Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Prevent interfacial peeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

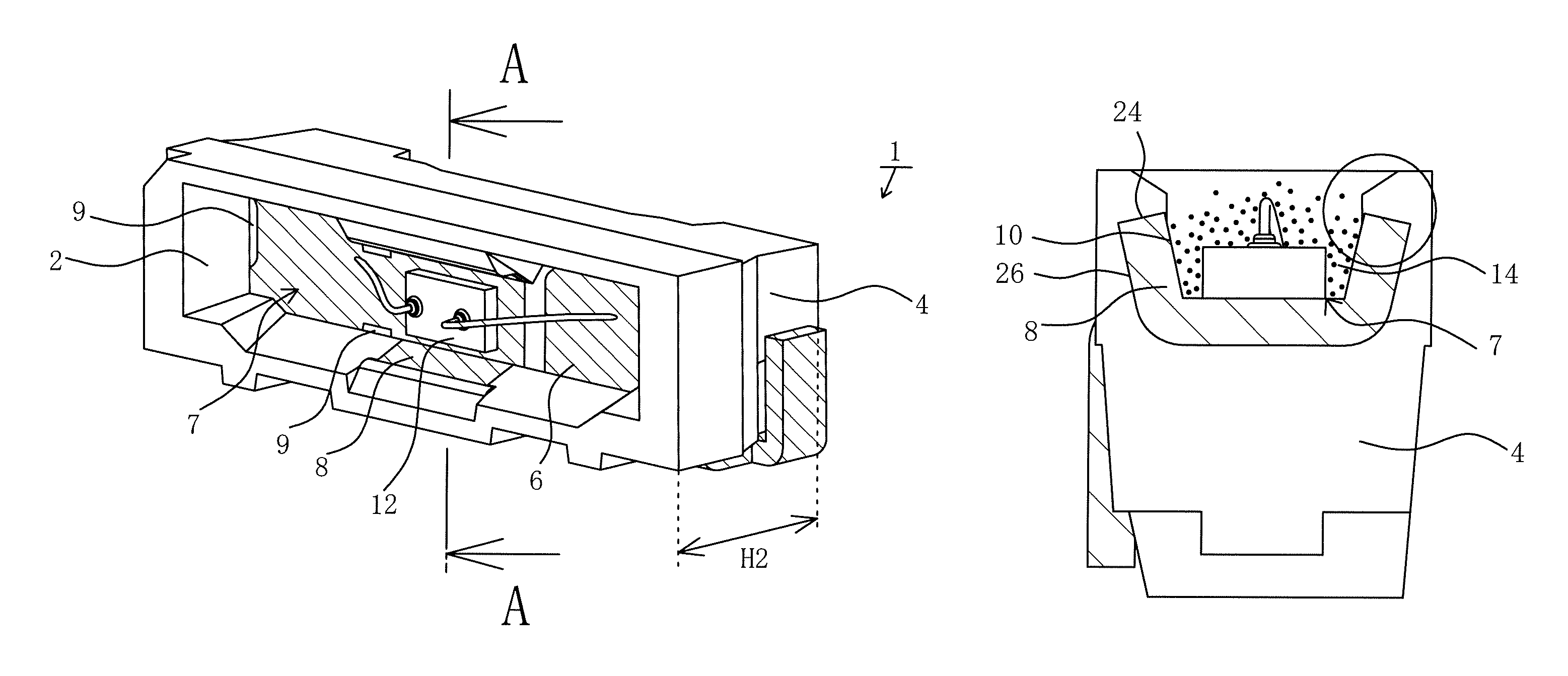

Light emitting device

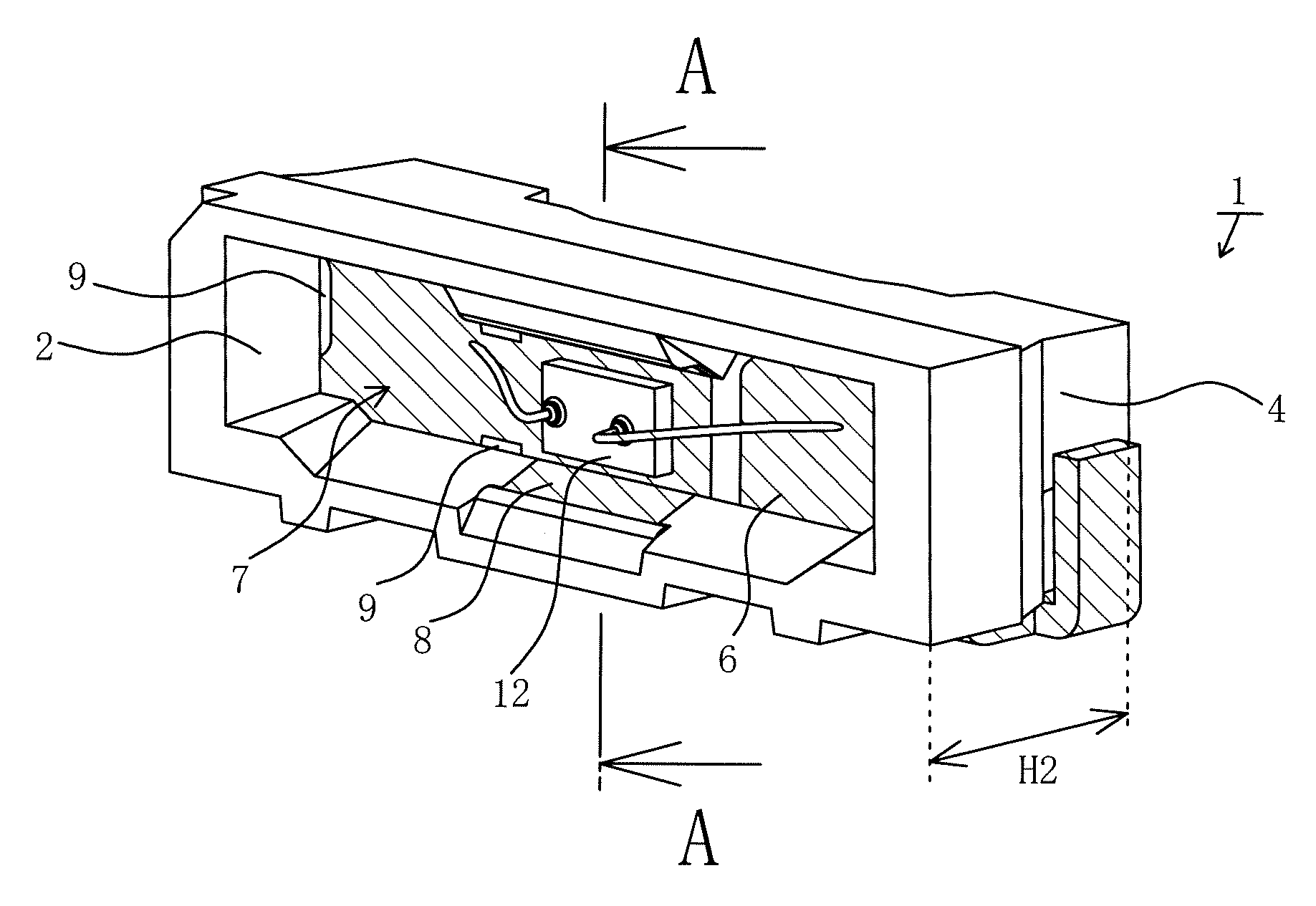

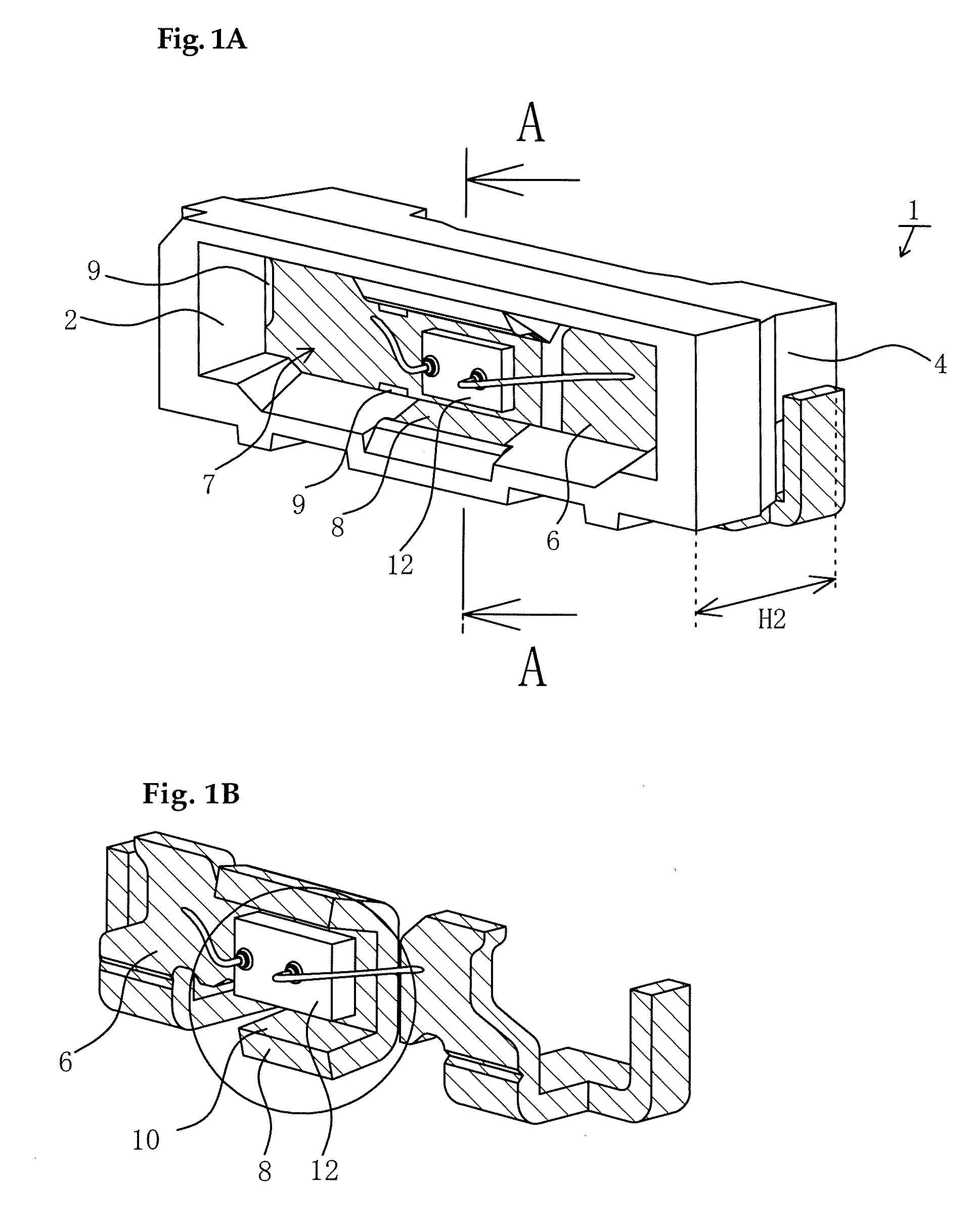

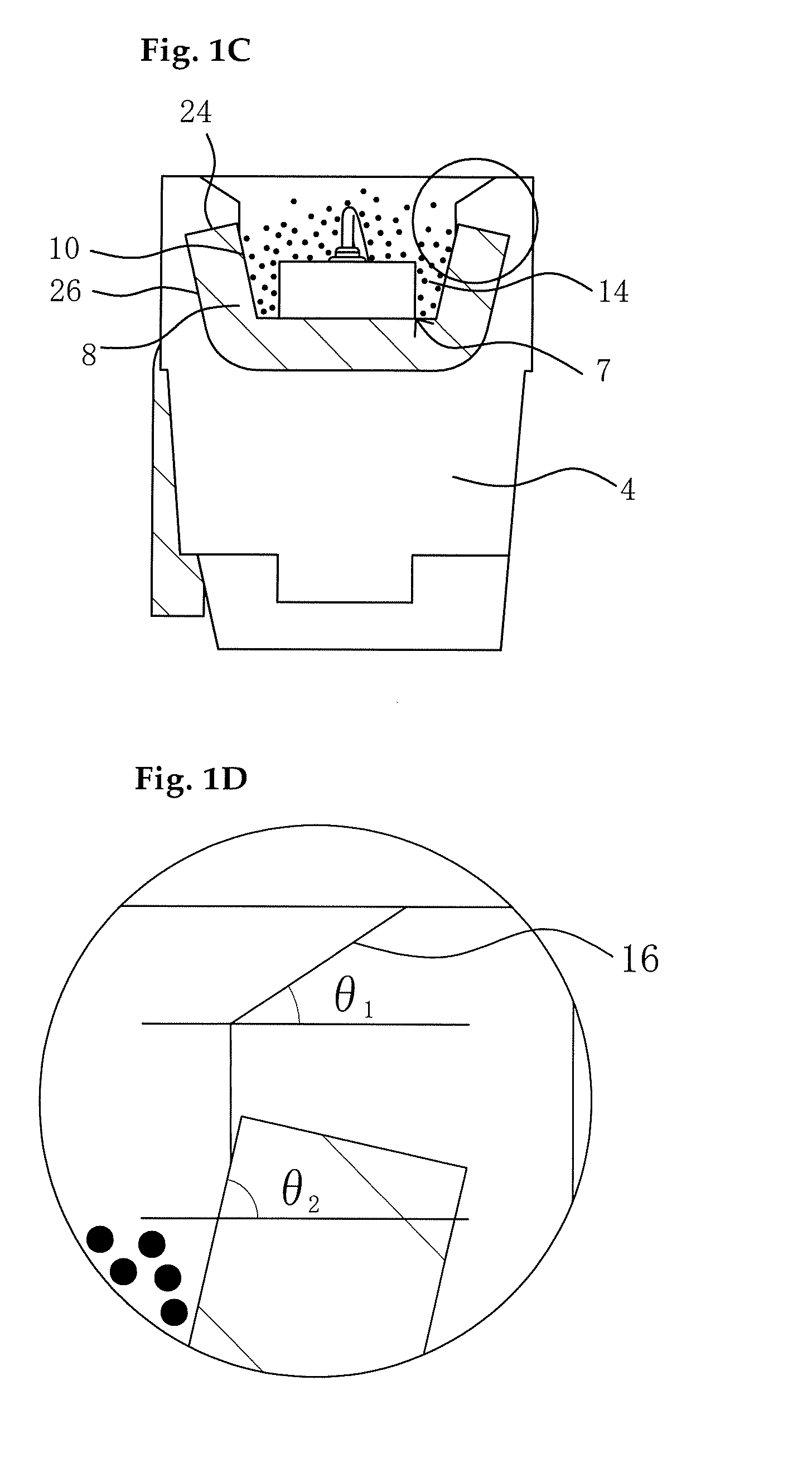

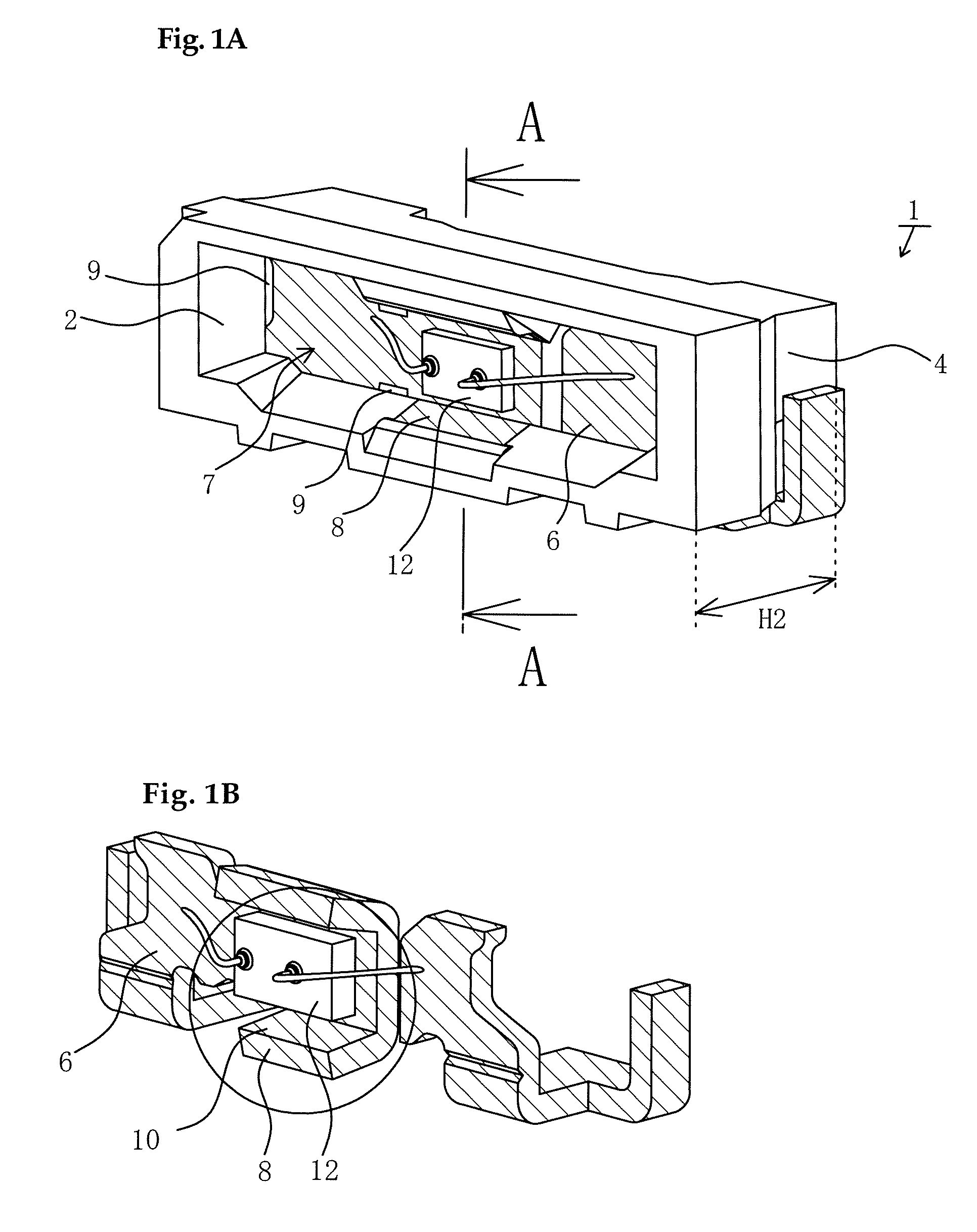

ActiveUS20110175127A1Improve adhesionPrevent interfacial peelingSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

A light emitting device has a package having an opening provided with a side surface and a bottom surface, and a lead frame exposed to the bottom surface. The lead frame includes a reflection portion bent on the side surface, and a portion of an inner wall surface of the reflection portion is positioned in an inner portion of the package. A light emitting device has a package having a recessed portion on a front surface, a lead frame exposed to a bottom surface of the recessed portion, a light emitting element disposed on the lead frame, and a sealing resin filled into the recessed portion. The lead frame includes a bent portion bent towards the front surface of the package in the recessed portion, and a projecting portion bent to project from the package towards an outer portion, and disposed on a face opposed to the front surface.

