Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

92results about How to "Ensure joint strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vehicle-body structure of vehicle and manufacturing method of the same

InactiveUS20130049405A1Improve comfortable rideReduce noiseVehicle seatsMetal-working apparatusEngineeringMechanical engineering

Owner:MAZDA MOTOR CORP

Vehicle-body structure of vehicle and manufacturing method of the same

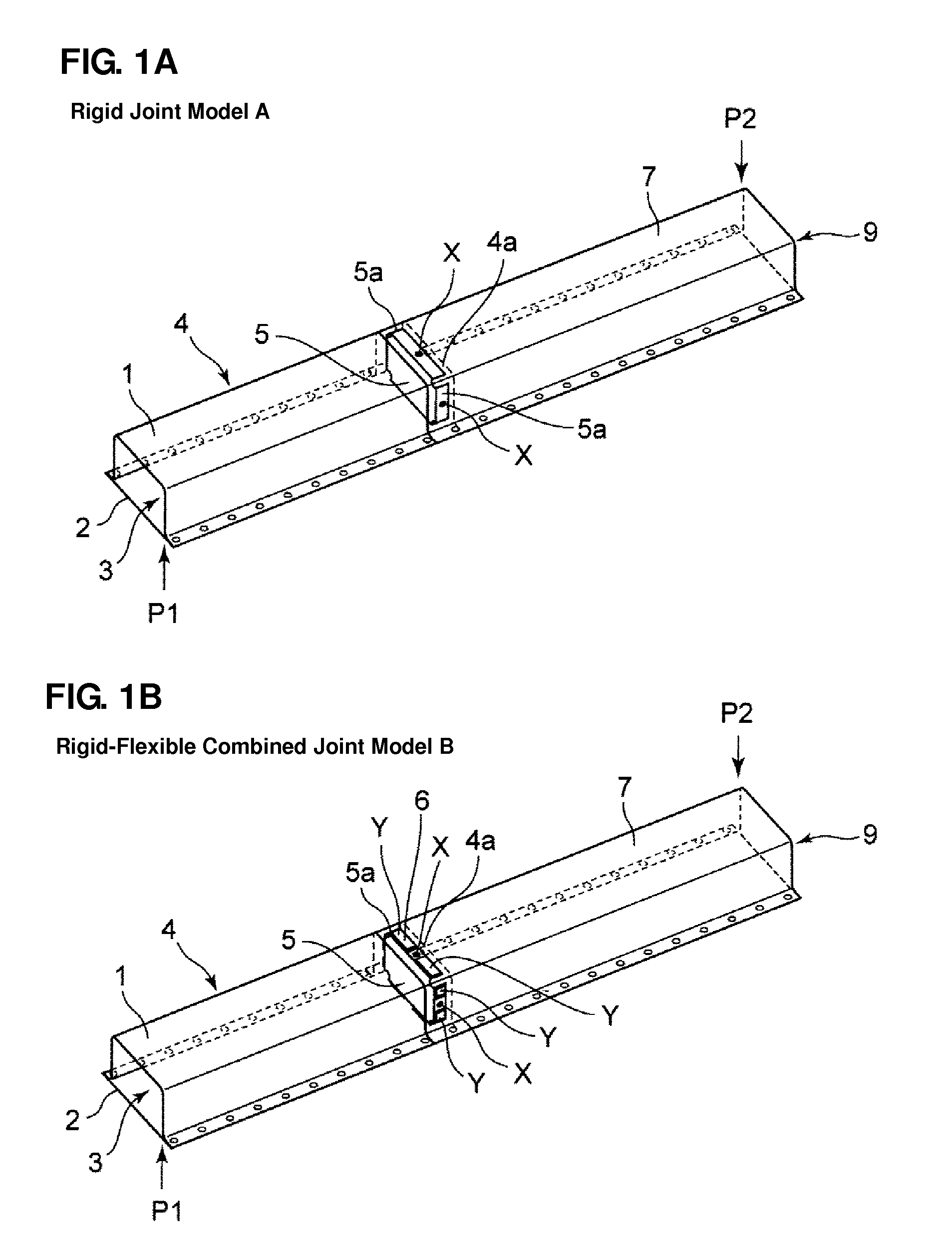

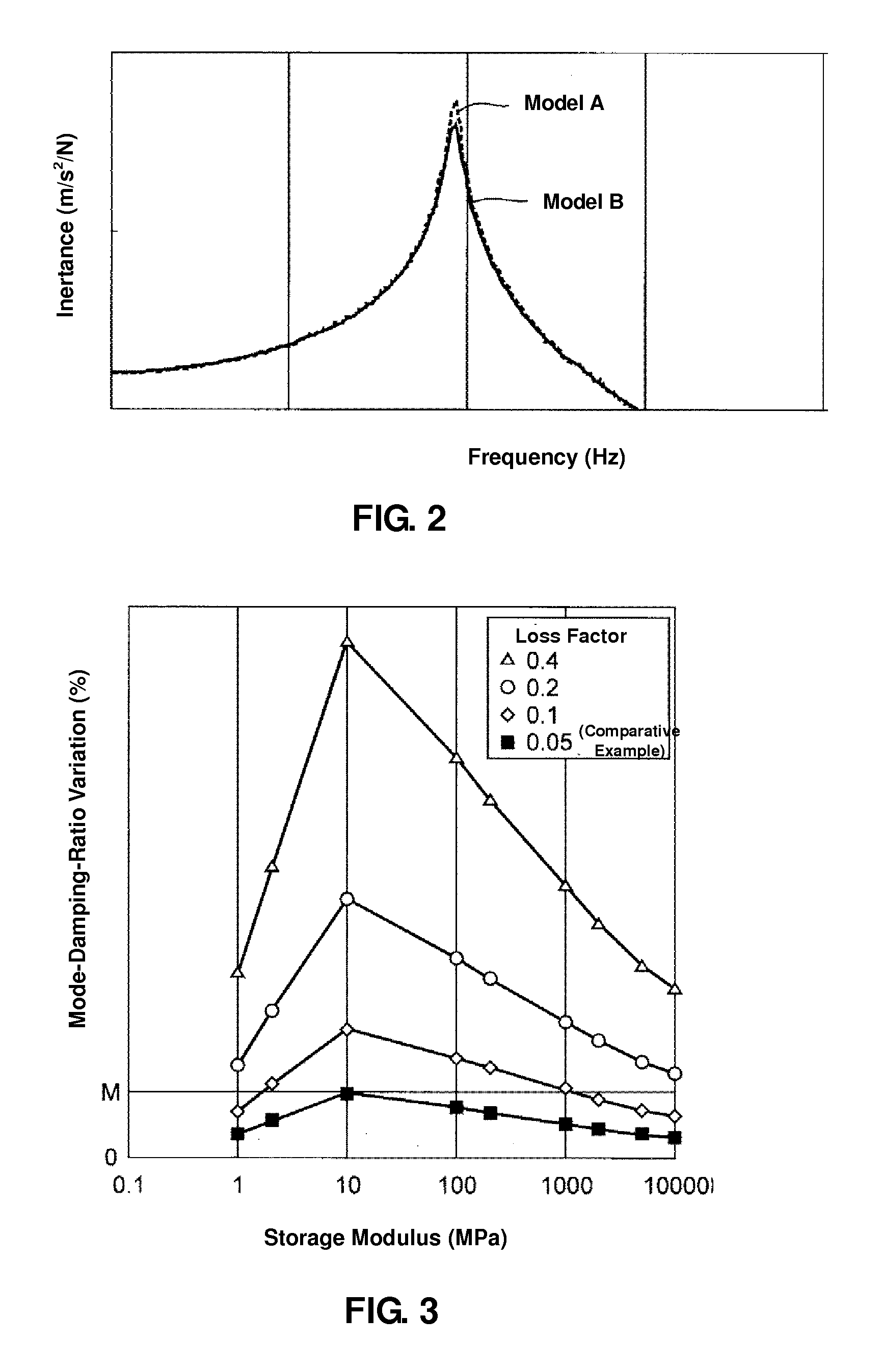

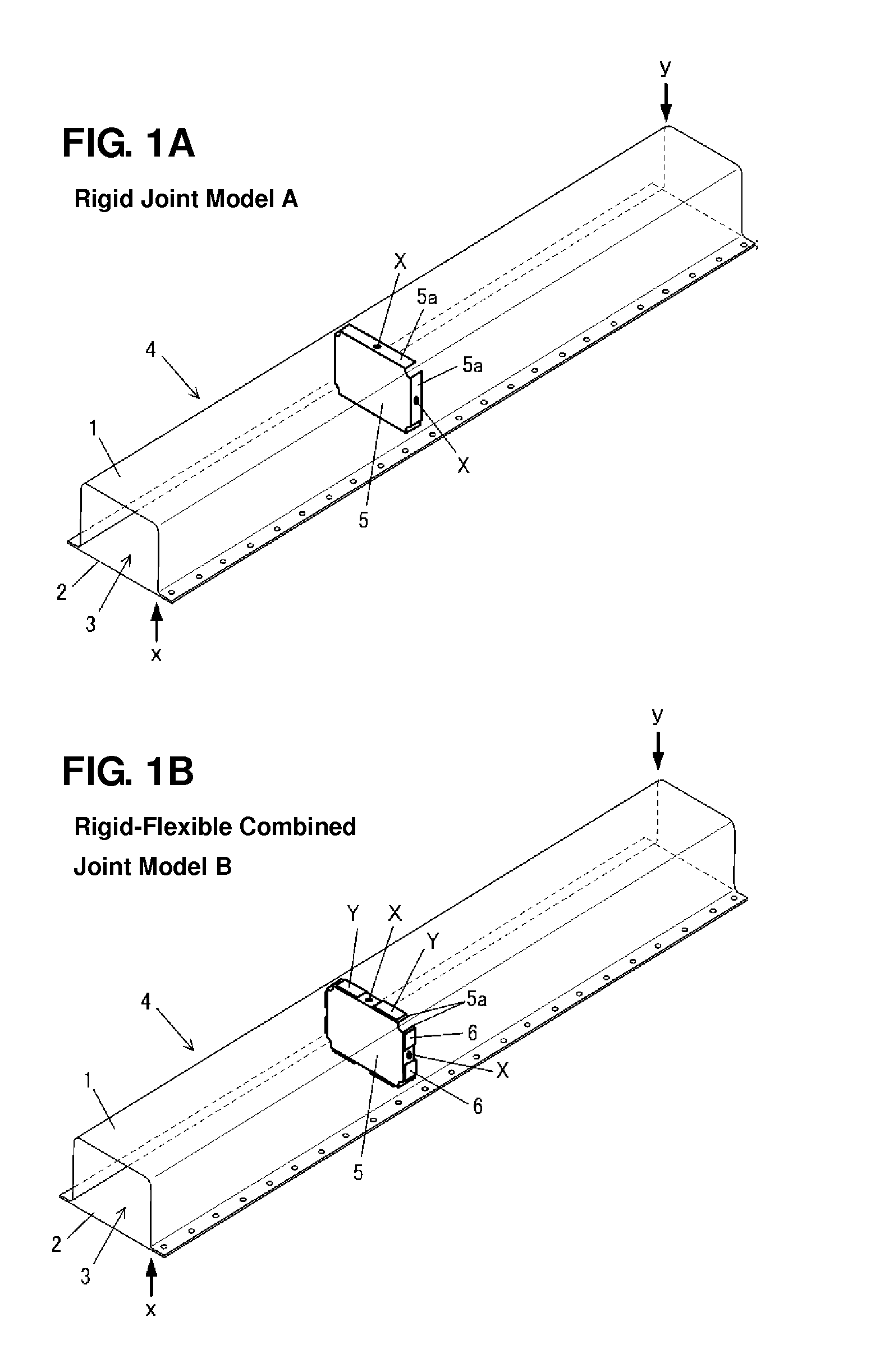

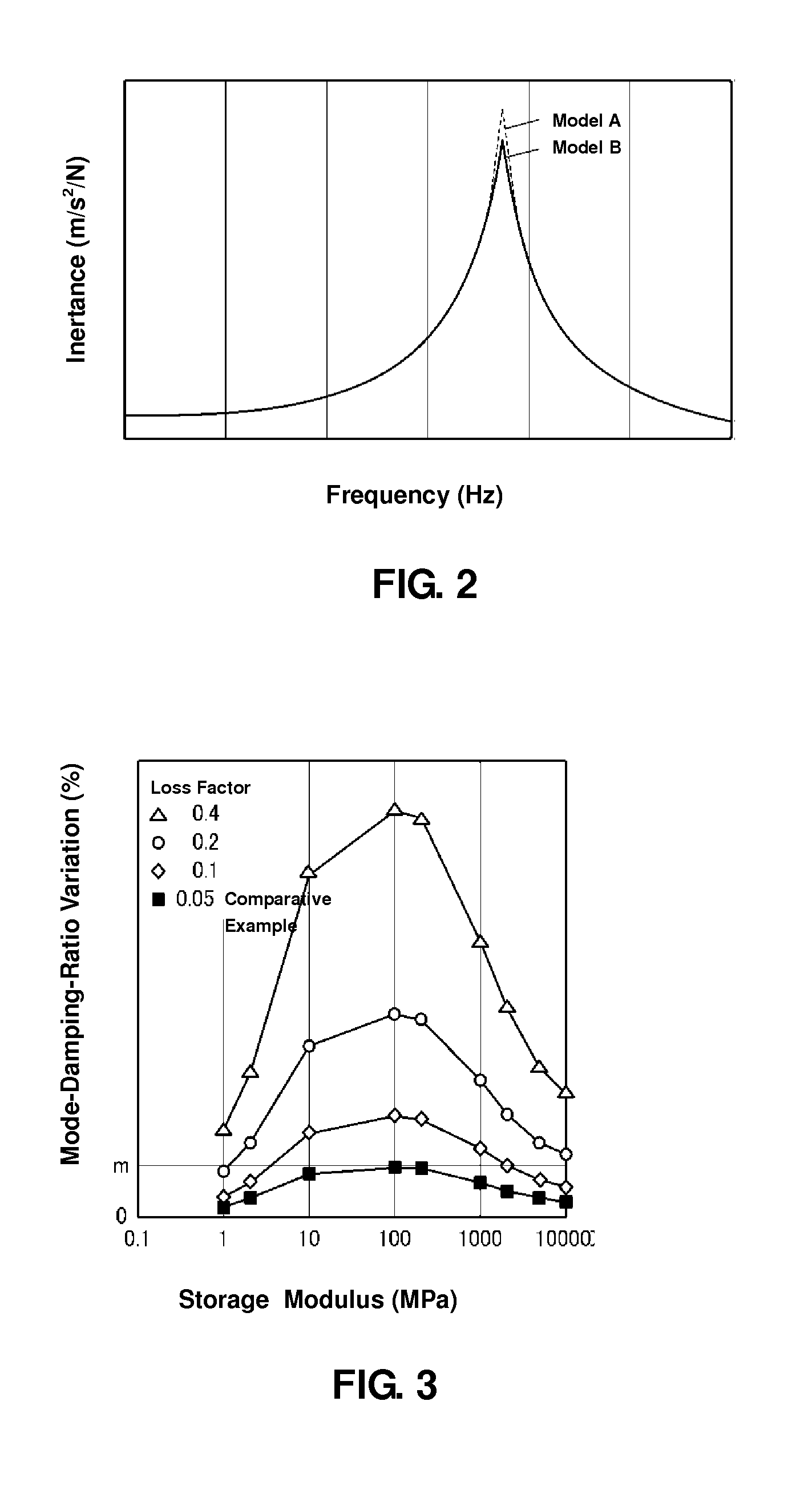

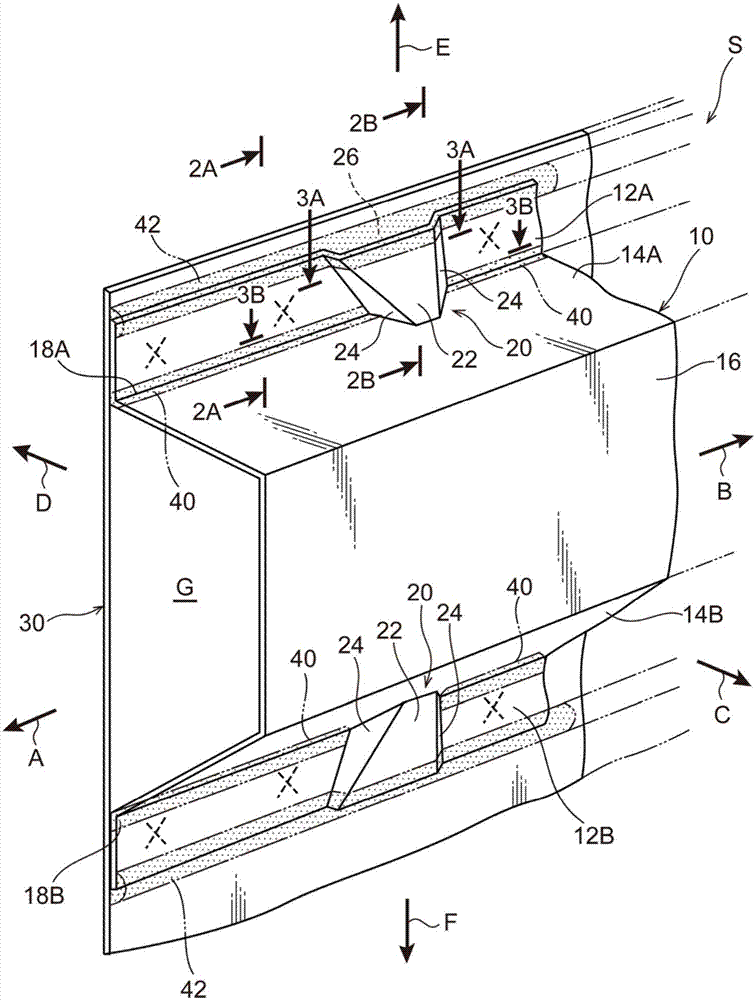

ActiveUS20130049391A1Improve comfortable rideReduce noiseVehicle seatsMetal-working apparatusSpot weldingFlange

