Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

160results about How to "Prevent quality deterioration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

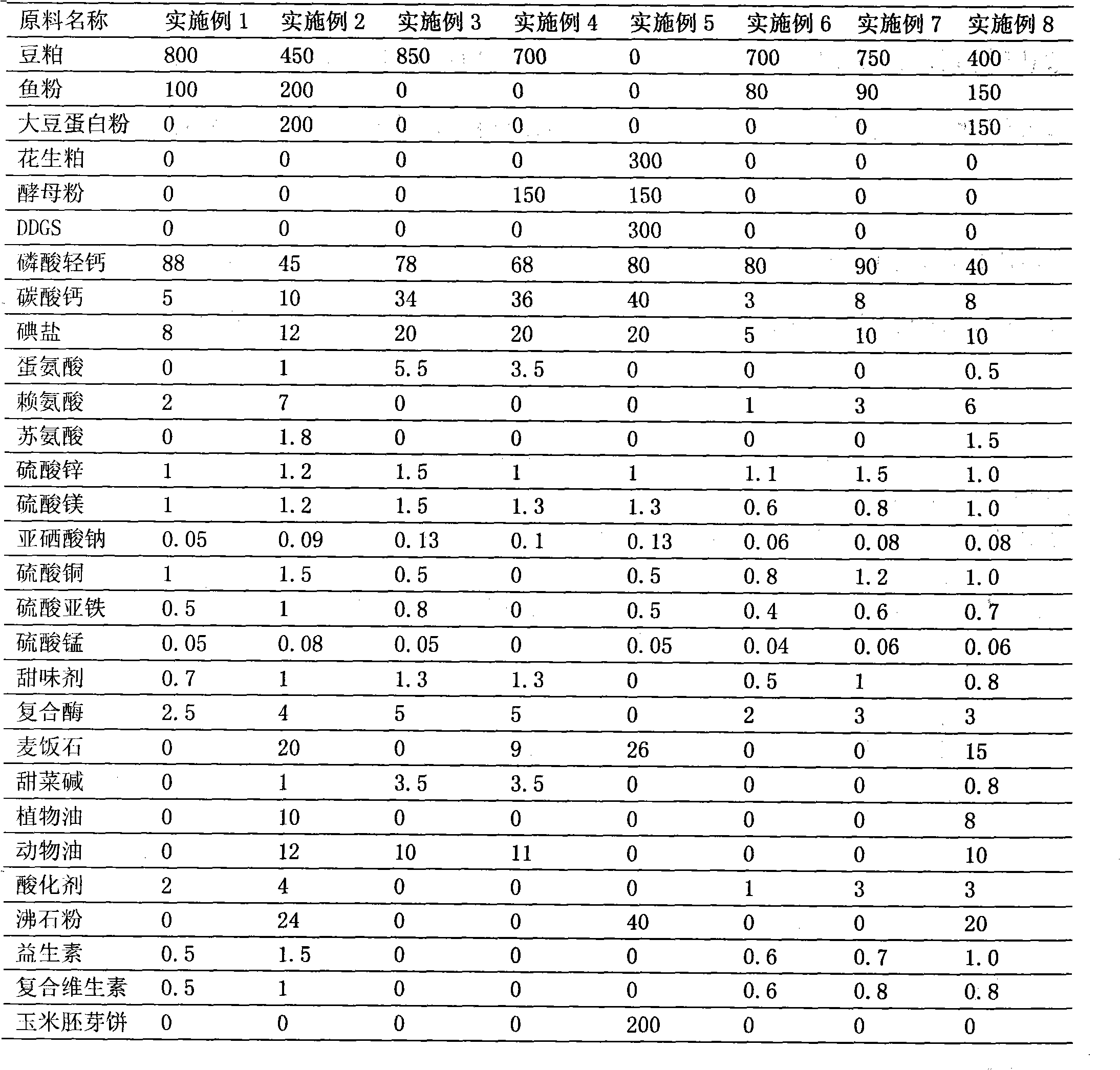

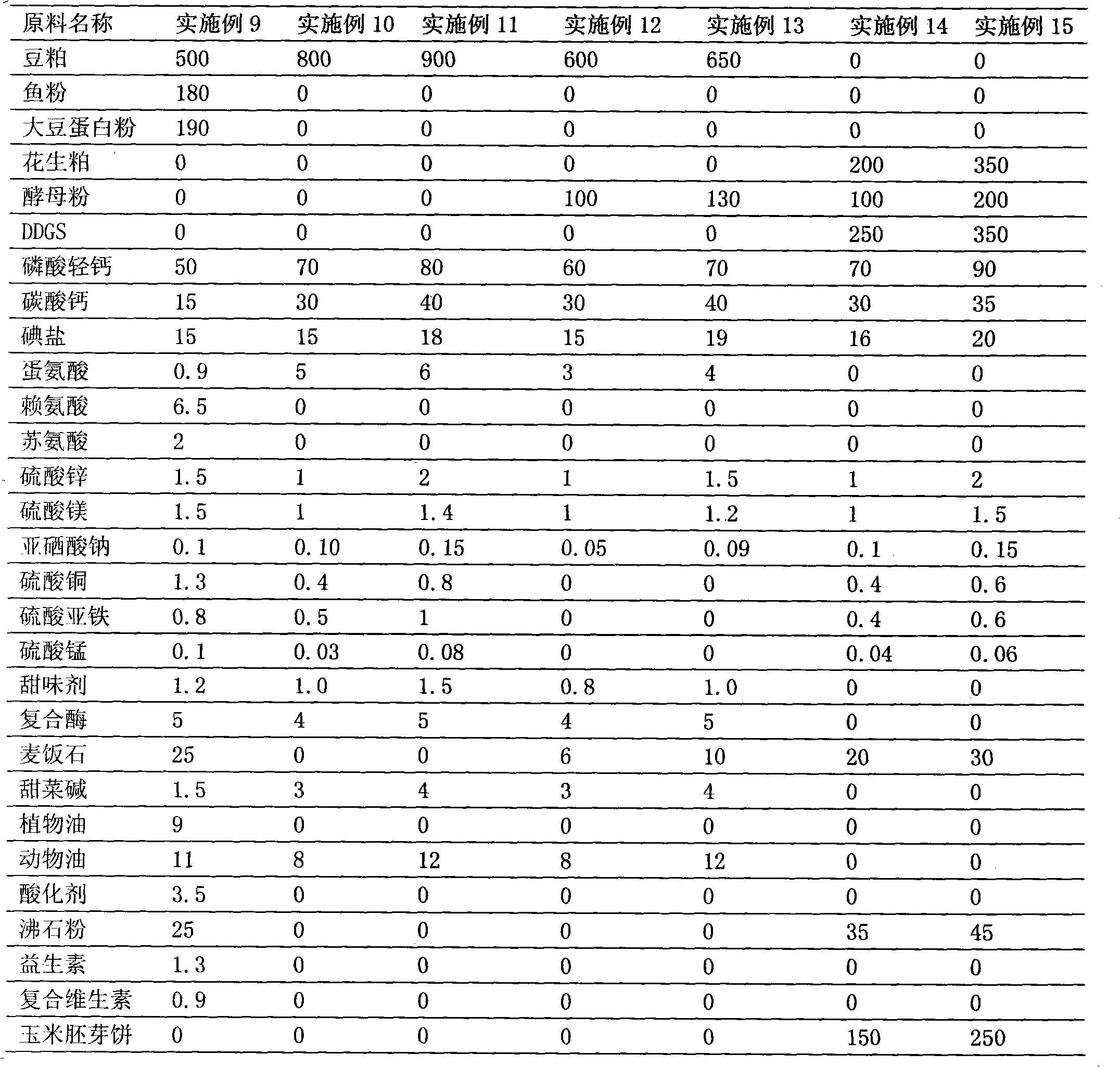

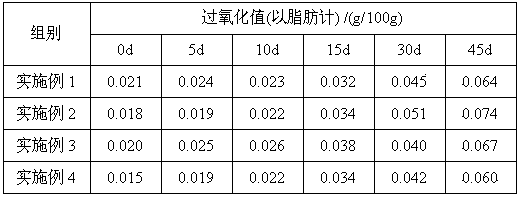

Pig antibiotic-free concentrated feed

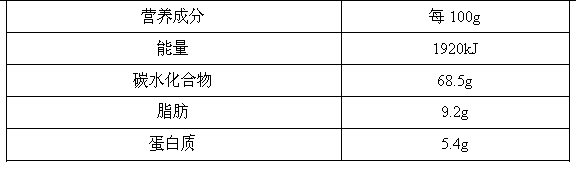

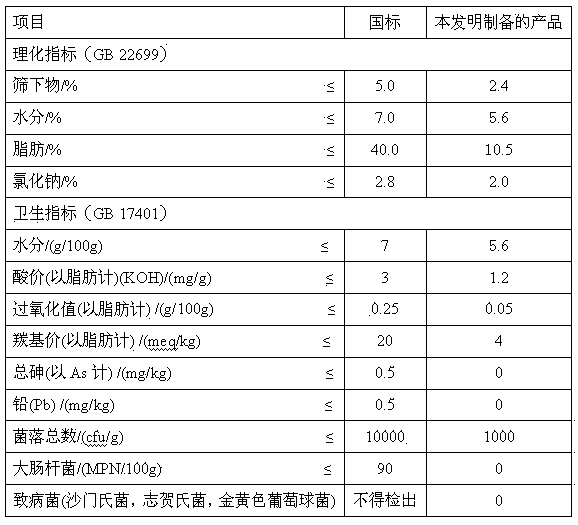

The invention relates to pig concentrated feed which does not contain antibiotic and hormone. The pig concentrated feed is mainly prepared from the following materials: protein materials, calcium hydrogen phosphate, calcium carbonate, iodinated salt, amino acid, zinc sulfate, sodium selenite, magnesium sulfate and the like. As the pig concentrated feed does not contain the materials such as the antibiotic, the hormone and the like and is added with a proper amount of microelements, the pig concentrated feed can supplement nutrient components of conventional feed, prevent feed quality degradation, improve palatability of the feed, improve the feed utilization rate for pigs, improve disease resistance of the pigs, prompt normal development and quick growth of the pigs, and improve the growth quality of the pigs; and after the pig concentrated feed which serves as an additive is prepared into complete feed, residue of mineral elements in pork and livers of the pigs (the component content is controlled to be within the safety value during the fattening period) is reduced, edible safety of pork products is ensured, the feed cost is lowered, and the environmental pollution of swine waste is reduced on the premise of not influencing growth performance of the pigs.

Owner:河南基正生态农业科技有限公司

Preparation method of instant crisp okra slices

ActiveCN103844217AGuaranteed uniformityElimination of deterioration in sensory qualityFood coatingFood shapingNutritionProcess engineering

The invention relates to a preparation method of instant crisp okra slices. The preparation method mainly comprises the following steps: selecting; blanching; slicing; quick-freezing; vacuum frying and pre-puffing; vacuum deoiling; separating fruits from seeds; spraying; puffing again; and packaging. The instant crisp okra slices prepared by the method provided by the invention are low in oil ratio, crisp rather than greasy and stable in quality, and the original shape, flavor and nutritional quality of okra are maintained.

Owner:HUNAN AMAZING GRACE BIOTECH

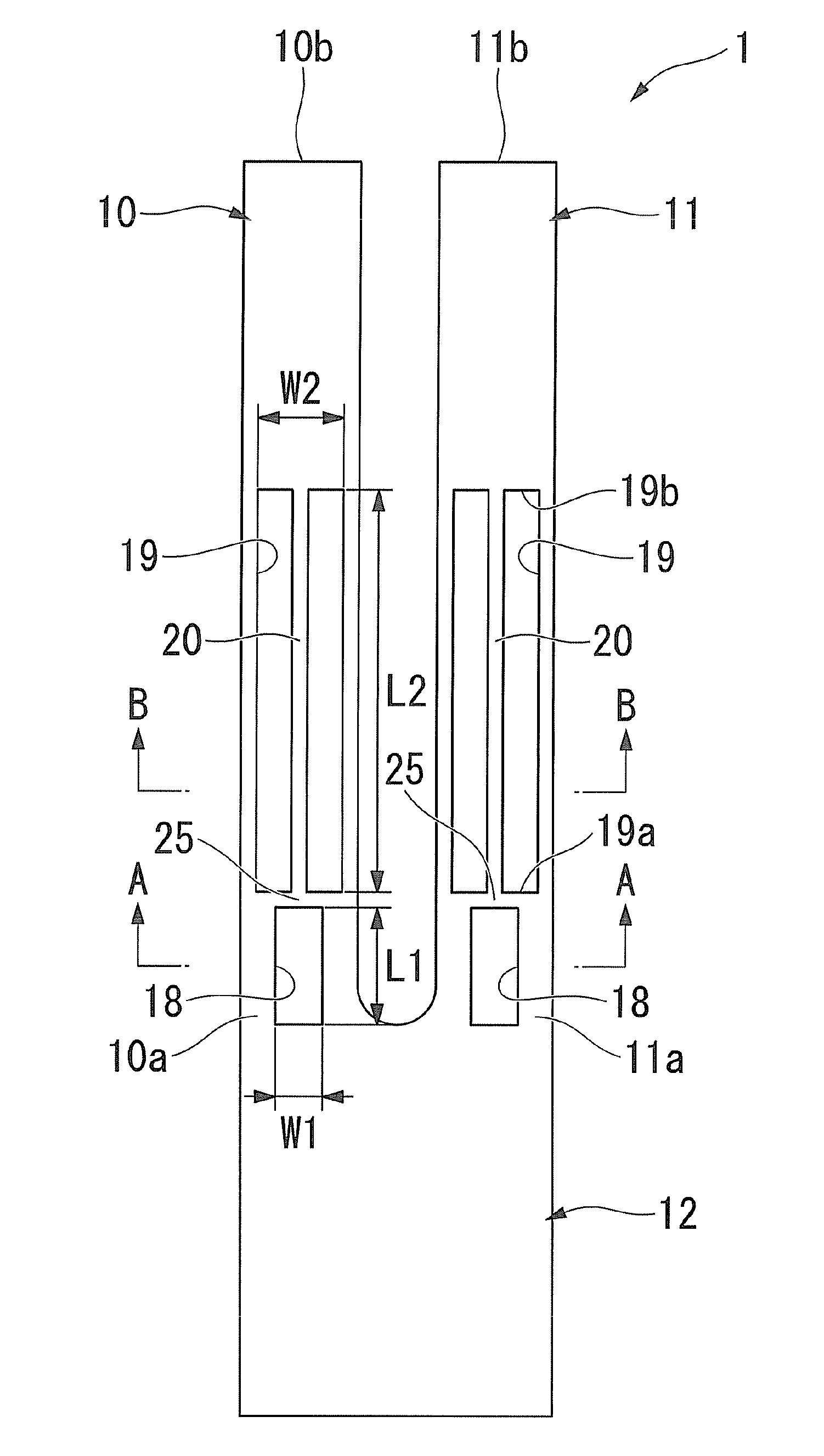

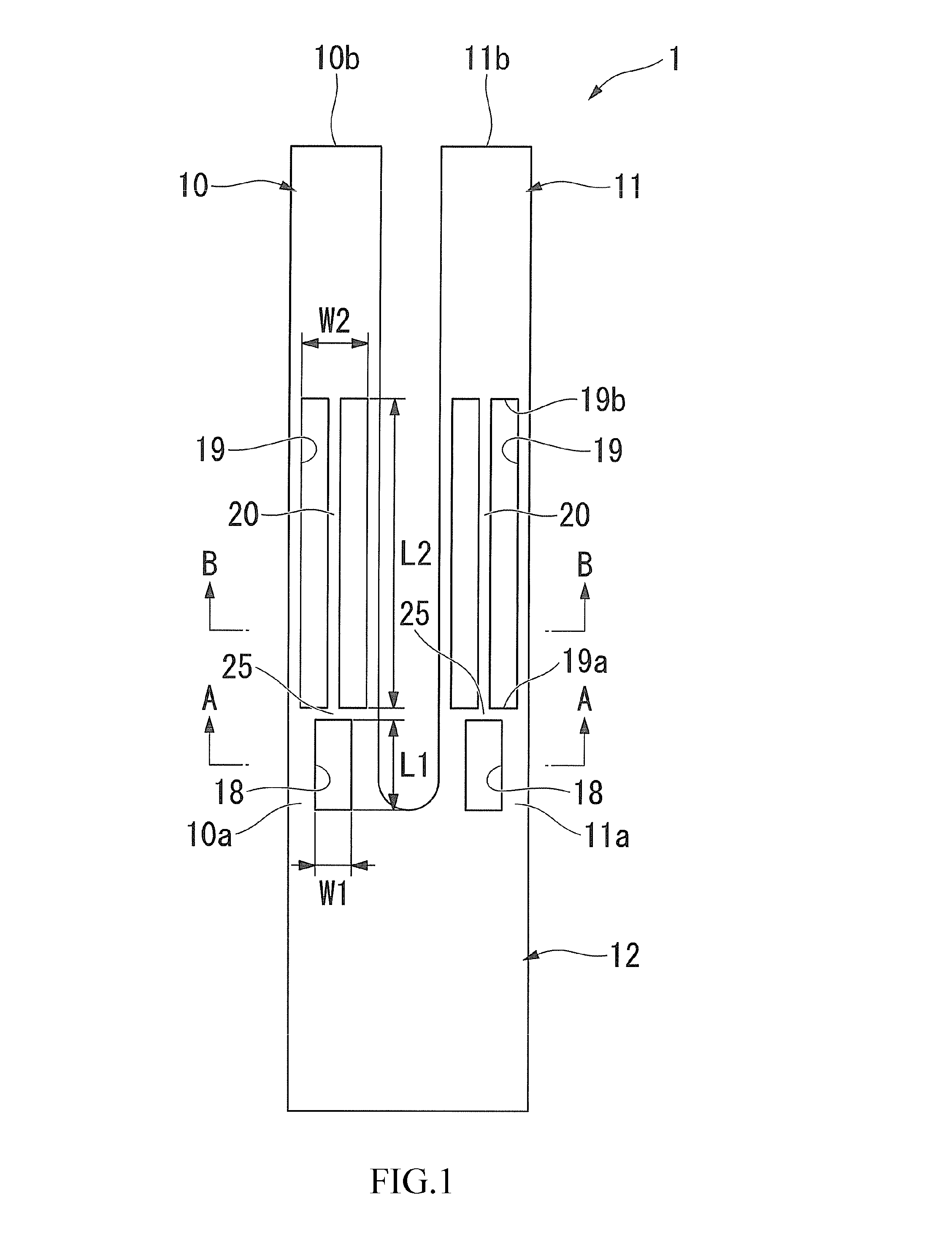

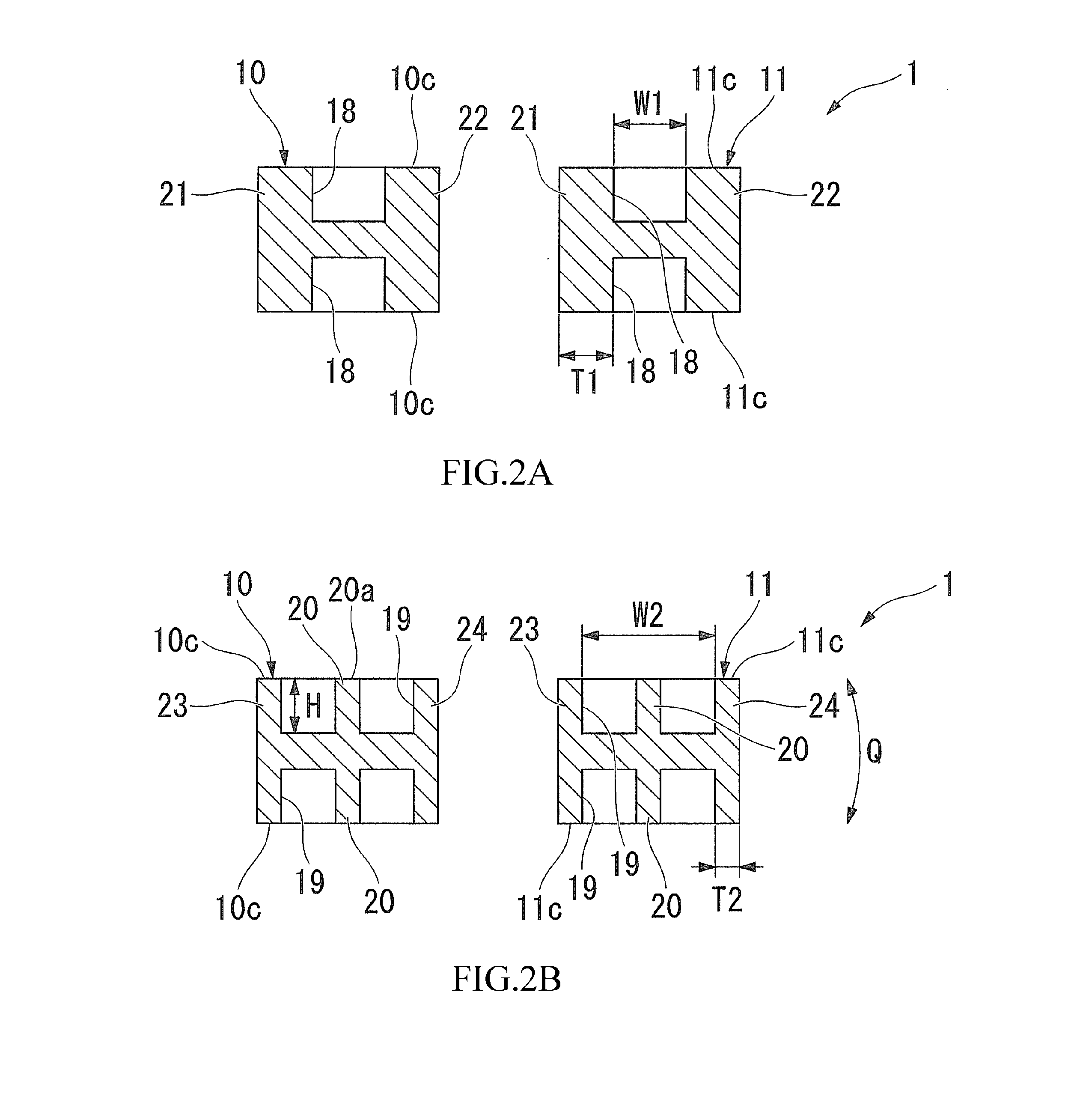

Piezoelectric Vibration Reed, Piezoelectric Vibrator, Oscillator, Electronic Instrument, and Radio Timepiece

ActiveUS20130076211A1Inhibition decreasedPrevent quality deteriorationImpedence networksPiezoelectric/electrostriction/magnetostriction machinesElectronic instrumentEngineering

Owner:SII CRYSTAL TECH

Transferring method of powder toner for electrophotograph and transferring apparatus thereof, and filling method of powder toner and the filling apparatus thereof

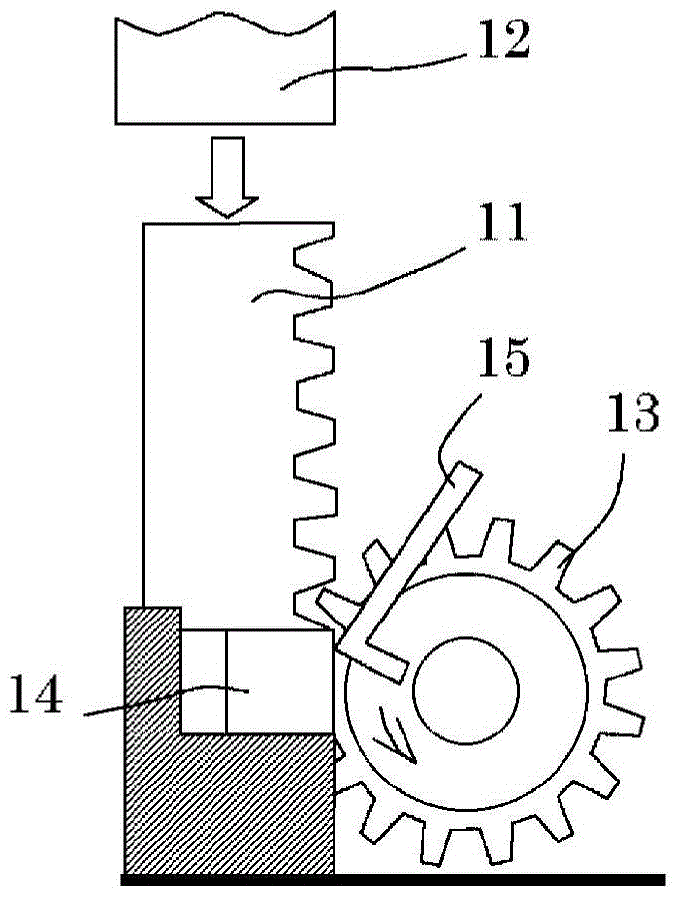

InactiveCN101103316AQuality assurancePrevent proliferationSolid materialElectrographic process apparatusEngineeringReciprocating motion

The present invention aims at providing a powder toner transferring method which fluidizes a powder toner with a gas supplied from an air supply means, sucks the fluidized powder toner with a suction means and transfers the powder toner by discharging the powder toner in a toner storage container, where the suction of the powder toner by means of the suction means is performed with a reciprocating-motion pump. The present invention also aims at providing a powder toner filling method that comprises the powder toner transferring process.

