Transmission belt

A technology of transmission belt and rubber layer, which is applied in the field of transmission belt to achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

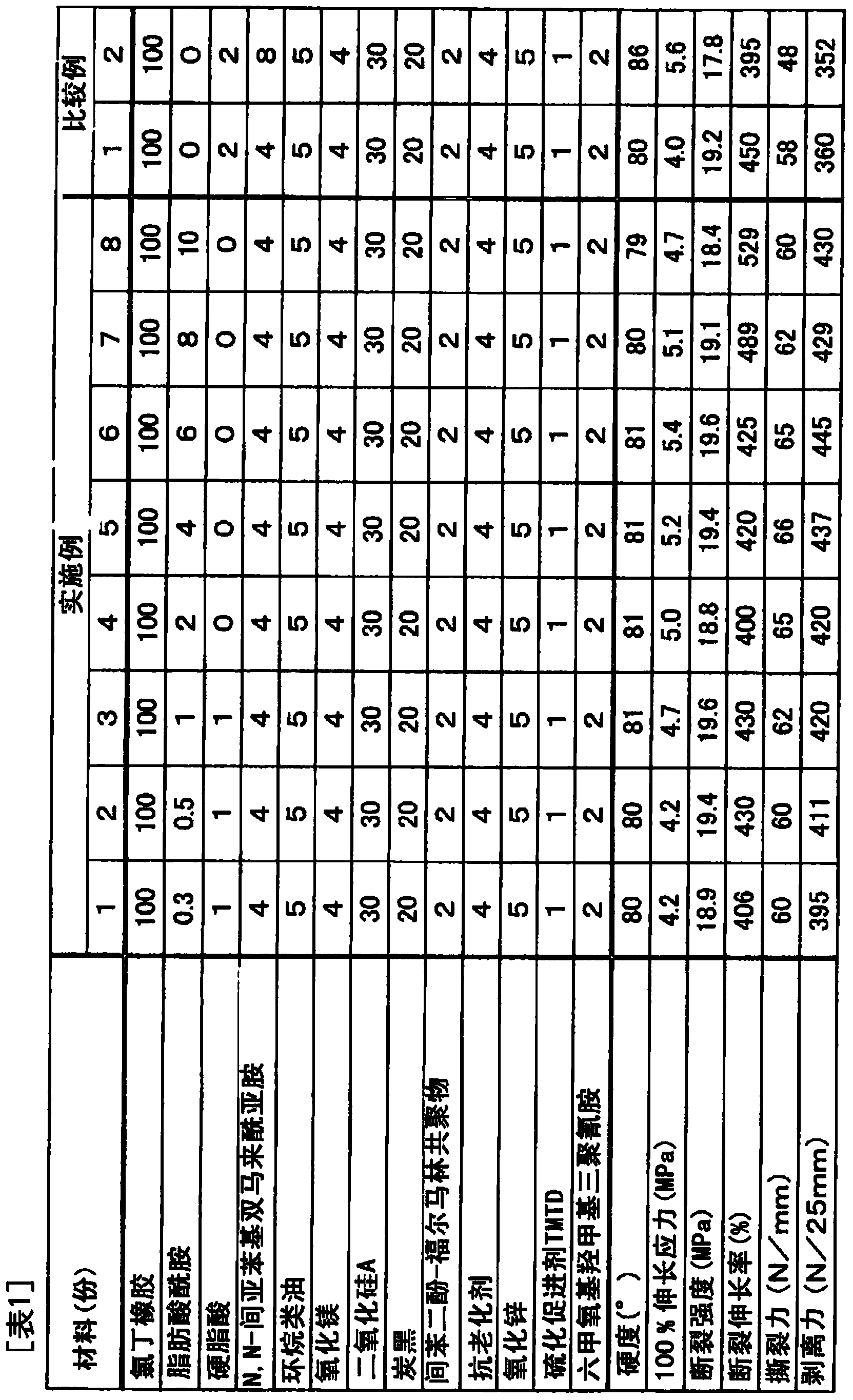

Embodiment 1~5 and comparative example 1~2

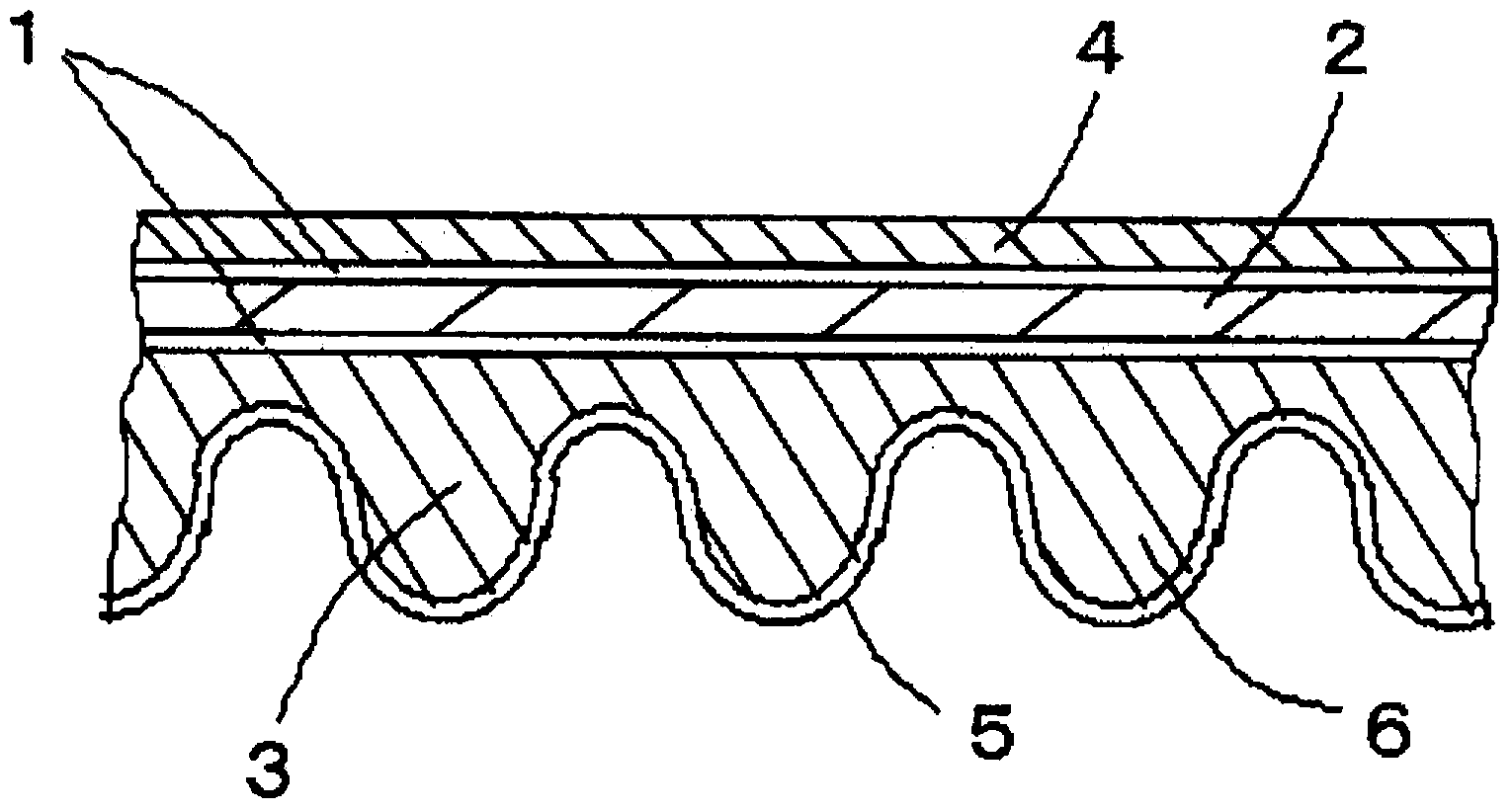

[0105] (formation of rubber layer)

[0106] The rubber compositions in Tables 1 to 2 (adhesive rubber layer) and Table 3 (inner rubber layer and back rubber layer) were kneaded using a known method such as a Banbury mixer, and the kneaded rubber was pressed from a press. The smooth roll is passed to produce a rolled rubber sheet (sheet for adhesive rubber layer, sheet for inner rubber layer, sheet for back rubber layer).

[0107] In Table 3, the material for the inner surface rubber layer and the material for the back rubber layer are set to the same rubber composition, rubber 1 is for medium-load applications, and rubber 2 is for high-load applications. Regarding compounding, rubber 2 has aramid short fibers, carbon black, and N,N'-m-phenylene bismaleimide in an increased amount compared to rubber 1, making the rubber composition harder and improving Modulus (lateral pressure resistance) fit.

[0108] In Table 1, Examples 4 to 8 have changed the amount of fatty acid amide (...

Embodiment 11 and 12

[0129] The physical properties of the vulcanized rubber were evaluated by changing the type of fatty acid amide. That is, the compounding of the rubber composition was the same as in Example 4 except that the type of fatty acid amide was changed. In Example 11, 2 parts by mass of fatty acid bisamide was compounded, and in Example 12, 2 parts by mass of fatty acid ester amide was compounded. The results of the physical properties of the vulcanized rubber are shown in Table 5 together with the results of Example 4 and Comparative Example 1.

[0130] [table 5]

[0131]

[0132] As can be seen from the results in Table 5, compared with Comparative Example 1 using stearic acid in Examples 4, 11, and 12 using fatty acid amide, hardness, 100% elongation stress, breaking strength, and tearing force all showed higher values. , The elongation at break of Examples 4 and 11 decreased slightly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com