Owner:NICHIA CORP

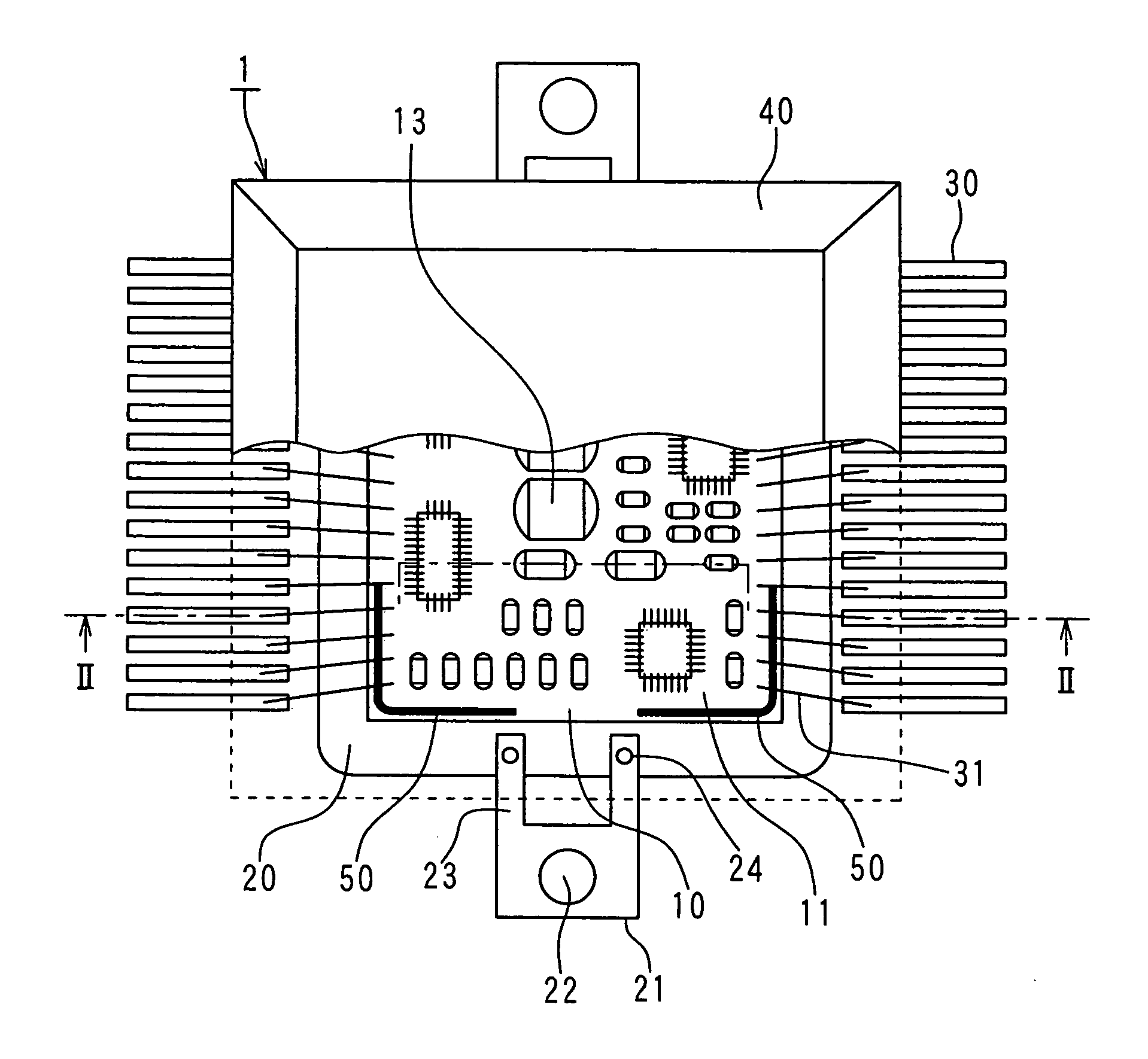

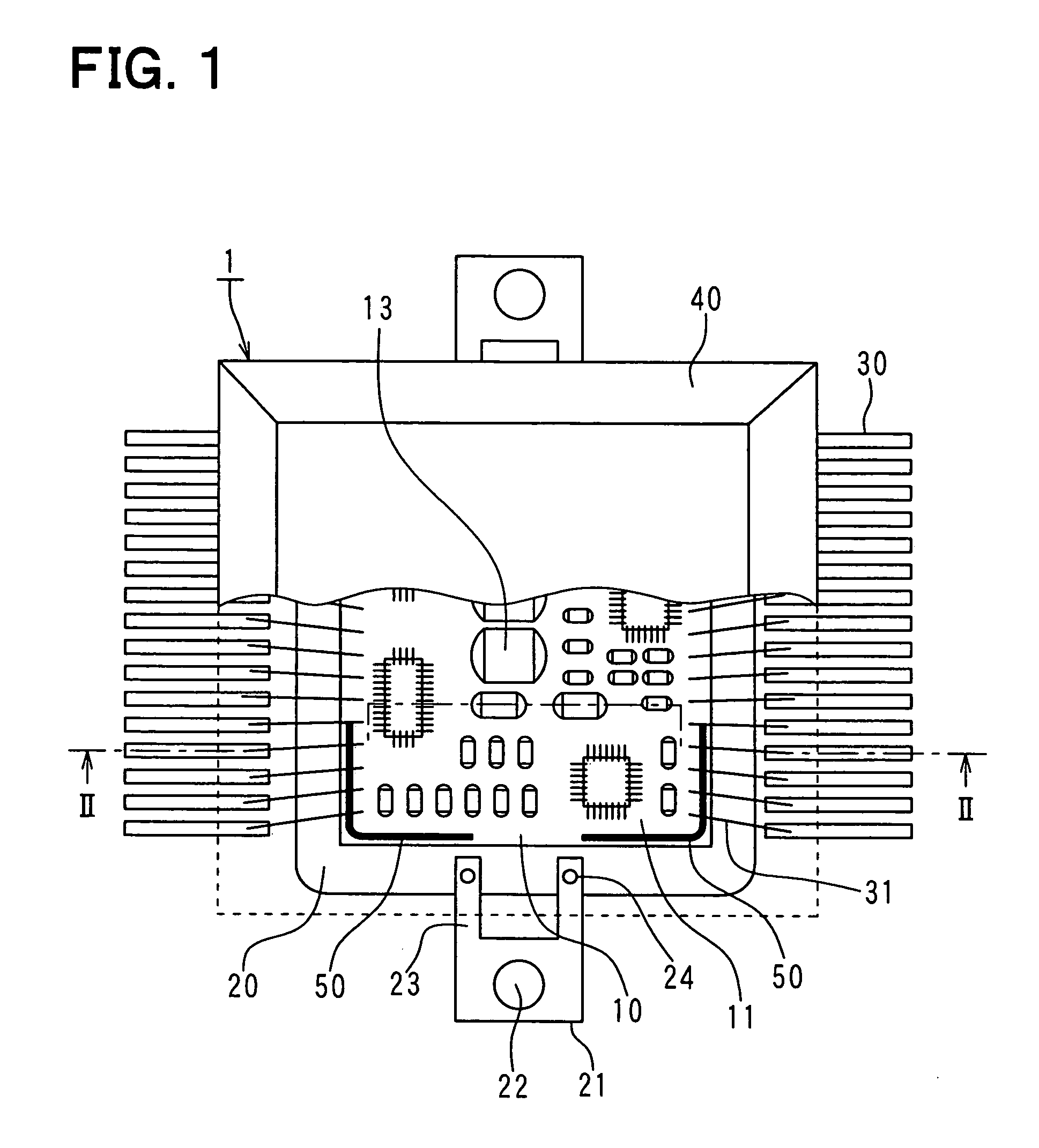

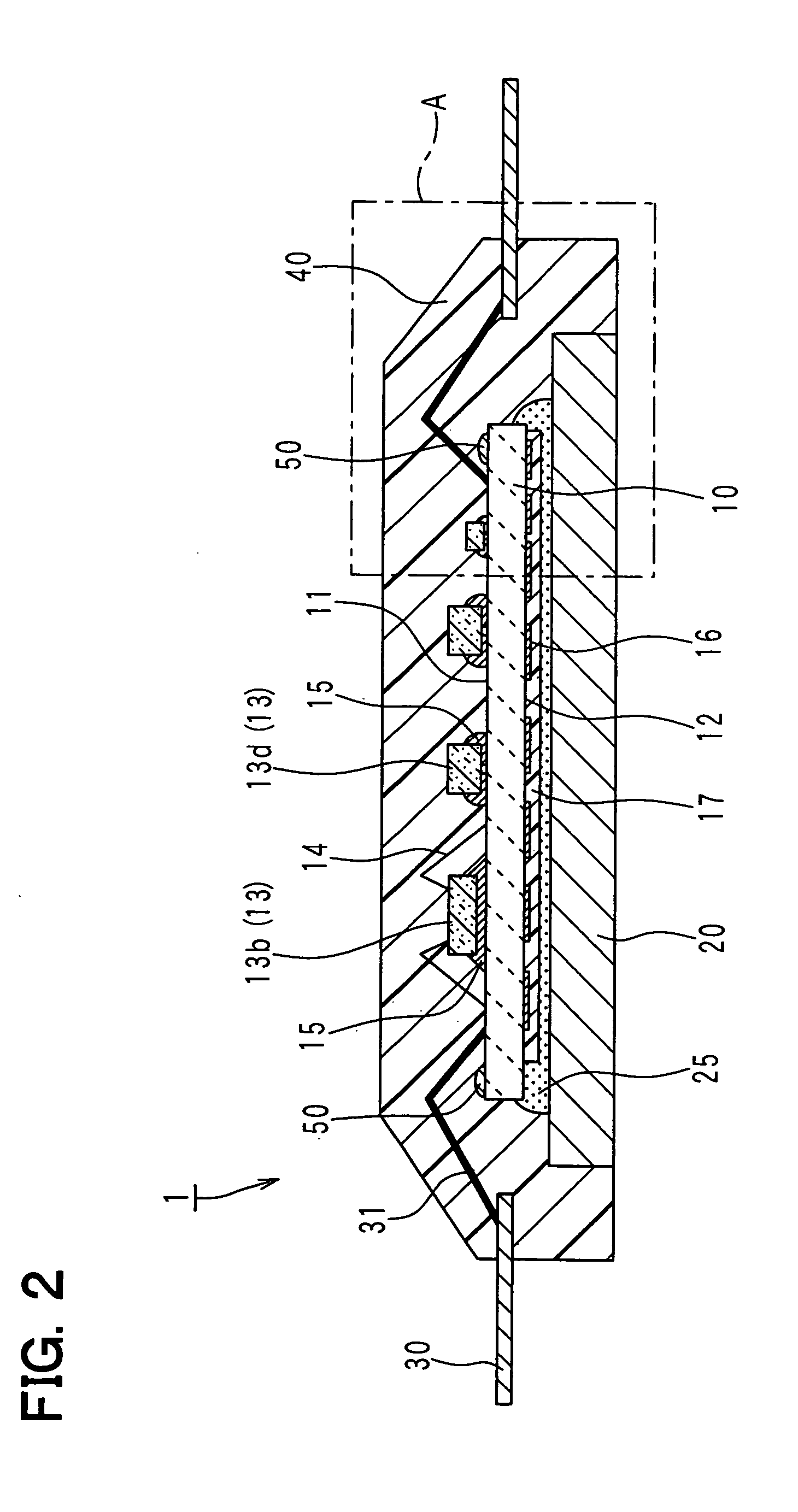

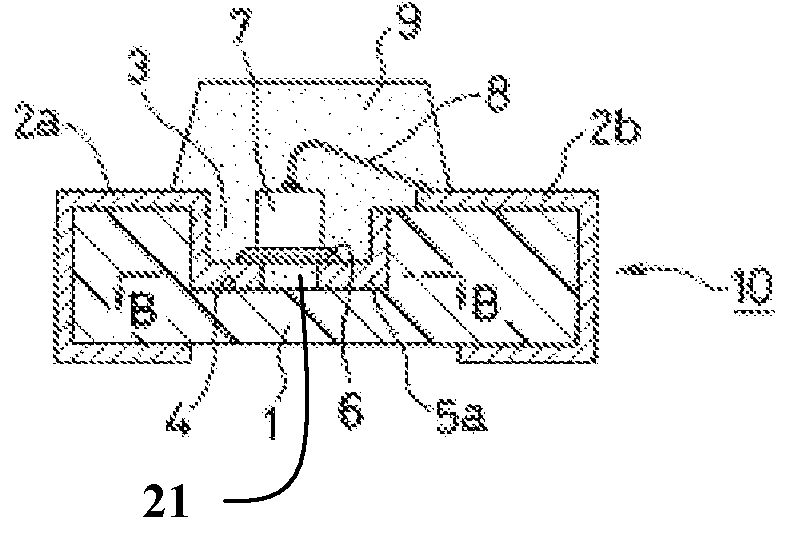

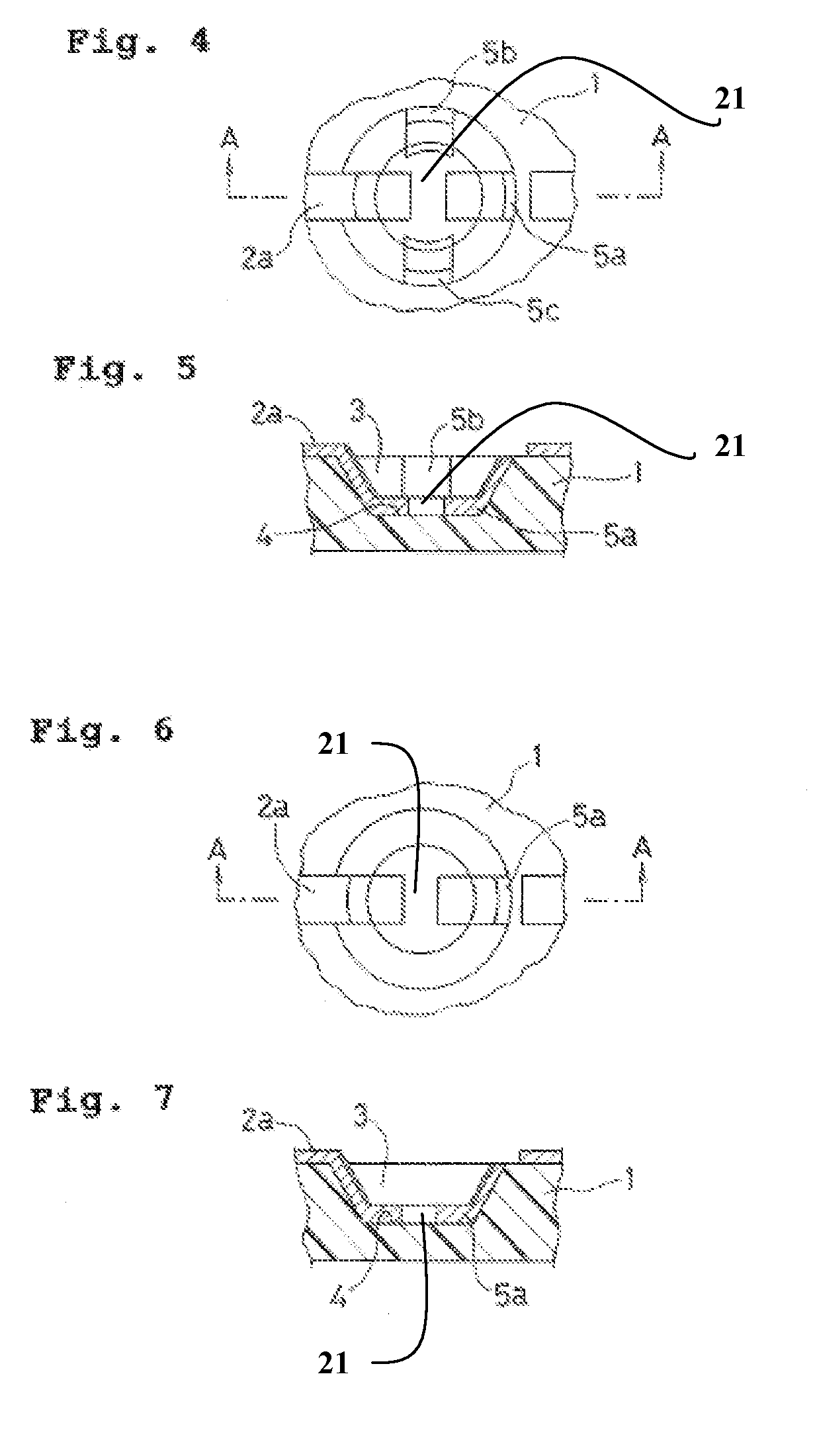

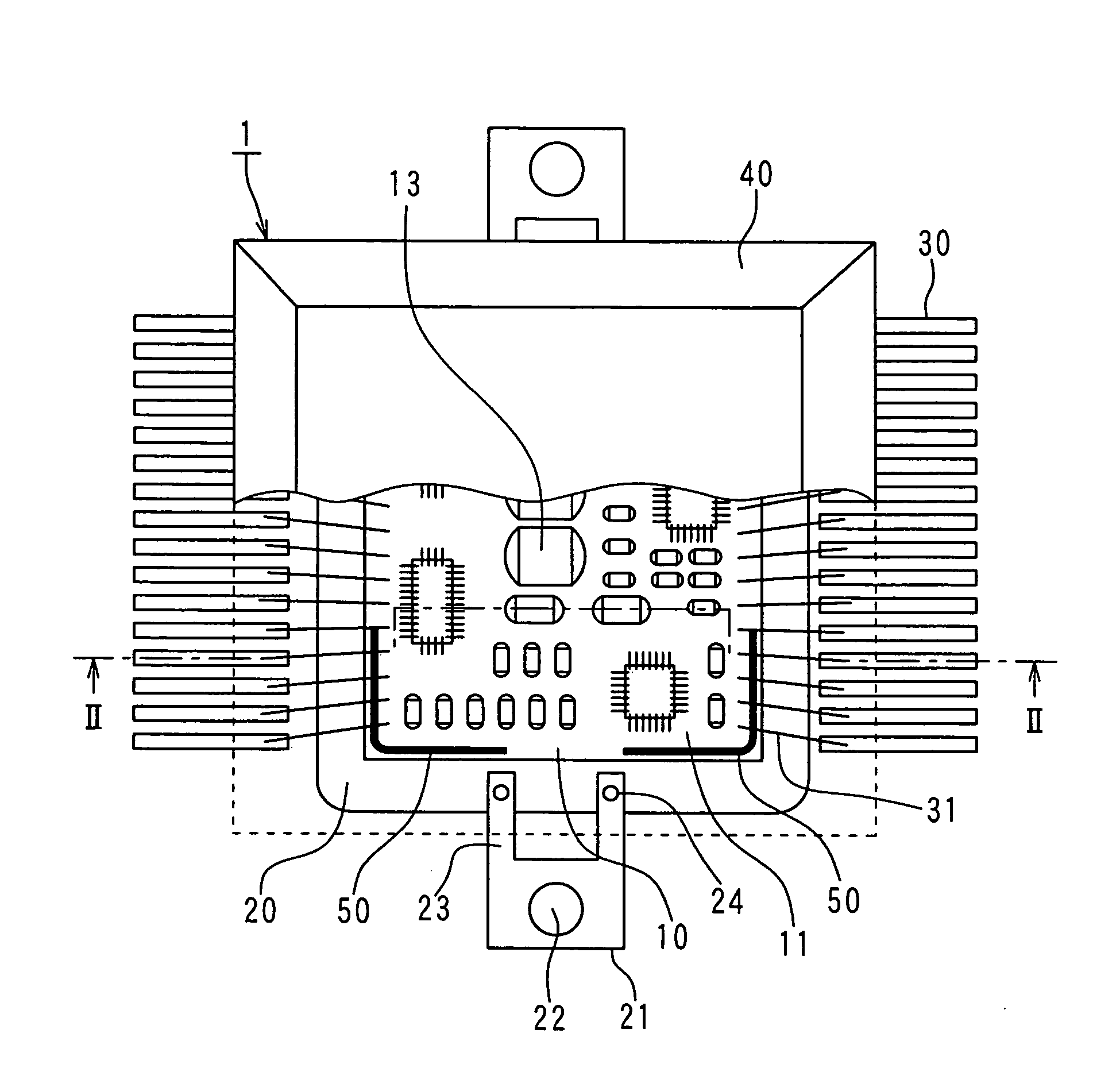

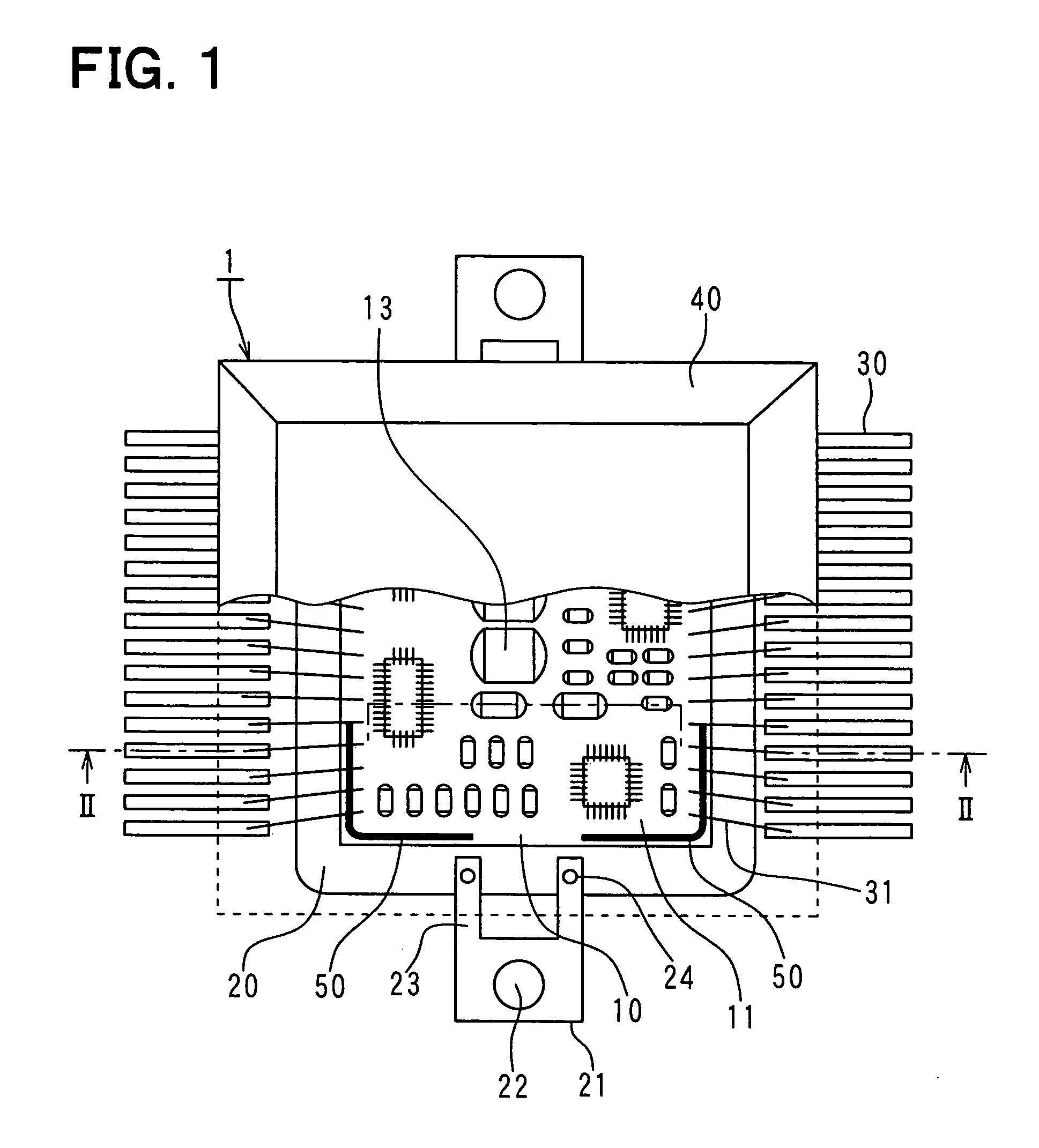

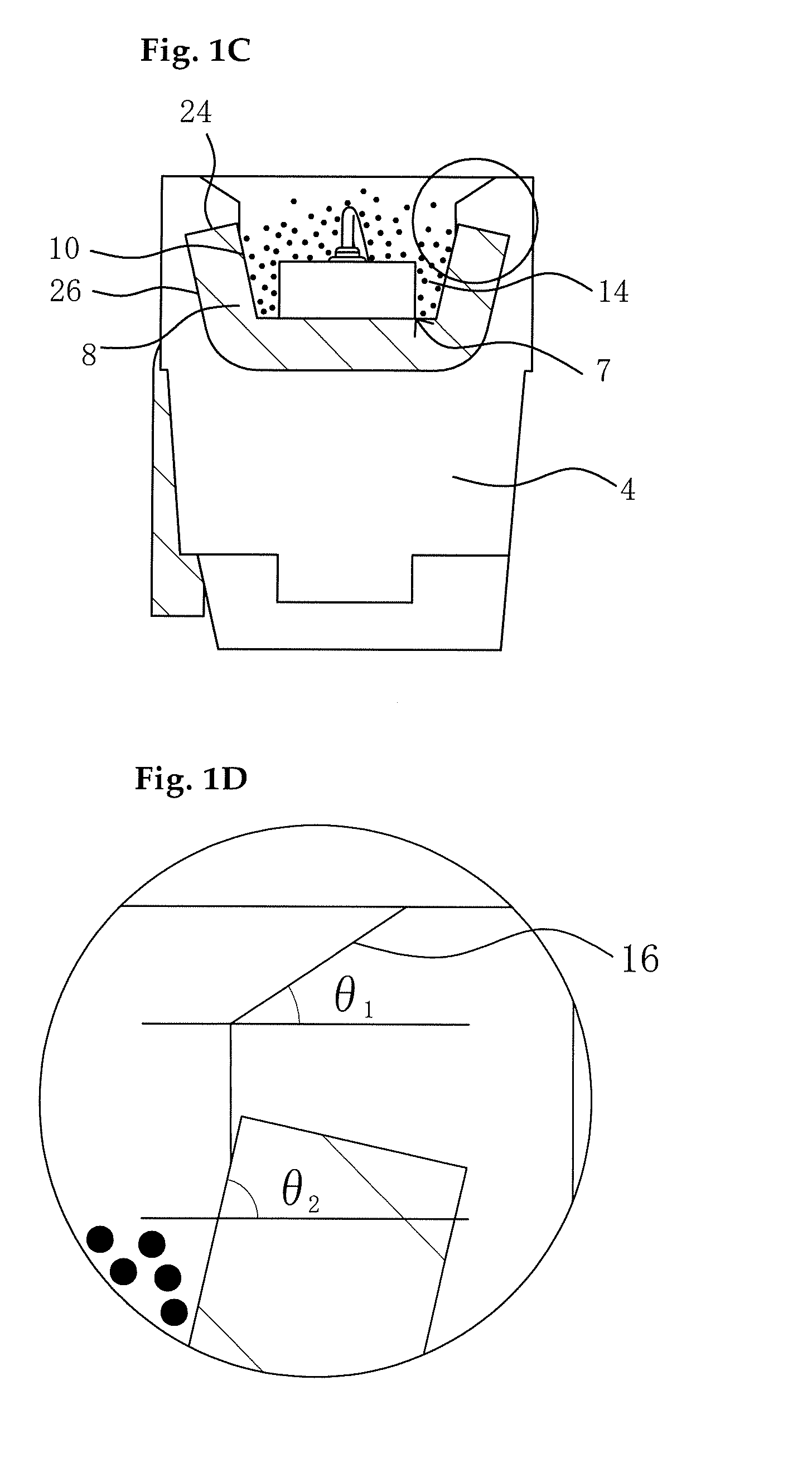

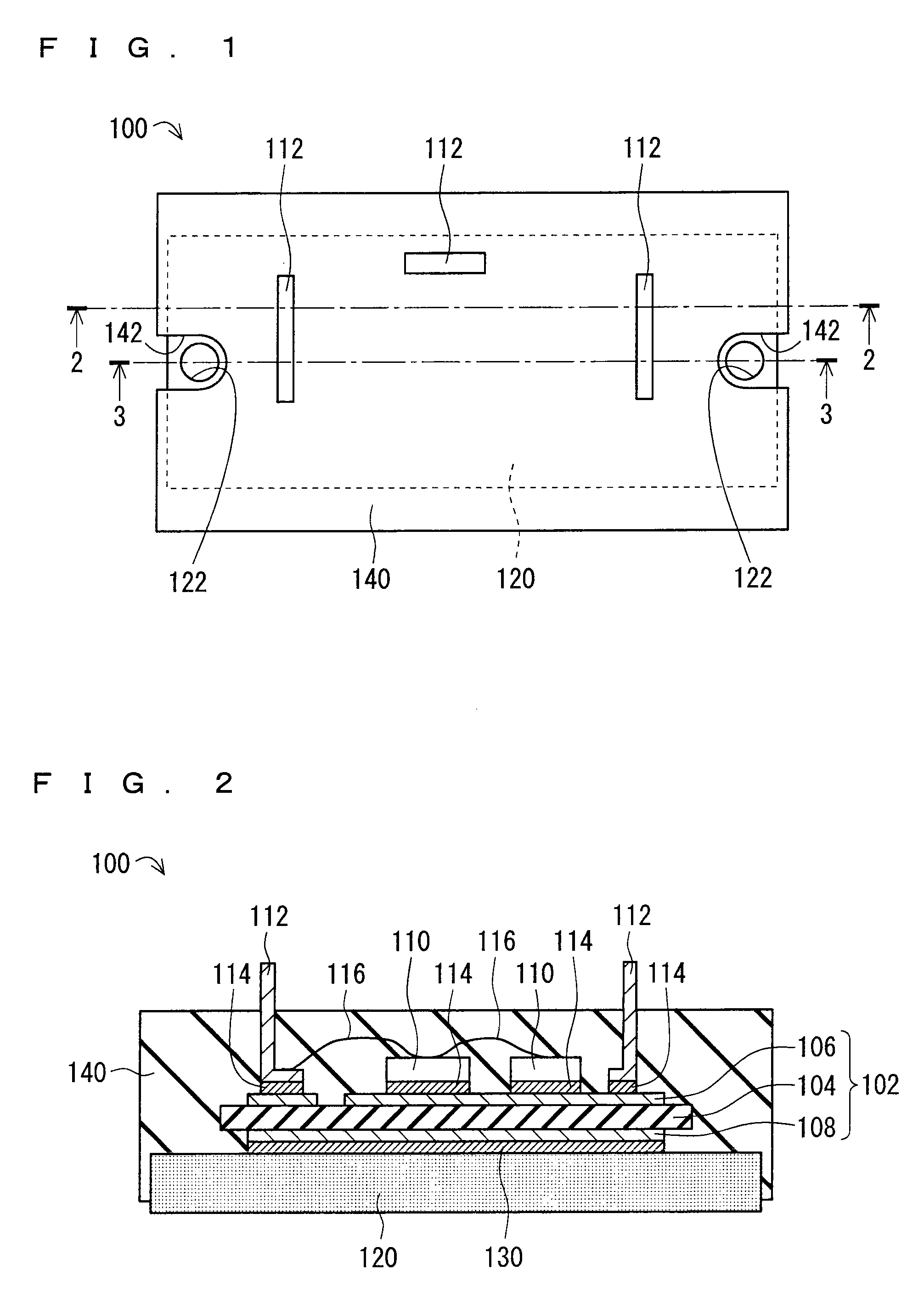

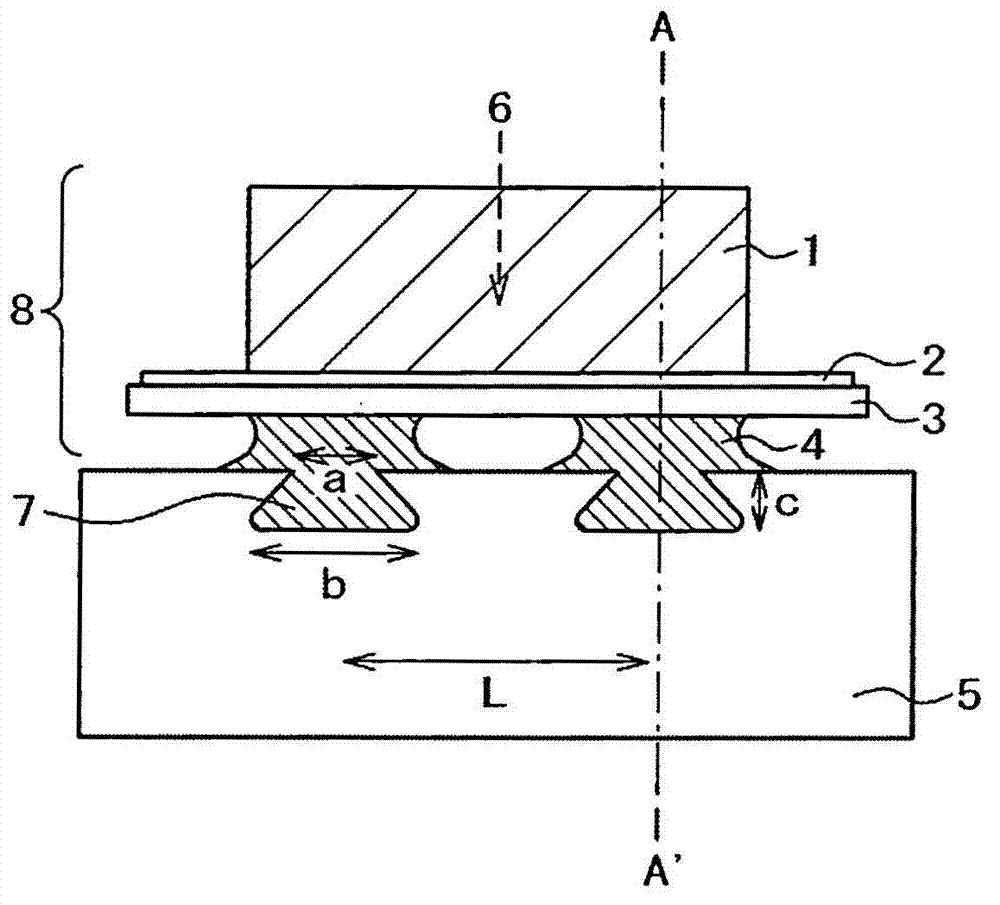

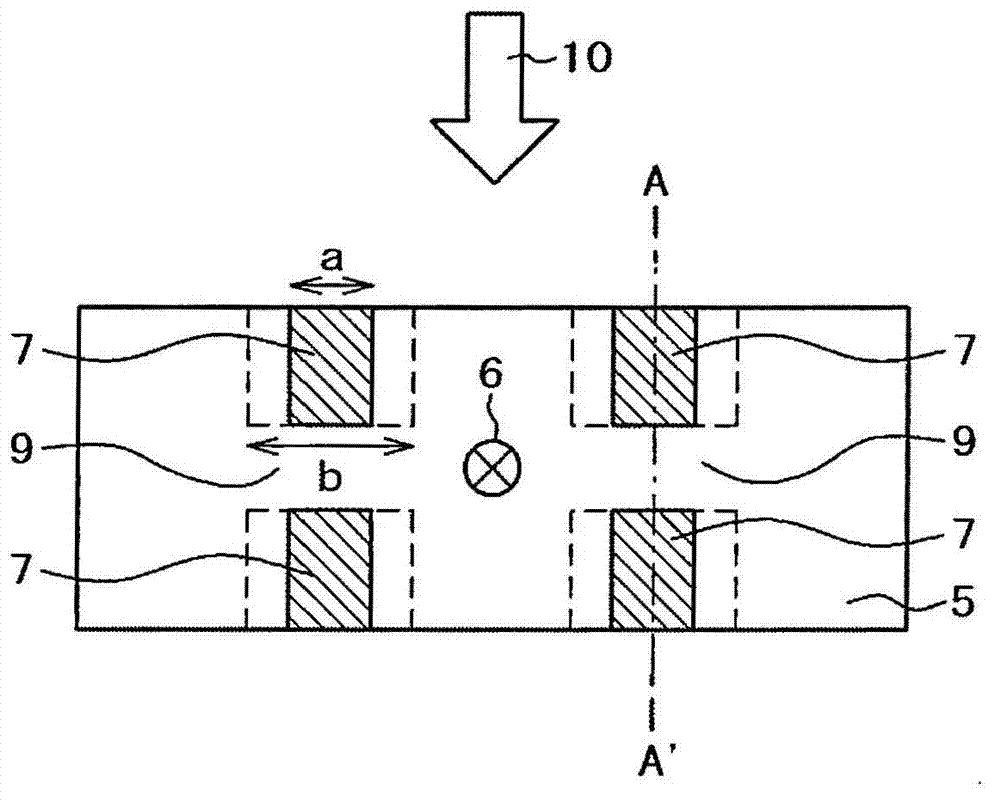

Electronic control device

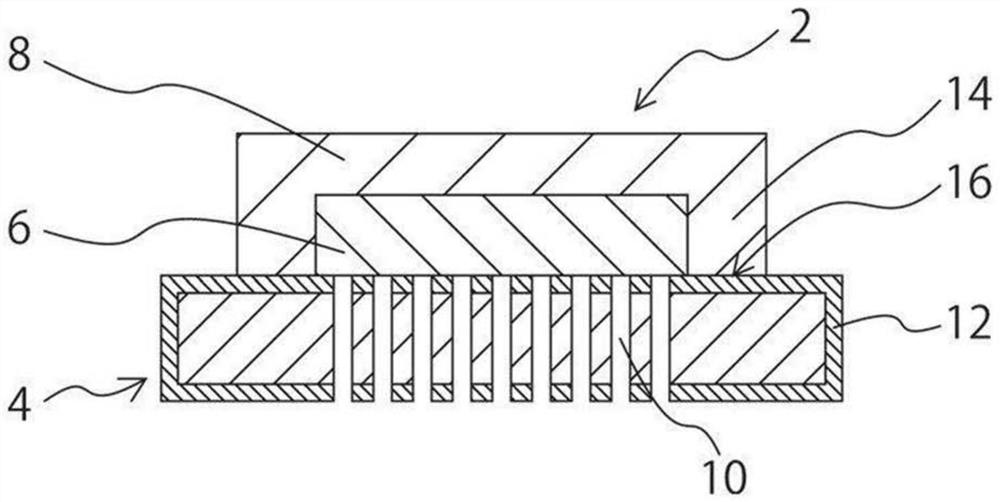

ActiveUS20100097775A1Secure radiation performanceRelieve pressurePrinted circuit aspectsPrinted circuits stress/warp reductionEngineeringElectrically conductive adhesive

In an electronic control device, an electrically-conductive adhesive is arranged on an outer edge portion of a first surface of a circuit board as a stress reducing portion for reducing stress of the circuit board received by a molding resin. An elastic modulus of the electrically-conductive adhesive is lower than that of the circuit board. The electrically-conductive adhesive is covered by an adhesion improving member. When peeling stress is applied to the circuit board from the molding resin, the electrically-conductive adhesive and the adhesion improving member receive the peeling stress to be deformed. Therefore, the peeling stress to the circuit board is reduced.

Owner:DENSO CORP

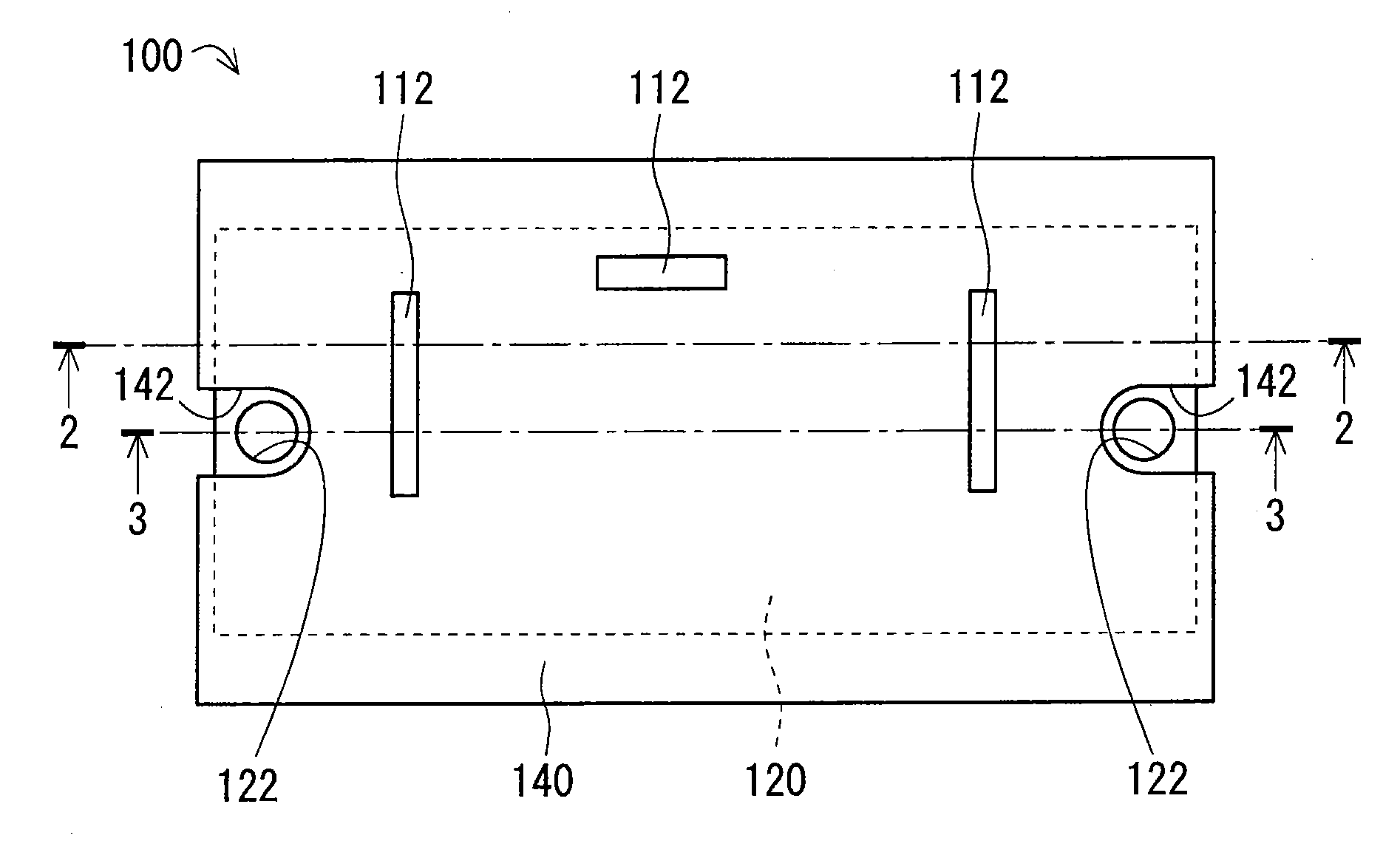

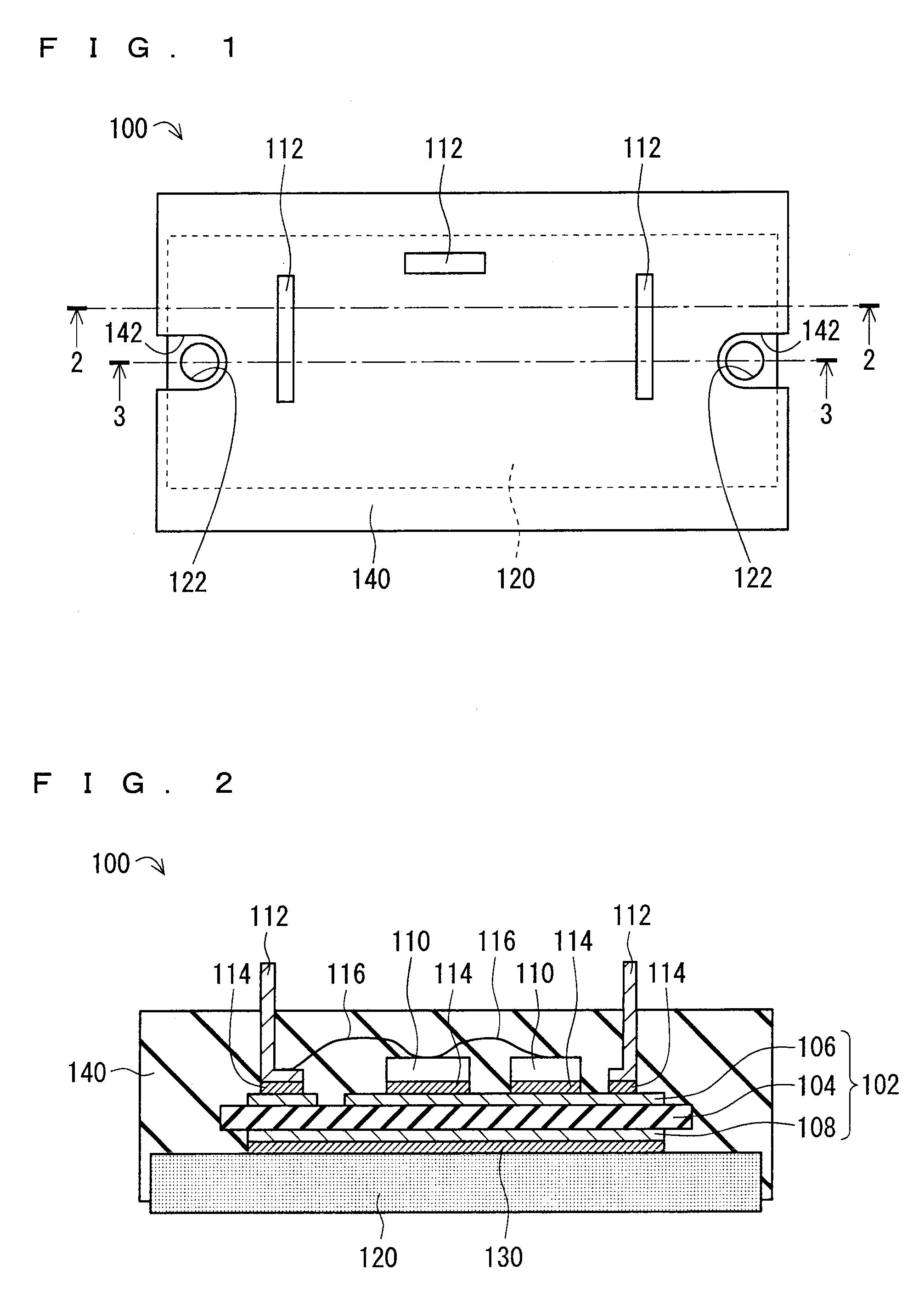

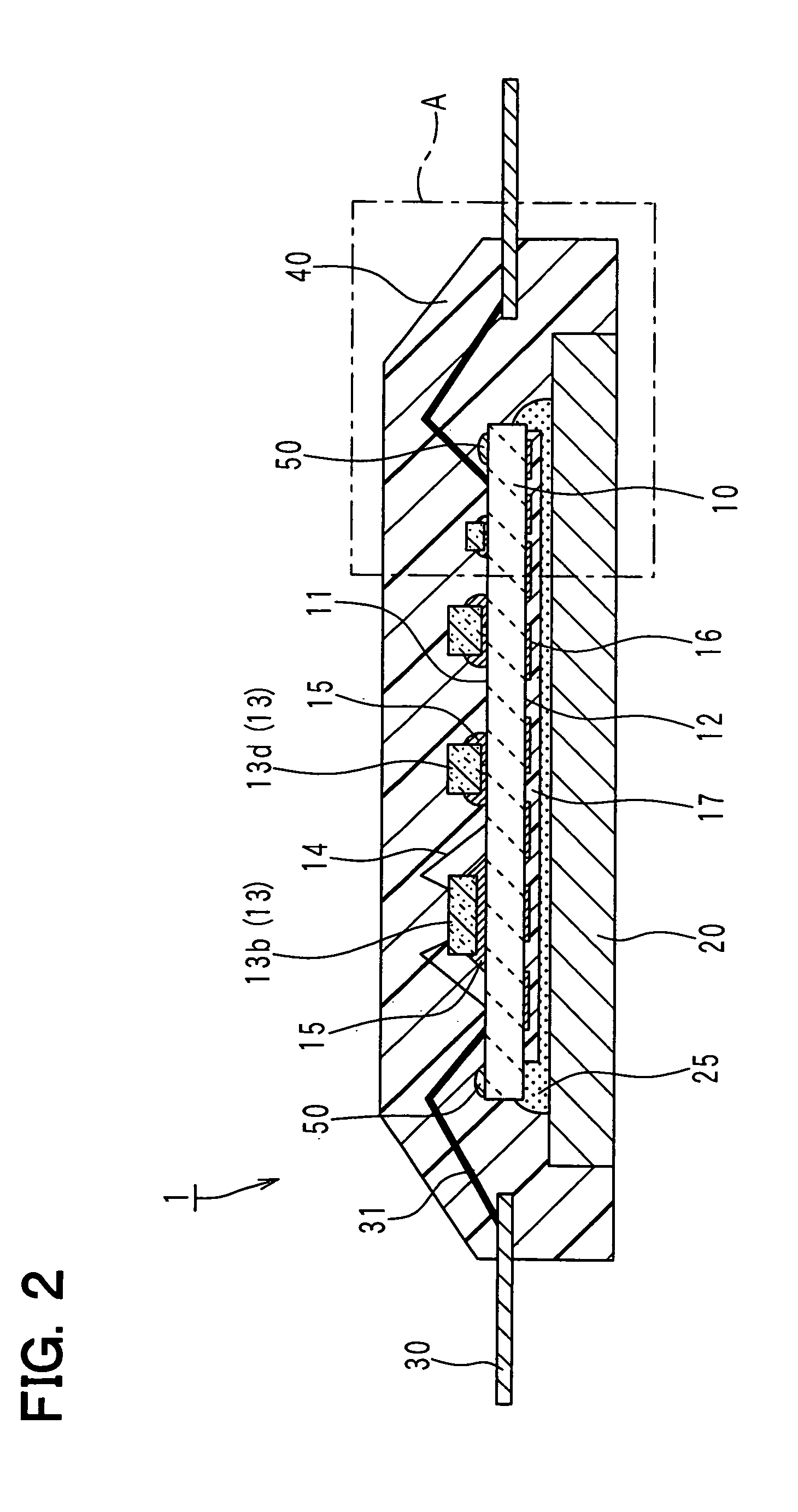

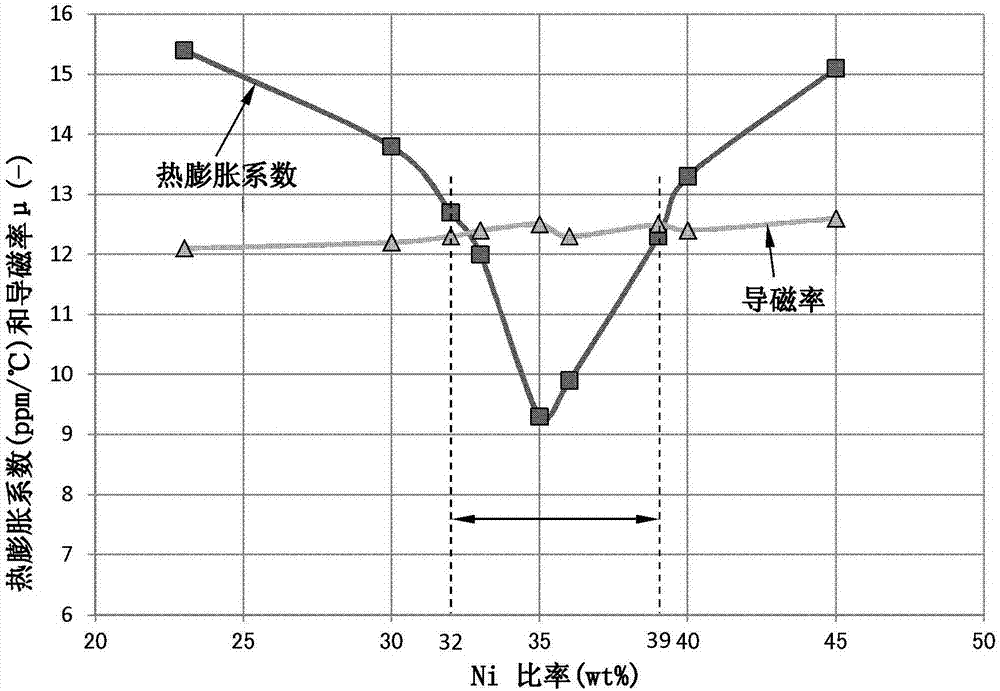

Semiconductor device

