Conveyor belt

A technology for conveyor belts and belt bundles, applied in the field of conveyor belts, can solve the problems of low wear resistance, unfavorable durability, and increased material costs, and achieve the effects of not easy peeling, seeking durability, and inhibiting interface peeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

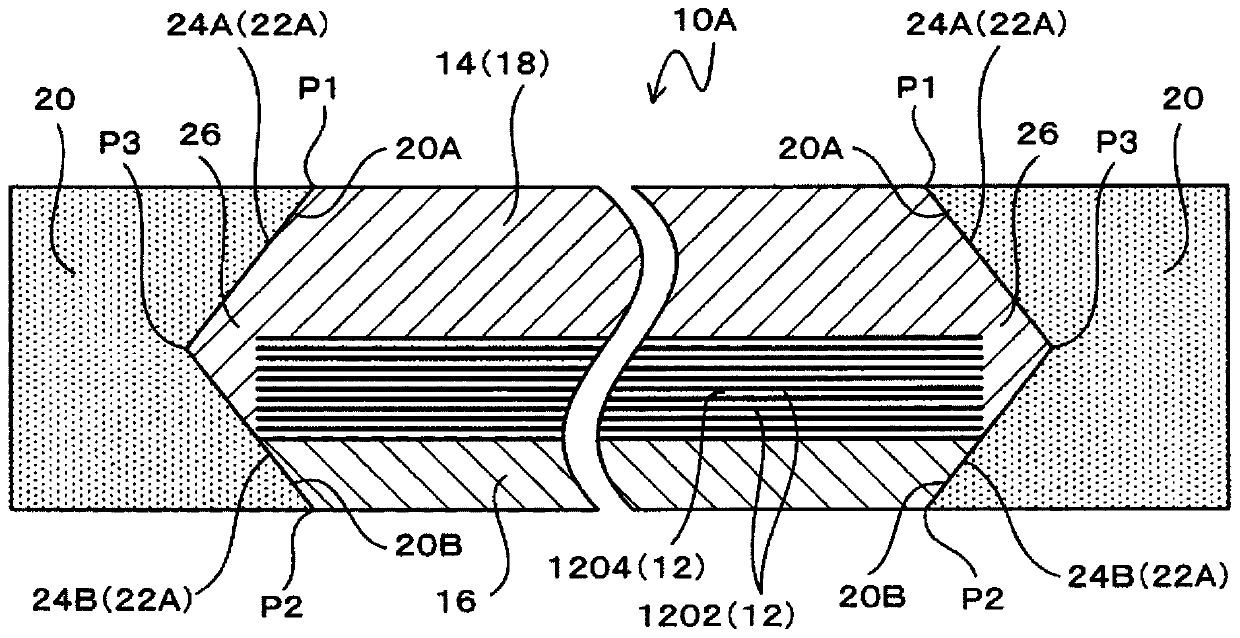

[0035] First, refer to figure 1 The description will start with the first embodiment.

[0036] The conveyor belt 10A includes a belt main body 18, a flame-retardant rubber portion 20, and a joint area increasing portion 22A.

[0037] The belt main body 18 is configured to include a core reinforcing layer 12 , an upper surface protective rubber layer 14 , and a lower surface protective rubber layer 16 .

[0038] The core reinforcement layer 12 is configured to include a plurality of core materials 1202 and a coating rubber 1204 covering the core materials 1202 .

[0039] Conventionally known various materials such as steel cords, canvas, and organic fibers can be used as the core material 1202 , but steel cords are used as the core material 1202 in the present embodiment.

[0040] The core reinforcement layer 12 is a portion that supports the tensile load applied to the conveyor belt 10A and maintains the tension of the conveyor belt 10A.

[0041] The upper surface protectiv...