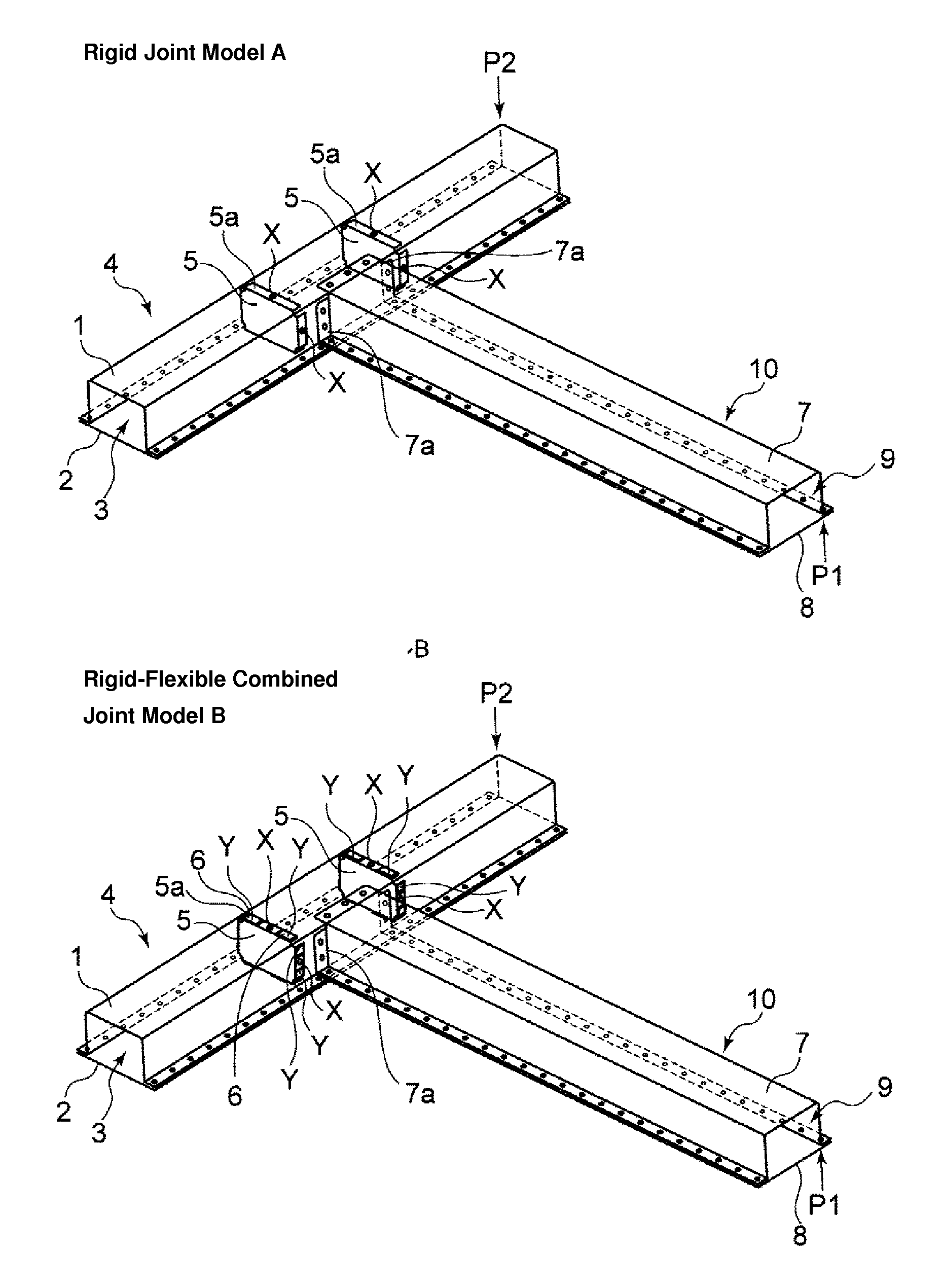

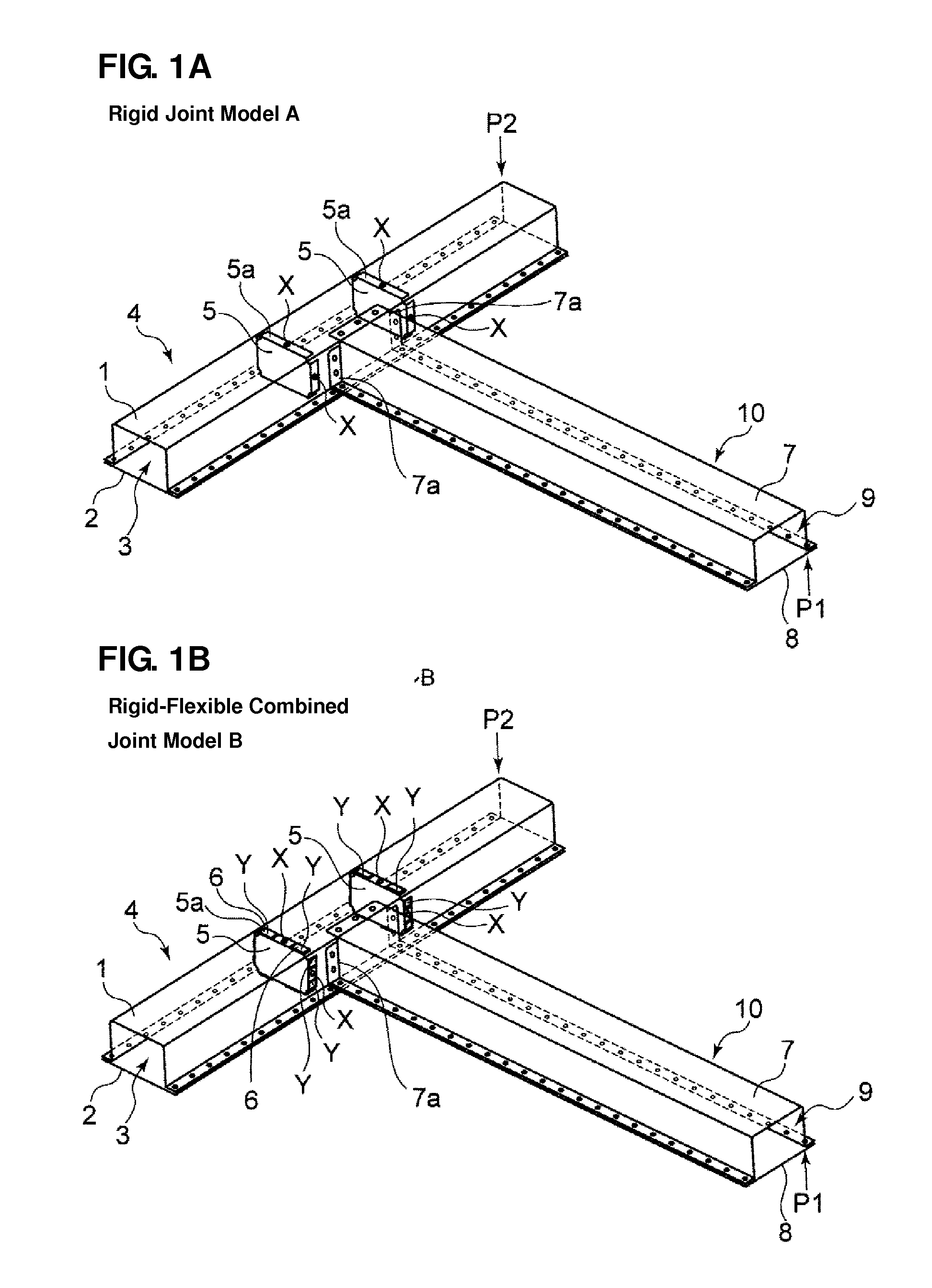

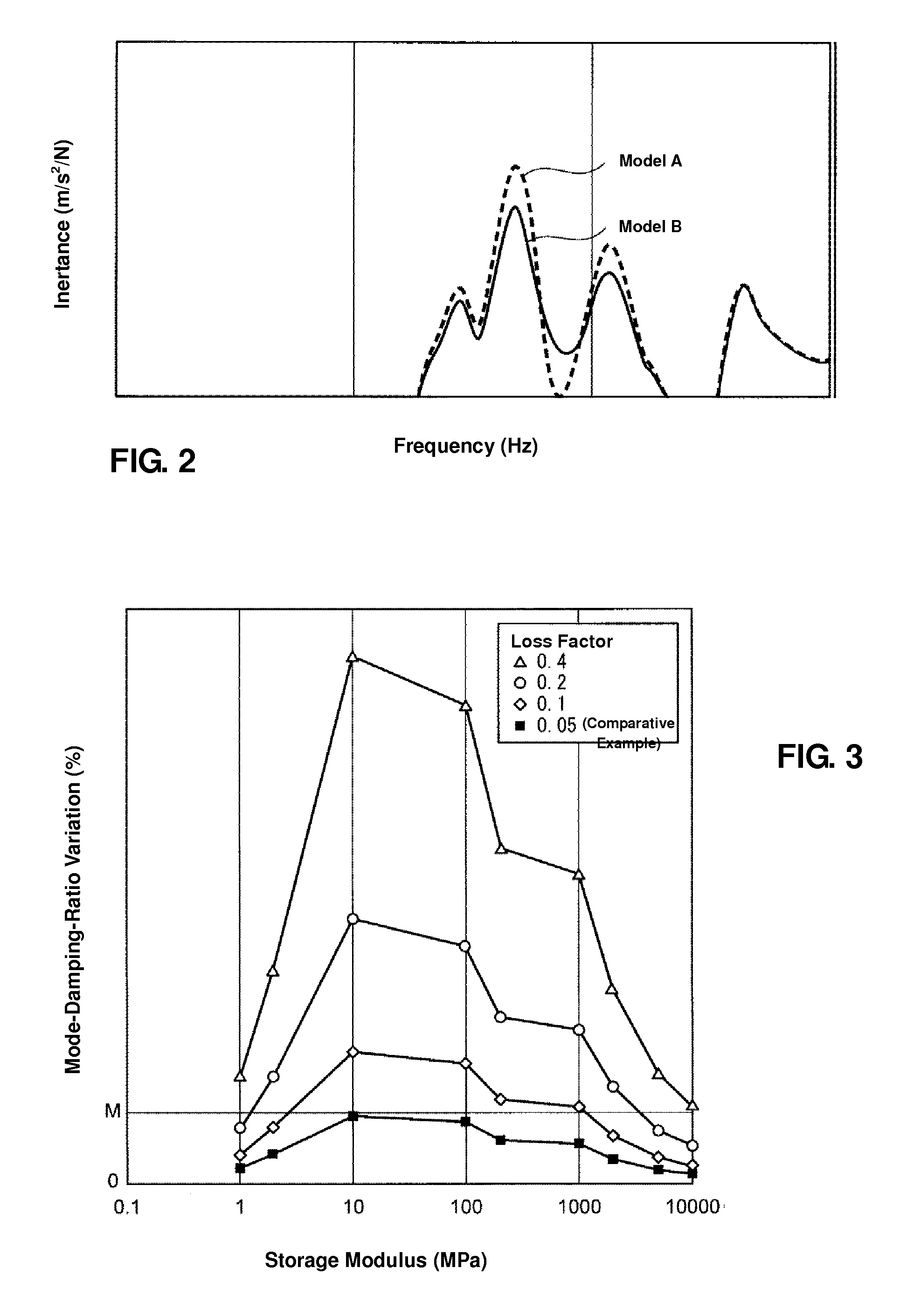

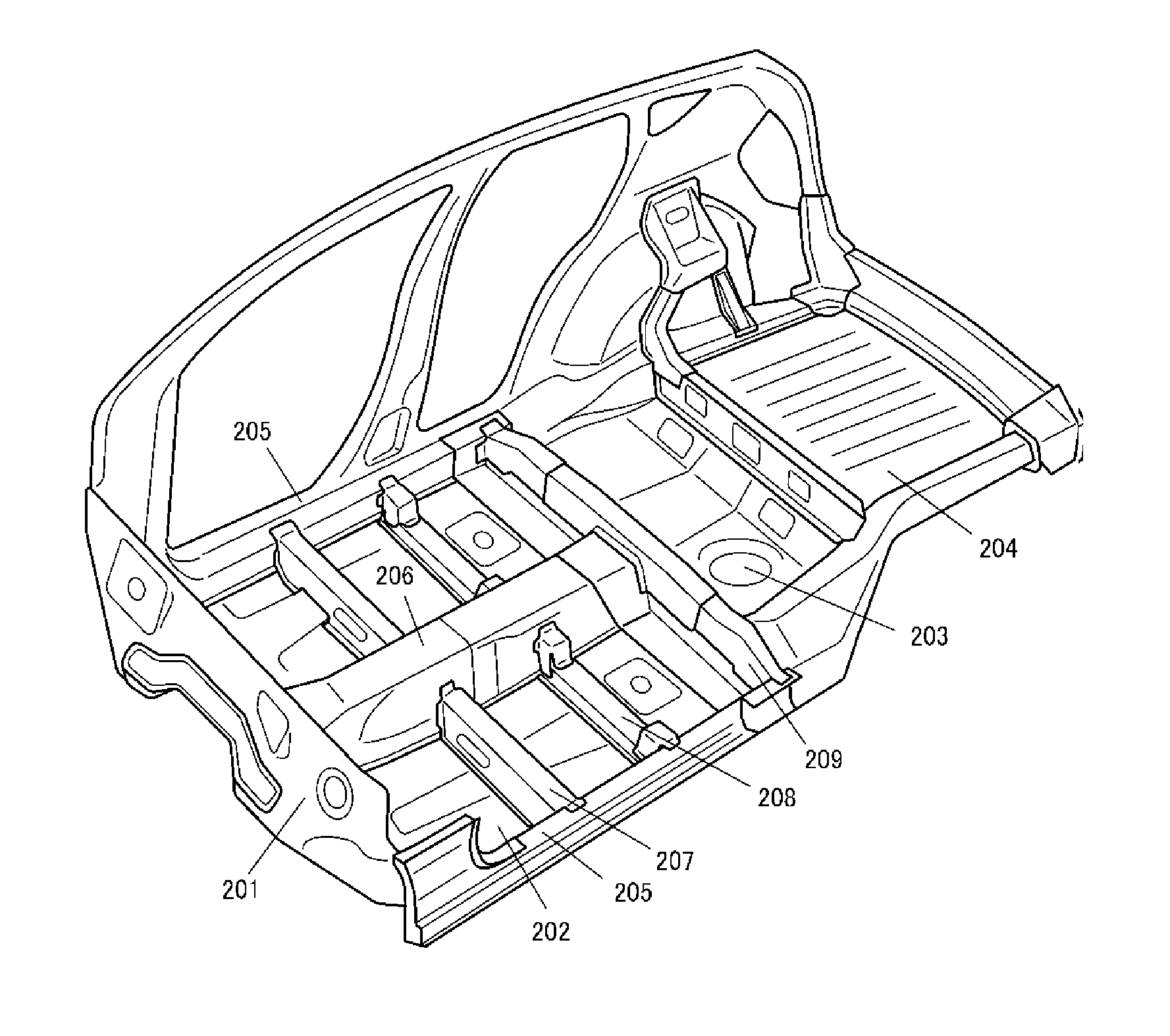

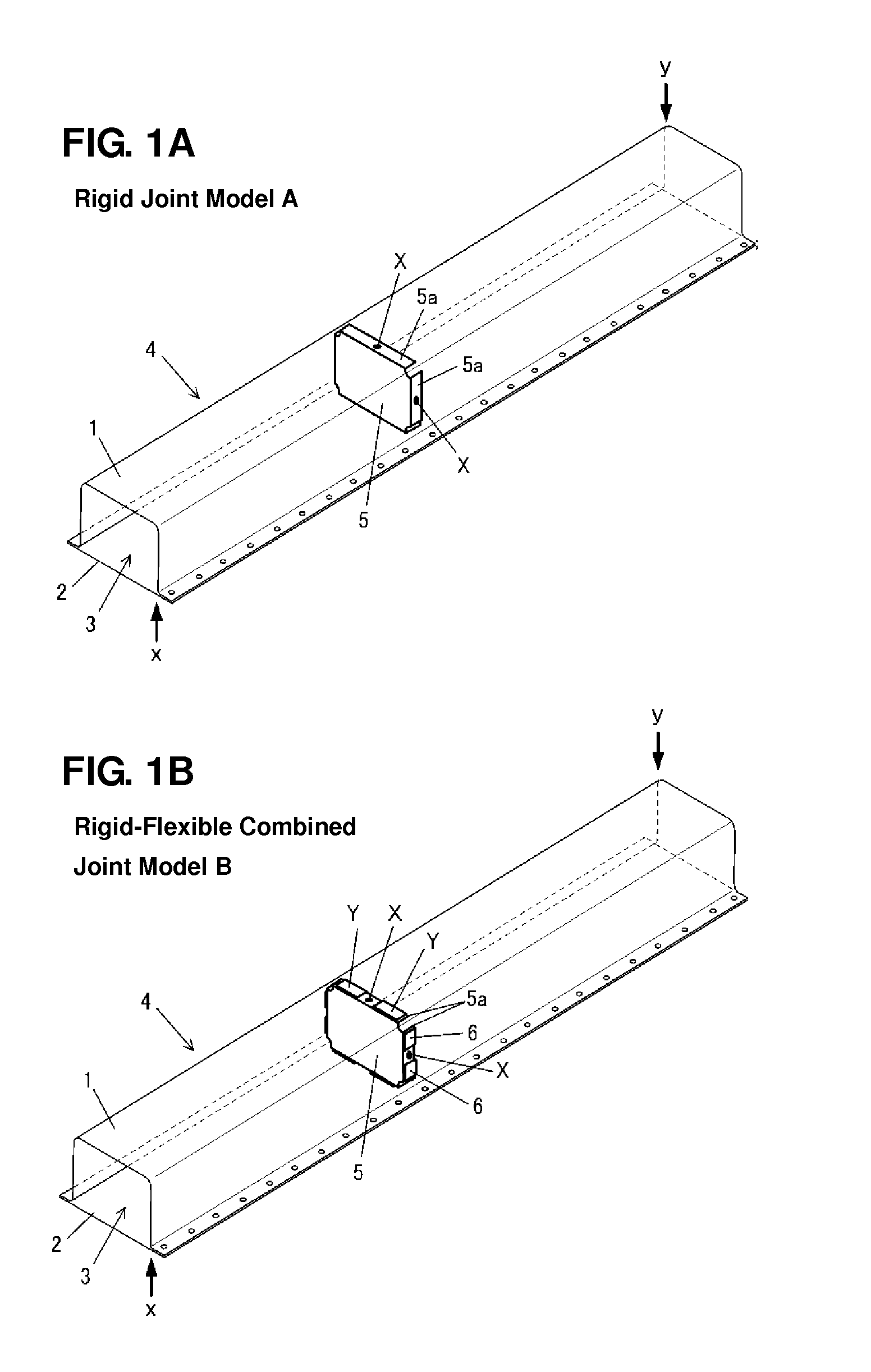

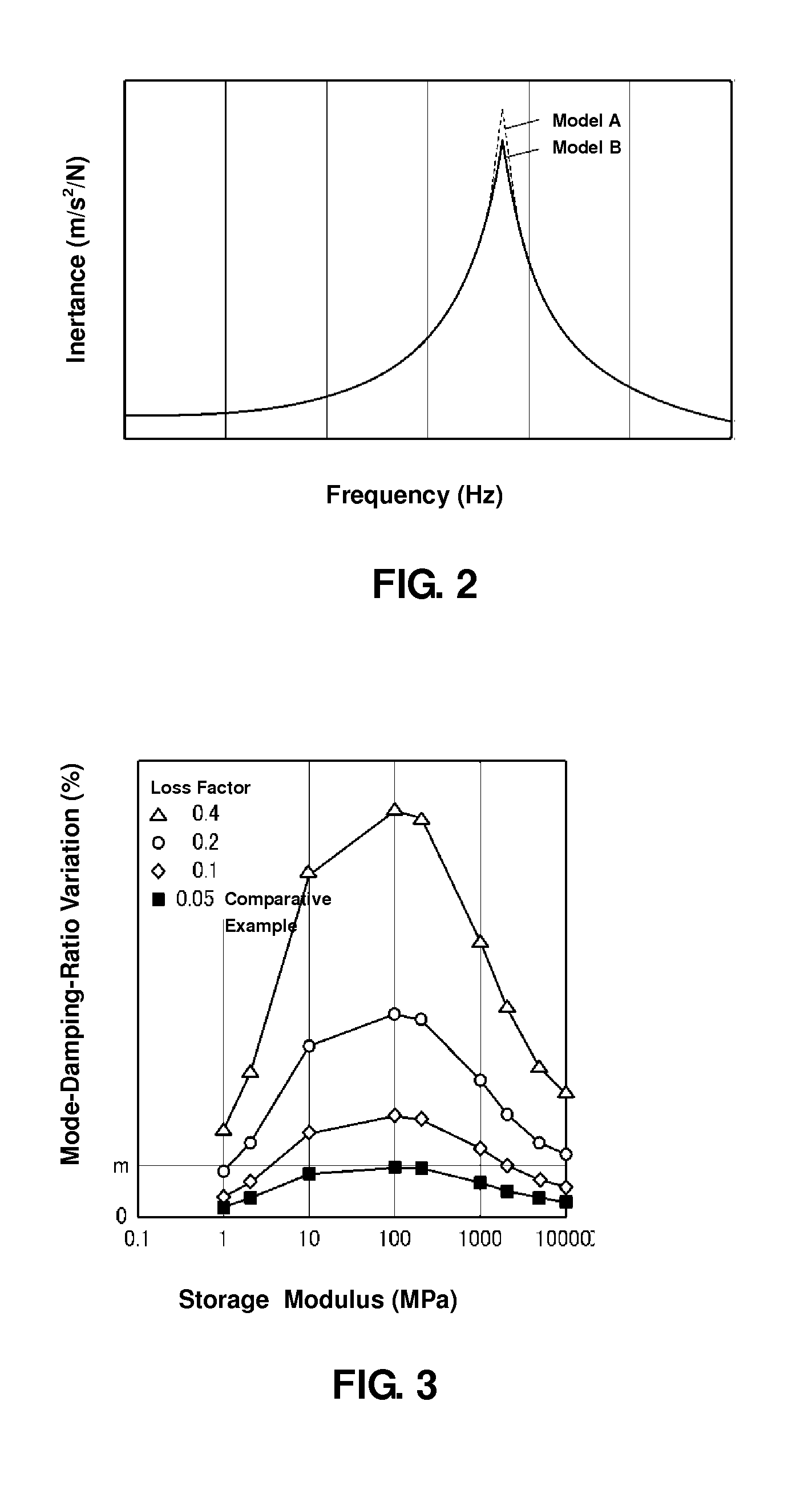

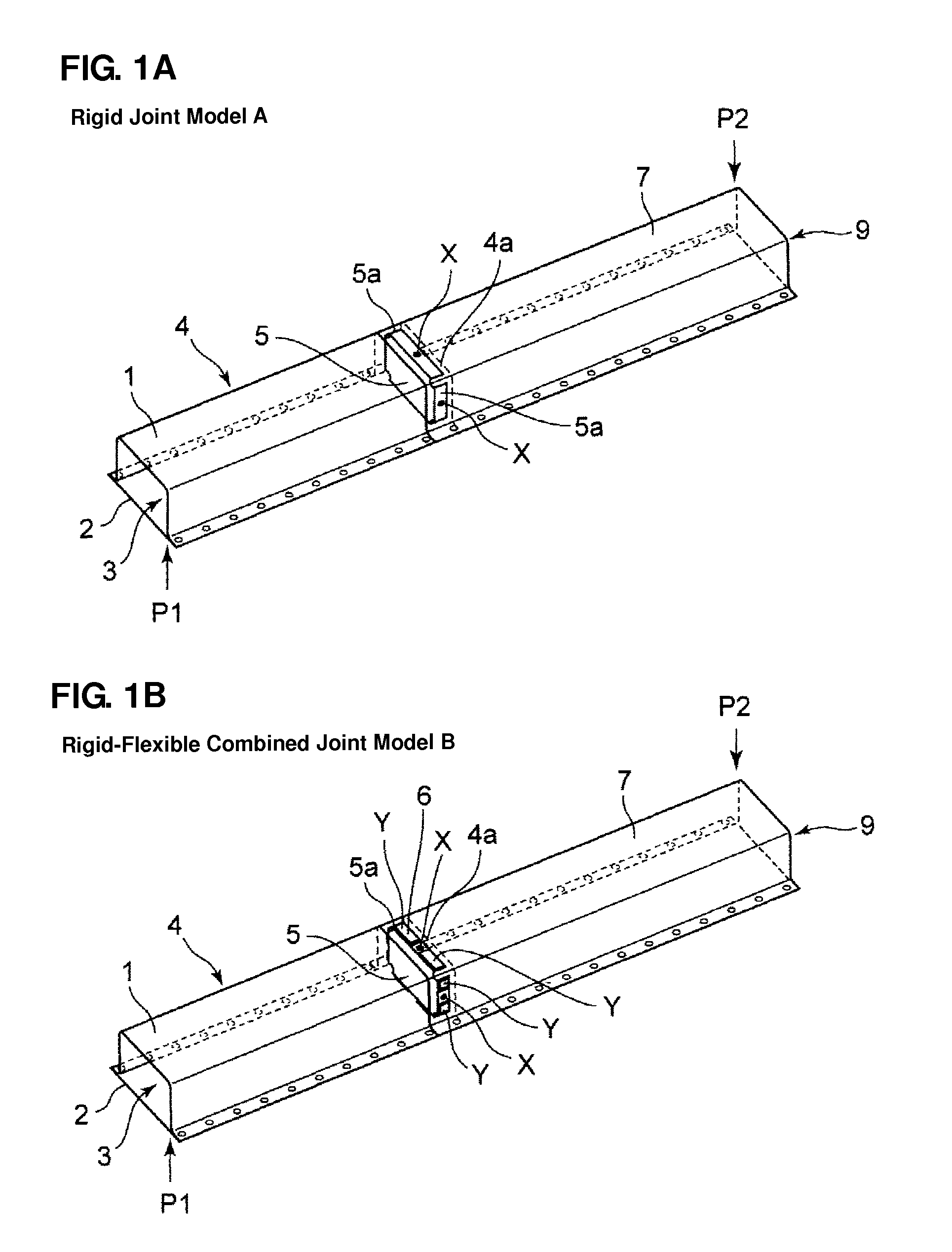

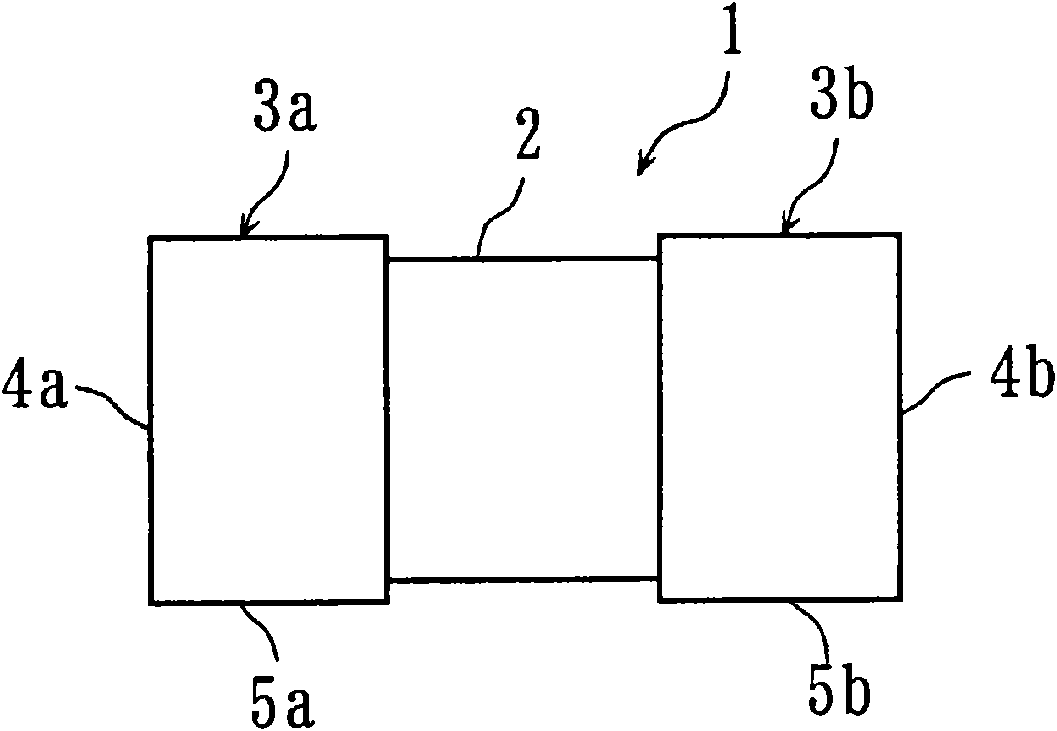

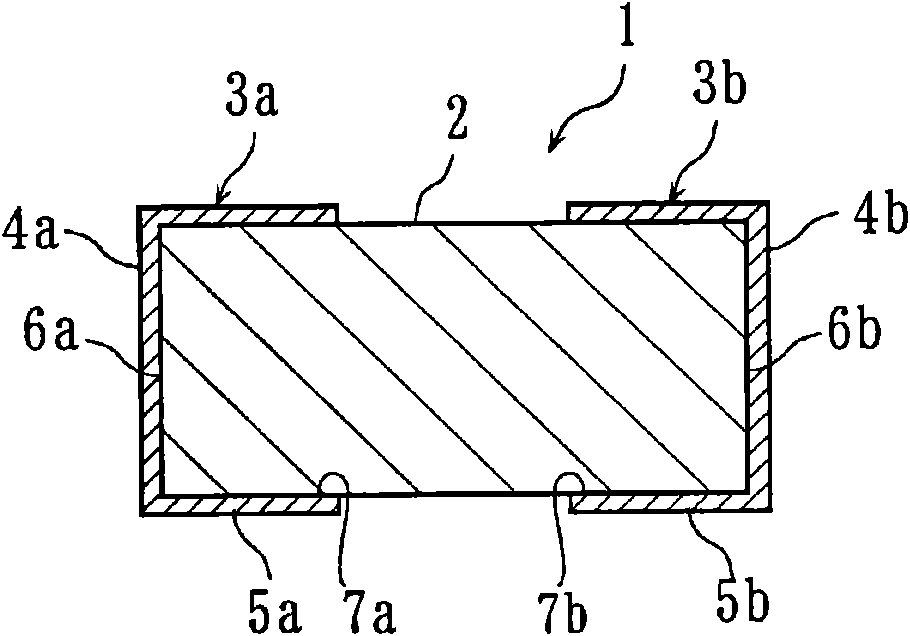

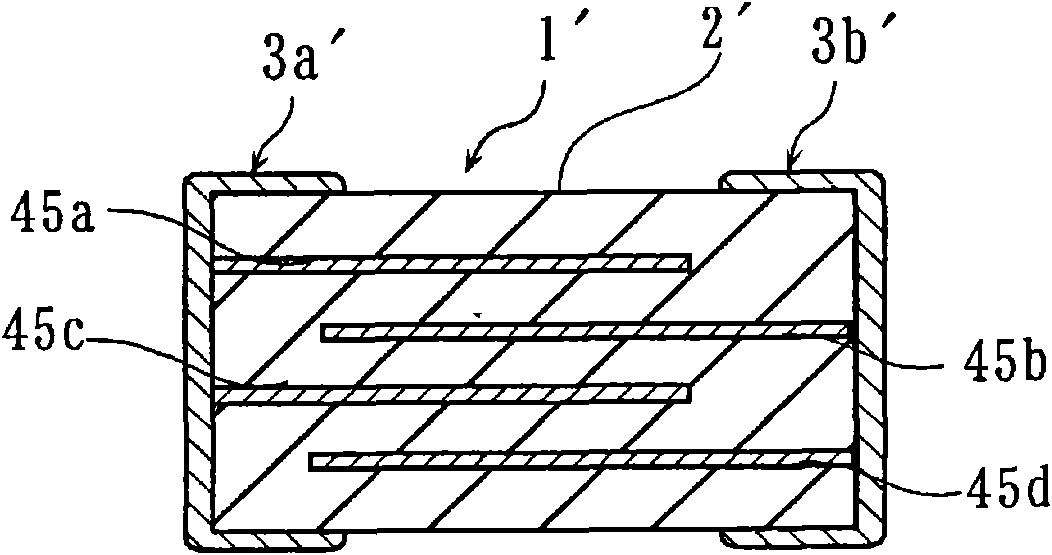

In a frame having a closed-section portion which is formed by joining a first member having a U-shaped section and a second member having a flat-plate shape, a bulkhead is provided in the closed-section portion as a reinforcing member, flanges of the bulkhead and the first and second members are joined with a rigid joint portion where they are joined by a spot welding and a flexible joint portion where they are joined via a damping member. Thereby, transmission of vibrations can be properly restrained, improving the rigidity of the portion having the closed-section portion.

Owner:MAZDA MOTOR CORP

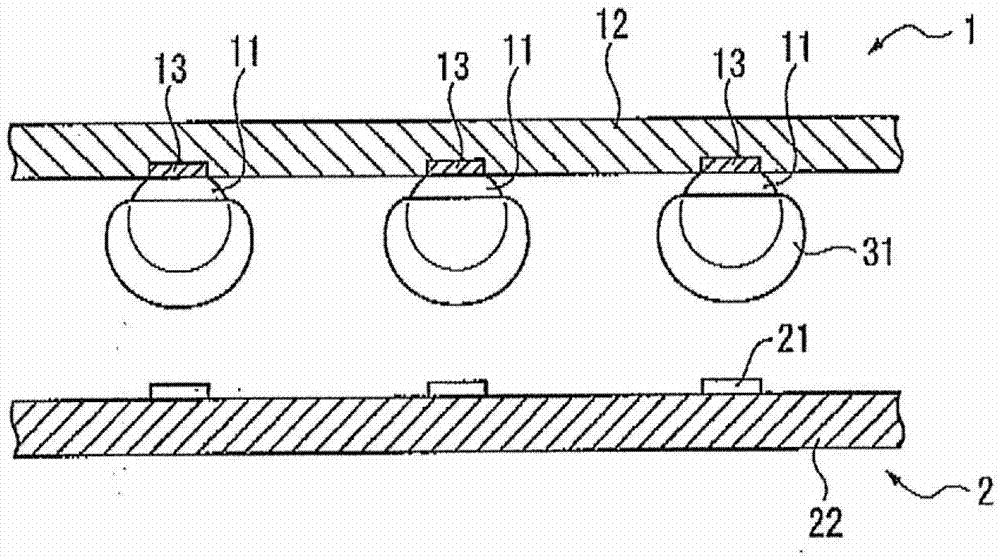

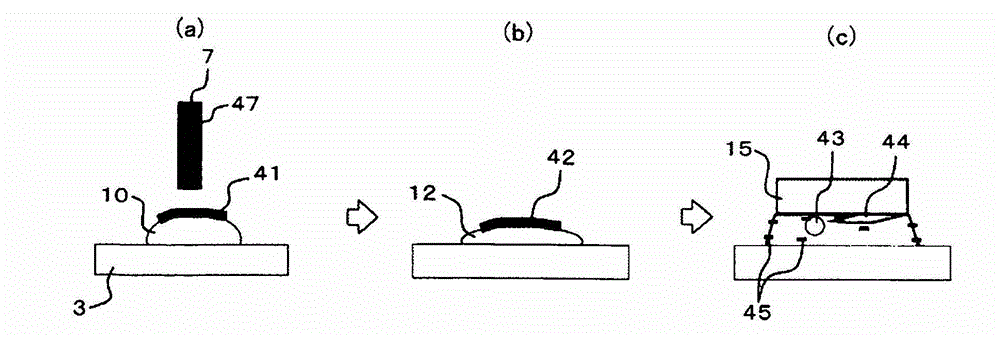

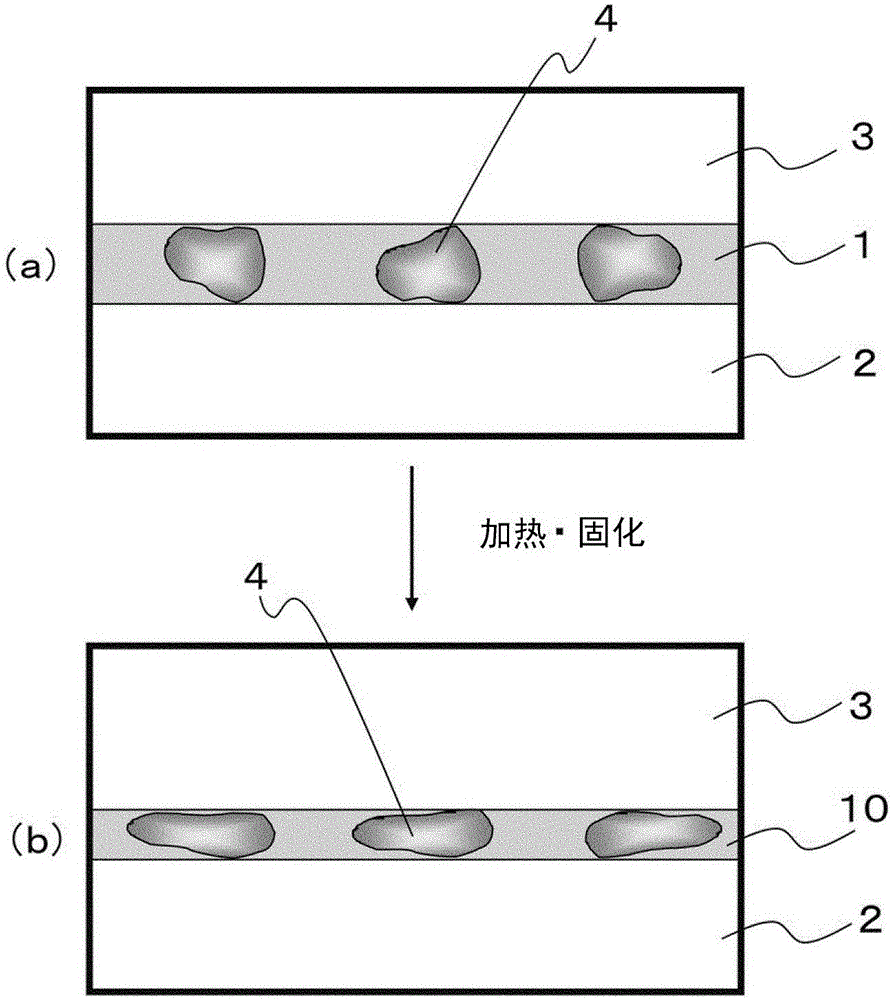

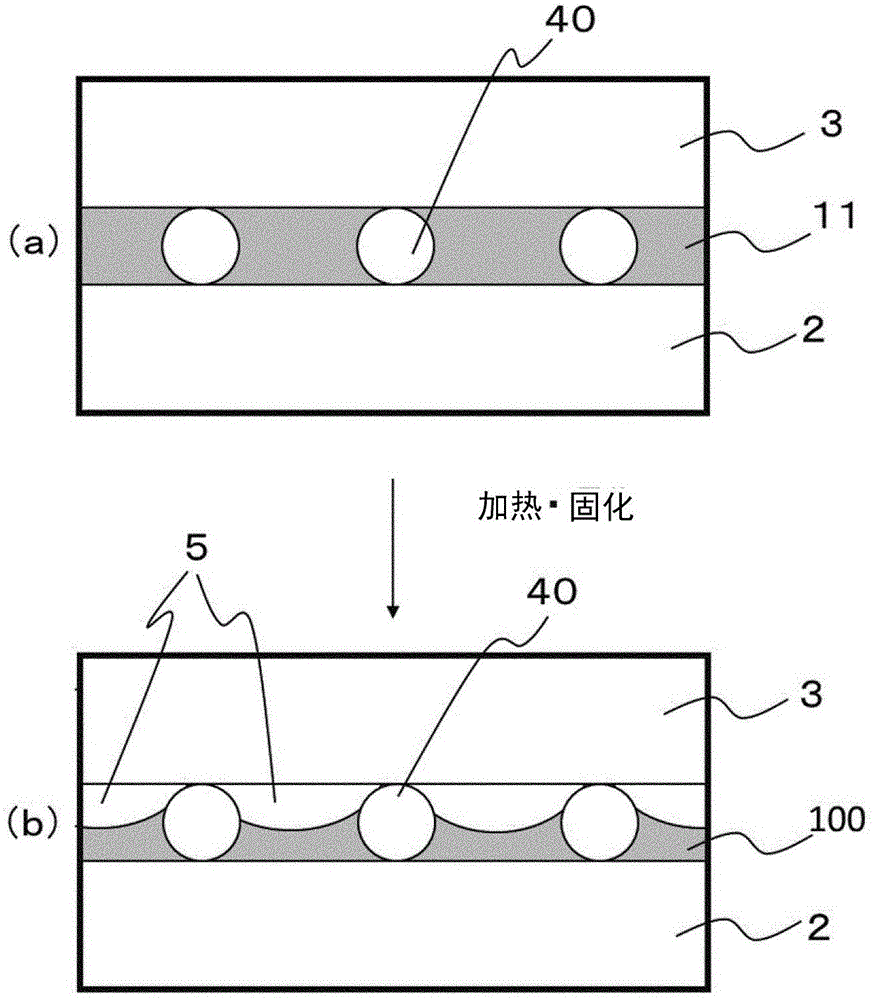

Thermosetting resin composition

InactiveCN103289621AEnsure joint strengthNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsOrganic acidEpoxy

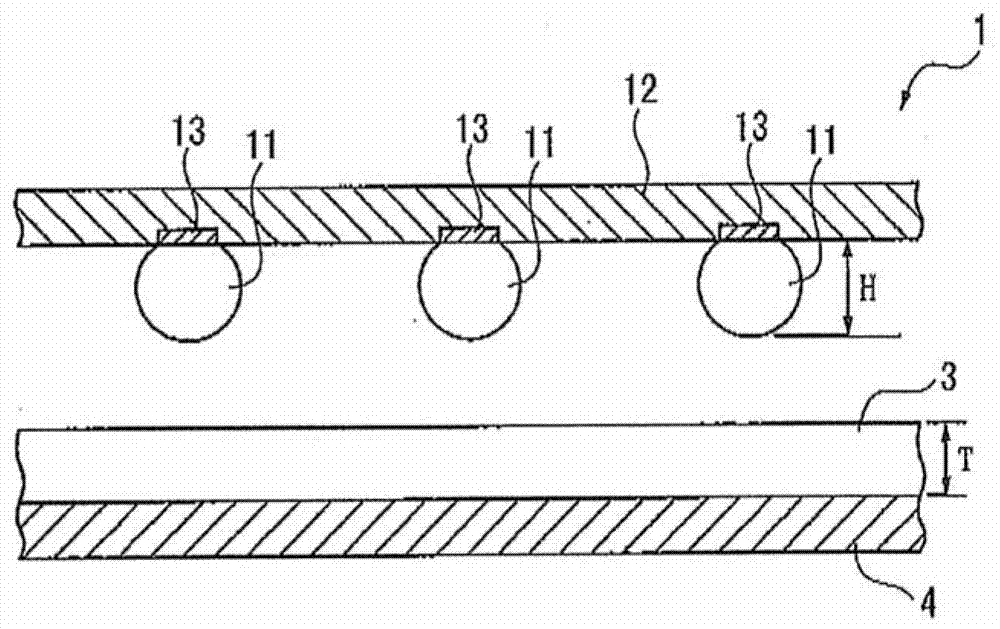

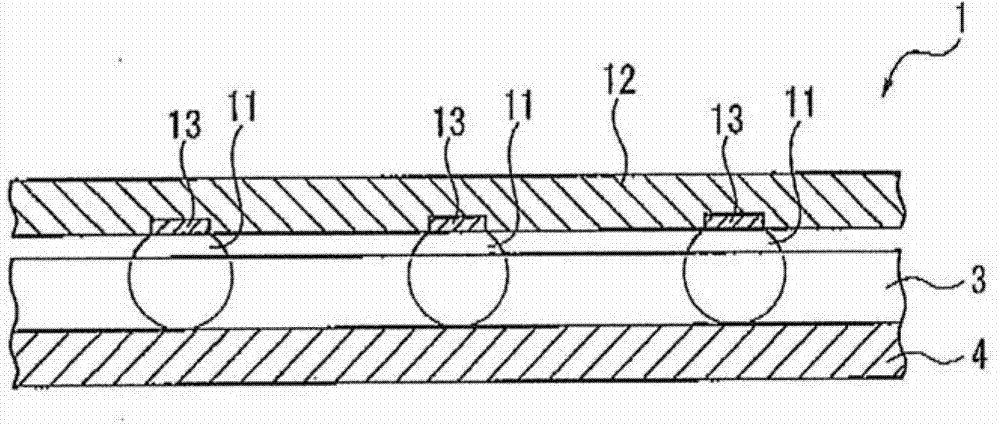

The invention provides a thermosetting resin composition for a joining method of a packaging part. The thermosetting resin composition contains epoxy resin, organic acid and thixotropic agent, wherein the epoxy resin contains dimeric-dibasic-acid type epoxy resin. The joining method of the packaging part comprises a film forming process, a resin-composition adhesion process, a loading process and a reflow soldering process.

Owner:TAMURA KK

Vehicle-body structure of vehicle and manufacturing method of the same

ActiveUS20130049392A1Improve comfortable rideReduce noiseMetal-working apparatusSuperstructure subunitsEngineeringMechanical engineering

Owner:MAZDA MOTOR CORP

Vehicle-body structure of vehicle and manufacturing method of the same

ActiveUS8708390B2Reduce noiseRigid enoughVehicle seatsMetal-working apparatusEngineeringMechanical engineering

Owner:MAZDA MOTOR CORP

Electronic component with lead wire

InactiveCN101677151AImprove reliabilityIncrease contact areaThermometers using electric/magnetic elementsSoldered/welded conductive connectionsElectrical connectionElectrical bonding

The present invention provides an electronic component including a lead wire, which has improved bonding strength with a simple structure and low cost and which has improved electrical connection andhigh reliability. In an electronic component, first and second lead wires include coated portions and first and second metal wire exposed portions. The coated portions include metal wires that are coated with insulating members. Each of the first and second metal wire exposed portions have a flat shape. The first lead wire and the second lead wire are arranged parallel or substantially parallel toeach other. The second lead wire is shorter than the first lead wire. The first metal wire exposed portion is soldered to the side surface folded portion of the terminal electrode. The second metal wire exposed portion is soldered to the side surface folded portion of the terminal electrode. The first and second metal wire exposed portions are located substantially in the same plane. A solder fillet is provided not only on the side surface folded portions, but also on end surface portions and in a gap.

Owner:MURATA MFG CO LTD

Vehicle-body structure of vehicle and manufacturing method of the same

In a frame having a closed-section portion which is formed by joining a first member having a U-shaped section and a second member having a flat-plate shape, a bulkhead is provided in the closed-section portion as a reinforcing member, flanges of the bulkhead and the first and second members are joined with a rigid joint portion where they are joined by a spot welding and a flexible joint portion where they are joined via a damping member. Thereby, transmission of vibrations can be properly restrained, improving the rigidity of the portion having the closed-section portion.