Owner:RICOH KK

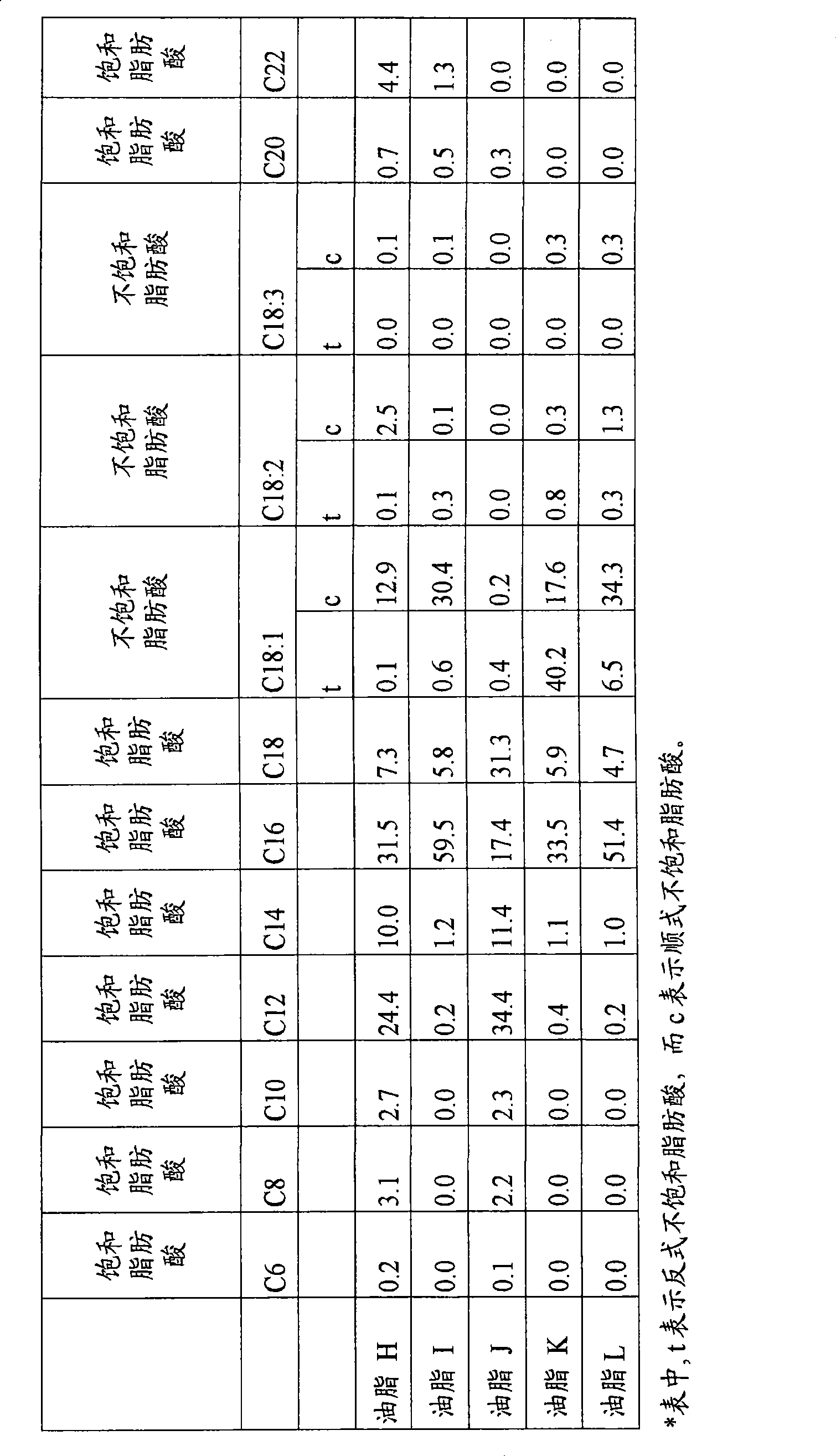

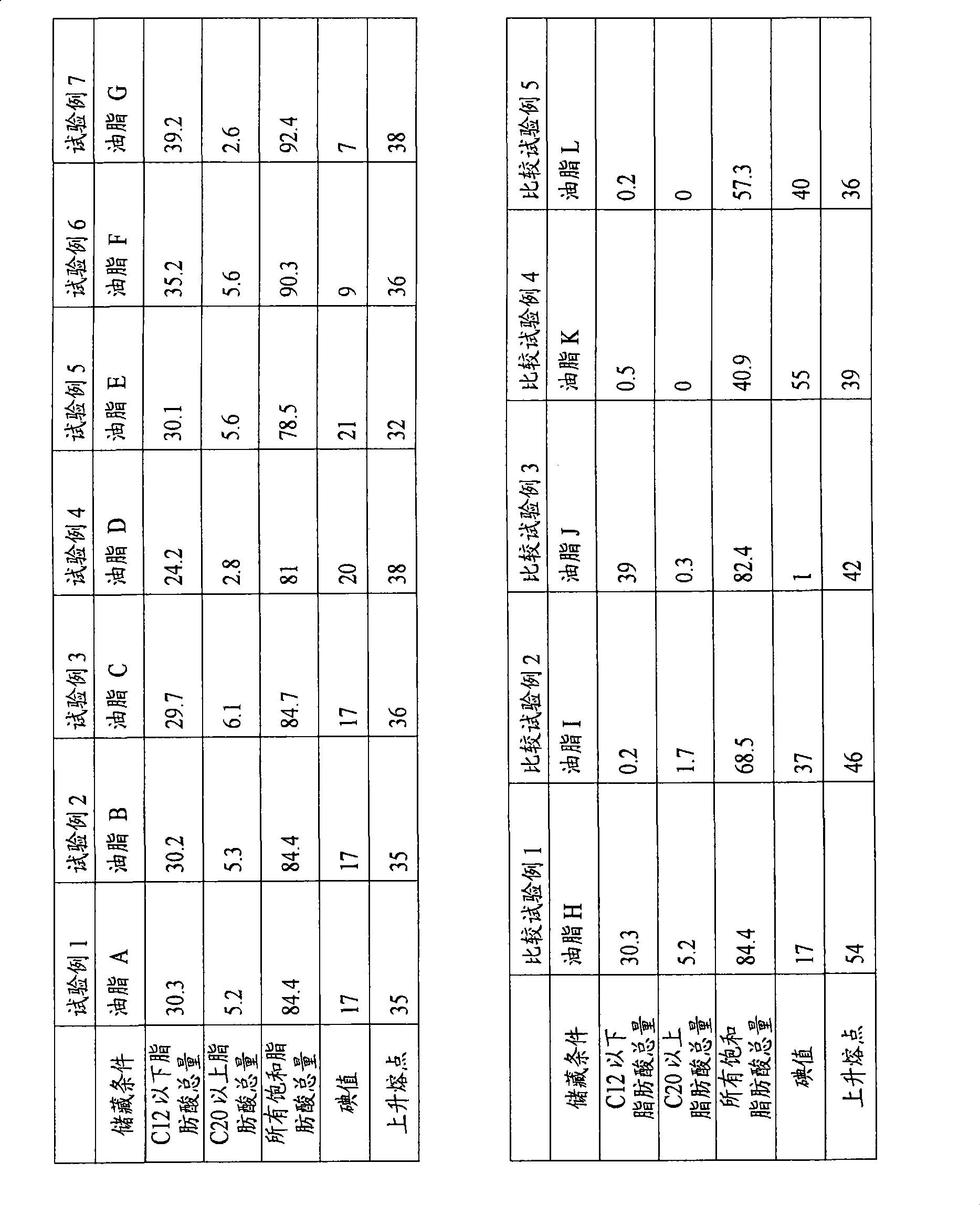

Oil and fat composition for chocolate

ActiveCN101478884APrevent quality deteriorationNo need to use tempering operationFatty acid esterificationCocoaUnsaturated fatty acidButter cocoa

It is intended to provide chocolate excellent in flavor of containing cocoa butter and a melting texture in mouth obtained without resort to a tempering operation in the production of chocolate, in which quality deterioration is prevented during storage over time, and an oil and fat composition to be used in the chocolate. An oil and fat composition for chocolate obtained by ester exchange between an oil and fat containing 30% or more of a fatty acid having 12 carbon atoms or less and an oil and fat containing 30% or more of a saturated fatty acid having 20 carbon atoms or more, and containing 10% or less of a trans-unsaturated fatty acid. A method for producing chocolate using the oil and fat composition in an amount of 20 to 68% by weight of the total chocolate.

Owner:FUJI OIL CO LTD

Isothermal sintering process of iron ore powder

The invention, relating to the field of iron ore powder sintering in metallurgy production system, particularly discloses an isothermal sintering process of iron ore powder, comprising uniformly mixing, distributing materials, igniting, sintering by air draft, cooling, and granulating to obtain a finished agglomerate, wherein in the step of distributing materials of a sintering machine, an atomization spray device is used for adding water to the sintering mixture; small water addition is adopted in material distribution of the middle and upper portion of the mixture material layer on the sintering machine, the water content is 6-6.5%; the water content of the lower portion of the material layer is raised by 1.0-2.0%, thus the water content reaches 7-8.5%. According to the invention, under the condition of applying thick material layer sintering technology, the water contents of the middle and lower portions of the sintering material layer are properly raised, the heat exchange efficiency of the sintering material layer is raised, the hot permeability deterioration at different height positions of the mixture in the sintering process is improved, the agglomerate quality deterioration is effectively avoided, the yield and quality of the agglomerate are raised, and the sintering solid burn-up is reduced.

Owner:山东德钧精工机械有限公司

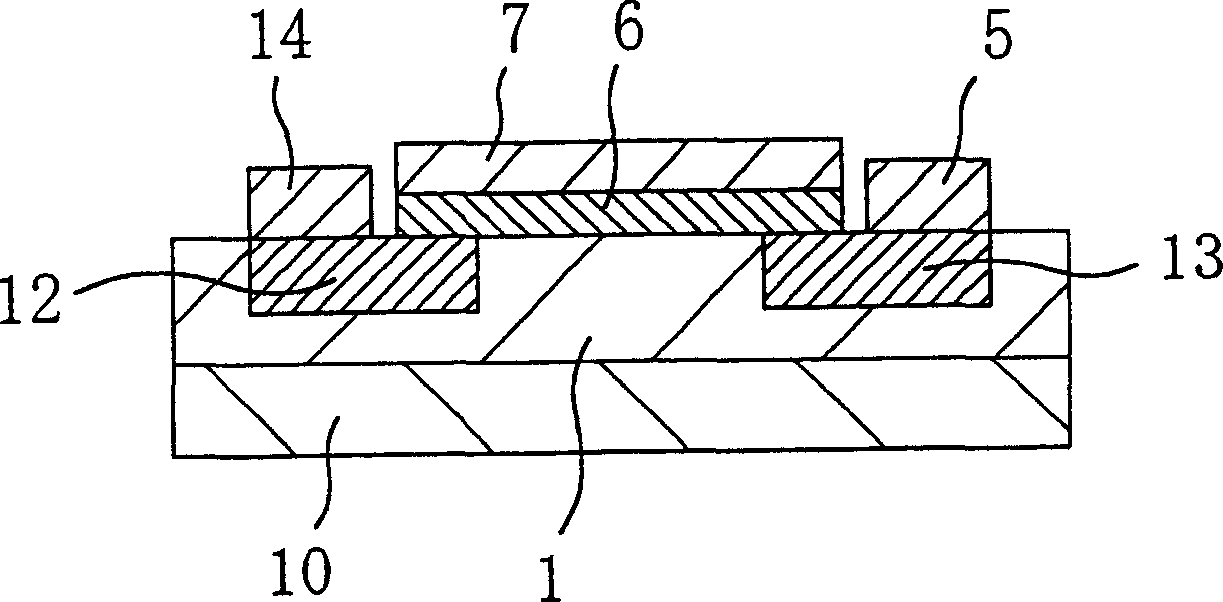

Semiconductor device and production method therefor

InactiveCN1599961APrevent quality deteriorationImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesSic substrateSemiconductor device

An upper part of a SIC substrate 1 is oxidized at a temperature of 800 to 1400 DEG C., inclusive, in an oxygen atmosphere at 1.4x10<2>Pa or less, thereby forming a first insulating film 2 which is a thermal oxide film of 20 nm or less in thickness. Thereafter, annealing is performed, and then a first cap layer 3, which is a nitride film of about 5 nm in thickness, is formed thereon by CVD. A second insulating film 4, which is an oxide film of about 130 nm in thickness, is deposited thereon by CVD. A second cap layer 5, which is a nitride film of about 10 nm in thickness, is formed thereon. In this manner, a gate insulating film 6 made of the first insulating film 2 through the second cap layer 5 is formed, thus obtaining a low-loss highly-reliable semiconductor device.

Owner:PANASONIC CORP

Rehydration method for sea cucumber

The invention discloses a rehydration method for sea cucumber, which comprises the following steps: placing dry sea cucumber into clear water and washing surface dust and salinity; placing sea cucumber in clean water, heating to 30-60 DEG C. by micro wave, keeping the temperature for 20-90 min, and cooling naturally; cleaning the sea cucumber internal organ and impurity, placing sea cucumber into purified water, heating to 60-95 DEG C. by microwave, and keeping the temperature for 20-40 min, cooling naturally, heating to 60-95 DEG C again, keeping the temperature for 10-30 min; finally placing sea cucumber into purified water after cooling, placing in an enclosed container for vacuum-pumping, keeping the degree of vacuum at 0.02-0.09 MP, placing the sea cucumber into -4-4 DEG C. for rehydration about 6-10 hours, and obtaining the finished product, and the invention has the advantages of short time, low temperature, less nutrition loss, large rehydration multiple, plump and complete shape and glistened color.

Owner:DALIAN XIAOQIN FOOD

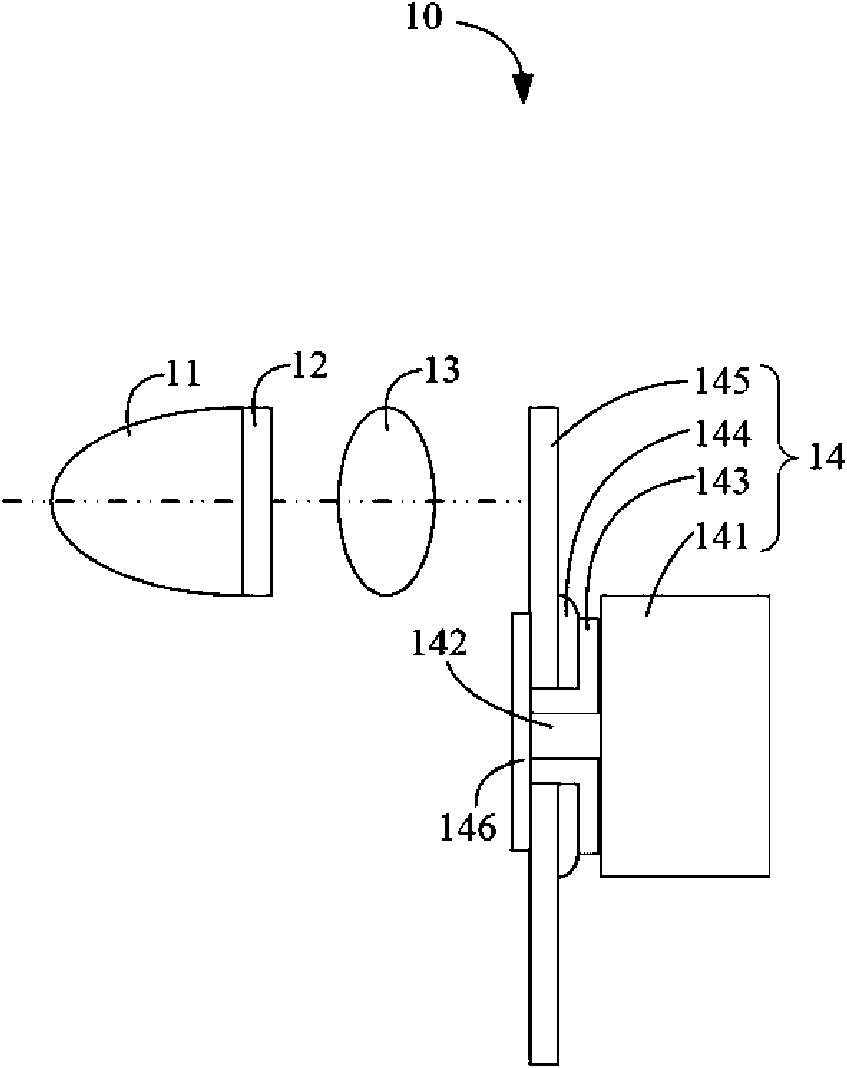

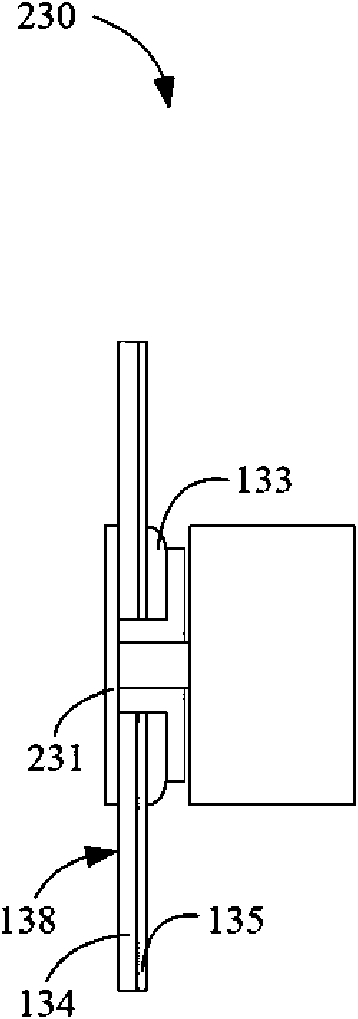

Color wheel and digital optical processing projector

InactiveCN101604057ABlocking radiationPrevent quality deteriorationProjectorsMountingsOptical processingUltraviolet lights

The invention provides a color wheel comprising a motor, a carrier, a color wheel piece and an ultraviolet optical filter, wherein the motor is provided with a rotor, the carrier is fixed on the rotor, the color wheel piece is connected with the carrier by solidification glue, and the ultraviolet optical filter is positioned on one side of the solidification glue opposite to the motor. The shape of the ultraviolet optical filter is matched with that of the color wheel piece. The ultraviolet optical filter can effectively obstruct ultraviolet light rays from entering the color wheel piece to refract or obstruct ultraviolet light refracting for plural times in the color wheel piece from irradiating on the solidification glue, and can prevent the connected quality of the solidification glue from deteriorating. In addition, the invention also provides a digital optical processing projector provided with the color wheel.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

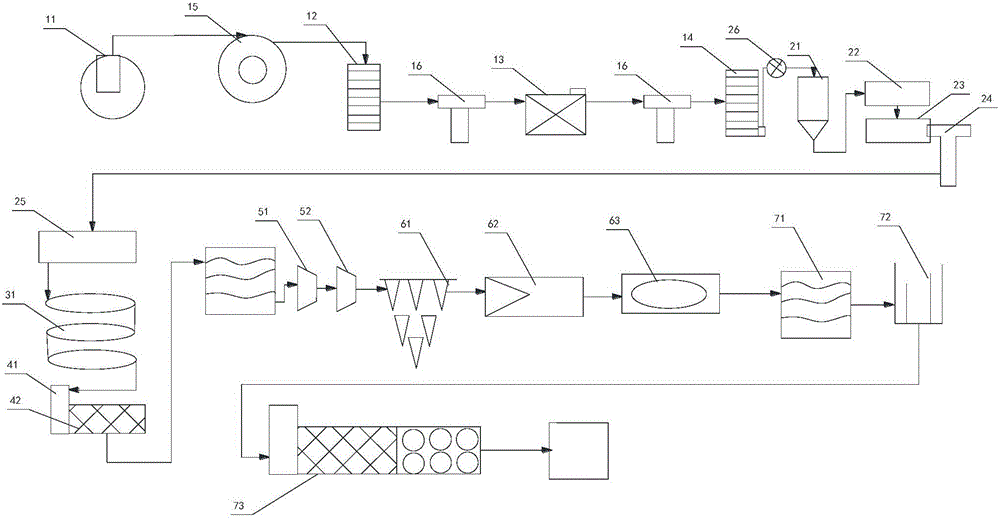

Method and system for producing pure cotton pulp in dry cutting method

InactiveCN105887539AReduce production energy consumptionLess investment in equipmentPretreatment with alkaline reacting compoundsDryer sectionFiberEnergy consumption

The invention discloses a method and system for producing pure cotton pulp in a dry cutting method. The method comprises the following steps: picking cotton, dry cutting, preparing alkali, impregnating, cooking and bleaching, concentrating, pulping, removing impurities, drying the pulp, and molding. The system comprises a cutting device, an impregnating device, a cooking-bleaching device, a concentrating device, a pulping device, an impurity removal device, a pulp drying device and a molding device, which are successively connected with one another. According to the method and system for producing the pure cotton pulp in the dry cutting method, a cooking, bleaching and molding process is completed in one step by cutting the material in a dry cutting method, and the material is first cut off and then is cooked and bleached by virtue of a steam pressure pipe, so that the continuous cooking production is realized, the blocking and intertwining problem of long fibers in screws of a subsequent step is solved, and the production energy consumption is reduced; and the technical difficulty in equipment investment and complexity of operation is alleviated, the quality worsening caused by unreasonable application of medicinal liquid in a production process of fibers is solved, the energy consumption can be reduced by 90 percent compared with the prior art, and high-quality pure cotton pulp can be produced.