ActiveUS20120313252A1Easy to installAvoid defectsSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A semiconductor device includes a base plate having one main surface joined to an insulating substrate on which a semiconductor chip and the like are mounted and a transfer mold resin which is so provided as to cover the one main surface of the base plate, the insulating substrate, the semiconductor chip, and the like and expose the other main surface of the base plate. The coefficient of linear expansion of the base plate is lower than that of copper and the coefficient of linear expansion of the transfer mold resin is not higher than 16 ppm / ° C. The transfer mold resin has such scooped shapes as to expose opposed short-side centers and the vicinity of the base plate, respectively. The base plate has mounting holes in portions exposed by the scooped shapes of the transfer mold resin.

Owner:MITSUBISHI ELECTRIC CORP

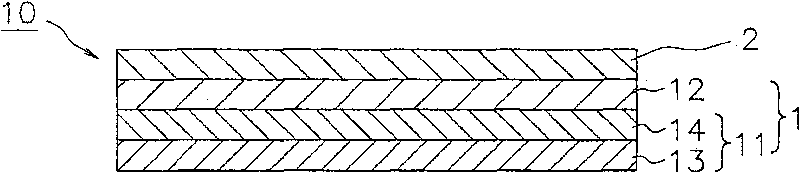

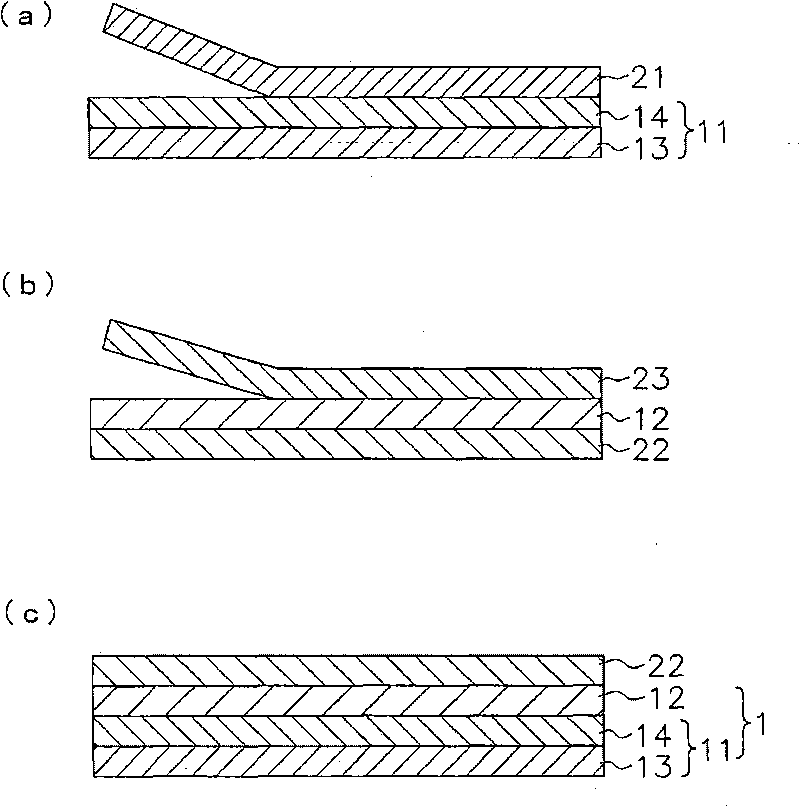

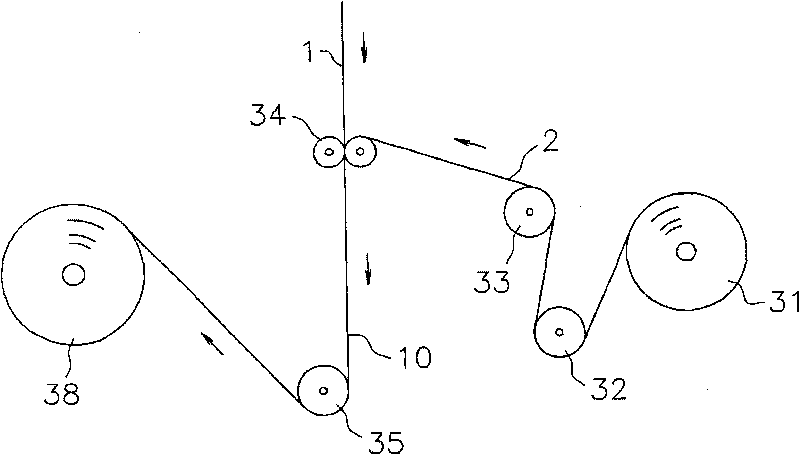

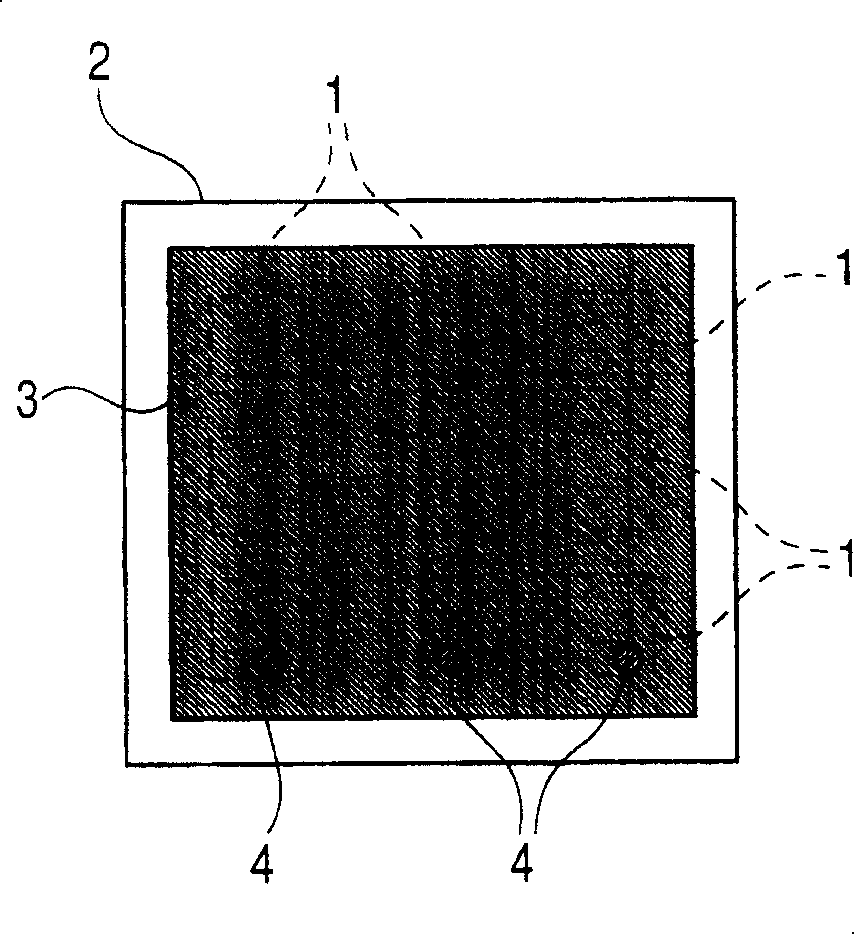

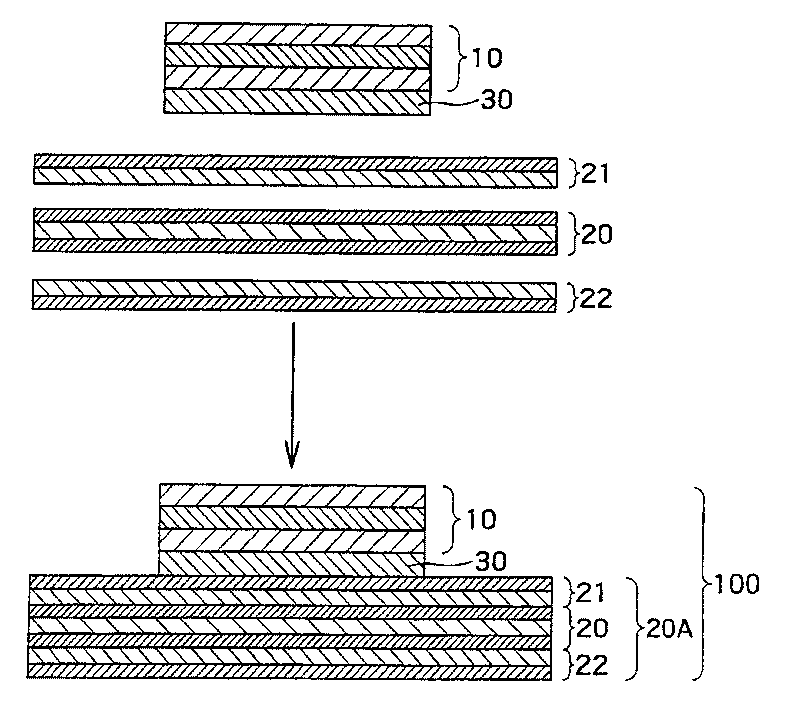

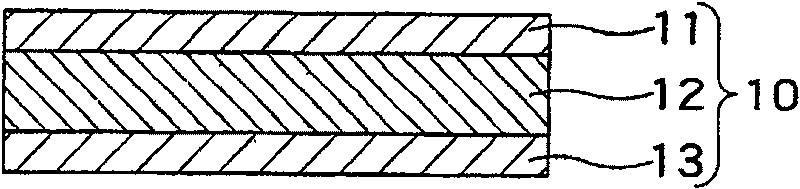

Film for manufacturing semiconductor device and method of manufacturing the same

InactiveCN101752217APrevent floating phenomenonPrevent interfacial peelingLamination ancillary operationsLayered product treatmentEngineeringSemiconductor

A present invention relates to a film for manufacturing a semiconductor device in which a cover film is pasted onto a laminated film, wherein the shrinkage in the longitudinal direction and in the lateral direction in the laminated film after peeling the cover film and leaving for 24 hours at a temperature of 23+-2 DEG C. is in a range of 0 to 2% compared to the laminated film before pasting of the cover film.