Owner:MAZDA MOTOR CORP

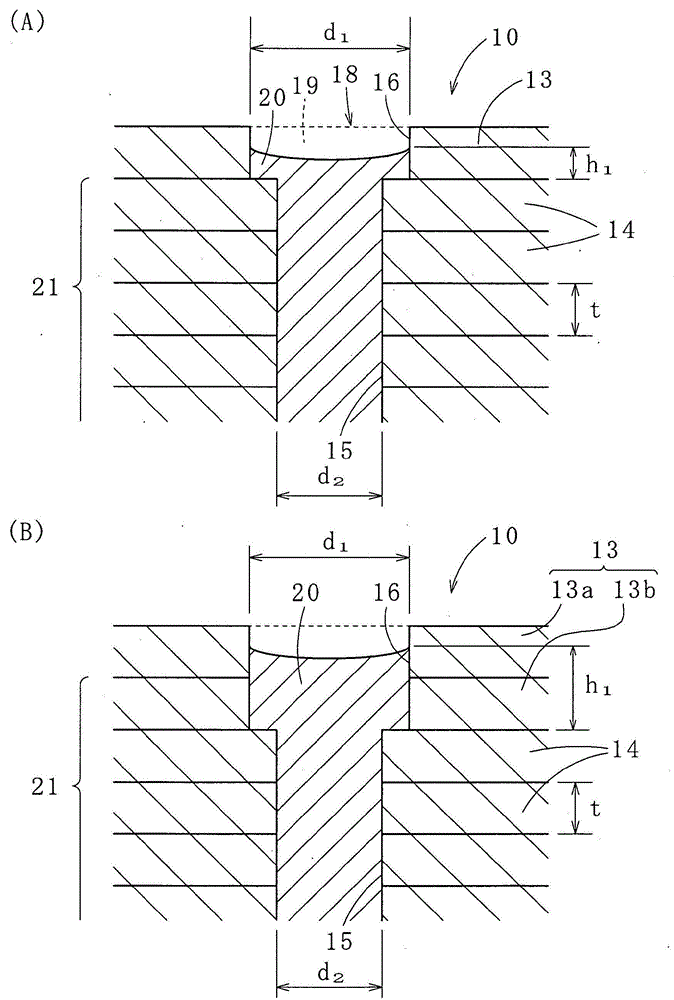

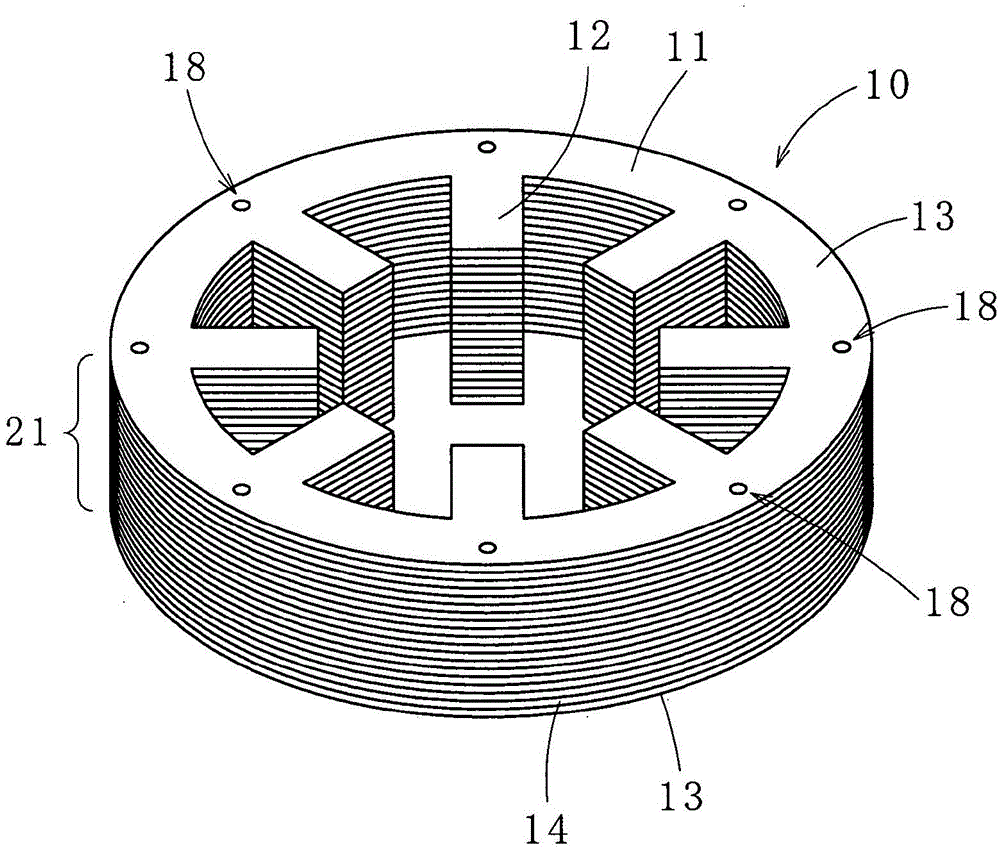

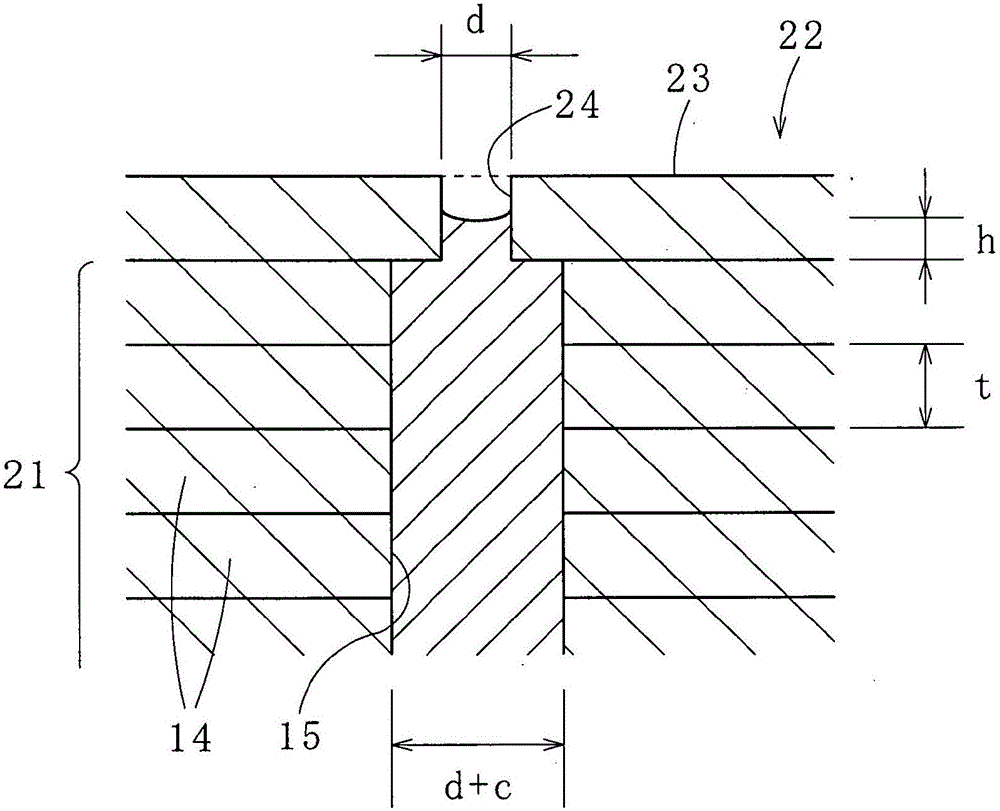

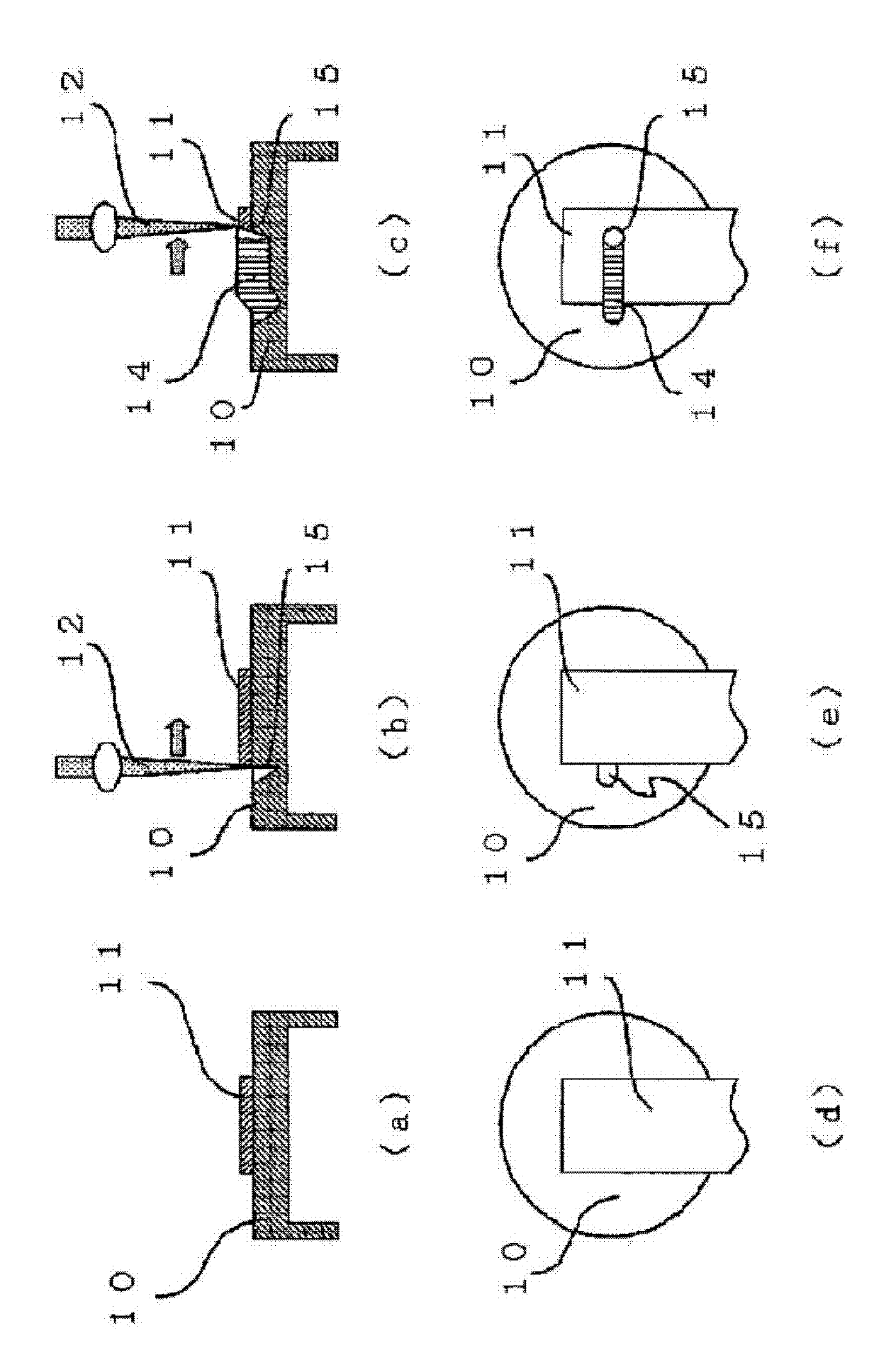

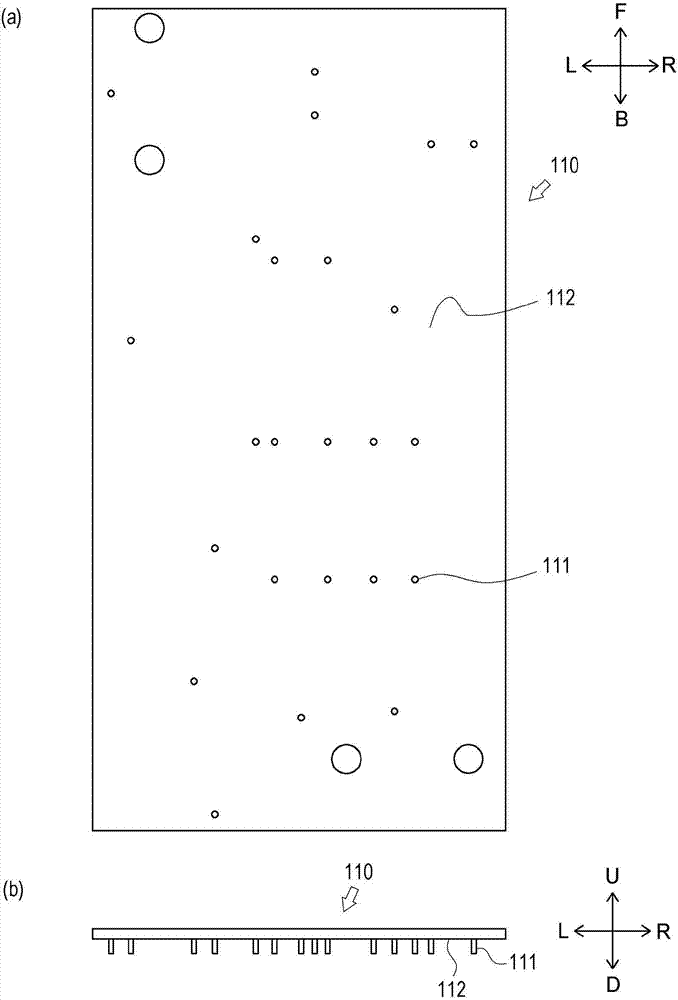

Laminated core and method for manufacturing the same

ActiveCN104578462AEnsure joint strengthPrevent peelingMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringUltimate tensile strength

A laminated core 10 including a plurality of laminated iron core pieces, each of the iron core pieces being connected in a laminating direction by filling resin in a plurality of resin holes penetrating the laminated core 10 in the laminating direction, and a method for manufacturing the laminated core 10, by making a junction area of an iron core piece (A) 13 and resin larger than a junction area of an iron core piece (U) 14 and resin, the iron core piece (A) 13 being provided on an end in an axial direction, the iron core pieces (U) 14 being arranged at positions other than the end in the axial direction, or by providing locking portions at tip portions of resin, acquired joint strength of the iron core piece (A) 13.

Owner:MITSUI HIGH TEC INC

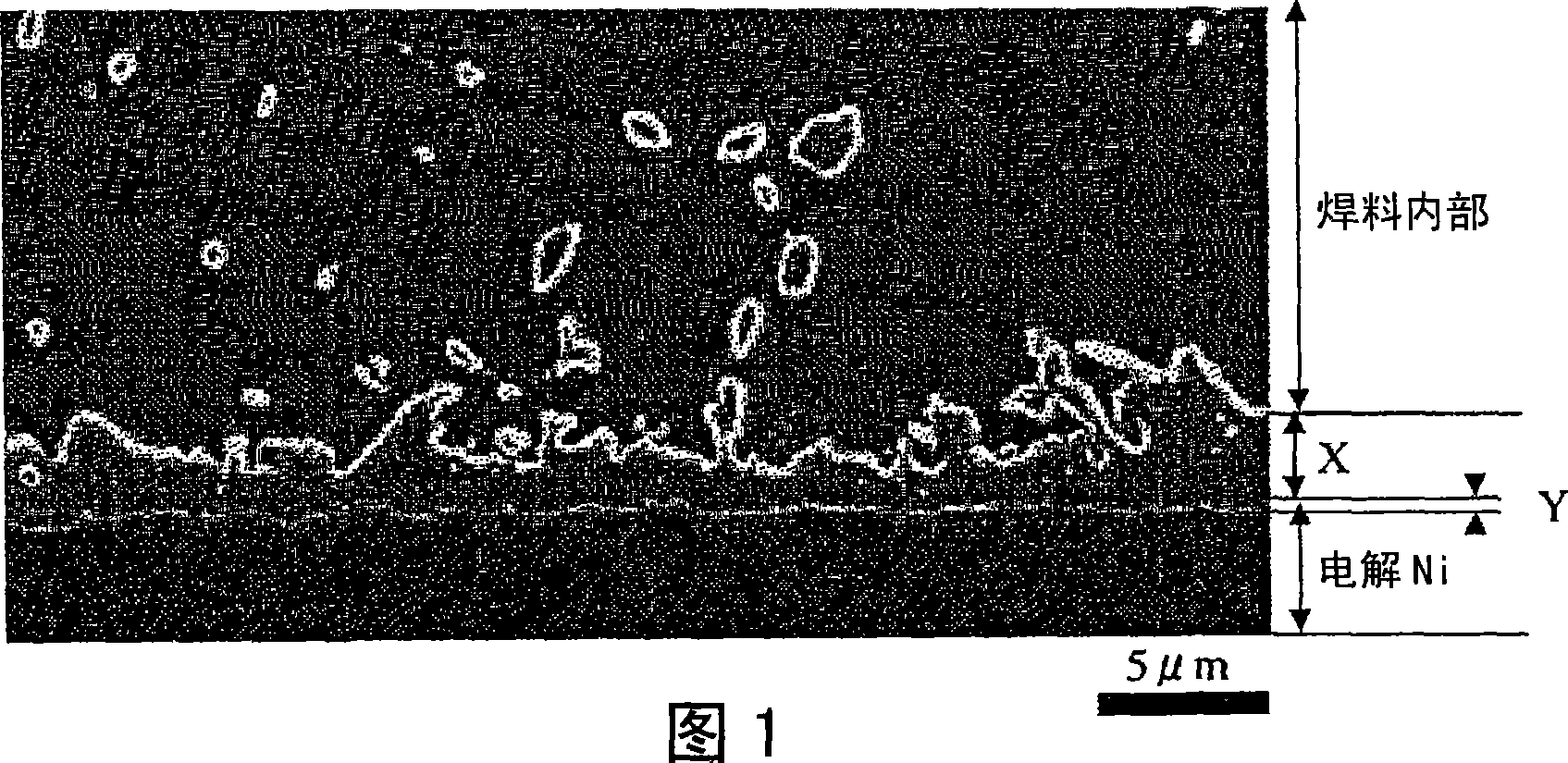

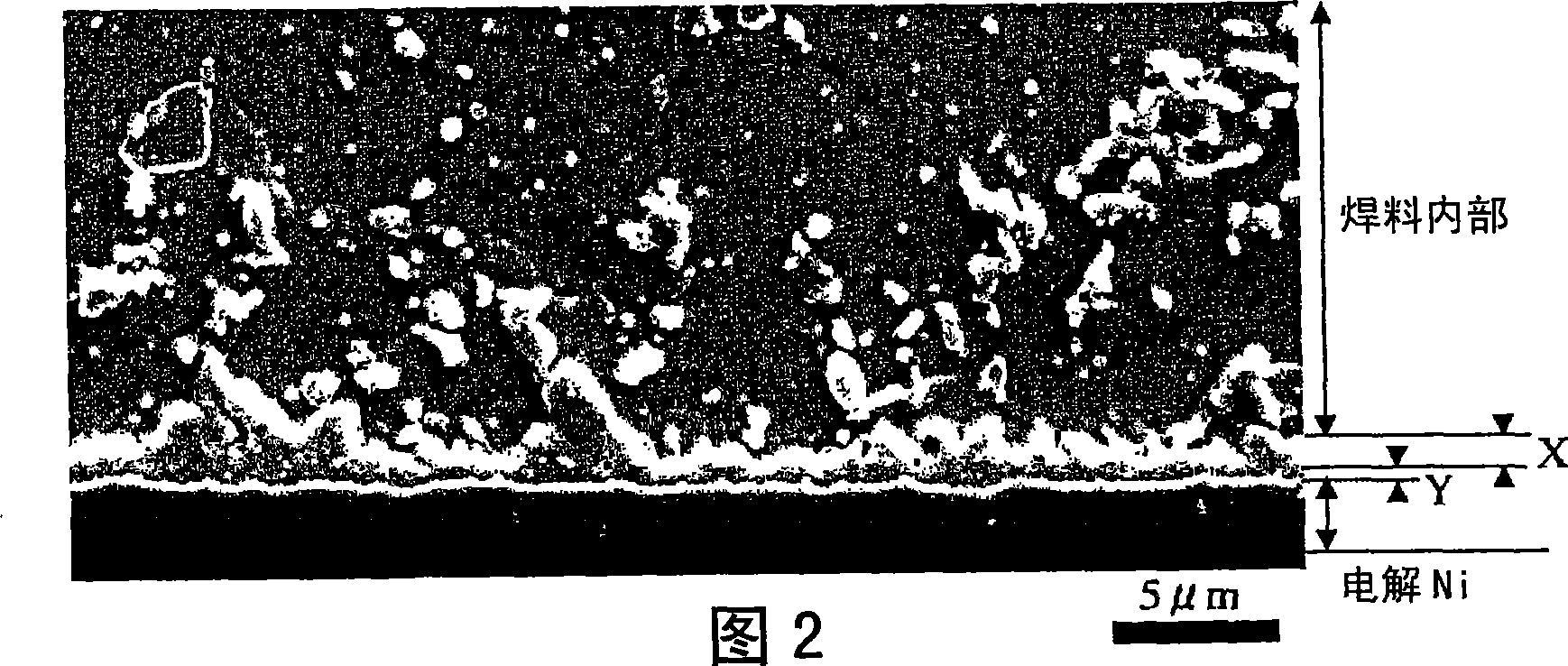

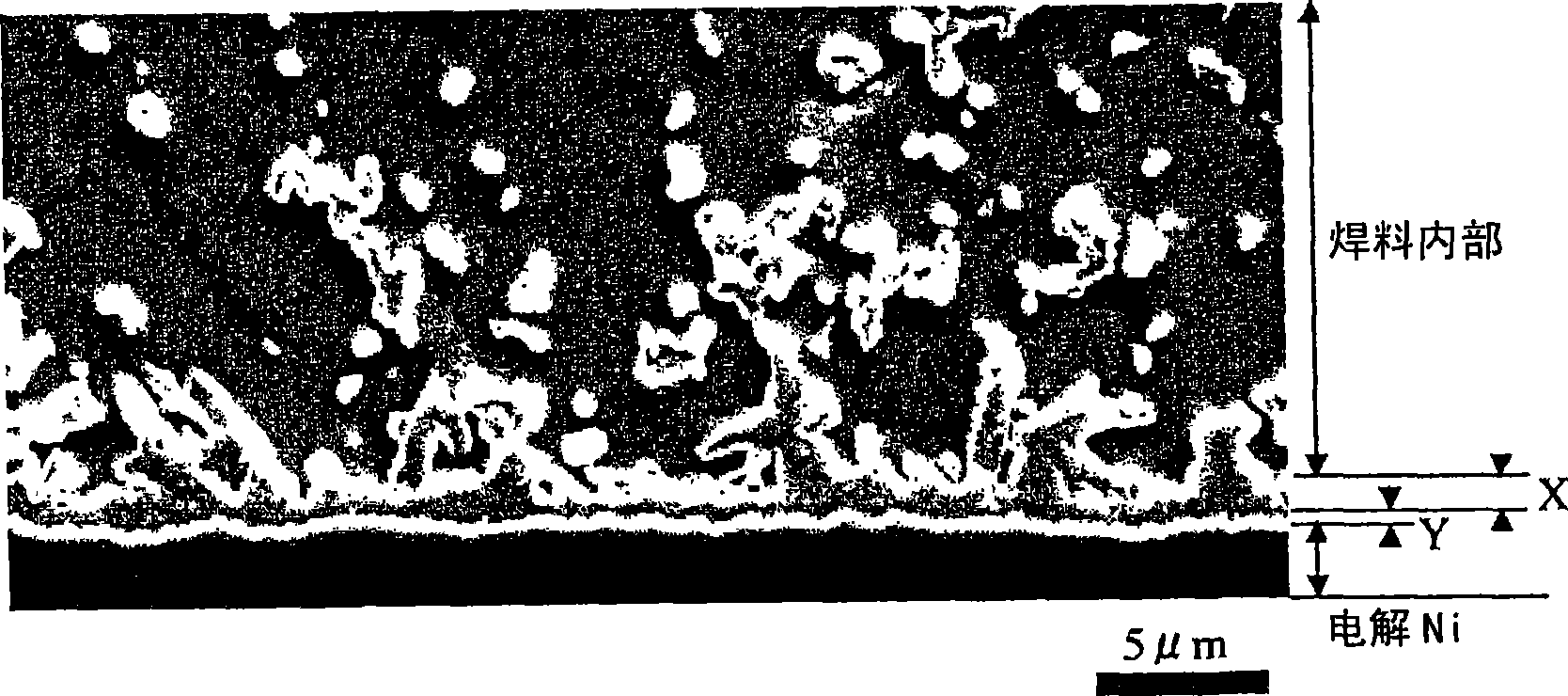

Solder alloy, solder ball and solder joint using same

InactiveCN101374630AImprove connection reliabilityEnsure joint strengthPrinted circuit assemblingSolid-state devicesDrop impactSolder ball

Disclosed is a Pb-free solder alloy consisting of, in mass%, 0.1-1.5% of Ag, 0.5-0.75% of Cu, Ni in an amount satisfying 12.5 = Cu / Ni = 100, and the balance of Sn and unavoidable impurities. The solder alloy preferably contains, in mass%, 0.3-1.2% of Ag and 0.01-0.04% of Ni. Also disclosed is a solder ball obtained by spheroidizing the solder alloy. In addition, the solder alloy is suitable for a solder joint onto an Ni electrode. The solder alloy has excellent drop impact resistance, while being suppressed in decrease of joining strength under high temperature conditions for a long time.

Owner:HITACHI METALS LTD

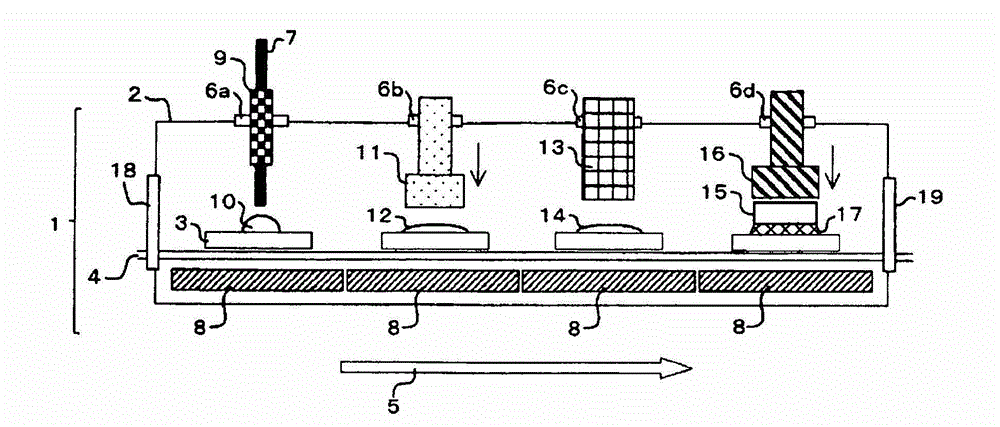

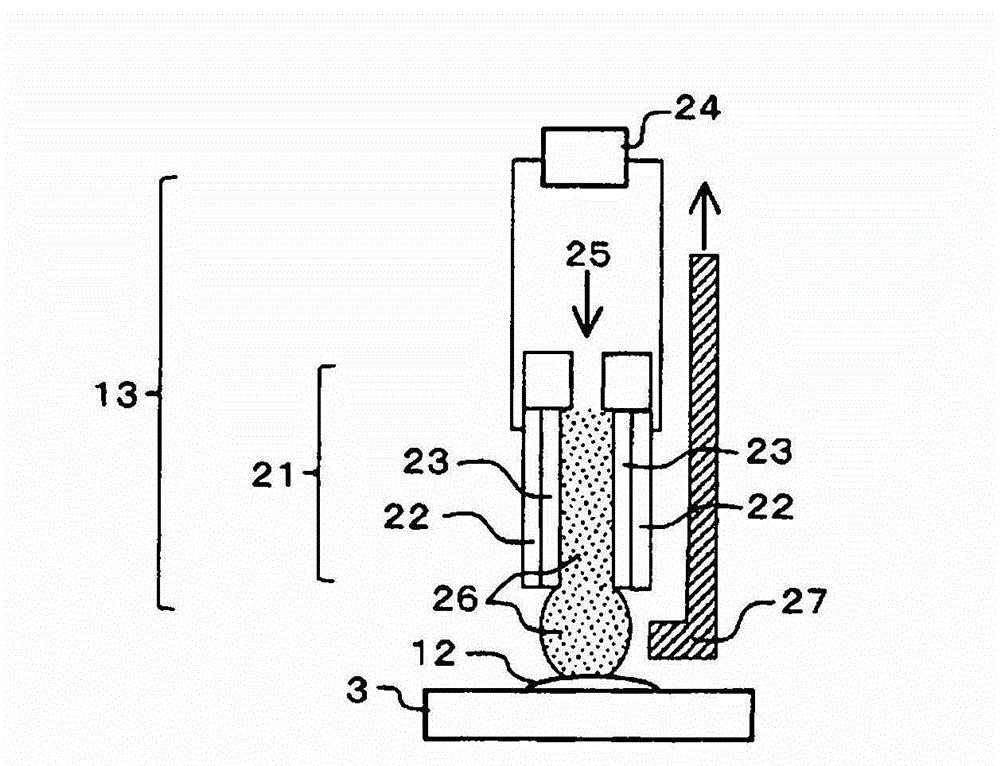

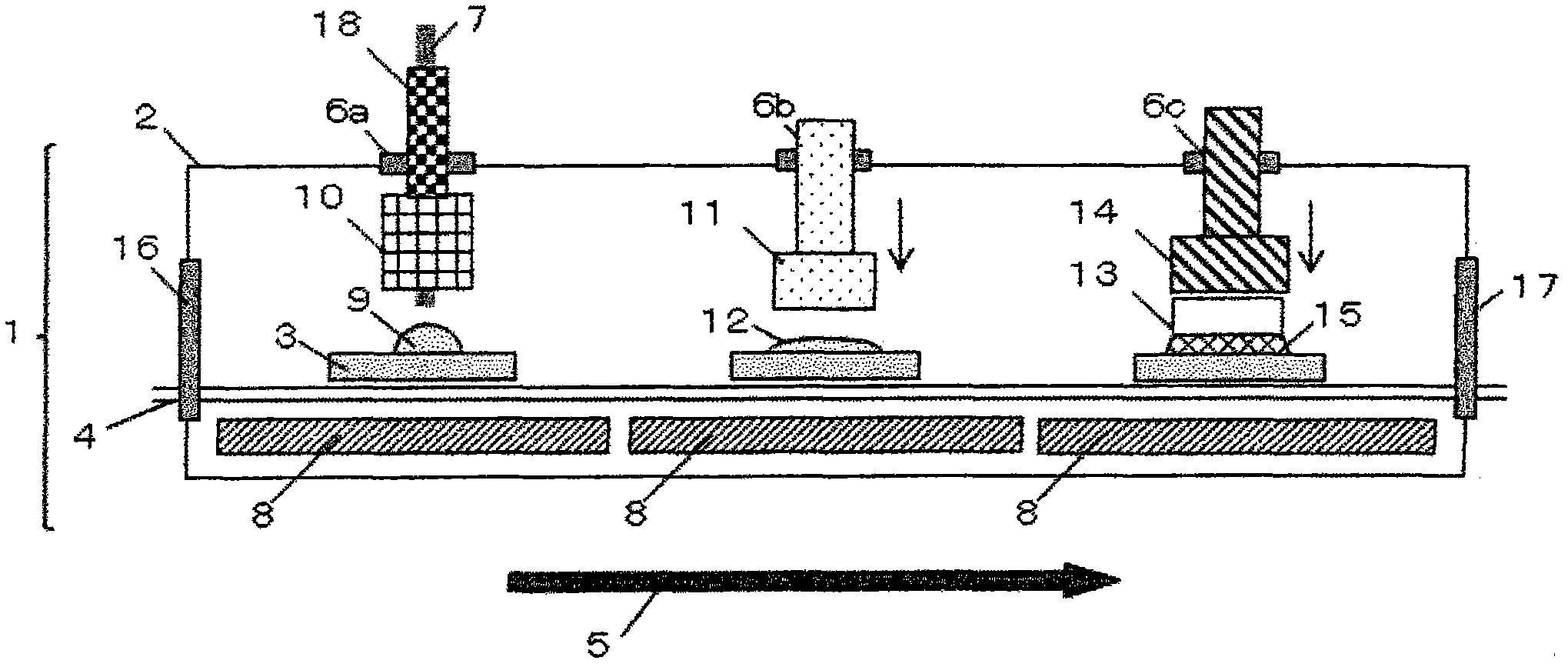

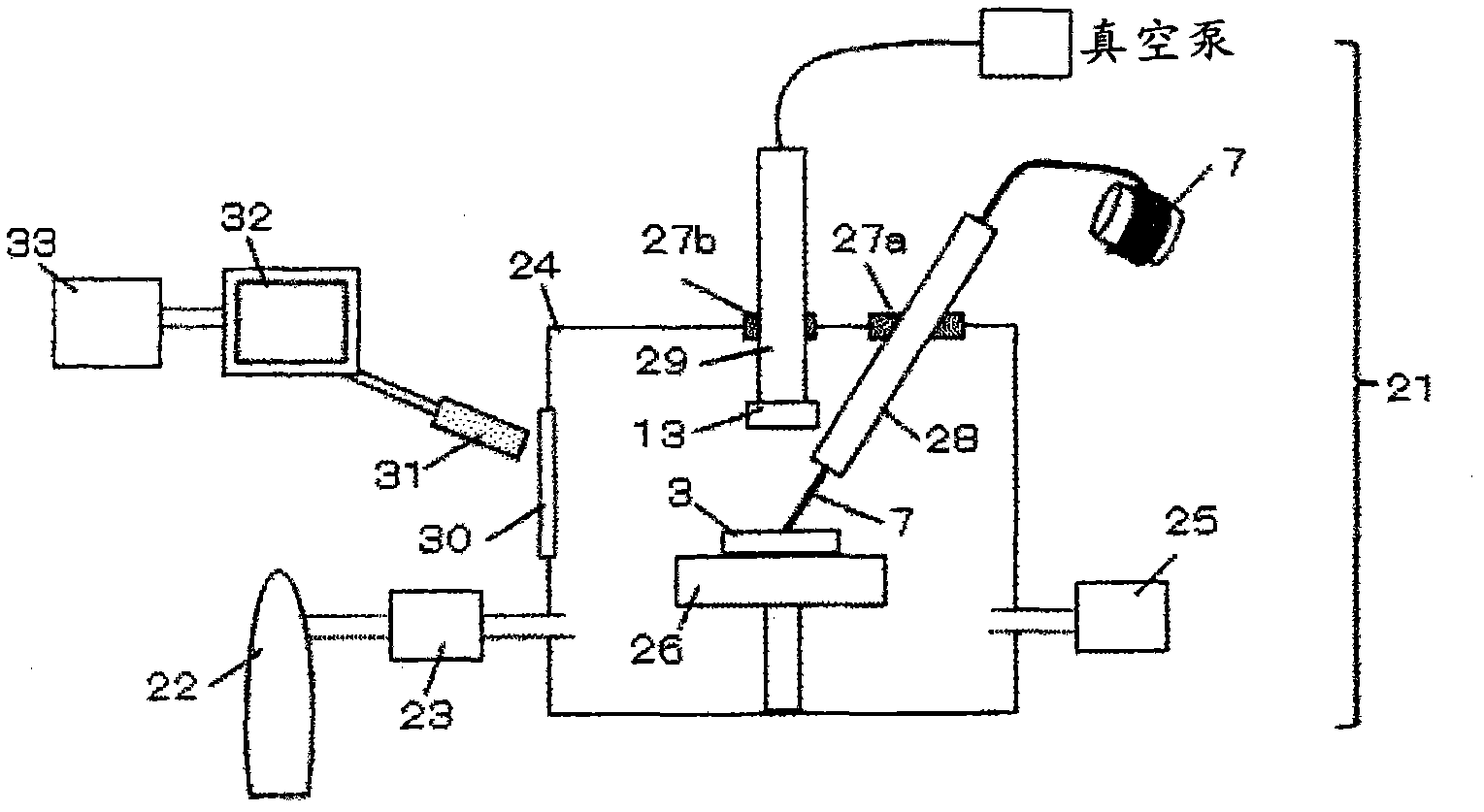

Chip engagement device and chip engagement method

InactiveCN103065987AInhibitionGuaranteed cooling effectSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipEngineering

The present invention provides a chip engagement device and a chip engagement method which can reduce voids in a solder engagement portion and poor interface engagement. A chip engagement machine which engages a semiconductor chip on a lead frame or a substrate by the solder comprises a conveying unit for conveying the above lead frame or the substrate, a solder supply unit for supplying the solder to the above lead frame or the substrate, and a carrying unit for carrying and engaging the above semiconductor chip onto the above lead frame or the substrate. The chip engagement machine also has a surface clean unit. The surface clean unit removes an oxide film on the solder surface melt in a furnace after the solder is supplied to the lead frame or the substrate. Chip engagement quality can be increased by the above chip engagement device.