Owner:HANDAN XIANGYUAN SPEICAL FIBERS CO LTD

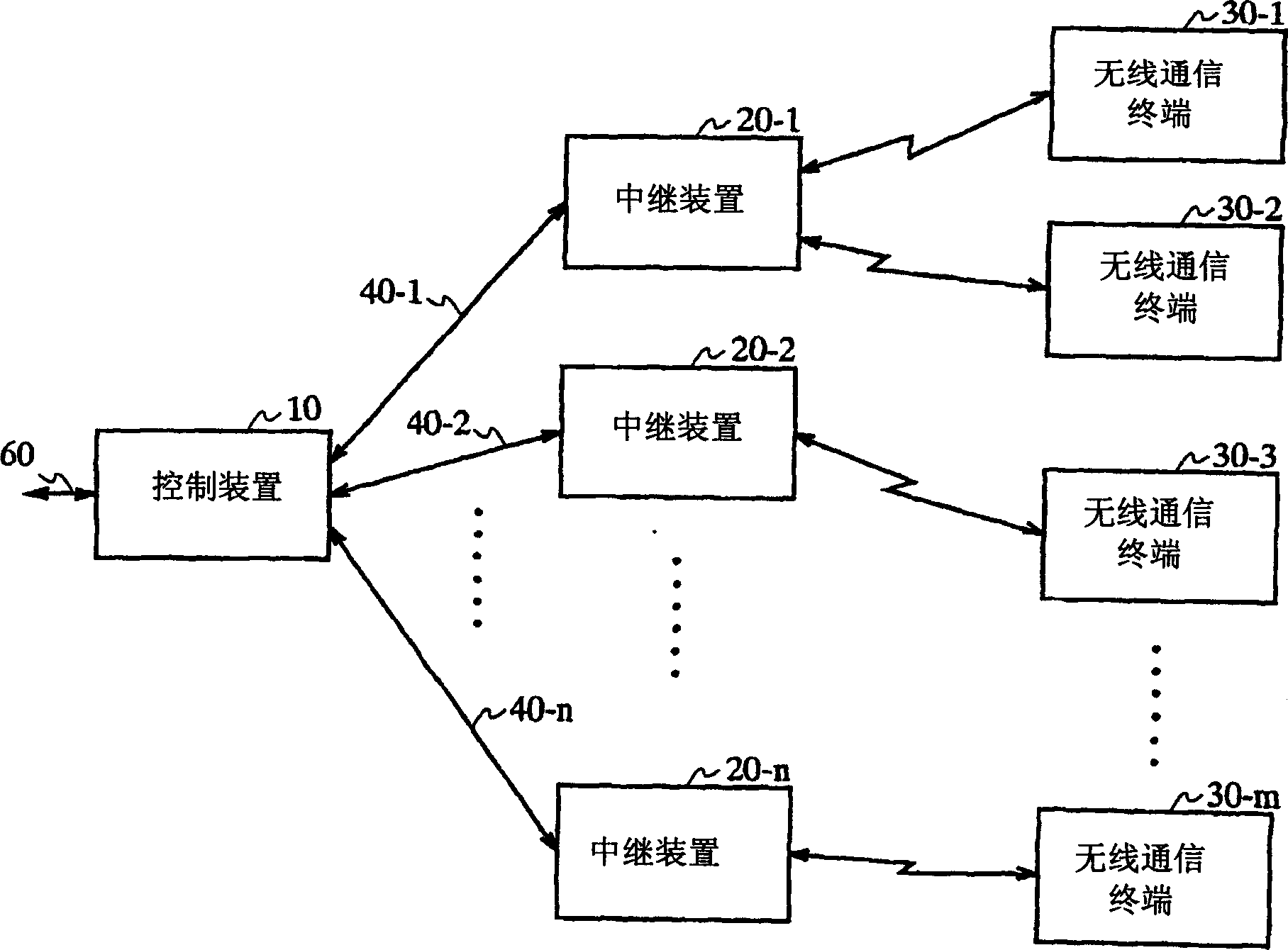

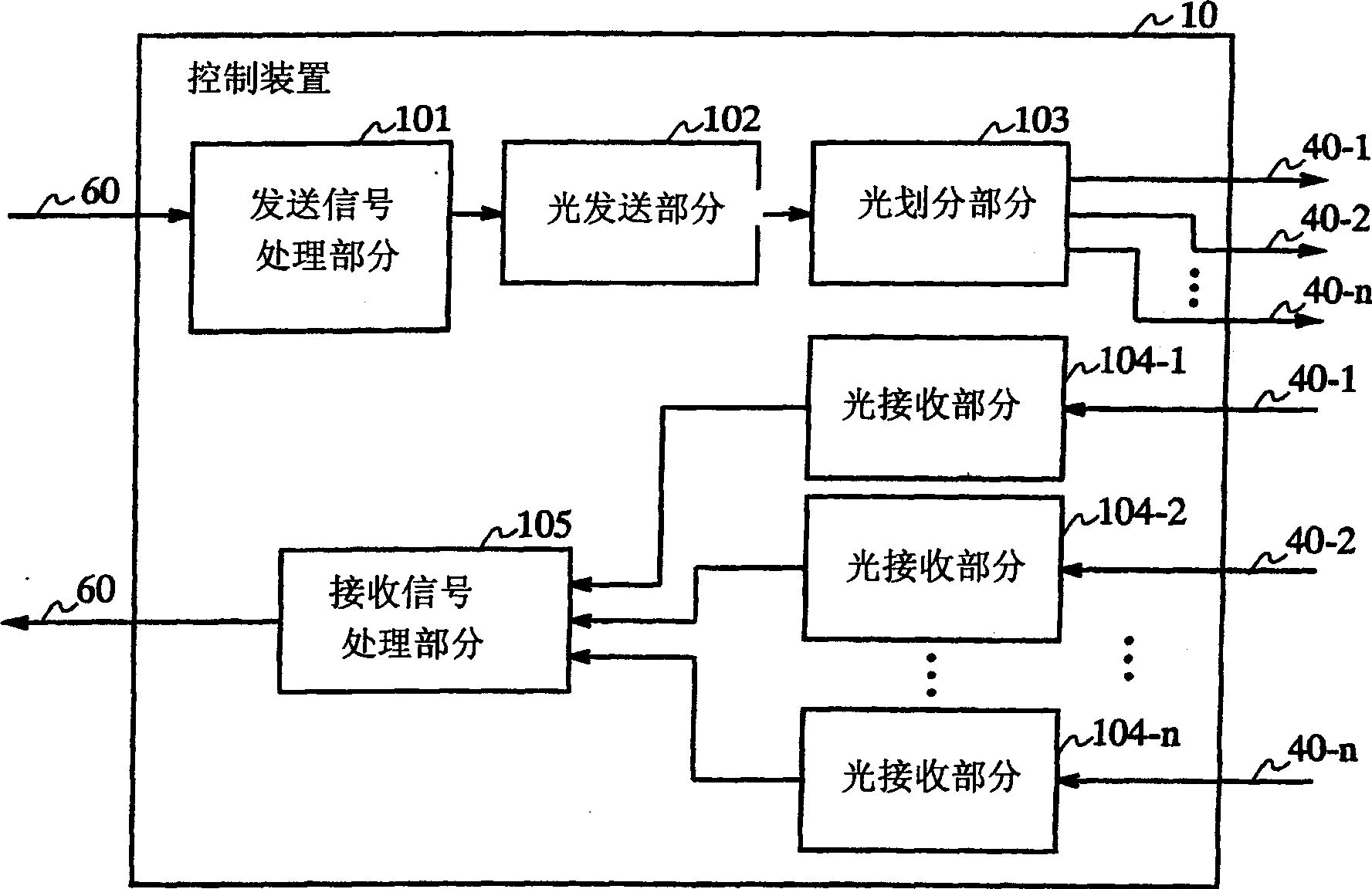

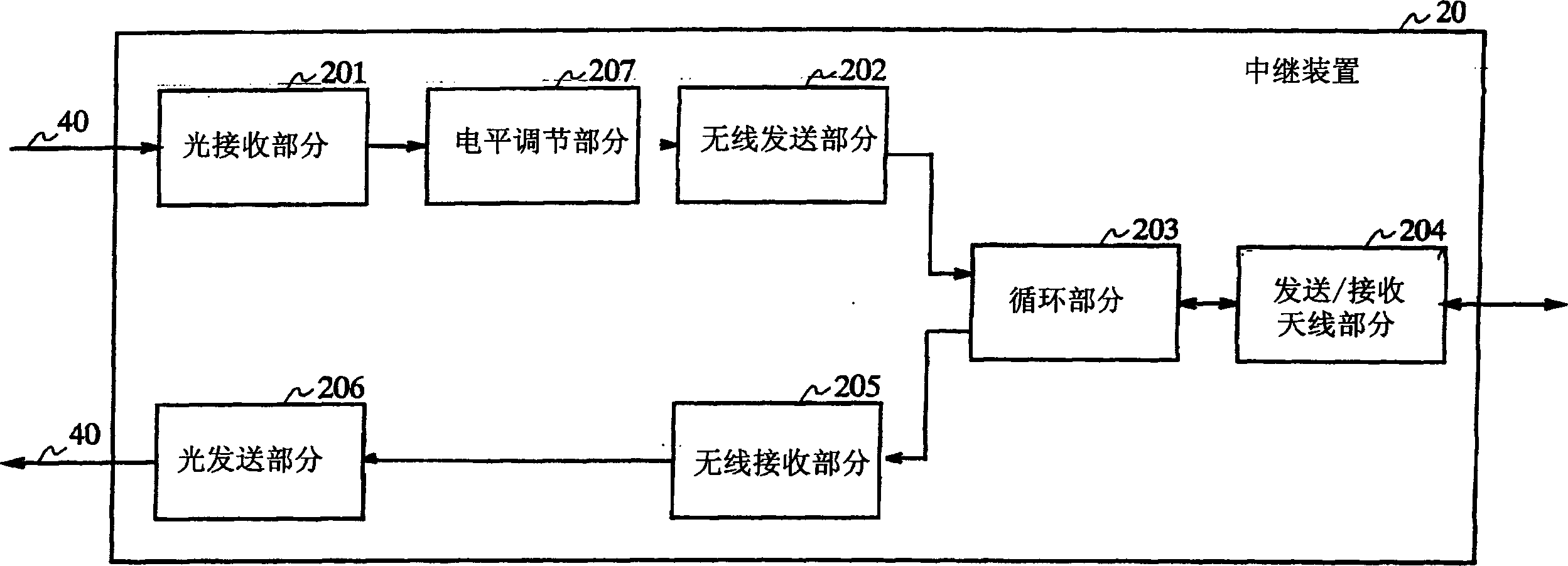

Radio communication system

InactiveCN1717949AAvoid light reflectionPrevent quality deteriorationPower managementData switching by path configurationCommunications systemEngineering

A radio communication system wherein the level of a radio signal received by a relay apparatus (20) can be confined within a predetermined dynamic range. In a control apparatus (10), a transmission part (102) converts a downstream electric signal to a downstream optical signal and transmits the downstream optical signal to the relay apparatus (20) via an optical transmission path (40). The relay apparatus (20) then converts the received downstream optical signal to the downstream electric signal and transmits this downstream electric signal as a radio signal from a transmission / reception antenna part (204) to a radio communication terminal (30). In the relay apparatus (20), a level adjustment part (207) adjusts the level of radio signals, which is to be transmitted by the relay apparatus (20), such that the reception intensity of radio signals to be received by the relay apparatus will be confined within a predetermined range.

Owner:PANASONIC CORP

Method of producing filling for filled food product and food product comprising filling

InactiveCN101889702AWater retention percentage improvementPrevent quality deteriorationDough treatmentFood coatingCelluloseAdditive ingredient

Provided are a method of producing a filling which improves water-retention capability during heating conducted after the filling is wrapped, and which has an excellent texture, and a filled food product produced by using the filling. Specifically, provided is a filling for a filled food product, the filling comprising at least one or more heat-processed filling ingredients and water-soluble cellulose ether which is gelable during heating. Also provided is a method of producing a filling for a filled food product comprising at least the steps of: heat-processing one or more filling ingredients; and mixing the heat-processed filling ingredients with water-soluble cellulose ether which is gelable during heating, to thereby obtain a filling. Further provided is a filled food product obtained by performing any one of heating, baking, and frying of: a filling comprising at least one or more heat-processed filling ingredients and water-soluble cellulose ether which is gelable during heating; and a dough skin which wraps the filling.

Owner:SHIN ETSU CHEM IND CO LTD

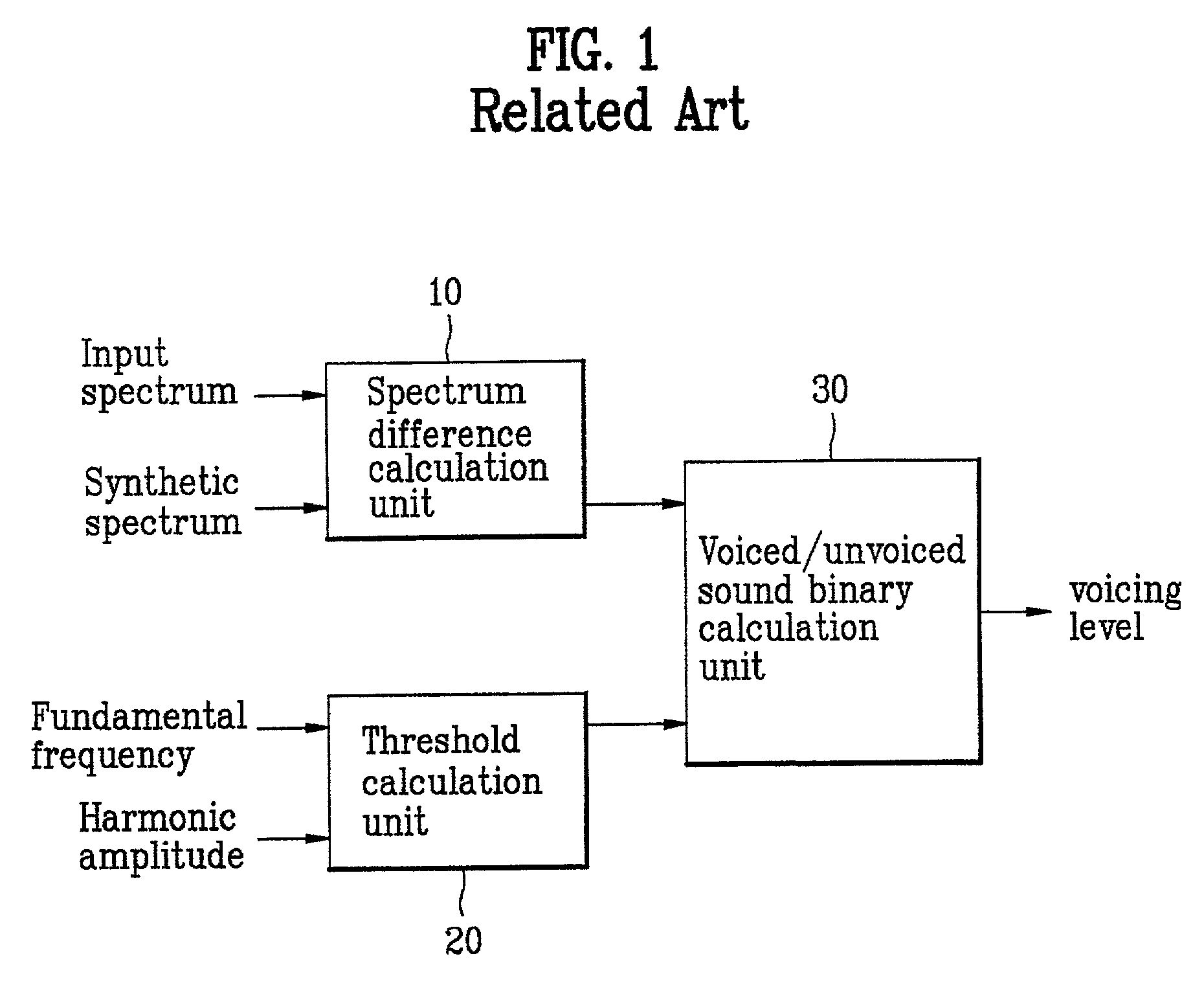

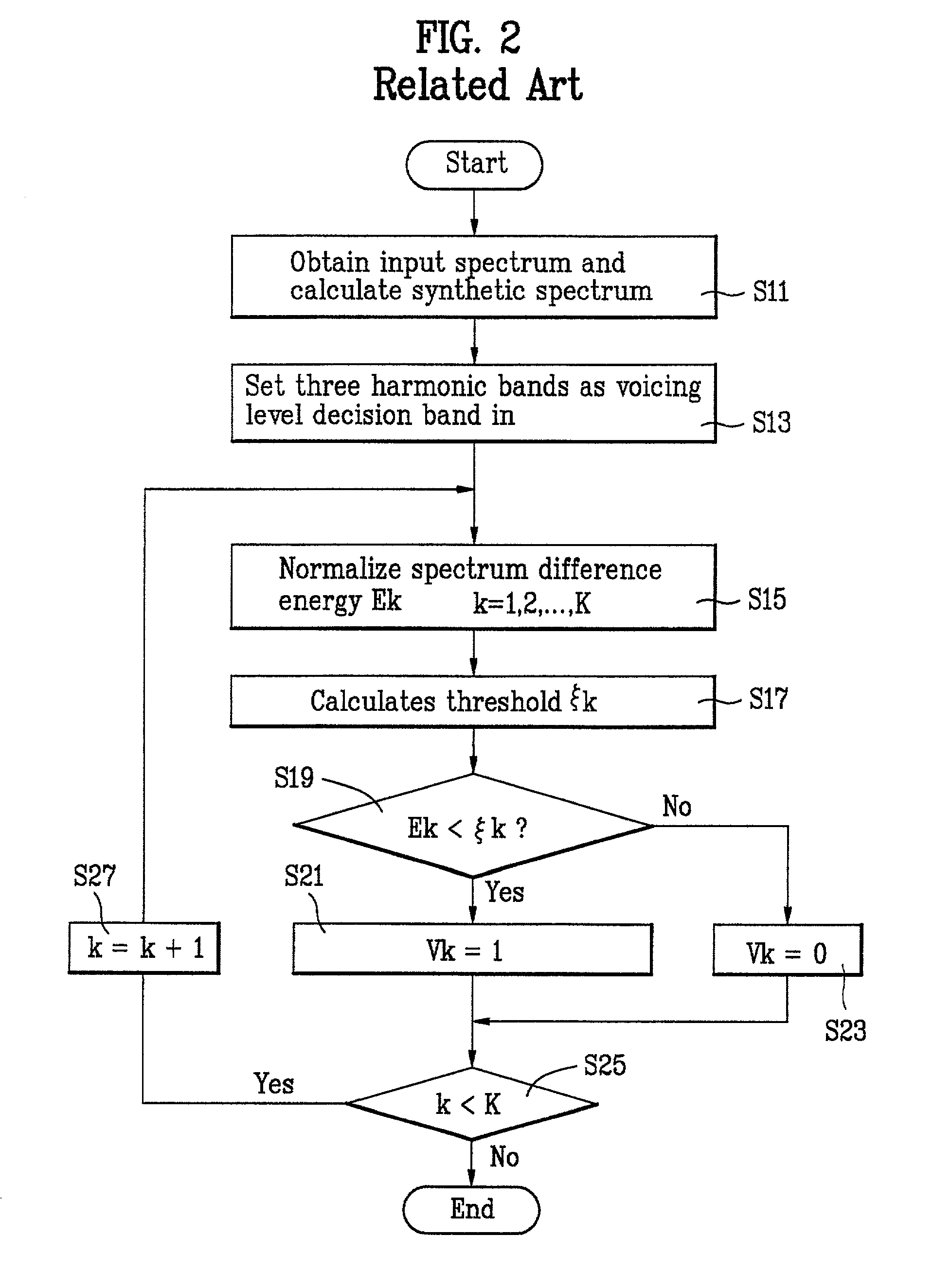

Voiced/unvoiced information estimation system and method therefor

ActiveUS7016832B2Prevent quality deteriorationReduce levelSpeech analysisFrequency bandSynthetic spectrum

A voiced / unvoiced information estimation system uses input spectrum and synthetic spectrum to produce a voicing level spectrum. The estimation system uses a spectrum difference calculation unit to normalize a spectrum difference energy for each harmonic band in unit of harmonic band, and further uses a voicing level calculation unit to calculate a voicing level. The voicing level of each harmonic band has a continuous value between 1 and 0. The estimation system is effective in vector quantization of voiced / unvoiced information at a low bit rate. Because it is unnecessary to calculate a threshold for deciding a voiced / unvoiced information, a decision anomaly occurring due to threshold is eliminated, and the accuracy of a voicing level is improved. Furthermore, since a spectrum is represented by mixing a voiced element and a unvoiced element in a harmonic band, the estimation system improves the audio quality of a combined sound.

Owner:ERICSSON LG ENTERPRISE

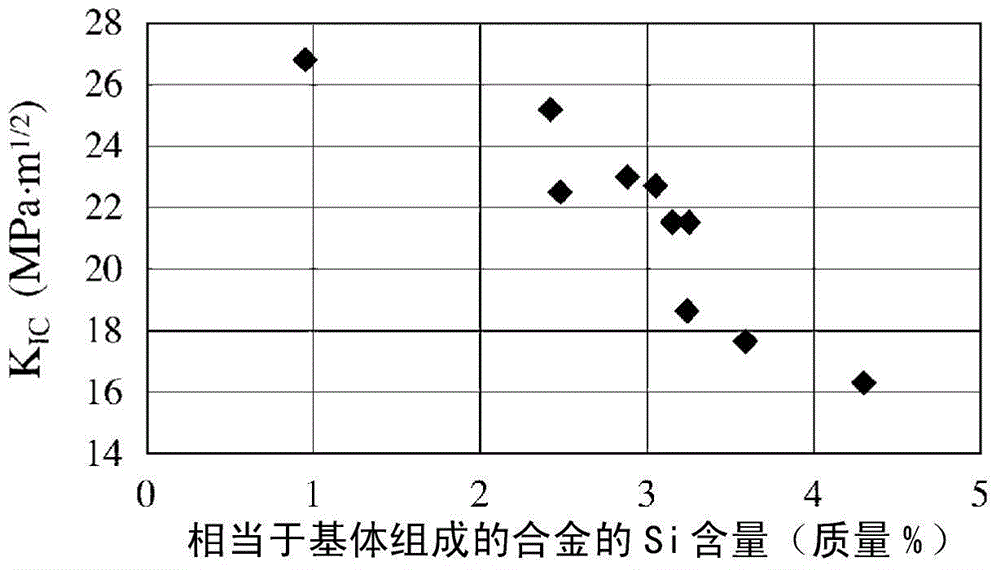

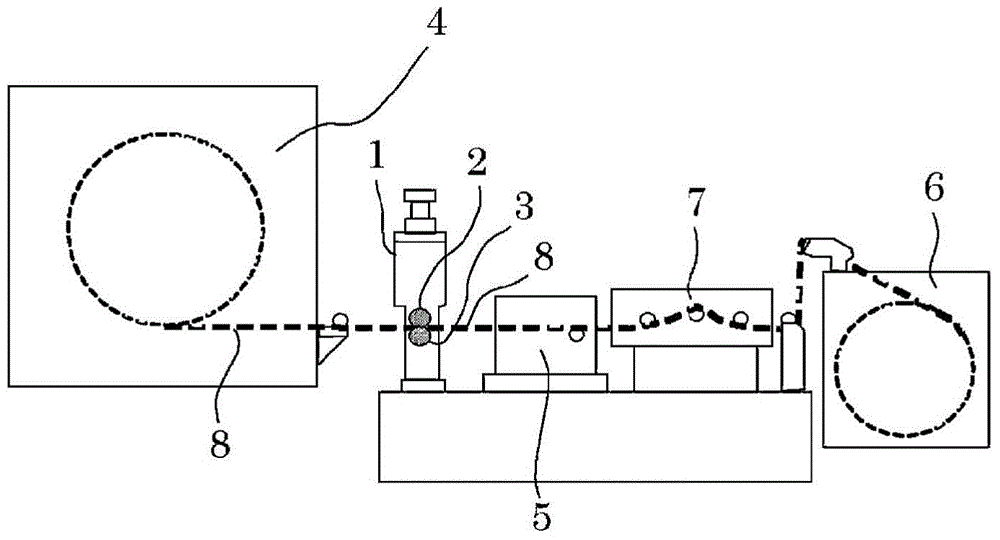

Hot-rolling composite roll produced by cetrifugal casting

ActiveCN105121044AImprove wear resistanceGood anti-occlusion performanceFurnace typesRollsChemical compositionGraphite

A centrifugally cast hot-rolling composite roll comprising (a) an outer layer made of cast iron having a chemical composition comprising by mass 2.5-3.5% of C, 1.3-2.4% of Si, 0.2-1.5% of Mn, 3.5-5.0% of Ni, 0.8-1.5% of Cr, 2.5-5.0% of Mo, 1.8-4.0% of V, and 0.2-1.5% of Nb, the balance being Fe and inevitable impurities, a mass ratio of Nb / V being 0.1-0.7, and a mass ratio of Mo / V being 0.7-2.5, and meeting the condition of 2.5 ‰¤ V + 1.2 Nb ‰¤ 5.5, and having a structure comprising 0.3-10% by area of a graphite phase; (b) a shaft portion made of ductile cast iron in which the area ratio of ferrite is 35% or less; and (c) an intermediate cast iron layer.

