Convenient preserved meat dish and superheated steam processing method thereof

A superheated steam and processing method technology, applied in the field of food processing, can solve the problems of complex production process, fuzzy processing time, variable cooking temperature, etc., and achieve the effect of rich nutrition, short processing time and bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

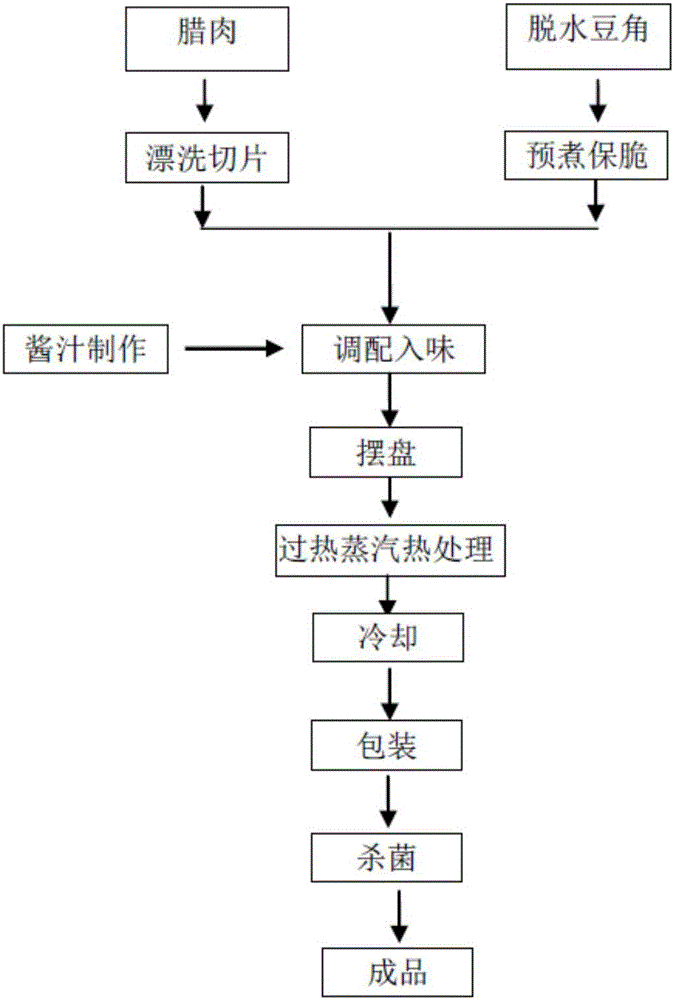

[0033] A superheated steam processing method for bacon instant dishes, comprising the steps of:

[0034] (1) Pretreatment of bacon

[0035] Use high-quality hind leg bacon, rinse the bacon meat base in boiling water for 20 seconds, cut into thin slices with a length of 6 cm, a width of 3 cm, and a thickness of 2 mm, and heat it in boiling water for 1-3 minutes before use.

[0036] (2) Rehydration pretreatment of dehydrated beans

[0037] Cut the dehydrated green beans into 3cm strips, precook them in boiling water for 20 minutes, take out and drain the water, soak them in 0.1% anhydrous calcium chloride solution to keep them crisp for 10 minutes and set aside.

[0038] (3) Sauce making

[0039] The auxiliary materials for making the sauce include (according to 100 parts of raw meat): 4 parts of chili sauce, 2 parts of pepper oil, 5 parts of minced green onion, 5 parts of minced ginger, 5 parts of minced garlic, 1 part of monosodium glutamate, 3 parts of dark soy sauce, 4 par...

Embodiment 2

[0047] A superheated steam processing method for bacon instant dishes, comprising the steps of:

[0048] (1) Pretreatment of bacon

[0049] Use high-quality hind leg bacon, rinse the bacon meat base in boiling water for 60 seconds, cut into thin slices with a length of 7 cm, a width of 4 cm, and a thickness of 3 mm, and heat it in boiling water for 3 minutes before use.

[0050] (2) Rehydration pretreatment of dehydrated beans

[0051] Cut the dehydrated green beans into 4cm strips, precook them in boiling water for 20 minutes, take out and drain the water, soak them in 0.5% anhydrous calcium chloride solution to keep them crisp for 30 minutes and set aside.

[0052] (3) Sauce making

[0053] The auxiliary materials for making the sauce include (according to 100 parts of raw meat): 5 parts of chili sauce, 3 parts of pepper oil, 10 parts of minced green onion, 10 parts of minced ginger, 10 parts of minced garlic, 2 parts of monosodium glutamate, 4 parts of dark soy sauce, 5 par...

Embodiment 3

[0061] A superheated steam processing method for bacon instant dishes, comprising the steps of:

[0062] (1) Pretreatment of bacon

[0063] Use high-quality hind leg bacon, rinse the bacon meat in boiling water for 40 seconds, cut into thin slices of 6.5cm in length, 3.5cm in width and 2.5mm in thickness, heat in boiling water for 2 minutes and set aside.

[0064] (2) Rehydration pretreatment of dehydrated beans

[0065] Cut the dehydrated green beans into 3.5cm long strips, pre-cook them in boiling water for 20 minutes, take out and drain the water, soak them in 0.1-0.5% anhydrous calcium chloride solution to keep them crisp for 10-30 minutes and set aside.

[0066] (3) Sauce making

[0067] The auxiliary materials for making the sauce include (according to 100 parts of raw meat): 4.5 parts of chili sauce, 2.5 parts of pepper oil, 7.5 parts of minced green onion, 7.5 parts of minced ginger, 7.5 parts of minced garlic, 1.5 parts of monosodium glutamate, 3.5 parts of dark soy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com