Semiconductor device

A semiconductor and sealing resin technology, applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve the problems of product life reduction, interface peeling or cracks, etc., to achieve uniform thickness, ensure life, and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

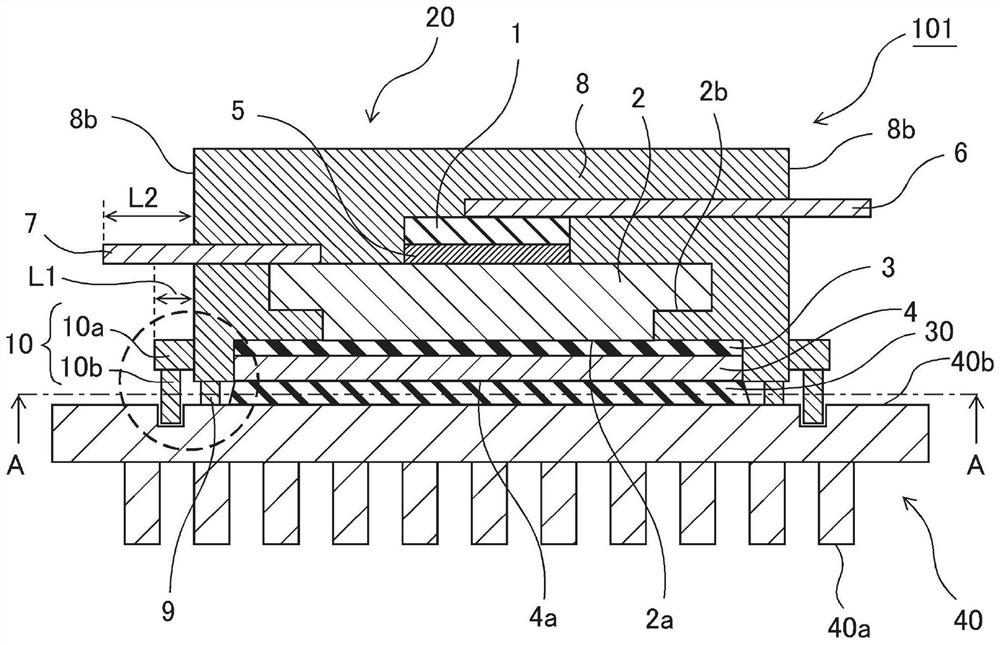

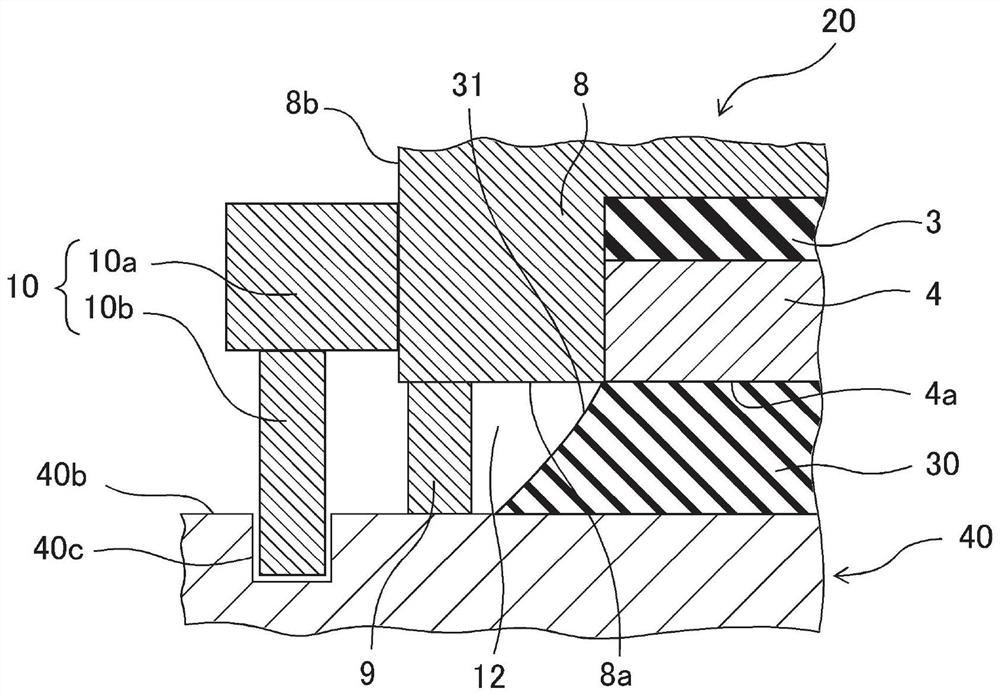

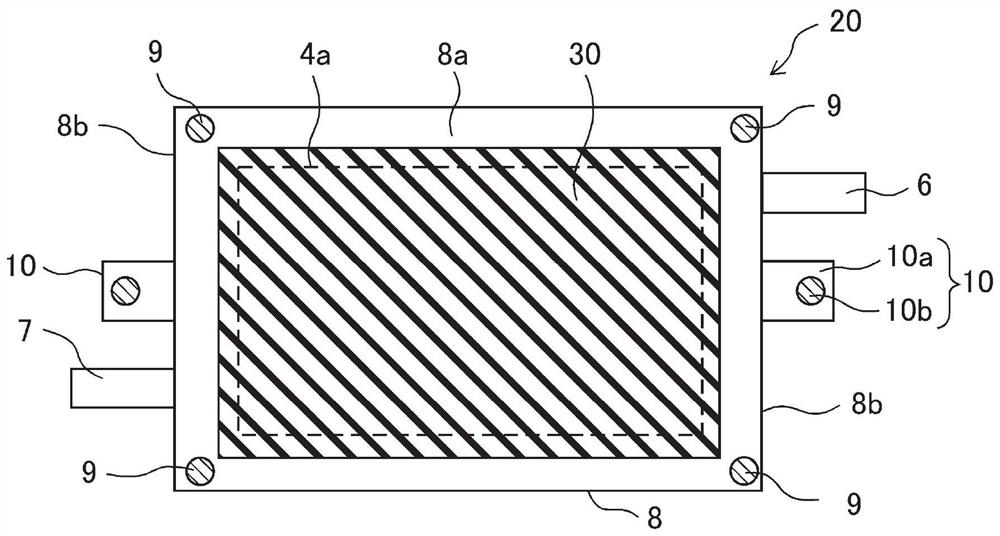

[0027] Next, the semiconductor device according to Embodiment 1 will be described based on the drawings. figure 1 is a side cross-sectional view showing a schematic configuration of the semiconductor device according to Embodiment 1, figure 2 and image 3 It is a figure explaining the thickness regulation protrusion and the positioning protrusion of the semiconductor device of Embodiment 1, figure 2 yes figure 1 A partial enlarged cross-sectional view of the part indicated by the dotted circle in , image 3 is viewed from the direction of the arrow figure 1 A cross-sectional view of the portion of the junction region indicated by A-A in . In addition, in each figure, the same code|symbol is attached|subjected to the same or a corresponding part.

[0028] The semiconductor device 101 of Embodiment 1 includes a semiconductor module 20 and a cooler 40 as basic components. The semiconductor module 20 includes: the semiconductor element 1 mounted on one surface of the metal...

Embodiment approach 2

[0075] Figure 5 is a side cross-sectional view showing a schematic configuration of a semiconductor device according to Embodiment 2, Figure 6 and Figure 7 It is a figure explaining the thickness control and positioning protrusion of the semiconductor device of Embodiment 2, Figure 6 yes Figure 5 A partial enlarged cross-sectional view of the part indicated by the dotted circle in , Figure 7 is viewed from the direction of the arrow Figure 5 Cross-sectional view of the portion of the junction region indicated by B-B in .

[0076] A semiconductor device 102 according to Embodiment 2 includes a semiconductor module 20A and a cooler 40 , and the semiconductor module 20A and the cooler 40 are bonded via solder 30 . In the semiconductor module 20A, a positioning protrusion for positioning the semiconductor module 20A and the cooler 40 is formed on the side 8b of the sealing resin 8 on which the main electrode wirings 6, 7 protrude, and the positioning protrusion also se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com