Hot-rolling composite roll produced by cetrifugal casting

A technology of centrifugal casting and composite rolls, applied in the direction of rolls, metal rolling, heat treatment furnaces, etc., can solve problems such as shrinkage cavities, and achieve the effects of preventing quality deterioration, excellent wear resistance, and excellent seizure resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

[0146] Examples 1-7, Comparative Examples 1-5

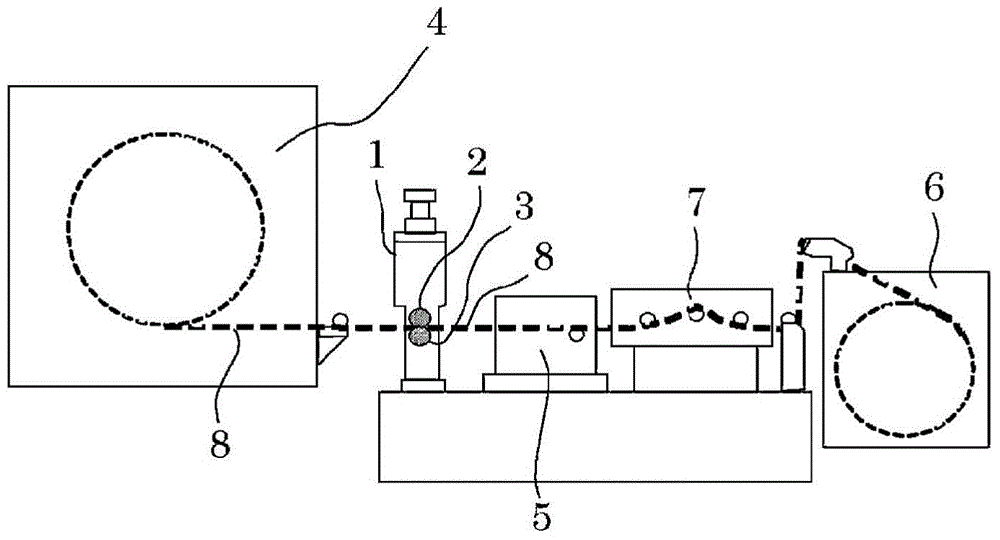

[0147] (1) Manufacture of compound roll

[0148] Each molten solution of the composition (mass %) shown in Table 1 was cast in a centrifugal casting cylindrical mold made of ductile cast iron with an inner diameter of 400mm, a length of 1500mm and a thickness of 276mm rotating at a high speed (the inner surface is coated with zirconium with a thickness of 3mm). In the coating with stone as the main body), the outer layer is centrifugally cast. The casting temperature of the melt for the outer layer is between Ts+80° C. and Ts+100° C. (where Ts is the austenite crystallization start temperature.). The gravity multiple of the outer periphery is 120G. The resulting outer layer had an average thickness of 96 mm and a scrap diameter of 65 mm from the surface.

[0149] Before the innermost surface of the outer layer is solidified, on the inner surface of the outer layer, cast a melt for the intermediate layer having the following co...

Embodiment 8

[0211] According to the same method as in Examples 1 to 7, the melts for the outer layer and the melts for the intermediate layer having the compositions shown in Table 5 were cast into centrifugal castings made of ductile cast iron with an inner diameter of 760 mm, a length of 2700 mm, and a thickness of 320 mm. A cylindrical mold (coated with zircon-based paint with a thickness of 3 mm on the inner surface) was formed by centrifugal casting to form an outer layer with an average thickness of 91 mm, and an intermediate layer with an average thickness of 20 mm. Thereafter, the shaft core portion was formed by the same method as in Examples 1 to 7. The distribution of Cr, V, and Nb in the vicinity of the intermediate layer was measured for a test piece cut from the roll body end surface of the obtained composite roll at a position separated by about 100 mm in the roll axis direction. The results are shown in Figure 5-1 middle.

[0212] 【table 5】

[0213]

[0214] Depend ...

Embodiment 9

[0218] By the same method as in Examples 1 to 7, the melt for the outer layer and the melt for the intermediate layer having the compositions shown in Table 7 were cast into a centrifugal casting made of ductile cast iron with an inner diameter of 795 mm, a length of 2700 mm, and a thickness of 302.5 mm. The outer layer with an average thickness of 85 mm and the middle layer with an average thickness of 10 mm were formed by a centrifugal casting method using a cylindrical mold (the inner surface was coated with a coating mainly composed of zircon with a thickness of 3 mm). Thereafter, the shaft core portion was formed by the same method as in Examples 1 to 7. The distribution of Cr, V, and Nb in the vicinity of the intermediate layer was measured for a test piece cut from the roll body end surface of the obtained composite roll at a position separated by about 100 mm in the roll axis direction. The results are shown in Figure 5-2 middle.

[0219] 【Table 7】

[0220]

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com