Owner:PROTERIAL LTD

Sashimi cryopreservation method

InactiveCN102986827APrevent quality deteriorationGood effectMeat/fish preservation by freezing/coolingCold airEngineering

The invention discloses a sashimi cryopreservation method comprising the following steps: spreading fresh sliced sashimi on absorbent paper, removing water on the surface of the sashimi by using an ozonizer containing cold air, immediately freezing the sashimi in cold air of 25-30 DEG C below zero, coating a transparent preservative film on the sashimi, placing the sashimi and the absorbent paper into a storage bag with a deoxidant to carry out vacuum package, and then, cryopreserving the sashimi at 15-20 DEG C below zero. The invention provides the sashimi cryopreservation method which can be used for preventing the quality of the sashimi from being worsened, storing the sashimi for at least over half a year and simply putting the sashimi on a counter or dining table without carrying out secondary processing on the sashimi after the sashimi is unfrozen.

Owner:三伊水产株式会社

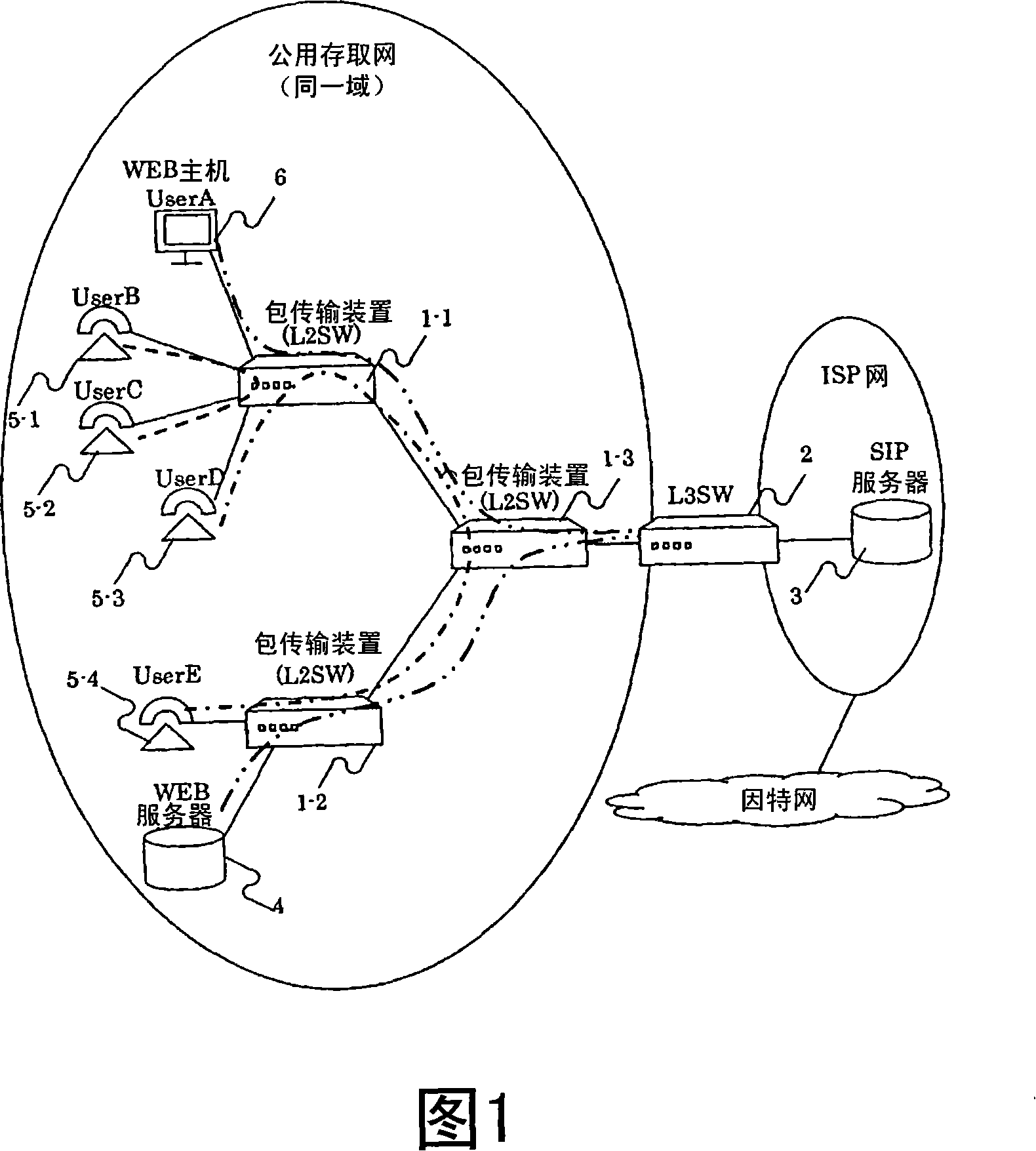

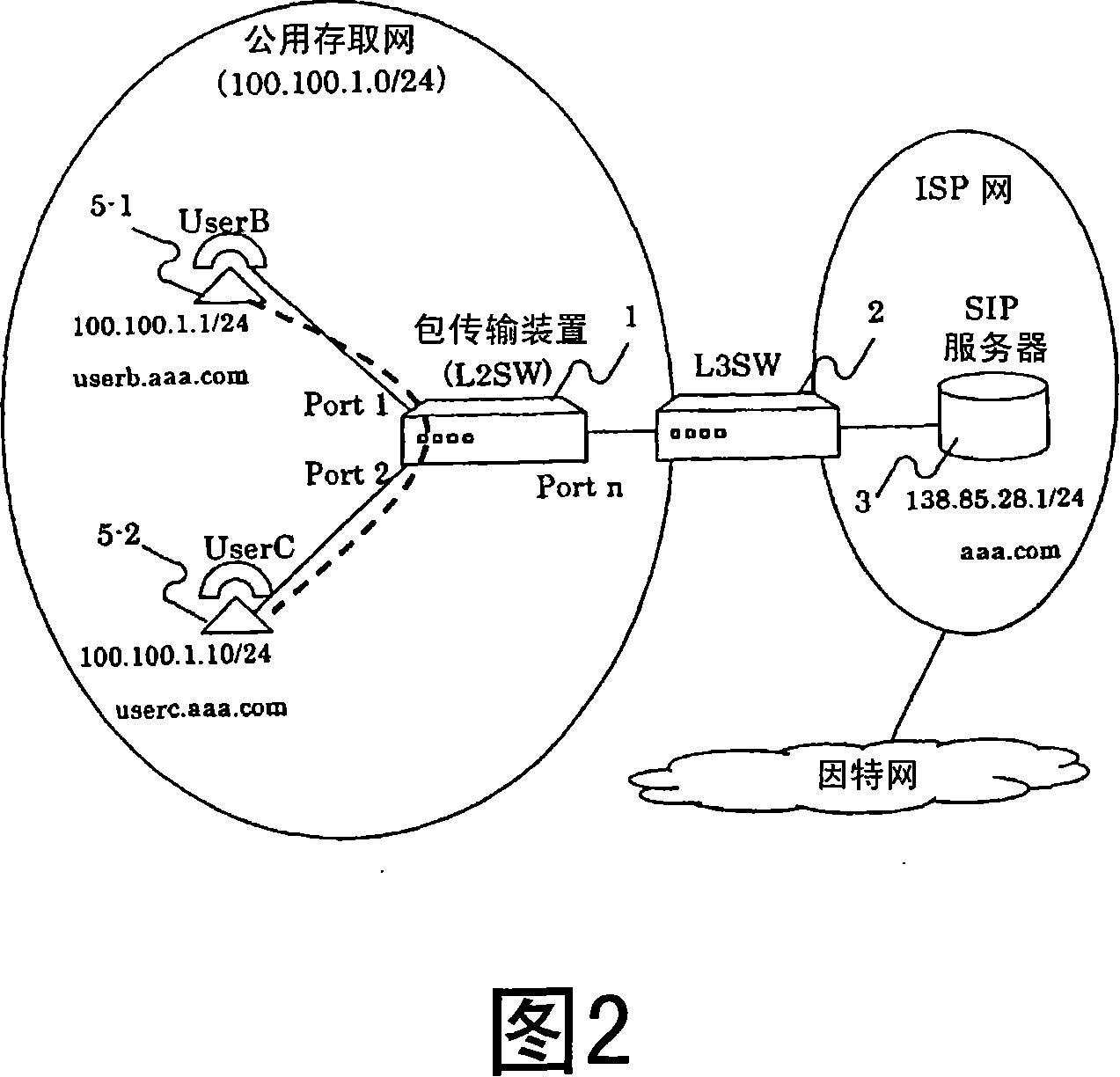

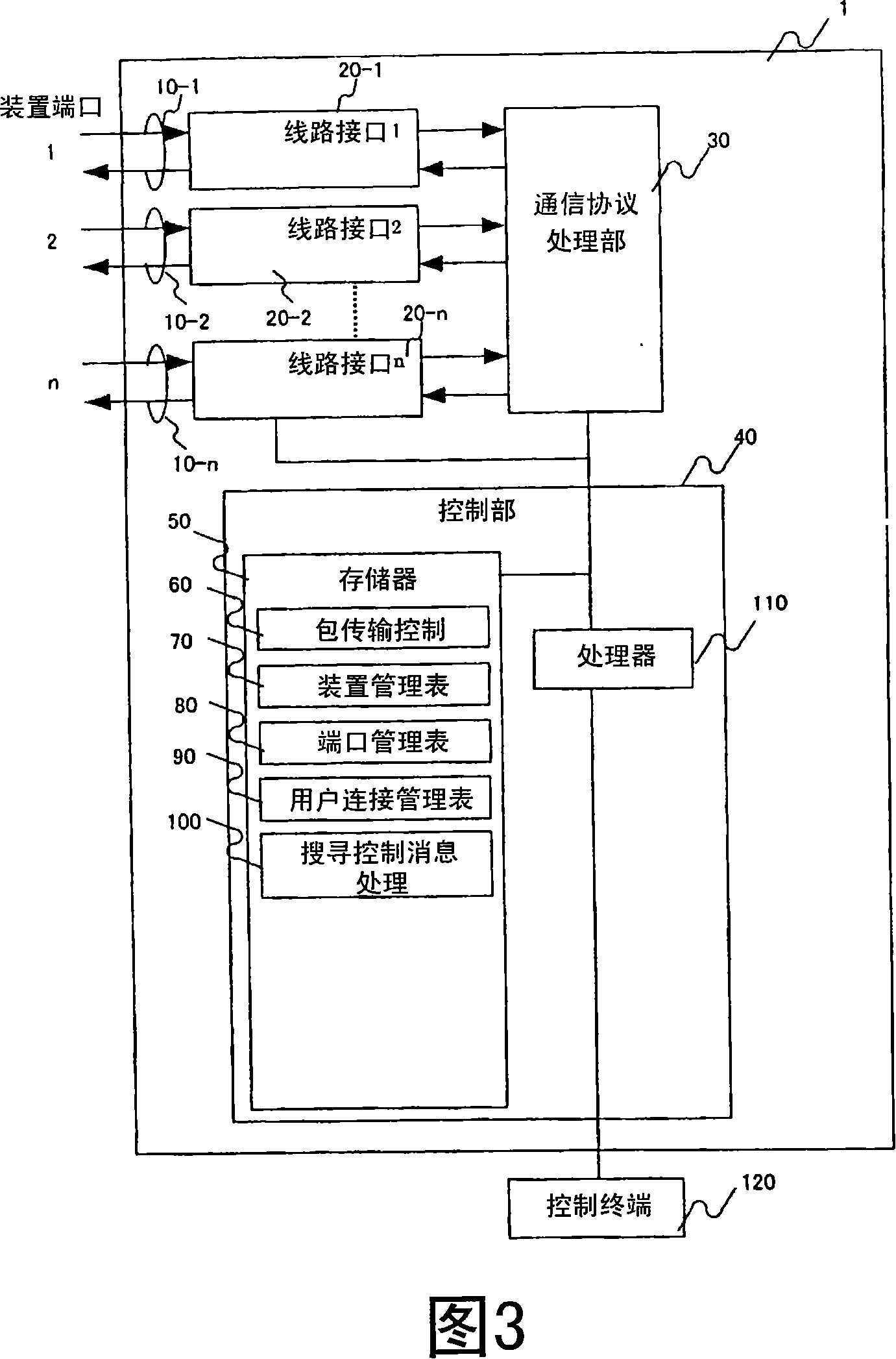

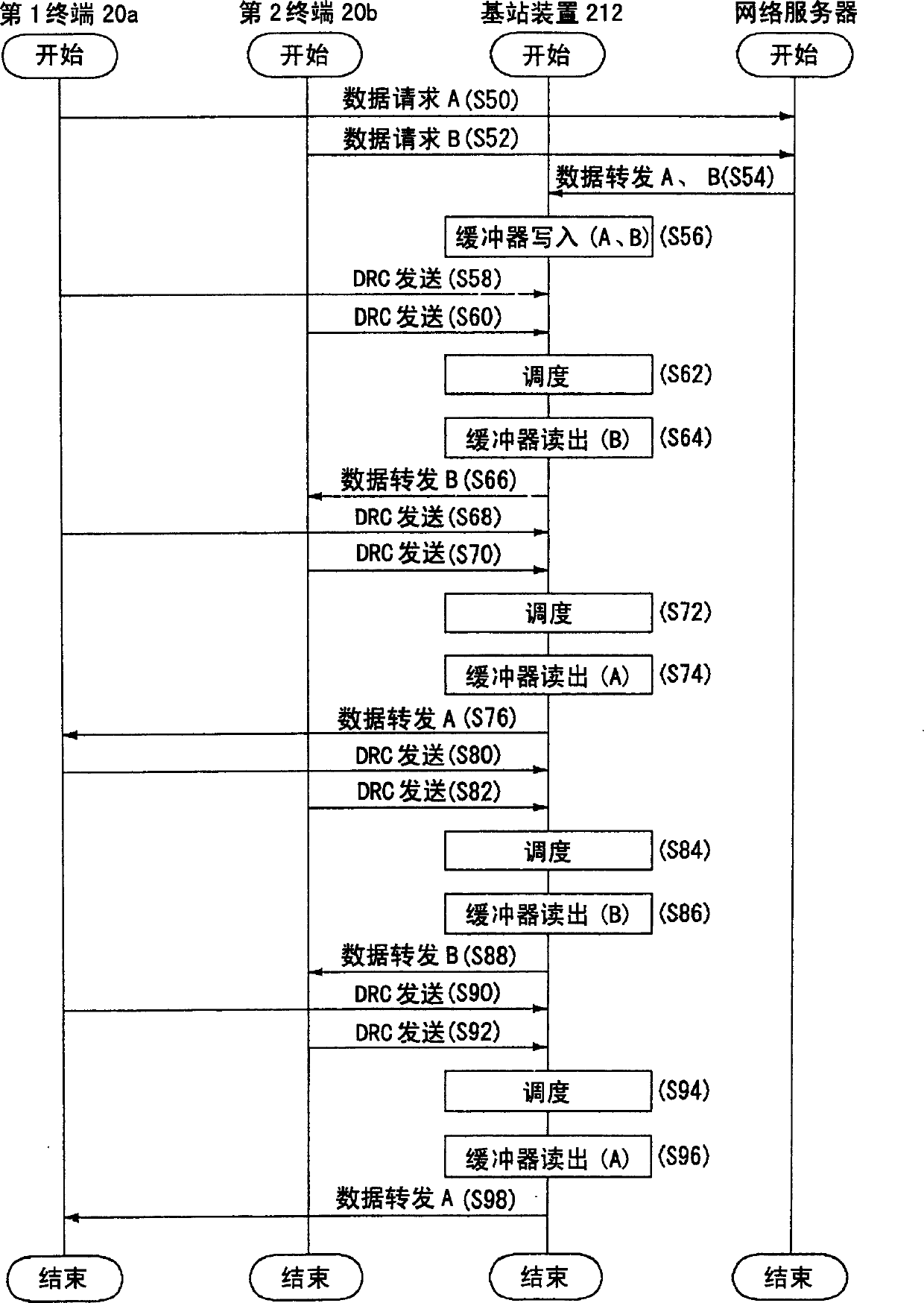

Packet transfer device and communication system

InactiveCN101106524AAvoid transmission delaysReduce transmission delayInterconnection arrangementsNetworks interconnectionCommunications systemSession control

In a network having an L2SW in which uplink VLAN is set, a transfer delay of a voice call packet is prevented. In a process of establishing a session between terminals ( 5 ), a packet transfer device ( 1 ) stores information capable of specifying a sending terminal ( 5 - 1 ) and a receiving terminal ( 5 - 2 ) and a correspondence relation (user connection information) to a connection port into a table. A SIP message of a session control packet communicated between the terminals ( 5 ) is snooped, and a destination IP address, a transmission source IP address, a destination port number, a transmission source port number, a connection port etc. are stored into the table. In a case where an RTP packet as voice data is received after the session is established, the packet transfer device ( 1 ) performs a loopback transfer or transfers it to an uplink port in accordance with the table.