Owner:HITACHI HIGH TECH INSTR CO LTD

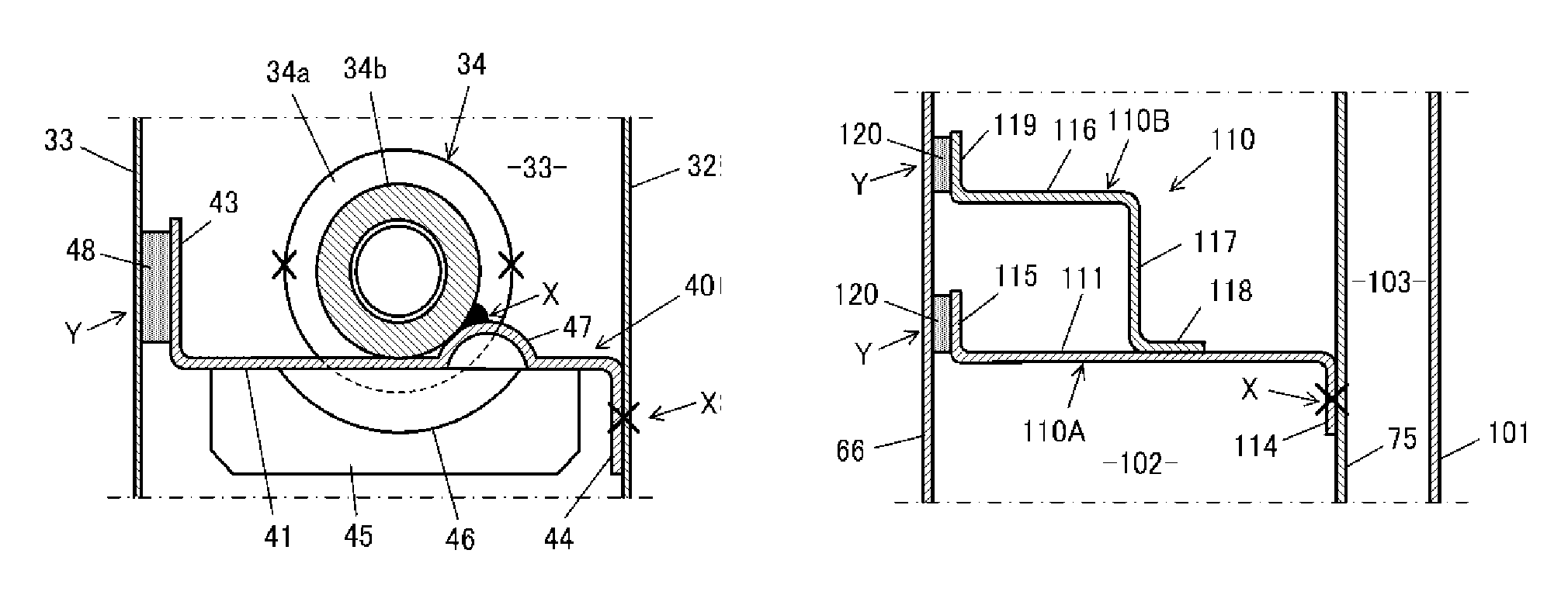

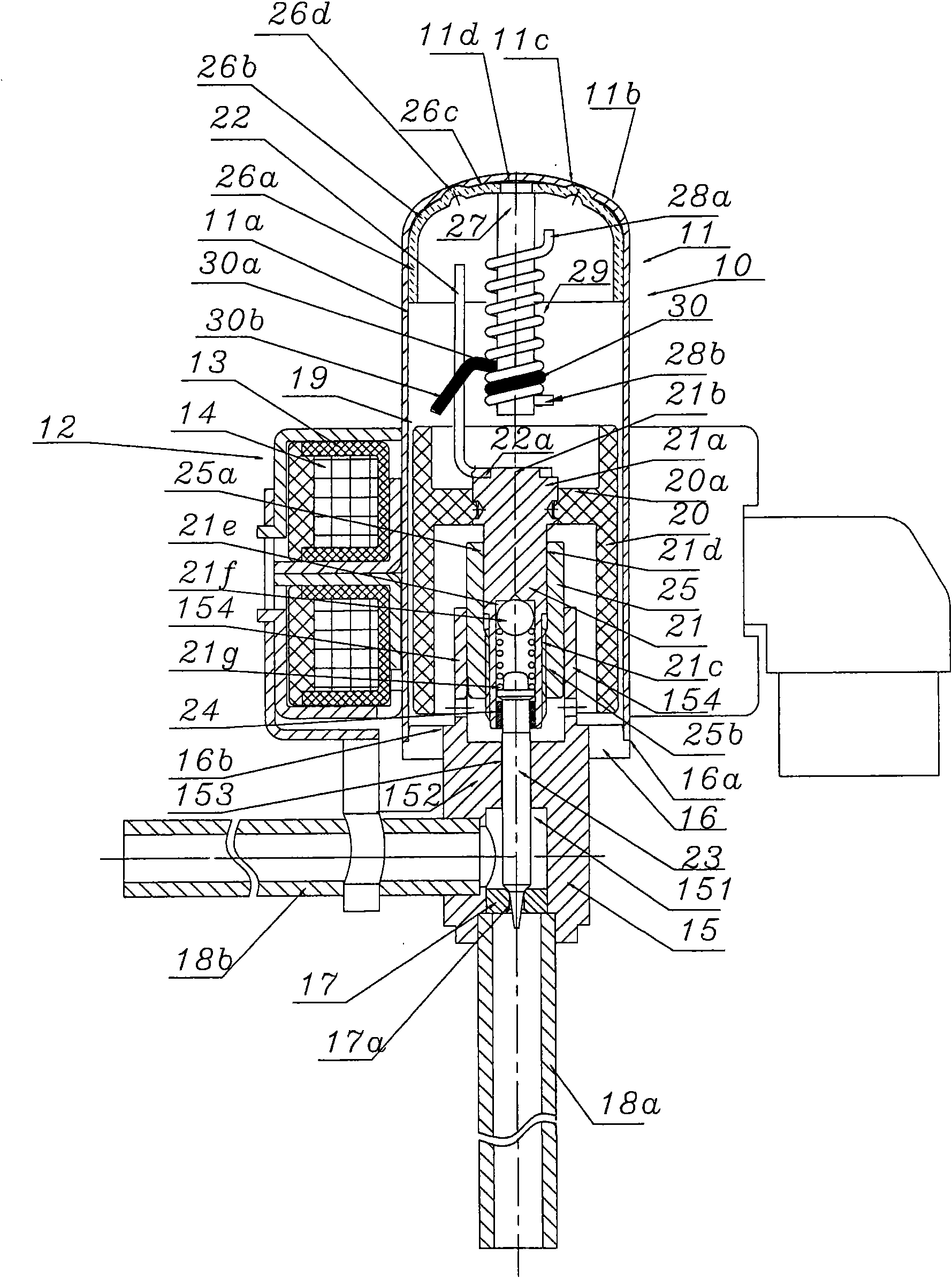

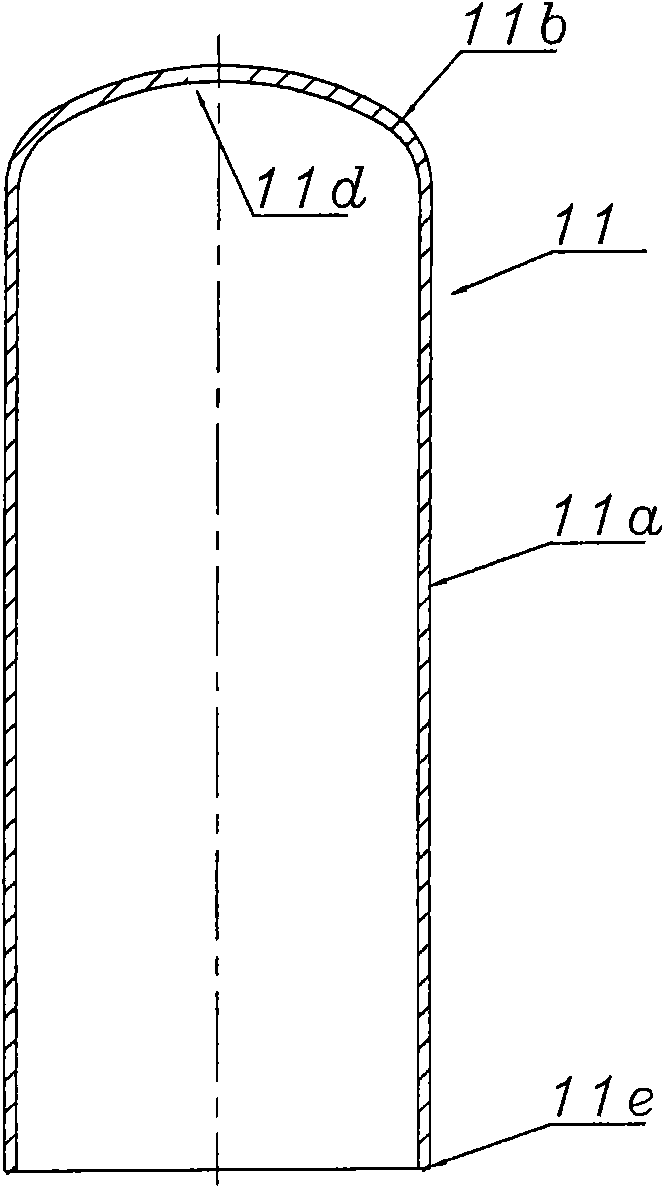

Electrically operated valve

ActiveCN101769389AMiniaturizationLimit stop motionOperating means/releasing devices for valvesFluid circulation arrangementStator coilEngineering

An electrically operated valve comprises a sealed housing in which the bottom is fixed on a valve body provided with a valve chamber and a throttling hole; a step motor installed inside the sealed housing comprises a stator coil and an rotor in opposite configuration; a valve needle approaches to or leaves away from the throttling hole according to the driving of the step motor; the inner part of the sealed housing is provided with a stop mechanism for stopping the rotation of the rotor; the stopping mechanism limits the up and down movement of the valve needle so as to control the flow rate of the fluid passing in and out of the valve chamber; the sealed housing comprises a cylindrical wall part, a bent part, an arc part, and a cover-shaped shield component; the cover-shaped shield component comprises a short cylindrical wall part formed on the inner periphery surface of the head part connected through spot welding on the arc part; the cover-shaped shield component comprises a bent part and a top part which are integrally formed; the short cylindrical wall part, the bent part and the top part are respectively formed into the external periphery shapes of the short cylindrical wall part, the bent part, and the top part along the sealed housing; and simultaneously, the cover-shaped shield component is provided with the stop mechanism.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

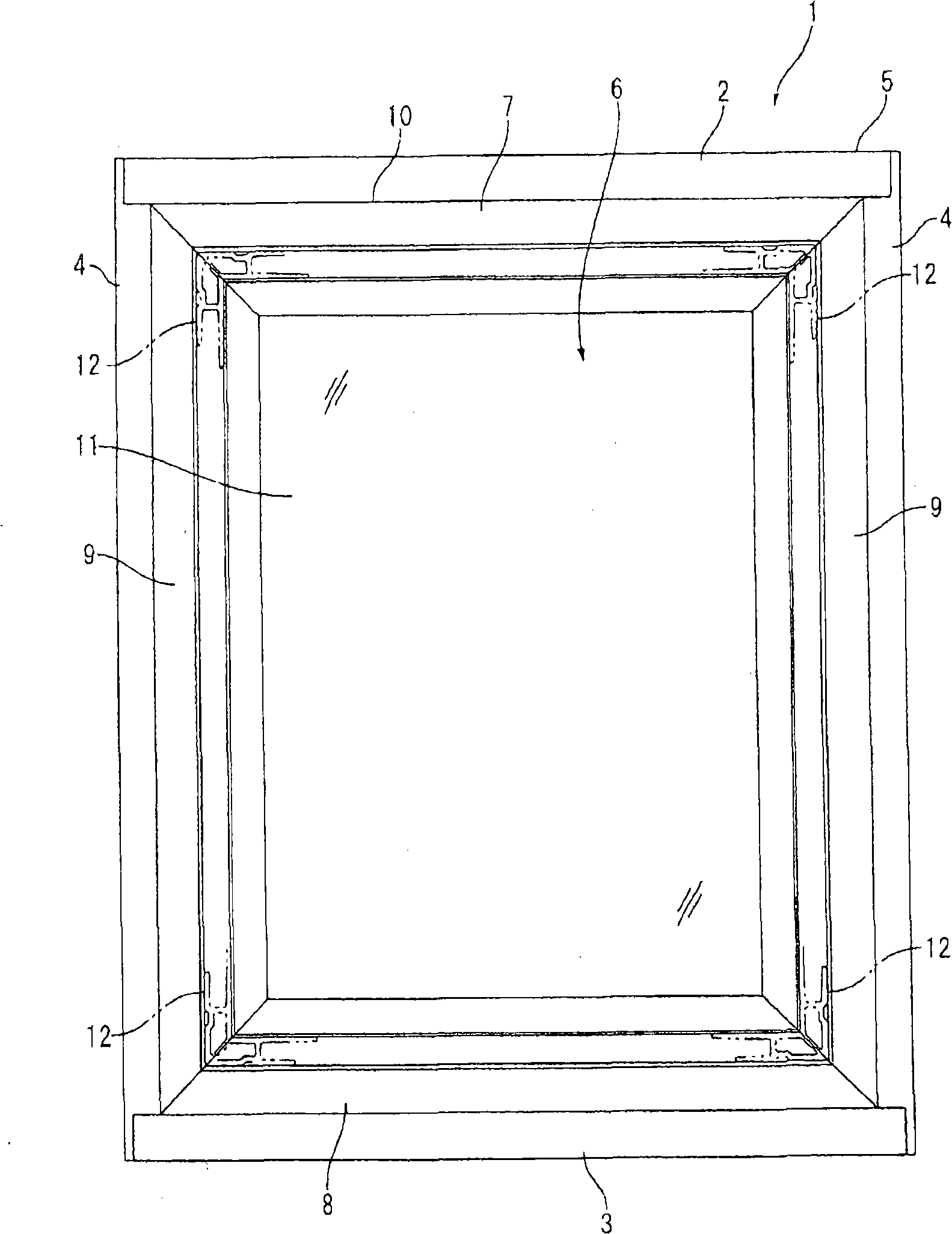

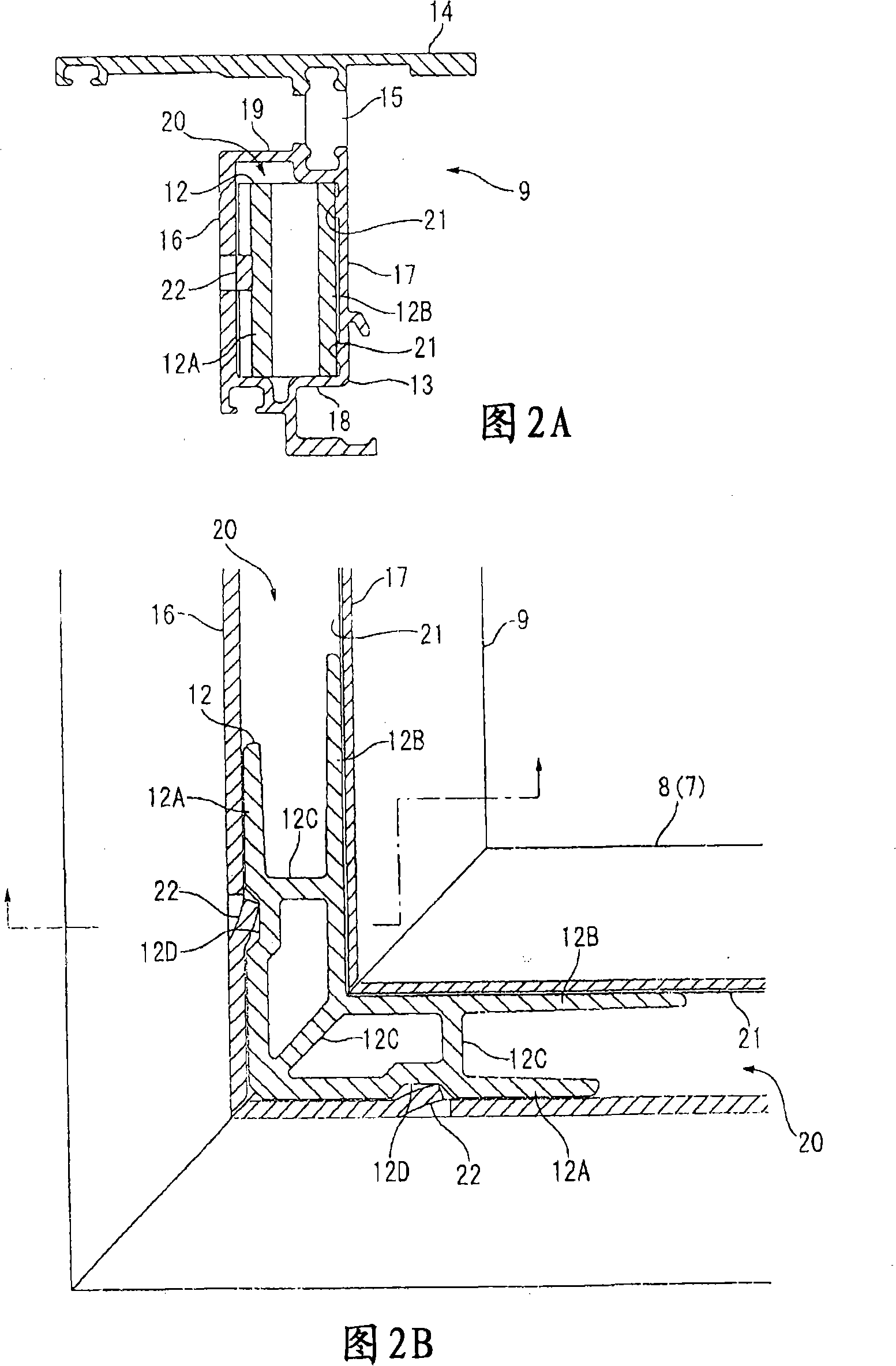

Joint construction, door and window frame, and manufacturing process of the oor and window frame

InactiveCN101260774AAvoid deflectionEnsure joint strengthDoors/windowsMetal-working apparatusEngineeringContact position

The invention discloses a joint constructure, fitting and manufacturing process of fitting. Since an inside piece of a joint block is abutted to a rib of a second opposed piece under a pressure by engaging a first opposed piece of a frame member with the joint block, the inside piece can be securely abutted at the position of the rib even when the second opposed piece and the joint block are slightly deformed, which secures a predetermined joint intensity by preventing a variation of the abutment position. Since the joint block is abutted with the rib, the pressure per a dimension can be more increased than abutting with the whole surface of the inside piece, which consequently increases the frictional force to improve the joint intensity.

Owner:YKK AP INC

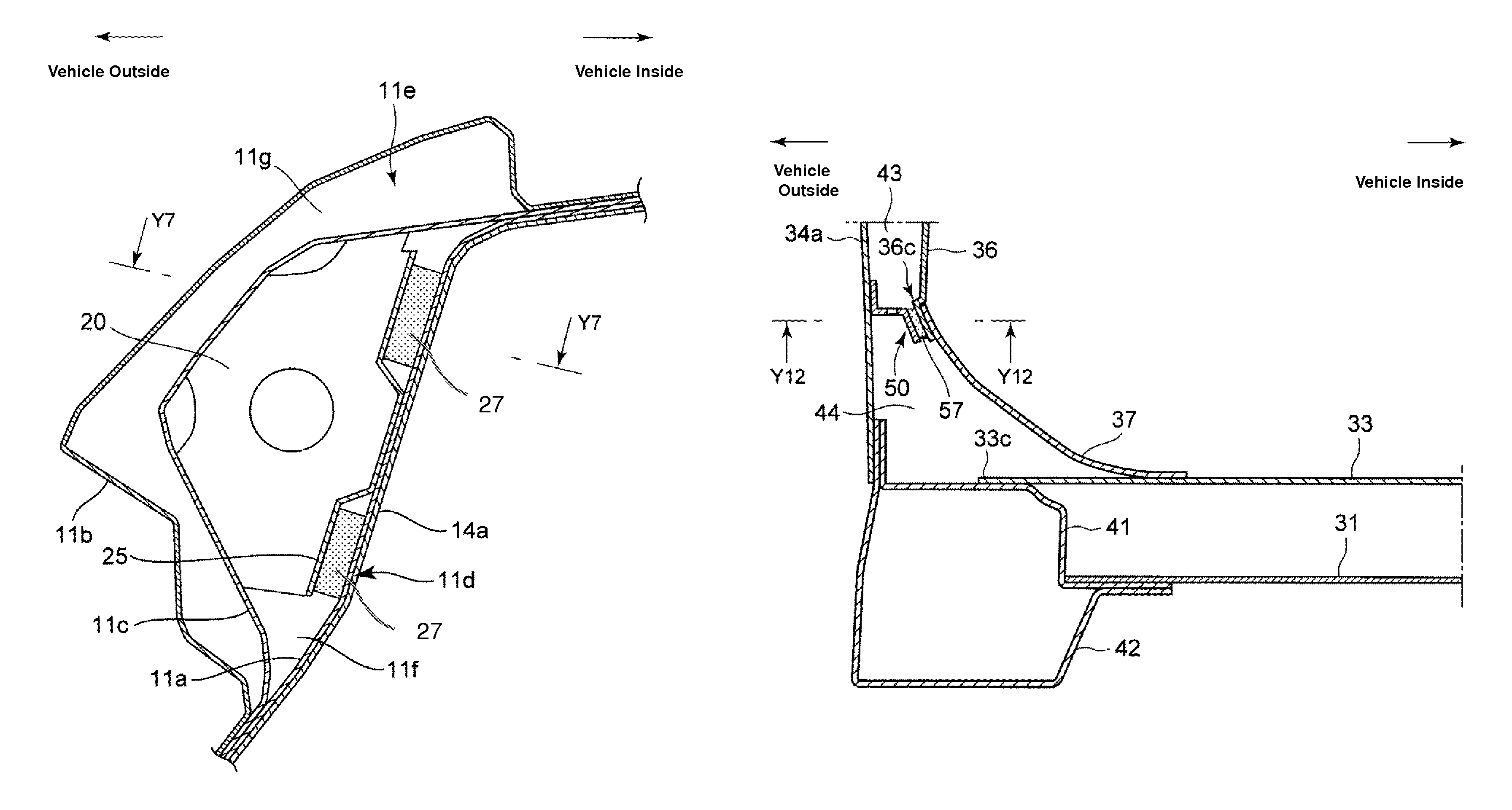

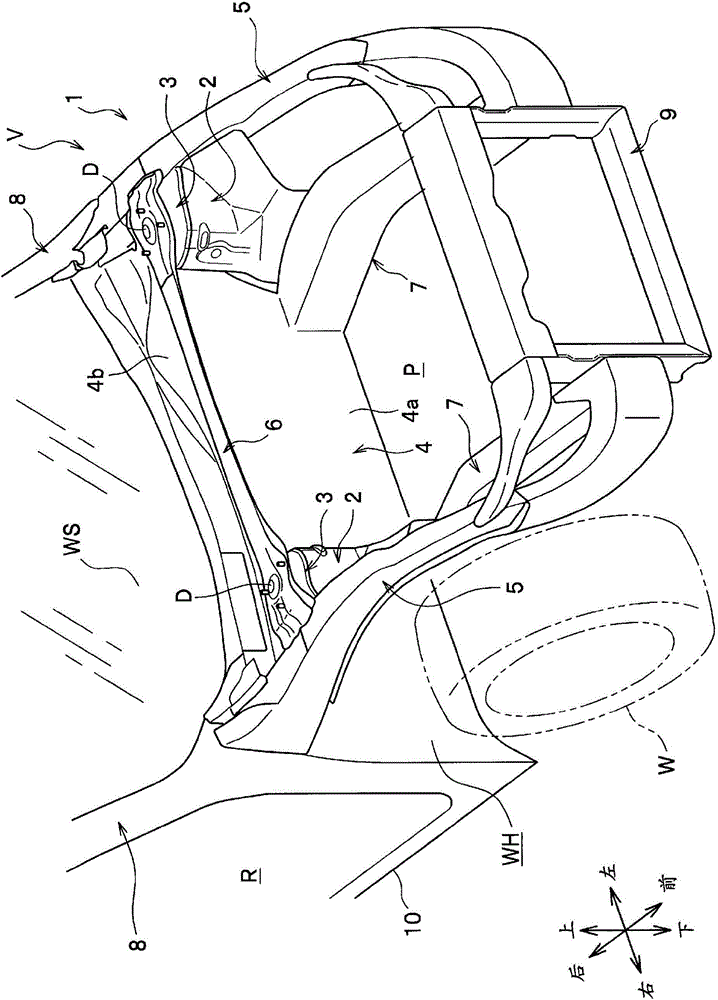

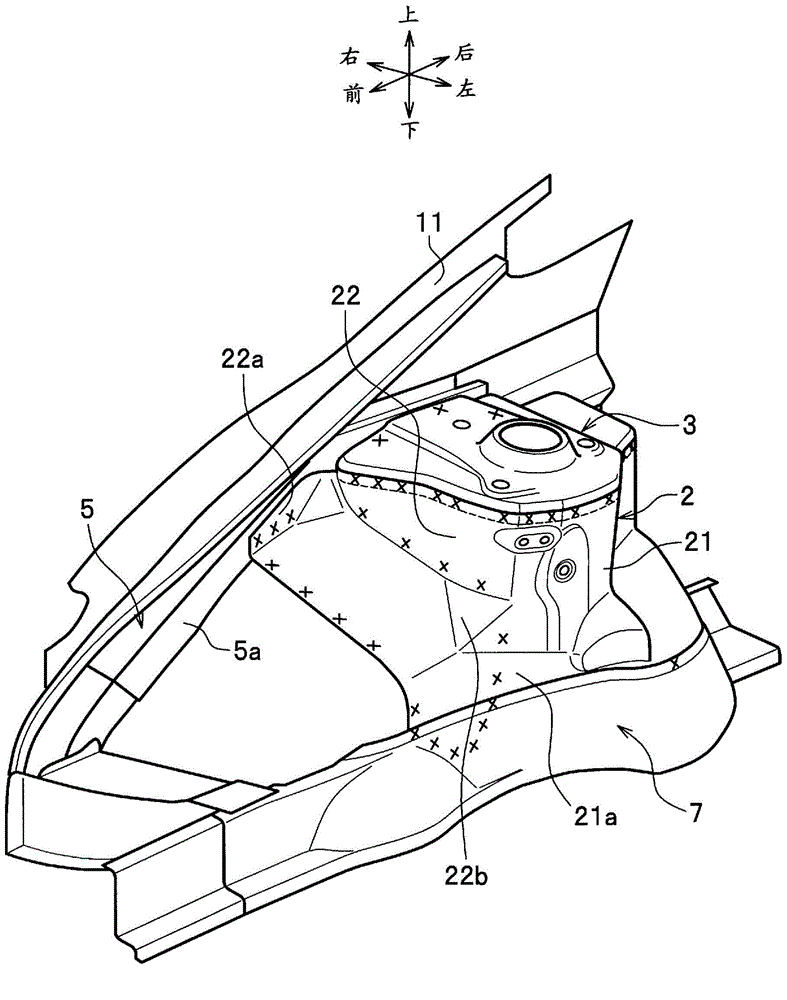

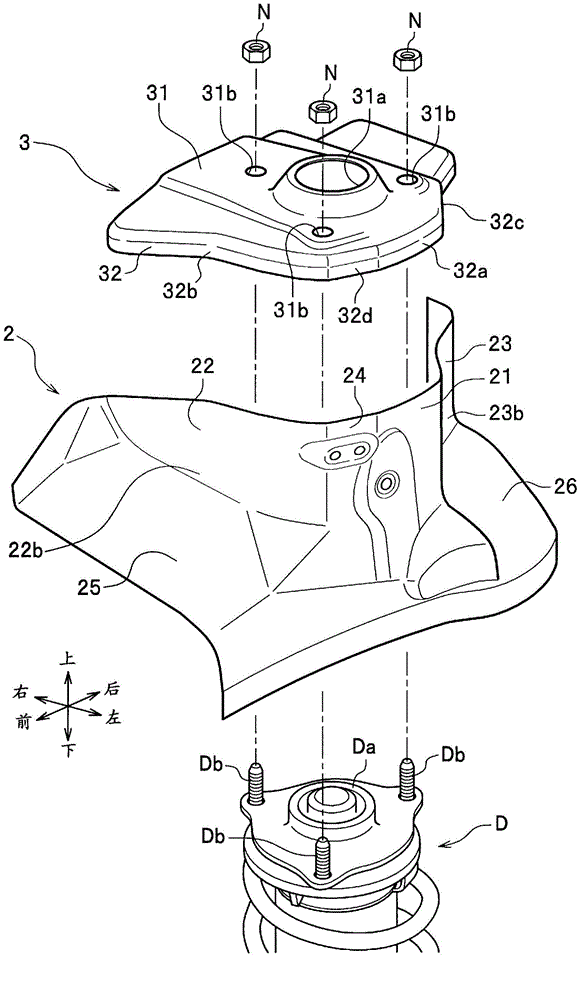

Damper housing structure body and damper housing structure body fabrication method

ActiveCN104349969AEnsure joint strengthAvoid weight gainWelding electric supplySuperstructure subunitsMan-hourEngineering

Owner:HONDA MOTOR CO LTD

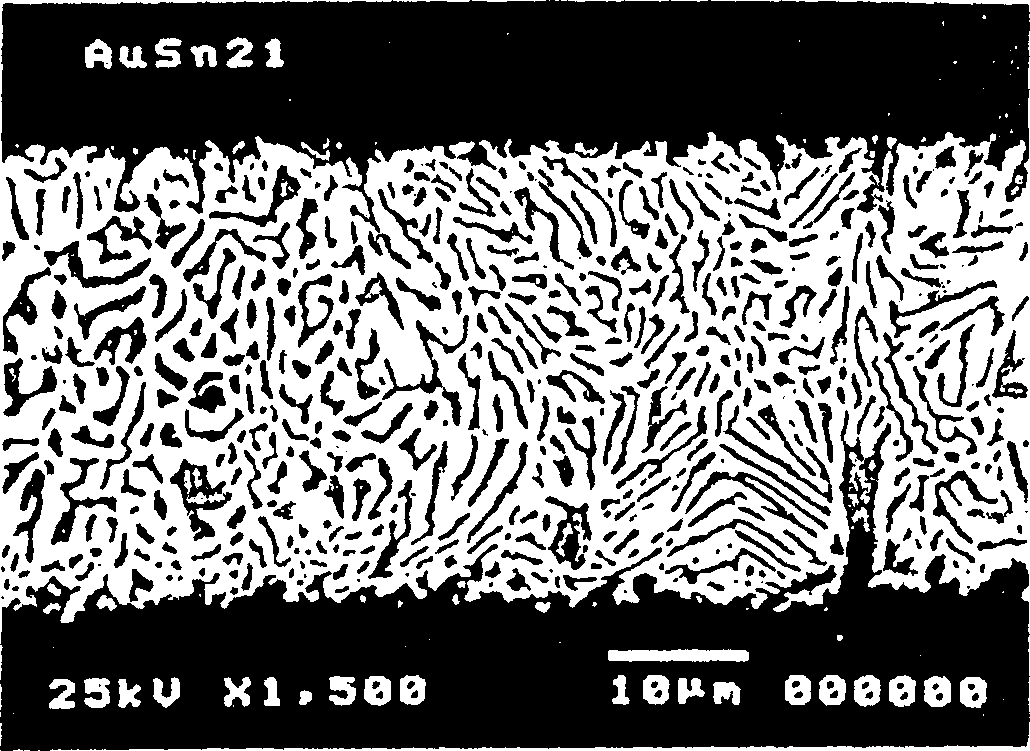

Method for hermetic sealing of electronic parts

InactiveCN1394359ASuppress generationUniform thicknessSemiconductor/solid-state device detailsSolid-state devicesMetallurgyHermetic seal

There is provided a method of hermetically sealing electronic parts, comprising the step of bonding a base having semiconductor devices mounted thereon and a cap together via a solder. The solder is composed, by weight, of 78% or more but less than 79.5% Au, and the balance Sn. It is particularly preferred that the bonding is performed with the use of a solder composition composed, by weight, of 78% or more but 79% or less Au, and the balance Sn as the solder and furthermore through plating the cap with gold.