Owner:NITTO DENKO CORP

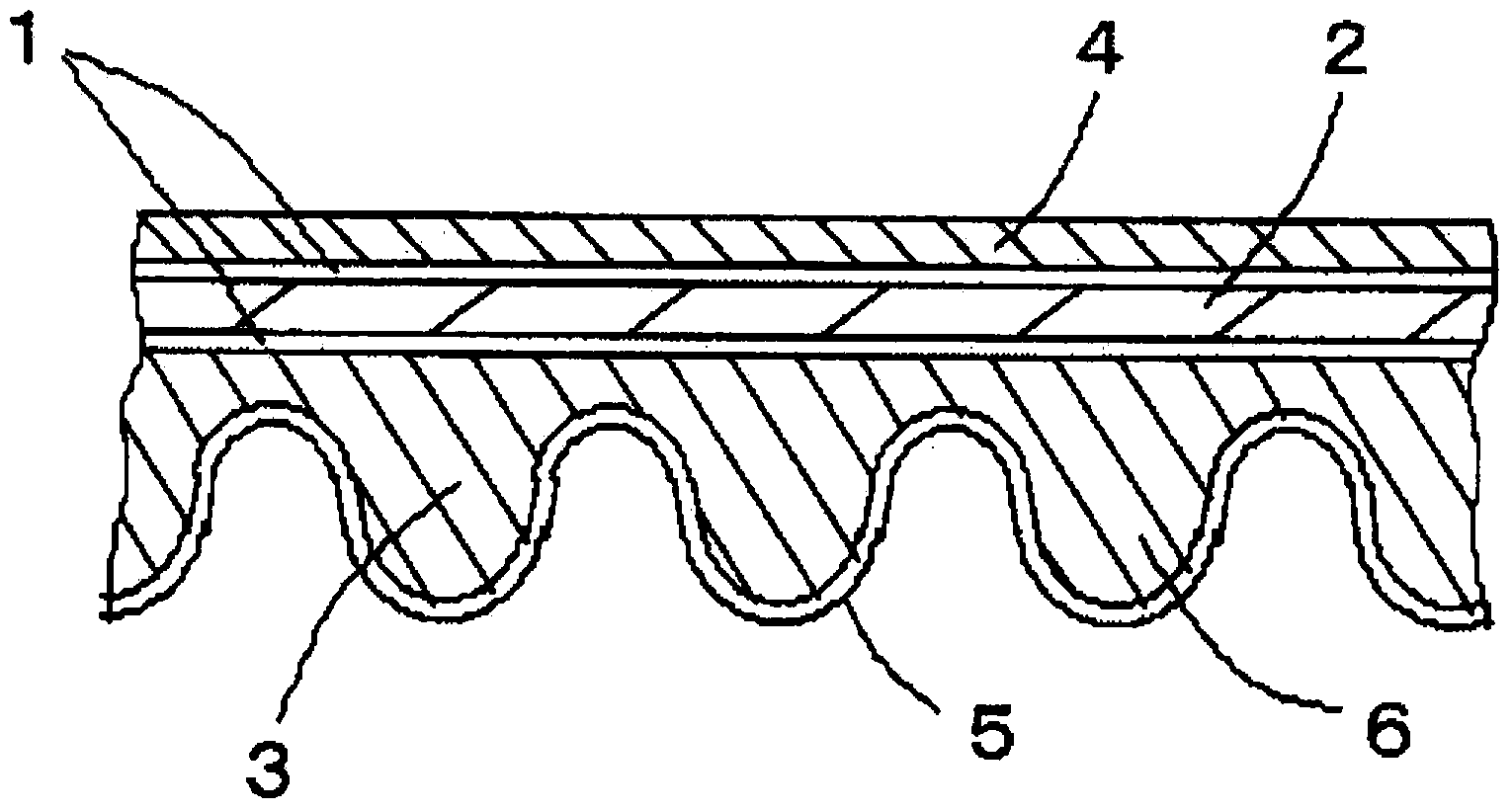

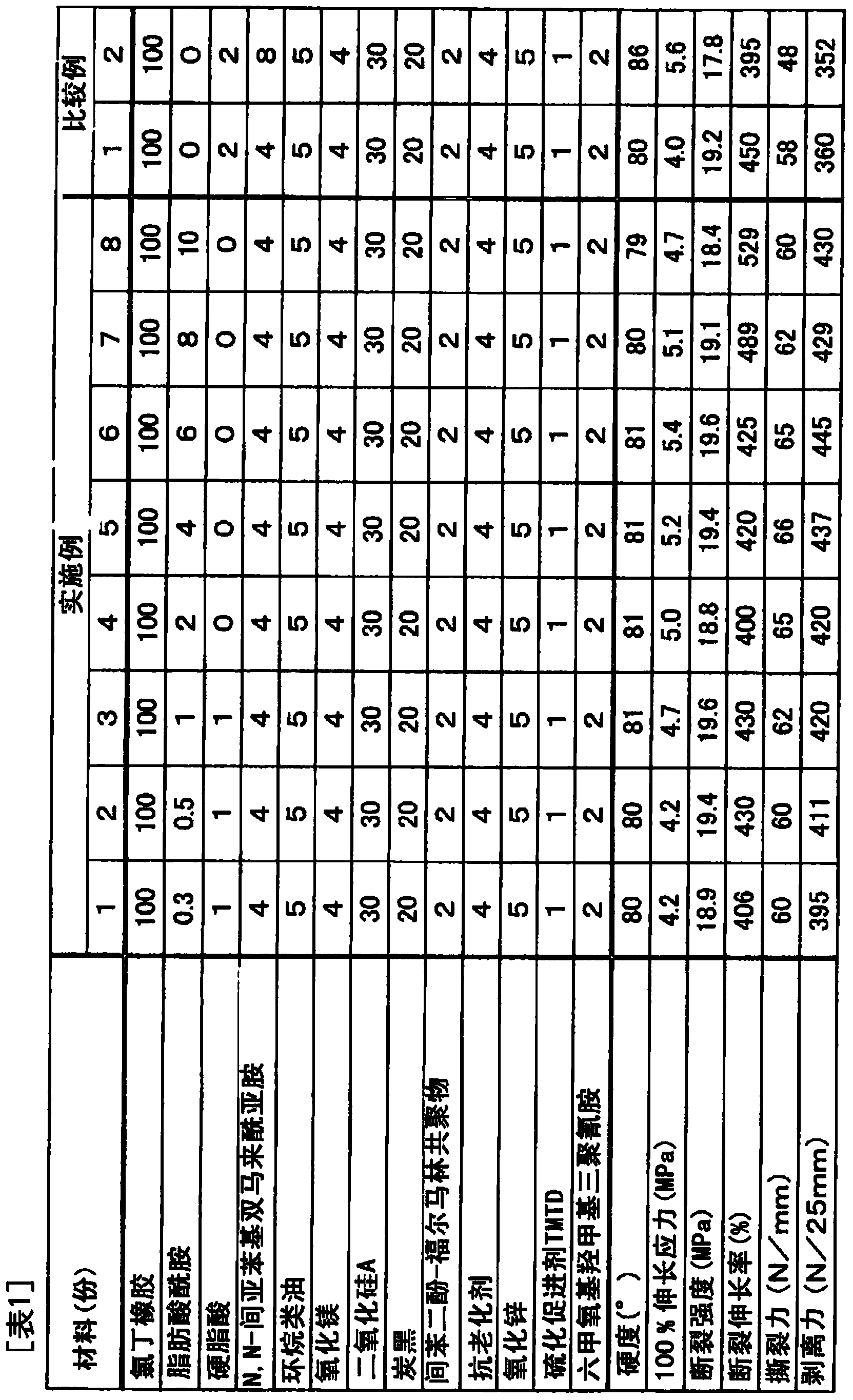

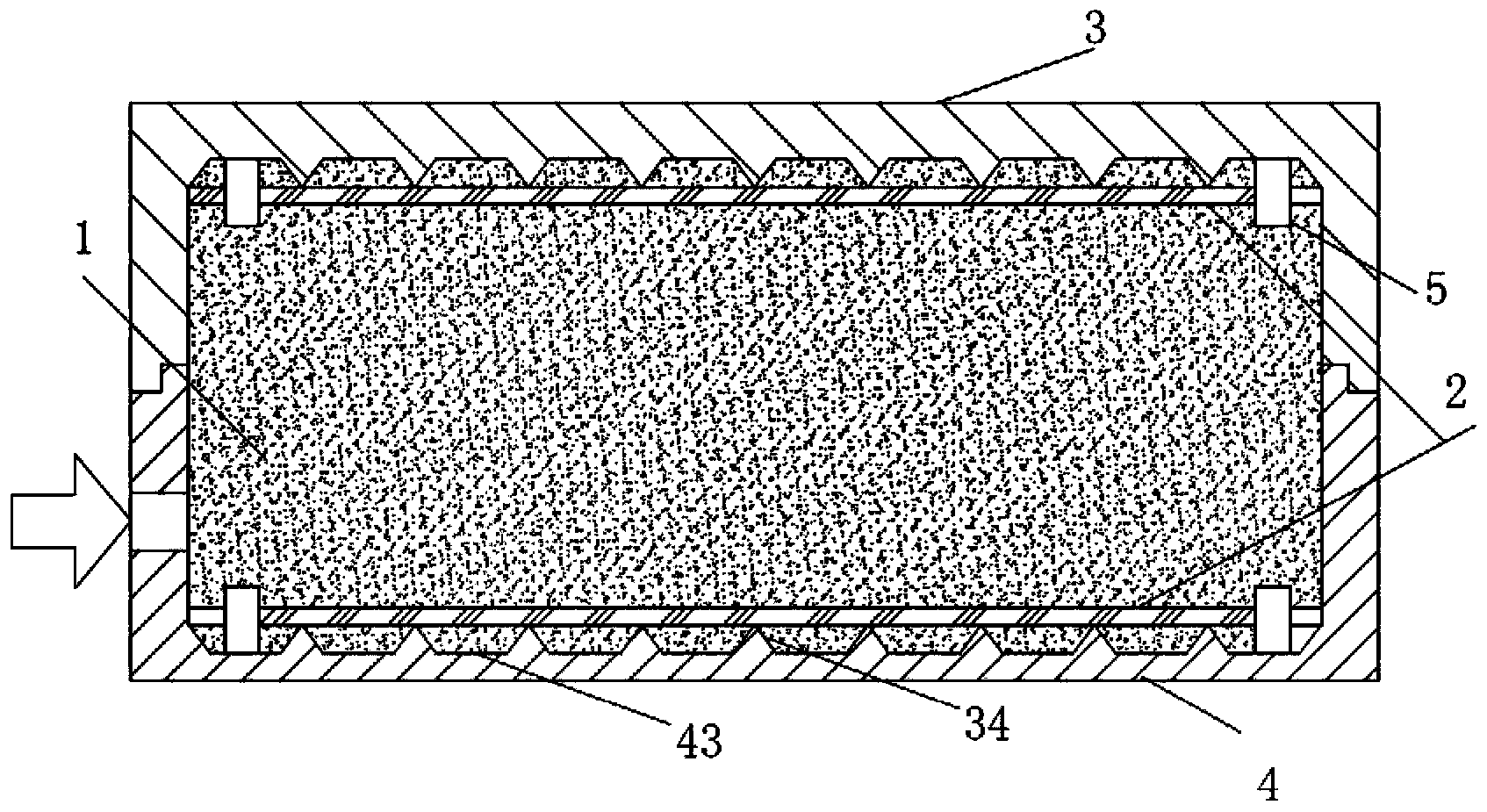

Transmission belt

ActiveCN104254709AIncreased durabilityPrevent interfacial peelingV-beltsDriving beltsTransmission beltConveyor belt

The present invention provides a transmission belt which is provided with: a core wire extending in the lengthwise direction of the belt; an adhesive rubber layer in contact with at least part of the core wire; a back surface rubber layer which is formed on one surface of the adhesive rubber layer; and an inner surface rubber layer which is formed on the other surface of the adhesive rubber layer and engages or makes contact with a pulley. The adhesive rubber layer is formed by a vulcanized rubber composition including a rubber component, a fatty acid amide and silica.

Owner:MITSUBOSHI BELTING LTD

Surface mount LED

InactiveUS20060151799A1Strong intimate contact forcePrevent peelingDischarge tube luminescnet screensLamp detailsAdhesiveSurface mounting

In a surface mount LED, circuit patterns can be formed on selective portions of the bottom and inner circumferential surfaces of a recess in a substrate in which an LED chip is mounted. A sealant material composed of a light transmissive resin can be applied to cover the LED chip for sealing. An intimate contact interface is formed between the material of the insulator / substrate which is exposed at a portion with no circuit pattern formed thereon, and the light transmissive resin. The strength of intimate contact can be enhanced to prevent the circuit patterns and conductive adhesive from peeling off at an interface therebetween.

Owner:STANLEY ELECTRIC CO LTD

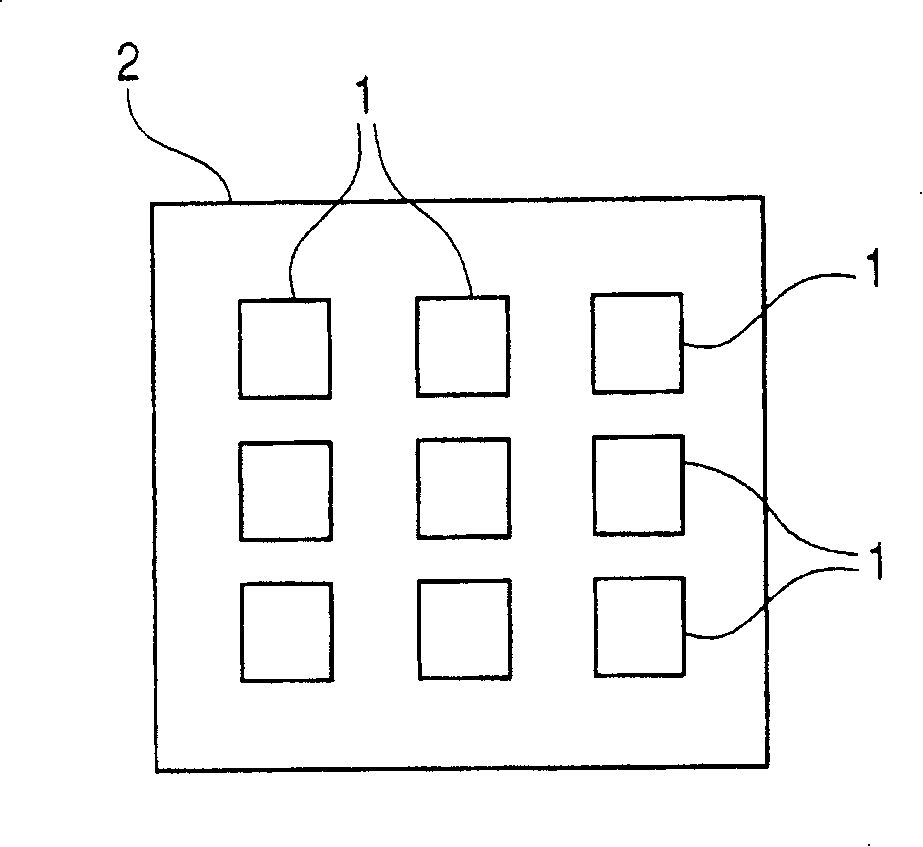

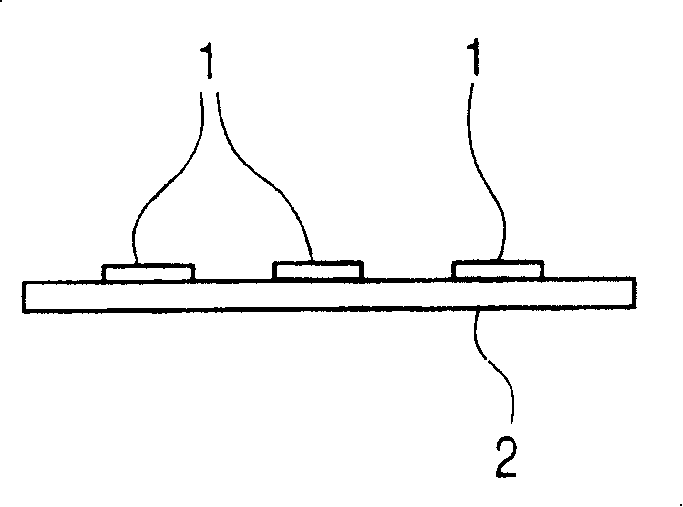

Leadframe semiconductor integrated circuit device using the same, and method of and process for fabricating the two

InactiveUSRE43443E1Wide range of sizesSuppress package body crackingSemiconductor/solid-state device detailsSolid-state devicesFlexible manufacturing systemCrack resistance

In order to improve the package body cracking resistance of an LSI package at the reflow soldering and to provide both a leadframe suitable for fabricating the LSI package according to the flexible manufacturing system and an LSI using the leadframe, the adhered area between a semiconductor chip 2 and a resin is enlarged by making the external size of a die pad 3 smaller than that of the semiconductor chip to be mounted thereon. Moreover, a variety of semiconductor chips 2 having different external sizes can be mounted on the die pad 3 by cutting the leading ends of leads 5 to a suitable length in accordance with the external sizes of the semiconductor chips 2.

Owner:RENESAS ELECTRONICS CORP

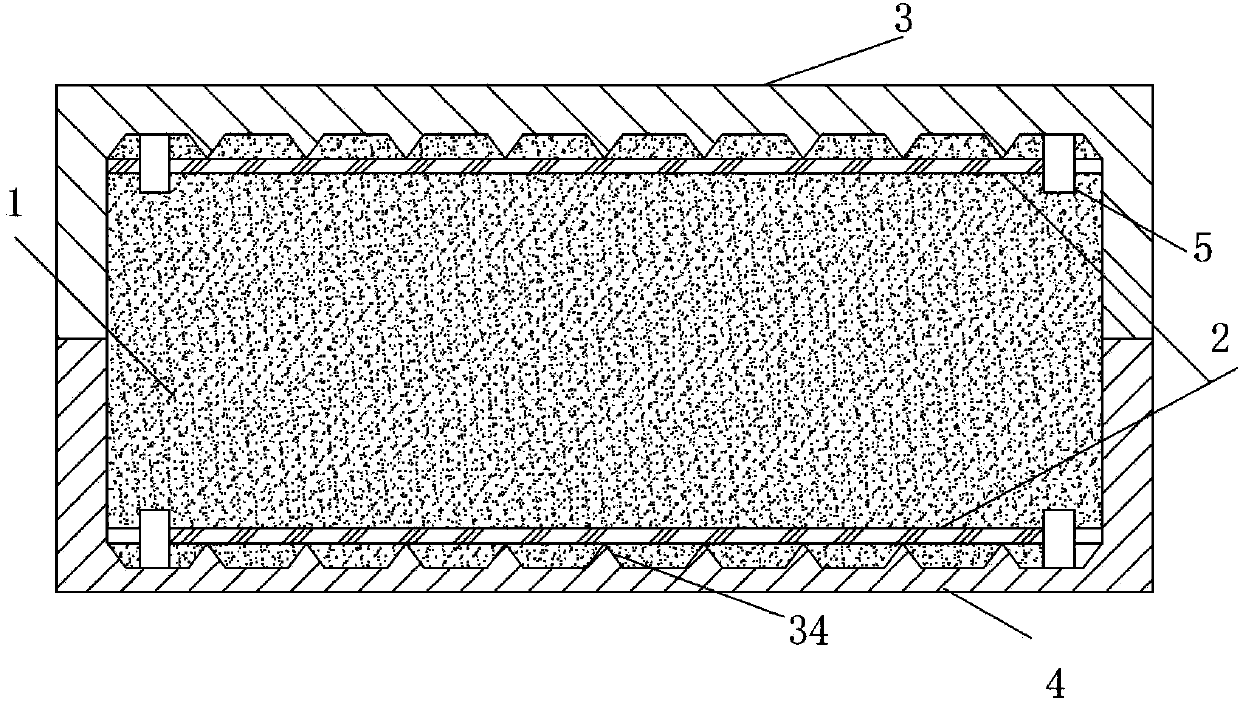

Compression molding forming method of plastic plate containing fiber net

The invention relates to a compression molding forming method of a plastic plate containing a fiber net. The compression molding forming method is characterized by fixing the fiber net on the surface of an upper die and / or a lower die of a mould pressing die and embedding the fiber net in the plastic plate by virtue of concave-convex lines on the surface of the die, so that the fiber floating condition when the fiber net is fixed on the surface of the upper die and / or the lower die by a conventional method can be avoided, so that the service life of the plastic plate is prolonged; meanwhile, the method is also capable of tensioning the fiber net during forming the plastic plate, so that the strength of the plastic plate is ensured; in addition, the fiber net is embedded in the single plastic material, but not fixed on the plastic plate by virtue of manners of adhesion and the like, so that the two sides of the fiber net are made of the same material, and thus the problem that the interface is stripped in the conventional manners of adhesion, fixation and the like is avoided; the strength of the produced plastic plate is improved; the plastic plate produced by the method can be used as a building template.