Owner:HITACHI LTD

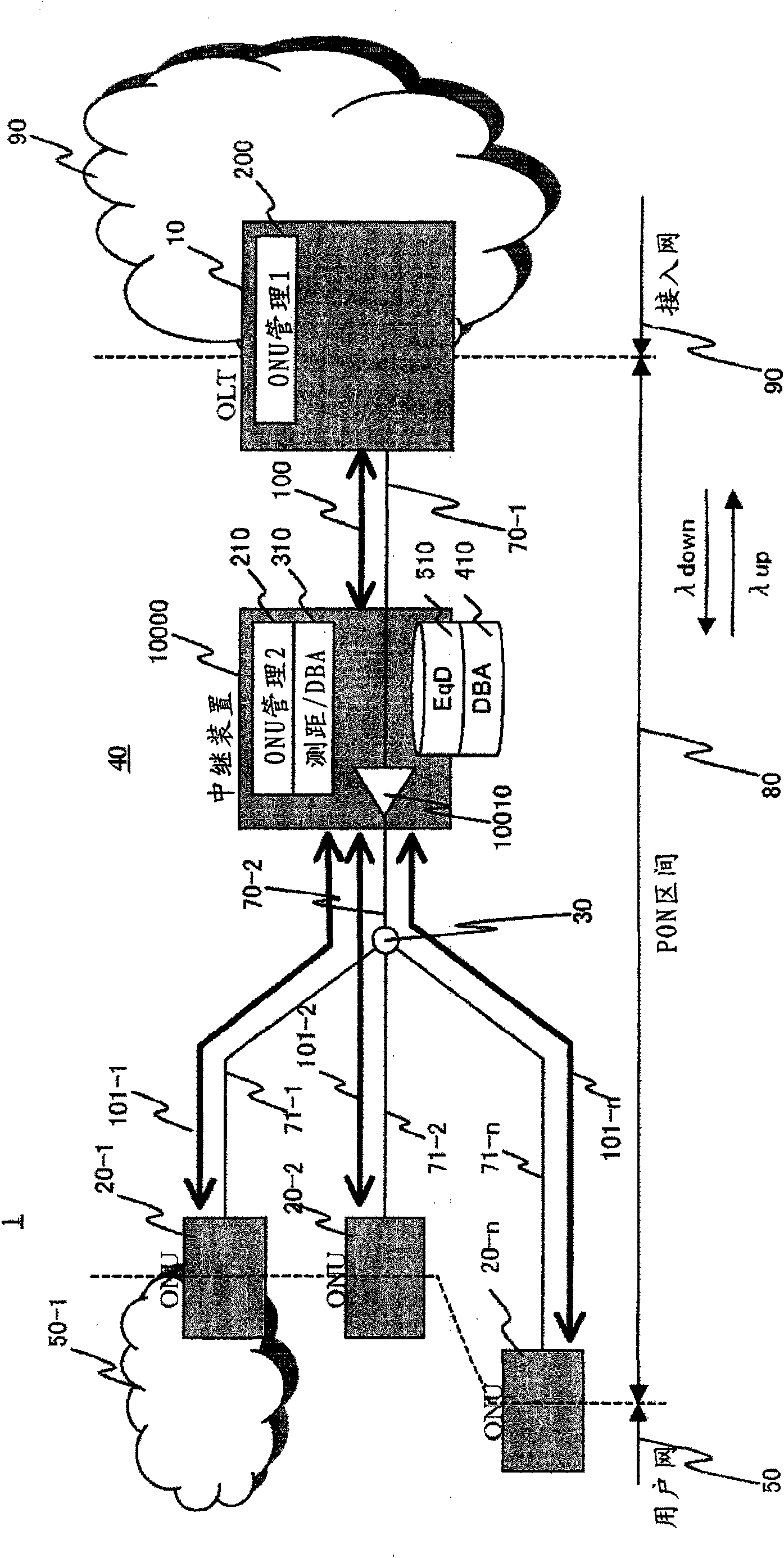

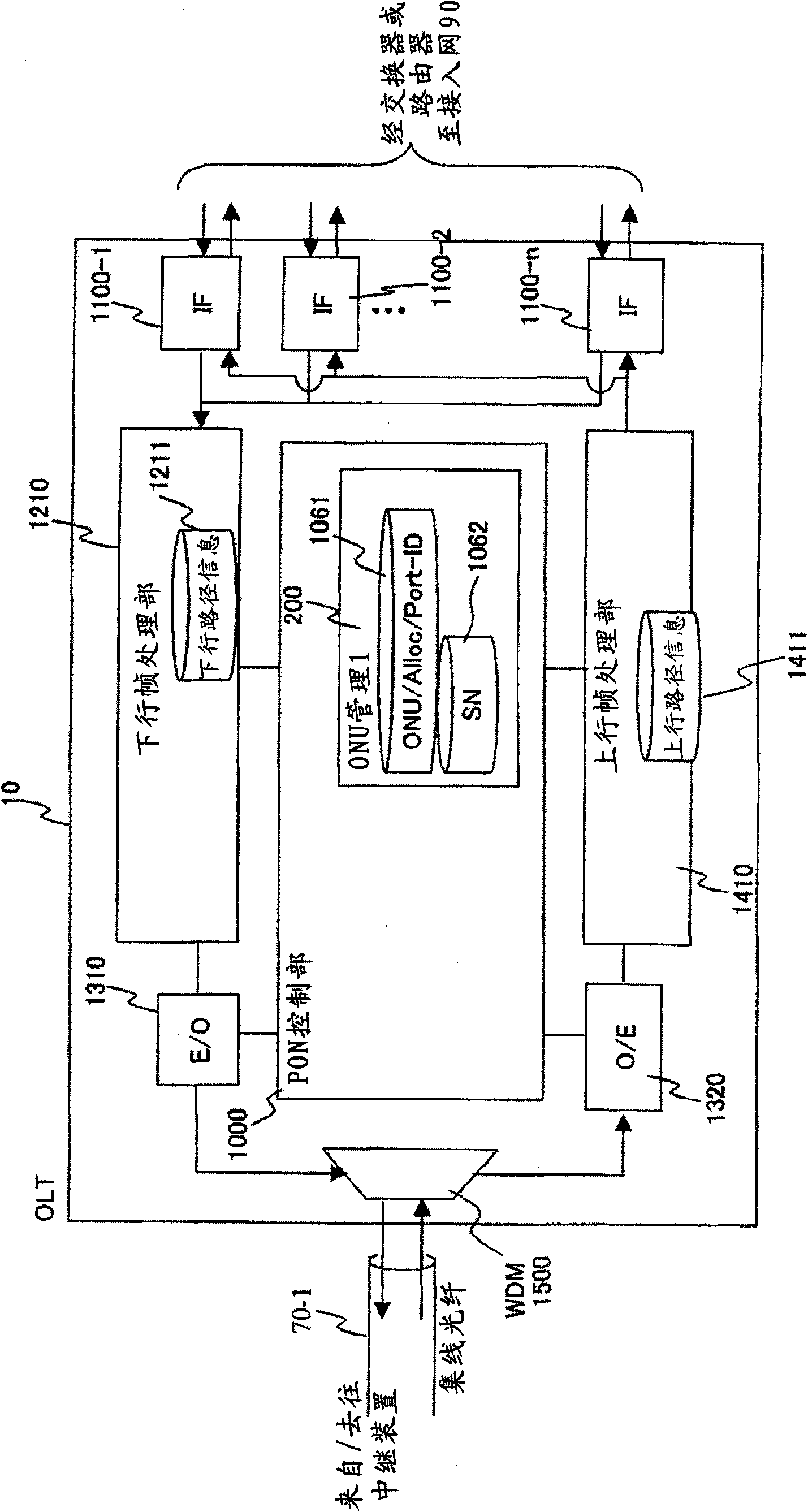

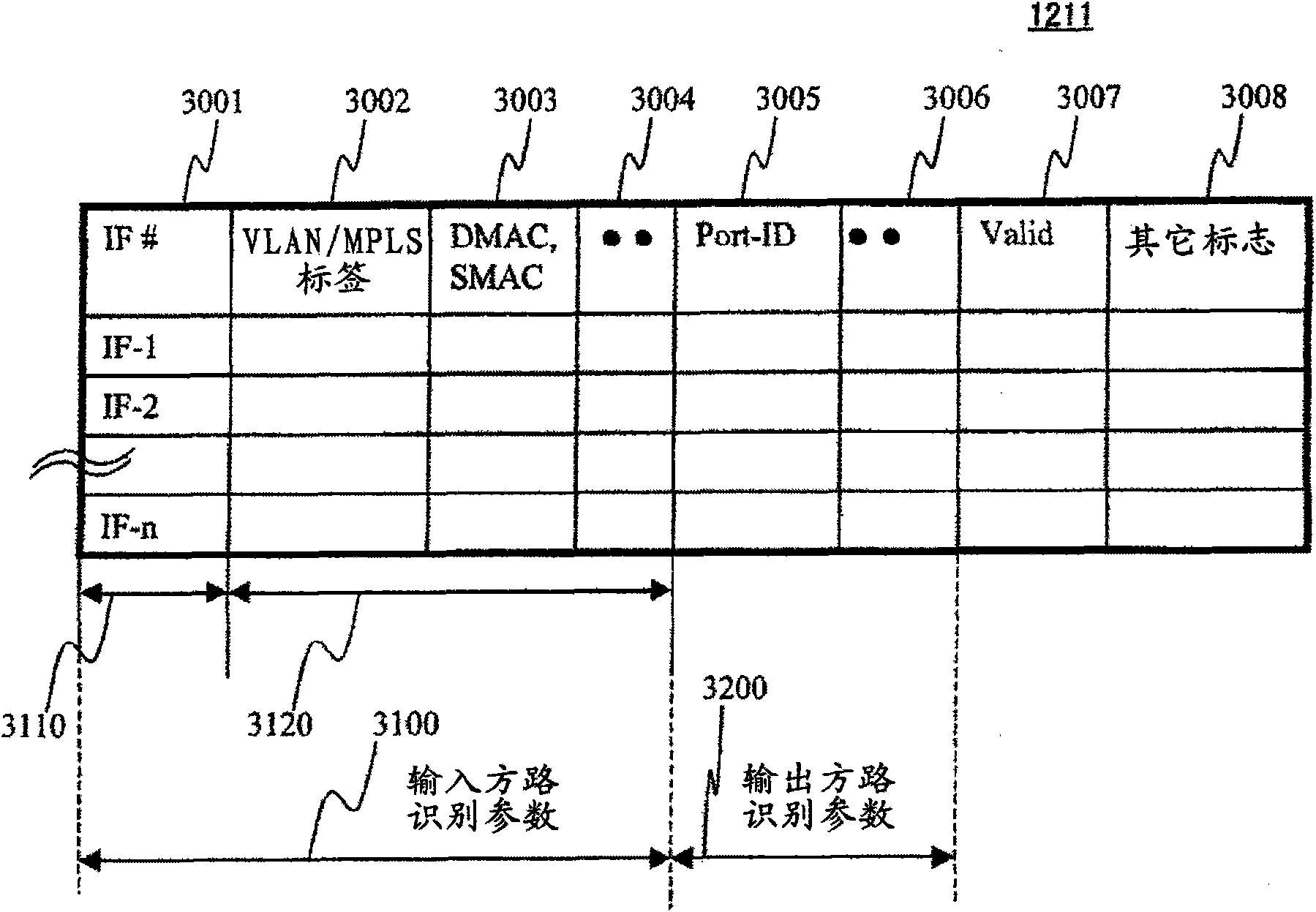

Passive optical network system and its operation method

InactiveCN101873175AAchieve simplicityLow costMultiplex system selection arrangementsError preventionCommunications systemPrimary station

In the configuration of an optical communication system interconnecting a parent station and a plurality of child stations via an optical fiber network equipped with an optical splitter, RE is provided having a measuring unit for measuring a transmission distance or time to a child station, a determining unit for determining a timing when a child station transmits a signal, in accordance with a transmission bandwidth request from the child station, and a signal processing unit for processing a signal received from a child station and transmitting the processed signal to the parent station. When a burst signal is received from each child station at the determined timing, a portion of the header of the burst signal is deleted, and a dummy signal is inserted into the deleted area and a gap area between received burst signals to convert the burst signals into a series of signals to be sent to the parent station.

Owner:HITACHI LTD

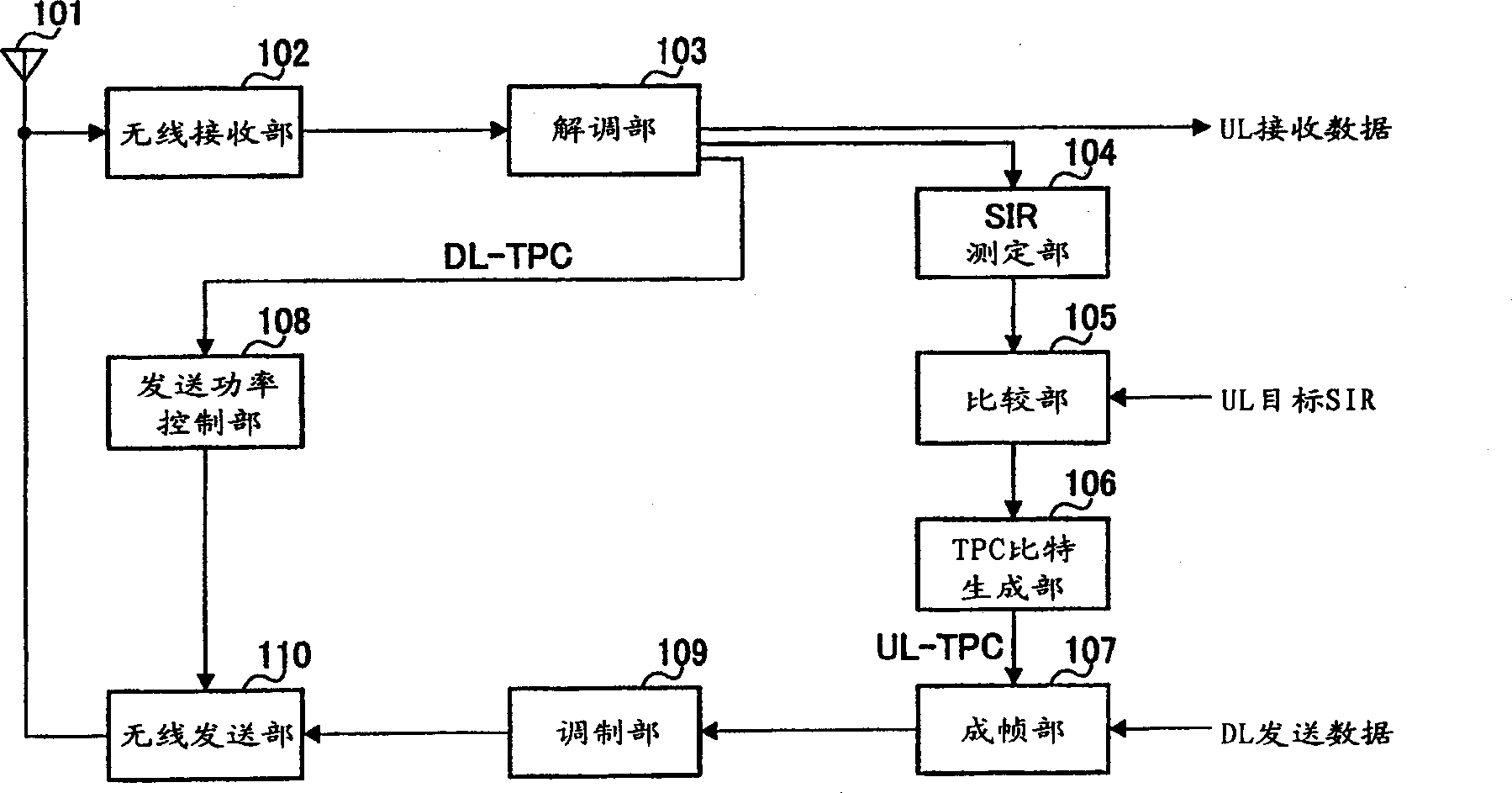

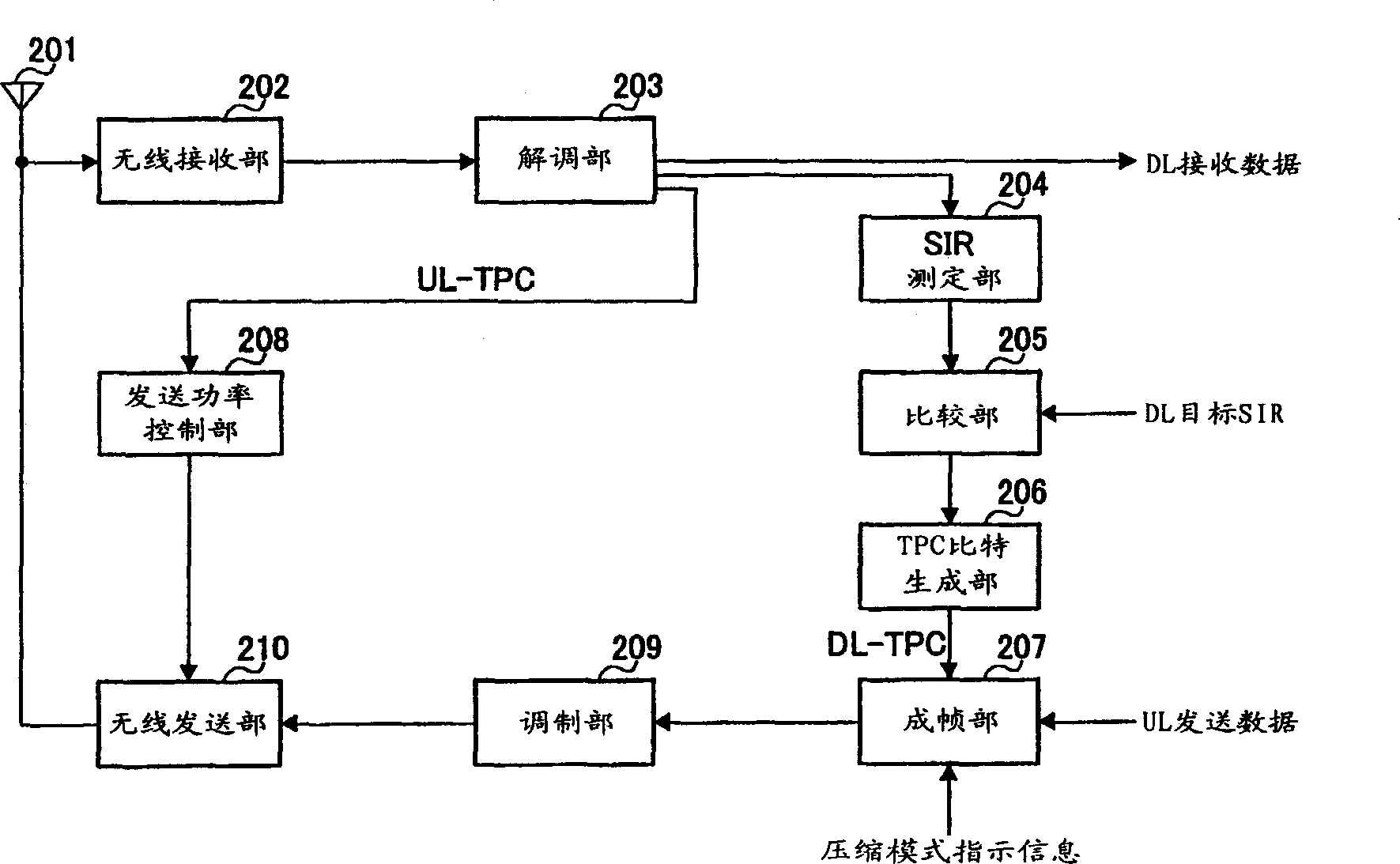

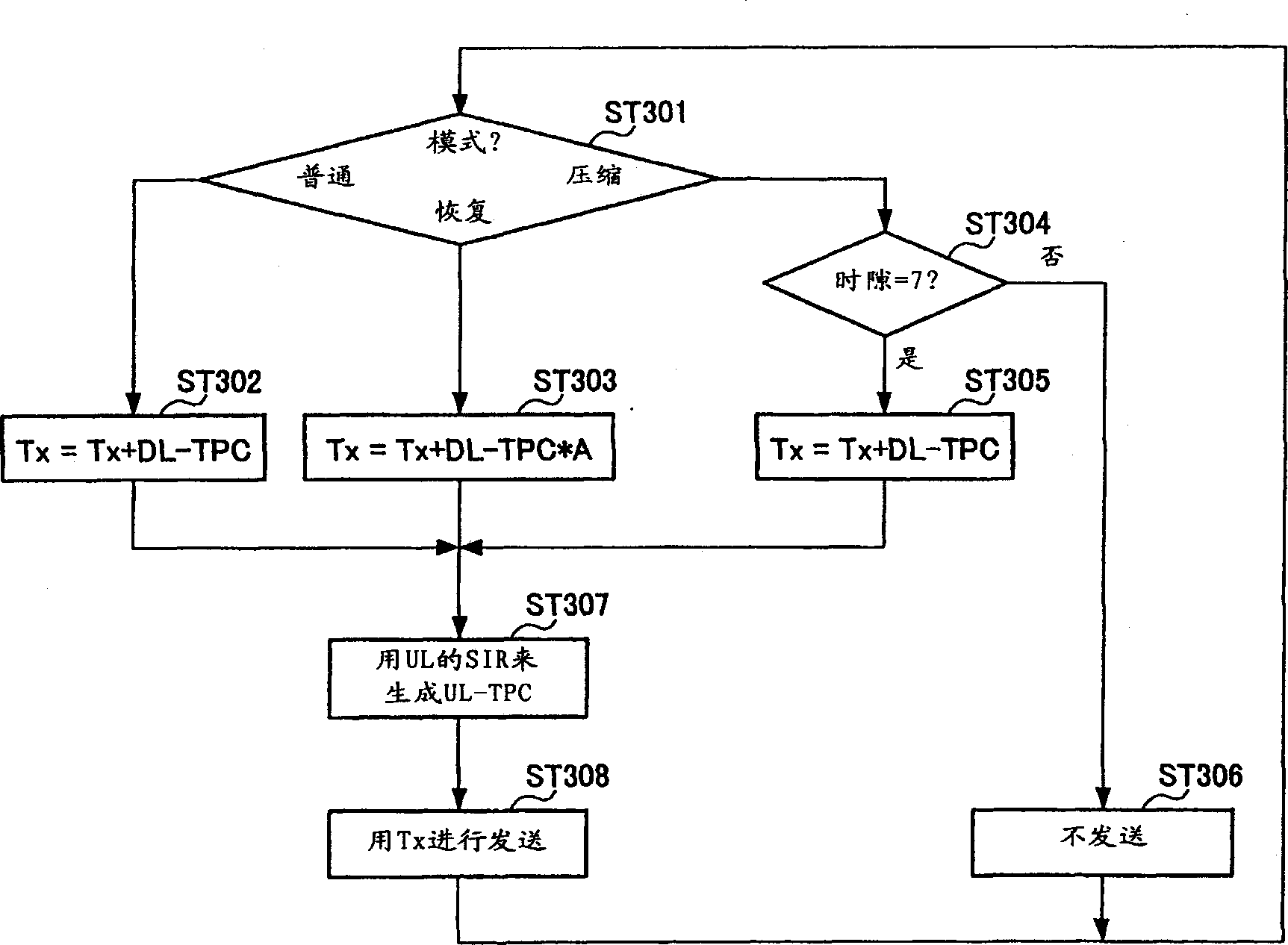

Base station device, communication terminal and transmission power control method

InactiveCN1319285APrevent quality deteriorationImprove interferencePower managementEnergy efficient ICTSignal qualityEngineering

Transmission power commands are fed on up link signals before one slot after estimation of transmission power of a down link just before return for convergence of transmission power values in a first slot into an ideal transmission power value at restart of transmission after suspension. Thereby, it may be realized that a converging rate of the above transmission power values is improved; signal quality of related users sides is improved, or interference power with signals of other users except the above users is reduced.

Owner:PANASONIC CORP

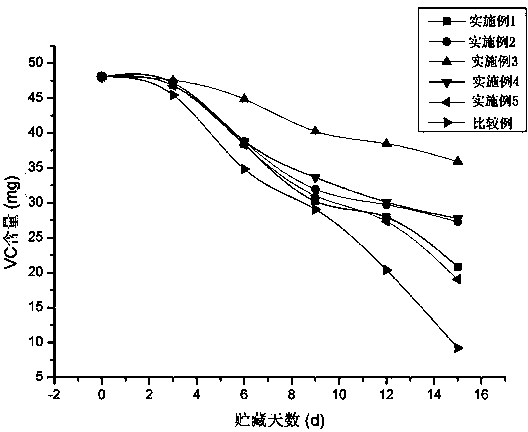

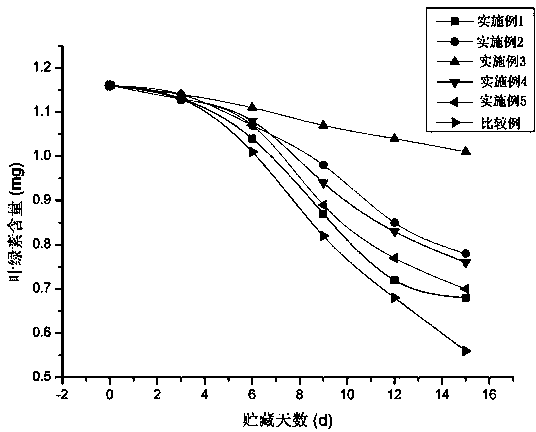

Modified atmosphere freshness keeping production technology of wild Marsilea quadrifolia

InactiveCN103392788AMinimize Variation in Nutrient CompositionKeep freshFruits/vegetable preservation by freezing/coolingPlastic wrapMarsilea quadrifolia

The invention relates to a modified atmosphere freshness keeping production technology of wild Marsilea quadrifolia. The modified atmosphere freshness keeping production technology is characterized in that the technology comprises the following steps: picking a raw material, and pre-cooling; 2, choosing the raw material; 3, immersion: immersing in an immersion liquid composed of a material and water according to a volume ratio of 1:9-11, wherein the material comprises a 1% salt solution; 4, cleaning: removing dusts and silts; 5, dehydration: dehydrating by using a centrifuge; 6, disinfection: disinfecting through using an ultraviolet ray sterilizer; 7, modified atmosphere packaging: carrying out seal packaging of the Marsilea quadrifolia through using a freshness keeping film, and filling a mixed gas composed of O2, CO2 and N2 according to a certain ratio; and 8, refrigerating. The modified atmosphere freshness keeping production technology allows the Marsilea quadrifolia to be packaged by the mixed gas composed of O2, CO2 and N2 according to a certain ratio and to be stored at a low temperature, so the change of the nutritional components of the modified atmosphere Marsilea quadrifolia is reduced, and the original freshness, color and flavor of the Marsilea quadrifolia are furthest kept to realize the prolongation of the storage life and the regulation of the market surplus and deficiency.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

Method of smelting low-phosphorus steel

ActiveCN109593907AThe smelting process is stableGuaranteed Composition IndexManufacturing convertersProcess efficiency improvementTemperature controlSteelmaking

The invention belongs to the technical field of steelmaking, and discloses a method of smelting low-phosphorus steel. The method comprises the following steps of a reladling station molten iron silicon proportioning control step, a waste steel selection and waste steel ratio control step, a converter loading amount control step, a converter blowing gun position, an oxygen supply strength and a bottom blowing flow comprehensive control step; a carbon content and a temperature control step in a smelting process, a semi-steel slag and final slag R and MgO% control step, an steel tapping slag discharging control step, as well as a steel ladle selecting and slag sticking quantity control step. According to the method of smelting the low-phosphorus steel has the advantages that parameters and procedures are optimized, under the condition that the molten iron and steel scrap are given, a qualified cast blank of a finished product which P is less than or equal to 0.005 percent can be producedfinally.