Owner:TANAKA PRECIOUS METAL IND

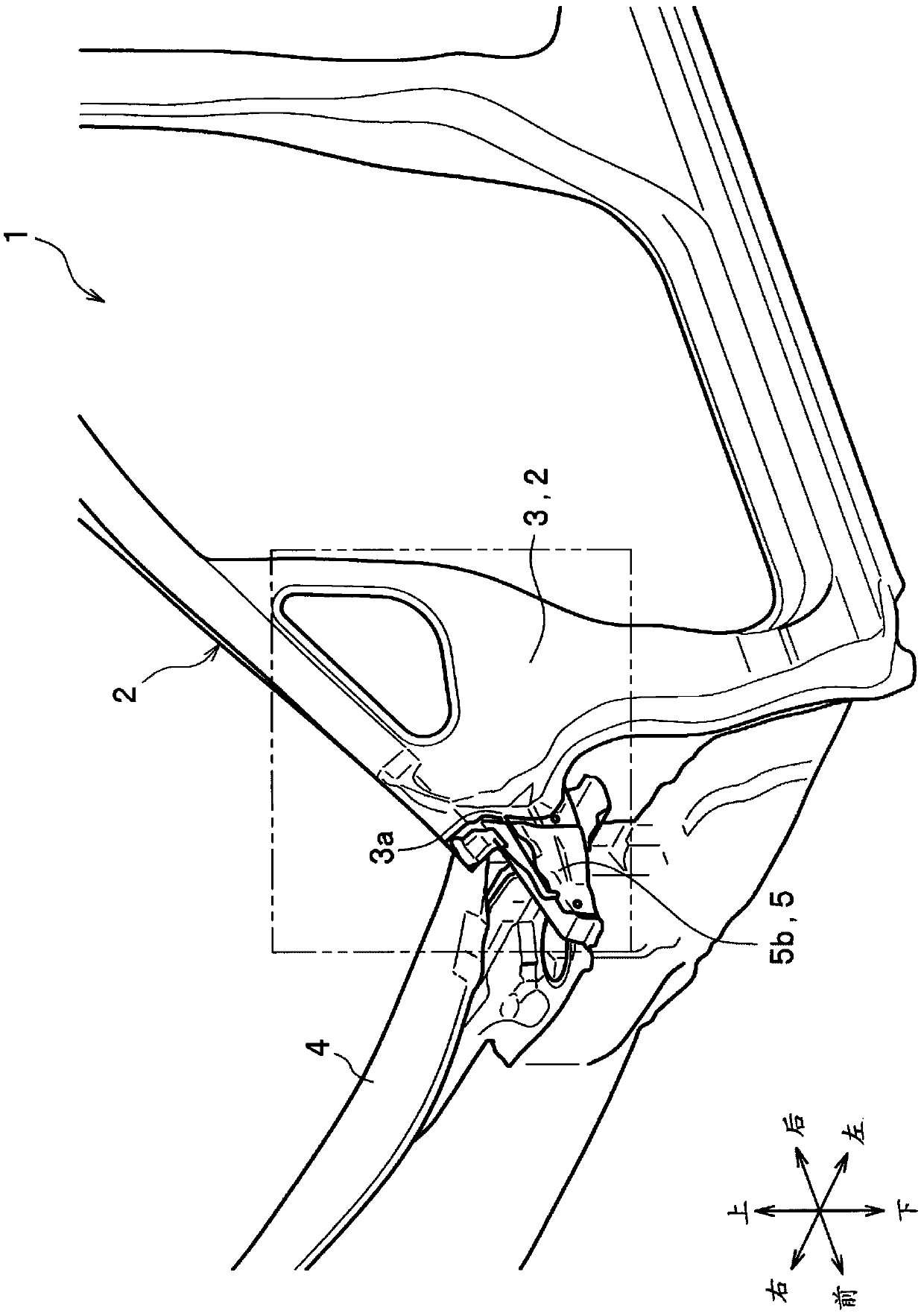

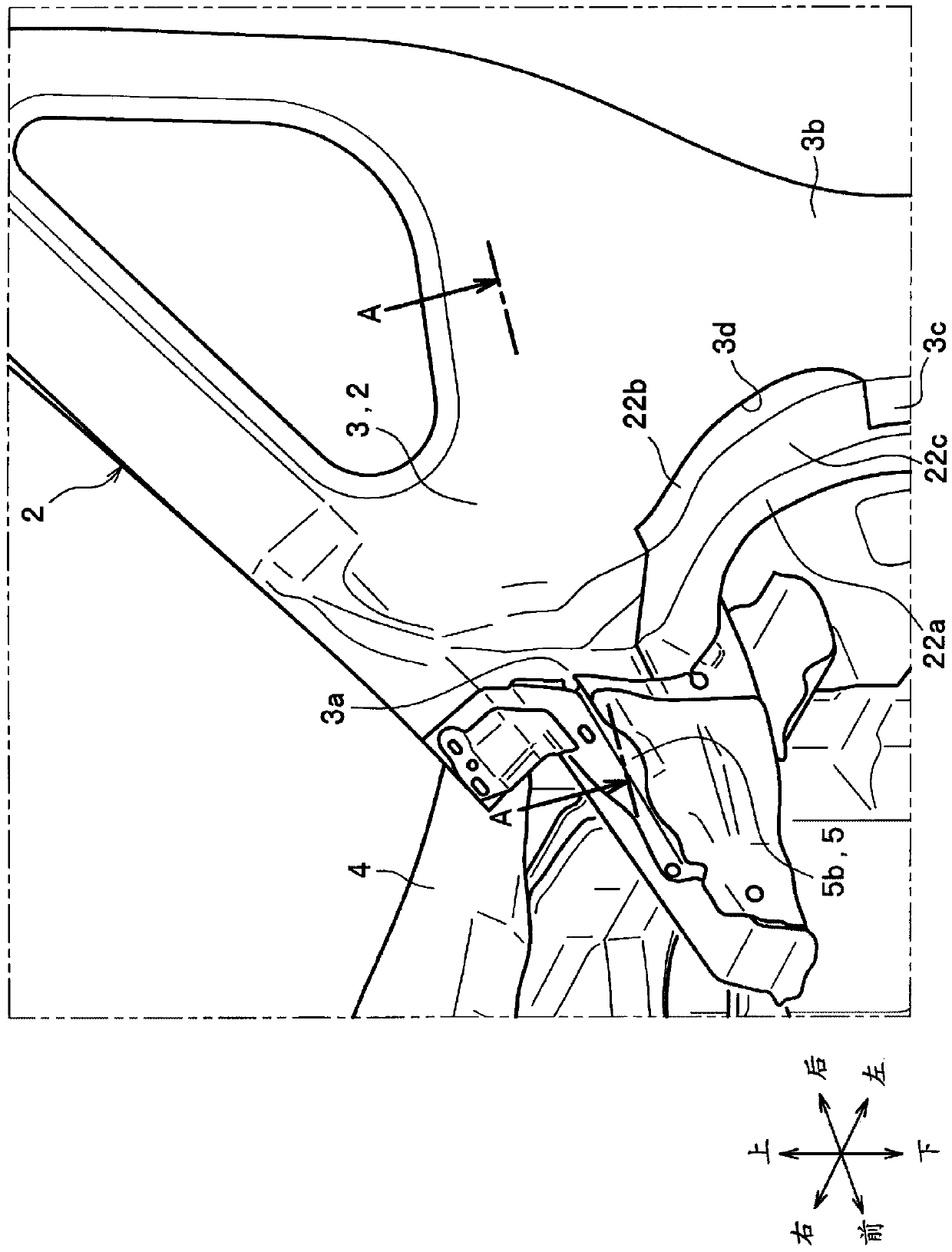

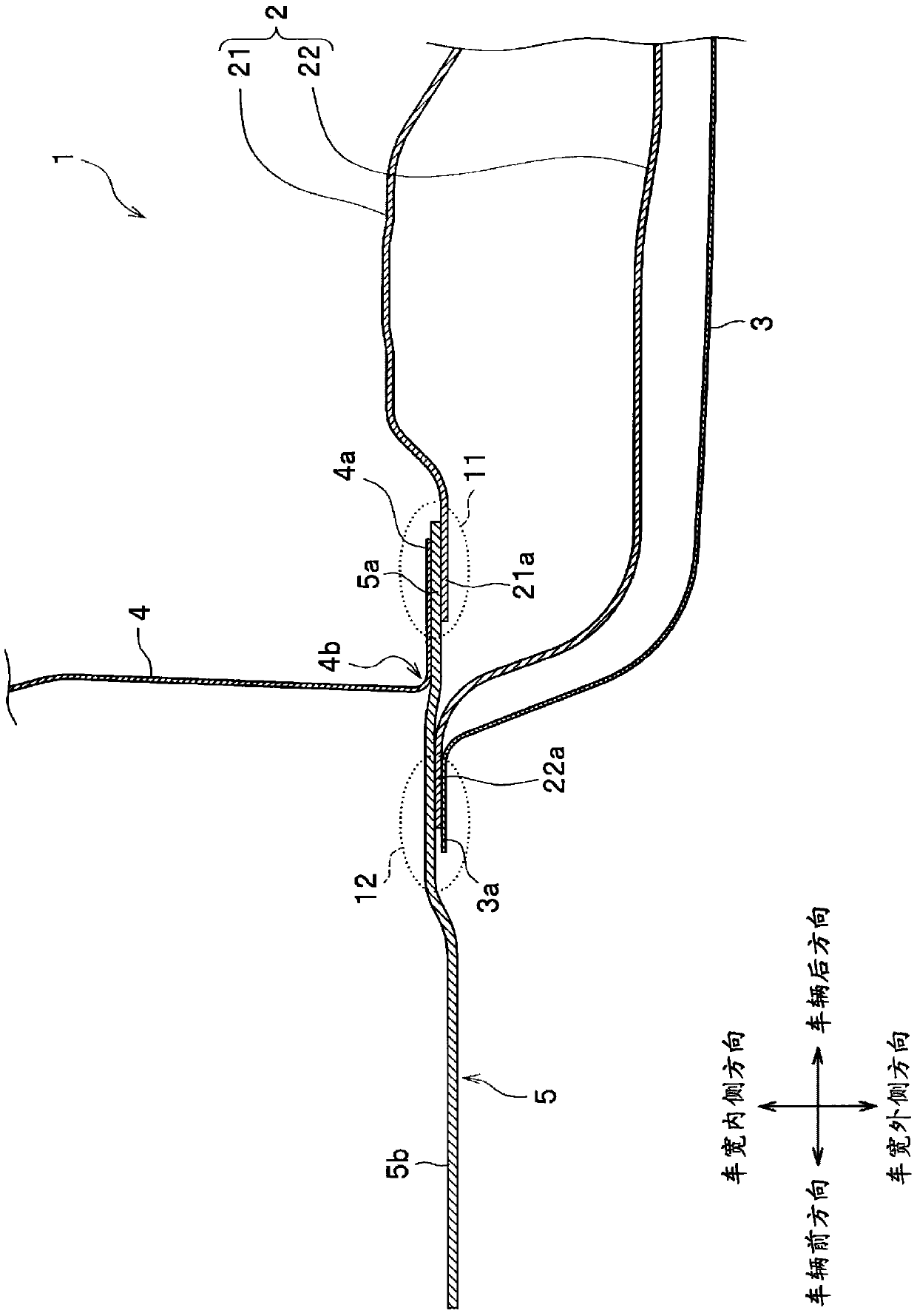

Vehicle body front portion structure, and vehicle body assembly method

ActiveCN105517881AQuantity reduction and simplification of assembly processSimplified quantitySuperstructure subunitsSuperstructure connectionsIn vehicleEngineering

Provided are a vehicle body front portion structure that enables an increase in vehicle body rigidity and strength while suppressing an increase in weight and a decrease in layout freedom, and a vehicle body assembly method. A vehicle body front portion structure (1) is provided with: a first weld portion (11) where a shield lower flange (4a) of a windshield lower member (4) is abutted on a closed cross section of a front pillar (2), and where the shield lower flange (4a), an inner front flange (21a), and a rear end portion (5a) are spot-welded; and a second weld portion (12) where a general portion (5b) of a side member (5), a stiffener front flange (22a), and an outer front flange (3a) are spot-welded at a position forwardly of the first weld portion (11).

Owner:HONDA MOTOR CO LTD

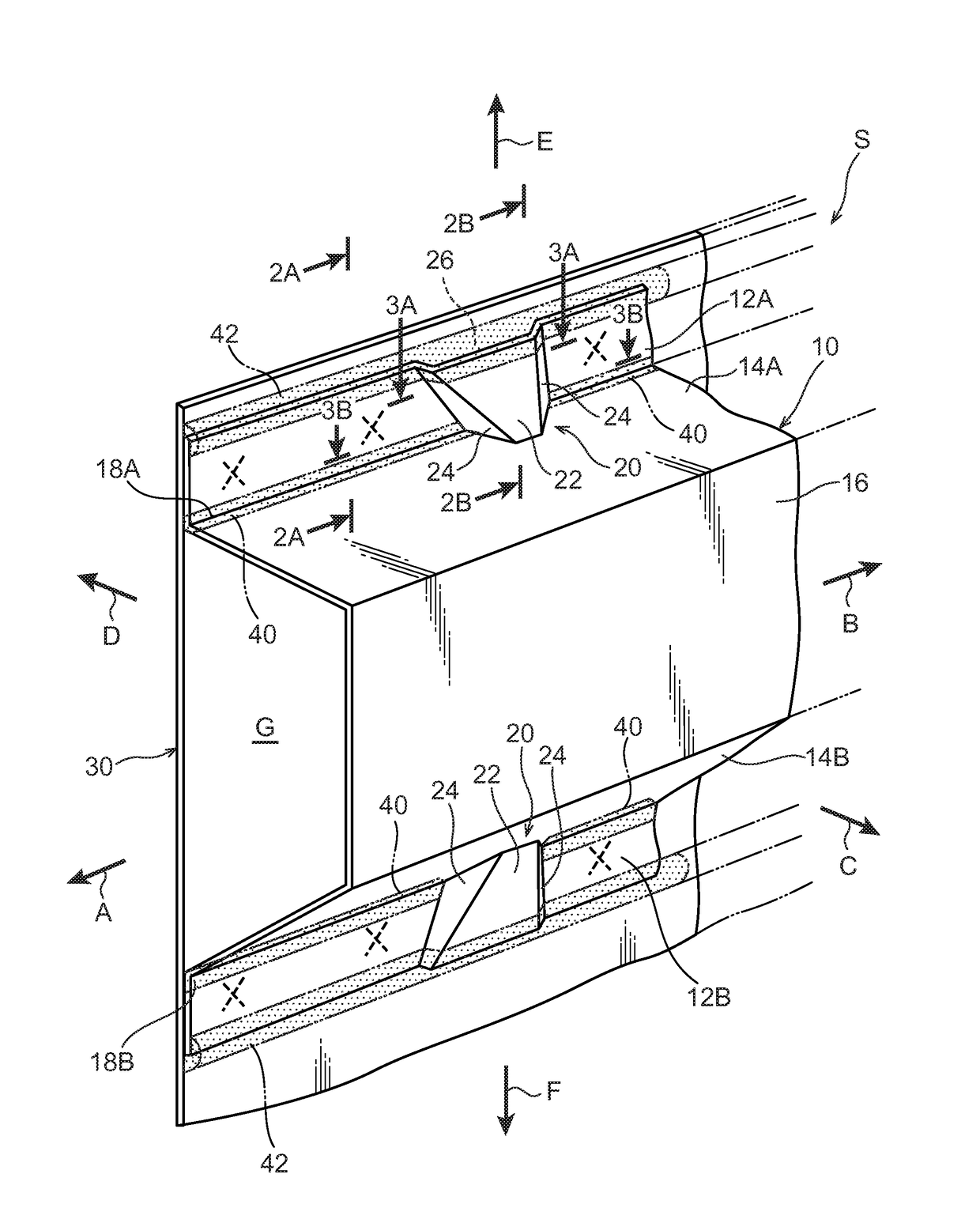

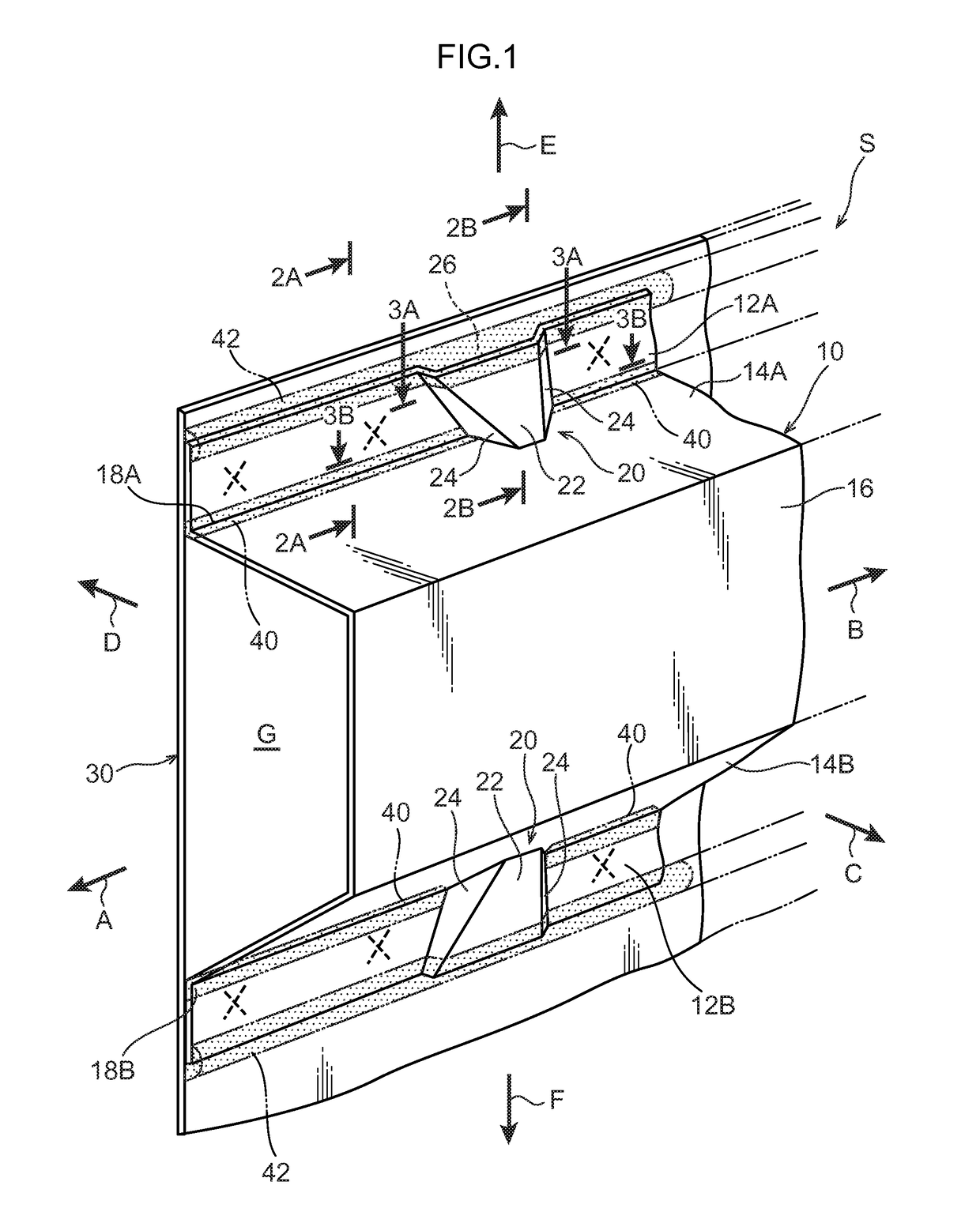

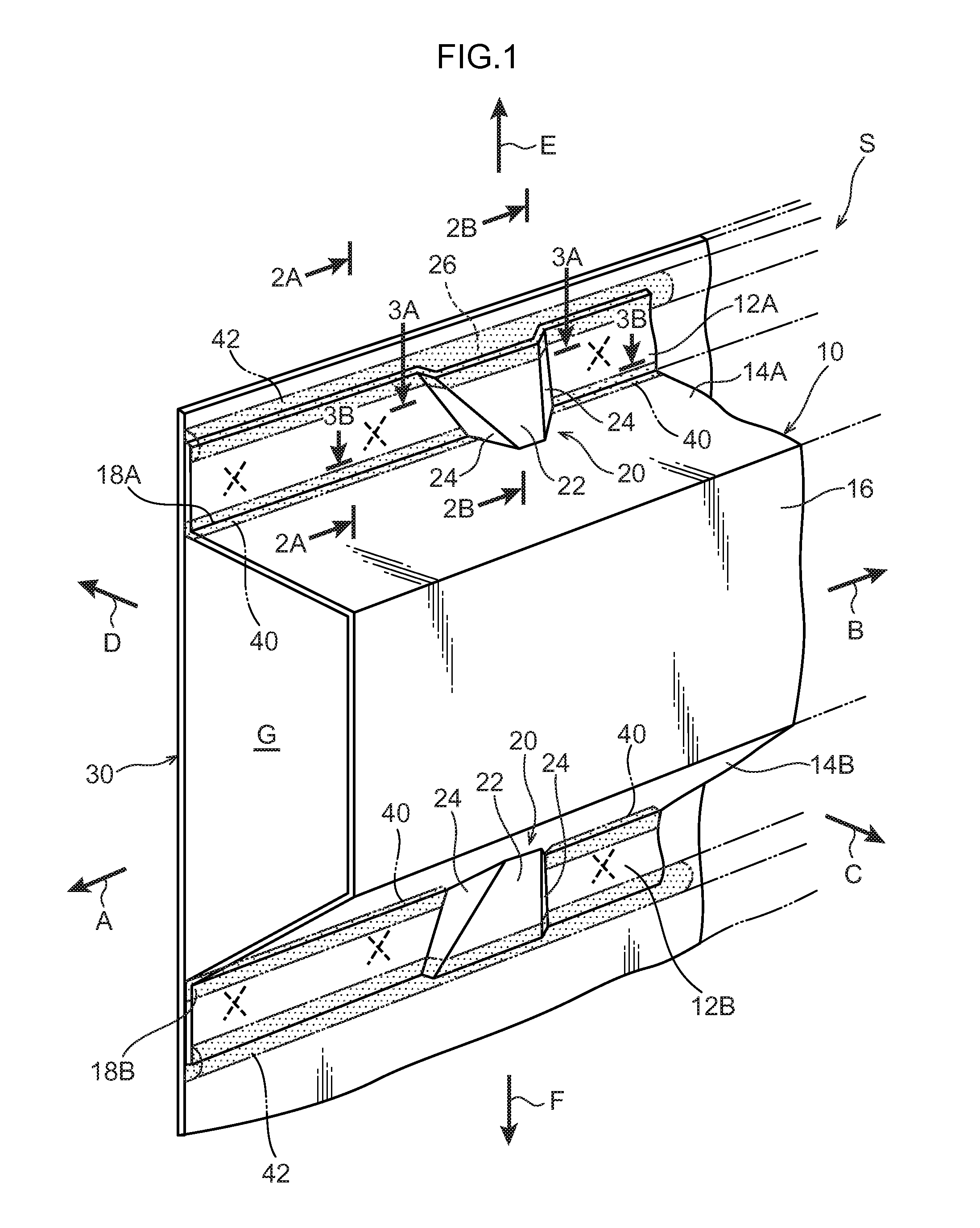

Panel joint structure

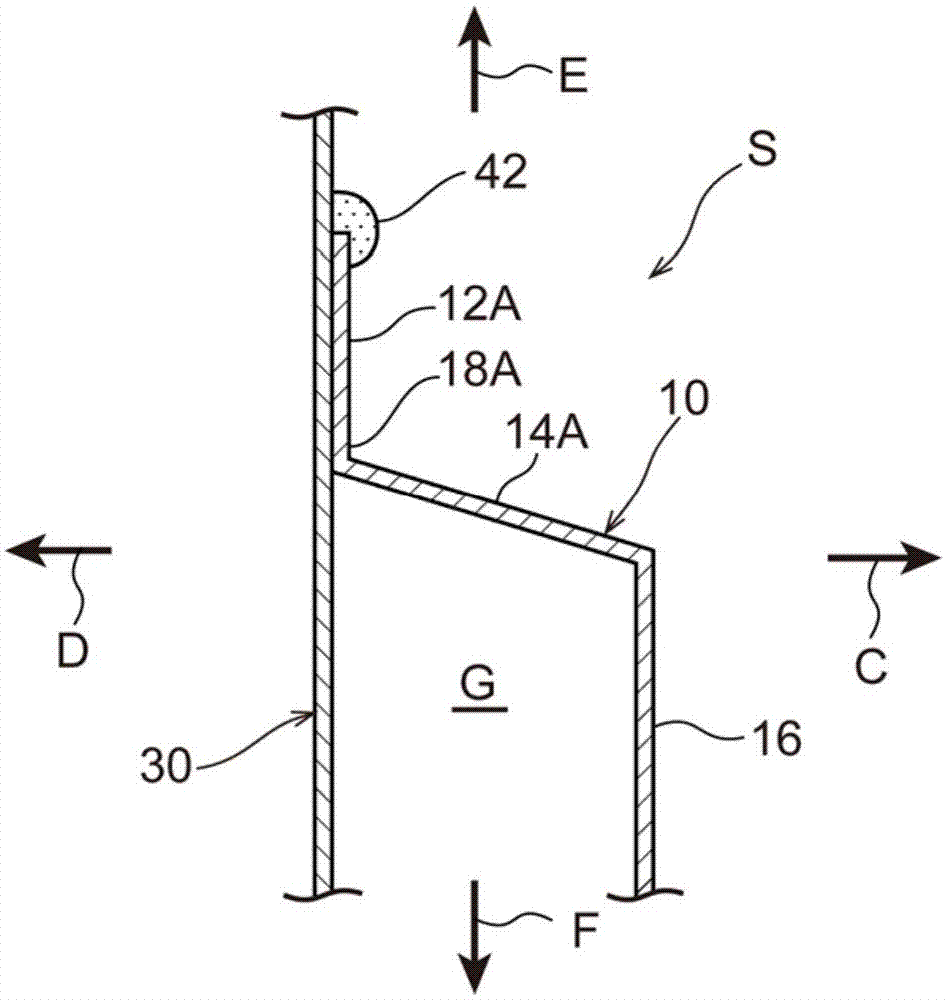

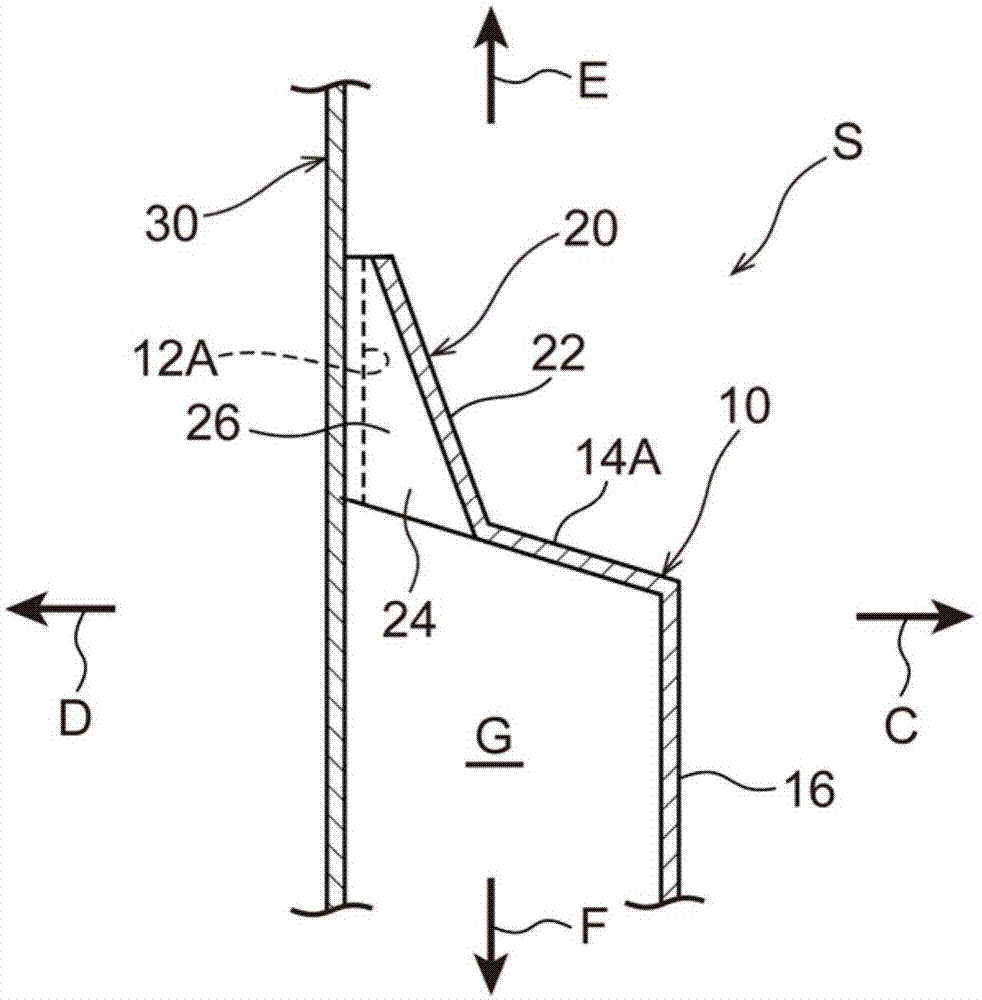

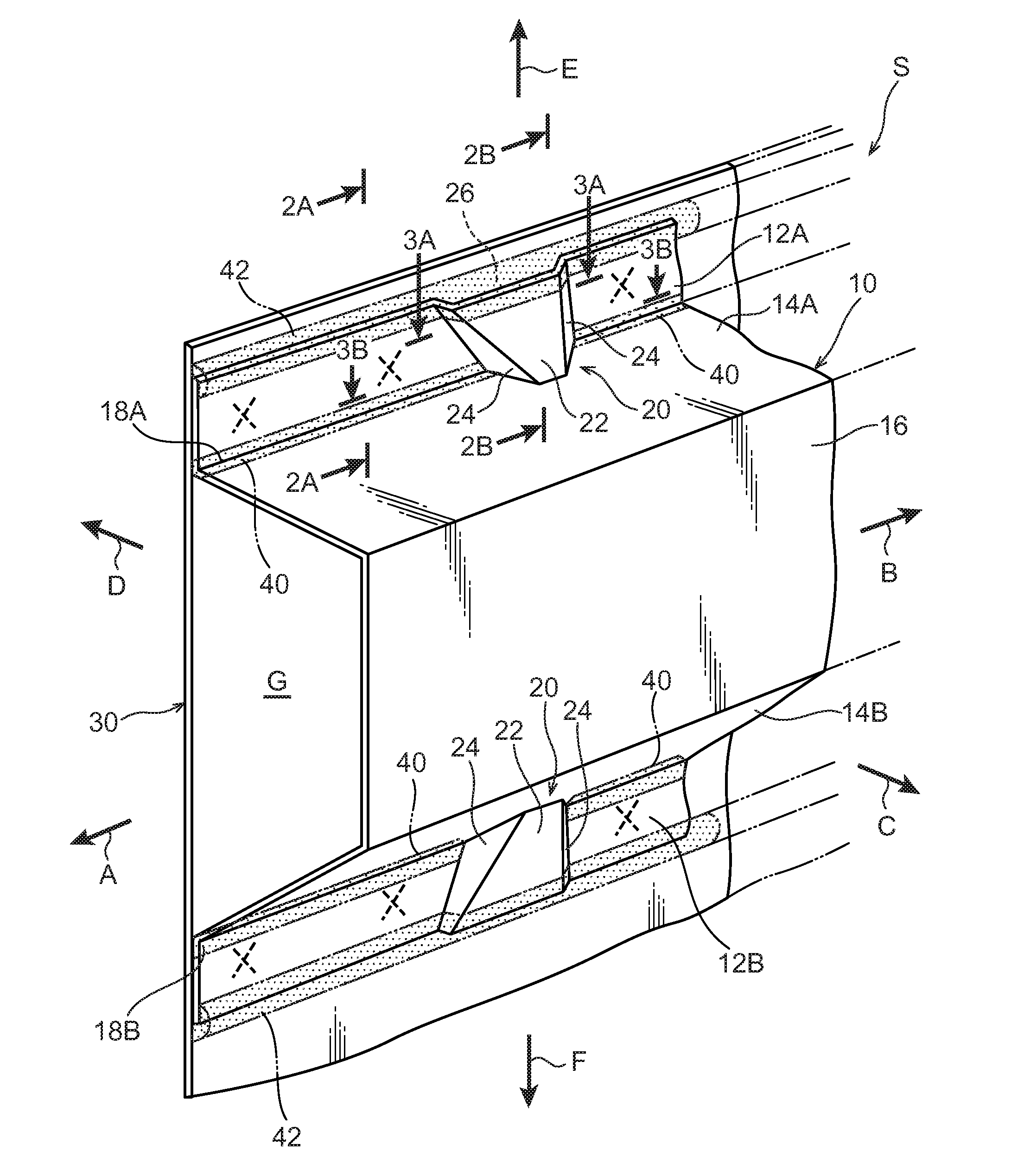

ActiveUS9643661B2Good effectEnsure joint strengthSuperstructure subunitsSuperstructure connectionsEngineeringFlange

A panel joint structure including: a first panel; a second panel that forms a space between itself and the first panel; a joint portion; a seal member that seals a gap between a distal end portion of the joint flange portion and the second panel; and a first panel bead portion that is formed in a region of the joint flange portion adjacent to the joint portion in the lengthwise direction of the first panel, that projects in a direction away from the second panel, that extends from a distal end to a base end of the joint flange portion, that forms with the second panel an air vent hole communicated with the space, and that slopes in a direction away from the second panel heading toward the base end side of the joint flange portion as seen from the lengthwise direction of the first panel.