no. 2 approach

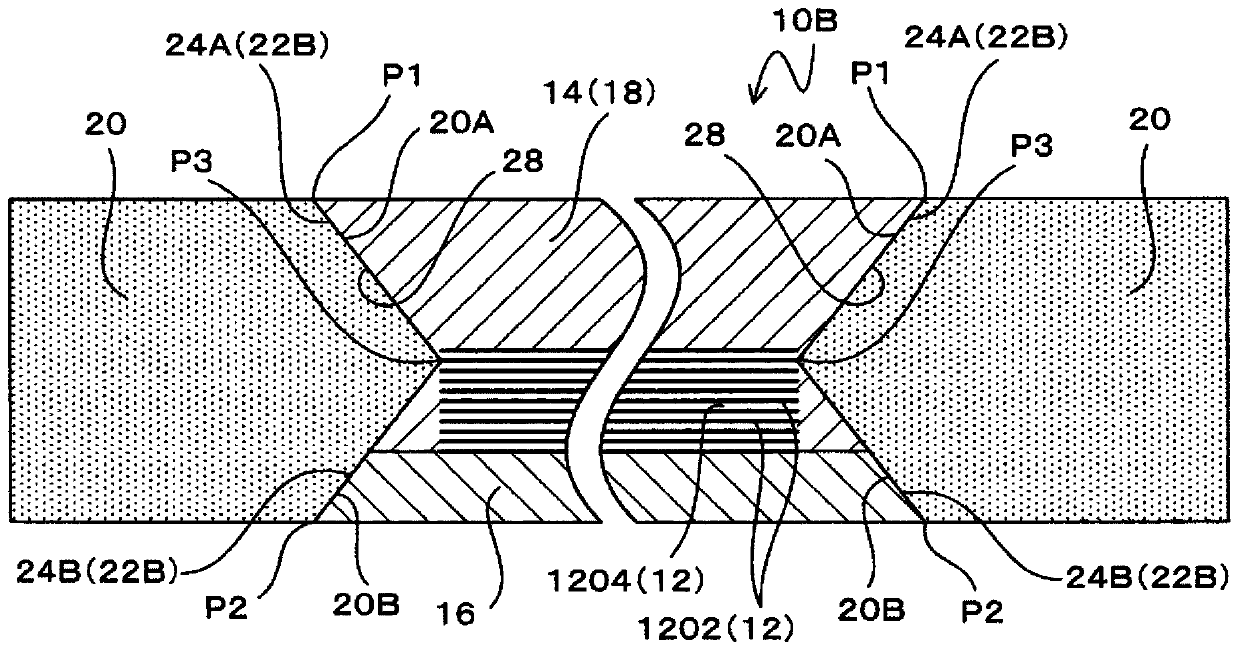

[0063] Next, refer to figure 2 A second embodiment will be described.

[0064] It should be noted that, in the description of the following embodiment, the same parts as those of the first embodiment are given the same reference numerals and their descriptions are omitted, and the different points will be described emphatically.

[0065] In the conveyor belt 10B of the second embodiment, recessed portions 28 are formed on both side portions of the belt main body 18 to protect the lower surface of the rubber layer 16 from the upper surface of the upper surface protective rubber layer 14 and the lower surface of the lower surface of the rubber layer 16 . The thickness of the belt main body 18 is gradually reduced to the center of the width direction of the belt main body 18 , and the flame-retardant rubber part 20 is embedded.

[0066] More specifically, the upper inclined surface 24A is formed on the upper surface protective rubber layer 14 so that both ends in the width dire...

no. 3 approach

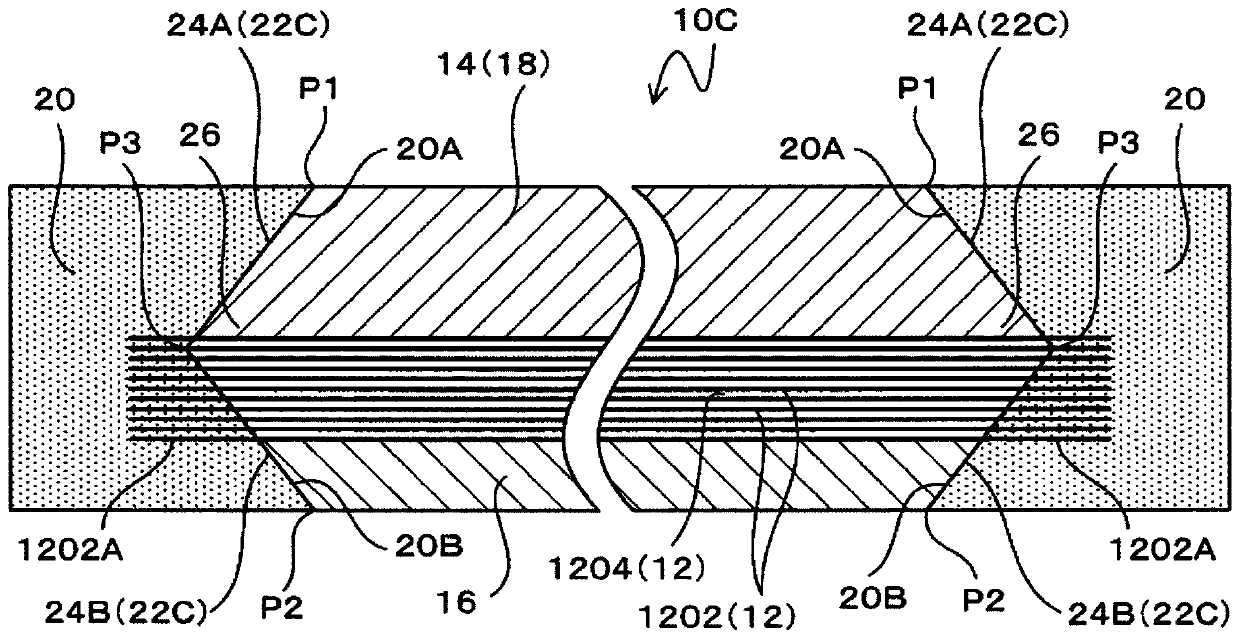

[0073] Next, refer to image 3 A third embodiment will be described.

[0074] The conveyor belt 10C of the third embodiment is a modified example of the first embodiment, and the configuration of the joint area increasing portion 22C is different from that of the first embodiment.

[0075] That is, on both sides in the width direction of the core reinforcement layer 12, a plurality of core material protrusions 1202A in which the core material 1202 protrudes from the coating rubber 1204 and is embedded in the flame-retardant rubber part 20 is provided, and the joint area increasing part 22C is configured to include Core protrusion 1202A.

[0076] That is, the joint area increasing portion 22C is composed of the upper and lower inclined surfaces 24A, 24B constituting the surface of the convex portion 26 and the plurality of core materials 1202 constituting the core material protruding portion 1202A.

[0077] In the third embodiment, the upper inclined surface 24A is formed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com