Owner:BEIJING SHOUGANG CO LTD

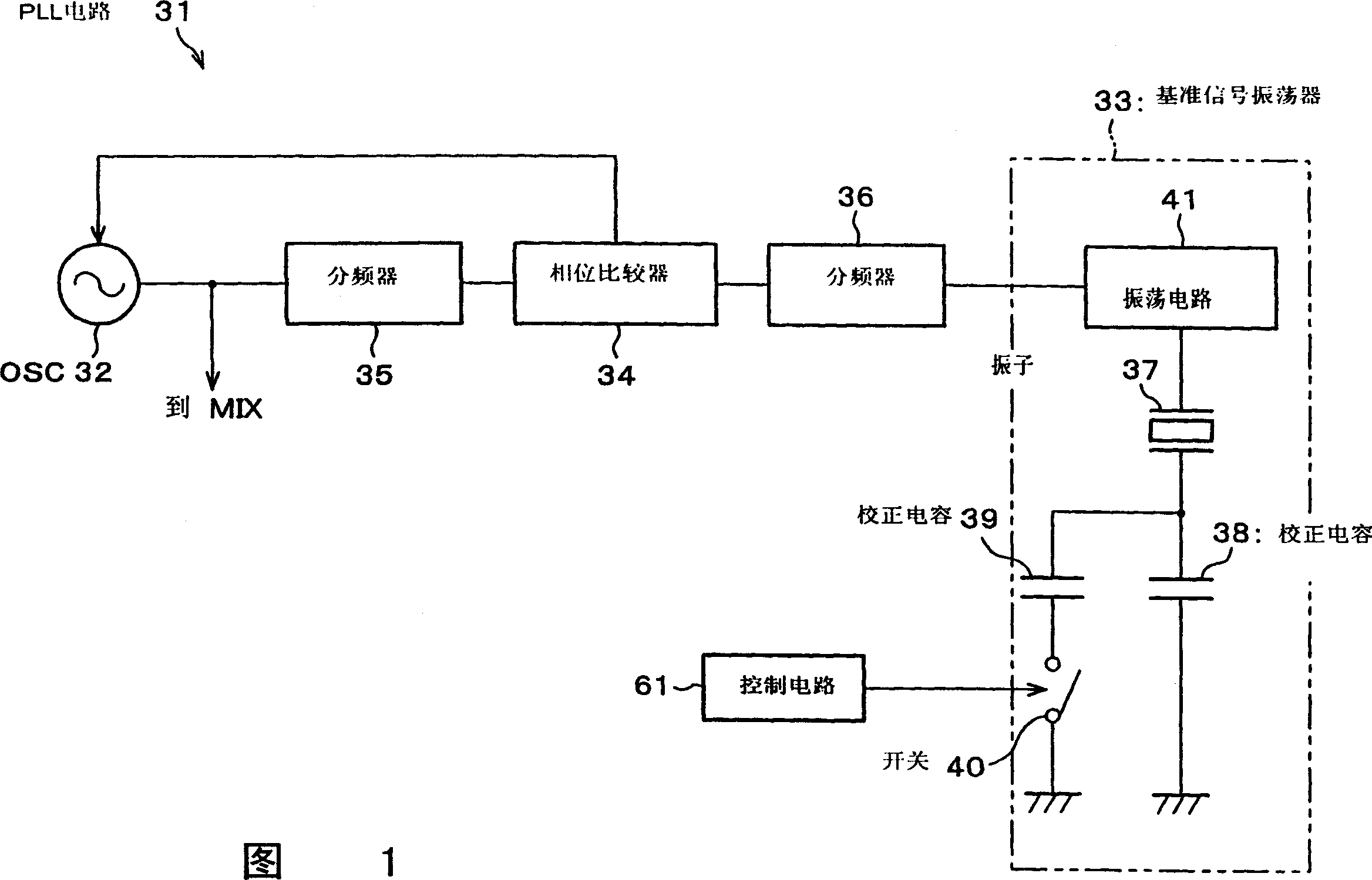

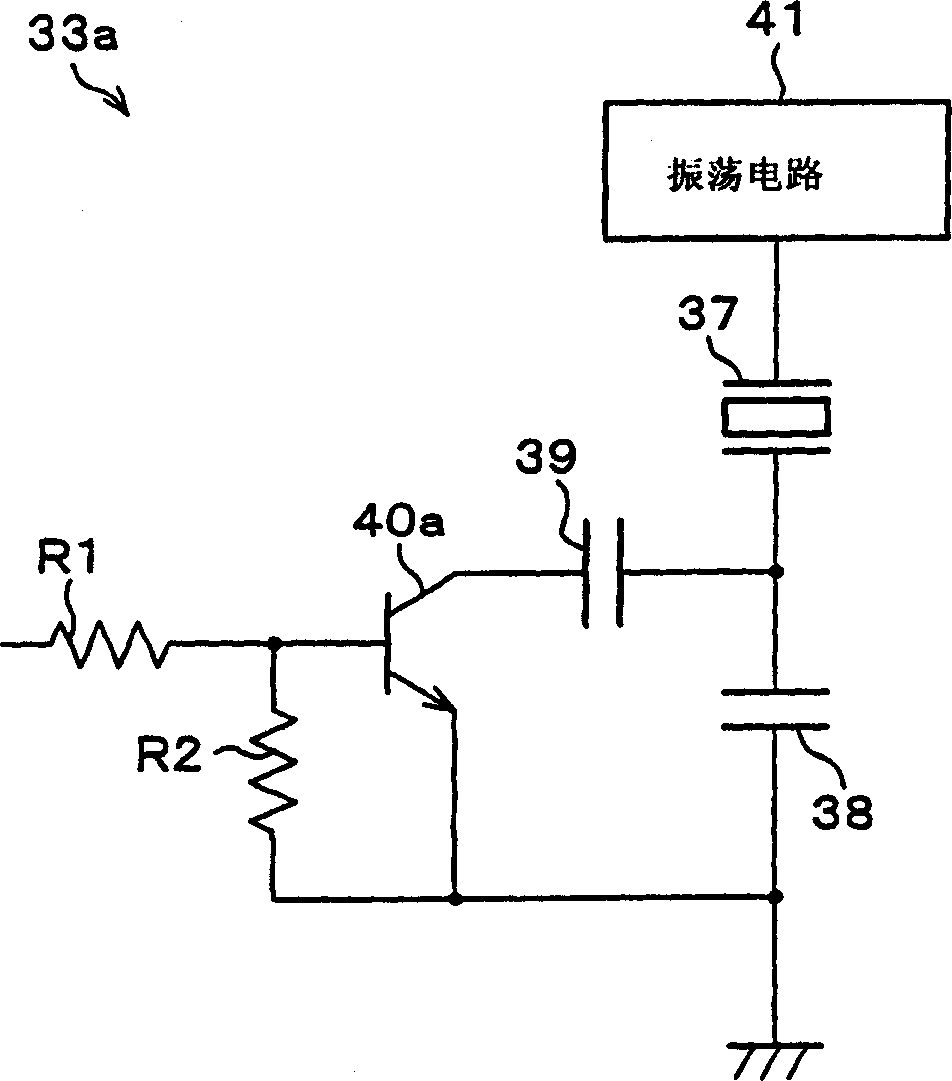

PLL circuit and TV receiver using it, and improvement in beat of TV receiver

InactiveCN1540874APrevent quality deteriorationTelevision system detailsPulse automatic controlCapacitanceTelevision receivers

A PLL circuit is used for a super-heterodyne television receiver. In the PLL circuit, a reference signal oscillator circuit generates a reference signal, and the reference signal is compared to a LO signal in a phase comparator. The phase comparator includes an oscillating circuit, a series circuit of a correcting capacitor and an oscillator corresponding to a predetermined IF signal frequency, another correcting capacitor, and a switch. The switch is turned ON or OFF only when receiving a particular channel in which interference occurs, so as to shift the frequency of the reference signal by several ten kHz. This reduces beats in a particular channel, and prevents deterioration of picture quality in other channels. That is, interference in a particular channel can be reduced without causing any adverse effects in other channels having a relatively high frequency.

Owner:SHARP KK

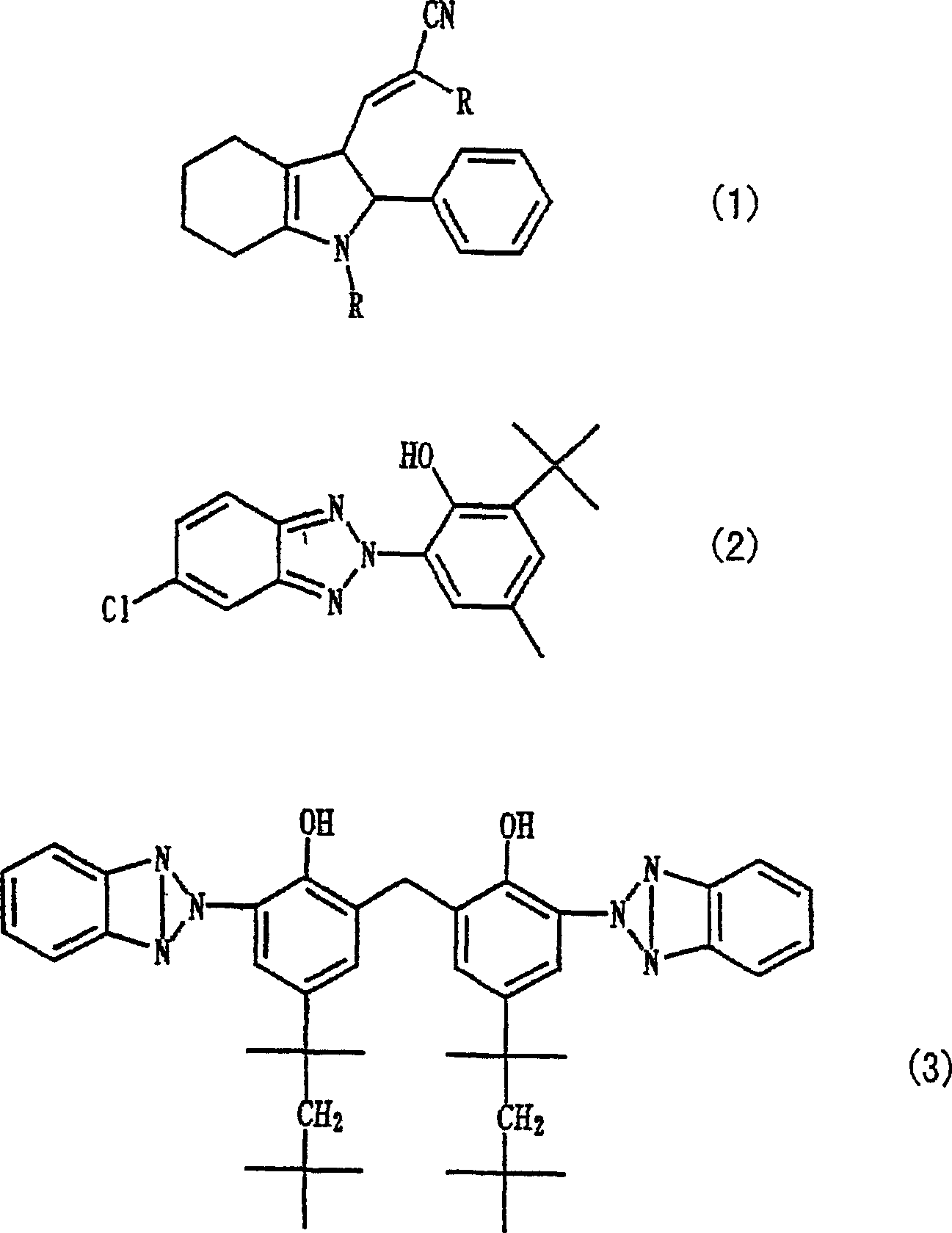

Heat-shrinkable polyester film and heat-shrinkable polyester film roll

A heat-shrinkable polyester-based film, characterized in that it exhibits a heat-shrinking percentages in (A) a warm water of 70 DEG C and (B) warm water of 85 DEG C of (A) 10 to 50 % in the maximum shrinkage direction and (B) 75 % or more in the maximum shrinkage direction and 10 % or less in the direction orthogonal to the maximum shrinkage direction, (C) the difference in heat-shrinking percentages DeltaX (%) representing X0 - X10 is 10 to 20 %, wherein X0 (%) represents the heat-shrinking percentage in the maximum shrinkage direction in a warm water of 95 DEG C and X10 (%) represents the heat-shrinking percentage of a film having been heat-shrunk by 10 % in the maximum shrinkage direction in a warm water of 95 DEG C, (D) the three-dimensional surface roughness SDeltaa of 0.008 to 0.04 and (E) the three-dimensional surface roughness SRz of 0.6 to 1.5 mum. The heat-shrinkable polyester-based film exhibits good accomplishment of shrinkage, the reinforcement function for the resulting shrink-coated container and good resistance to blocking and is also excellent in workability in film making and processability, even when it is used for full labeling. Further, the present invention provides a heat-shrinkable polyester-based film capable of absorbing ultraviolet rays and a heat-shrinkable polyester-based film roll which exhibits uniform heat-shrinking characteristics over the whole of a long film.

Owner:TOYOBO CO LTD

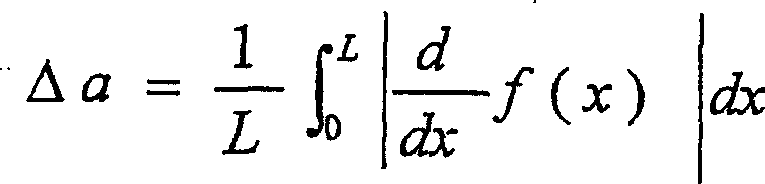

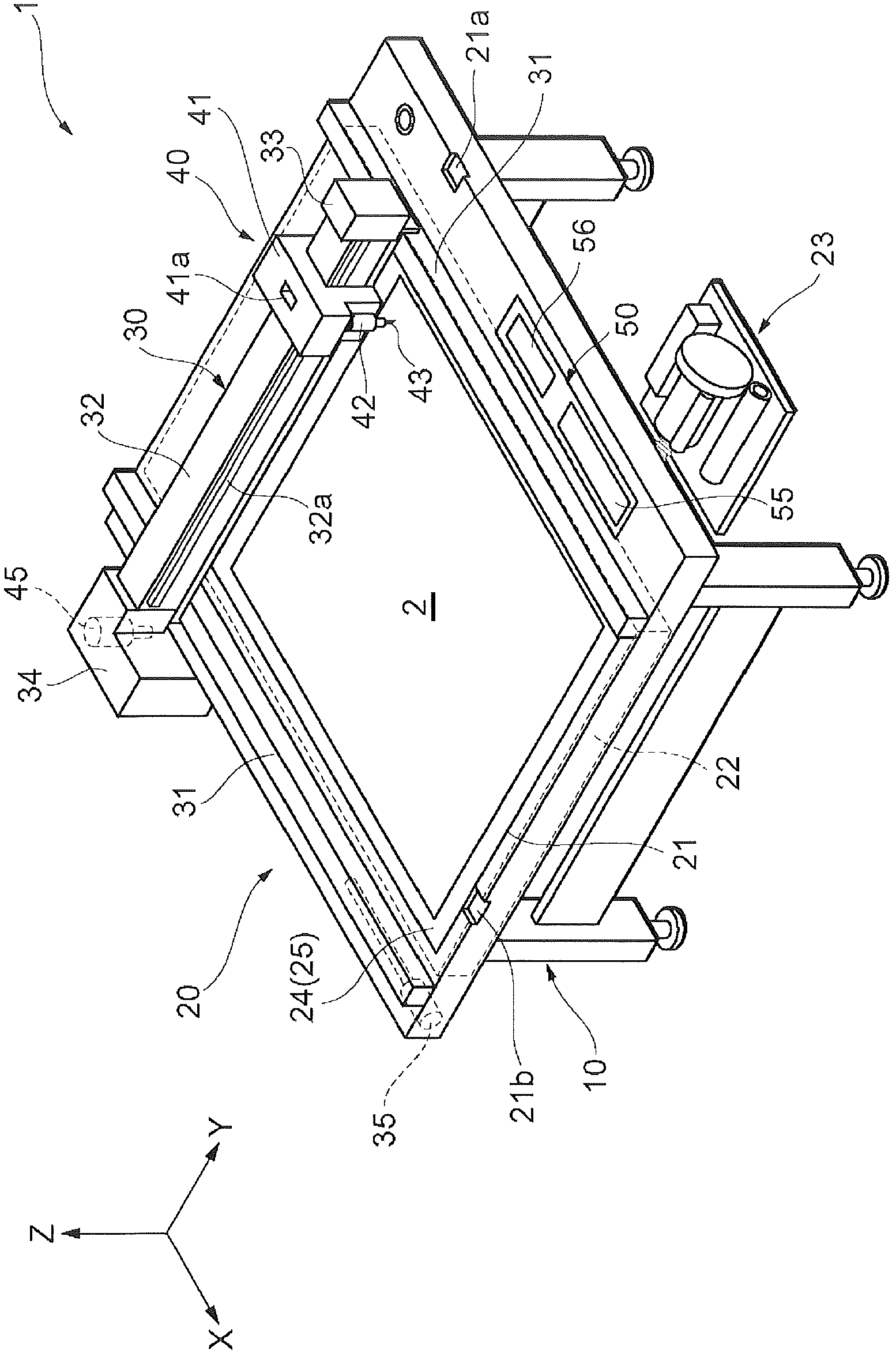

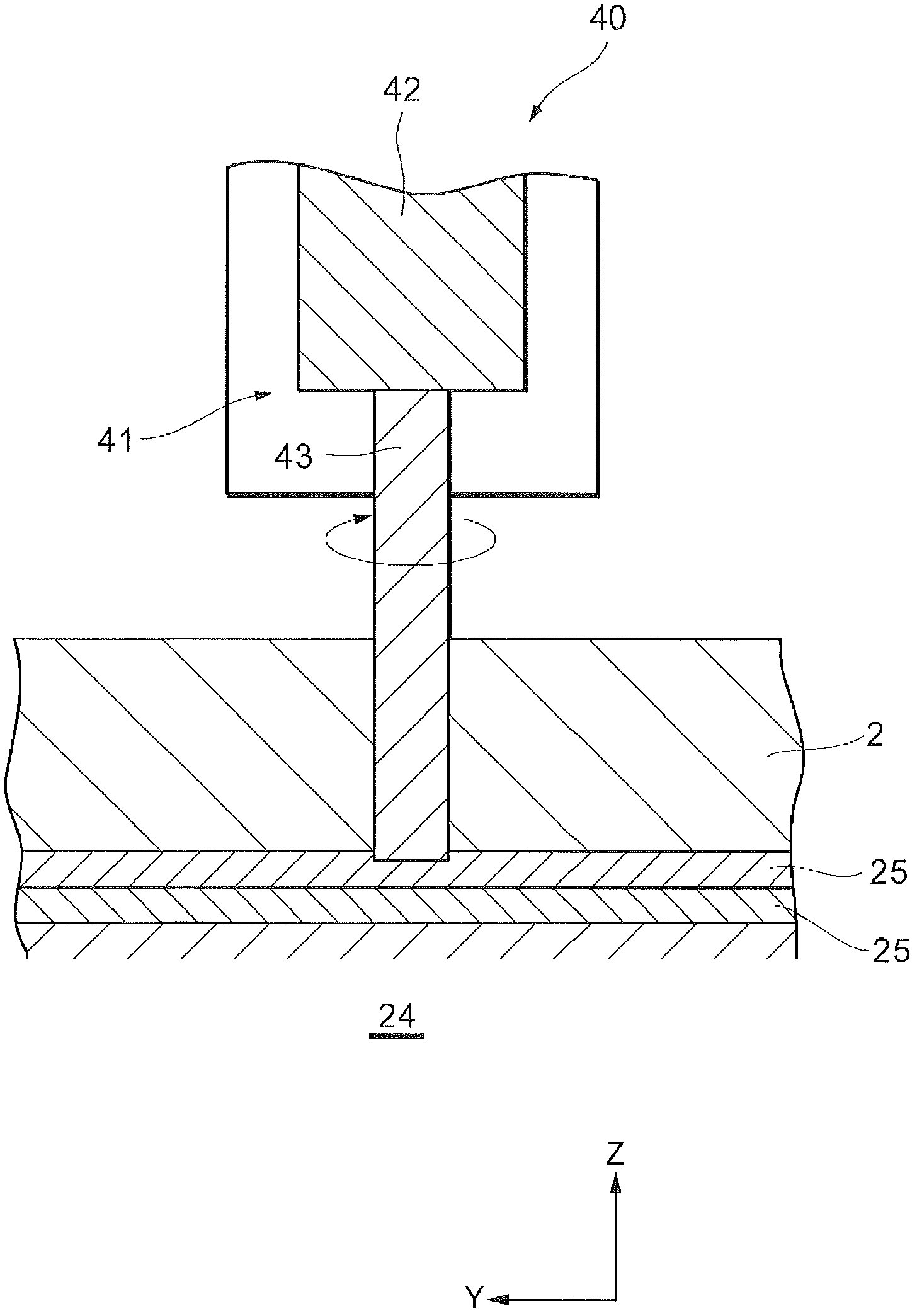

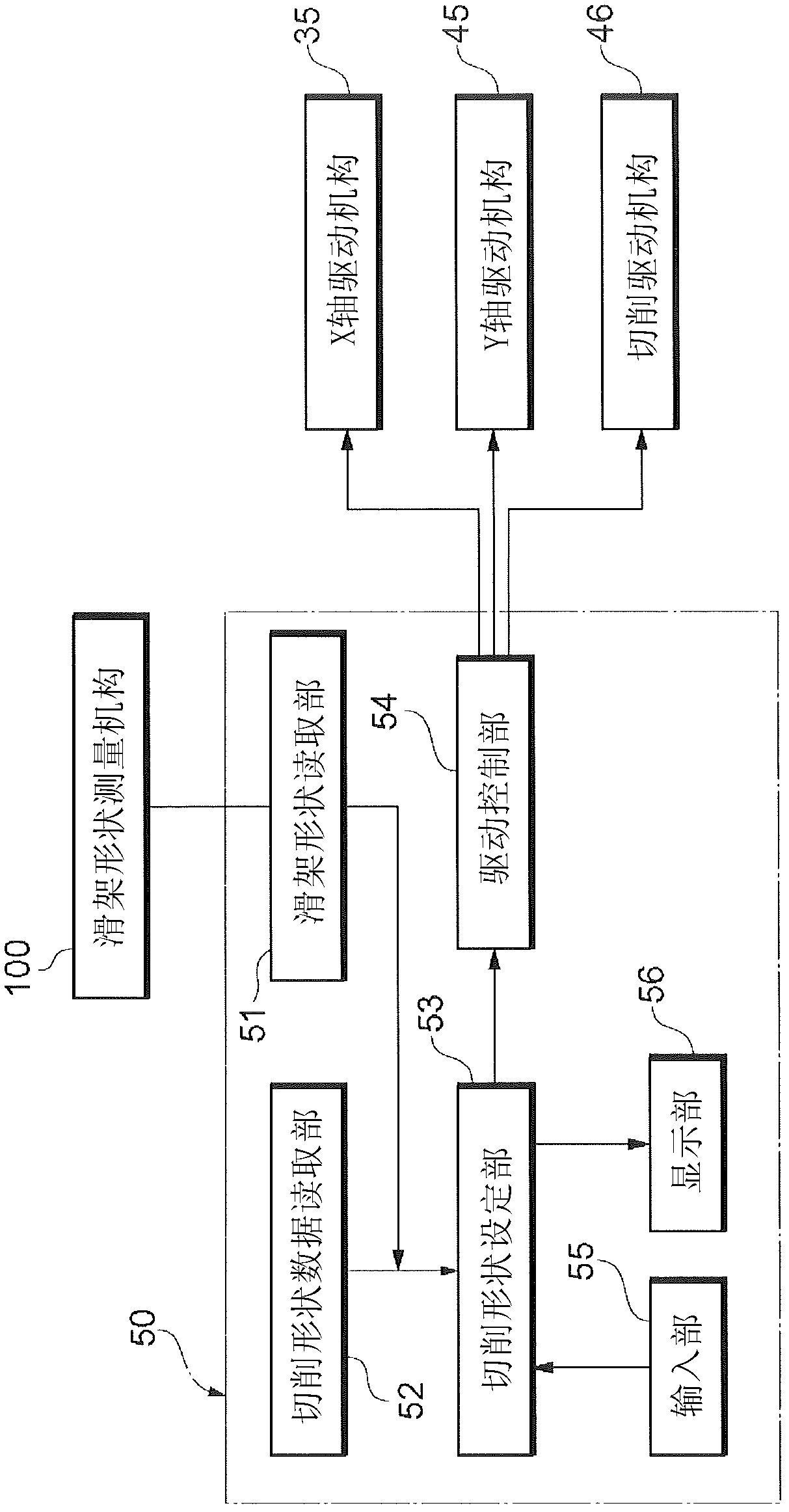

Cutting plotter

InactiveCN102497956APrevent quality deteriorationProgramme controlProgramme-controlled manipulatorMilling cutterEngineering

Disclosed is a cutting plotter that, even if warpage occurs in a guide rail or the like that movably supports a carriage, can prevent loss of cutting quality due to said warpage. The cutting plotter is provided with: a work table that supports a sheet-shaped medium that is being worked; an end mill that is provided above the medium supported by the work table and that cuts said medium; guide rails (31), a Y-bar (32), and a cutting drive mechanism that are provided above the work table and that support the end mill such that the end mill can move forward and backward, left and right, and up and down; and a control unit (50) that moves the end mill forward and backward, left and right, and up and down, and controls the end mill so as to cut the medium that is being worked. The cutting plotter is also provided with a carriage shape measurement mechanism (100) that detects warpage in the guide rails (31) and the Y-bar (32). The movements of the work tool are corrected on the basis of the detected warpage of the guide rails (31) and Y-bar (32).