Owner:TOYOTA JIDOSHA KK

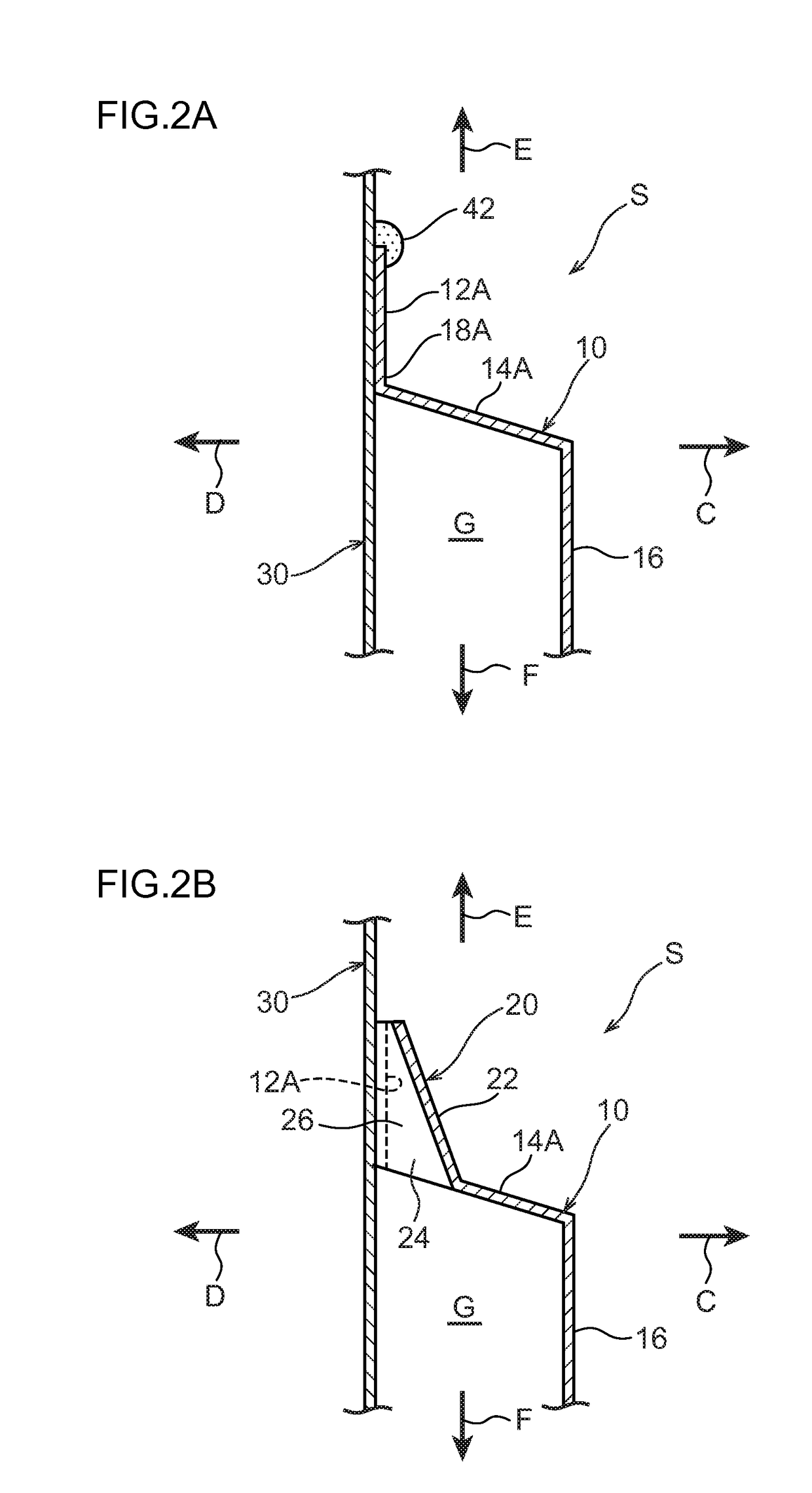

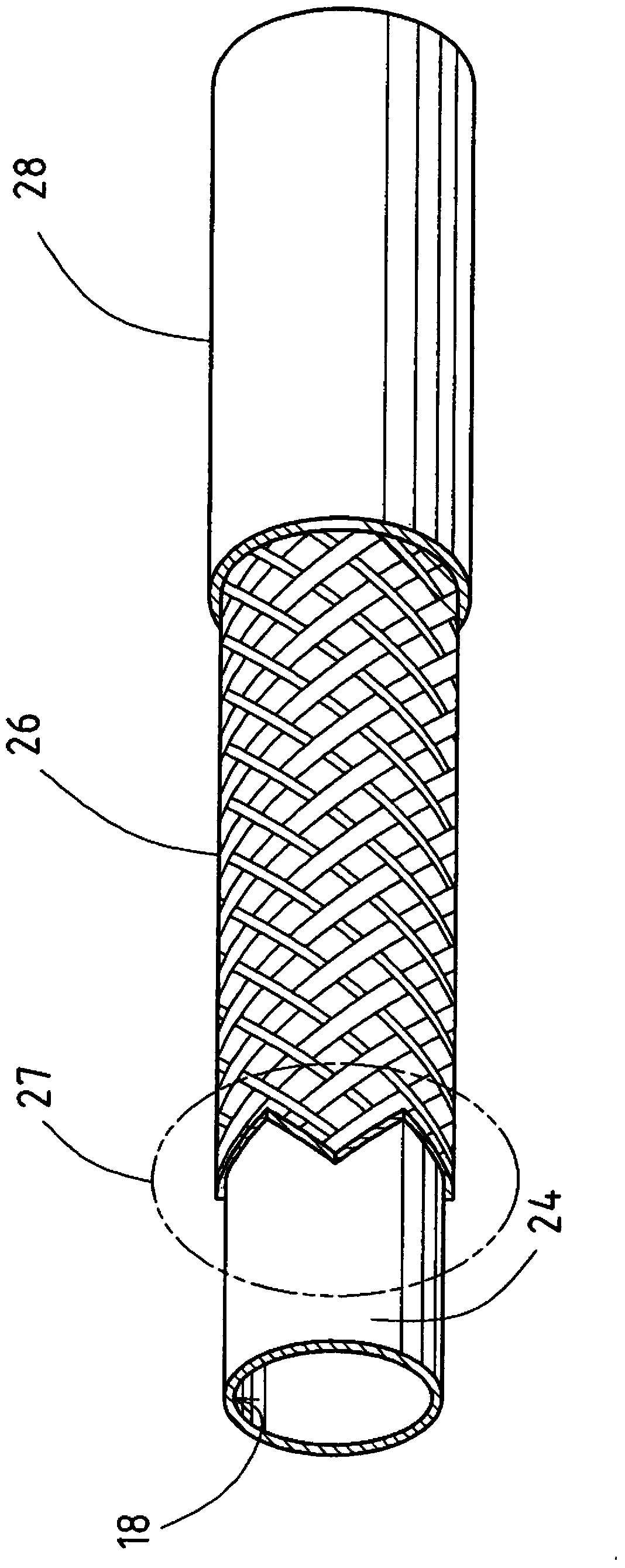

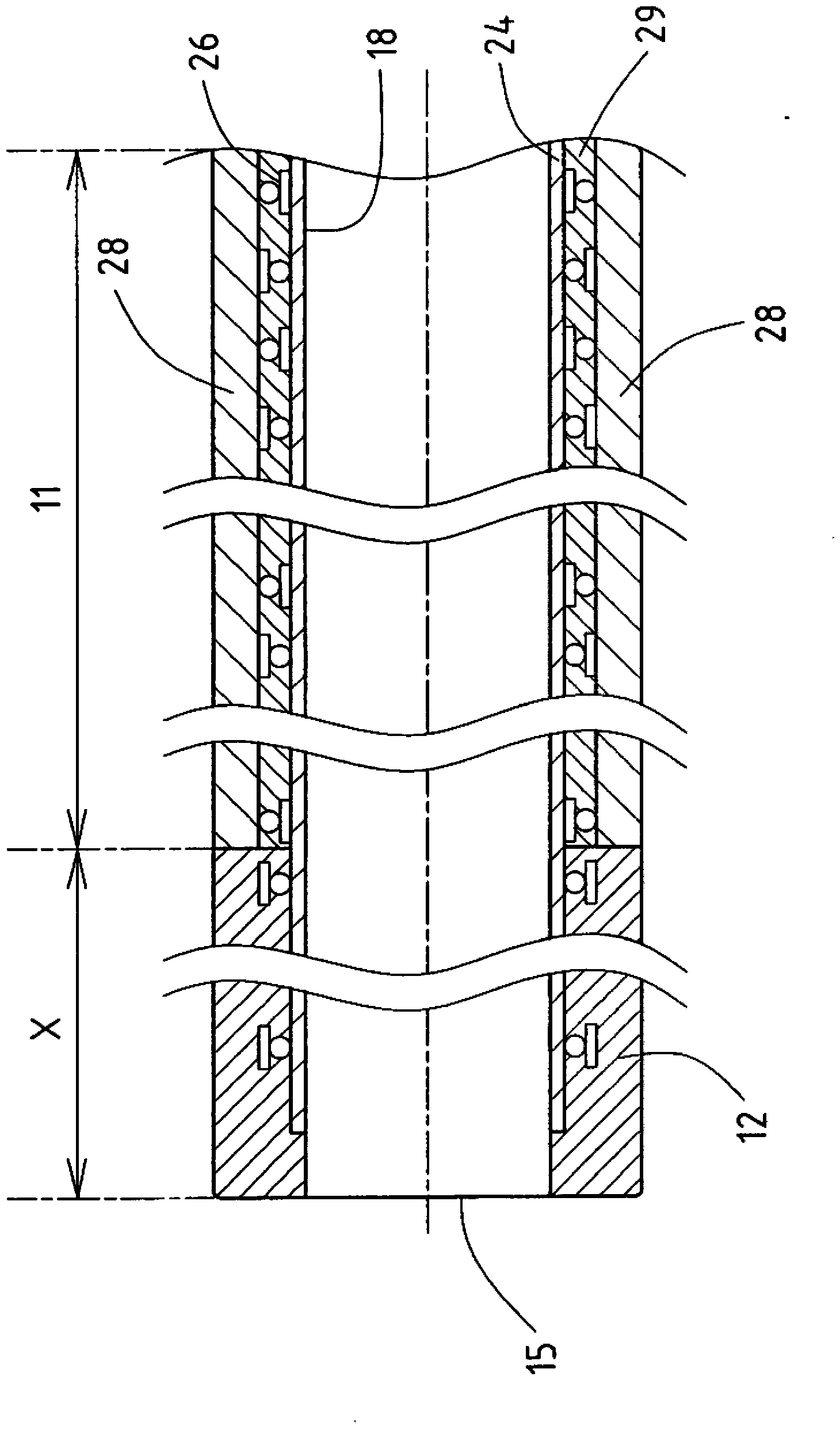

Catheter

ActiveCN103566449AAdjust joint strengthInhibit sheddingCatheterDomestic articlesCatheterUltimate tensile strength

A body (10) of a catheter (1) includes an inner layer (24), a braid (26), and an outer layer (28). The braid (26) includes first and second wires (26a and 26b). The first and second wires (26a and 26b) can be joined together such that the distal end portion (40) of the first wire (26a) winds itself around a side surface of the second wire (26b). A joint (100, 200) includes a first joint portion (110, 210) positioned at the intersection point (30), a second joint portion (120, 220) positioned beyond the first wire (26a) in a width direction (N) of the first wire (26a), and a third joint portion (130, 230) positioned beyond the second wire (26b) in a width direction (N') of the second wire (26b). Thus, even when the first and second wires (26a and 26b) have small thicknesses for size reduction of the braid (26), the first and second wires (26a and 26b) can be joined together with high joint strength by increasing the area of the second joint portion (120, 220) or the thickness of the third joint portion (130, 230).

Owner:ASAHI INTECC CO LTD

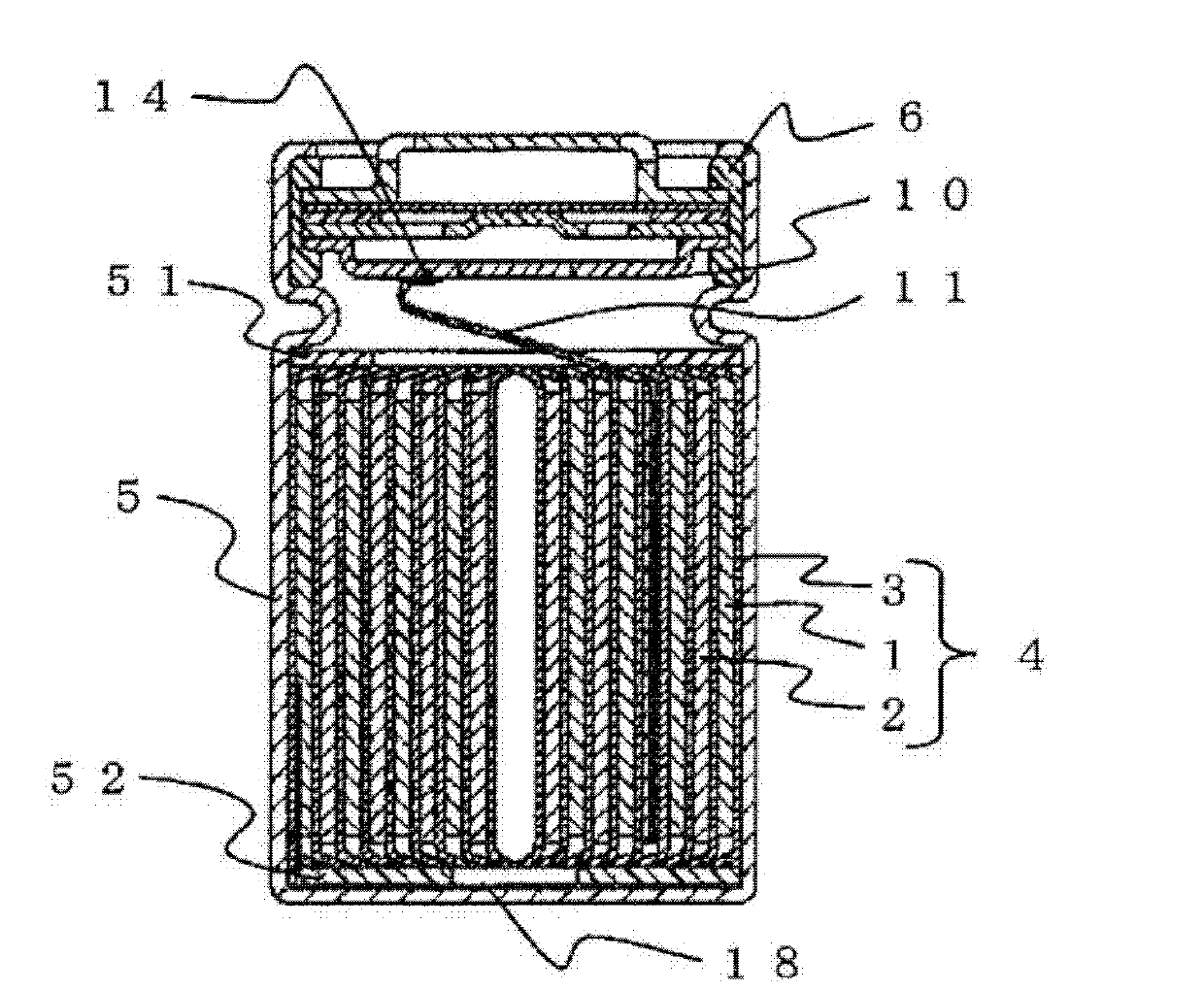

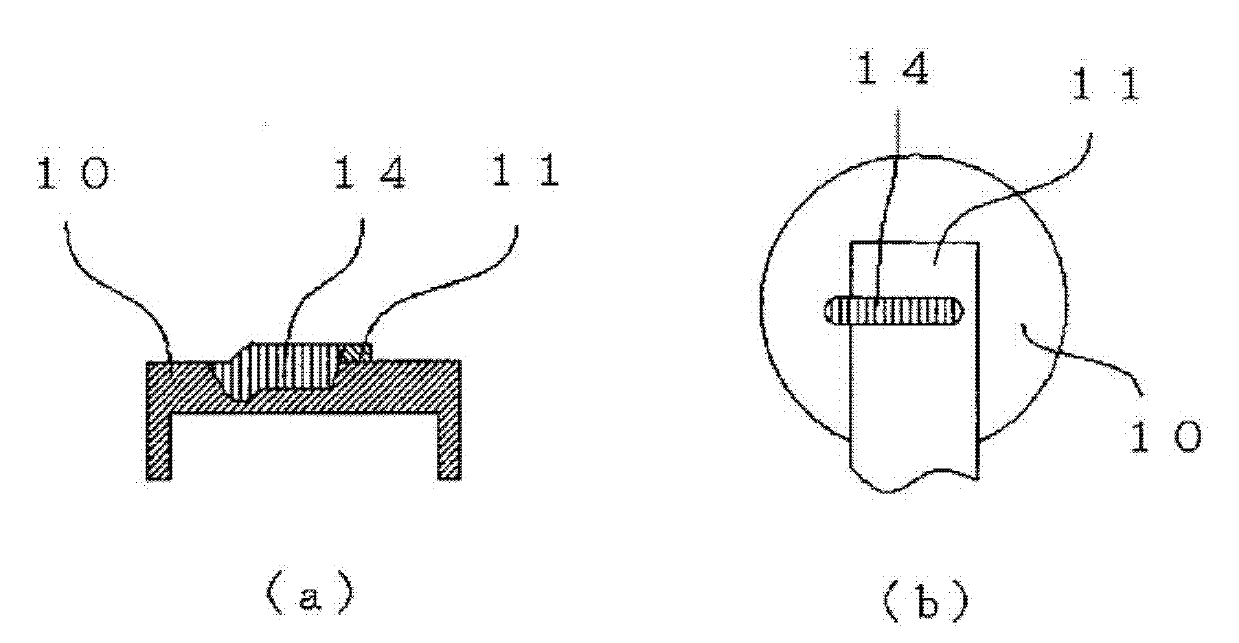

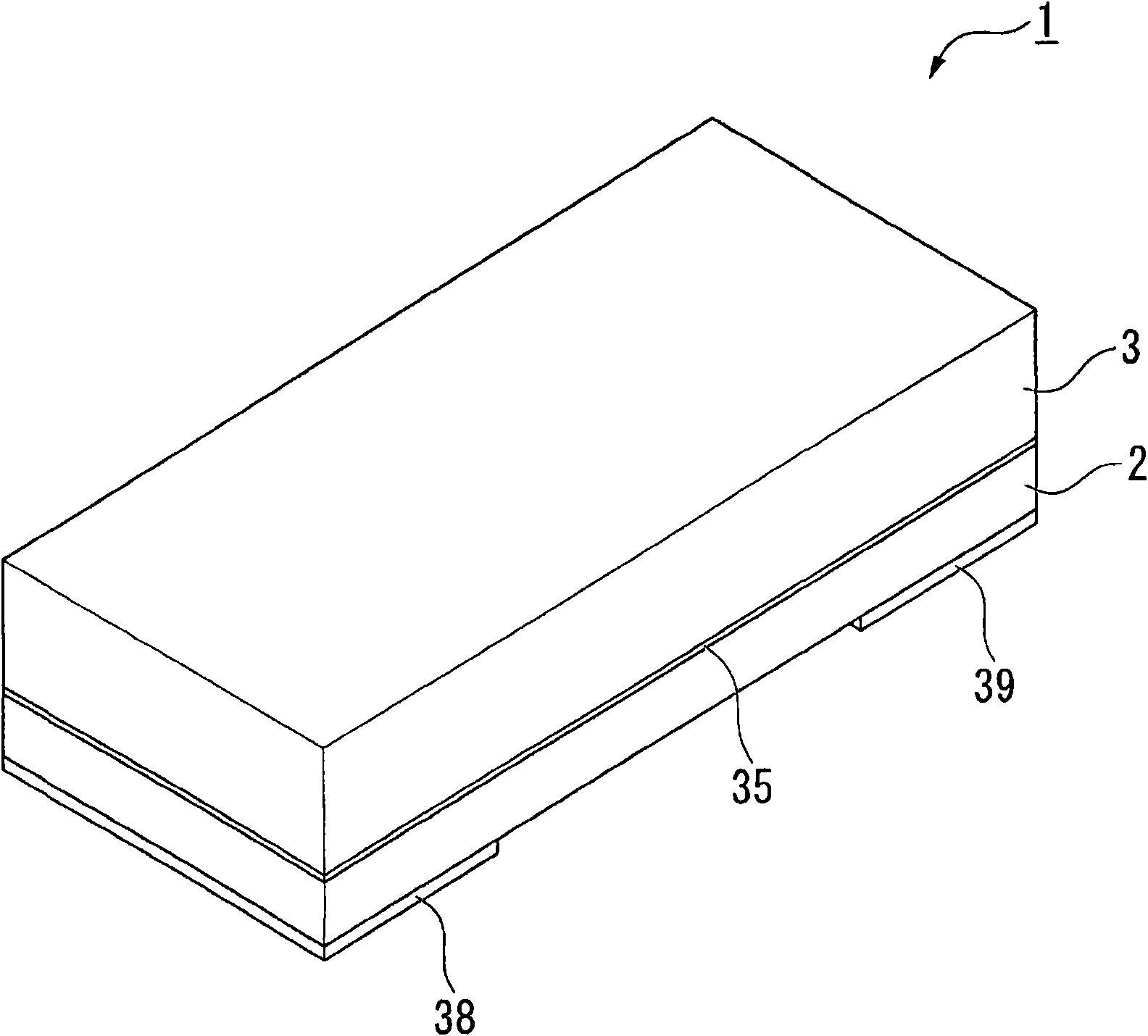

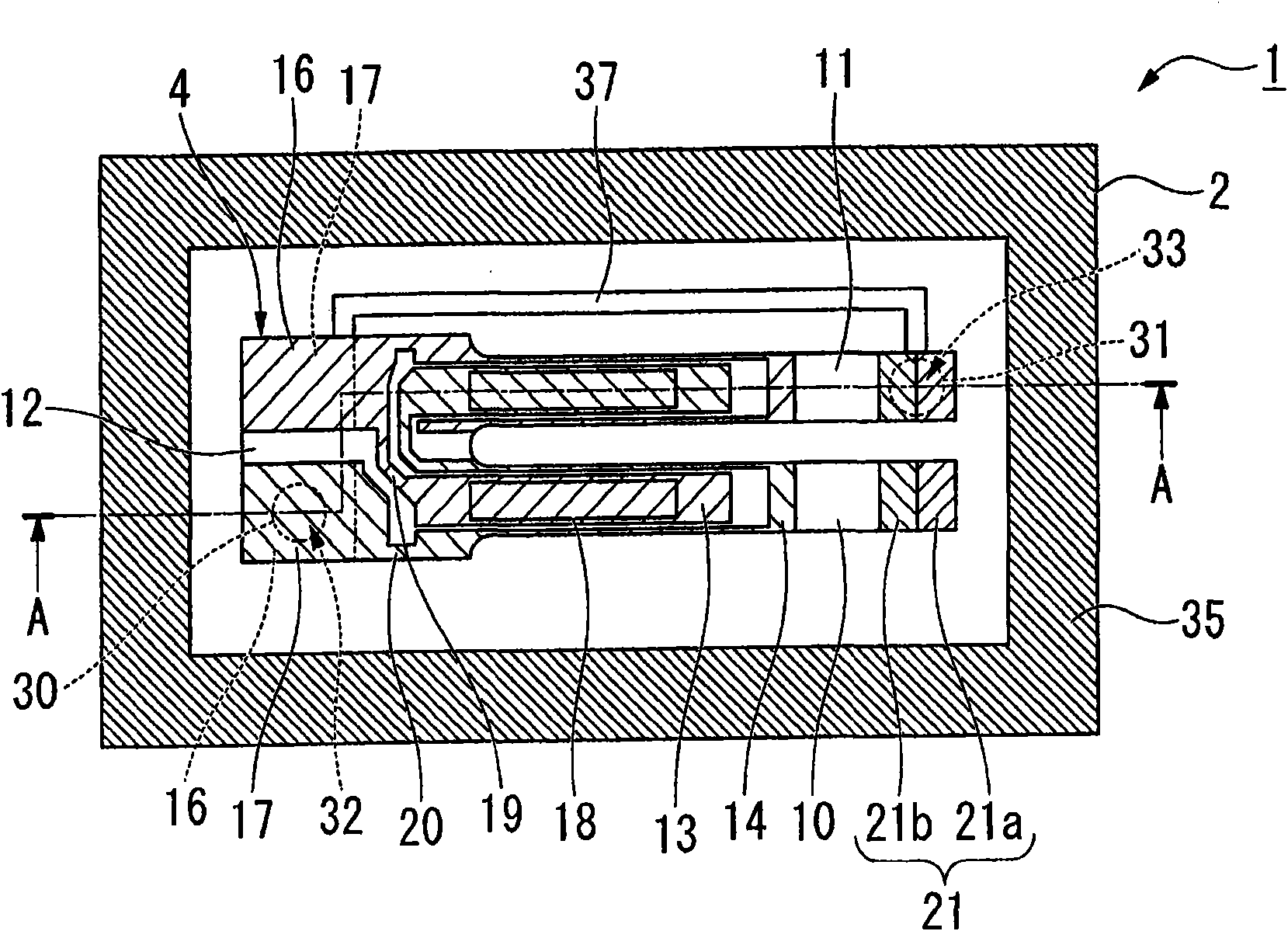

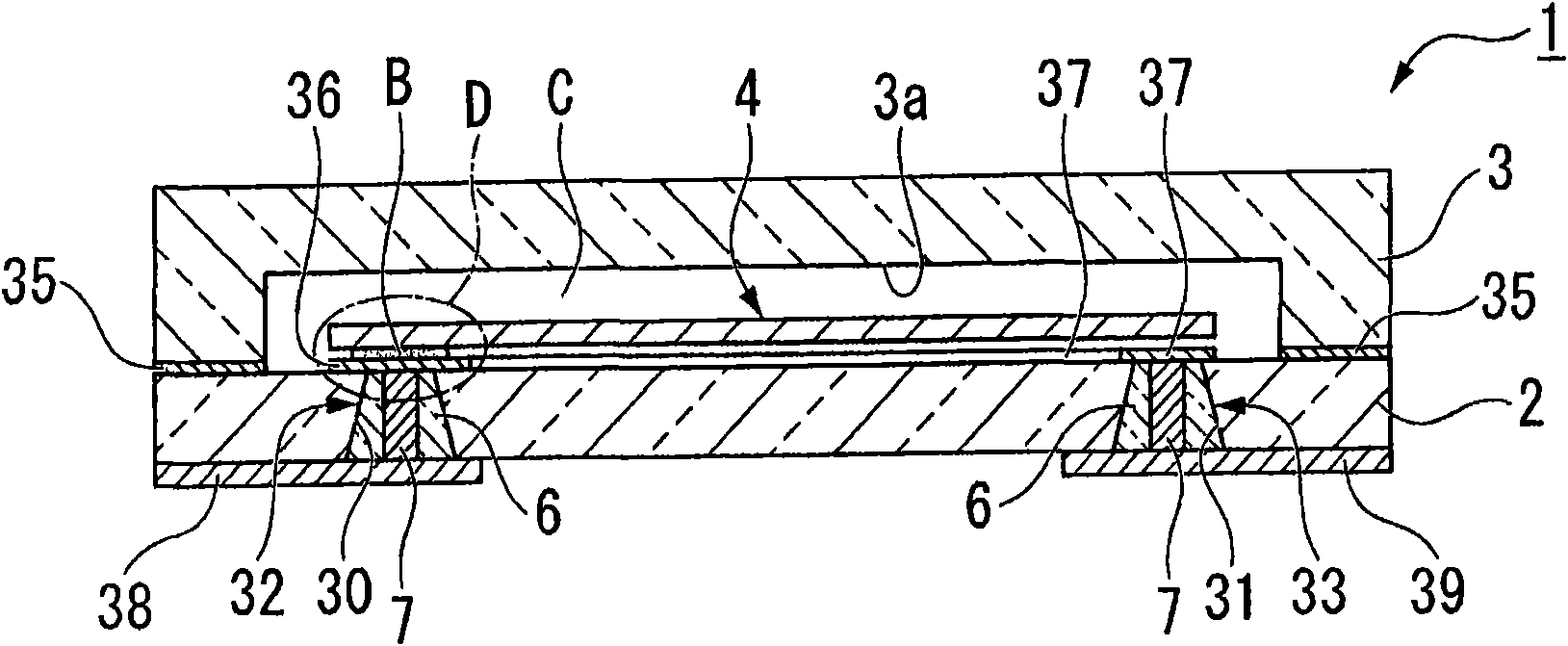

Hermetically sealed battery and method for manufacturing the same

InactiveCN102203983AEnsure joint strengthSuppress mix-inFinal product manufactureWound/folded electrode electrodesEngineeringLaser

Disclosed is a hermetically sealed battery comprising an electrode group (4) which is formed by coiling or laminating a positive electrode plate (1) and a negative electrode plate (2) with a separator (3) interposed therebetween and which is accommodated in a battery casing (5), the battery casing (5) including an opening which is sealed with a sealing plate (10). A lead (11) which leads out from either of the electrode plates in the electrode group (4) is laser-welded to the sealing plate (10), and a weld (14) between the lead (11) and the sealing plate (10) is formed as a line extending across at least the end of the lead (11).

