Oil and fat composition for chocolate

A technology for oil and fat composition and chocolate, applied in the directions of edible oil/fat, food science, fatty acid esterification, etc., can solve the problems such as the health problems of trans-unsaturated fatty acids that are not particularly recognized, and achieve the effect of preventing quality deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

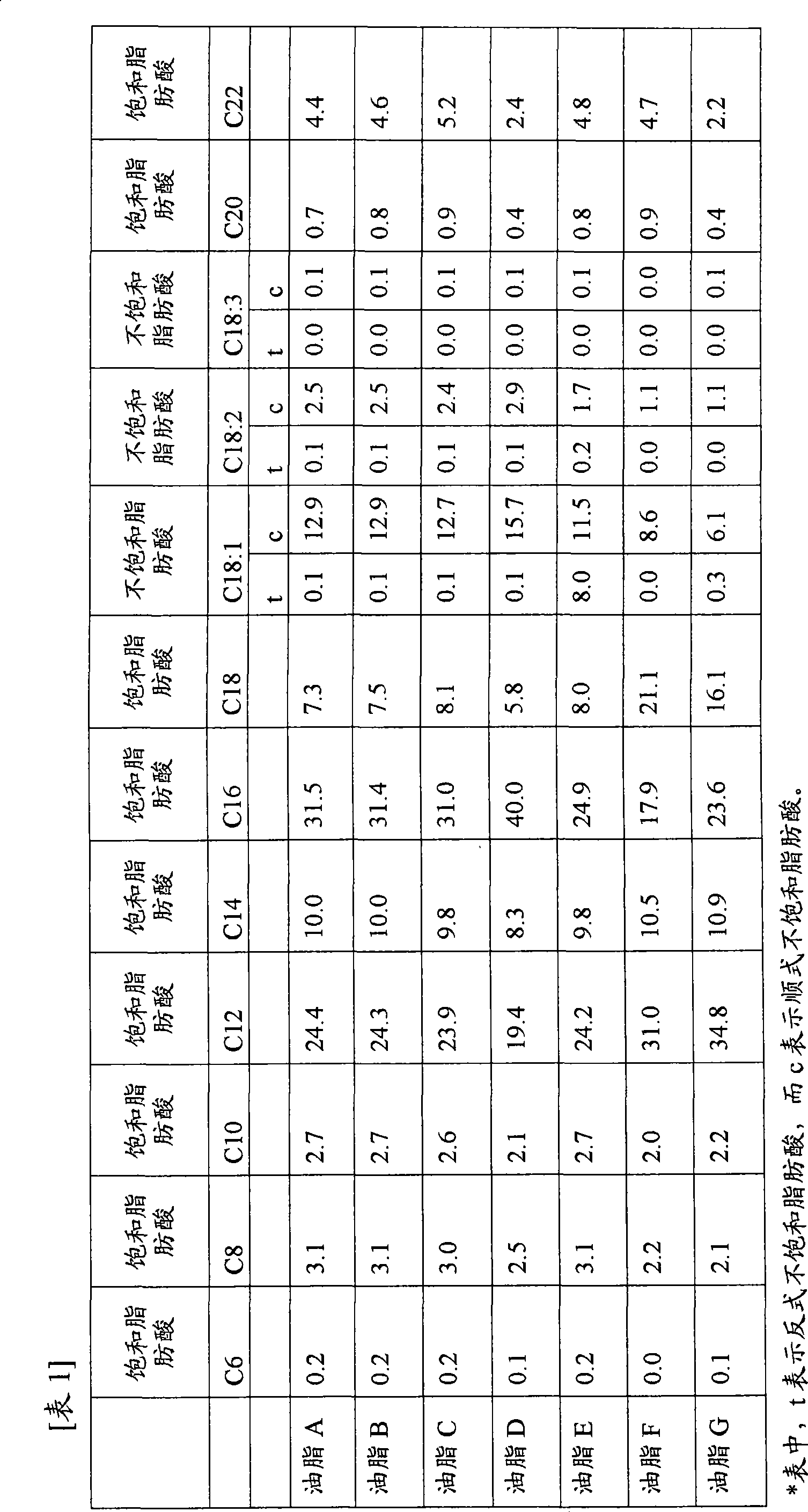

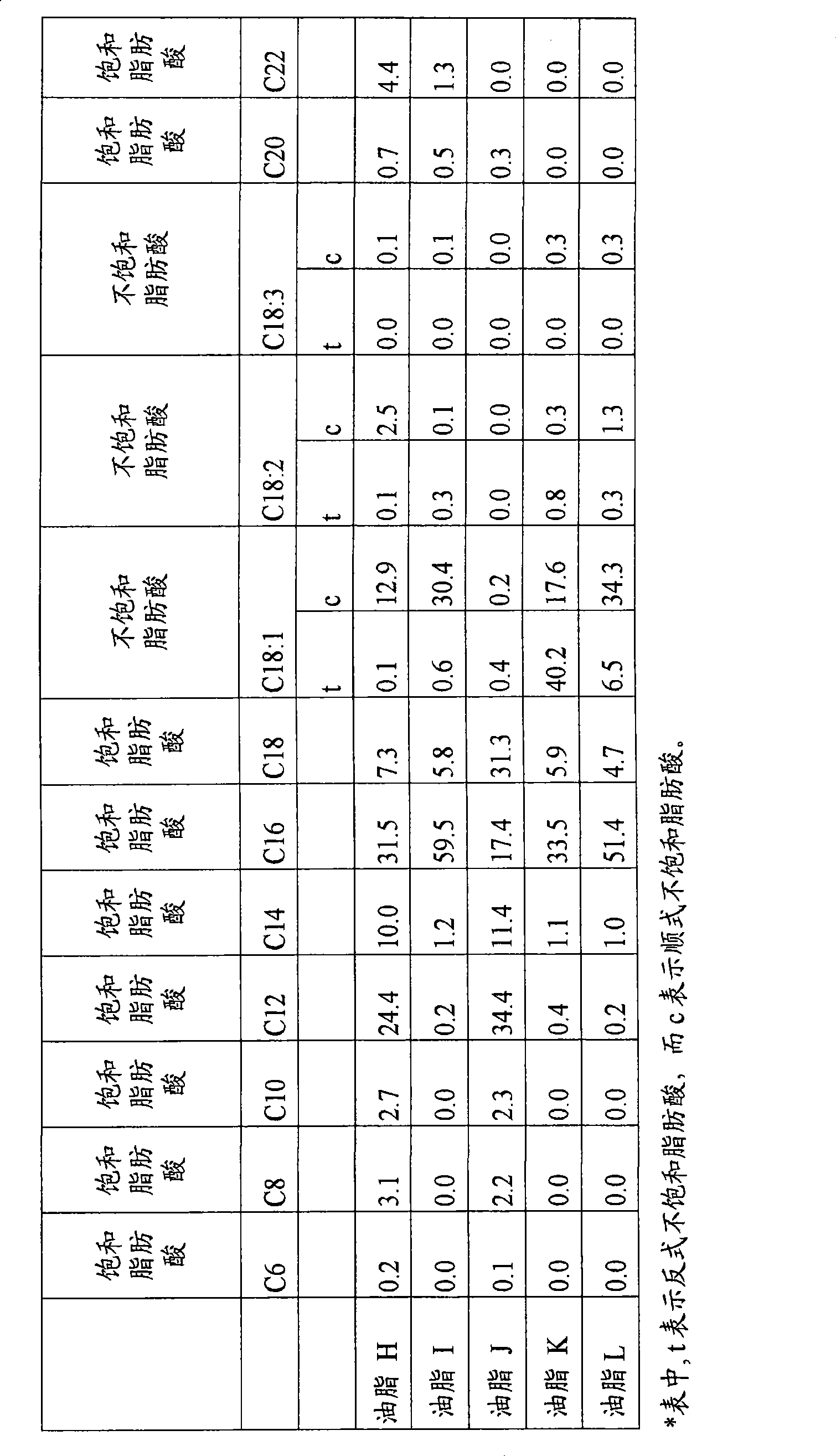

Image

Examples

Embodiment 1

[0066] 8 parts of cocoa mass, 15 parts of cocoa powder, 43 parts of sucrose, and 20 parts of oil A obtained in Test Example 1 were mixed with a mixer to prepare a dough (mix). The dough was passed through a refiner to adjust the particle size to about 20 μm (refining). The resulting flakes are stirred and kneaded. In the final stage of mixing and kneading, add 14 parts of remaining fat A and 0.4 parts of lecithin to make chocolate. The final blending amount of the chocolate is shown in Table 4.

[0067] [Table 4]