Owner:JIANGYIN DATIAN TECH SERVICE

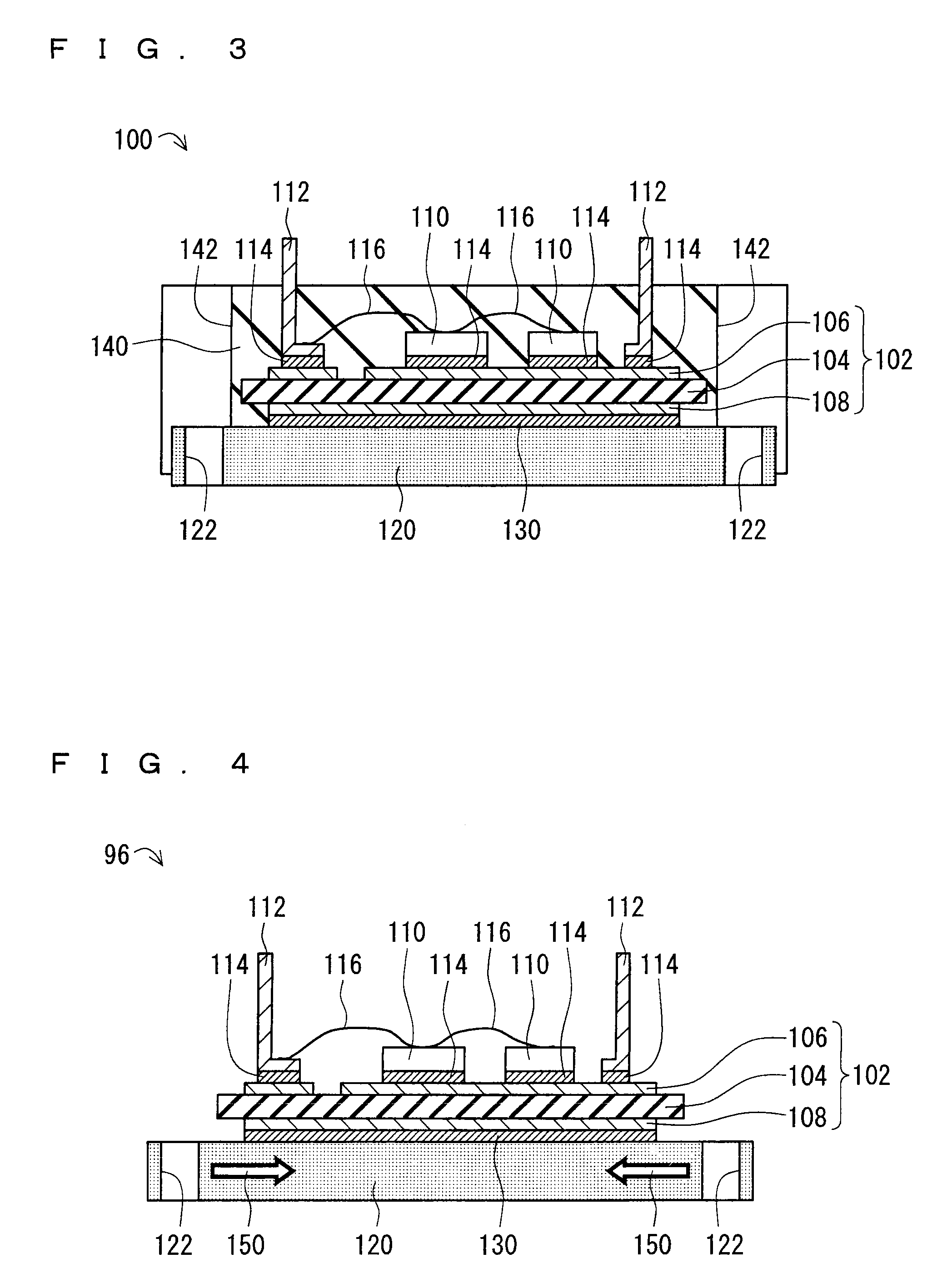

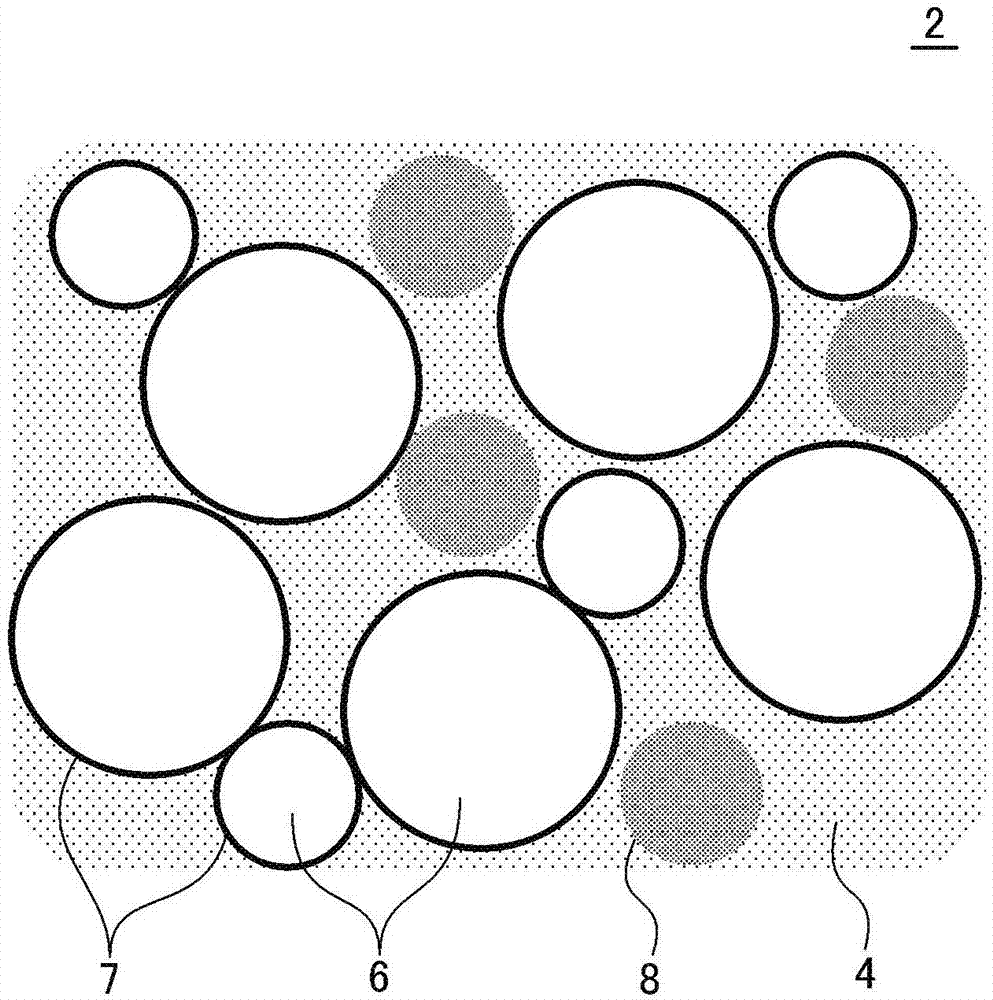

Electronic circuit package using composite magnetic sealing material

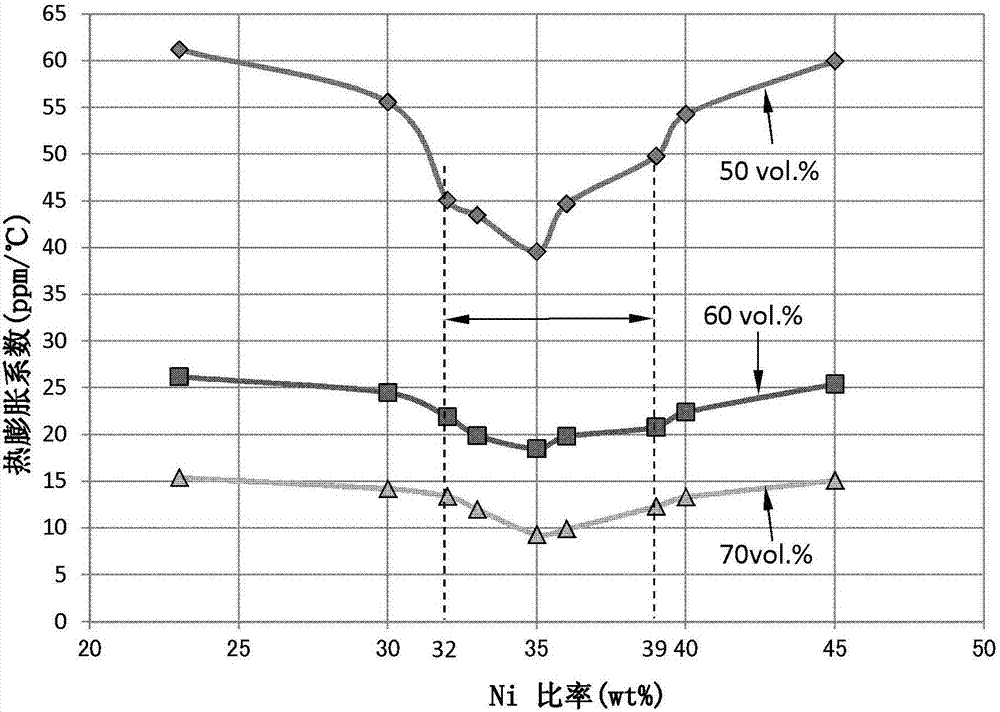

ActiveCN107424961APrevent interfacial peelingAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesThermal expansionElectronic component

The invention provides an electronic circuit package using a composite magnetic sealing material as a mold material. Disclosed herein is an electronic circuit package includes a substrate, an electronic component mounted on a surface of the substrate, and a magnetic mold resin covering the surface of the substrate so as to embed therein the electronic component. The magnetic mold resin includes a resin material and a filler blended in the resin material in a blended ratio of 30 vol. % or more to 85 vol. % or less. The filler includes a magnetic filler containing Fe and 32 wt. % or more and 39 wt. % or less of a metal material contained mainly of Ni, thereby a thermal expansion coefficient of the magnetic mold resin is 15 ppm / DEG C. or less.

Owner:TDK CORPARATION

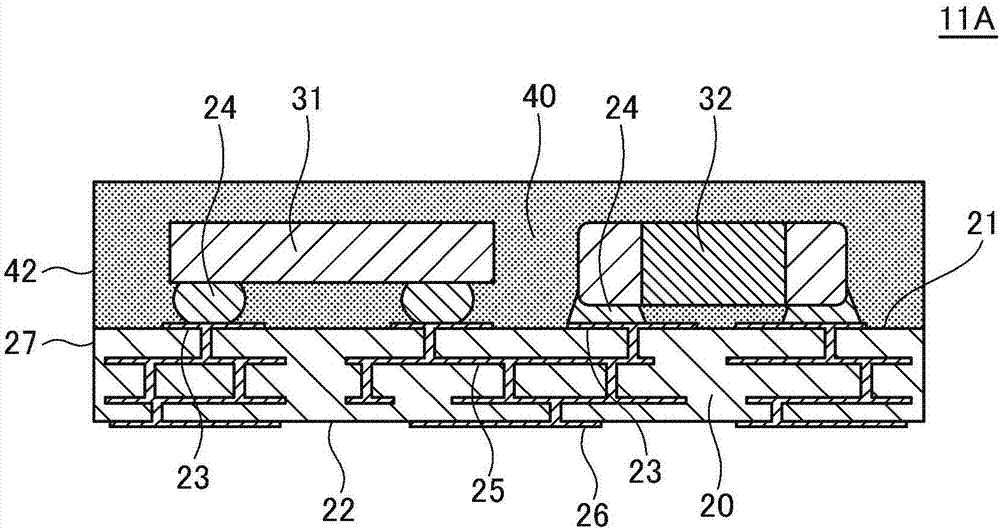

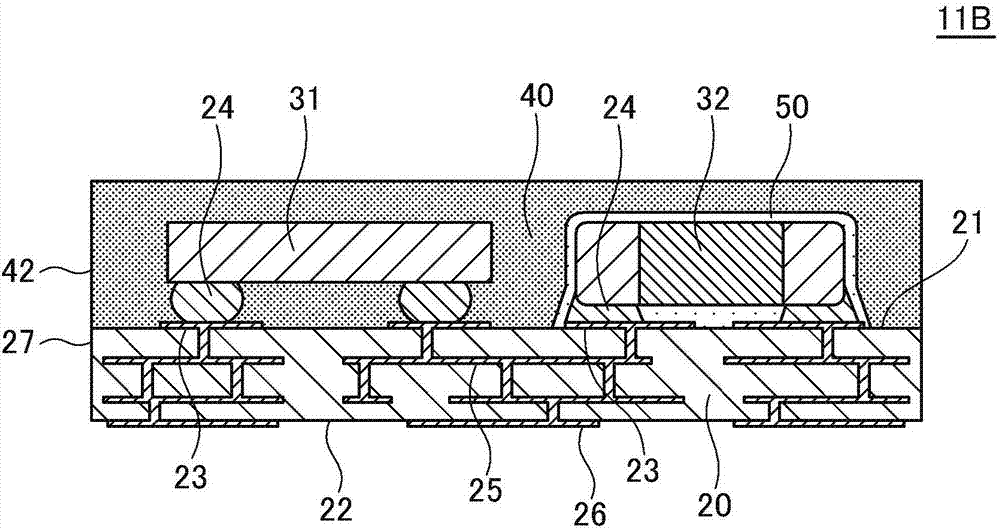

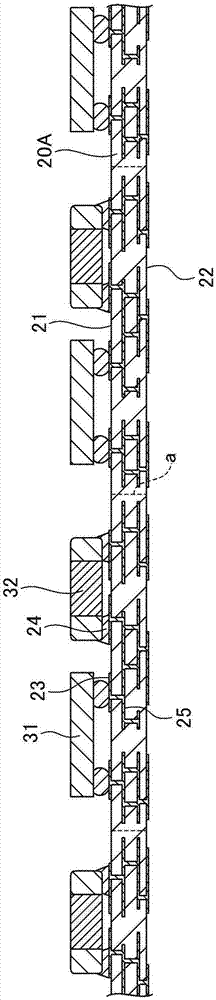

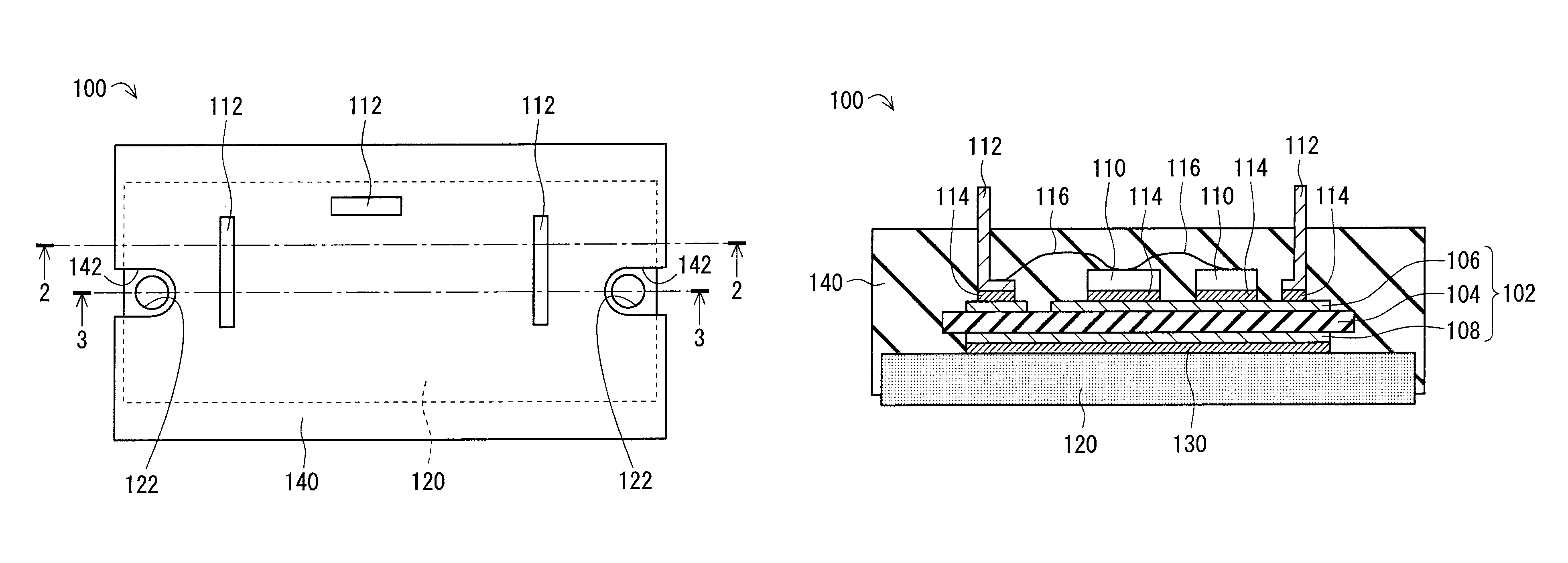

Electronic control device

ActiveUS8358514B2Prevent interfacial peelingSecure radiation performanceSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringElectrically conductive adhesive

In an electronic control device, an electrically-conductive adhesive is arranged on an outer edge portion of a first surface of a circuit board as a stress reducing portion for reducing stress of the circuit board received by a molding resin. An elastic modulus of the electrically-conductive adhesive is lower than that of the circuit board. The electrically-conductive adhesive is covered by an adhesion improving member. When peeling stress is applied to the circuit board from the molding resin, the electrically-conductive adhesive and the adhesion improving member receive the peeling stress to be deformed. Therefore, the peeling stress to the circuit board is reduced.

Owner:DENSO CORP

Injection molding method of fiber network-containing plastic board

InactiveCN104227929AAvoid tensionExtended service lifeCoatingsInjection molding machineFiber network

The invention relates to an injection molding method of a fiber network-containing plastic board. According to the injection molding method, a fiber network is fixed on the surface of a female mold and / or a male mold in a mold cavity and is embedded in the plastic board by concave-convex lines on the surface of the mold, and therefore, a phenomenon that the fiber network is only fixed on the surface of the female mold and / or the male mold to cause the fiber flotation is avoided, and the service life of the plastic board is prolonged; and besides, according to the method, the fiber network can be tensioned in a plastic board forming process, and therefore, the strength of the plastic board is ensured; in addition, the fiber network is embedded in a single plastic material and is fixed together with the plastic board without bonding and the like, so that two sides of the fiber network are made of the same material, the interface stripping problem in the traditional bonding and fixing mode is avoided, and the strength of the plastic board is improved; and the plastic board produced by the method can be used as a building template and the like.

Owner:JIANGYIN DATIAN TECH SERVICE

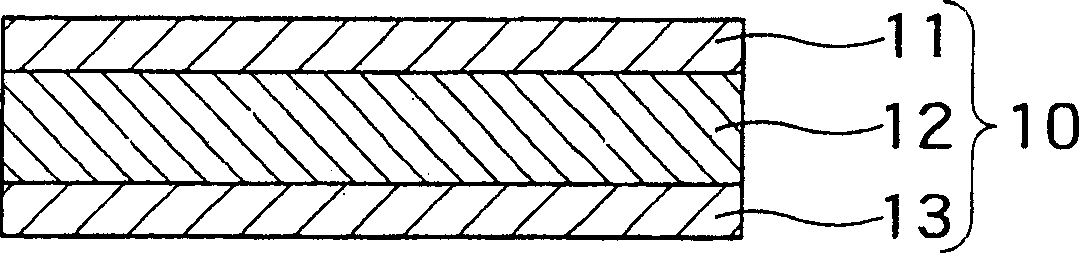

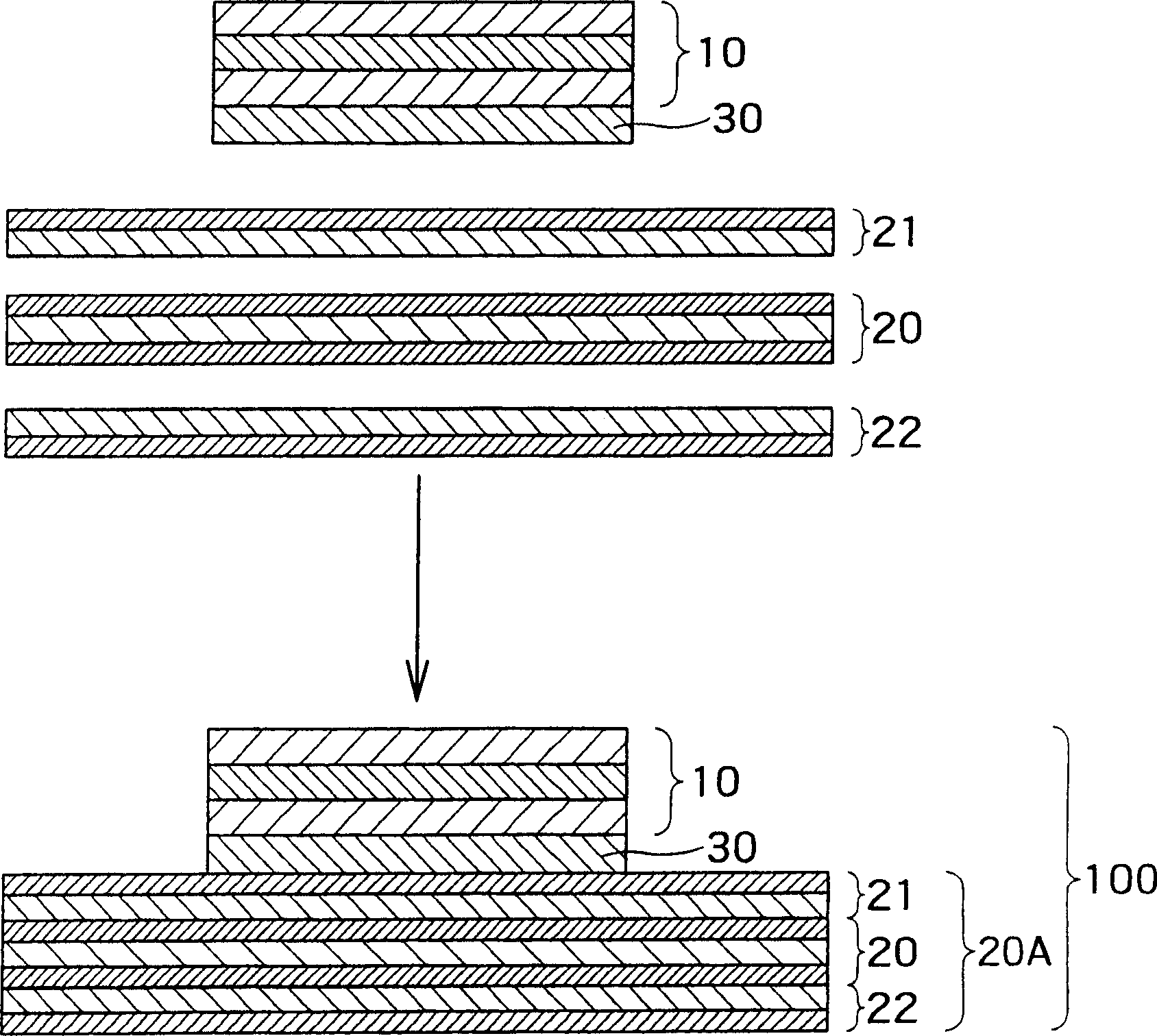

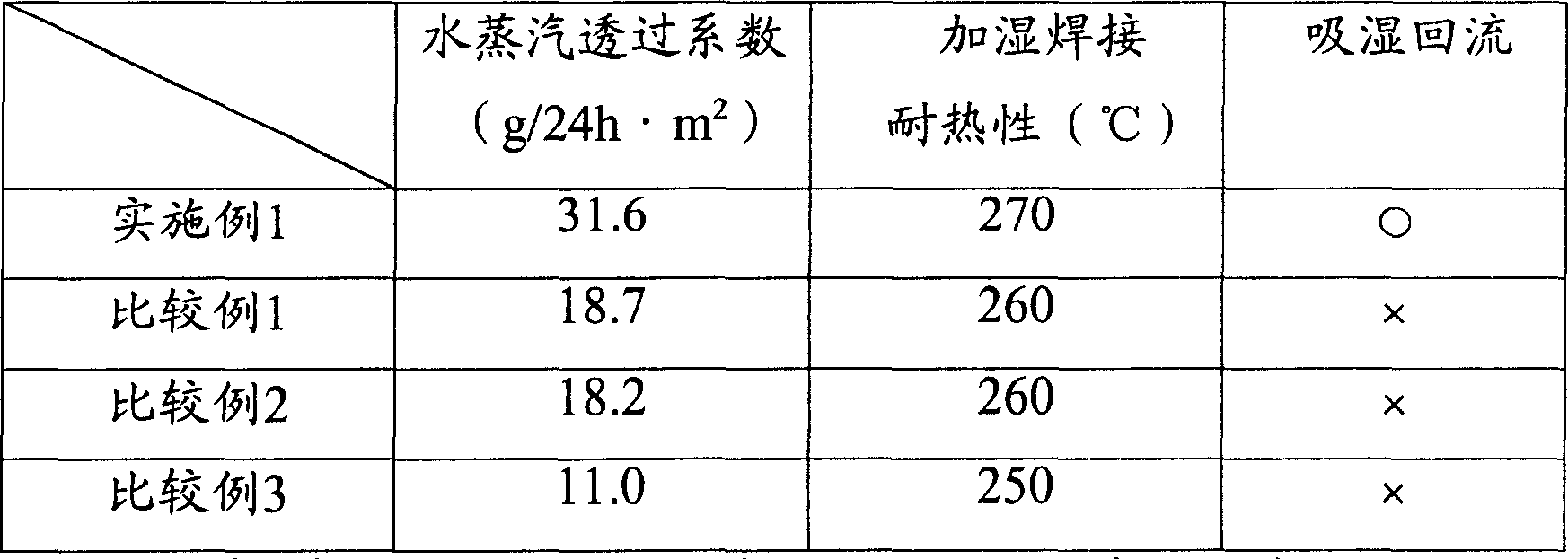

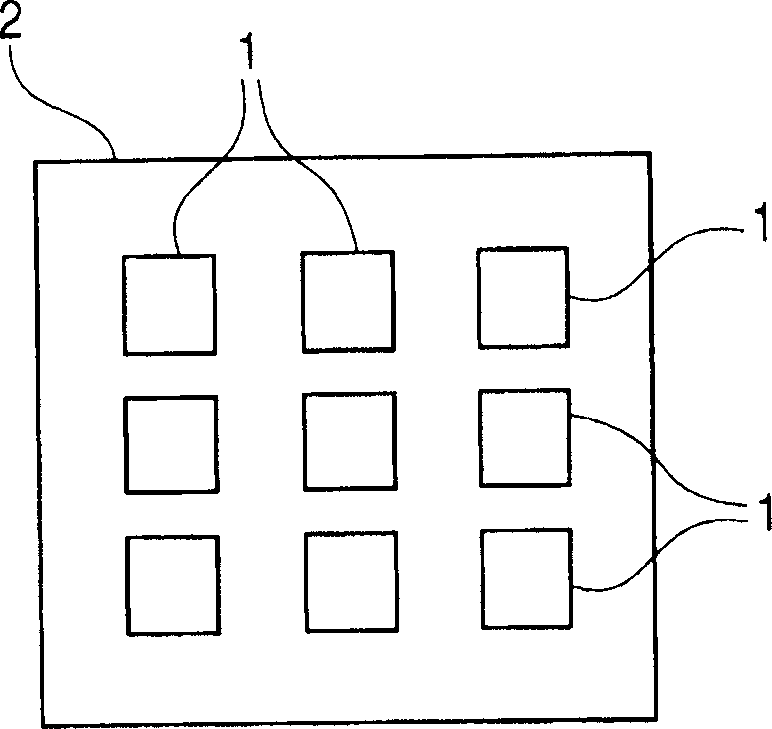

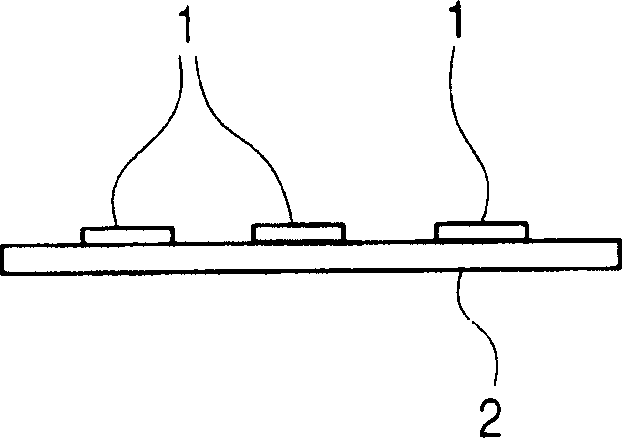

Reinforced film for flexible printing circuit board

InactiveCN1897788APrevent interfacial peelingPrinted circuit assemblingPrinted circuit detailsFlexible electronicsPrinted circuit board

Owner:NIPPON MEKTRON LTD

Separation-resistant gas-barrier laminate

InactiveUS20110123744A1Prevent peelingPrevent interfacial peelingSynthetic resin layered productsRecord information storagePolyester resinSurface roughening

In a gas-barrier laminate having a layer structure of aromatic polyester resin / polyglycolic acid resin / aromatic polyester resin, a small amount of an aromatic polyester resin polymerized with a germanium compound (catalyst) is blended to the polyglycolic acid resin forming the core layer, thereby surface-roughening the polyglycolic acid resin layer. As a result, the peeling resistance between the polyglycolic acid resin / aromatic polyester resin layers is practically improved while maintaining a good gas-barrier property.