Owner:PANASONIC CORP

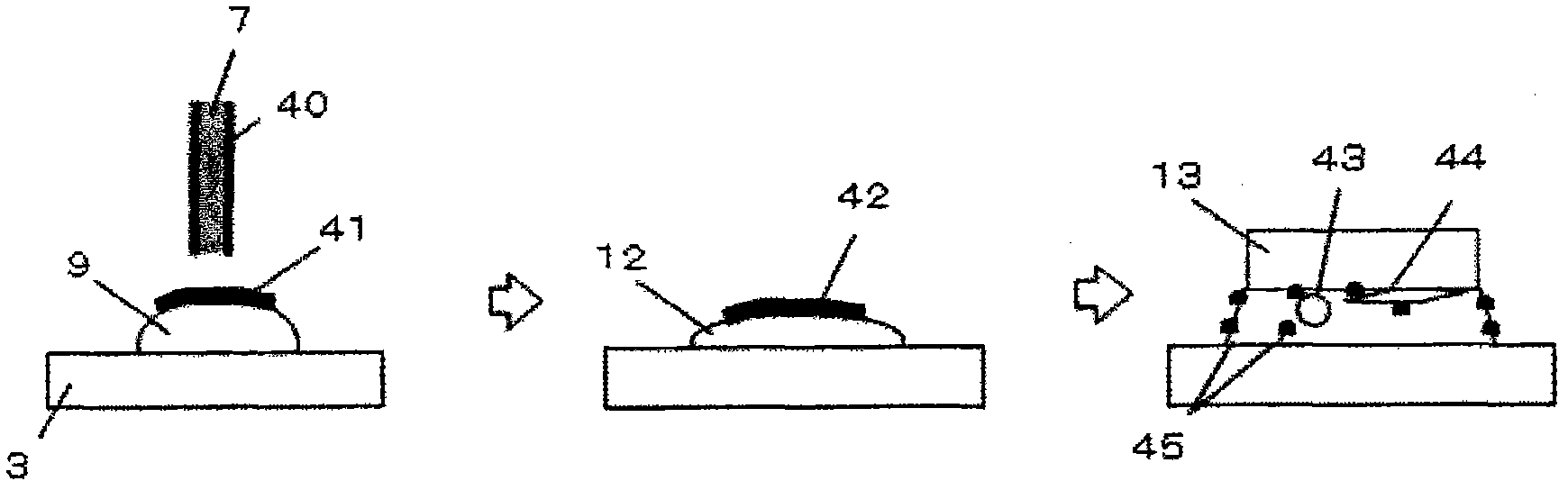

Piezoelectric vibrating reed, piezoelectric vibrator, method for manufacturing piezoelectric vibrator, oscillator, electronic apparatus, and radio-controlled timepiece

InactiveCN102142828AEnsure joint strengthIncrease productivityPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksUltimate tensile strengthElectron

The present invention provides a piezoelectric vibrating reed capable of securing a stable bonding strength between a bump and the piezoelectric vibrating reed, a piezoelectric vibrator, a method for manufacturing the piezoelectric vibrator, and an oscillator, an electronic apparatus, and a radio-controlled timepiece. The piezoelectric vibrating reed (4) includes: a vibrating portion; a base portion (12) adjacent to the vibrating portion; excitation electrodes formed in the vibrating portion; mount electrodes (16, 17) formed in the base portion; and extraction electrodes for electrically connecting the excitation electrodes and the mount electrodes to each other. A bonding film (72) made of gold is formed on the surfaces of the mount electrodes, and the bonding film is formed to a thickness such that, when the bonding film is ultrasonically bonded to a bump (B) made of gold, mutual diffusion occurs over approximately the entire area in the thickness direction of the bonding film.

Owner:SEIKO INSTR INC

Panel joint structure

InactiveCN105438267AEnsure joint strengthImproved outgassingSuperstructure subunitsSuperstructure connectionsEngineeringFlange

A panel joint structure including: a first panel; a second panel that forms a space between itself and the first panel; a joint portion; a seal member that seals a gap between a distal end portion of the joint flange portion and the second panel; and a first panel bead portion that is formed in a region of the joint flange portion adjacent to the joint portion in the lengthwise direction of the first panel, that projects in a direction away from the second panel, that extends from a distal end to a base end of the joint flange portion, that forms with the second panel an air vent hole communicated with the space, and that slopes in a direction away from the second panel heading toward the base end side of the joint flange portion as seen from the lengthwise direction of the first panel.

Owner:TOYOTA JIDOSHA KK

Panel joint structure

ActiveUS20160083021A1Good effectEnsure joint strengthSuperstructure subunitsSuperstructure connectionsEngineeringFlange

A panel joint structure including: a first panel; a second panel that forms a space between itself and the first panel; a joint portion; a seal member that seals a gap between a distal end portion of the joint flange portion and the second panel; and a first panel bead portion that is formed in a region of the joint flange portion adjacent to the joint portion in the lengthwise direction of the first panel, that projects in a direction away from the second panel, that extends from a distal end to a base end of the joint flange portion, that forms with the second panel an air vent hole communicated with the space, and that slopes in a direction away from the second panel heading toward the base end side of the joint flange portion as seen from the lengthwise direction of the first panel.

Owner:TOYOTA JIDOSHA KK

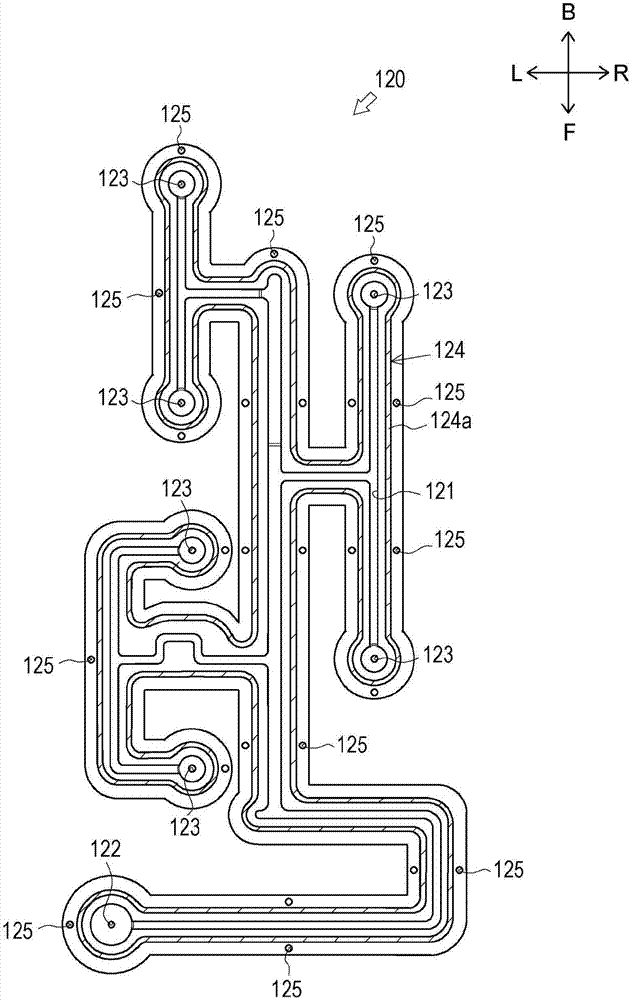

Joined synthetic resin body, and production method therefor

InactiveCN107249861AGuaranteed tightnessEnsure joint strengthCasingsLubrication of auxillariesEngineeringUltimate tensile strength

Provided are: a joined synthetic resin body which is capable of ensuring both flow-path sealing properties and joining strength between synthetic resin components, even if the surface areas of regions to be welded are small; and a production method therefor. The joined synthetic resin body of the present invention is provided with: a baffle plate 110; an oil-path-forming member 120 which is in contact with the baffle plate 110; an oil path 130 which is formed between the baffle plate 110 and the oil-path-forming member 120, and in which a lubricating oil circulates; seal parts 140 which seal the periphery of the oil path 130 as a result of the baffle plate 110 and the oil-path-forming member 120 being welded together outside the oil path 130; and joining parts 150 which join the baffle plate 110 and the oil-path-forming member 120.

Owner:TAIHO INDUSTRIES CO LTD

Conductive composition and electronic component using same

ActiveCN106795375AEnsure joint strengthInhibitionNon-macromolecular adhesive additivesConductive materialElectronic componentSolvent

Owner:NAMICS CORPORATION

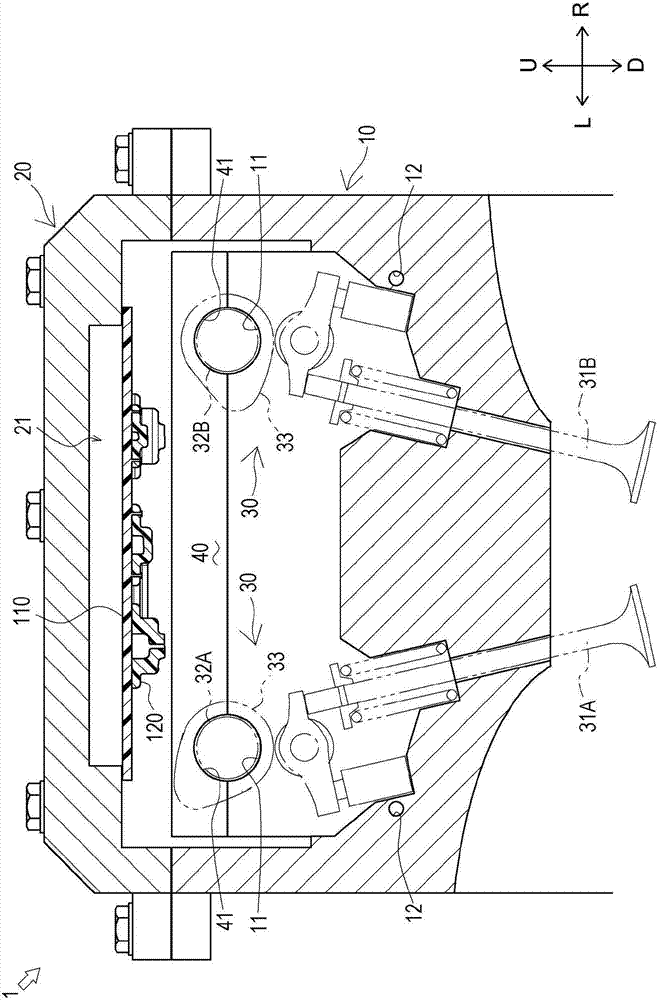

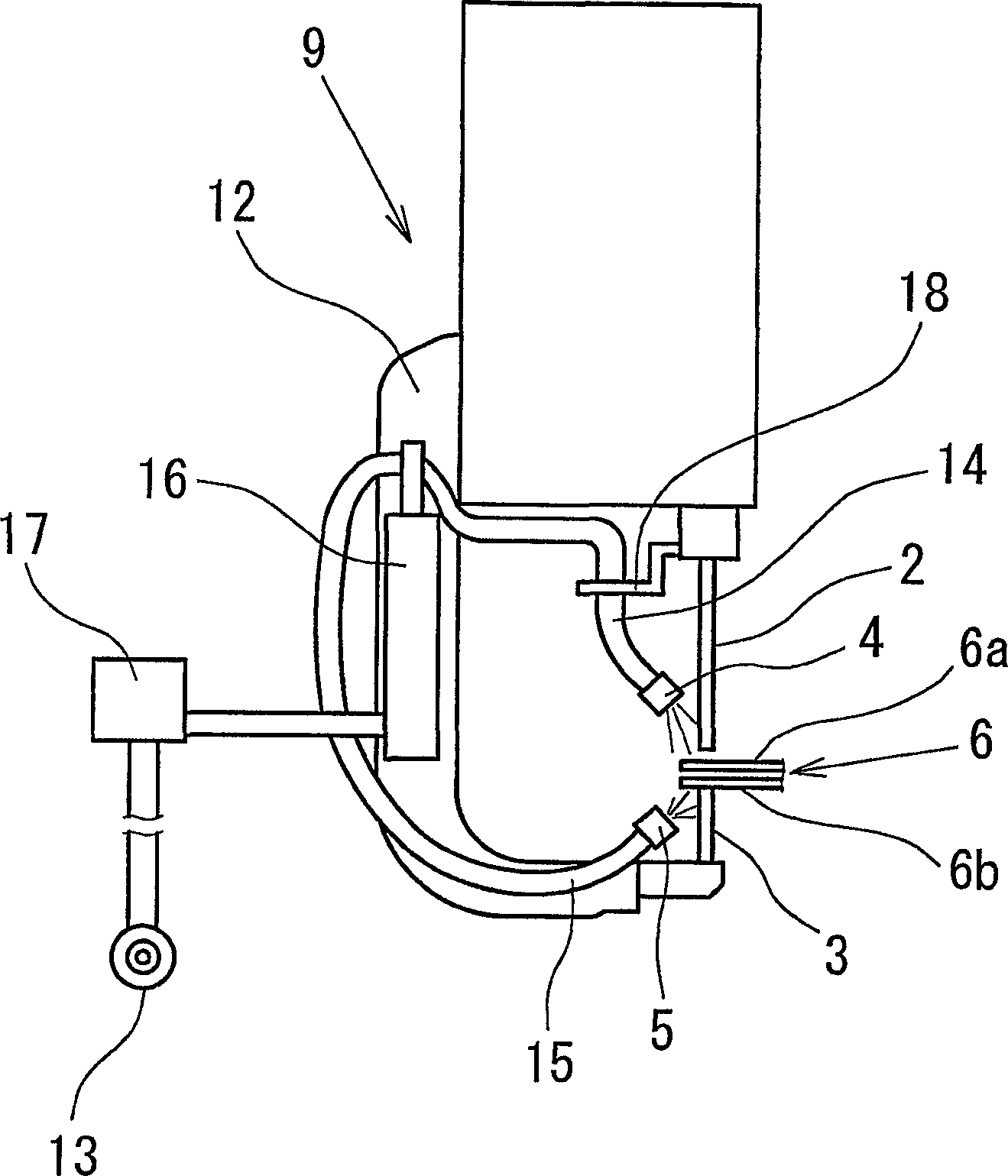

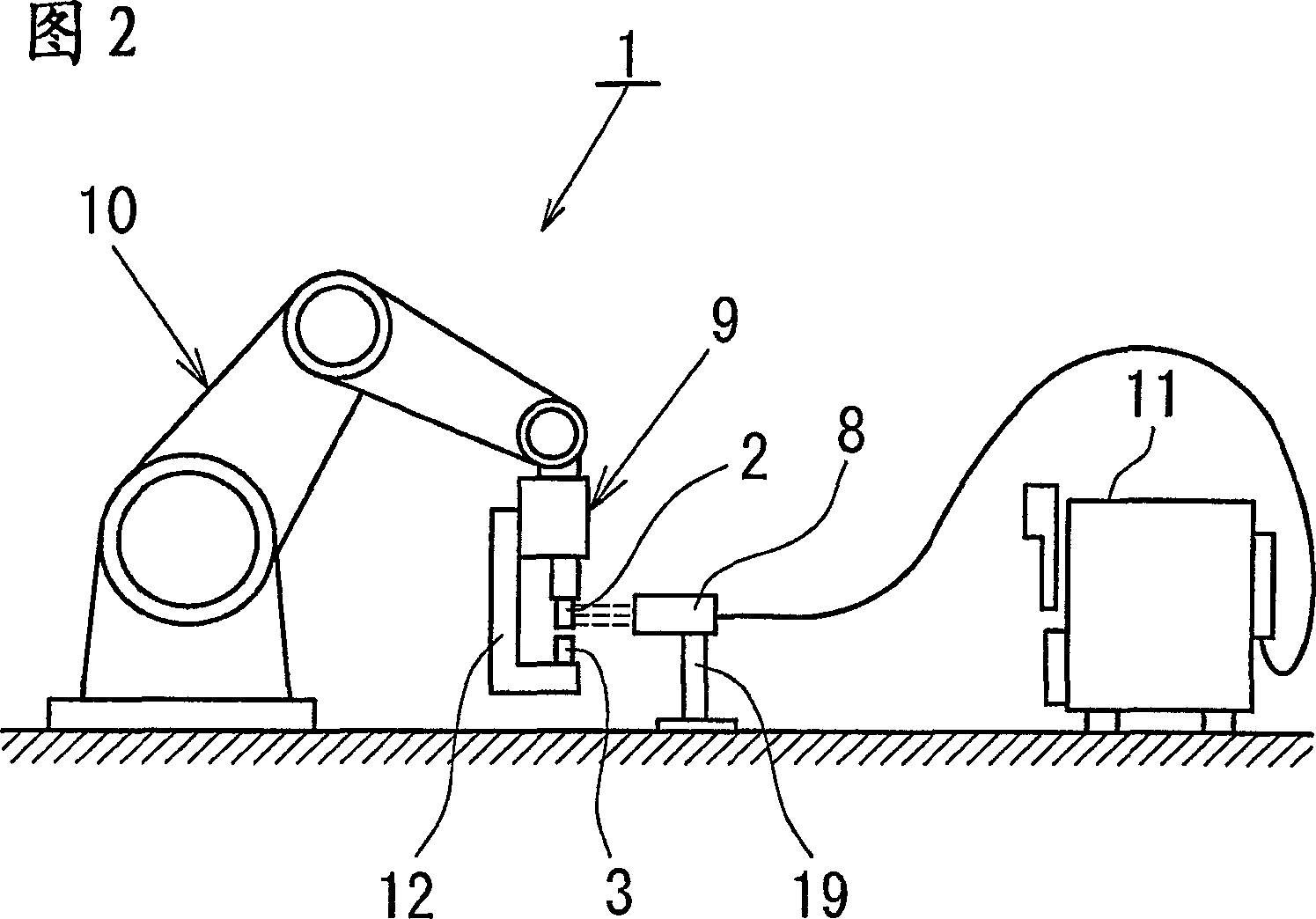

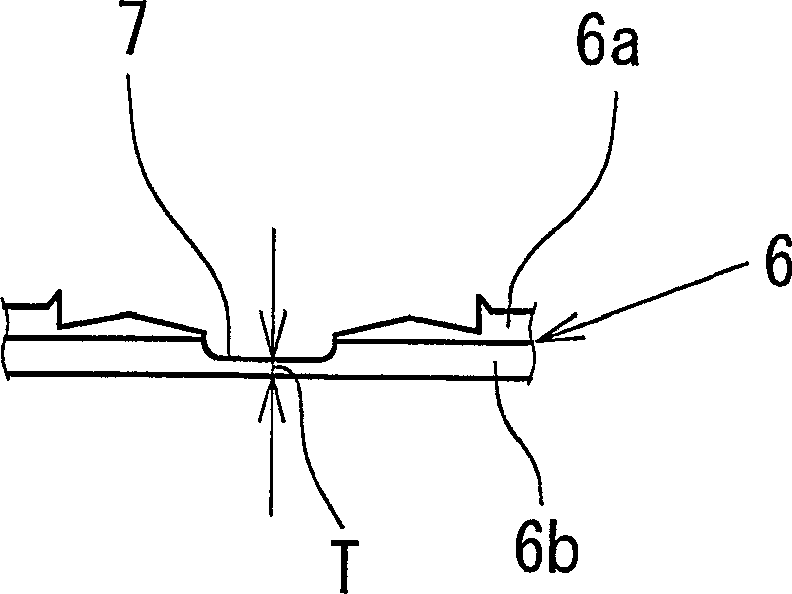

Method and device for friction stir welding

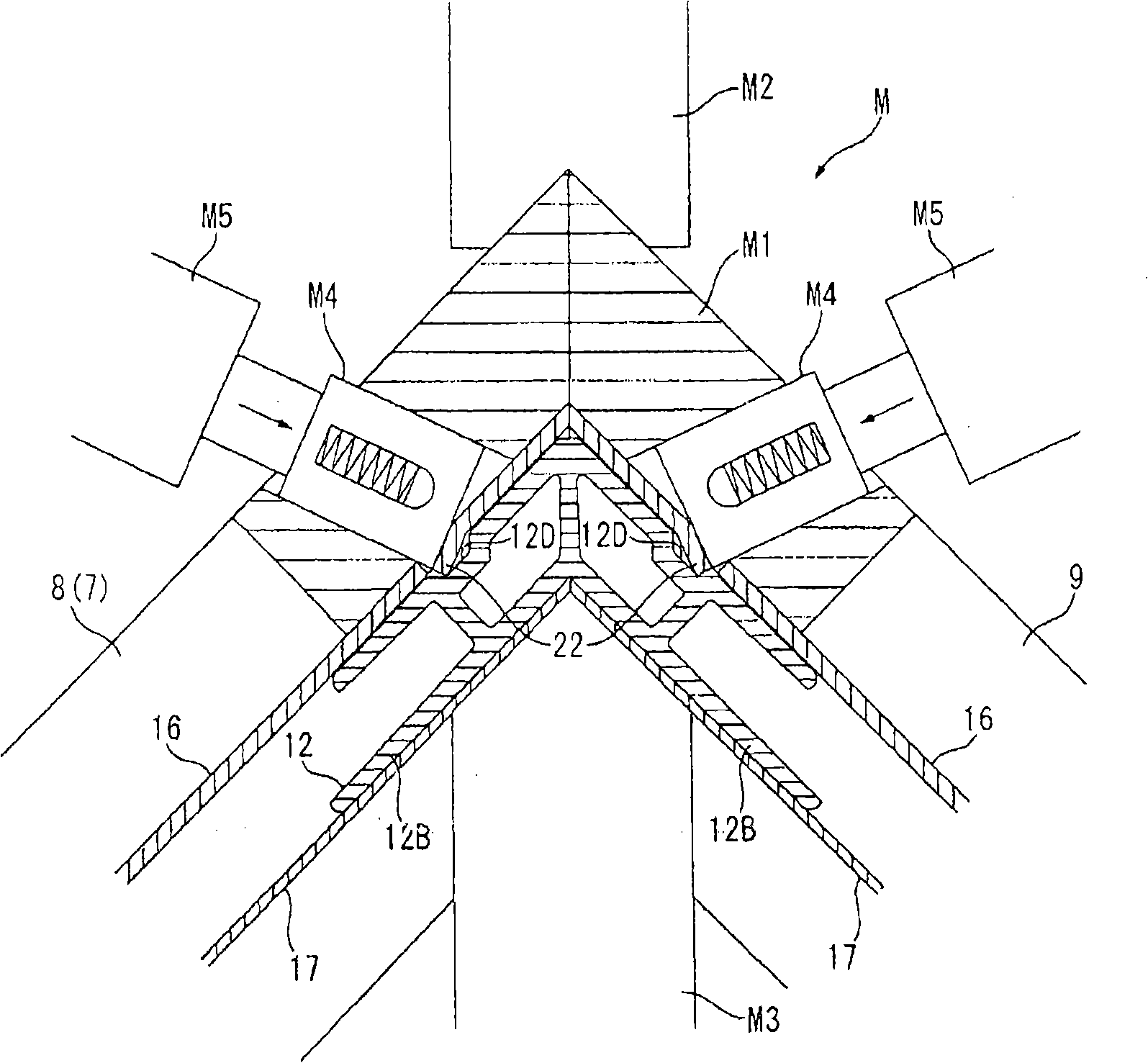

InactiveCN1839012AEnsure joint strengthNon-electric welding apparatusWeld strengthFriction stir welding

A method and a device for friction sir welding capable of achieving sufficient welding strength of a product. [MEANS FOR SOLVING PROBLEMS] Thermal expansion of each tool (2, 3) is prevented because each tool (2, 3) is cooled by air jetted from each air nozzle (4, 5), and this appropriately maintains a gap between an upper tool (2) and a lower tool (3). As a result, a friction stir-welded portion having a residual base plate thickness with an appropriate thickness between an outer panel (6a) and an inner panel (6b) is formed, achieving sufficient welding strength of an engine hood. Air cooled by an extreme low temperature air producer (16) is jetted from each air nozzle (4, 5) to cool each tool (2, 3), and each tool (2, 3) is effectively cooled. The structure above enables thermal expansion of each tool (2, 3) to be constrained to a minimum level to produce a friction stir-welded portion with a residual base plate thickness having a more stable thickness, and as a result, welding strength of the engine hood is sufficiently achieved.

Owner:TOYOTA JIDOSHA KK

Chip bonding device, chip bonding method and chip bonding quality evaluation equipment

InactiveCN102554388ATo preventReduced amount of oxide filmSolid-state devicesSemiconductor/solid-state device manufacturingBond qualitySemiconductor chip

The present invention provides a chip bonding device which can reduce unqualified bonding of gaps and interfaces in bonding parts, a chip bonding method using the same, and chip bonding quality evaluation equipment. Through the chip bonding device, chip bonding quality can be enhanced, and the chip bonding device can utilize soldering tin to bond a semiconductor chip on a lead frame or a substrate. The device is characterized in that the device is provided with a conveying part for conveying the above lead frame or the substrate; a soldering tin supplying part for providing soldering tin for the lead frame or the substrate; a lapping part for lapping and bonding the semiconductor chip to the soldering tin of the lead frame or the substrate; and a surface purification unit for erasing oxidation film of the surface of the soldering tin before the soldering tin is provided to the lead frame or the substrate.

Owner:HITACHI HIGH TECH INSTR CO LTD

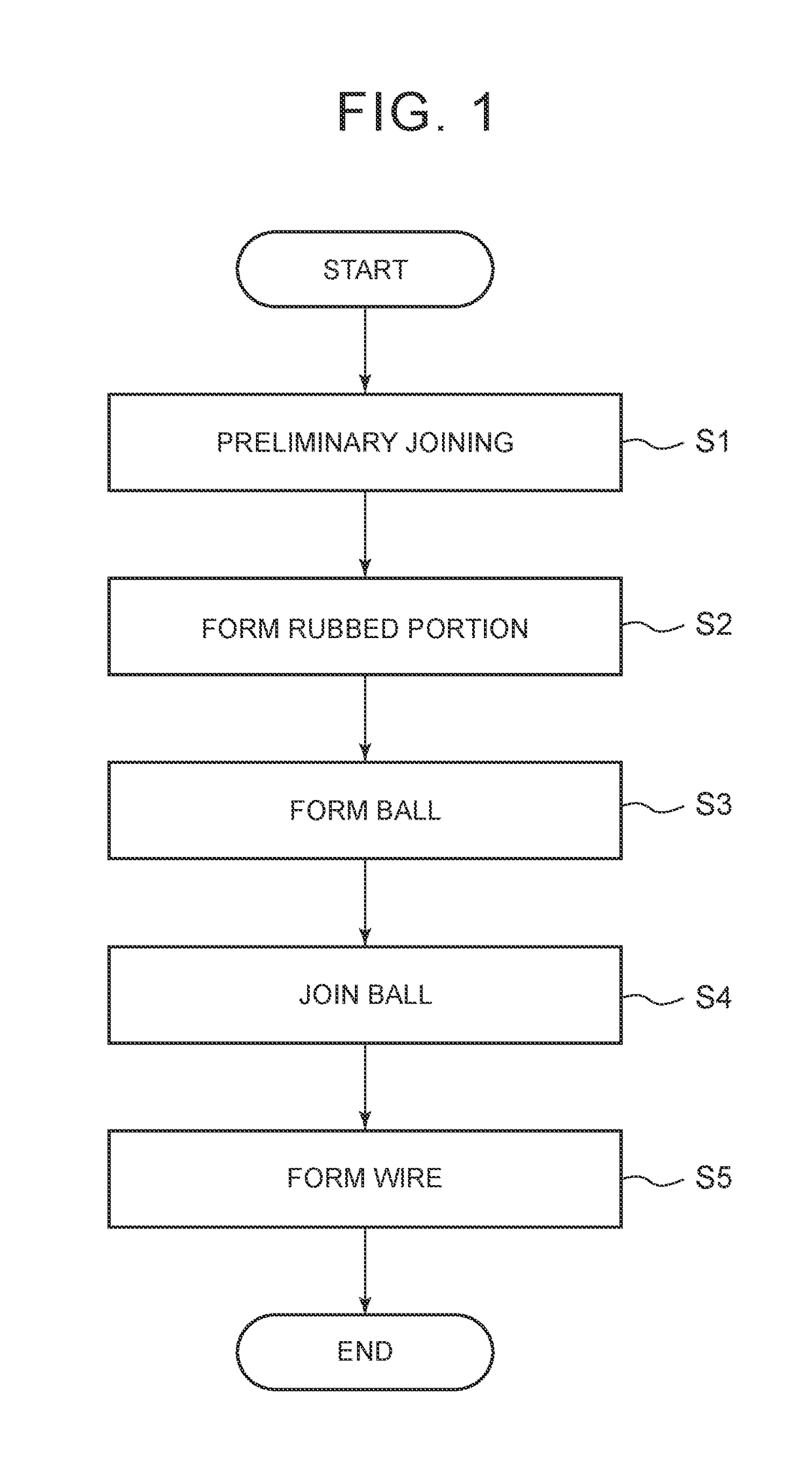

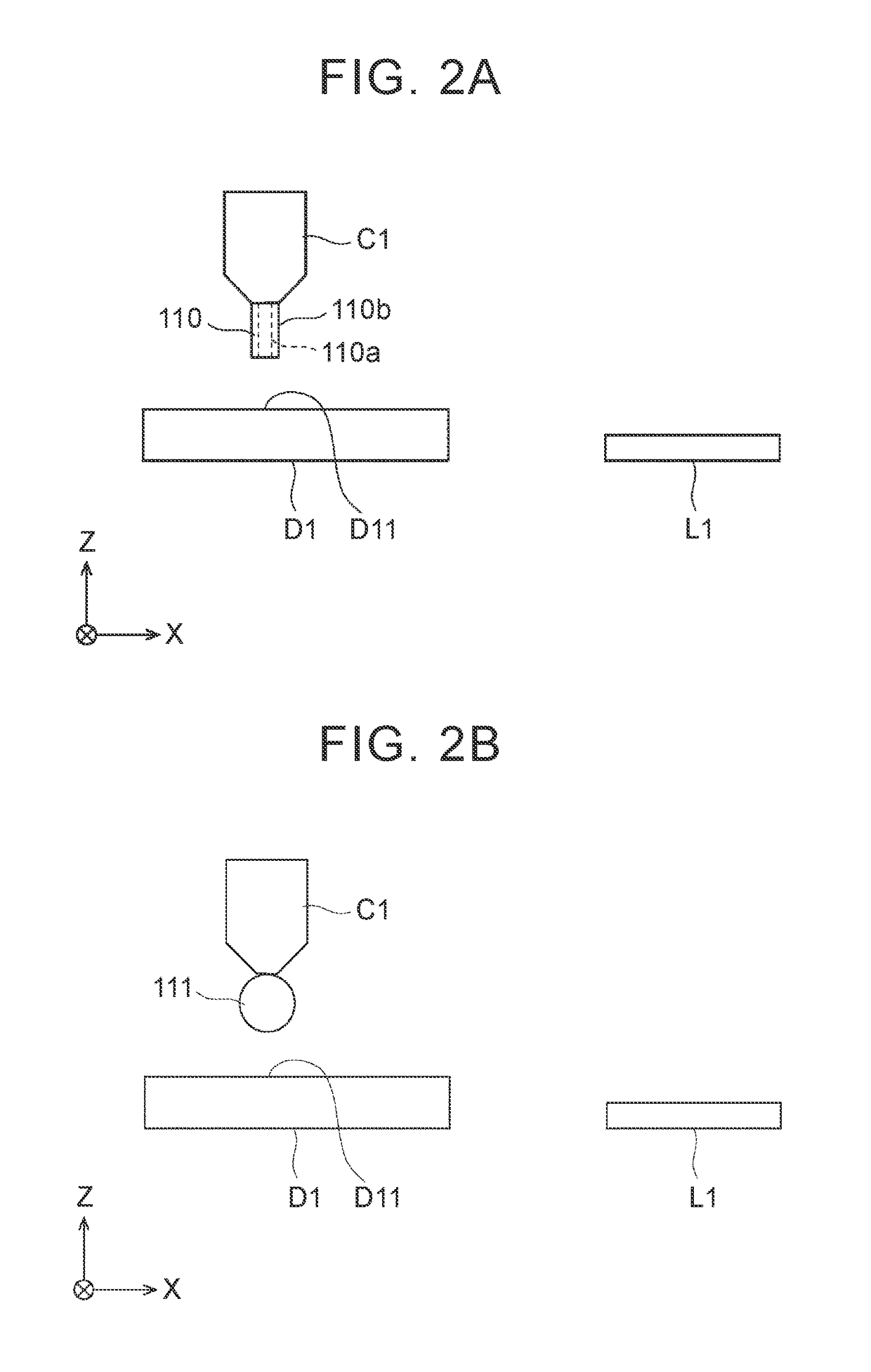

Copper wire and electrode joining method and joint structure

ActiveUS20170179075A1Less likelihoodJoint strength is ableSemiconductor/solid-state device detailsSolid-state devicesCopper wireMetallurgy

With this copper wire joining method, a rubbed portion on which a coating remains between an electrode and a core wire is formed on the electrode. Then, after a capillary is moved away from the rubbed portion, and a ball is formed by melting a copper wire at a tip end of the capillary. Next, the ball is joined to the rubbed portion by pressing the ball against the rubbed portion.

