Processing method for improving strength of polyurethane filaments

A technology of spandex filament and processing method, which is applied in the field of textile processing, and can solve problems such as the inability to effectively improve the uneven tension of the filament-wrapped spandex yarn, the inability to control the elastic elongation of the spandex, and the unevenness of the fabric surface, so as to improve the tension Unevenness, improvement of draft unevenness, and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

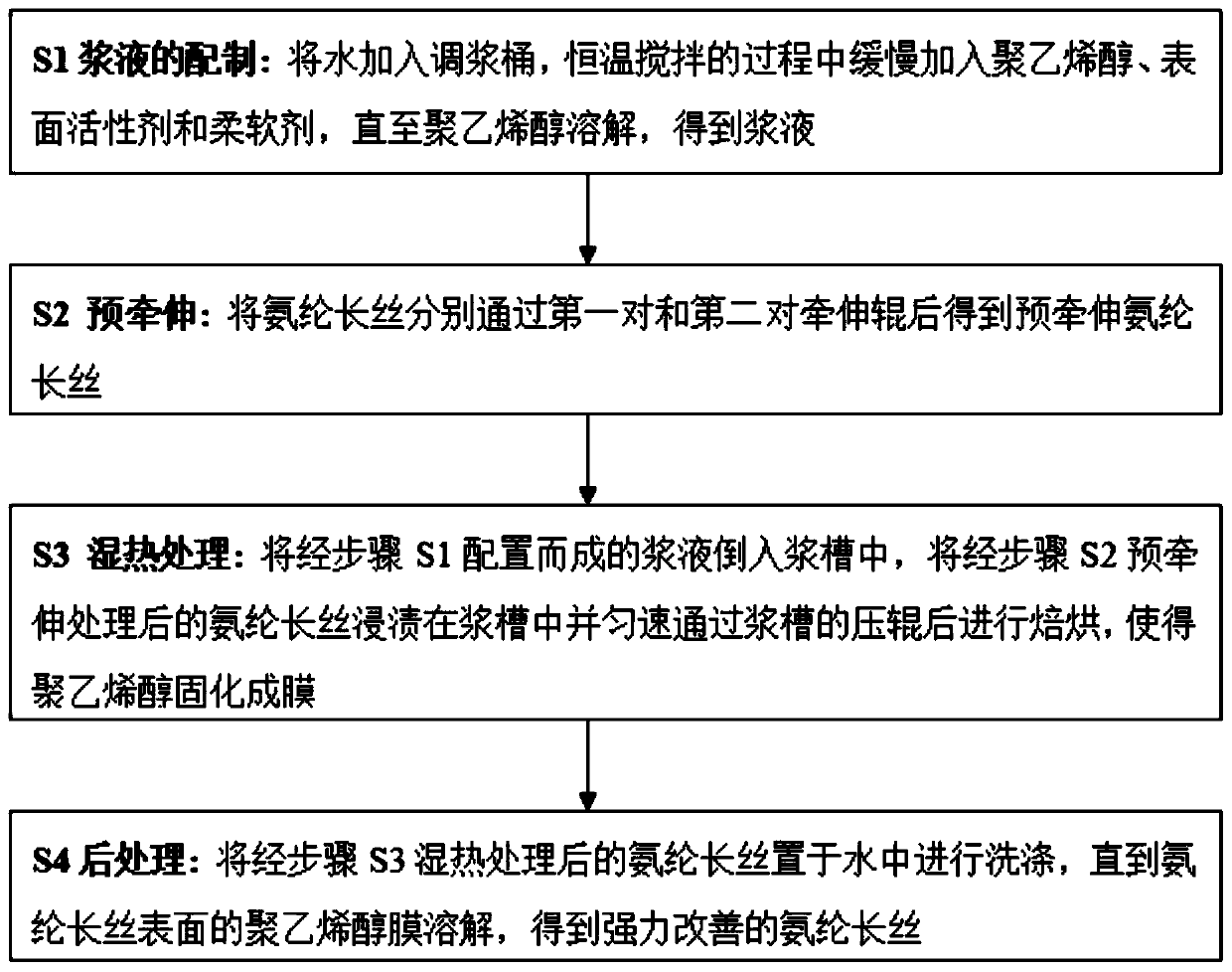

[0039] A processing method for improving the strength of spandex filaments, comprising the steps of:

