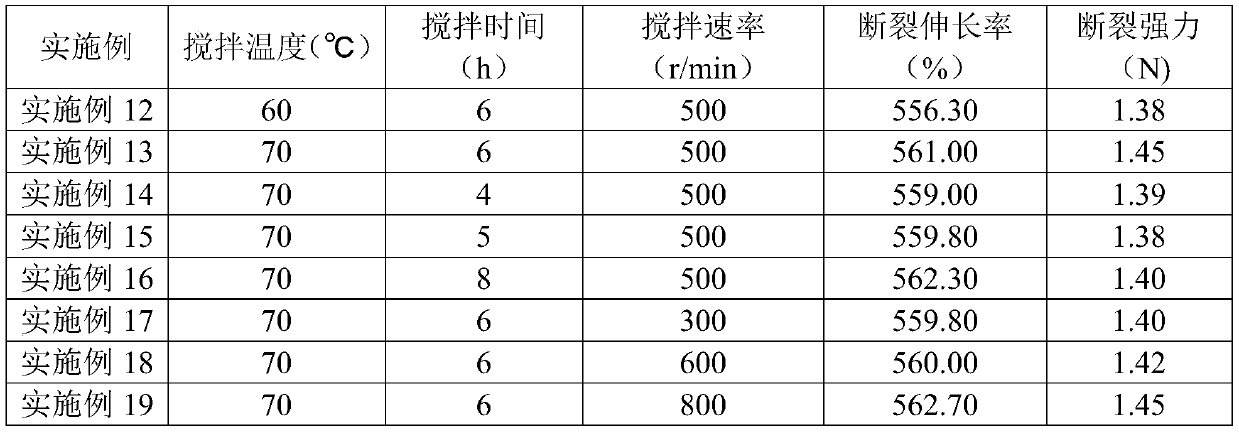

Processing method for improving strength of polyurethane filaments

ActiveCN110172791AImprove adhesionThe sizing process takes less timeFibre typesLiquid/gas/vapor removalPolyvinyl alcoholSlurry

The invention relates to a processing method for improving the strength of polyurethane filaments. The processing method comprises the following steps of first dissolving polyvinyl alcohol in water, preparing size under a certain condition, then performing pre-drawing on elastic polyurethane filaments, dipping the polyurethane filaments in a size vat for dipping, performing wet-heat processing, passing through a compression roller and then braking, curing polyvinyl alcohol to form a film, and putting the polyurethane filaments in water for washing, thereby obtaining the strength-improved polyurethane filaments. The wet-heat processing method is simple to operate, low in raw material cost, and short in processing time consumed, the elastic polyurethane filaments are processed on a common slasher, and meanwhile, the bad influence on subsequent processing, caused by non-uniform tension due to non-uniform polyurethane filament elasticity and elasticity loss, is improved.

Owner:WUHAN TEXTILE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com