Owner:MIMAKI ENG

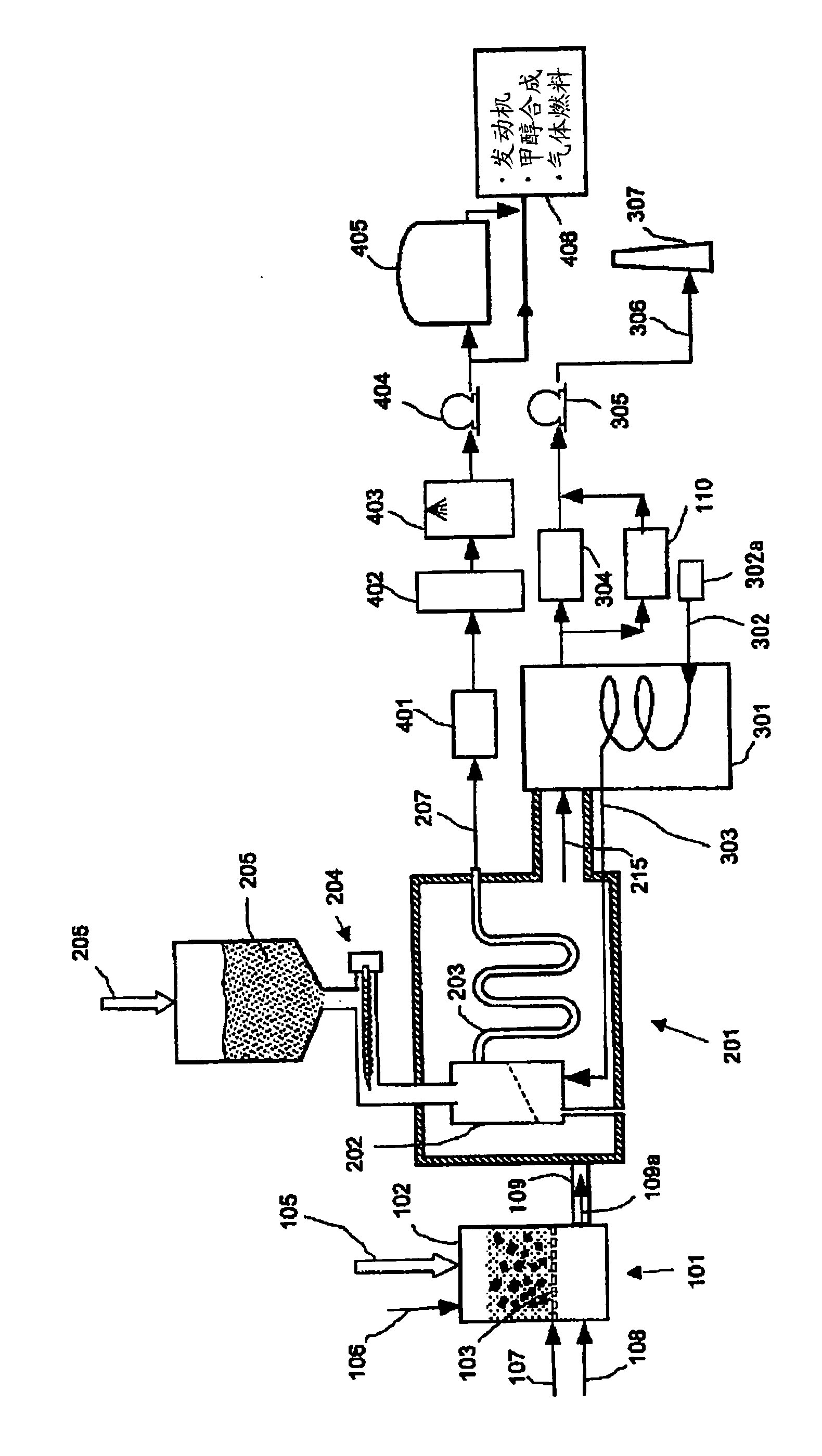

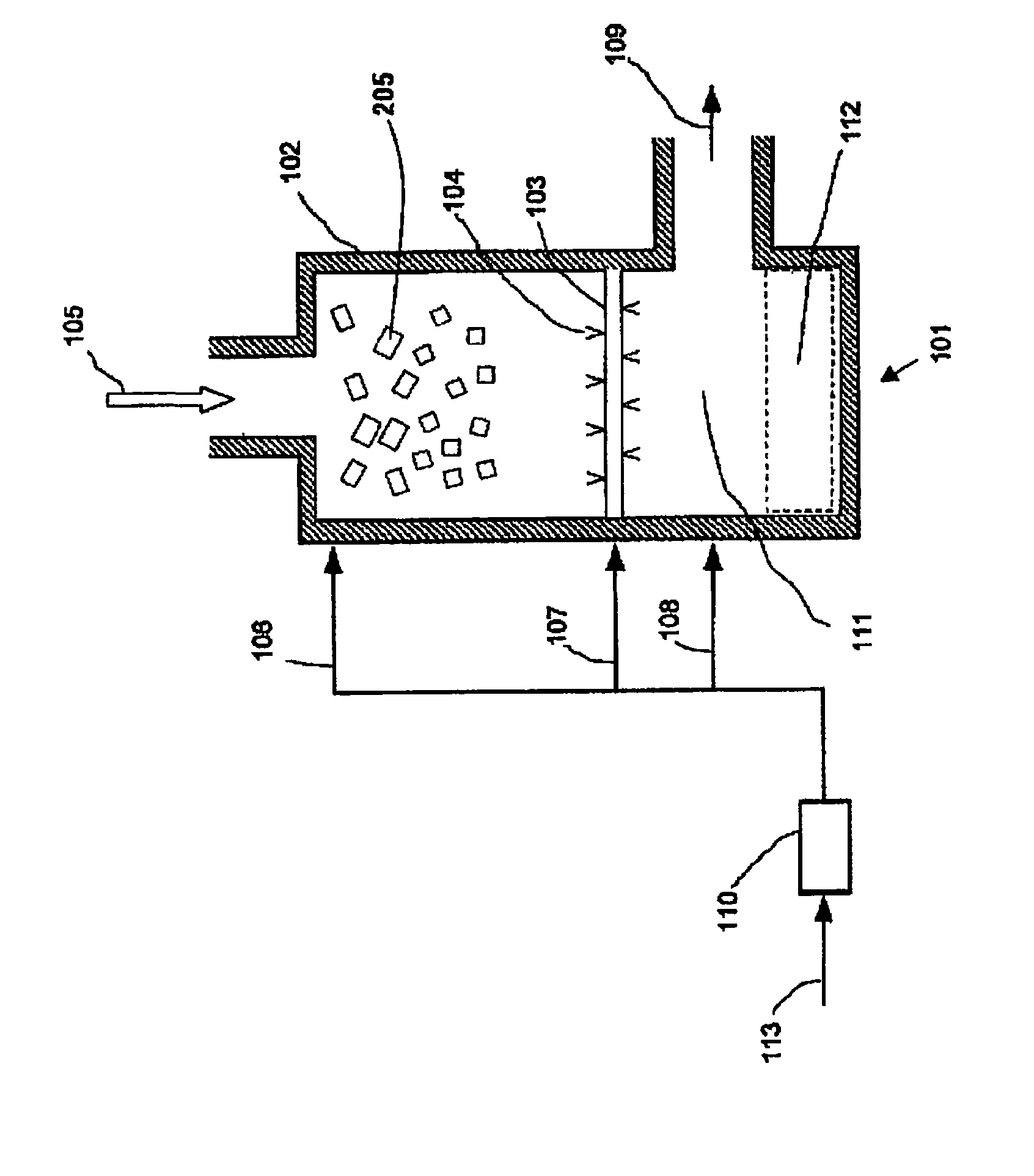

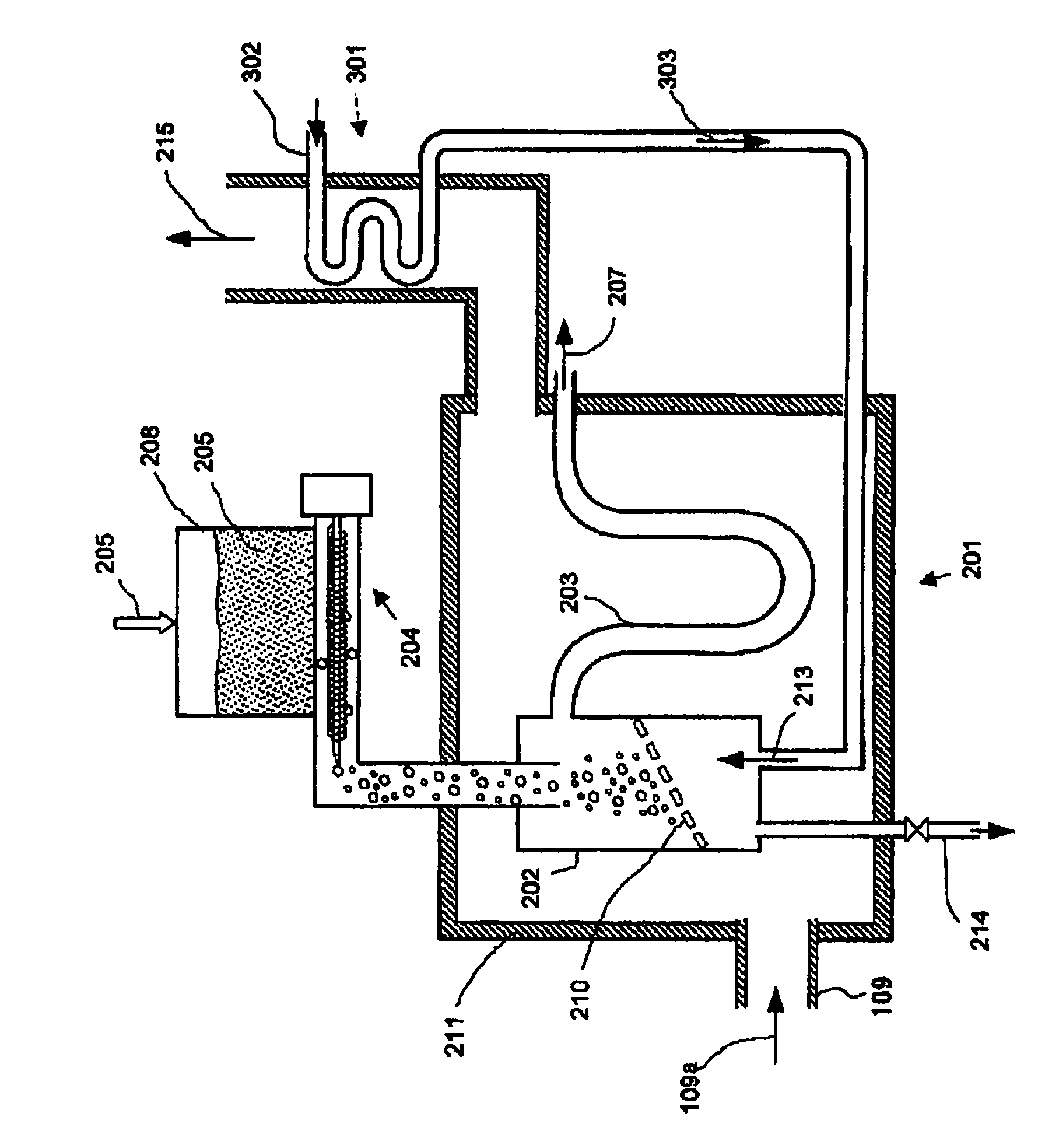

Biomass gasification apparatus

ActiveCN101541926APrevent moisture absorptionPrevent quality deteriorationProductsReagentsProduct gasProcess engineering

A biomass thermochemical gasification apparatus is provided that can manufacture high-quality fuel gas out of solid biomass in an industrial manner. This fuel gas can be used as fuel for a gas engine and a gas turbine for example and also can be used as synthesis gas for methanol synthesis. A high-temperature combustion gas generation apparatus (101) for biomass operates entirely by biomass and the heat source thereof does not depend on fossil fuel. A coarsely-ground powder biomass (205) subjected to gasification and gasification agent (303) are introduced to a primary gasification reaction room (202) and generate gasification reaction by, as reaction heat, radiation heat from a wall face of the primary gasification reaction room (202) heated by combustion gas (109a) generated in the high-temperature combustion gas generation apparatus (101) and are dissolved. Consequently, the biomass (205) is converted to clean and high-quality generated gas.

Owner:NAGASAKI INSTITUTE OF APPLIED SCIENCE

Oil pressing method for edible oil using pine nut as raw material

The method for effectively producing pine seed oil by using pine seed includes the following steps: firstly, breaking pine seed, mixing the kernel and broken hull according to the volume ratio of 60 plus or minus 20% and 40 plus or minus 20%; then placing them into an oil press with 70 deg.C-100 deg.C to press oil. Besides, a plate heating device with temp. control function is mounted between the shaft of oil press and outer side of transferring portion.

Owner:吉原 将纯 +1

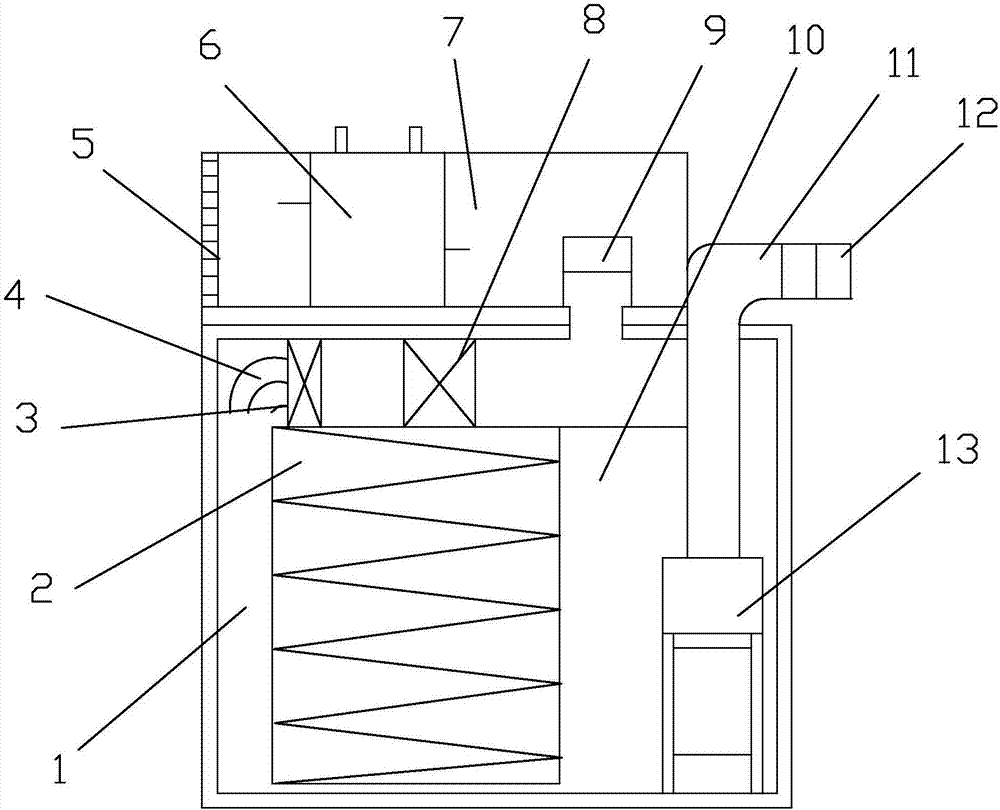

Medicinal material hot air drying device

InactiveCN106907902AReduce humidityReduce dust contentDrying gas arrangementsDrying solid materialsHot blastWaste management

The invention discloses a medicinal material hot air drying device. An air inlet chamber, a drying chamber and an exhaust chamber are arranged in the medicinal material hot air drying device. The air inlet chamber is arranged on the upper portion, and the drying chamber and an exhaust chamber are arranged on the lower portion. The air inlet chamber communicates with the drying chamber. The drying chamber communicates with the exhaust chamber. An air inlet chamber inlet is provided with a dedusting net. A dehumidifier is arranged in the air inlet chamber. A water drainage outlet of the dehumidifier communicates with the outside. The communicating position of the drying chamber and the air inlet chamber is provided with a primary filter. A medicinal material frame is arranged in the drying chamber. A flow deflector is arranged between the medicinal material frame and the primary filter. A heat engine is arranged between the flow deflector and the primary filter. An efficient filter is arranged between the heat engine and the flow deflector. The communicating position of the exhaust chamber and the drying chamber is provided with a fan. The fan communicates with the outside through an exhaust filter pipe. An outlet of the exhaust filter pipe is provided with an exhaust filter. Through the medicinal material hot air drying device, humidity and the dust content of a dry environment can be lowered, drying efficiency is improved, and degradation of the quality of the traditional Chinese medicinal materials is avoided.

Owner:GUILIN MEDICAL UNIVERSITY

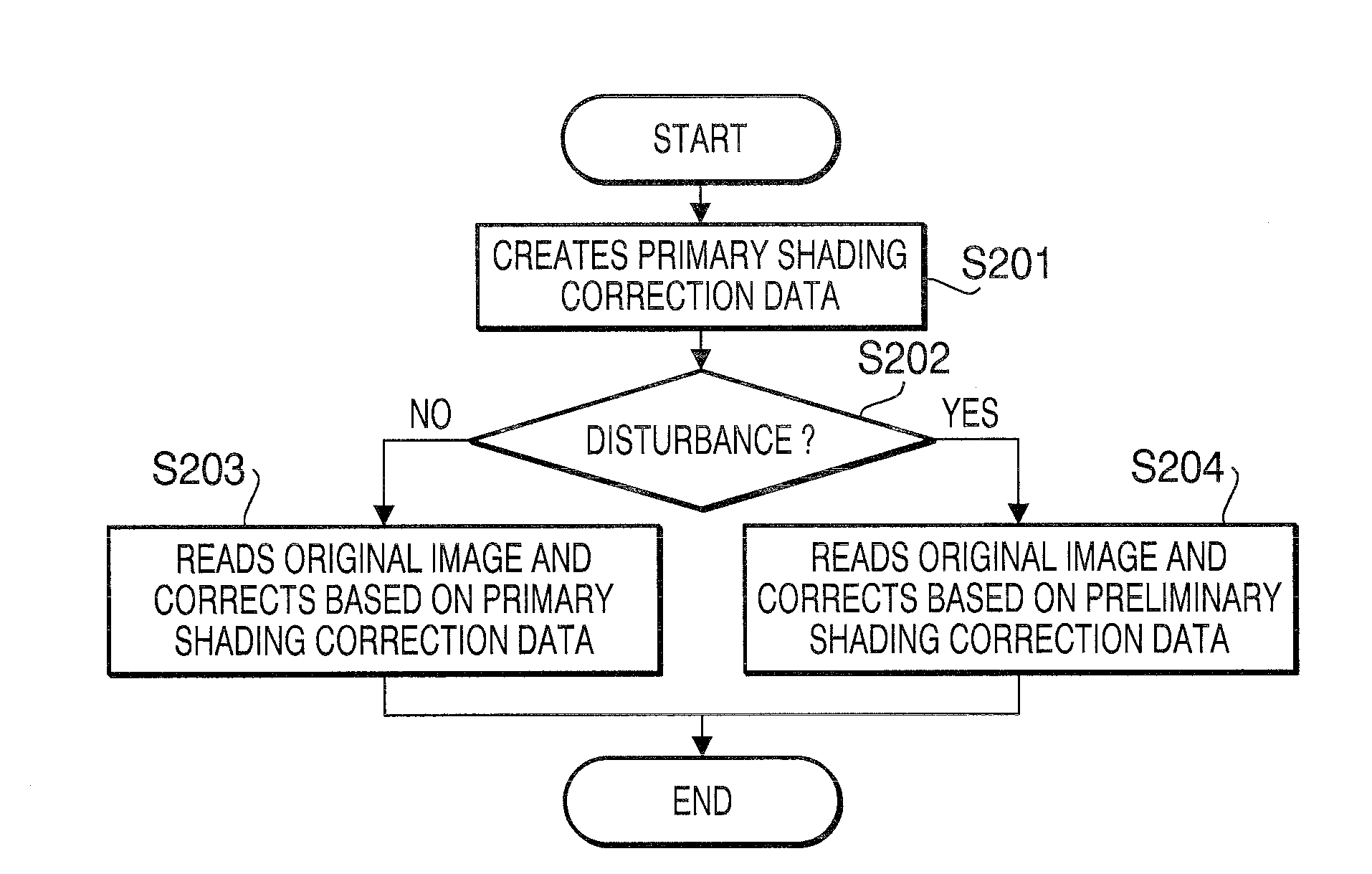

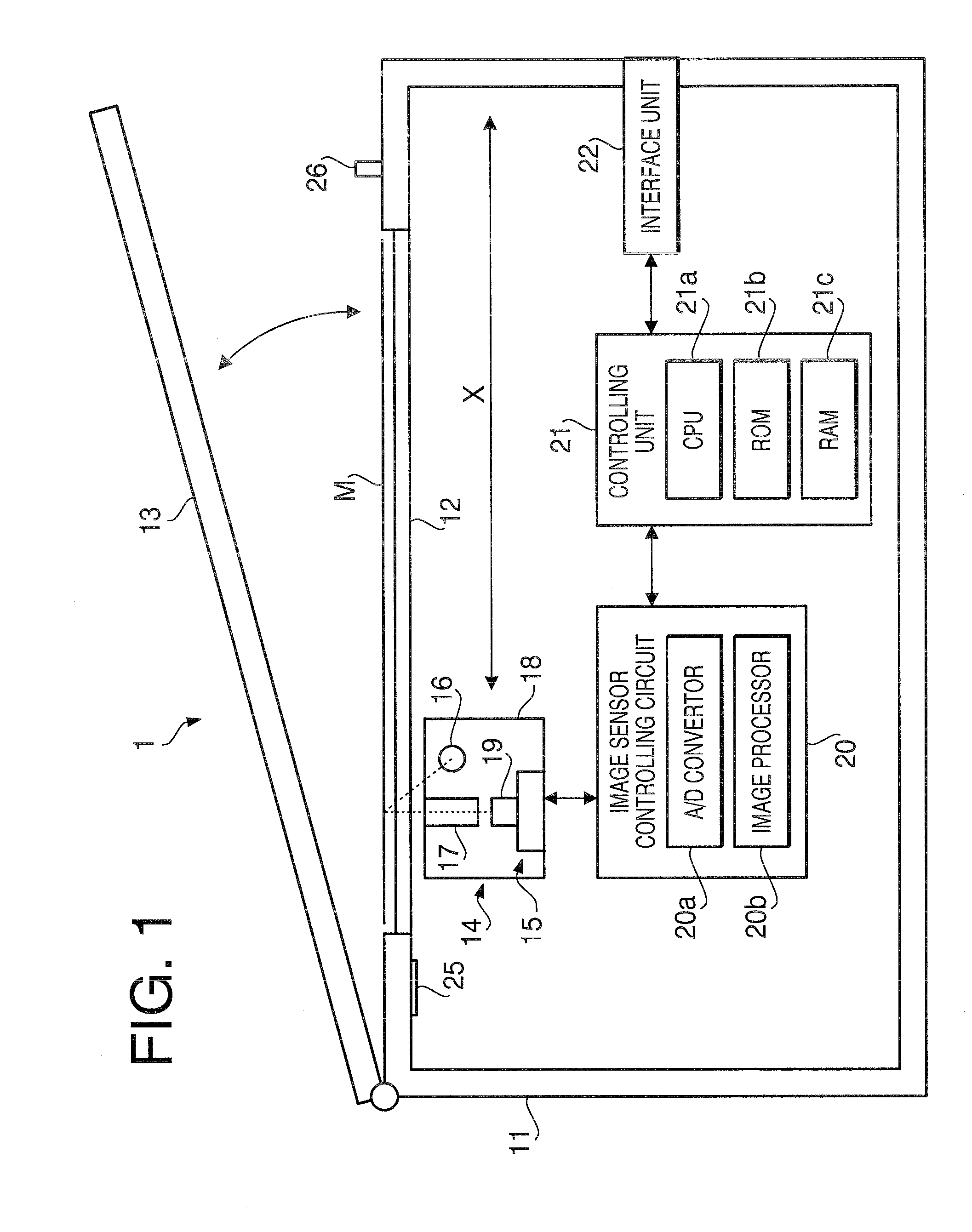

Image reading apparatus and method to correct images

ActiveUS20100053702A1Reduce reproducibilityQuality improvementCharacter and pattern recognitionPictoral communicationData memoryImage sensor

An image reading apparatus to read an image and generate pixel data representing the image is provided. The image reading apparatus includes an image sensor having a plurality of sensor units, each of which includes a plurality of light receiving elements, a data storage store shading correction data, which is used to correct unevenness caused in the pixel data, including first shading correction data, and a data corrector to correct the pixel data output from the light receiving elements based on the shading correction data. The data corrector corrects the pixel data based on the first shading correction data when a number of light receiving elements used to read the image in each sensor unit is greater than a number of pieces of correcting information in the first shading correction data.