Owner:TOYOTA JIDOSHA KK

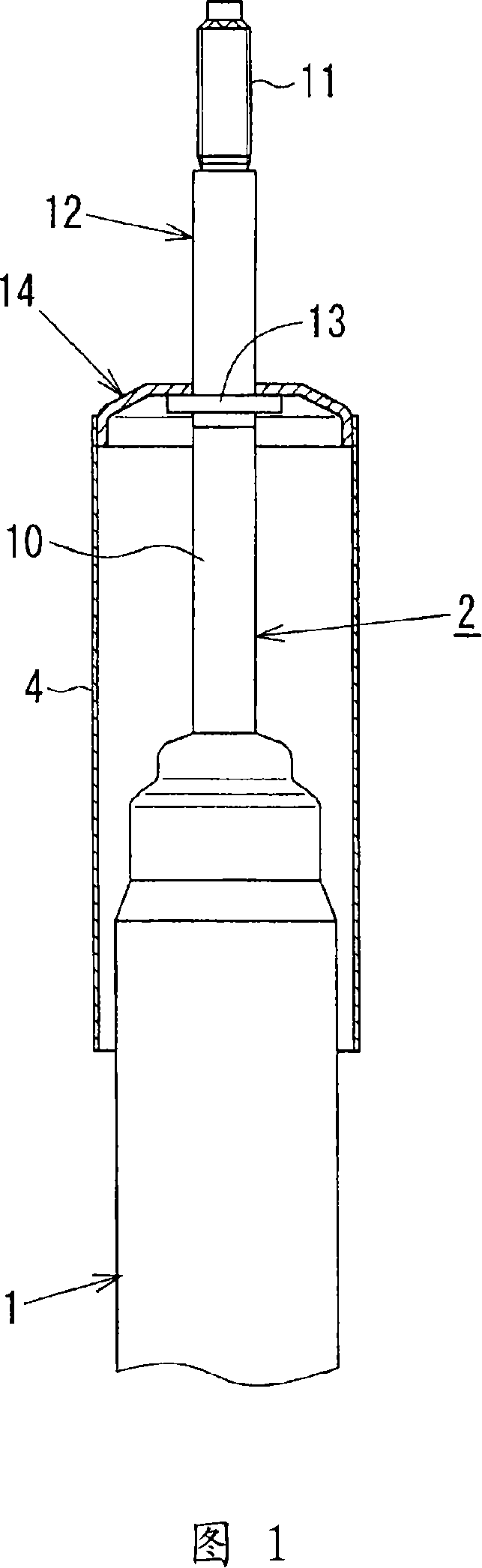

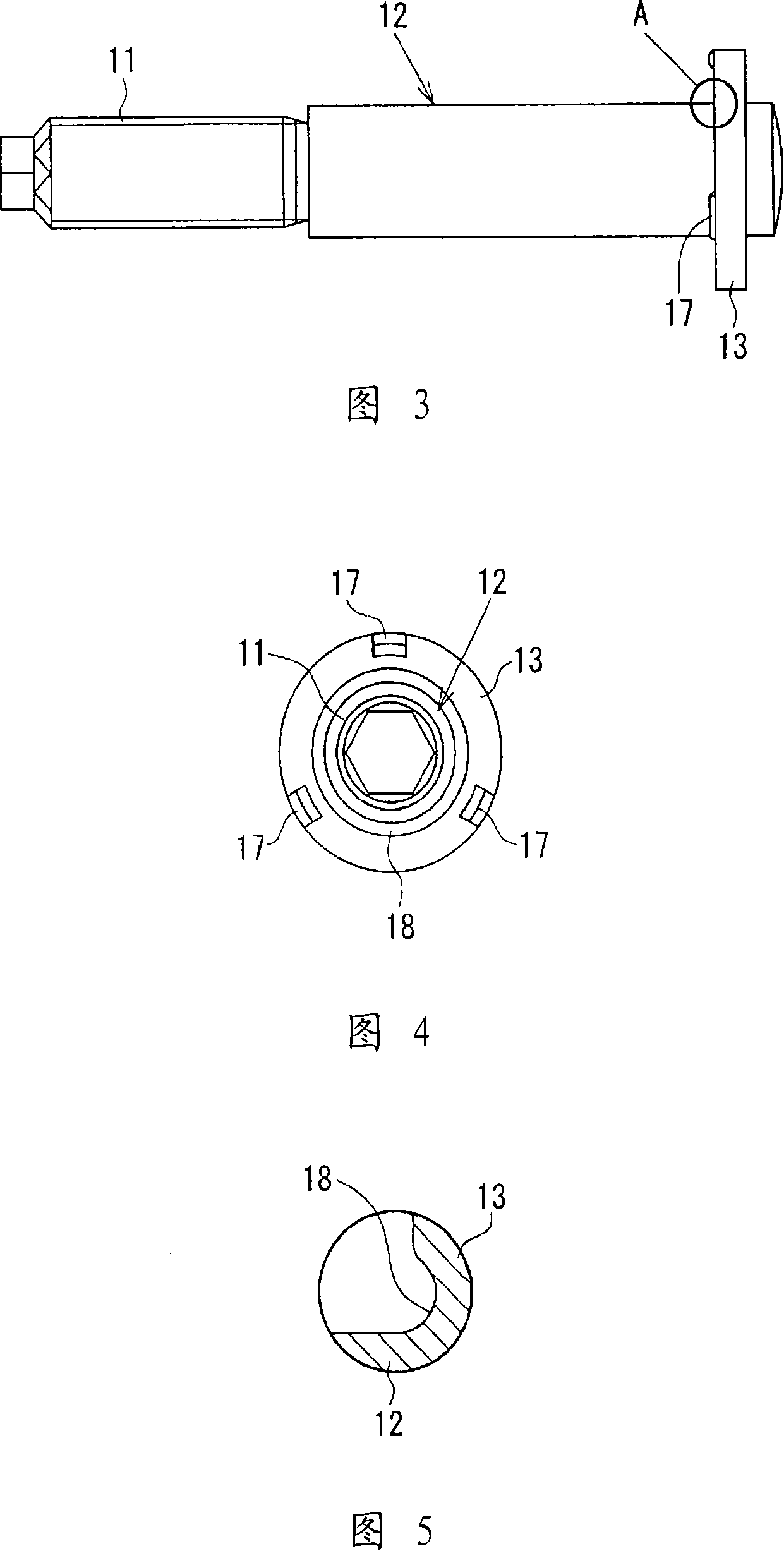

Cylinder device and method for manufacturing the same

ActiveCN101131190AEnsure joint strengthImprove reliabilitySpringsLiquid based dampersEngineeringButt joint

The present invention relates to a cylinder device and the making method, which will not lead to substantial increase of the manufacturing cost or the reduction of the jointing strength and can increase the tolerance of the cover body to the vibration. In the hydraulic bumper of the connecting rod (2) which is formed by butt-jointing the connecting rod main body (10) extending from the cylinder body (1) and the installing component (12) with a front end becoming the bolt shape part (11), and the connecting rod extends telescopically from the cylinder (1), a flaunching part (13) forms integratedly at the end side of the installing component (12) butt-jointing to the connecting rod main body (10), a flat part (16) which is used to install the cover body (14) of the protecting cover (4) is superposed on the flaunching part (13), the flaunching part and the flat part is jointed by projection welding. The torque moment which functions on the casing (14) in the swing rotating direction is borne by the wide flat surface of the cover body (14), therefore, the stress produced on the casing (14) is dispersed with a wide range, and the result is that fatigue cracking is hard to generate on the cover body even if at the condition that the RV vehicle, etc. function a furious vibration on the cover body (14).

Owner:HITACHI LTD

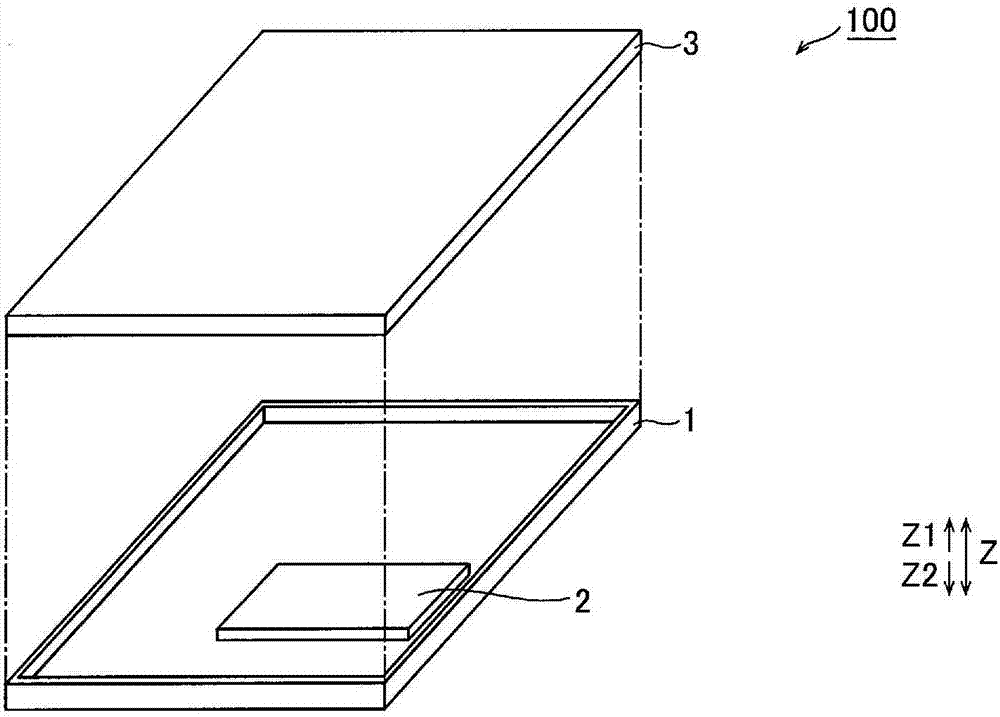

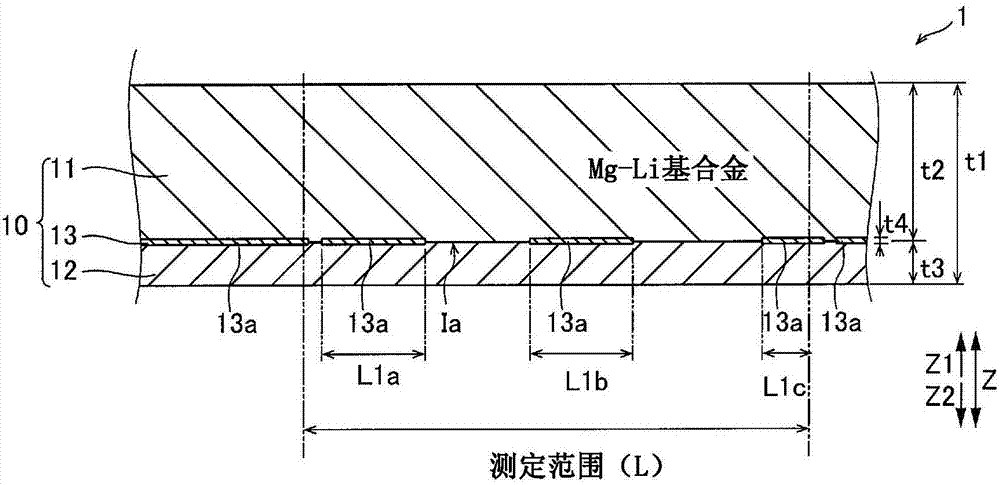

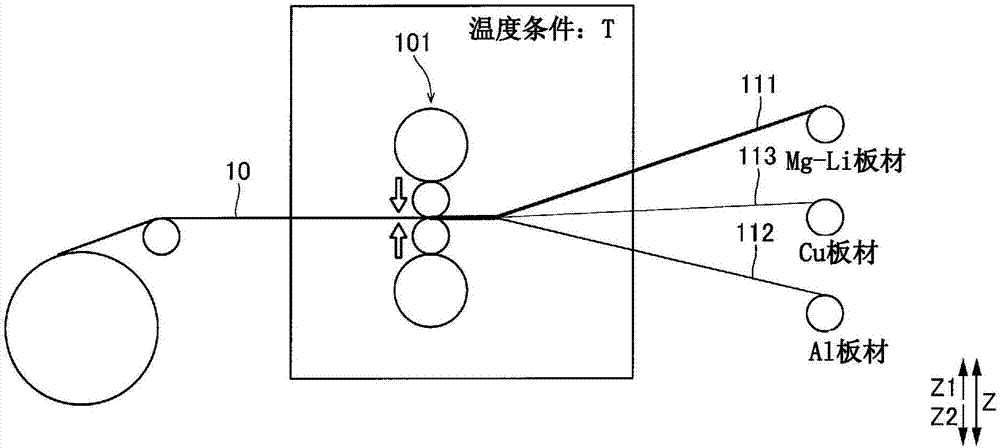

Cladding material and casing for electronic devices

ActiveCN107206747AEnsure joint strengthCasings/cabinets/drawers detailsMetal casingsAlloyElectric devices

A cladding material (10) is provided with: a first layer (11) that is configured from an Mg-Li-based alloy; a second layer (12) that is configured from an Al-based alloy; and a first junction part (13) which is configured from a Cu-based alloy and is positioned on the junction interface (Ia) between the first layer and the second layer when viewed in cross section in the thickness direction. This cladding material has a specific gravity of 2.10 or less.

Owner:PROTERIAL LTD

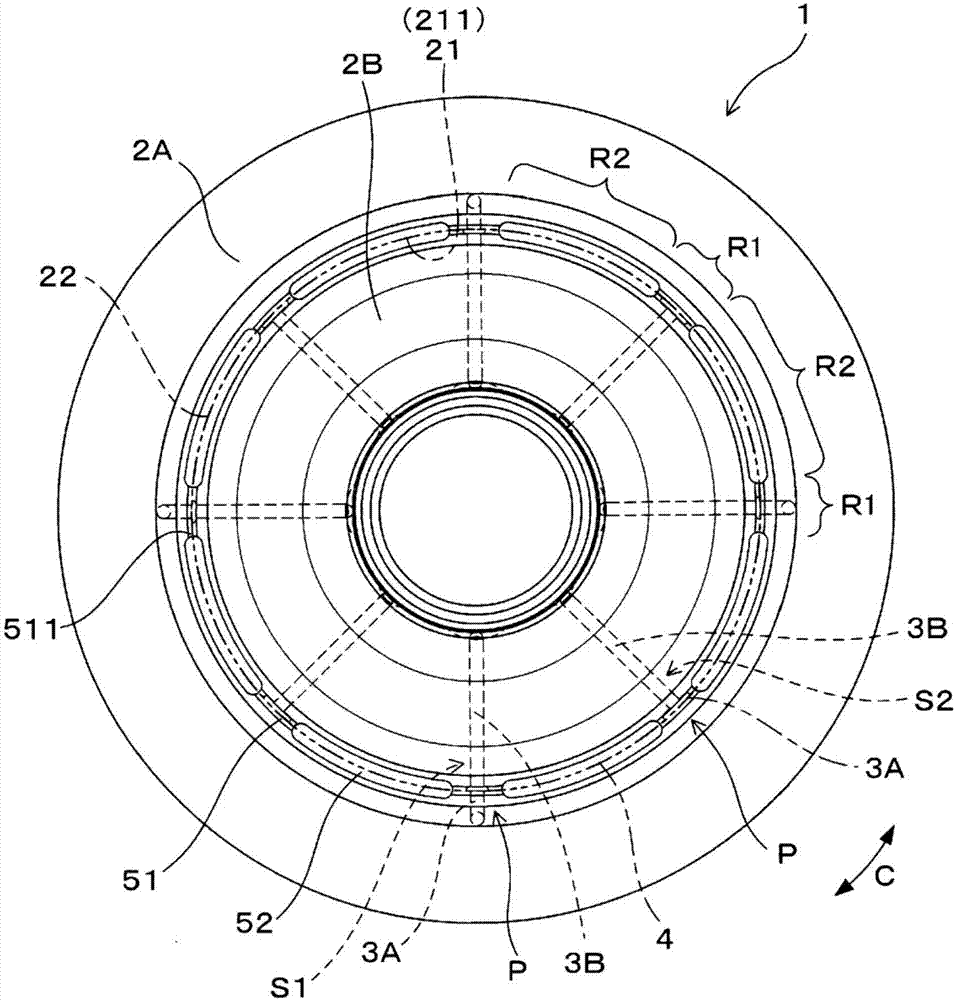

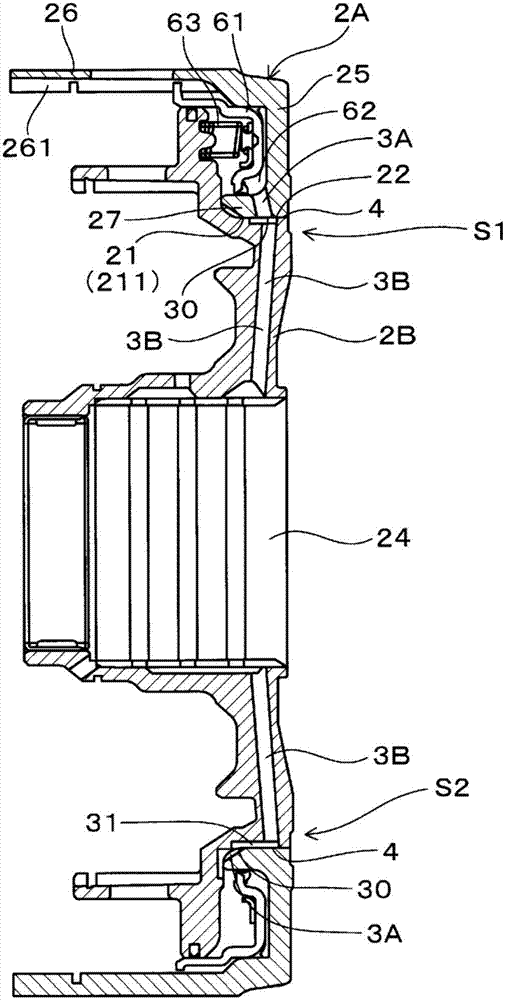

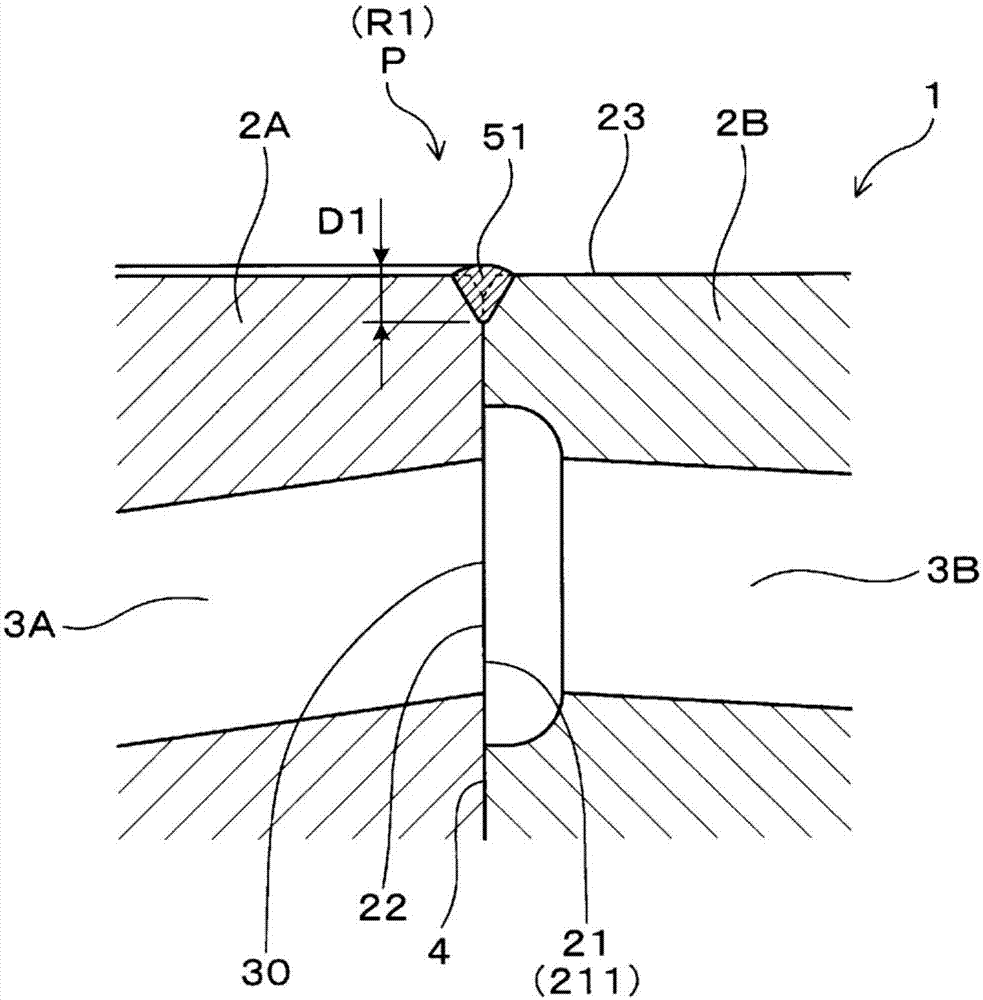

Joint component and method of manufacturing same

ActiveCN107405721AProtect the linkPrevent leakageFluid actuated clutchesRod connectionsJoint componentUltimate tensile strength

The objective of the present invention is to provide a joint component and a method of manufacturing the same, with which it is possible to protect a linking site between a first flow path and a second flow path, to prevent leakage of fluid from the first flow path and the second flow path, and to ensure the strength of a joint between a first metal piece and a second metal piece. In a joint component (1), a first flow path (3A) of an outside metal piece (2A) and a second flow path (3B) of an inside metal piece (2B) are linked together at a specific site (P) on a joining surface (4). A small bead portion (51) having a weld penetration depth that does not reach a linking site (30) is provided in a first region (R1) of the joining surface (4), including the specific site (P). A large bead portion (52) having a weld penetration depth that is greater than the weld penetration depth of the small bead portion (51) is provided in a second region (R2) excluding the first region (R1).

Owner:AISIN AW CO LTD

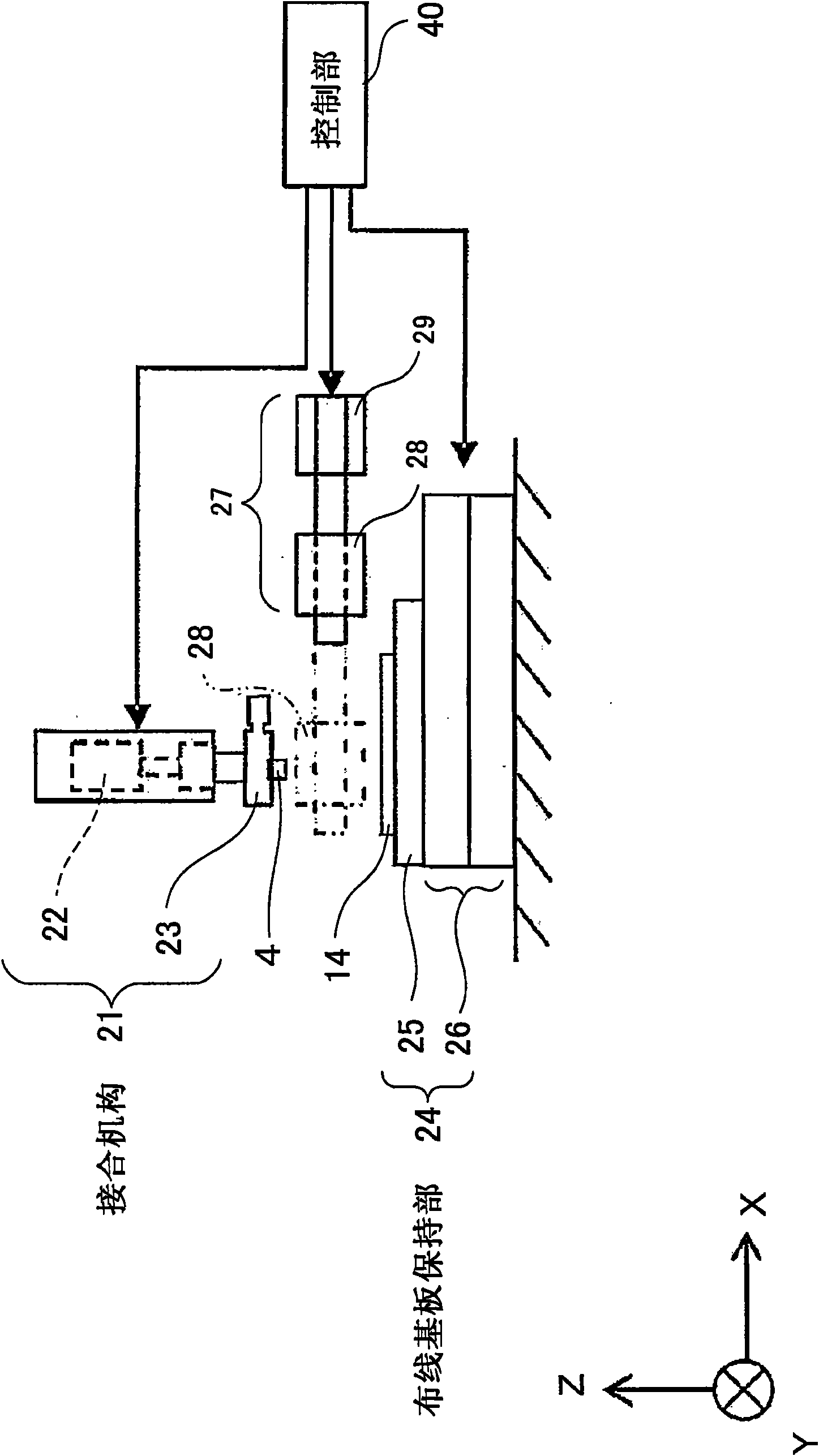

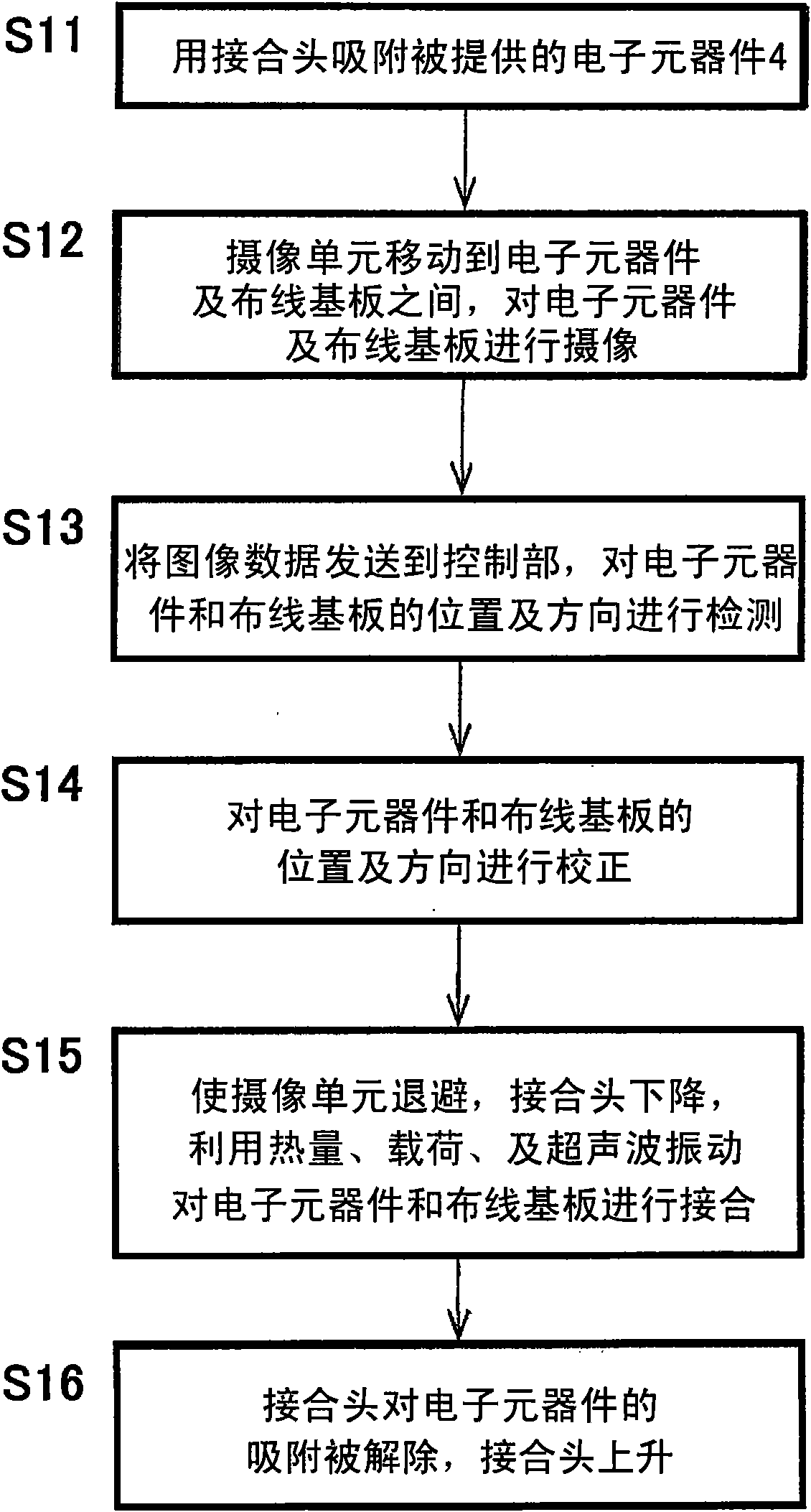

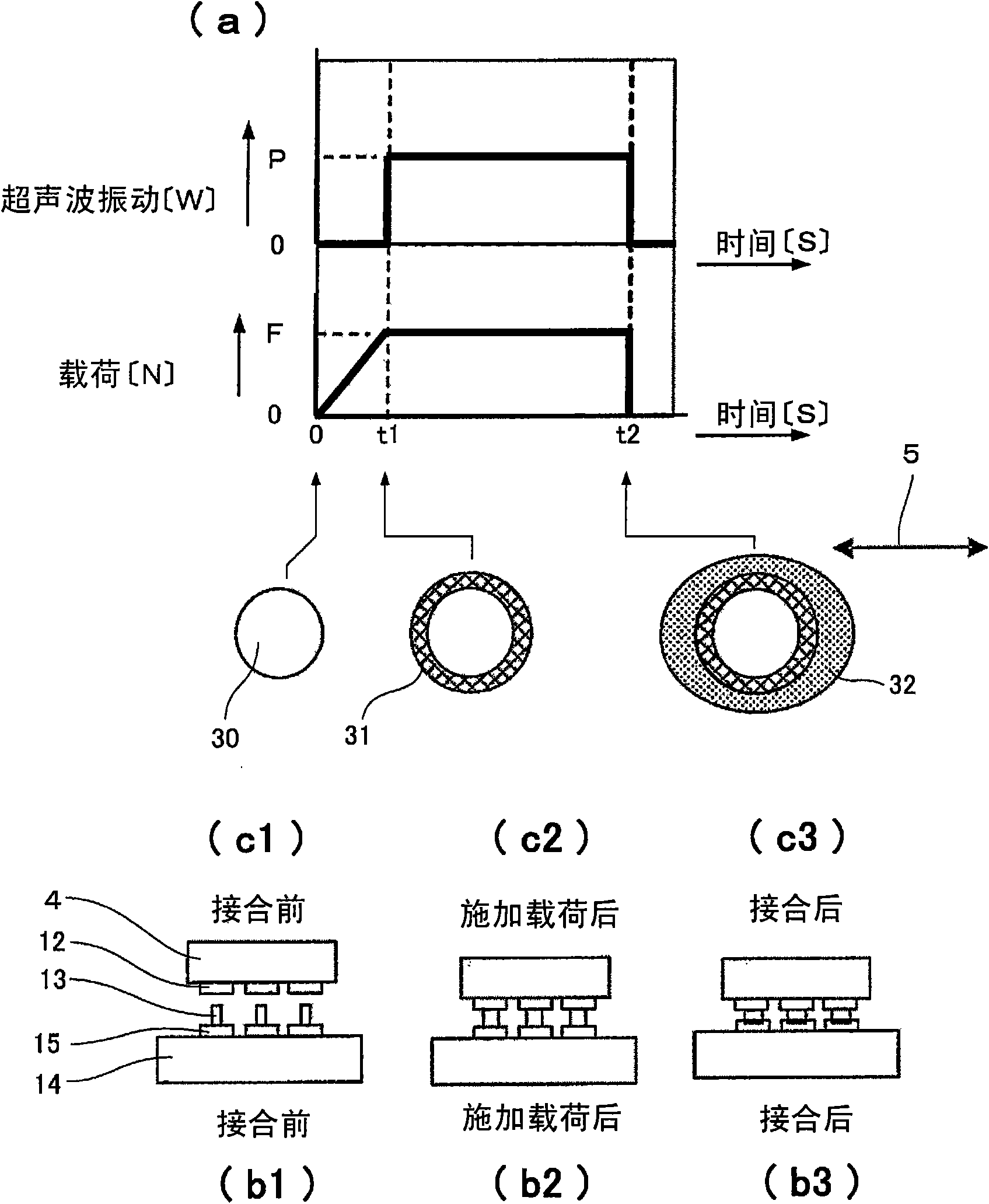

Electronic part mounting apparatus and method of mounting electronic part

InactiveCN101652845AEnsure joint strengthLarge range of joining conditionsSolid-state devicesSemiconductor/solid-state device manufacturingUltrasonic vibrationPhysics

In the direction parallel to the direction of ultrasonic vibration (5) generated by ultrasonic vibrator (1), the configuration of central part (3a) of tool (3) and the configuration of end part (3b) of the tool (3) are changed from each other so as to be different from each other in cross-sectional area, thereby rendering ultrasonic vibration amplitudes (9) in the direction perpendicular to the direction of ultrasonic vibration (5) substantially identical with each other. Accordingly, the difference between the ultrasonic vibration at the central part (3a) of the tool (3) and that at the end part (3b) of the tool (3) can be zeroed or reduced.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com