[0040] Preparation of S1 slurry: Pour water into a 500mL mixing bucket and heat it to 80°C in a water bath. Slowly add polyvinyl alcohol, sodium lauryl alcohol polyoxyethylene ether sulfate surfactant and softener while stirring at 80°C, 500r / min stirring for 4h until the polyvinyl alcohol is dissolved to obtain a slurry, wherein the mass fraction of polyvinyl alcohol is 10%, the mass fraction of surfactant is 1%, and the concentration of softening agent is 1%;

[0041] S2 Pre-drawing of spandex filaments: 270 denier spandex filaments are passed through two pairs of drafting rollers to obtain pre-drawing spandex filaments, wherein the speed of the first pair of drafting rollers is 50m / min, and the speed of the second pair of drafting rollers is 50m / min. The speed of the roller is 150m / min, and the draft ratio of the spandex filament is 3 times;

[0042] S3 Moist heat treatm...

Embodiment 2-11

[0048] Embodiment 2-11 provides a kind of processing method for improving the strength of spandex filament, compared with embodiment 1, the difference is that the mass fraction of polyvinyl alcohol and surfactant in step S1 is changed, and the concentration of softening agent, specifically The dosage is shown in Table 2.

[0049] Table 2

[0050]

[0051] The strength performance parameters of the PVA sizing spandex obtained in Examples 1-11 were compared, and the results are shown in Table 2.

[0052] The strength performance data of the PVA sizing spandex of Examples 2-5 are shown in Table 2. From the results in the table, it can be known that the greater the mass fraction of polyvinyl alcohol, the greater the elongation at break and the strength at break.

[0053] The strength performance data of the PVA sizing spandex of Example 3 and Examples 6-8 are shown in Table 2. From the results in the table, it can be seen that the greater the mass fraction of surfactant, the g...

Embodiment 12-19

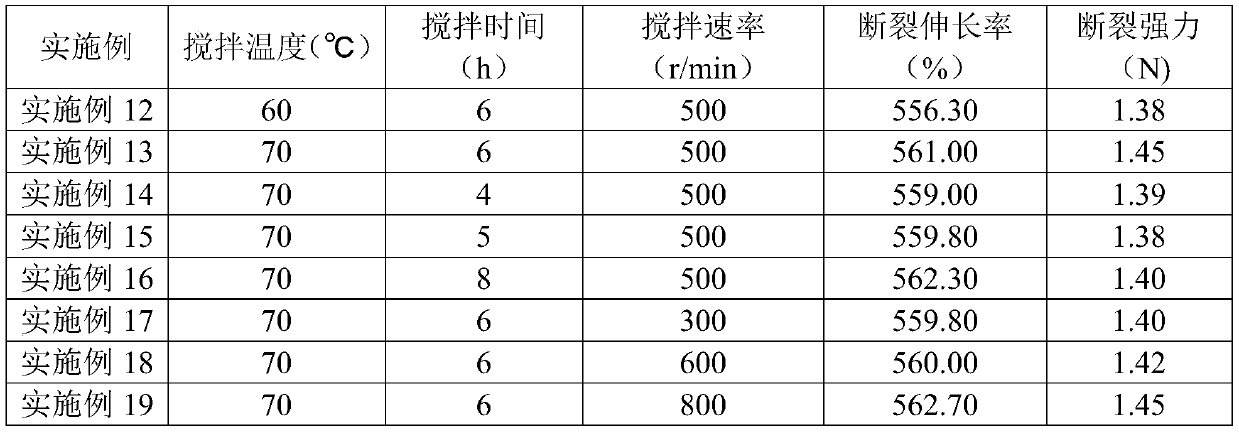

[0057] Embodiments 12-19 provide a processing method for improving the strength of spandex filaments. Compared with Embodiment 1, the difference is that the stirring temperature, stirring time and stirring rate in step S1 are changed. The specific methods are shown in Table 3.

[0058] table 3

[0059]

[0060] The strength performance parameters of the PVA sizing spandex obtained in Examples 12-19 were compared, and the results are shown in Table 3.

[0061] The strength performance data of the PVA sizing spandex in Examples 12-13 are shown in Table 3. From the results in the table, it can be seen that the elongation at break and the strength at break also increase as the stirring temperature increases.

[0062] The results of the strength performance data of the PVA sizing spandex of Examples 13-16 are shown in Table 3. From the results in the table, it can be seen that the elongation at break and the strength at break increase as the stirring time increases.

[0063] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com