Owner:BROTHER KOGYO KK

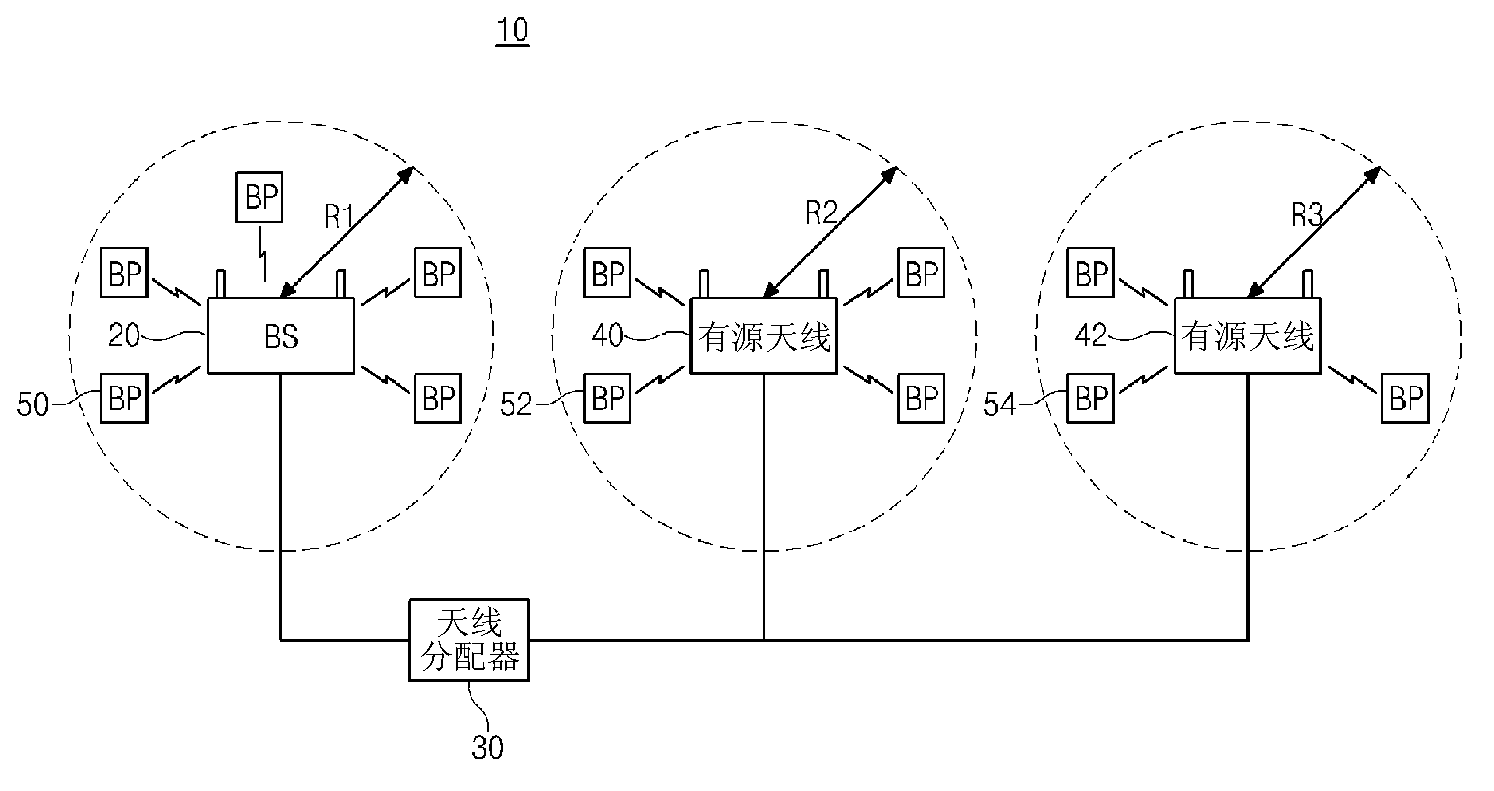

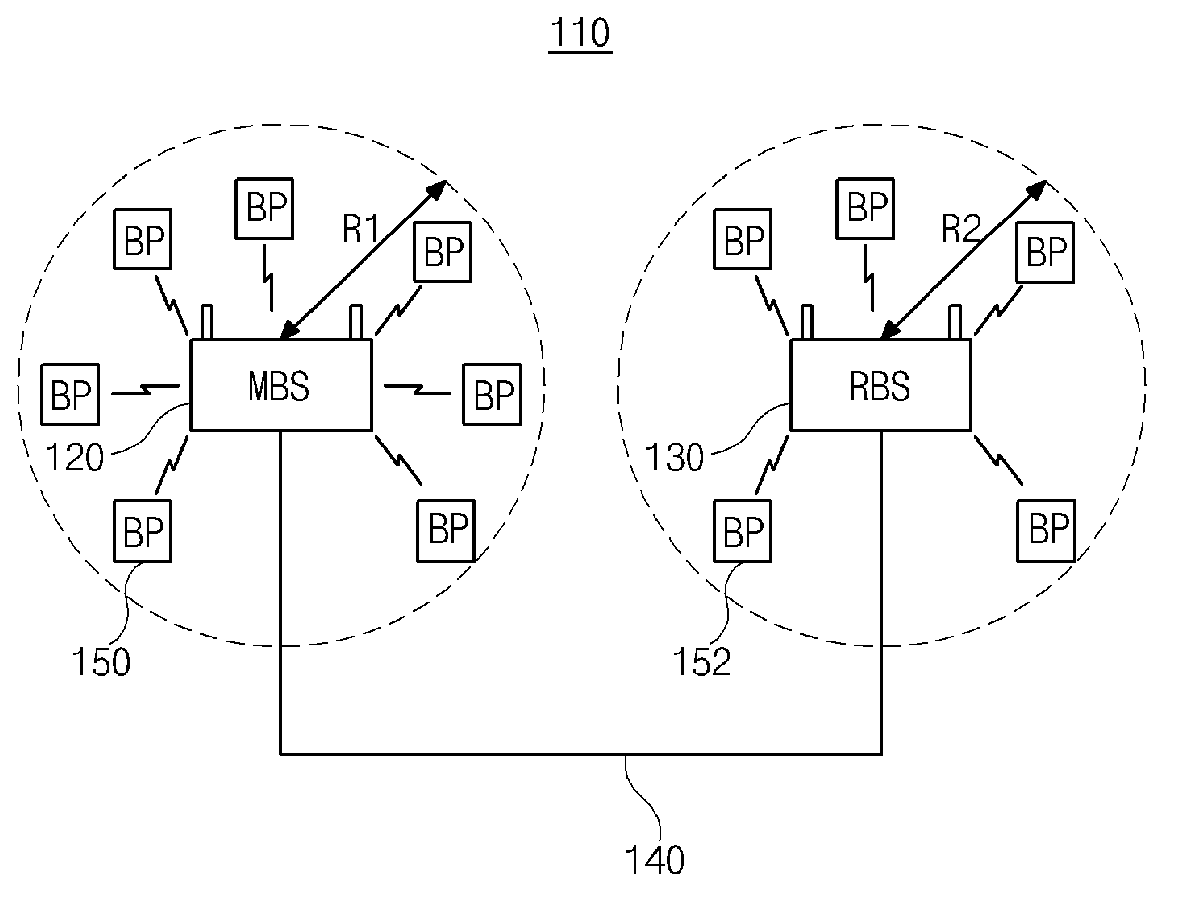

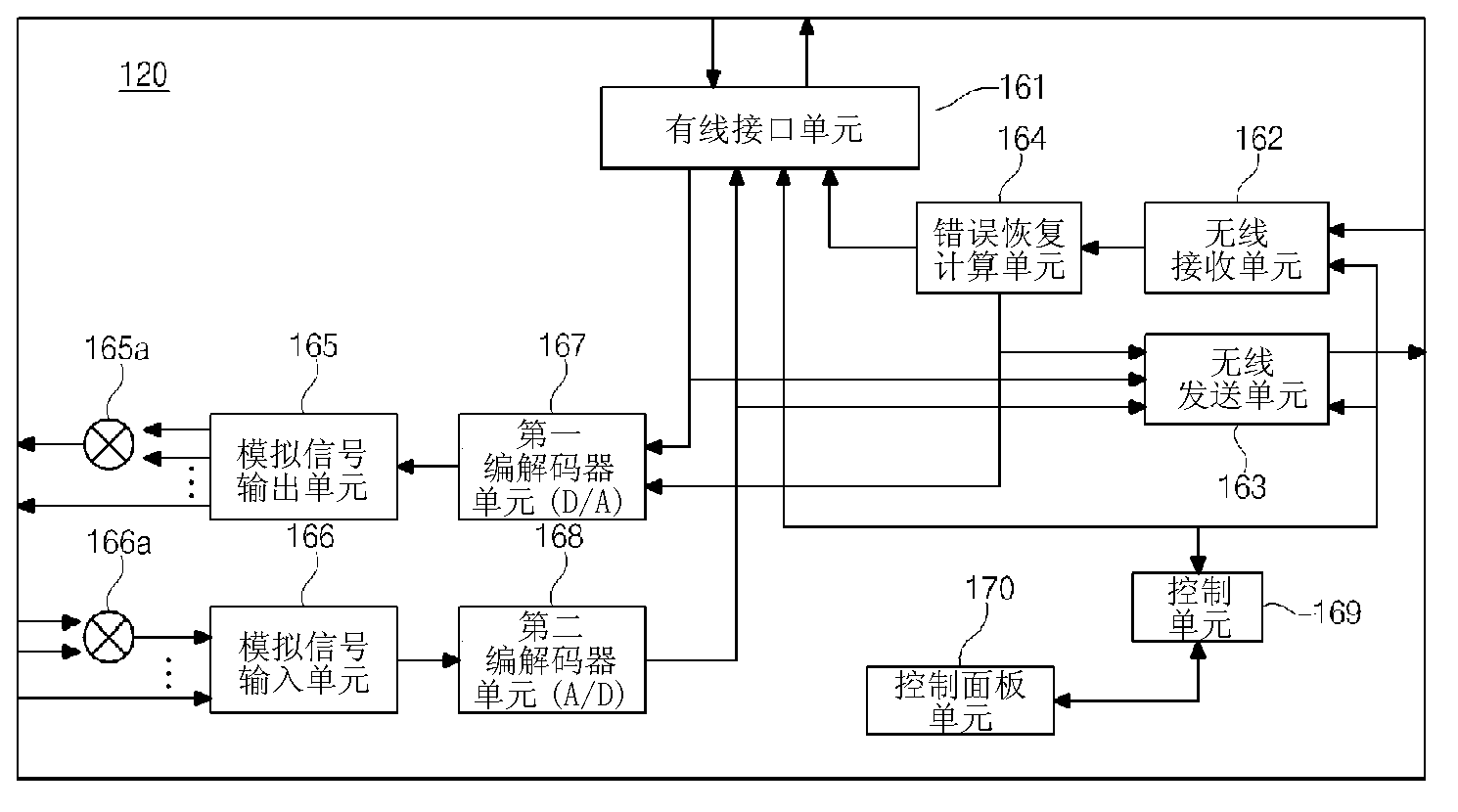

Digital wireless intercom system and driving method thereof

ActiveCN103181101AImprove communication distanceEliminate wireless shielding areasSynchronisation arrangementSubstation equipmentDigital dataCommunications system

The present invention provides a digital wireless intercom system comprising: at least one master base station; at least one remote base station which is connected to the at least one master base station by wire using at least one of LAN, LAN infrastructure network or the Internet, and transceives a synchronization signal and a digital data signal; a plurality of first mobile stations which are positioned within a transmission range of the at least one master base station and wirelessly transceives the synchronization signal and data signal; ; and a plurality of second mobile stations which are positioned within a transmission range of the at least one remote base station and wirelessly transceives the synchronization signal and data signal, wherein the at least one master base station and at least one remote base station are operated at different independent frequencies in consideration of frequency interference, and the synchronization signal and data signal transceived by the at least one master base station and at least one remote base station have different starting points of different cycles.

Owner:LAON TECH CO LTD

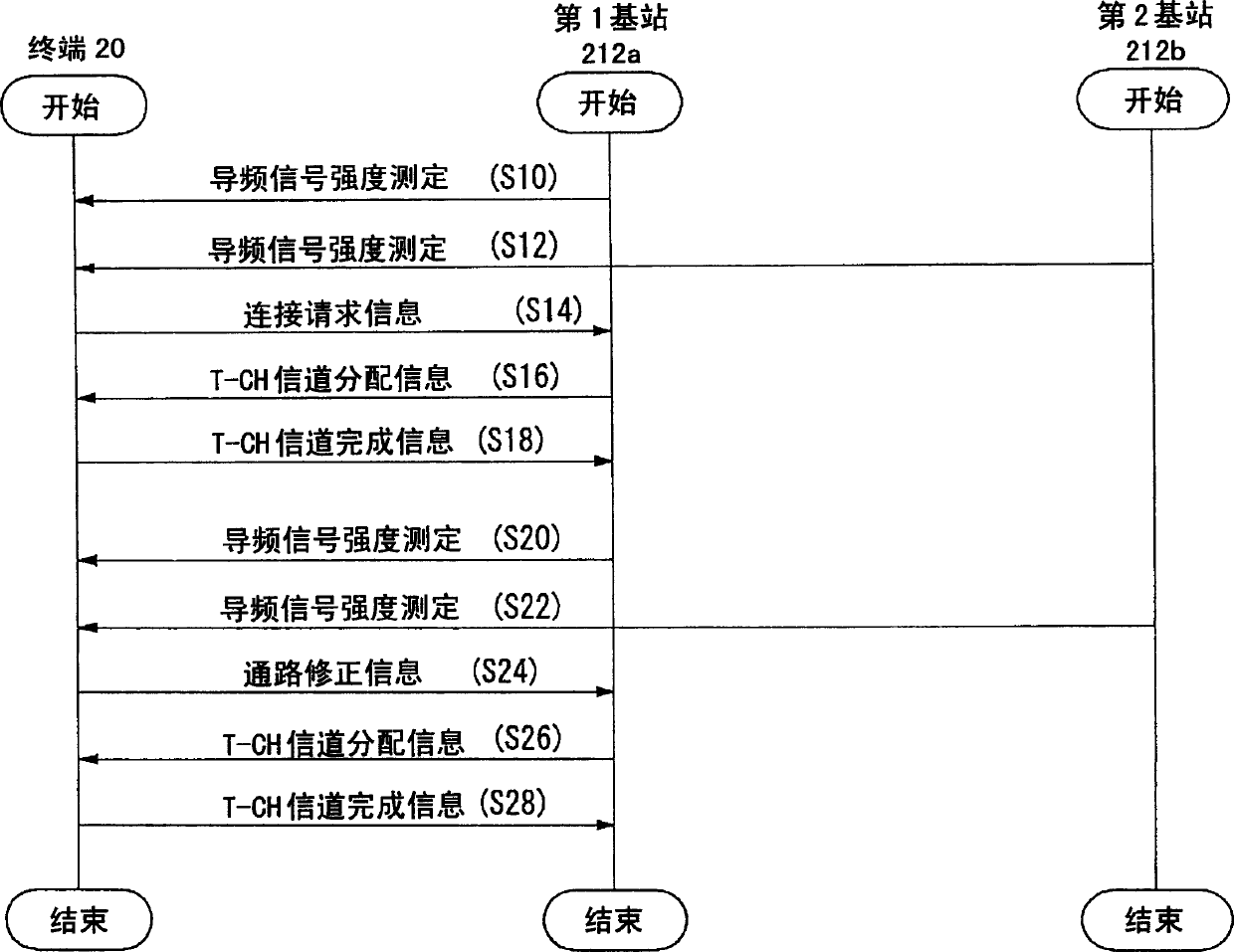

Communication terminal and base station selection method

InactiveCN1602098APrevent quality deteriorationAssess restrictionRadio/inductive link selection arrangementsCommunication unitSelection method

A communication unit adapted to the EV-DO standard communicates with a base station. An acquisition unit acquires the number of communication terminals in communication with the base station. A derivation unit measures the CIR from the received pilot signal to derive a DRC value corresponding to the measurement result. A storage unit stores the number of communication terminals obtained from the acquisition unit and the CRC value derived from the derivation unit. A calculation unit calculates an estimated communication rate based on the maximum transmission rate with the base station corresponding to the DRC value, the maximum DRC value, the derived DRC value from the derivation unit, and the number of communication terminals. A comparison unit selects a base station having a high estimated communication rate as a base station to communicate.

Owner:KYOCERA CORP

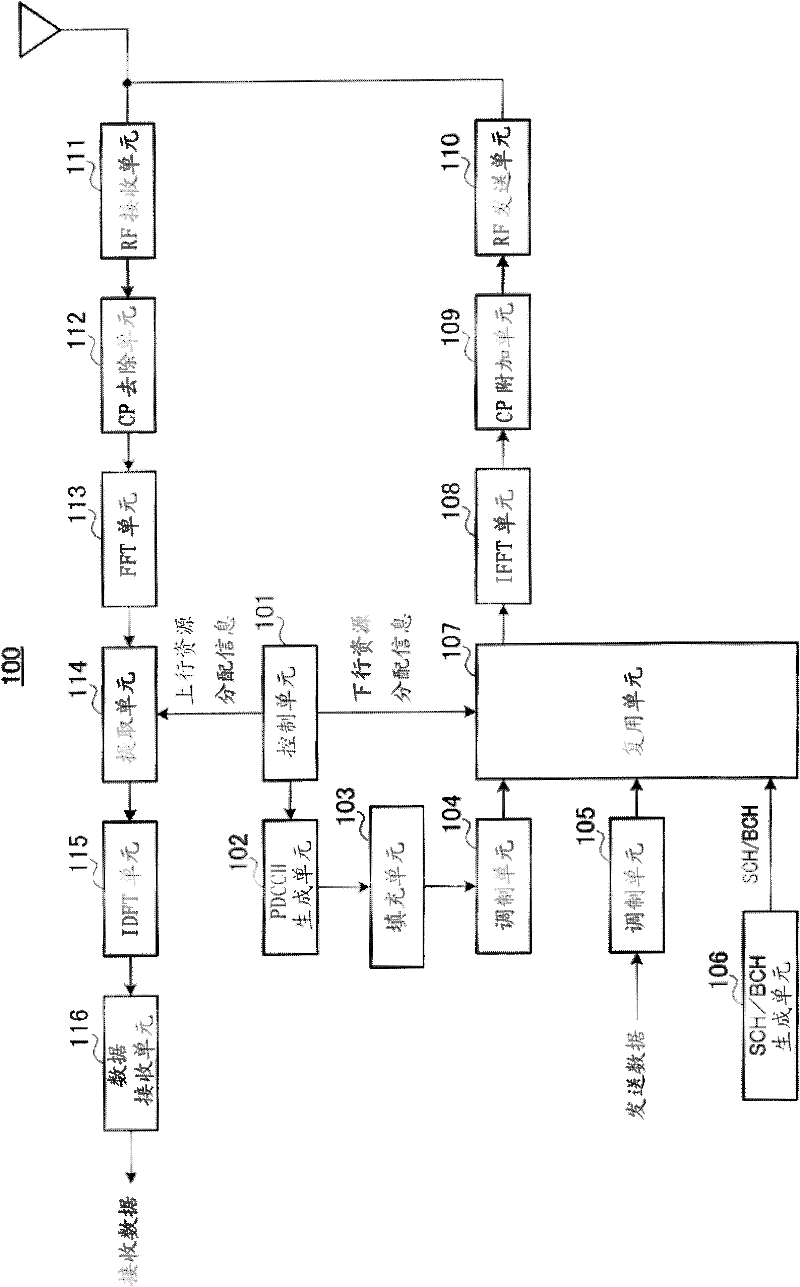

Radio terminal device, radio base station device, and channel signal forming method

ActiveCN102204323APrevent quality deteriorationNetwork traffic/resource managementTransmission path divisionTerminal equipmentComputer terminal

Provided are a radio terminal device, a radio base station device, and a channel signal forming method which can prevent quality degradation of the downlink source allocation information by reducing the frequency of the zero information addition process to the downlink resource allocation information when executing communication using an uplink unit band and a plurality of downlink unit bands correlated to the uplink unit band. A base station (100) can execute communication using the uplink unit band and a plurality of downlink unit bands correlated to the uplink unit band. The base station (100) includes: a PDCCH generation unit (102) which includes the uplink allocation information relating to the uplink unit band only in some of the channel signals formed for each of the downlink unit bands; and a padding unit (103) which adds zero information to the downlink allocation information only in the selected some channel signals having the bandwidth of the corresponding downlink unit band smaller than that of the uplink unit band until the downlink allocation information size becomes equal to the uplink allocation information size.

Owner:SUN PATENT TRUST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com