Manufacture method for improving solder resist hole plugging ink seepage

A manufacturing method and hole plugging technology, which are applied in printed circuit manufacturing, secondary processing of printed circuits, electrical components, etc., can solve the problems of removal, low production efficiency, and high processing costs, and improve production efficiency, production efficiency, and processing. Time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

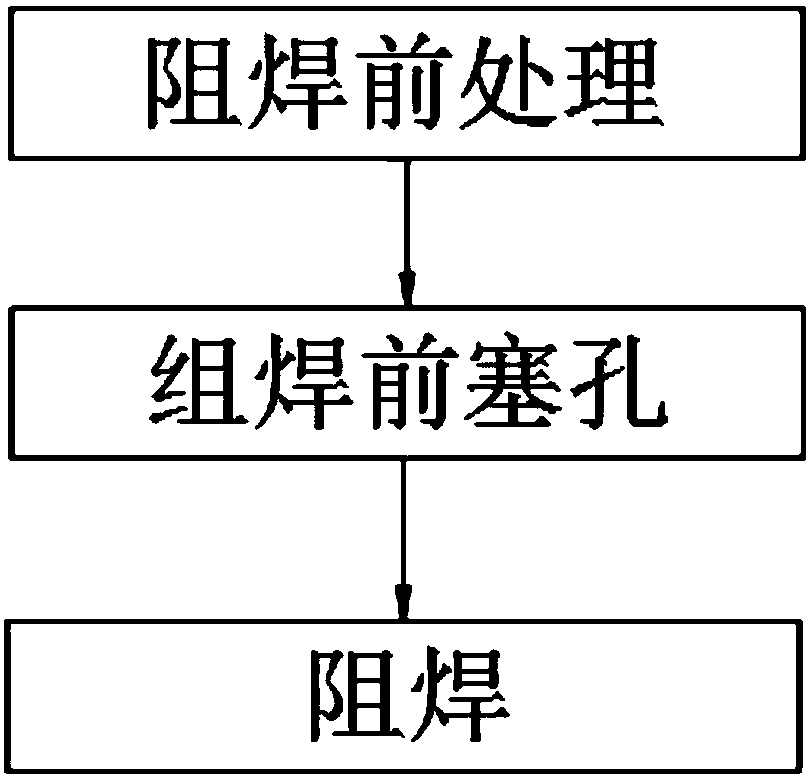

[0020] Example: such as figure 1 As shown, the present invention provides a method for improving oil spillage in solder resist plug holes, comprising the steps of:

[0021] 1) Solder mask pre-treatment: pre-baking plate treatment before solder mask pre-treatment, specifically, the baking plate treatment specifically includes: when the holes to be plugged on the circuit board include back-drilled holes, before the solder mask pre-treatment step Perform pre-baking plate treatment, and / or, perform post-baking plate treatment after the pre-treatment step of solder mask; when the hole to be plugged on the circuit board is a through hole with a high thickness-to-diameter ratio, perform post-baking after the pre-treatment step of solder mask Board treatment, when performing pre-baking board treatment, keep the temperature of 150°C±5°C for 60min-120min; when performing post-baking board treatment, keep the temperature of 75°C±5°C for 10min-30min; then remove the through hole oxides, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com