Owner:KUREHA KAGAKU KOGYO KK

Light emitting device

ActiveUS8525208B2Improve adhesionPrevent interfacial peelingSemiconductor/solid-state device detailsSolid-state devicesLead frameMechanical engineering

A light emitting device has a package having an opening provided with a side surface and a bottom surface, and a lead frame exposed to the bottom surface. The lead frame includes a reflection portion bent on the side surface, and a portion of an inner wall surface of the reflection portion is positioned in an inner portion of the package. A light emitting device has a package having a recessed portion on a front surface, a lead frame exposed to a bottom surface of the recessed portion, a light emitting element disposed on the lead frame, and a sealing resin filled into the recessed portion. The lead frame includes a bent portion bent towards the front surface of the package in the recessed portion, and a projecting portion bent to project from the package towards an outer portion, and disposed on a face opposed to the front surface.

Owner:NICHIA CORP

Metal-supported cell

ActiveCN107534164AExcellent adhesionPrevent interfacial peelingCell electrodesFinal product manufactureGadolinium-doped ceriaCerium(IV) oxide

This metal-supported cell comprises a laminate wherein a fuel electrode layer and a solid electrolyte layer are sequentially arranged in this order on a front surface of a metal support that is provided with a pore continuing from the front surface to the back surface thereof. The solid electrolyte layer covers all parts of the surface of the fuel electrode layer, said parts being not in contact with the metal support. The peripheral part of the solid electrolyte layer is in contact with the front surface of the metal support. The metal support has a metal oxide layer having a thickness of 1-5[mu]m on the front surface of the metal support. The fuel electrode layer contains, as conductive components, NiO and Ni in such amounts that the molar ratio NiO / (Ni + NiO) is 45% or more, while containing, as an ion-conducting component, gadolinium-doped ceria. The solid electrolyte layer mainly contains scandia-stabilized zirconia, while containing 0.1-10.0 mol of Bi atoms per 100 mol of Zr atoms and having a cross-sectional void fraction of 5.0% or less.

Owner:HONDA MOTOR CO LTD

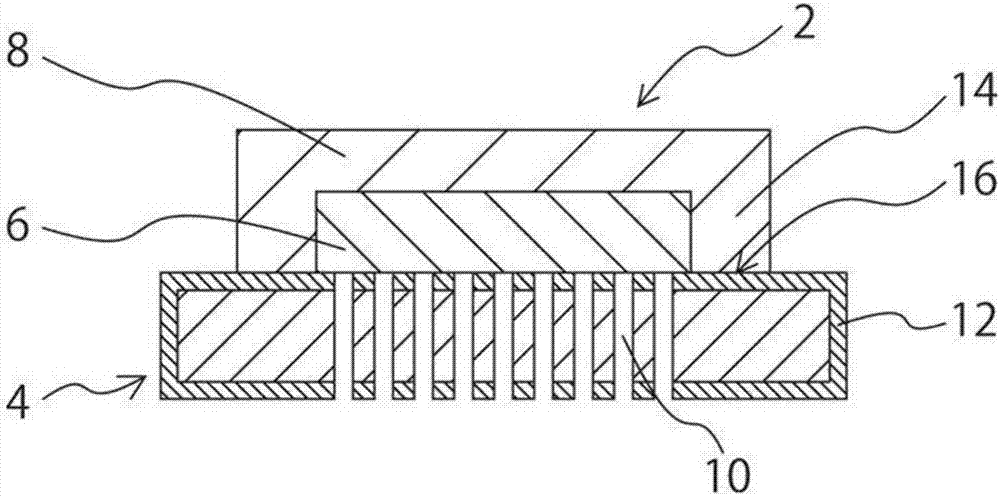

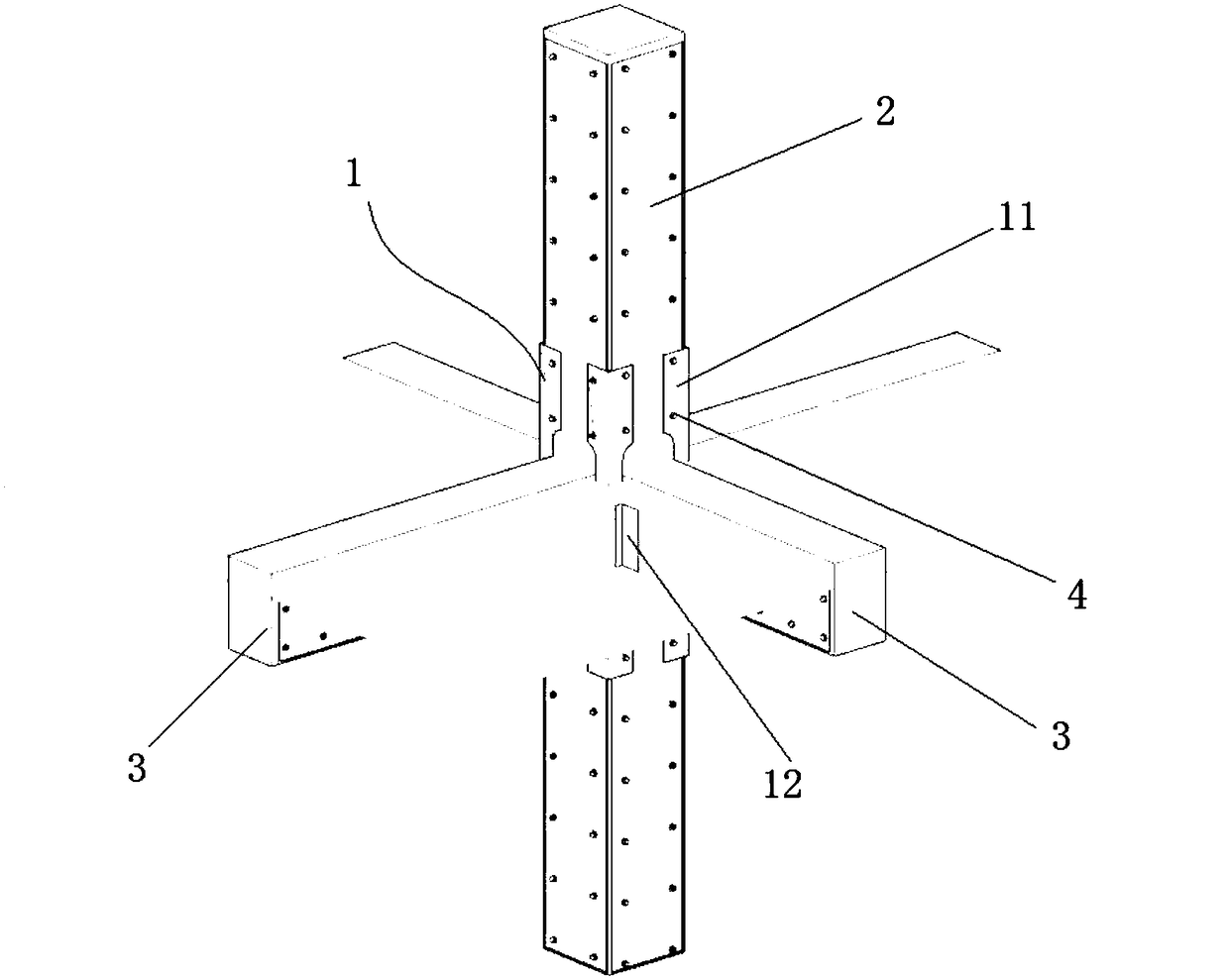

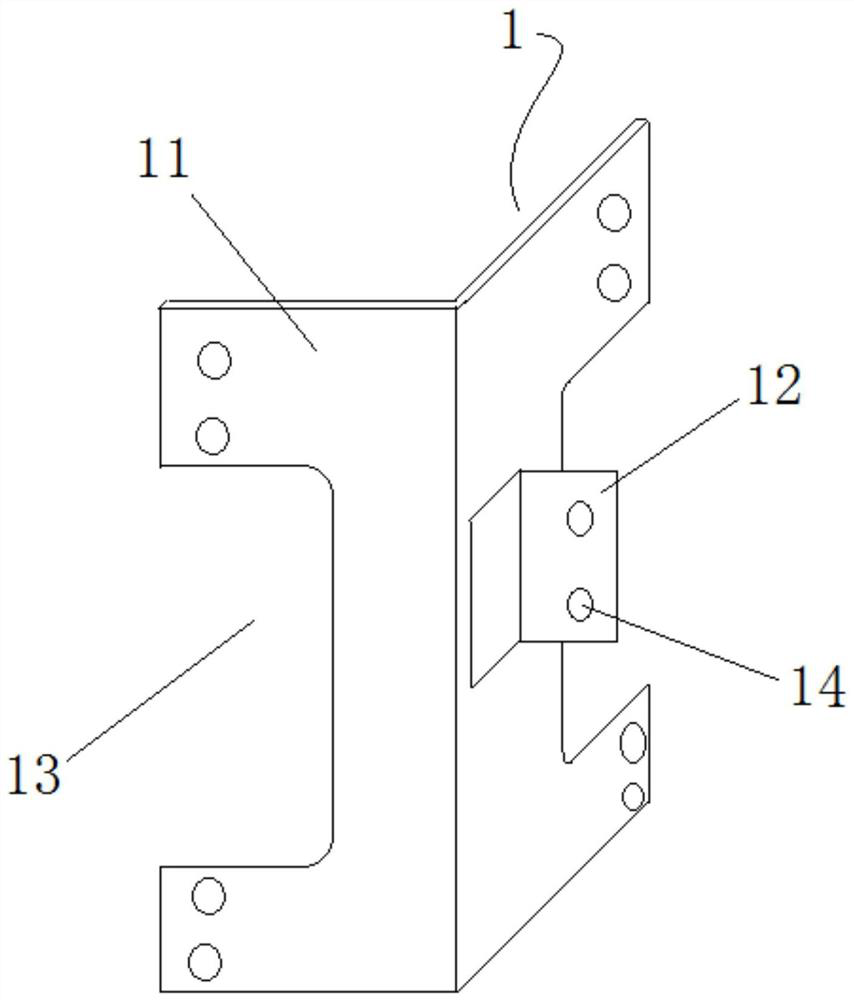

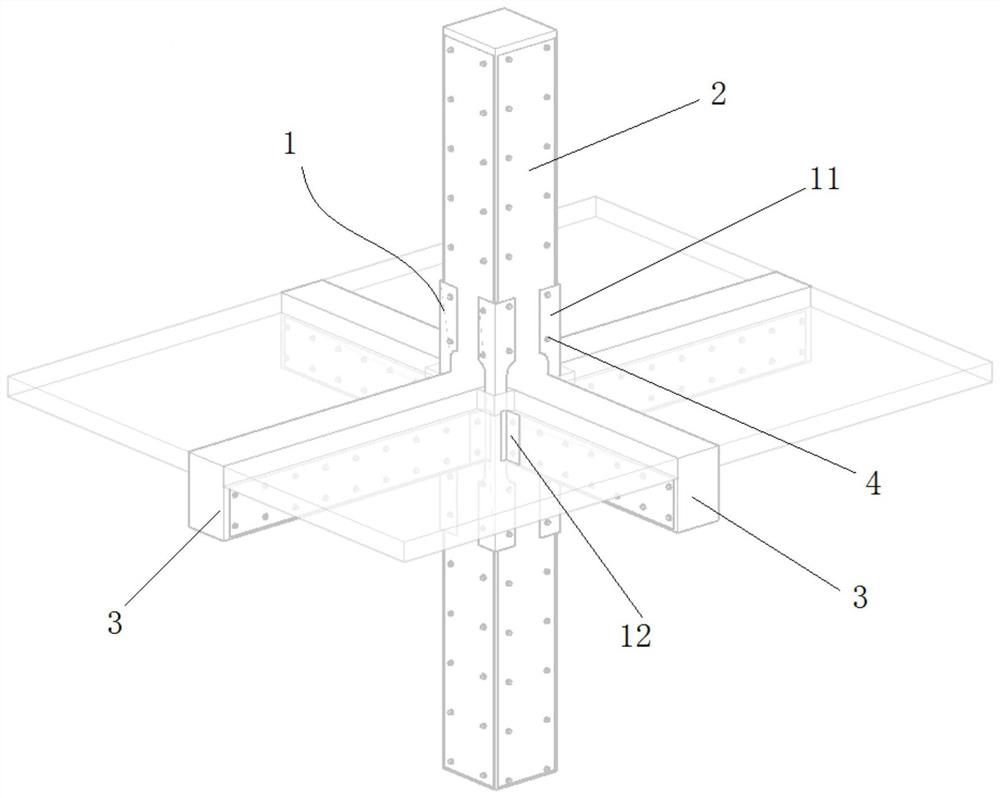

Externally-wrapped anchor steel reinforcement structure for concrete beam and column joint

ActiveCN108643602AAvoid peel damageSolve the problem of transferring weak points to nodesBuilding repairsFloor slabSheet steel

The invention discloses an externally-wrapped anchor steel reinforcement structure for a concrete beam and a column joint. The externally-wrapped anchor steel reinforcement structure is composed of penetration steel angles, beam side steel angles, beam side steel plates and column side steel plates, wherein the penetration steel angles, the beam side steel angles, the beam side steel plates and the column side steel plates are connected in a planting bar type post-installed fastening mode. The penetration steel angles penetrate through floors and are connected with the column side steel plates, the beam side steel plates are connected with the penetration steel angles by the beam side steel angle, and therefore a complete set of reinforcement scheme with reasonable force transmission is formed. When the bearing capacity of beams and columns is improved, the problem that a core area of the joint is relatively weak caused by beam and column reinforcement is solved, and brittle shear failure in the core area is avoided; and internal force transmitted to the core area of the joint through the penetration steel angles is evenly distributed onto bolts and steel plates, so that shearing resistance and energy dissipation performance of the core area are greatly improved.

Owner:TONGJI UNIV

Epoxy resin composition for semiconductor encapsulation and semiconductor device using the same

InactiveCN1696169APrevent interfacial peelingImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesEpoxySemiconductor

PROBLEM TO BE SOLVED: To provide an epoxy resin composition for sealing a semiconductor excellent in fillability and void resistance, for example, in a flip chip package and capable of suppressing generation of warpage.

Owner:NITTO DENKO CORP

Epoxy resin composition for semiconductor encapsulation and semiconductor device using the same

InactiveCN100391995CPrevent interfacial peelingImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesEpoxySemiconductor

PROBLEM TO BE SOLVED: To provide an epoxy resin composition for sealing a semiconductor excellent in fillability and void resistance, for example, in a flip chip package and capable of suppressing generation of warpage.

Owner:NITTO DENKO CORP

Semiconductor device

ActiveUS9029994B2Avoid crackingPrevent interfacial peelingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A semiconductor device includes a base plate having one main surface joined to an insulating substrate on which a semiconductor chip and the like are mounted and a transfer mold resin which is so provided as to cover the one main surface of the base plate, the insulating substrate, the semiconductor chip, and the like and expose the other main surface of the base plate. The coefficient of linear expansion of the base plate is lower than that of copper and the coefficient of linear expansion of the transfer mold resin is not higher than 16 ppm / ° C. The transfer mold resin has such scooped shapes as to expose opposed short-side centers and the vicinity of the base plate, respectively. The base plate has mounting holes in portions exposed by the scooped shapes of the transfer mold resin.

Owner:MITSUBISHI ELECTRIC CORP

Epoxy-acid anhydride coating capable of being cured and used at room temperature and preparation method of coating

InactiveCN110396354ASuit one's needsAchieve room temperature curingRubber derivative coatingsCarboxyl rubber coatingsEngineering plasticAlloy substrate

The invention discloses an epoxy-acid anhydride coating capable of being cured at room temperature and a preparation method of the coating. The formula of the coating comprises the following raw materials in parts by weight: 70-80 parts of epoxy resin, 20-30 parts of episulfide resin, a sulfydryl compound with a sulfydryl mole number of 0.10-0.30 of an epoxy mole number of the epoxy resin, an acidanhydride with an acid anhydride mole number of 0.7-1.0 of a sum of the epoxy mole number of the epoxy resin and the episulfide mole number of the episulfide resin, 20-50 parts of a toughening agent,and 100-300 parts of a solvent. According to the coating provided by the invention, the problem that an epoxy acid anhydride coating needs to be cured at a high temperature is solved, the tensile strength of a room-temperature cured coating layer is greater than 60 MPa, the binding force of the room-temperature cured coating layer on a Ly12 aluminum alloy substrate is greater than 12 MPa, the coating has good adhesive force on materials such as metals and engineering plastics, and the application range of the epoxy-acid anhydride coating is expanded.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Composite Magnetic Sealing Material

ActiveCN107452690ASmall coefficient of thermal expansionAvoid warpingSemiconductor/solid-state device detailsSolid-state devicesMetallic materialsMetal

Disclosed herein is a composite magnetic sealing material having a low thermal expansion coefficient. The composite magnetic sealing material includes a resin material and a filler blended in the resin material in a blended ratio of 30 vol. % or more to 85 vol. % or less. The filler includes a magnetic filler containing Fe and 32 wt. % or more and 39 wt. % or less of a metal material contained mainly of Ni, thereby the thermal expansion coefficient of the composite magnetic sealing material is 15 ppm / DEG C. or less.

Owner:TDK CORPARATION

metal support unit

ActiveCN107534164BExcellent adhesionPrevent interfacial peelingCell electrodesFinal product manufactureGadoliniumScandium oxide