[0068] Cocoa butter content 15% (in fat) blending amount

[0069] Cocoa nuggets 8 cocoa powder 15 sucrose 43 grease 34 Lecithin 0.4

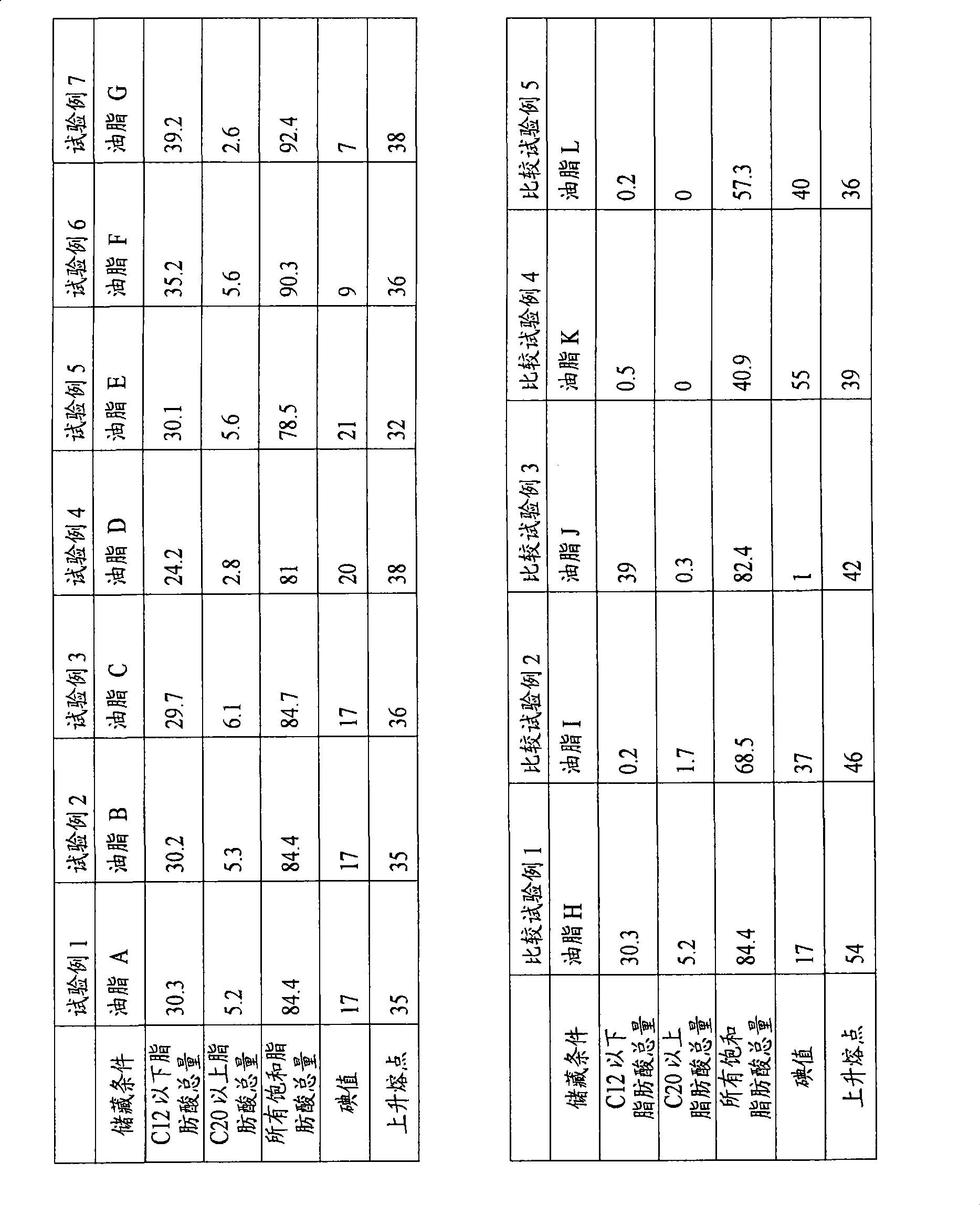

Embodiment 2-7 and comparative Embodiment 1-5

[0071]The chocolate of Example 2 was obtained by using the same composition and the same method as Example 1, except that the fat B was replaced with fat A.

[0072] Similarly, fat C was replaced with fat A to obtain the chocolate of Example 3. Similarly, chocolates of Example 4 to Example 7 and Comparative Example 1 to Comparative Example 5 were obtained.

[0073] Confirmation test of chocolate storage stability

[0074] The chocolate prepared as above is poured into a mold at a temperature (50°C) at which the fat is dissolved, and then cooled to 15-20°C to solidify. The storage stability of the cured chocolate was measured by the following method and evaluation.

[0075] The items of the confirmation test are the melting taste, the degree of blooming or crystallization, and the gloss.

[0076] Confirmation test of melted chocolate taste

[0077] A panel member (6 people) evaluated the melting texture of chocolate prepared using various fats and oils. As an evaluation, the panel ...

Embodiment 8

[0117] 8 parts of cocoa mass, 15 parts of cocoa powder, 2 parts of cocoa butter, 43 parts of sucrose and 18 parts of fat M obtained in Test Example 8 were mixed with a mixer to prepare a dough (mixing) The dough was passed through a refiner, Adjust the particle size to about 20 μm (refining). The resulting flakes are stirred and kneaded. In the final stage of mixing and kneading, add 14 parts of remaining oil M and 0.4 parts of lecithin to make chocolate. The final blending amount of the chocolate is shown in Table 9.

[0118] [Table 9]

[0119] Cocoa butter content 20% (in fat) blending amount

[0120] Cocoa nuggets 8 cocoa powder 15 sucrose 43 Coco fat 2 grease 32 Lecithin 0.4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com