Owner:HONDA MOTOR CO LTD

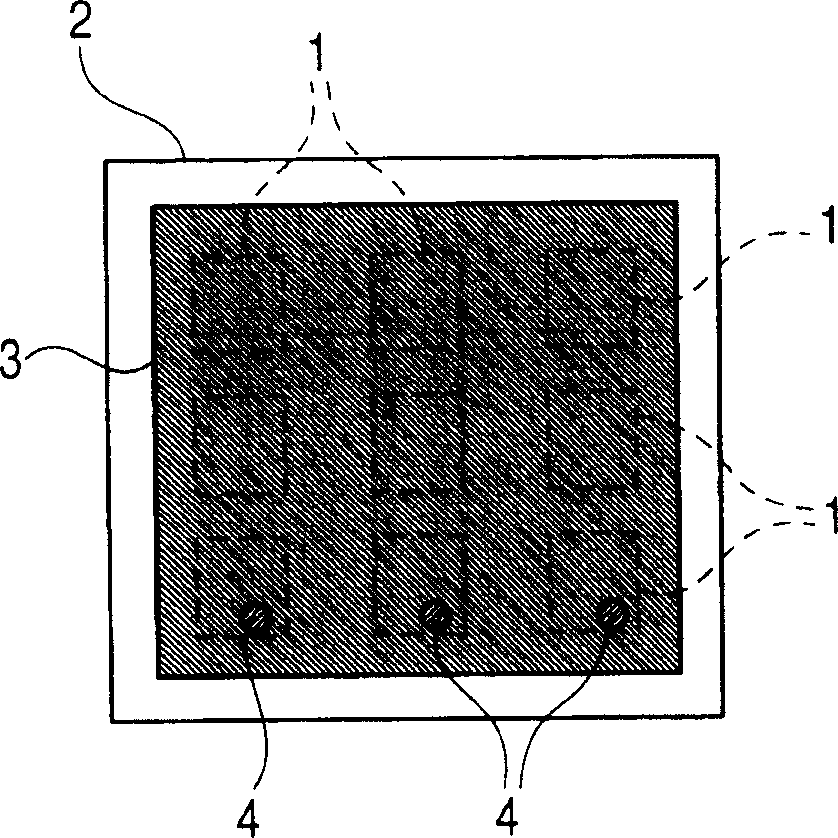

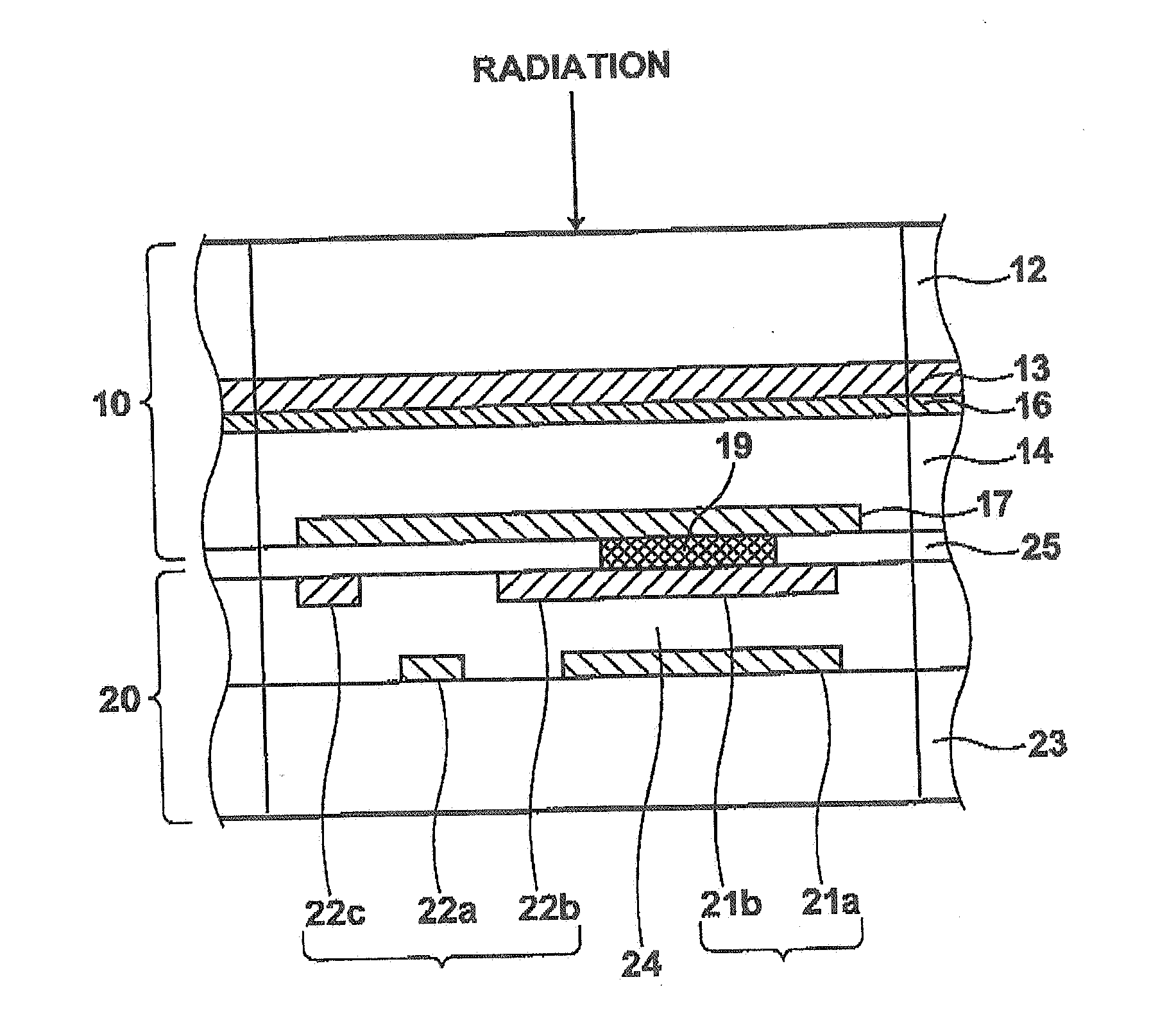

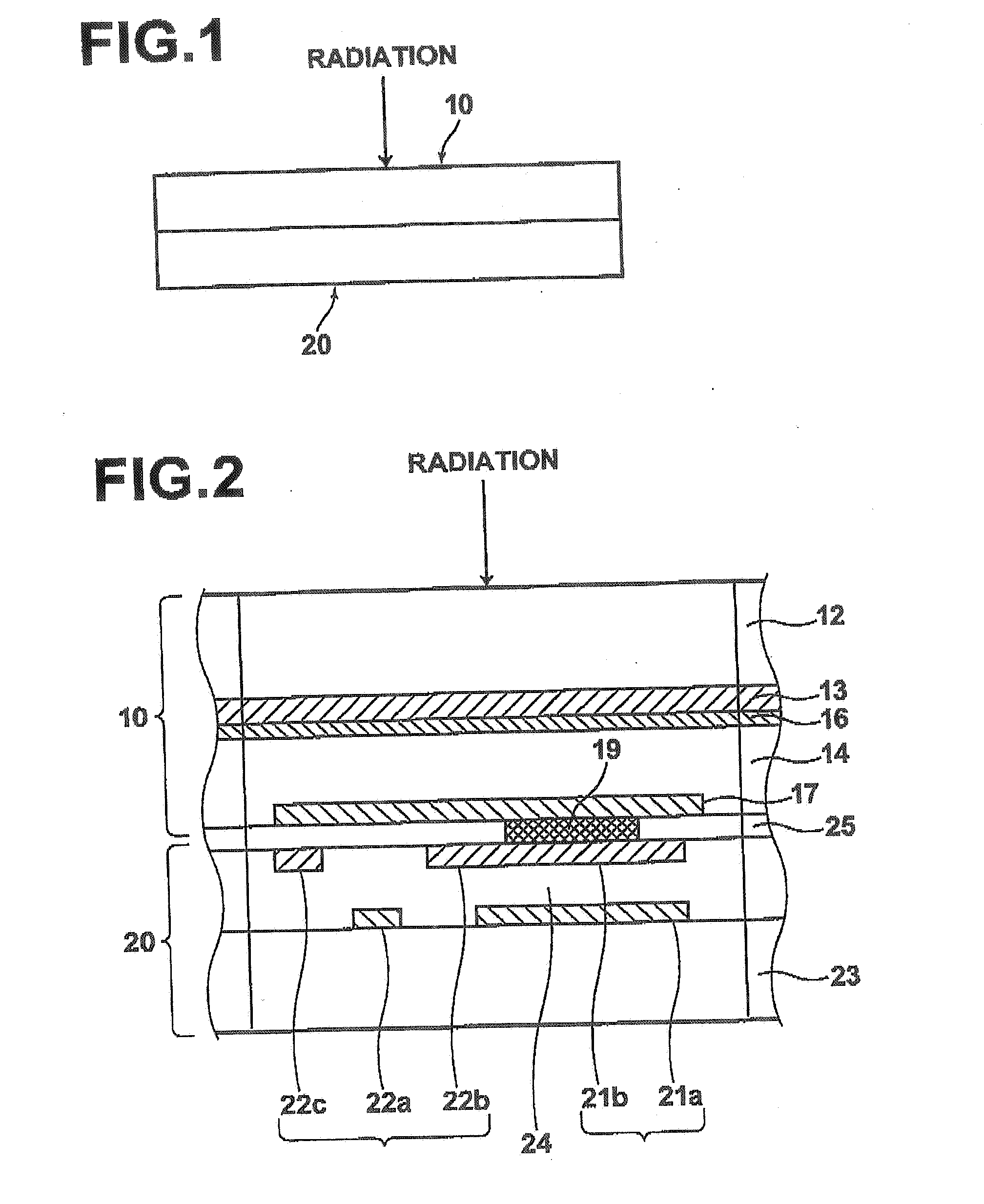

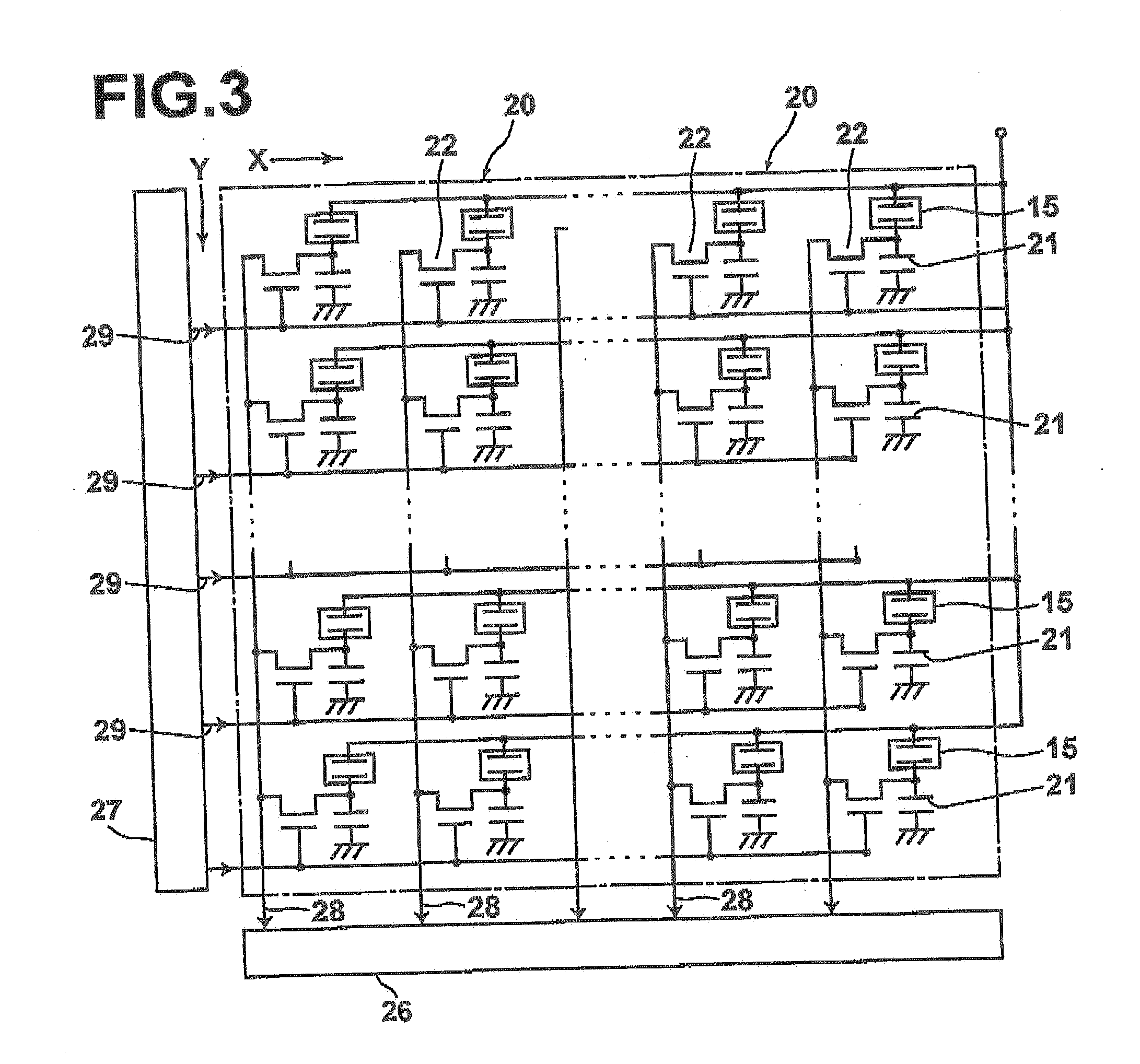

Radiation detecting system

ActiveUS20100163739A1Prevent crystallizationReduce the dark current without deteriorating the sensitivityMaterial analysis by optical meansRadiation intensity measurementThermal expansionElectric resistivity

In a radiation detecting system including an electric voltage imparting electrode through which a bias electric voltage is applied, a recording photoconductive layer which comprises a-Se and generates electric charges in response to receipt of projection of radiation, a carrier collecting electrode, a charge storing portion which stores electric charges generated in the recording photoconductive layer and a switching element for reading out charge signal stored in the charge storing portion, superposed one on another in this order, an organic resin dielectric layer which is not smaller than 0.01 μm and smaller than 1 μm in thickness, not lower than 1012 Ωcm in specific resistance and 6×10−6 to 1.5×10−4 / ° C. in thermal expansion coefficient is provided between the recording photoconductive layer and the electric voltage imparting electrode.

Owner:FUJIFILM CORP

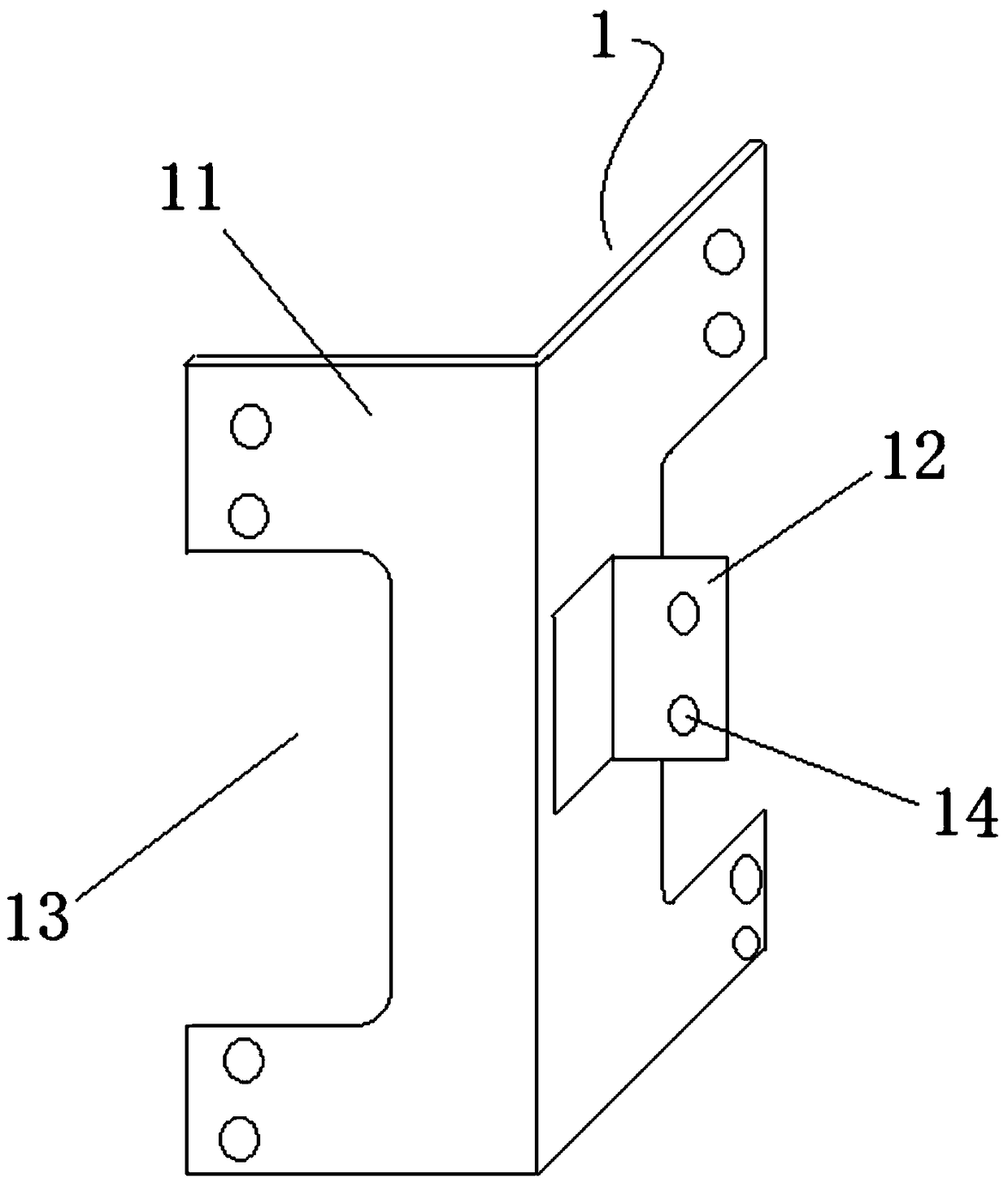

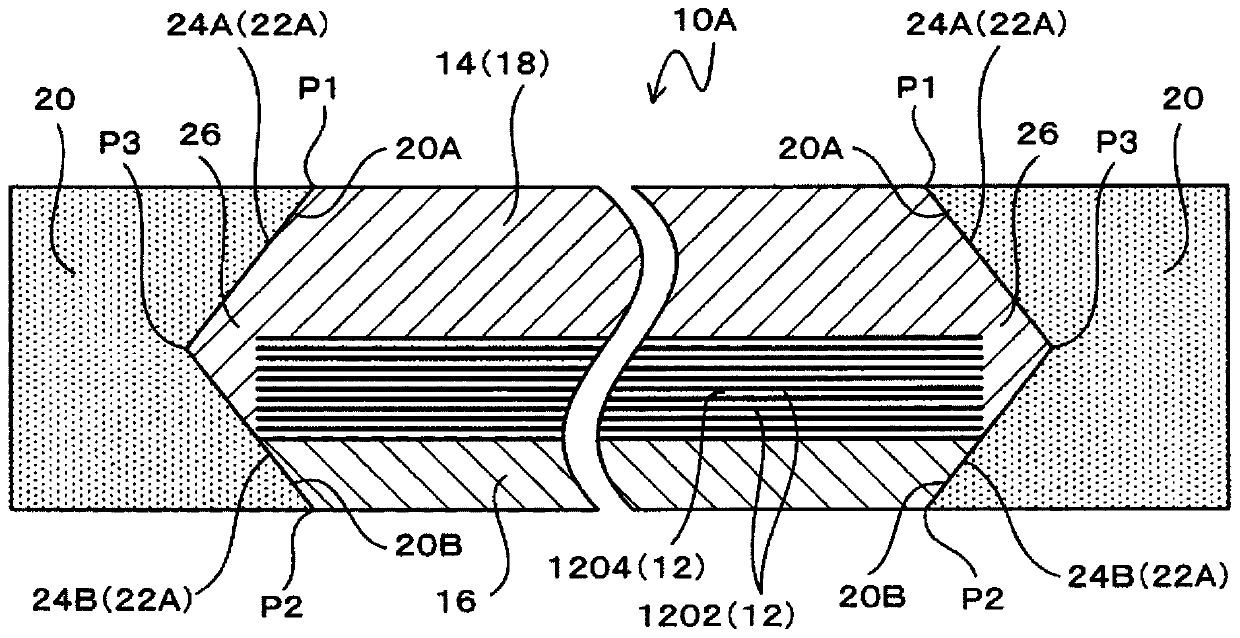

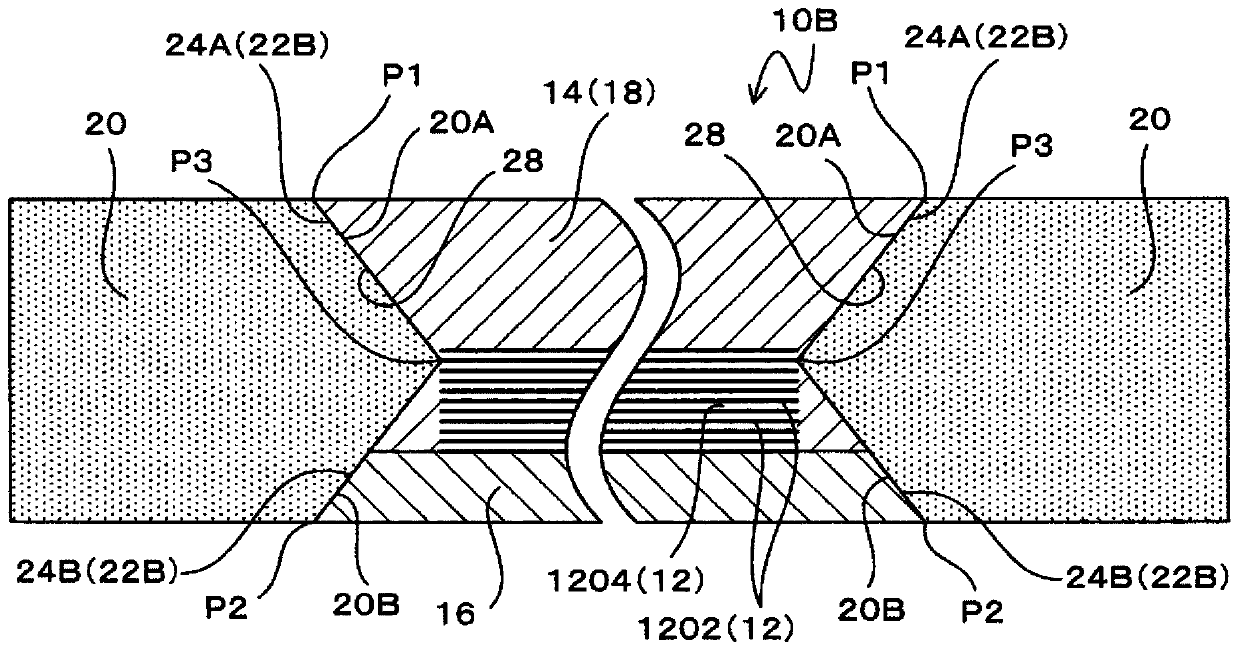

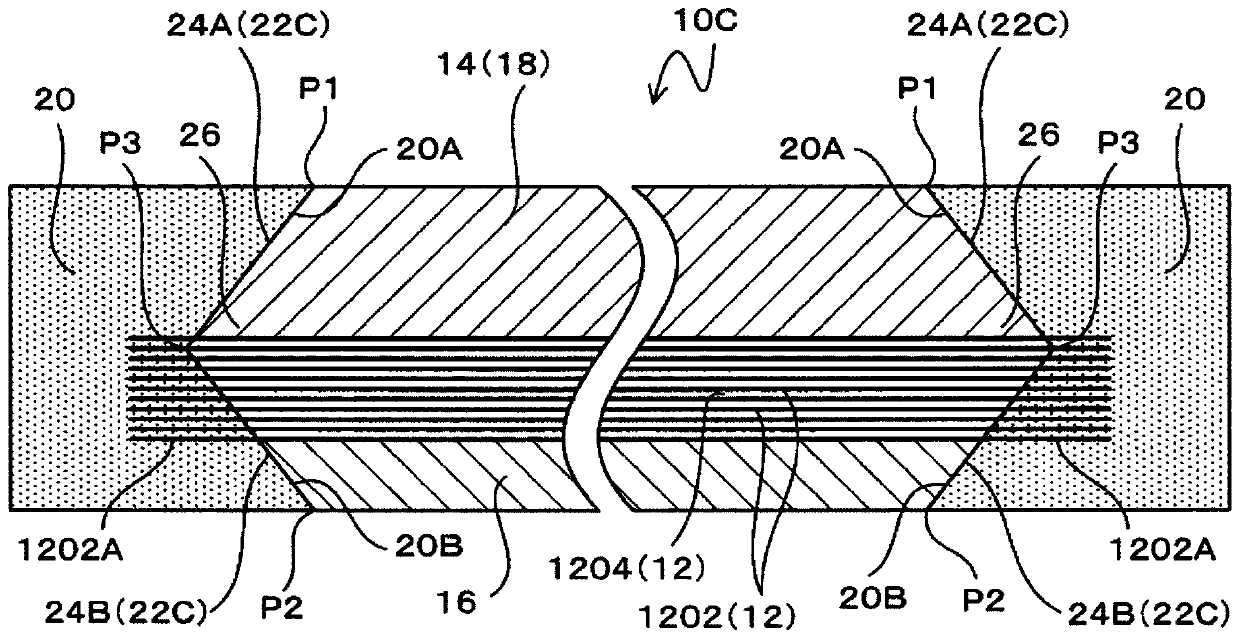

Conveyor belt

The present invention maintains the bonding strength of a flame-retardant rubber, minimizes damage caused by heat, and improves durability. In this conveyor belt, a bonding surface area-increasing section 22A is provided to a belt body 18 and is configured to include a total of two upper and lower inclined surfaces 24A, 24B that are inclined with respect to both the thickness direction and the width direction of the belt body 18 and that are oriented in opposite directions from each other. The upper inclined surface 24A is formed so that when both ends of the upper surface of an upper surfacecover rubber layer 14 in the width direction are designated as start points P1, said upper inclined surface 24A is increasingly displaced in a direction approaching the lower surface of a lower surface cover rubber layer 14 from the starting points P1 to both ends of the conveyor belt 10A in the width direction. The lower inclined surface 24B is formed so that when both ends of the lower surface of the lower surface cover rubber layer 16 in the width direction are designated as start points P2, said lower inclined surface 24B is increasingly displaced in a direction approaching the upper surface of the upper surface cover rubber layer 14 from the starting points P2 to both ends of the conveyor belt 10A in the width direction.

Owner:THE YOKOHAMA RUBBER CO LTD

An outsourcing anchor steel reinforcement structure suitable for concrete beam-column joints

ActiveCN108643602BPrevent interfacial peelingImprove ductilityBuilding repairsFloor slabConcrete beams

Owner:TONGJI UNIV

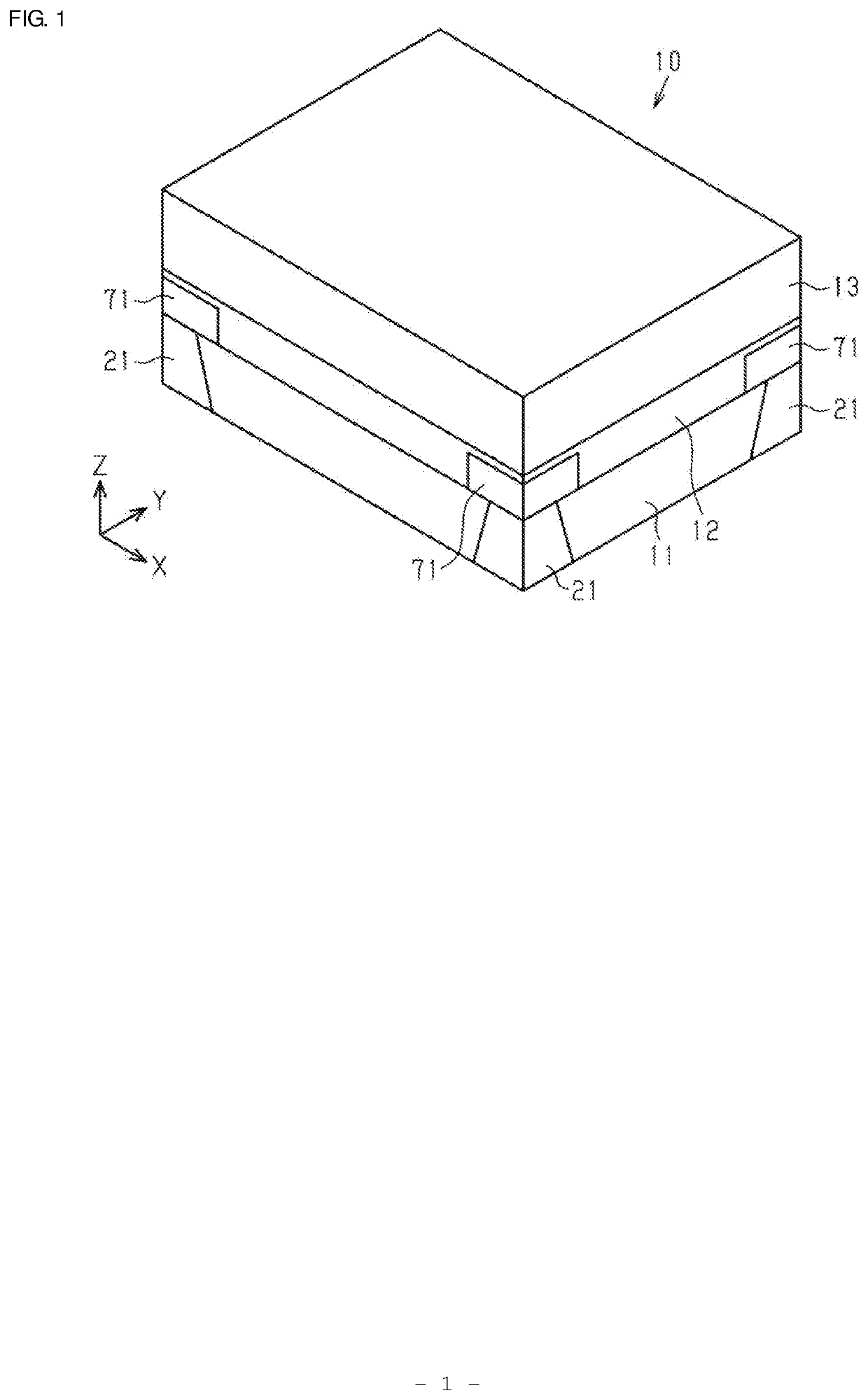

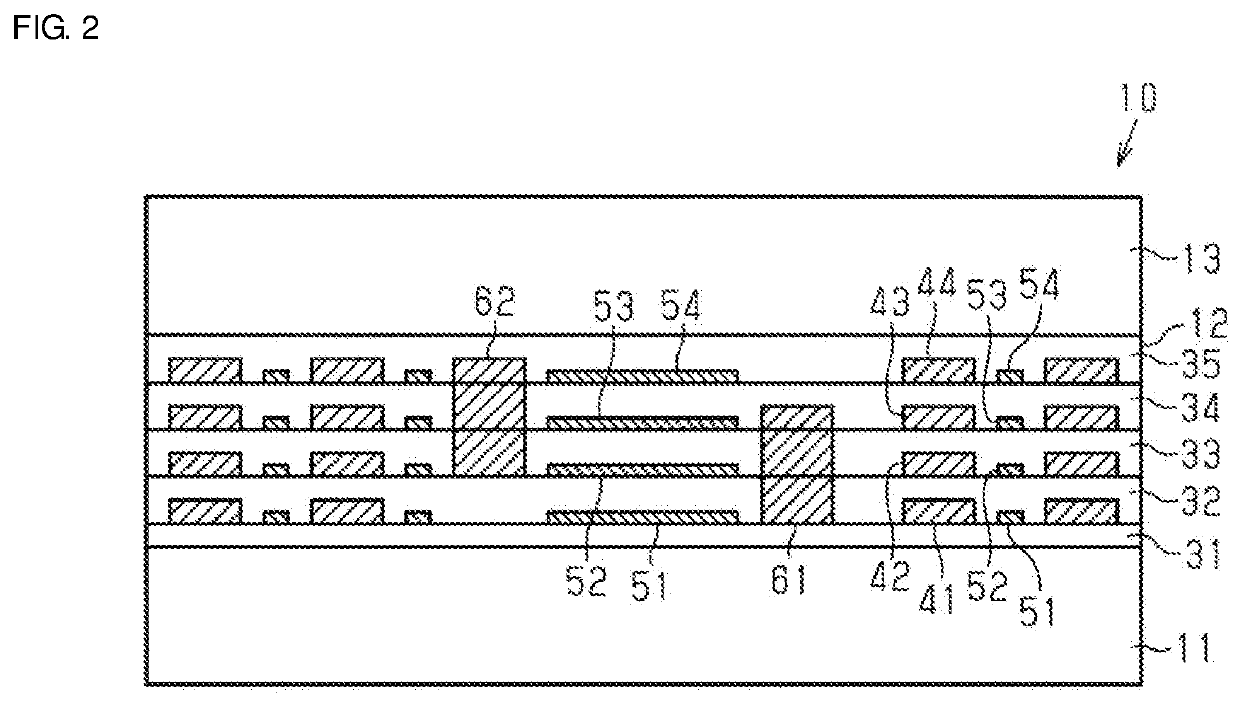

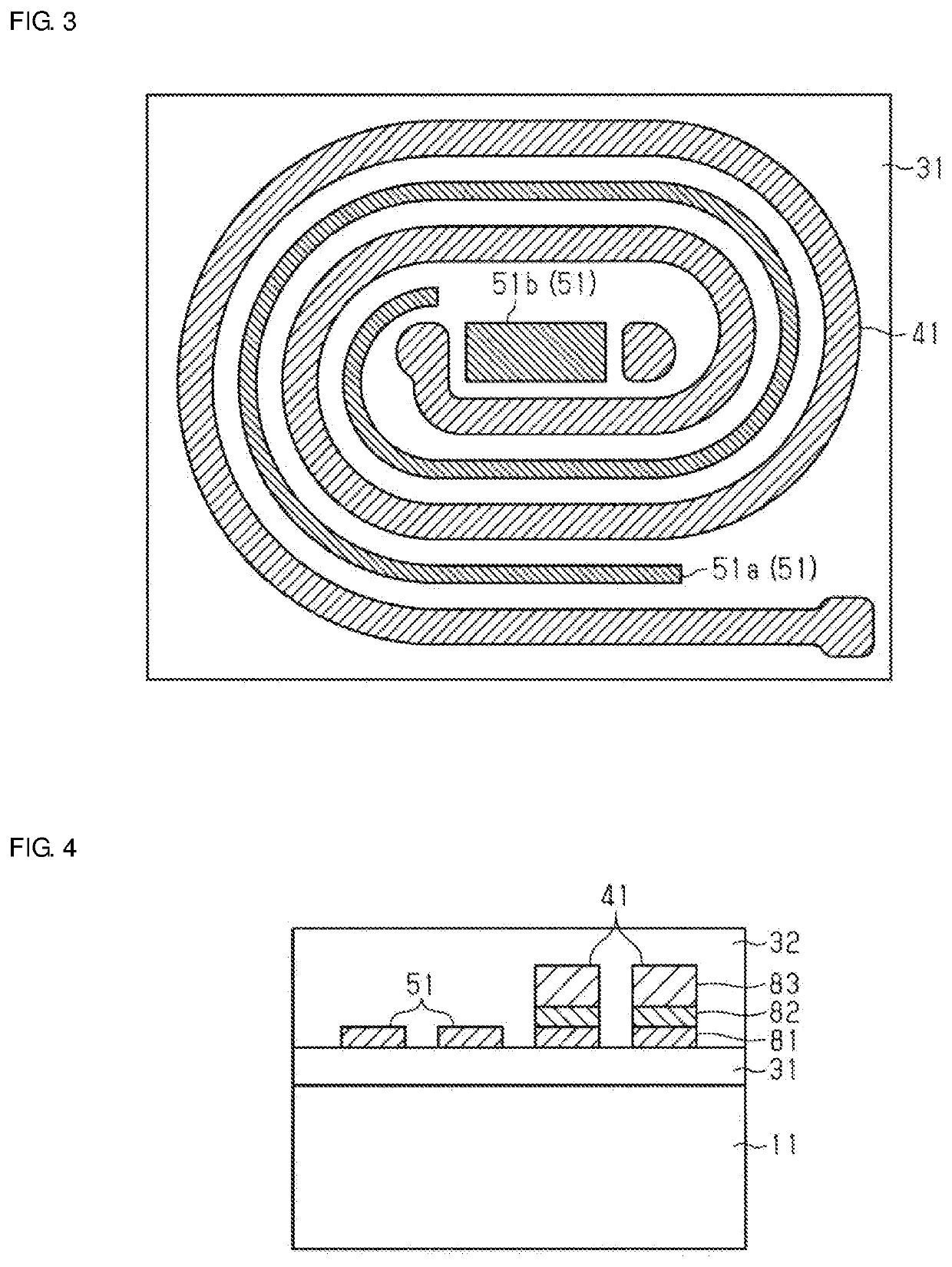

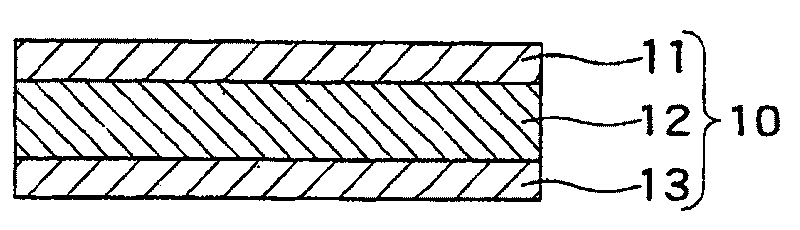

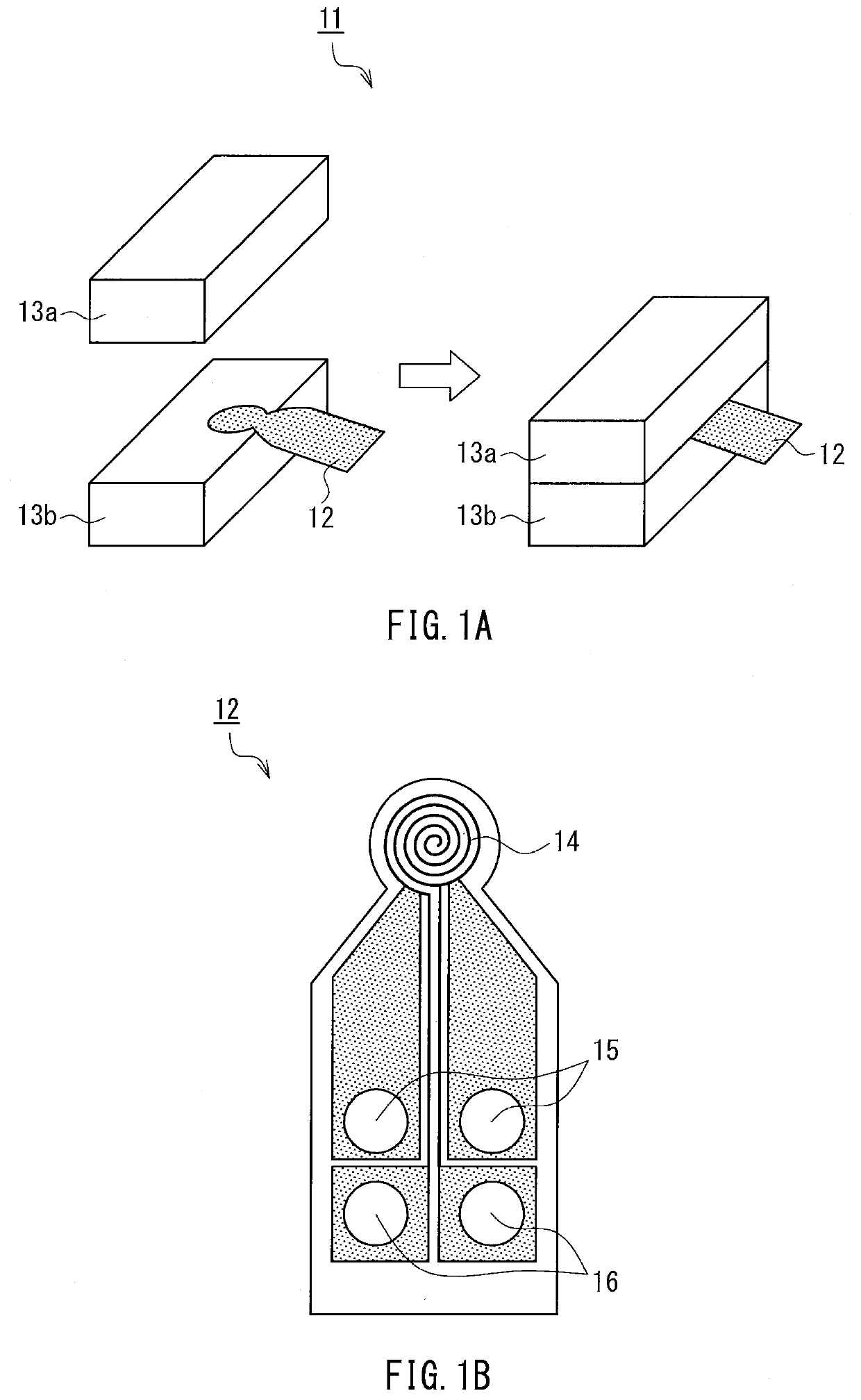

Coil component and manufacturing method for the same

ActiveUS20200043645A1Prevent interfacial peelingIncrease inductanceTransformers/inductances coils/windings/connectionsCoils manufactureInsulation layerElectrical conductor

A coil component includes a multilayer body in which a plurality of resin insulation layers is laminated, a spiral-shaped coil conductor layer disposed on main surface of one of the resin insulation layers, and a close contact layer disposed at interfaces between two of the resin insulation layers and not connected to the coil conductor layer. The close contact layer contains a metal having desired adhesion to the resin insulation layers.

Owner:MURATA MFG CO LTD

Reinforced film for flexible printing circuit board

InactiveCN1897788BPrevent interfacial peelingPrinted circuit assemblingPrinted circuit detailsFlexible electronicsPrinted circuit board

The present invention provided a reinforcing film for flexible printed circuit board for controlling interface peeling generated between the flexible printed circuit board and reinforcing film in thereflow process during mounting. The reinforcing film for flexible printed circuit board is formed of a heat-resistant resin of the layered structure including at least one bubble mixing layer.

Owner:NIPPON MEKTRON LTD

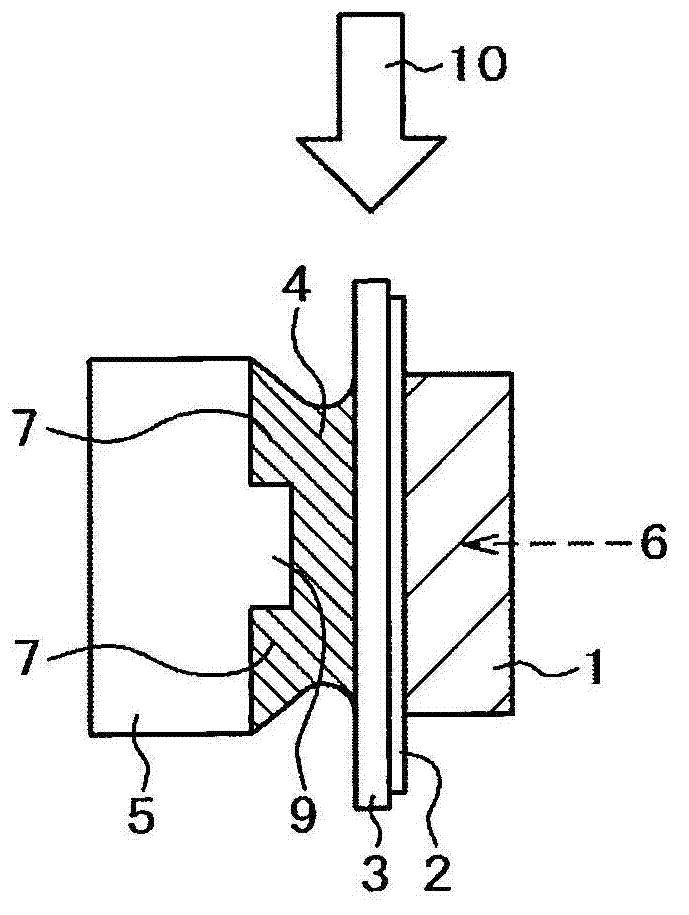

Optical pickup device

InactiveCN102810323AImprove qualityCohesive failure strength will not decreaseRecord information storageOptical beam guiding meansOptical pickupBond interface

An optical pickup device, which is capable of inhibiting peeling from a bonded interface and deviation of an optical axis from being caused even by long-term environmental variations, has a photonic device (1), a flexible printed substrate (2), a holding member (3), an optical pickup case (5) and a bonding connection (4) for bonding the holding member (3) and the optical pickup case (5) together. The adhesive enters an inside of the optical pickup case. The adhesive has a cross-sectional area on the outer surface of the optical pickup case in communication with the inside smaller than a cross-sectional area in the inside of the optical pickup case.

Owner:HITACHI MEDIA ELECTORONICS CO LTD

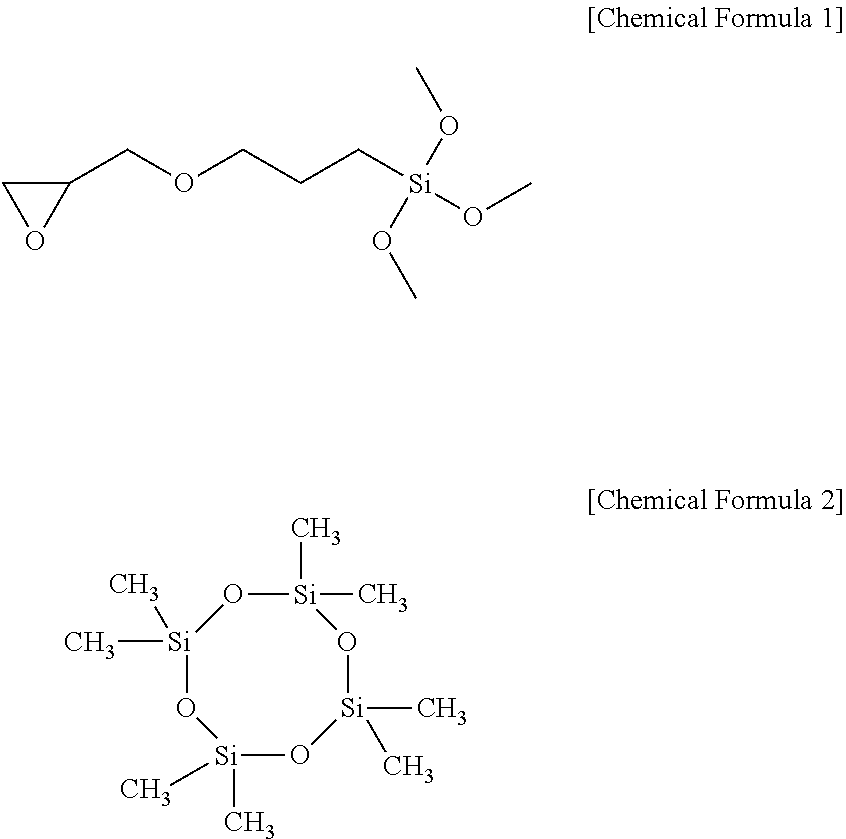

Thermally conductive composition, thermally conductive sheet and method for producing the same

PendingUS20210189188A1Increase elasticityPrevent interfacial peelingNon-macromolecular adhesive additivesHeat-exchange elementsPolymer scienceOligomer

A thermally conductive composition 26 contains a base polymer, an adhesive polymer, and thermally conductive particles. A thermal conductivity of the thermally conductive composition 26 is 0.3 W / mK or more. The base polymer is a silicone polymer. The adhesive polymer contains a methyl hydrogen polysiloxane, an epoxy group-containing alkyltrialkoxysilane, and a cyclic polysiloxane oligomer. The amount of the adhesive polymer is 5 to 35 parts by weight with respect to 100 parts by weight of the base polymer. A thermally conductive sheet of the present invention includes the thermally conductive composition in the form of a sheet. Thus, the present invention provides a thermally conductive composition that has high thermal conductive properties and excellent resilience and that can prevent interfacial peeling due to stress, a thermally conductive sheet including the thermally conductive composition, and a method for producing the thermally conductive sheet.

Owner:FUJI POLYMER INDUSTRIES CO LTD +1

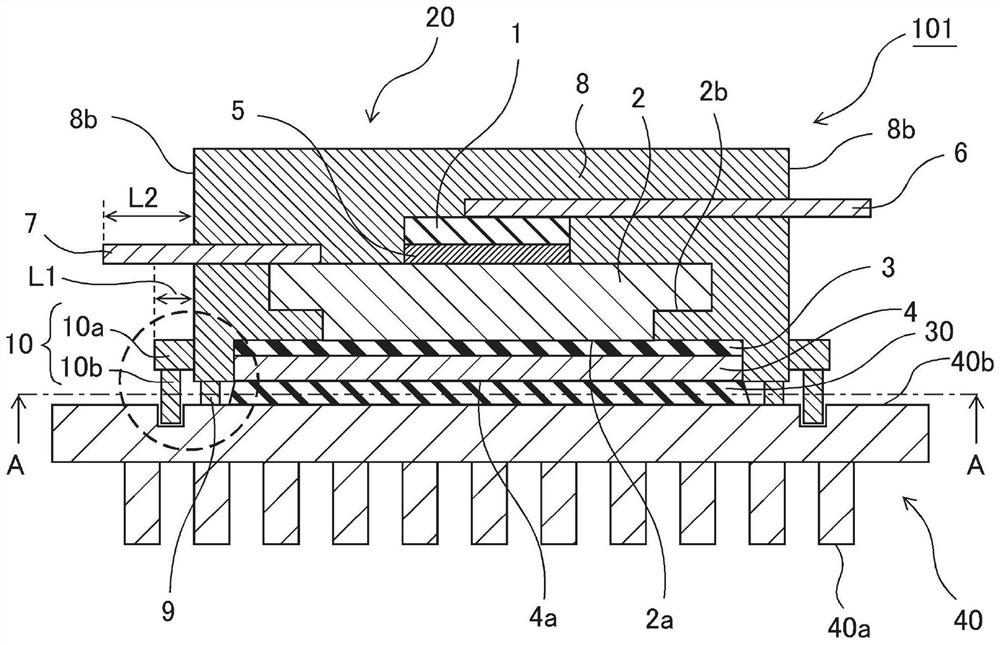

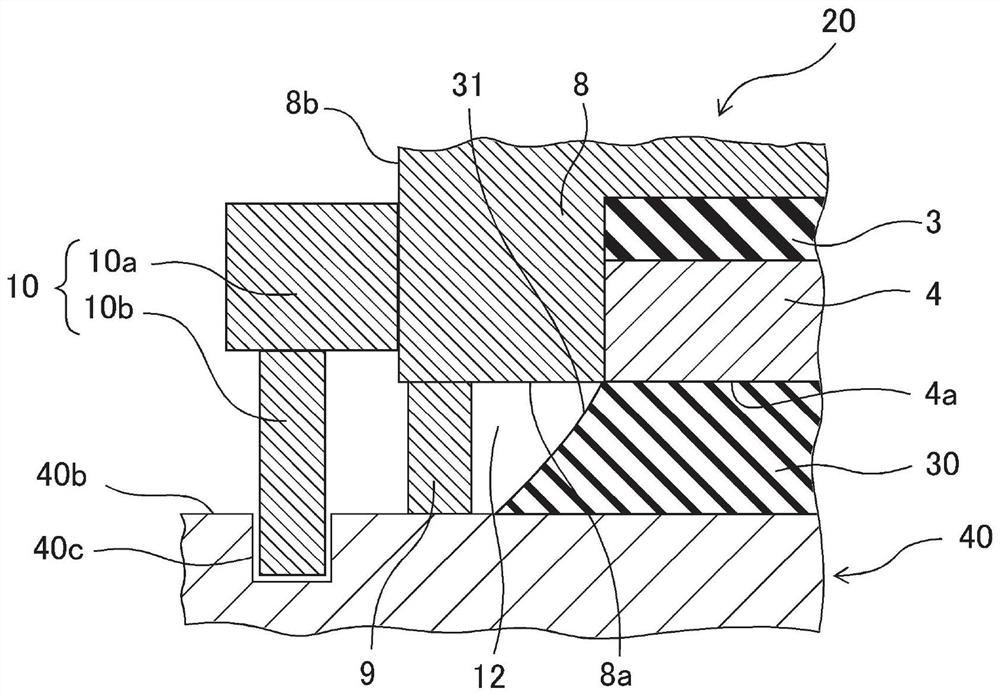

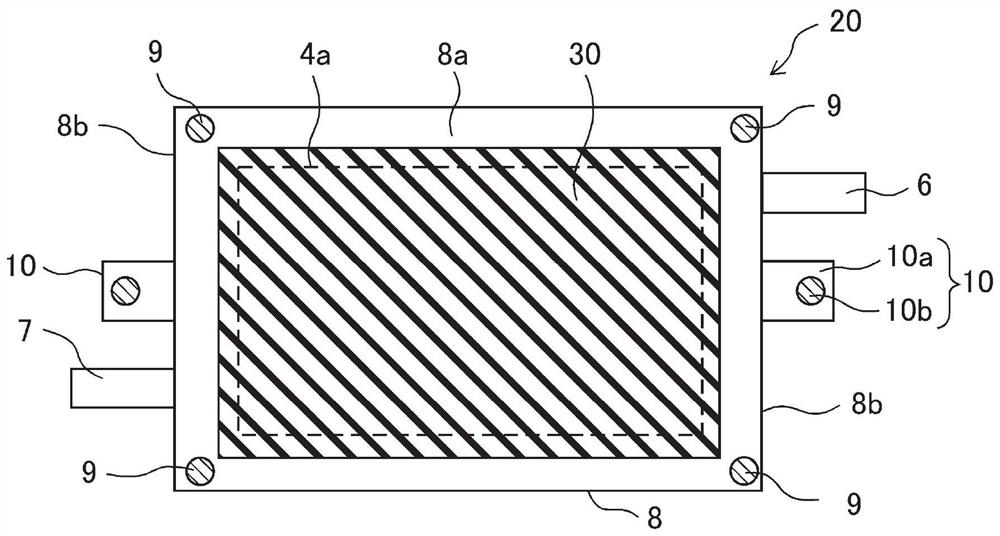

Semiconductor device

PendingCN114446899AImprove cooling effectImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering physics

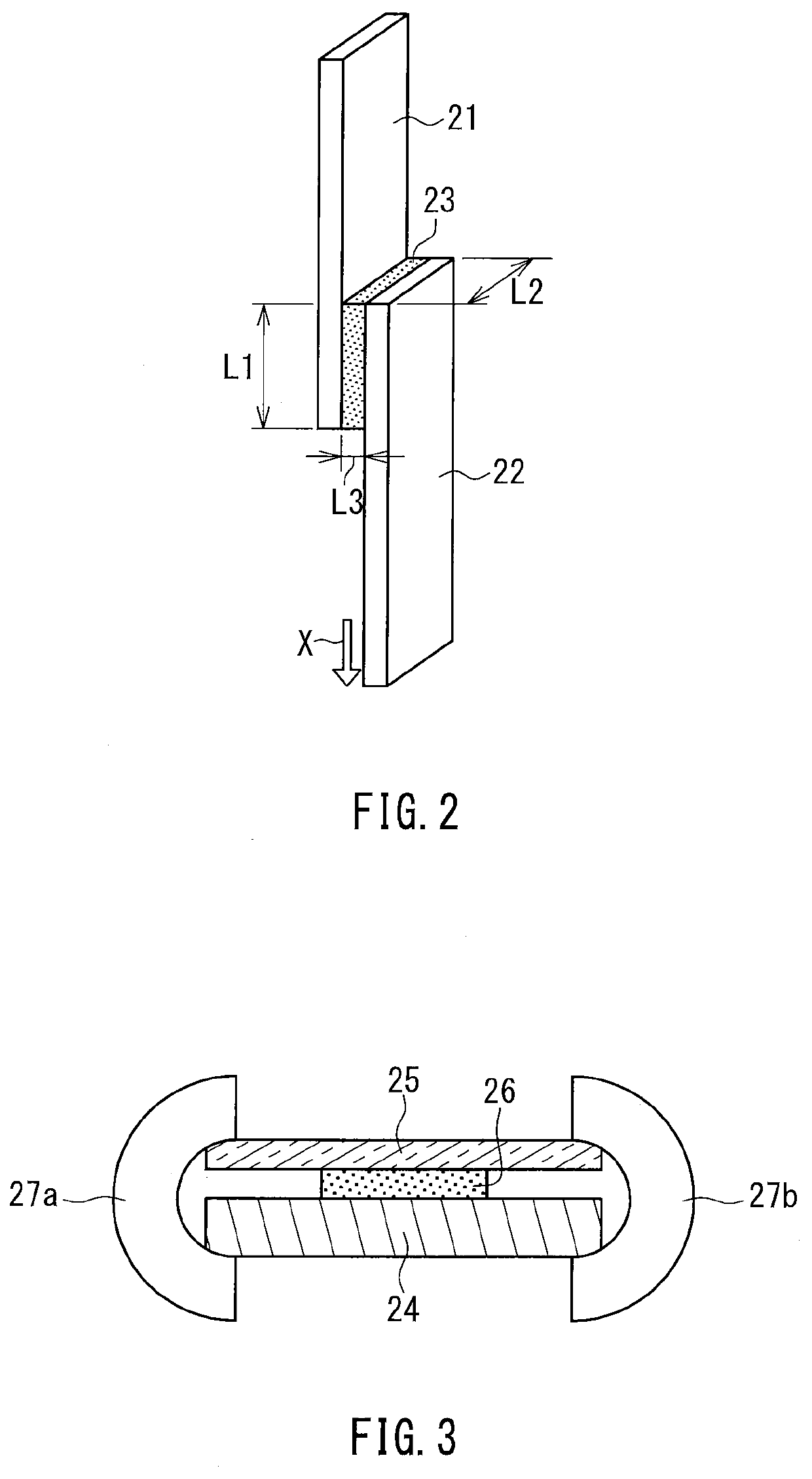

The invention provides a semiconductor device having high heat dissipation performance and reliability without enlarging the external shape of a semiconductor module. In a semiconductor device (101), a positioning protrusion (10) is formed on a side surface (8b) of a sealing resin (8) from which one end of a main electrode wiring (6, 7) protrudes. Therefore, the outer shape of the sealing resin (8) can be reduced compared with a case in which the positioning projection is formed on the bottom (8a) of the sealing resin (8). Furthermore, since the thickness-regulating protrusion (9) is provided so as to have a space (12) between the thickness-regulating protrusion (9) and the solder (30), interface peeling or cracking occurring starting from a contact portion between the thickness-regulating protrusion (9) and the solder (30) can be prevented, and the lifetime of a joint portion between the semiconductor module (20) and the cooler (40) can be ensured. Therefore, a semiconductor device (101) having high heat dissipation performance and reliability can be obtained without expanding the outer shape of the semiconductor module (20).

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com